Sweat-Resistant Parylene-C Encapsulated Conductive Textiles for Active Thermal Management

Abstract

1. Introduction

- (1)

- Effective isolation of the metallic copper layer from sweat-induced electrolytic corrosion and ion diffusion;

- (2)

- Retention of air and moisture permeability by maintaining partially open porosity within the nonwoven architecture; and

- (3)

- Preservation of electrical continuity and Joule heating capability for reliable active thermal management.

2. Materials and Methods

2.1. Material

2.1.1. Greige Material

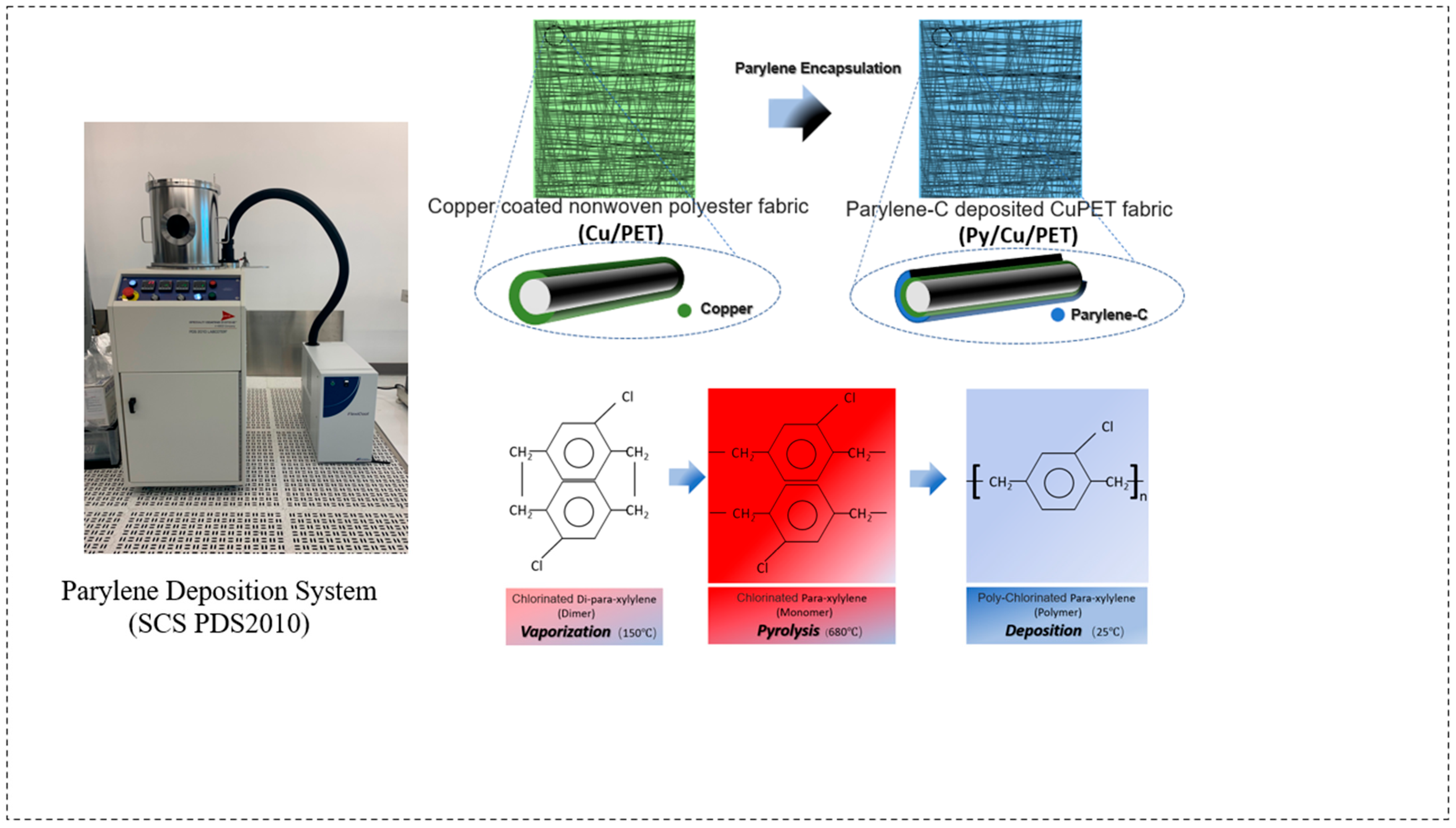

2.1.2. Fabrication of PyCuPET Samples

2.2. Characterization and Evaluation

