Effect of Strengthening Location on Seismic Performance of Masonry Domes Retrofitted with Composite Material

Abstract

1. Introduction

2. Materials and Methods

2.1. Characteristics of Khorasan Mortar

2.2. Characteristics of Stone

2.3. CFRP Materials

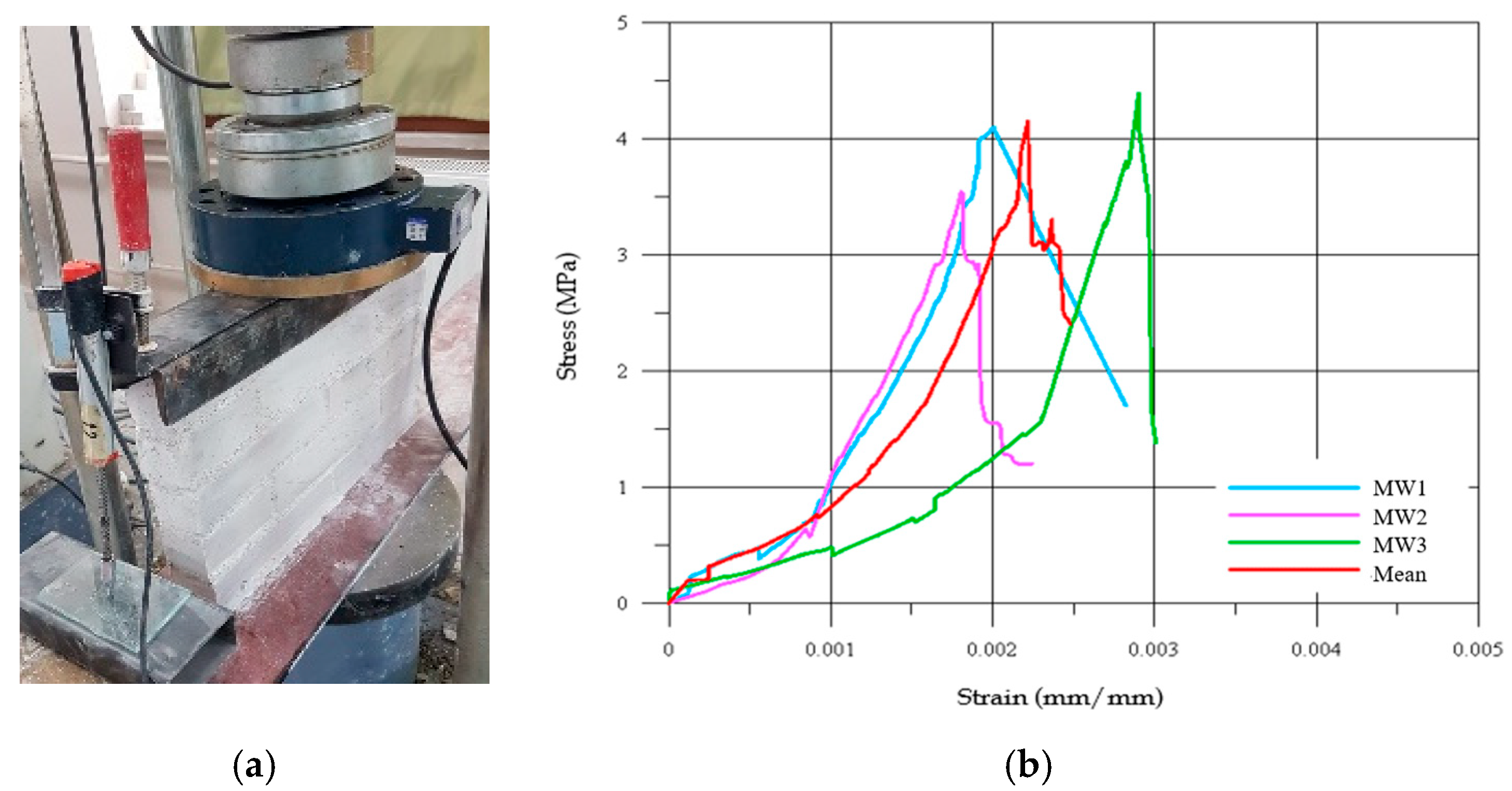

2.4. Masonry Wall Specimens

3. Experimental Tests on Masonry Domes

