A Simple Coloration of Calcium Alginate Fiber via Structural Colors

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Synthesis of Monodisperse SiO2 Microspheres

2.2.1. PDA/SiO2 Amorphous Photonic Crystal Synthesis

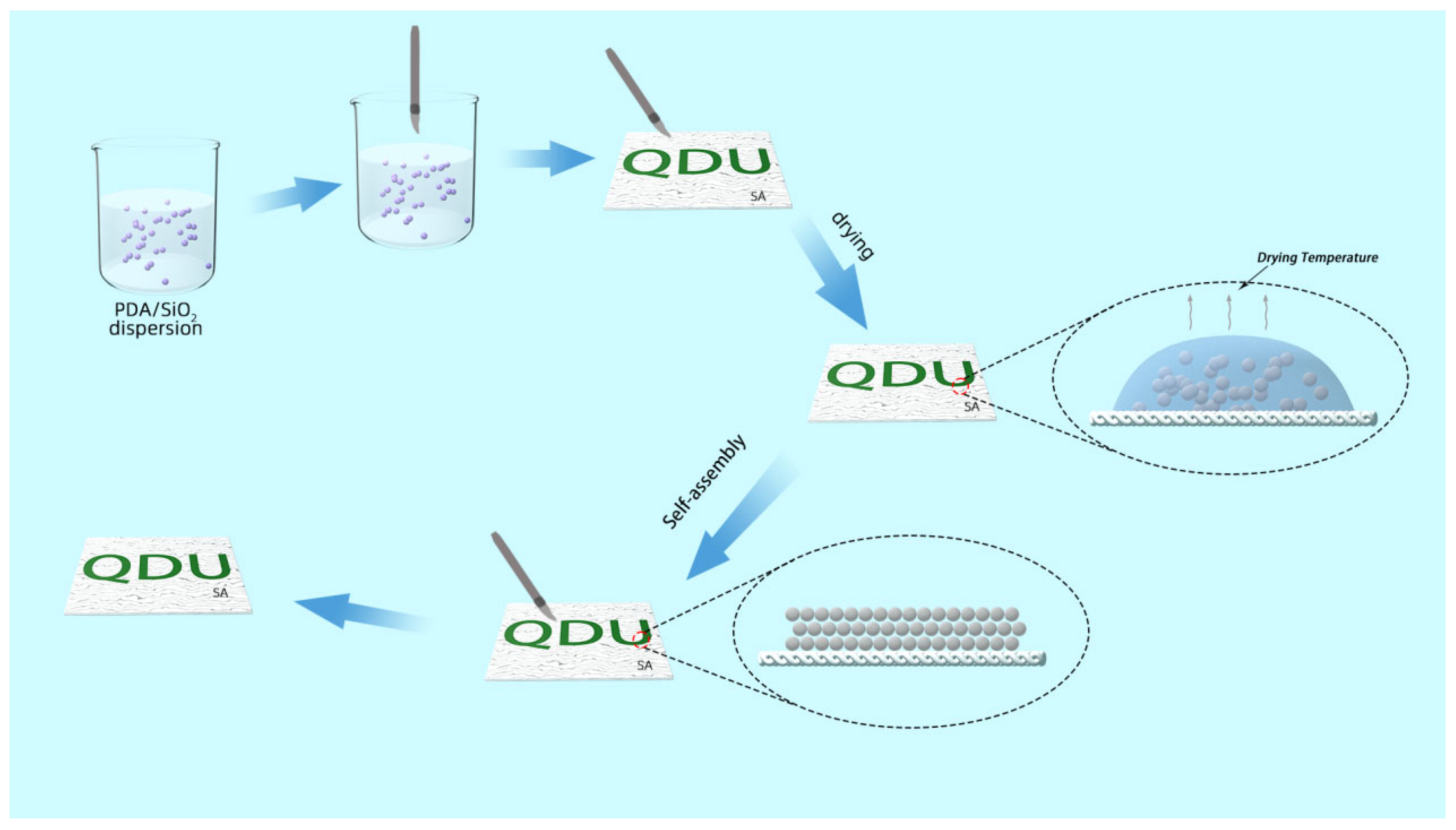

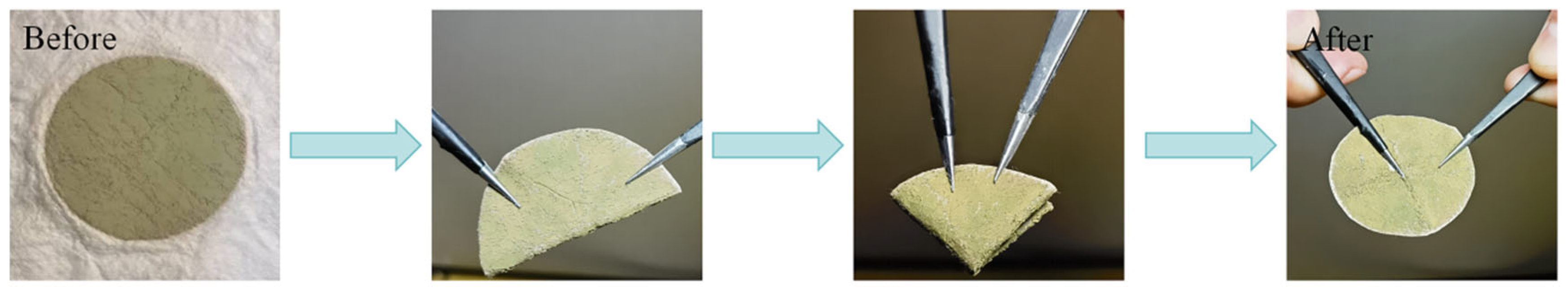

2.2.2. Synthesis of Composite Material PDA/SiO2/SA

2.3. Structural Characterization and Performance Testing

3. Results and Discussion

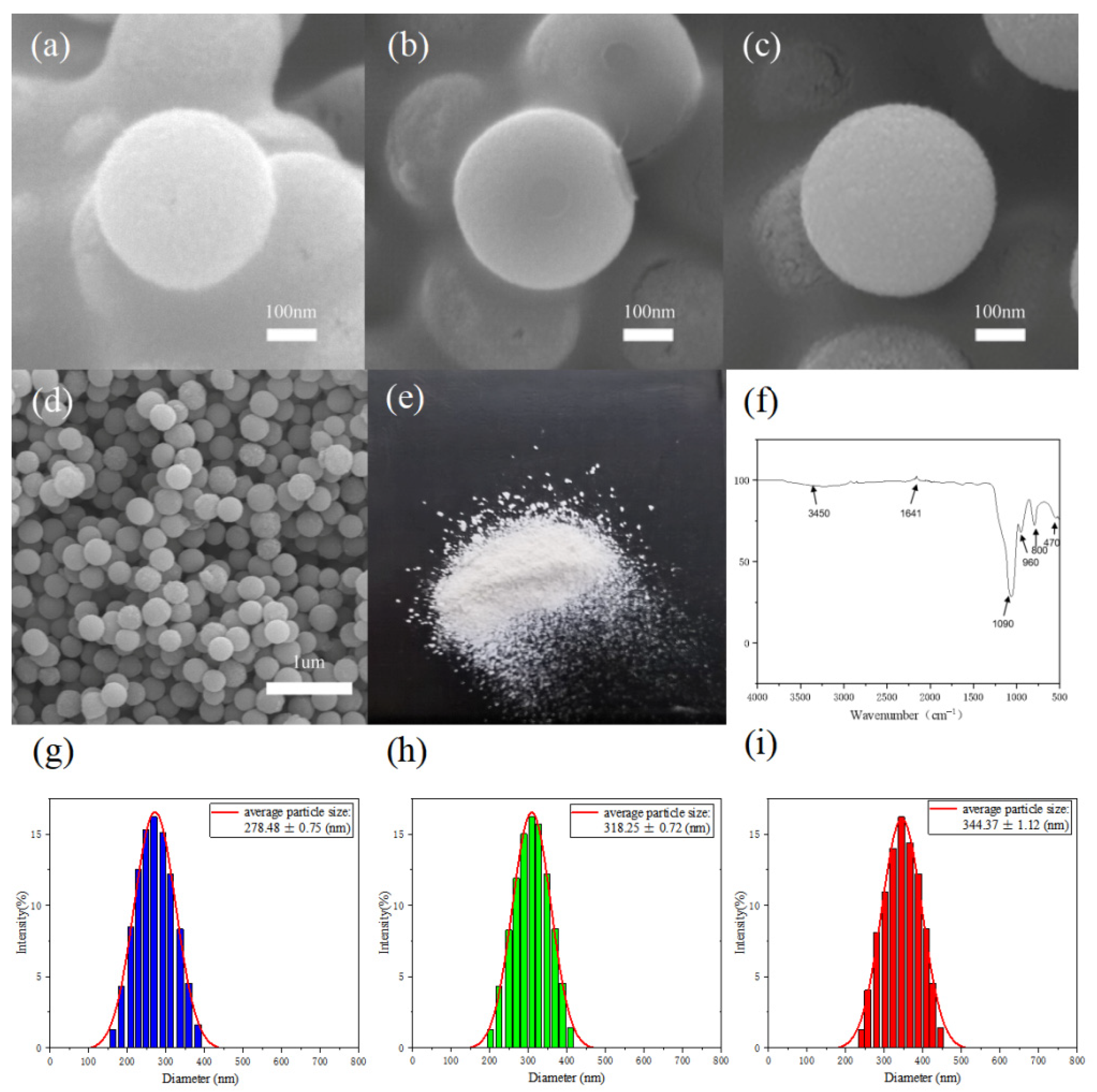

3.1. Characterization of Monodisperse SiO2 Microspheres