2.2.1. Physical Characterization

2.2.2. Air Permeability

2.2.3. Water Vapor Permeability Test

2.2.4. Thermal Conductivity and Resistance Test

2.2.5. Joule Heating Test

2.2.6. Artificial Sweat Socking and Released Cu Analysis

3. Results and Discussion

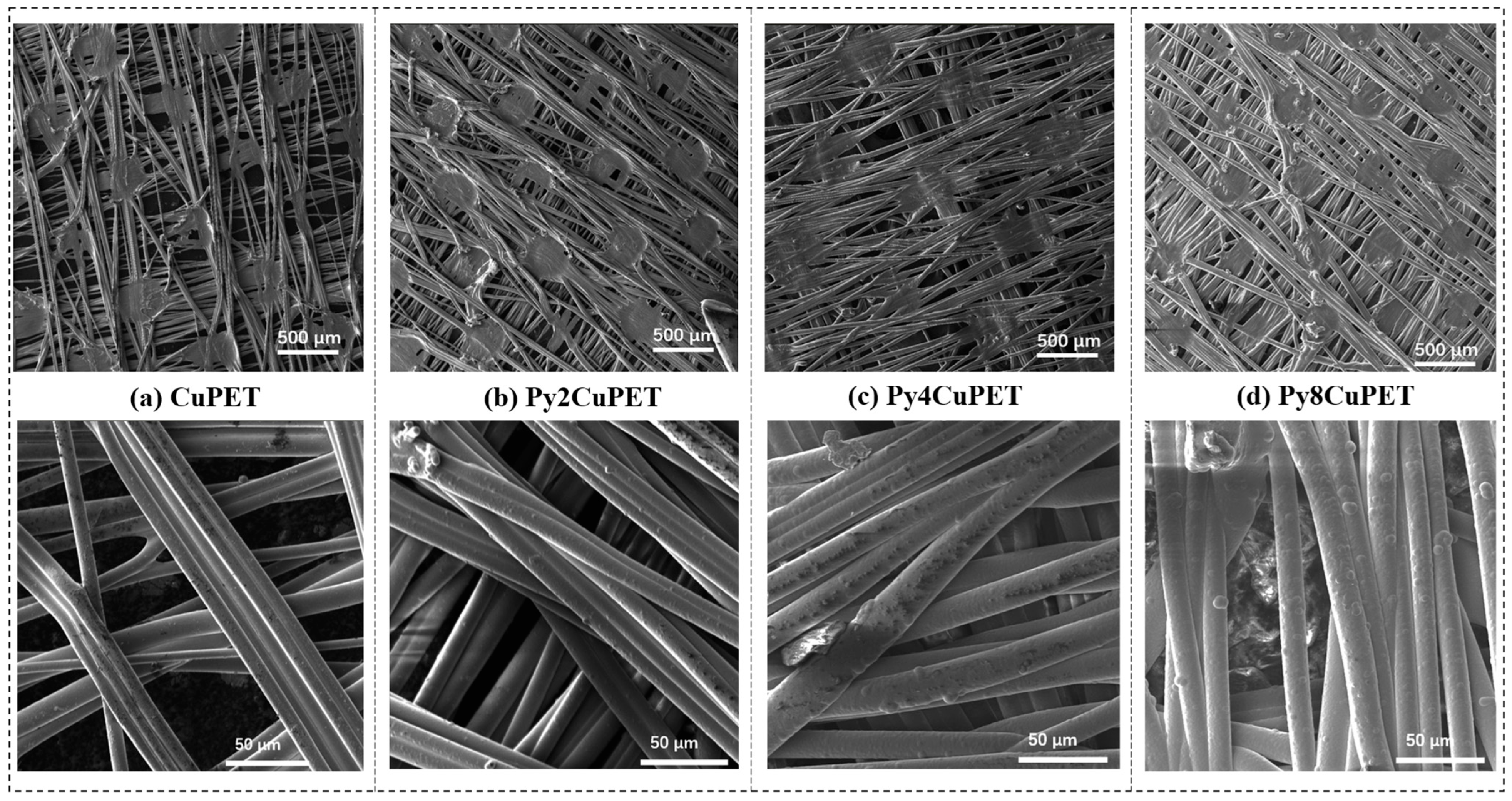

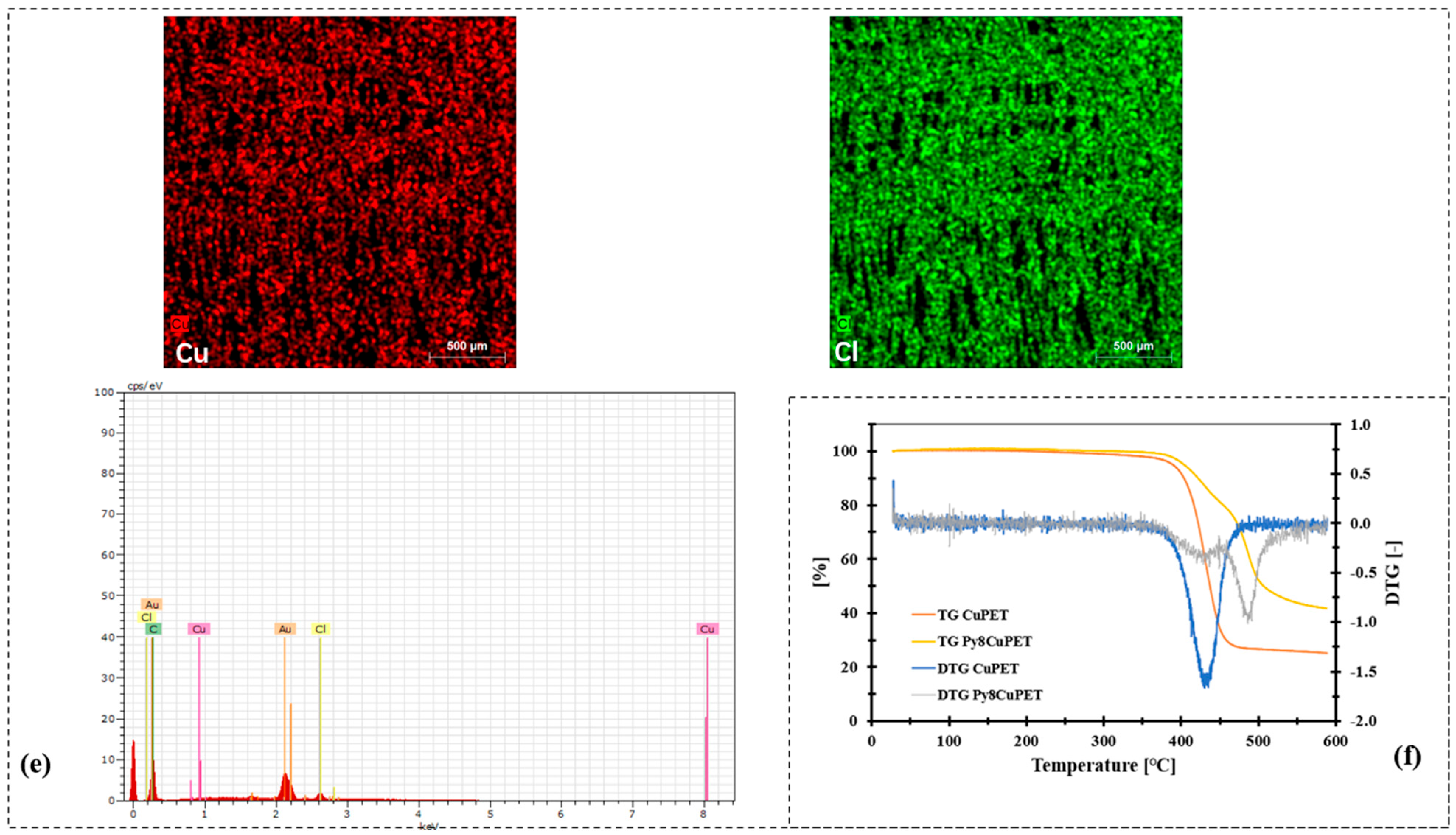