3.2. Characterization of Monodisperse PDA/SiO2 Photonic Crystals

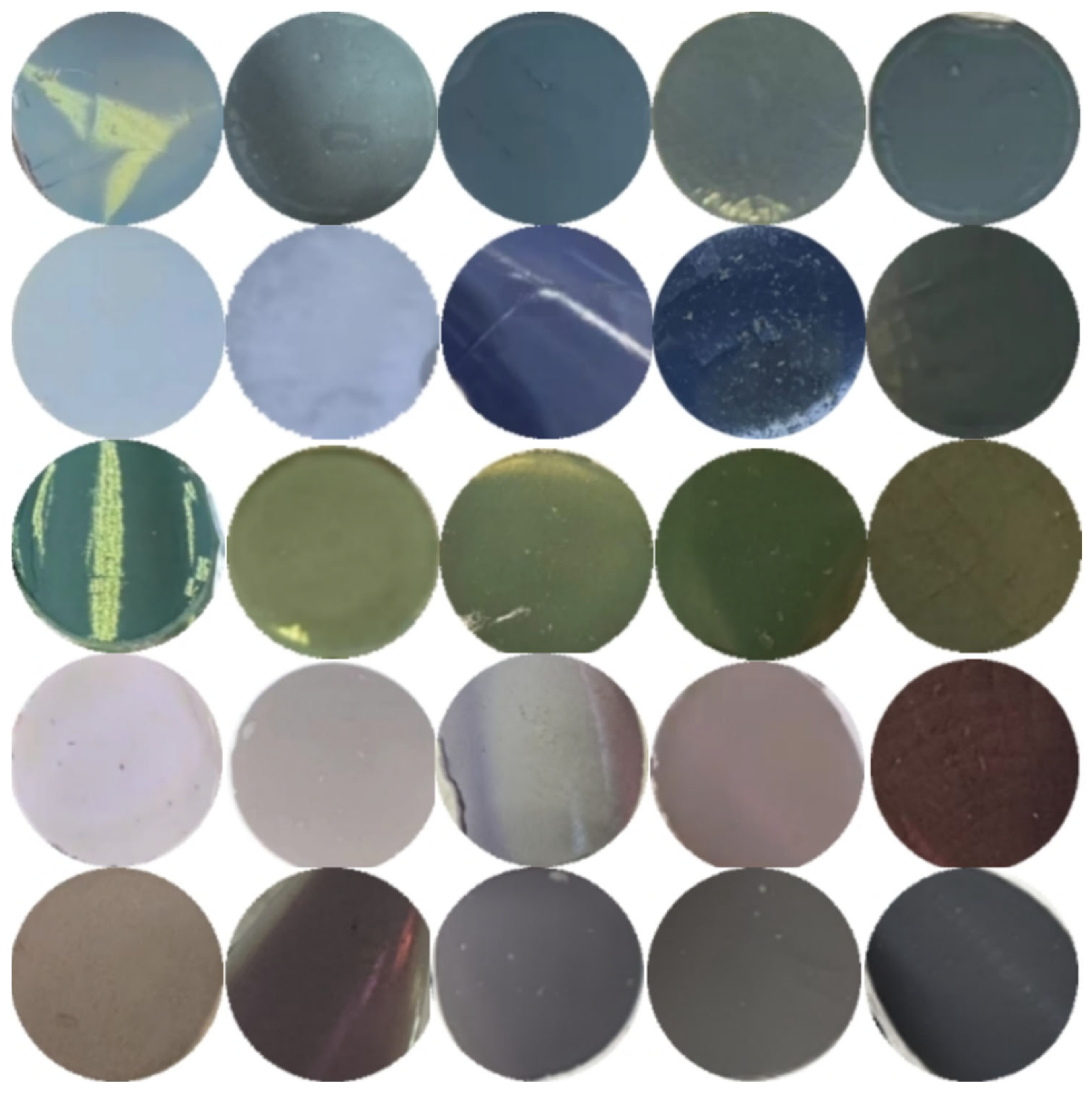

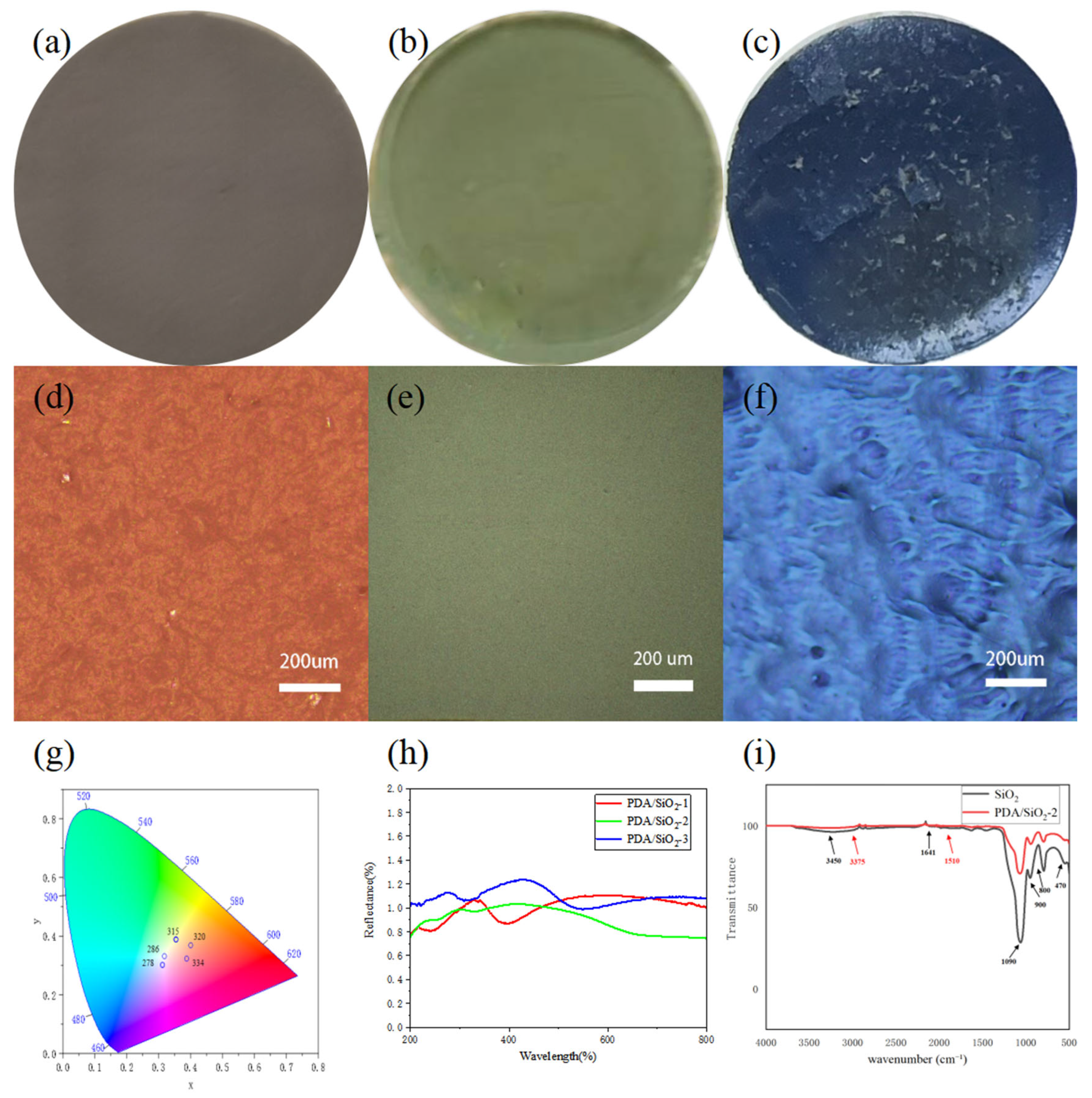

3.3. Characterization and Application of PDA/SiO2/SA Structured Color Seaweed Fibers

4. Conclusions

- (1)

- The particle size of monodisperse SiO2 microspheres is controllable and homogeneous, and the particle size decreases with the increase of reaction temperature. Three kinds of monodisperse SiO2 microspheres with particle sizes of 287, 318 and 344 nm can be produced at reaction temperatures of 70 °C, 50 °C and 30 °C, respectively.

- (2)

- Monodispersed SiO2 microspheres with three particle sizes of 278, 318 and 344 nm coated with PDA exhibit blue, green and red amorphous photonic crystals PDA/SiO2.

- (3)

- With the successful introduction of the amorphous photonic crystal PDA/SiO2 into SA, a structure-colored composite material, PDA/SiO2/SA, has been produced.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Azizi, N.; Eslami, R.; Moghaddam, P.E.; Karpov, I.; Johnson, C.; Zarrin, H. Revealing nature’s beauty through crafting structural color-coated fabrics with bioinspired modification of MXene. J. Colloid Interface Sci. 2024, 679, 1253–1265. [Google Scholar] [CrossRef] [PubMed]

- Ju, J.; Yang, J.; Zhang, W.; Wei, Y.; Yuan, H.; Tan, Y. Seaweed polysaccharide fibers: Solution properties, processing and applications. J. Mater. Sci. Technol. 2022, 140, 1–18. [Google Scholar] [CrossRef]

- Qin, Y.; Hu, H.; Luo, A. The conversion of calcium alginate fibers into alginic acid fibers and sodium alginate fibers. J. Appl. Polym. Sci. 2006, 101, 4216–4221. [Google Scholar] [CrossRef]

- Arora, E.K.; Sharma, V.; Sethi, G.; Puthanagady, M.S.; Meena, A. Bioinspired designer surface nanostructures for structural color. Nanotechnol. Environ. Eng. 2024, 9, 461–472. [Google Scholar] [CrossRef]

- Chen, G.; Yi, B.; Huang, Y.; Liang, Q.; Shen, H. Development of bright and low angle dependence structural colors from order-disorder hierarchical photonic structure. Dye. Pigment. 2018, 161, 464–469. [Google Scholar] [CrossRef]