3.1. Morphology Characterization

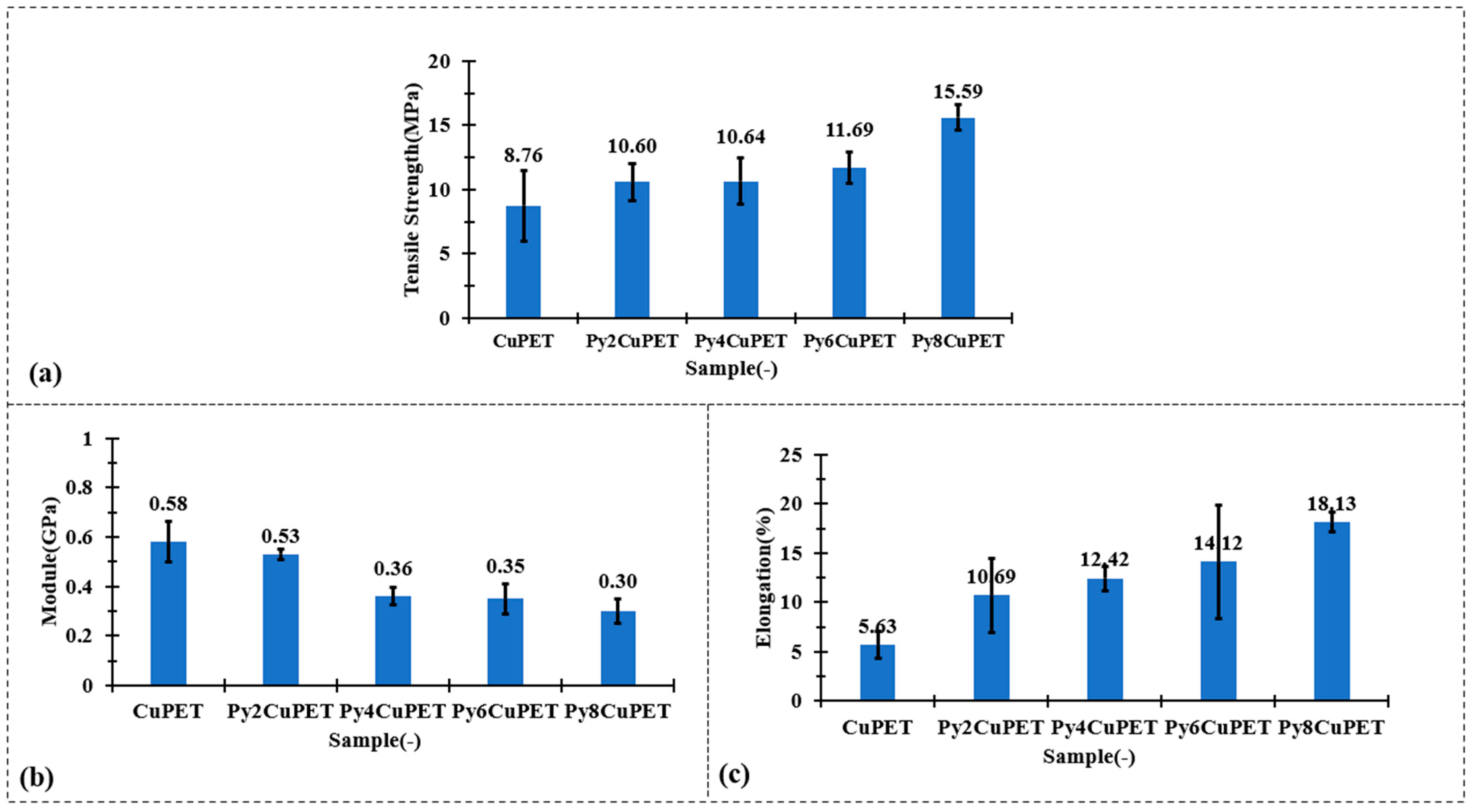

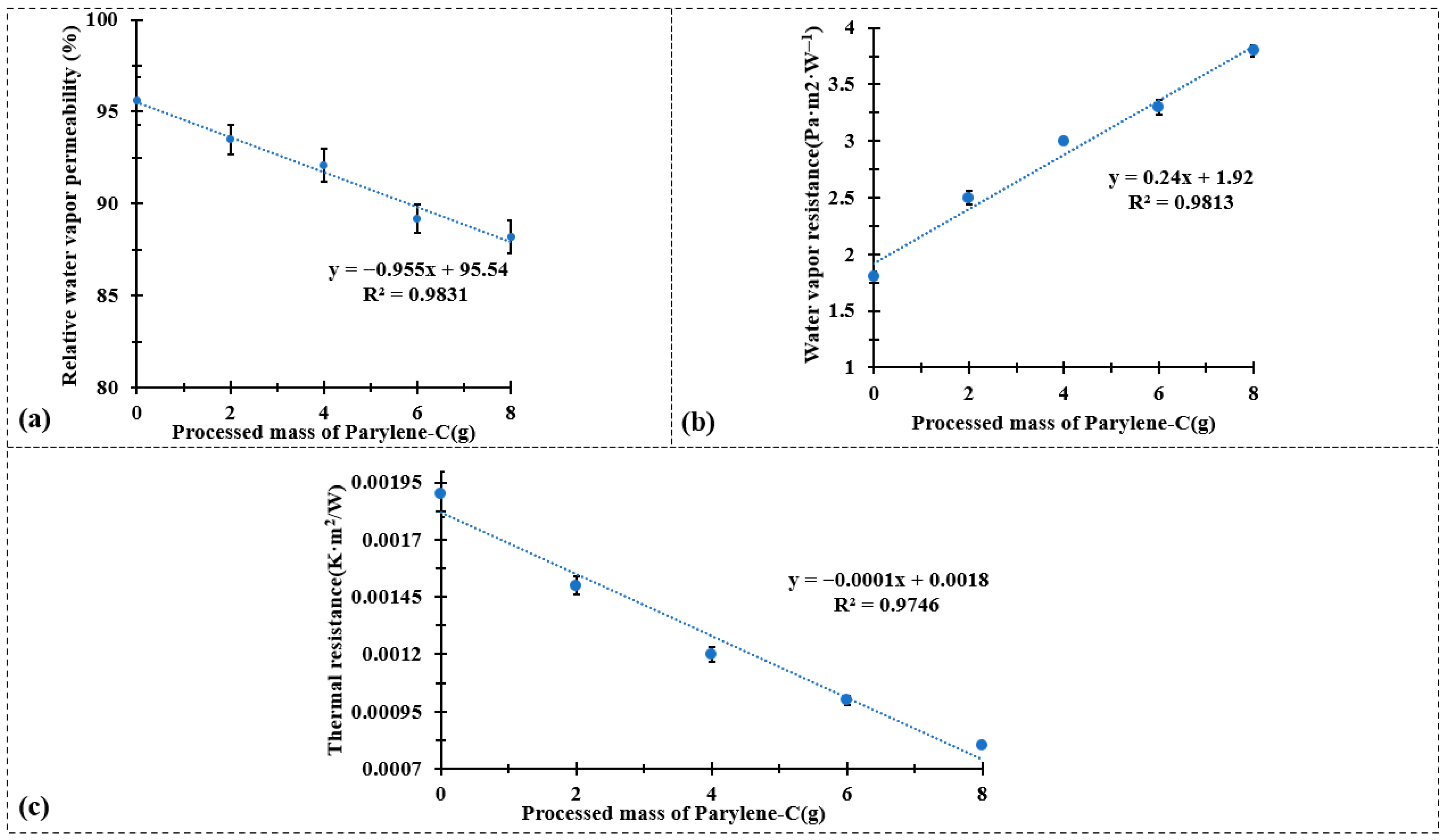

3.2. Wearing Comfort-Related Properties of CuPET and PyCuPET

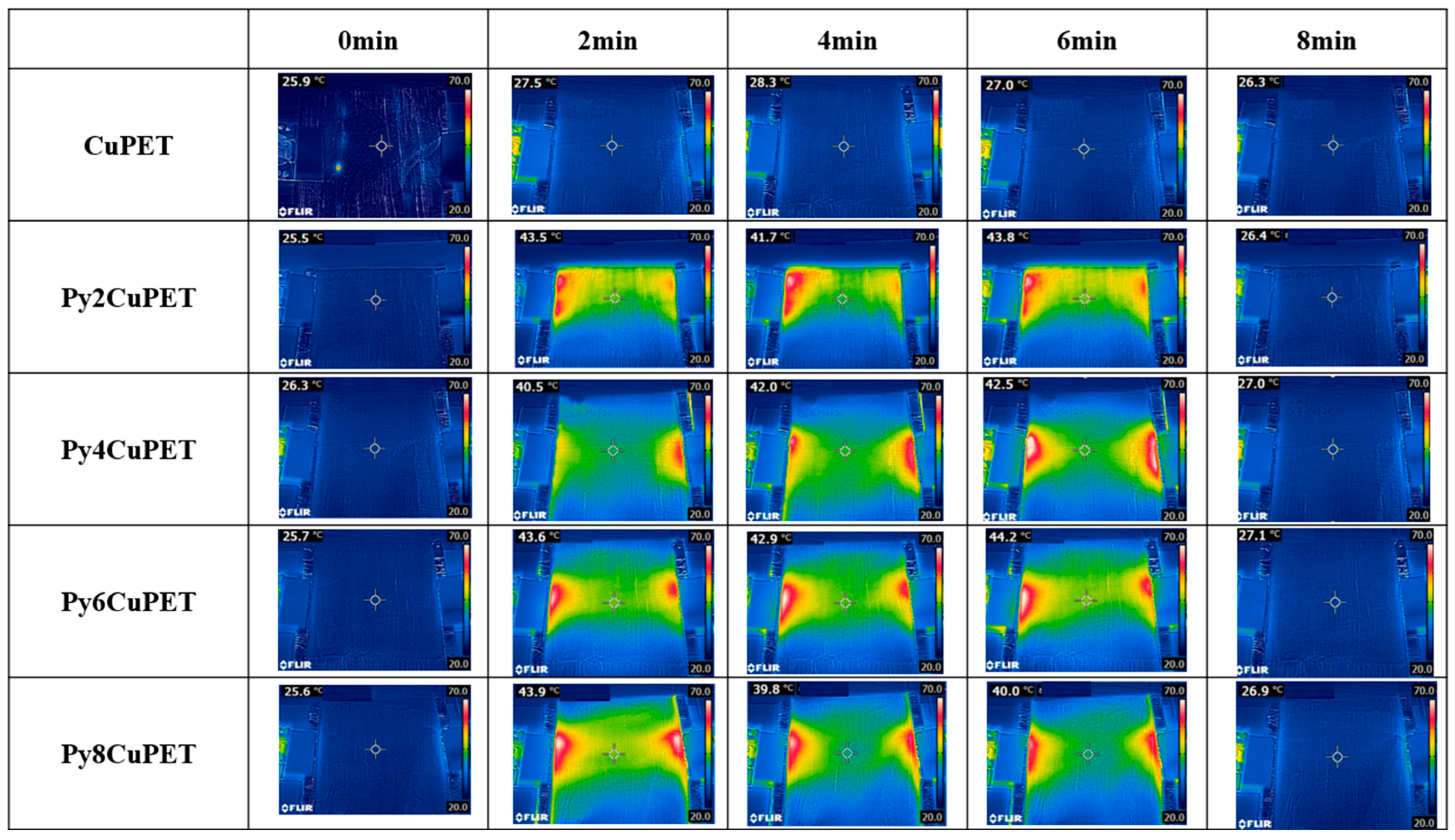

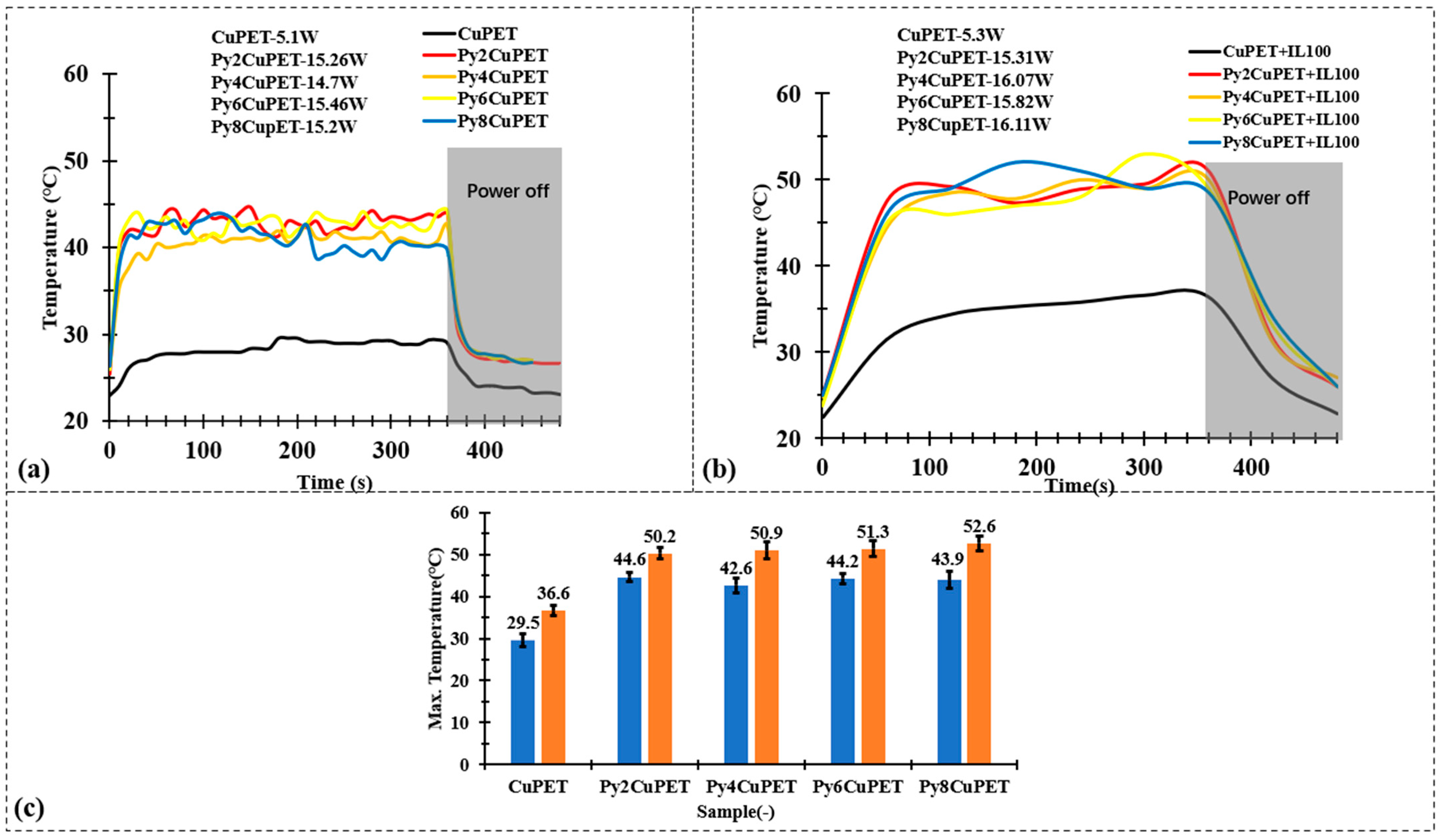

3.3. Joule Heating Performance with and Without Thermal Resistance Layer