- Cheng, X.; Peng, S.; Tan, Z.; Zhou, Y.; Yang, H.; Deng, B. Preparation of high color fastness structural colored cotton fabric via SiO2@PDA photonic crystal. Dye. Pigment. 2024, 226, 112151. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Zhou, L.; Chai, L.; Fan, Q.; Shao, J. Structural colouration of textiles with high colour contrast based on melanin-like nanospheres. Dye. Pigment. 2019, 169, 36–44. [Google Scholar] [CrossRef]

- Yu, J.; Wang, W.; Jin, S.; Kan, C.-W. Direct fabrication of template-free beads-on-a-string three-dimensional structural color yarn. Cellulose 2023, 30, 11797–11812. [Google Scholar] [CrossRef]

- Guo, Q.; Yang, G.; Huang, D.; Cao, W.; Ge, L.; Li, L. Synthesis and characterization of spherical silica nanoparticles by modified Stöber process assisted by slow-hydrolysis catalyst. Colloid Polym. Sci. 2018, 296, 379–384. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, B.; Chen, A.; Liu, X.; Shi, L.; Zi, J. Using Cuttlefish Ink as an Additive to Produce Non-iridescent Structural Colors of High Color Visibility. Adv. Mater. 2015, 27, 4719–4724. [Google Scholar] [CrossRef]

- Ren, G.; Su, H.; Wang, S. The combined method to synthesis silica nanoparticle by Stöber process. J. Sol-Gel Sci. Technol. 2020, 96, 108–120. [Google Scholar] [CrossRef]

- Zhou, L.; Wu, Y.; Chai, L.; Liu, G.; Fan, Q.; Shao, J. Study on the formation of three-dimensionally ordered SiO2 photonic crystals on polyester fabrics by vertical deposition self-assembly. Text. Res. J. 2016, 86, 1973–1987. [Google Scholar] [CrossRef]

- Wang, X.; Shen, J.; Xu, M.; Huang, Y.; Gao, M.; Liu, W.; Wang, Y. Effect of angular error on weighting coefficient in multiangle dynamic light scattering. Infrared Laser Eng. 2018, 47, 1017004. [Google Scholar] [CrossRef]

- Nakamae, K.; Hano, N.; Ihara, H.; Takafuji, M. Thermally stable high-contrast iridescent structural colours from silica colloidal crystals doped with monodisperse spherical black carbon particles. Mater. Adv. 2021, 2, 5935–5941. [Google Scholar] [CrossRef]

- Li, S.; Jia, L.; Dong, P.; Shan, G.; Liu, R. Construction of photonic crystal structural colors on white polyester fabrics. Opt. Mater. 2021, 116, 111115. [Google Scholar] [CrossRef]

- Li, S.; Jia, L.; Wang, L.; Li, P.; Fan, X. Preparation of robust fully encapsulated structural color fabrics and their application to display. Dye. Pigment. 2023, 212, 111150. [Google Scholar] [CrossRef]

- Su, X.; Xia, H.; Zhang, S.; Tang, B.; Wu, S. Vivid structural colors with low angle dependence from long-range ordered photonic crystal films†. Nanoscale 2016, 9, 3002–3009. [Google Scholar] [CrossRef]

- Huang, D.; Zeng, M.; Wang, L.; Zhang, L.; Cheng, Z. Biomimetic colloidal photonic crystals by coassembly of polystyrene nanoparticles and graphene quantum dots†. RSC Adv. 2018, 8, 34839–34847. [Google Scholar] [CrossRef]

- Chen, J.; Liu, P.; Du, X.; Xie, Z. Clickable Colloidal Photonic Crystals for Structural Color Pattern. Langmuir 2018, 34, 13219–13224. [Google Scholar] [CrossRef]

- Liu, X.; Yan, P.; Fang, Y. Structural Coloration of Polyester Fabrics with High Colorfastness by Copolymer Photonic Crystals Containing Reactive Epoxy Groups. ACS Omega 2021, 6, 28031–28037. [Google Scholar] [CrossRef]