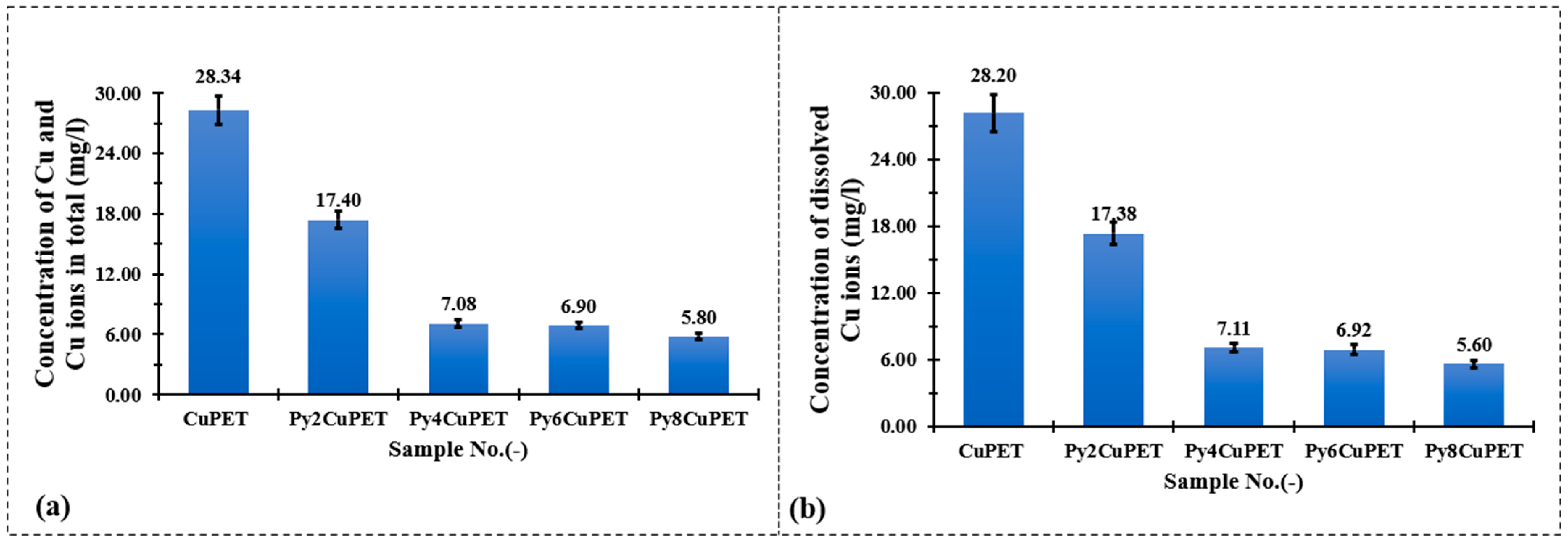

3.4. Cu Residue After Sweat Socking and Electrical Behavior Change

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cherenack, K.; van Pieterson, L. Smart Textiles: Challenges and Opportunities. J. Appl. Phys. 2012, 112, 091301. [Google Scholar] [CrossRef]

- Cho, G.; Lee, S.; Cho, J. Review and Reappraisal of Smart Clothing. Int. J. Hum.-Comput. Interact. 2009, 25, 582–617. [Google Scholar] [CrossRef]

- Depla, D.; Segers, S.; Leroy, W.; Van Hove, T.; Van Parys, M. Smart Textiles: An Explorative Study of the Use of Magnetron Sputter Deposition. Text. Res. J. 2011, 81, 1808–1817. [Google Scholar] [CrossRef]

- Hu, S.; Wang, D.; Yang, K.; Wang, Y.F.; Yang, T.; Peng, Q.Y.; Tan, X.D.; Kremenakova, D.; Militky, J.; Venkataraman, M.; et al. Copper Coated Textiles for Inhibition of Virus Spread. In Proceedings of the Textile Bioengineering and Informatics Symposium Proceedings 2020—13th Textile Bioengineering and Informatics Symposium, TBIS 2020, Online, 7–10 July 2020; pp. 84–91. [Google Scholar]

- Xu, C.; Zhao, J.; Chao, Z.; Wang, J.; Wang, W.; Zhang, X.; Li, Q. Developing Thermal Regulating and Electromagnetic Shielding Textiles Using Ultra-Thin Carbon Nanotube Films. Compos. Commun. 2020, 21, 100409. [Google Scholar] [CrossRef]

- Baheti, V.; Wang, Y. Ohmic Heating and Mechanical Stability of Carbon Fabric/Green Epoxy Composites after Incorporation of Fly Ash Particles. Mater. Today Commun. 2021, 26, 2352–4928. [Google Scholar] [CrossRef]

- Du, P.; Zhang, J.; Guo, Z.; Wang, H.; Luo, Z.; Fan, Z.; Li, B.; Cai, Z.; Ge, F. A Novel Breathable Flexible Metallized Fabric for Wearable Heating Device with Flame-Retardant and Antibacterial Properties. J. Mater. Sci. Technol. 2022, 122, 200–210. [Google Scholar] [CrossRef]

- Borkow, G.; Felix, A.; Gabbay, J. Copper-Impregnated Antimicrobial Textiles; an Innovative Weapon to Fight Infection. In Medical and Healthcare Textiles; Elsevier Ltd.: Amsterdam, The Netherlands, 2010; pp. 14–22. ISBN 978-1-84569-224-7. [Google Scholar]

- Jiang, S.Q.; Newton, E.; Yuen, C.W.M.; Kan, C.W. Chemical Silver Plating and Its Application to Textile Fabric Design. J. Appl. Polym. Sci. 2005, 96, 919–926. [Google Scholar] [CrossRef]

- Babaahmadi, V.; Moradi, H.; Askari, G.; Nasouri, K. Flexible and Durable Conductive Nickel/Graphene-Coated Polyethylene Terephthalate Fabric for Highly Efficient Electromagnetic Shielding. Polym. Eng. Sci. 2023, 63, 3592–3603. [Google Scholar] [CrossRef]

- Bekmurzayeva, A.; Duncanson, W.J.; Azevedo, H.S.; Kanayeva, D. Surface Modification of Stainless Steel for Biomedical Applications: Revisiting a Century-Old Material. Mater. Sci. Eng. C 2018, 93, 1073–1089. [Google Scholar] [CrossRef]

- Althagafy, K.; Alhashmi Alamer, F. Metal-Coated Textiles in Composite Materials: Advances in Manufacturing Techniques, Properties, and Applications. Cellulose 2025, 32, 5709–5733. [Google Scholar] [CrossRef]

- Hu, S.; Wang, D.; Křemenáková, D.; Militký, J. Characterization and Multifunction Application of Metalized Textile Materials. In Advanced Multifunctional Materials from Fibrous Structures; Militký, J., Venkataraman, M., Eds.; Springer Nature: Singapore, 2023; pp. 131–161. ISBN 978-981-9960-02-6. [Google Scholar]

- Ojstršek, A.; Plohl, O.; Gorgieva, S.; Kurečič, M.; Jančič, U.; Hribernik, S.; Fakin, D. Metallisation of Textiles and Protection of Conductive Layers: An Overview of Application Techniques. Sensors 2021, 21, 3508. [Google Scholar] [CrossRef]

- Wang, Z.; Shin, J.; Park, J.-H.; Lee, H.; Kim, D.-H.; Liu, H. Engineering Materials for Electrochemical Sweat Sensing. Adv. Funct. Mater. 2021, 31, 2008130. [Google Scholar] [CrossRef]

- Asadi, M.; Nadhum Bahjat, M.; Hosseini, M. A Review on Wearable Sensors for Sodium Detection in Human Sweat. Anal. Bioanal. Electrochem. 2023, 15, 794–814. [Google Scholar] [CrossRef]

- Zhao, K.; Kang, B.; Zhou, B. Wearable Electrochemical Sensors for Monitoring of Inorganic Ions and pH in Sweat. Int. J. Electrochem. Sci. 2022, 17, 220452. [Google Scholar] [CrossRef]

- Gao, F.; Liu, C.; Zhang, L.; Liu, T.; Wang, Z.; Song, Z.; Cai, H.; Fang, Z.; Chen, J.; Wang, J.; et al. Wearable and Flexible Electrochemical Sensors for Sweat Analysis: A Review. Microsyst. Nanoeng. 2023, 9, 1. [Google Scholar] [CrossRef]