- Han, Y.; Meng, Z.; Wu, Y.; Zhang, S.; Wu, S. Structural Colored Fabrics with Brilliant Colors, Low Angle Dependence, and High Color Fastness Based on the Mie Scattering of Cu2O Spheres. ACS Appl. Mater. Interfaces 2021, 13, 57796–57802. [Google Scholar] [CrossRef]

- Liu, W.; Yang, L.; Li, T.; Liu, Y.; Tang, Z.; Hu, S.; Wang, X.; Tan, H. Rapid Construction of PVA@CDs/SiO2 Fluorescent/Structural Color Dual-Mode Anti-Counterfeiting Labels via Spray-Coating Method. Polymers 2024, 16, 2211. [Google Scholar] [CrossRef]

- Guoqiang, F.; Xiuqin, Z.; Xuemei, C.; Yahong, Z.; Xinyu, P.; Yankun, C.; Meng, S.; Minxuan, K.; Yanlin, S. Rapid fabrication of photonic crystal patterns with iridescent structural colors on textiles by spray coating. Dye. Pigment. 2021, 195, 109747. [Google Scholar] [CrossRef]

- Ma, W.; Zhang, J.; Jin, M.; Xiang, J.; Liu, G.; Zhu, G.; Zhou, L.; Shao, J.; Chai, L. Fabrication and Responsive Application of Flexible Yarns with Structural Colors Based on Photonic Crystal Hydrogels. ACS Appl. Polym. Mater. 2025, 7, 1851–1862. [Google Scholar] [CrossRef]

- Zhao, X.; Gao, W.; Yang, S.; Liu, J.; Hasan, M.S.; Zhang, Z.; Chen, H. From silica colloidal particles to photonic crystals: Progress in fabrication and application of structurally colored materials. Text. Res. J. 2023, 93, 2877–2893. [Google Scholar] [CrossRef]

- Dalmis, R.; Ak Azem, N.F.; Birlik, I.; Çelik, E. SiO2/TiO2 One-Dimensional Photonic Crystals Doped with Sm and Ce Rare-earth Elements for Enhanced Structural Colors. Appl. Surf. Sci. 2019, 475, 94–101. [Google Scholar] [CrossRef]

- Liu, X.-F.; Lai, Y.-K.; Huang, J.-Y.; Al-Deyab, S.S.; Zhang, K.-Q. Hierarchical SiO2@Bi2O3 core/shell electrospun fibers for infrared stealth camouflage†. J. Mater. Chem. C 2014, 3, 345–351. [Google Scholar] [CrossRef]

- Kong, M.; Guo, X.; Zhang, S.; Tang, B. Phase change polymer-based structural color photonic films for contactless and inkless writing irreversibly. Chem. Eng. J. 2024, 497, 154992. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Tian, X.; Zhang, Y.; Gao, P.; Hou, J.; Zhong, J. A Simple Coloration of Calcium Alginate Fiber via Structural Colors. Polymers 2025, 17, 2919. https://doi.org/10.3390/polym17212919

Yang X, Tian X, Zhang Y, Gao P, Hou J, Zhong J. A Simple Coloration of Calcium Alginate Fiber via Structural Colors. Polymers. 2025; 17(21):2919. https://doi.org/10.3390/polym17212919

Chicago/Turabian StyleYang, Xinyu, Xing Tian, Yu Zhang, Pengfei Gao, Jianhua Hou, and Junyu Zhong. 2025. "A Simple Coloration of Calcium Alginate Fiber via Structural Colors" Polymers 17, no. 21: 2919. https://doi.org/10.3390/polym17212919

APA StyleYang, X., Tian, X., Zhang, Y., Gao, P., Hou, J., & Zhong, J. (2025). A Simple Coloration of Calcium Alginate Fiber via Structural Colors. Polymers, 17(21), 2919. https://doi.org/10.3390/polym17212919