- Lansdown, A.B.G. Physiological and Toxicological Changes in the Skin Resulting from the Action and Interaction of Metal Ions. Crit. Rev. Toxicol. 1995, 25, 397–462. [Google Scholar] [CrossRef] [PubMed]

- Min, J.; Tu, J.; Xu, C.; Lukas, H.; Shin, S.; Yang, Y.; Solomon, S.A.; Mukasa, D.; Gao, W. Skin-Interfaced Wearable Sweat Sensors for Precision Medicine. Chem. Rev. 2023, 123, 5049–5138. [Google Scholar] [CrossRef]

- Gouda, A.A.; Elsheikh, R.; Atia, B.; Gado, M.A.; Weshahy, A.; Amen, A. Heavy Metal Treatment in Wastewater: The Problem of Heavy Metal Pollution. Bull. Fac. Sci. Zagazig Univ. 2025, 2025, 82–104. [Google Scholar] [CrossRef]

- Wu, J.; Wang, L.; He, J.; Zhu, C. In Vitro Cytotoxicity of Cu2+, Zn2+, Ag+ and Their Mixtures on Primary Human Endometrial Epithelial Cells. Contraception 2012, 85, 509–518. [Google Scholar] [CrossRef]

- Hostynek, J.J.; Maibach, H.I. Skin Irritation Potential of Copper Compounds. Toxicol. Mech. Methods 2004, 14, 205–213. [Google Scholar] [CrossRef]

- Hostýnek, J.J.; Reagan, K.E.; Maibach, H.I. Release of Nickel Ion from the Metal and Its Alloys as Cause of Nickel Allergy. In Nickel and the Skin; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Briffa, J.; Sinagra, E.; Blundell, R. Heavy Metal Pollution in the Environment and Their Toxicological Effects on Humans. Heliyon 2020, 6, e04691. [Google Scholar] [CrossRef]

- Tian, Y.; Ding, R.; Yoon, S.S.; Zhang, S.; Yu, J.; Ding, B. Recent Advances in Next-Generation Textiles. Adv. Mater. 2025, 37, 2417022. [Google Scholar] [CrossRef]

- Shou, D.; Li, Z. Personal Moisture Management by Advanced Textiles and Intelligent Wearables. Adv. Mater. 2025, e08831. [Google Scholar] [CrossRef]

- Xiang, H.; Li, Y.; Liao, Q.; Xia, L.; Wu, X.; Zhou, H.; Li, C.; Fan, X. Recent Advances in Smart Fabric-Type Wearable Electronics toward Comfortable Wearing. Energies 2024, 17, 2627. [Google Scholar] [CrossRef]

- Qi, P.; Xie, J.; Xia, G.; Wang, Y.; Xin, J.H. Advanced Bionic Textile Materials: From Principles to Functional Applications. Adv. Mater. 2025, e02118. [Google Scholar] [CrossRef]

- Zhu, G.-J.; Ren, P.-G.; Guo, H.; Jin, Y.-L.; Yan, D.-X.; Li, Z.-M. Highly Sensitive and Stretchable Polyurethane Fiber Strain Sensors with Embedded Silver Nanowires. ACS Appl. Mater. Interfaces 2019, 11, 23649–23658. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.-W.; Zhang, H.-B.; Liu, J.; Zhao, S.; Xie, X.; Liu, L.; Yang, R.; Koratkar, N.; Yu, Z.-Z. Multifunctional and Water-Resistant MXene-Decorated Polyester Textiles with Outstanding Electromagnetic Interference Shielding and Joule Heating Performances. Adv. Funct. Mater. 2019, 29, 1806819. [Google Scholar] [CrossRef]

- Xing, D.; Lu, L.; Xie, Y.; Tang, Y.; Teh, K.S. Highly Flexible and Ultra-Thin Carbon-Fabric/Ag/Waterborne Polyurethane Film for Ultra-Efficient EMI Shielding. Mater. Des. 2020, 185, 108227. [Google Scholar] [CrossRef]

- Zou, L.; Lan, C.; Yang, L.; Xu, Z.; Chu, C.; Liu, Y.; Qiu, Y. The Optimization of Nanocomposite Coating with Polyaniline Coated Carbon Nanotubes on Fabrics for Exceptional Electromagnetic Interference Shielding. Diam. Relat. Mater. 2020, 104, 107757. [Google Scholar] [CrossRef]

- Ortigoza-Diaz, J.; Scholten, K.; Larson, C.; Cobo, A.; Hudson, T.; Yoo, J.; Baldwin, A.; Weltman Hirschberg, A.; Meng, E. Techniques and Considerations in the Microfabrication of Parylene C Microelectromechanical Systems. Micromachines 2018, 9, 422. [Google Scholar] [CrossRef]

- Hsu, J.-M.; Rieth, L.; Normann, R.A.; Tathireddy, P.; Solzbacher, F. Encapsulation of an Integrated Neural Interface Device With Parylene C. IEEE Trans. Biomed. Eng. 2009, 56, 23–29. [Google Scholar] [CrossRef]

- Kohler, A.; Blendinger, F.; Müller, S.; Mescheder, U.; Bucher, V. Feasibility of Parylene C for Encapsulating Piezoelectric Actuators in Active Medical Implants. Front. Med. Technol. 2023, 5, 1211423. [Google Scholar] [CrossRef]

- Gorham, W.F. A New, General Synthetic Method for the Preparation of Linear Poly-p-Xylylenes. J. Polym. Sci. Part A Polym. Chem. 1966, 4, 3027–3039. [Google Scholar] [CrossRef]

- ISO 10993-1:2018; Biological Evaluation of Medical Devices Part 1: Evaluation and Testing Within a Risk Management Process. International Organization for Standardization: Geneva, Switzerland, 2018.

- Lee, S.H.; Lee, H.J.; Lee, S.; Kim, D.-H.; Kim, H.J.; Sunwoo, S.-H. Intrinsically Soft Implantable Electronics for Long-Term Biosensing Applications. Adv. Sens. Res. 2025, 4, 2500002. [Google Scholar] [CrossRef]

- Hu, S.; Wang, D.; Křemenáková, D.; Militky, J. Washable and Breathable Ultrathin Copper-Coated Nonwoven Polyethylene Terephthalate (PET) Fabric with Chlorinated Poly-Para-Xylylene (Parylene-C) Encapsulation for Electromagnetic Interference Shielding Application. Text. Res. J. 2023, 93, 004051752311684. [Google Scholar] [CrossRef]

- Hu, S.; Wang, D.; Kyosev, Y.; Kremenakova, D.; Militky, J. The Novel Approach of EMI Shielding Simulation for Metal Coated Nonwoven Textiles with Optimized Textile Module. Polym. Test. 2022, 114, 107706. [Google Scholar] [CrossRef]

- Wang, D.; Hu, S.; Kremenakova, D.; Militky, J. Evaluation of the Wearing Comfort Properties for Winter Used Electromagnetic Interference Shielding Sandwich Materials. J. Ind. Text. 2023, 53, 15280837231159869. [Google Scholar] [CrossRef]

- ASTM D5729-97(2004)E1; Standard Test Method for Thickness of Nonwoven Fabrics. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM E1131-20; Standard Test Method for Compositional Analysis by Thermogravimetry. ASTM: West Conshohocken, PA, USA, 2025.

- ISO 9237:1995; Textiles—Determination of the Permeability of Fabrics to Air. International Organization for Standardization: Geneva, Switzerland, 1995.

- ISO 11092:2014; Textiles—Physiological Effects—Measurement of Thermal and Water-Vapour Resistance Under Steady-State Conditions (Sweating Guarded-Hotplate Test). International Organization for Standardization: Geneva, Switzerland, 2014.

- SIST EN 1811:1999; Reference Test Method for Release of Nickel from Products Intended to Come into Direct and Prolonged Contact with the Skin. CEN: Brussels, Belgium, 1999.

- EN 1811:2023; Reference Test Method for Release of Nickel from All Post Assemblies Which are Inserted into Pierced Parts of the Human Body and Articles Intended to Come into Direct and Prolonged Contact with the Skin. CEN: Brussels, Belgium, 2023.

- Ai, Y.; Ke, B. Study on the Air Permeability of Knitted Underwear fabric in Wet State. J. Cloth Res. 2021, 6, 108–111. [Google Scholar]

- Wang, D.; Venkataraman, M.; Hu, S.; Kremenakova, D.; Militky, J.; Coetzee, D.; Karthik, D. Multifunctional Sandwich Materials with ROTIS Structure for Improved Thermal and Electrical Properties in Construction Application. J. Ind. Text. 2024, 54, 15280837241271786. [Google Scholar] [CrossRef]

| Process | Chemicals and Processing Parameters | |

|---|---|---|

| 1. Surface treatment | 2.5% NaOH | 40 °C for 10 min |

| 2. Activation | 1 g/100 mL SnCl2 | Room temperature for 10 min |

| 0.05 g/100 mL PdCl2 | Room temperature for 10 min | |

| 3. Deposition | 6.5 g/500 mL CuSO4·5H2O | Sample- Solution ratio: 5 g/500 mL, pH 12.75 (NaOH 2.5 g), 45 °C for 20 min |

| 10 g/500 mL EDTA·2Na | ||

| 10 g/500 mL KNaC4H4O6·4H2O | ||

| 0.04 g/500 mL K4[Fe(CN)6]·3H2O | ||

| 0.005 g/500 m 2′-2′-Bipyridine | ||

| 7.5 mL/500 mL formaldehyde CH2O | ||

| Sample | Component | Mass per Unit Area (g/m2) | Thickness (mm) | Deposition of Cu per Unit Area (g/m2) | Volume Porosity (%) |

|---|---|---|---|---|---|

| CuPET (Meftex 20) | Copper-coated PET nonwoven fabric | 24.01 | 0.074 ± 0.008 | 4.01 | 76.13 |

| IL100 (Insulation layer) | 100% polyester nonwoven with acrylic binder | 96.33 | 5.173 ± 0.4 | - | 89.12 |

| Sample Number | Mass per Unit Area (g/m2) | Calculated Parylene-C Mass per Unit Area (g/m2) | Net Parylene-C Film Mass in the Size of 13 × 13 cm (g) |

|---|---|---|---|

| Py2CuPET | 25.12 | 1.11 | 0.02 |

| Py4CuPET | 27.22 | 3.21 | 0.05 |

| Py6CuPET | 30.76 | 6.75 | 0.11 |

| Py8CuPET | 38.72 | 14.71 | 0.24 |

| Sample Number | Sample Thickness (μm) | Optical Porosity (%) | Volume Porosity (%) | Calculated Parylene-C Film Thickness (μm) |

|---|---|---|---|---|

| Py2CuPET | 78 | 13.35 | 68.24 | 4 |

| Py4CuPET | 84 | 12.14 | 63.29 | 10 |

| Py6CuPET | 88 | 8.92 | 58.17 | 14 |

| Py8CuPET | 90 | 6.38 | 53.23 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, S.; Wang, D.; Venkataraman, M.; Militký, J.; Křemenáková, D.; Palušák, M. Sweat-Resistant Parylene-C Encapsulated Conductive Textiles for Active Thermal Management. Polymers 2025, 17, 2952. https://doi.org/10.3390/polym17212952

Hu S, Wang D, Venkataraman M, Militký J, Křemenáková D, Palušák M. Sweat-Resistant Parylene-C Encapsulated Conductive Textiles for Active Thermal Management. Polymers. 2025; 17(21):2952. https://doi.org/10.3390/polym17212952

Chicago/Turabian StyleHu, Shi, Dan Wang, Mohanapriya Venkataraman, Jiří Militký, Dana Křemenáková, and Martin Palušák. 2025. "Sweat-Resistant Parylene-C Encapsulated Conductive Textiles for Active Thermal Management" Polymers 17, no. 21: 2952. https://doi.org/10.3390/polym17212952

APA StyleHu, S., Wang, D., Venkataraman, M., Militký, J., Křemenáková, D., & Palušák, M. (2025). Sweat-Resistant Parylene-C Encapsulated Conductive Textiles for Active Thermal Management. Polymers, 17(21), 2952. https://doi.org/10.3390/polym17212952