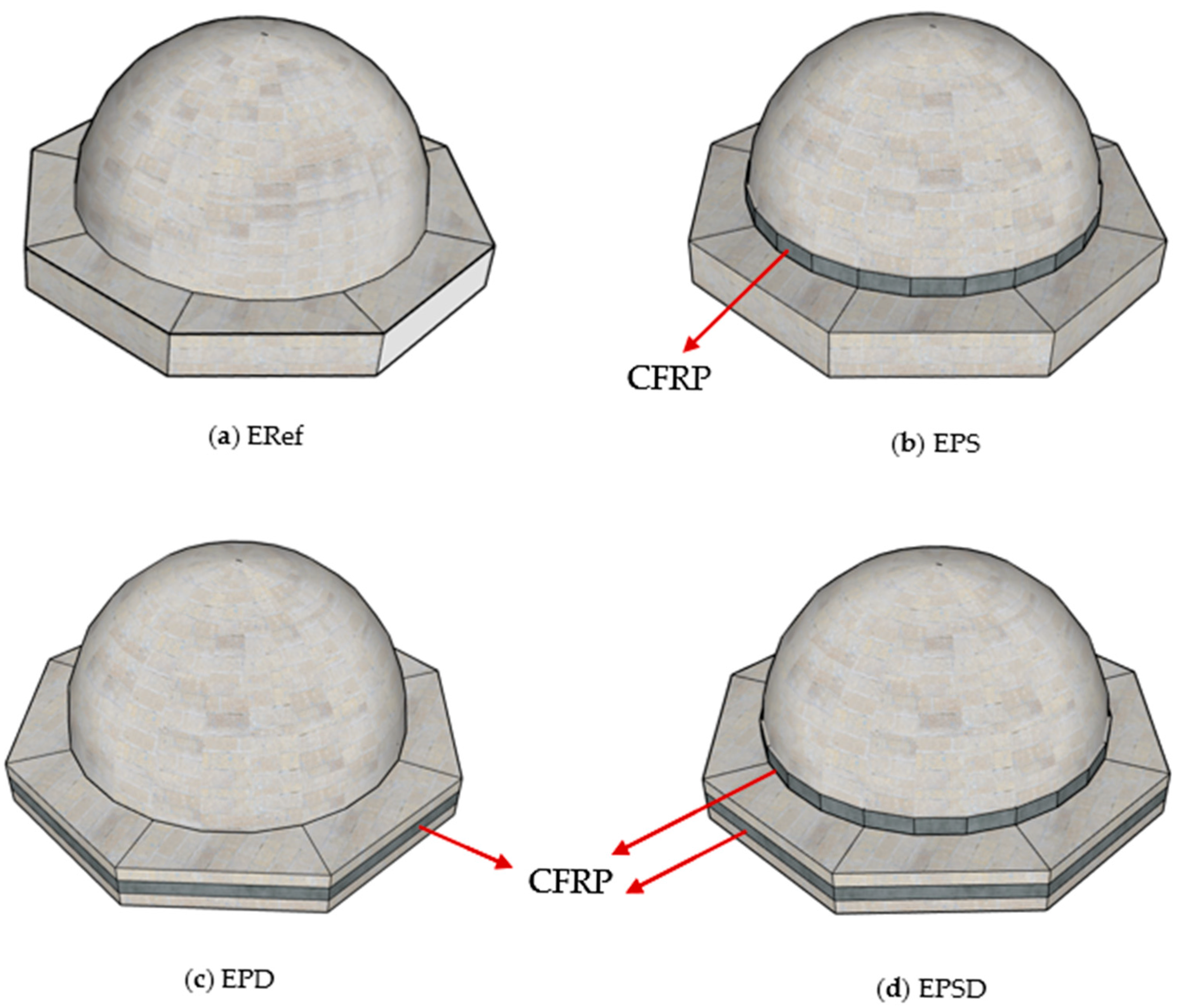

3.1. Dome Specimens

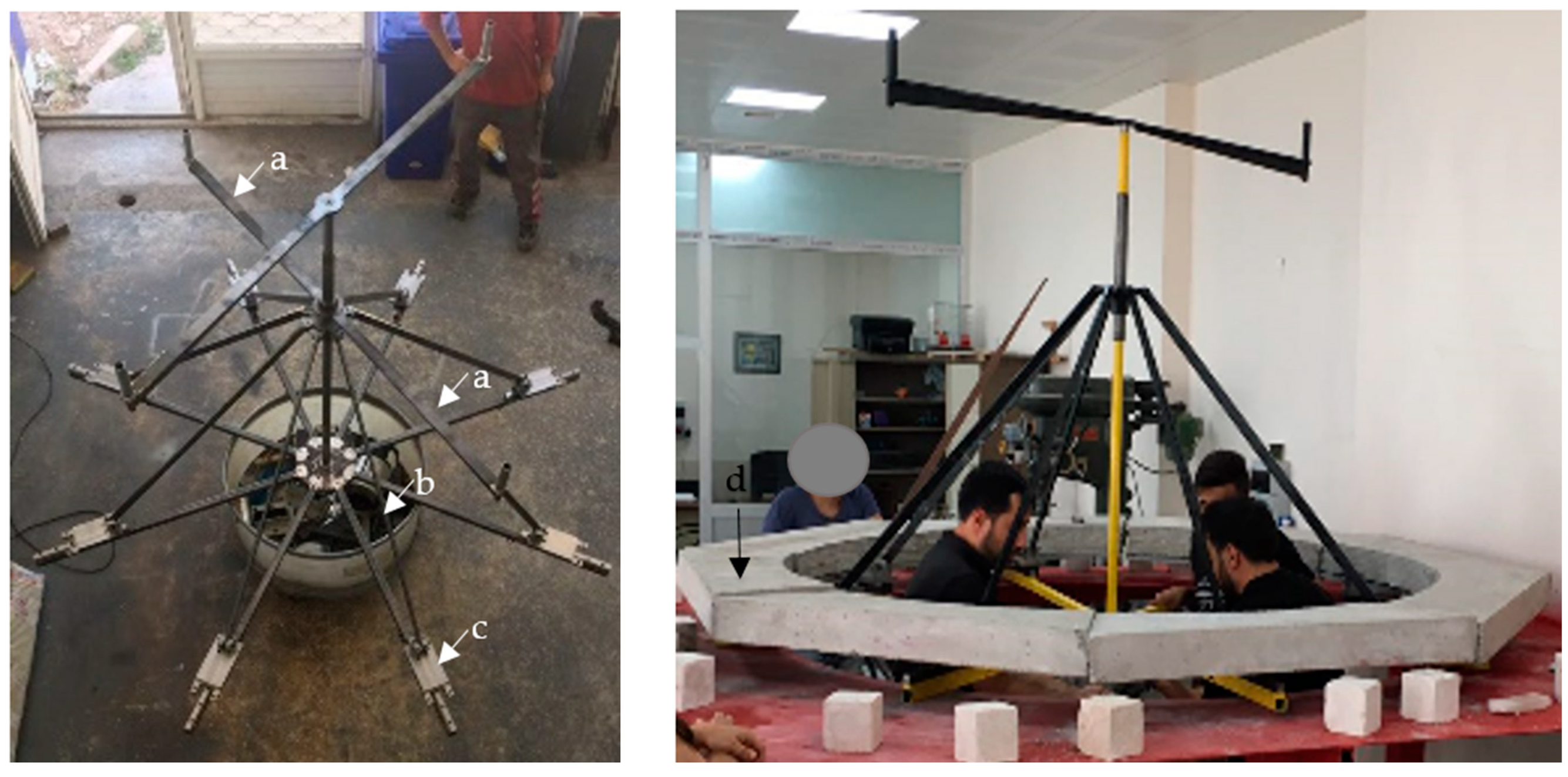

3.2. Test Setup and Instrumentation

4. Numerical Analysis of Masonry Domes

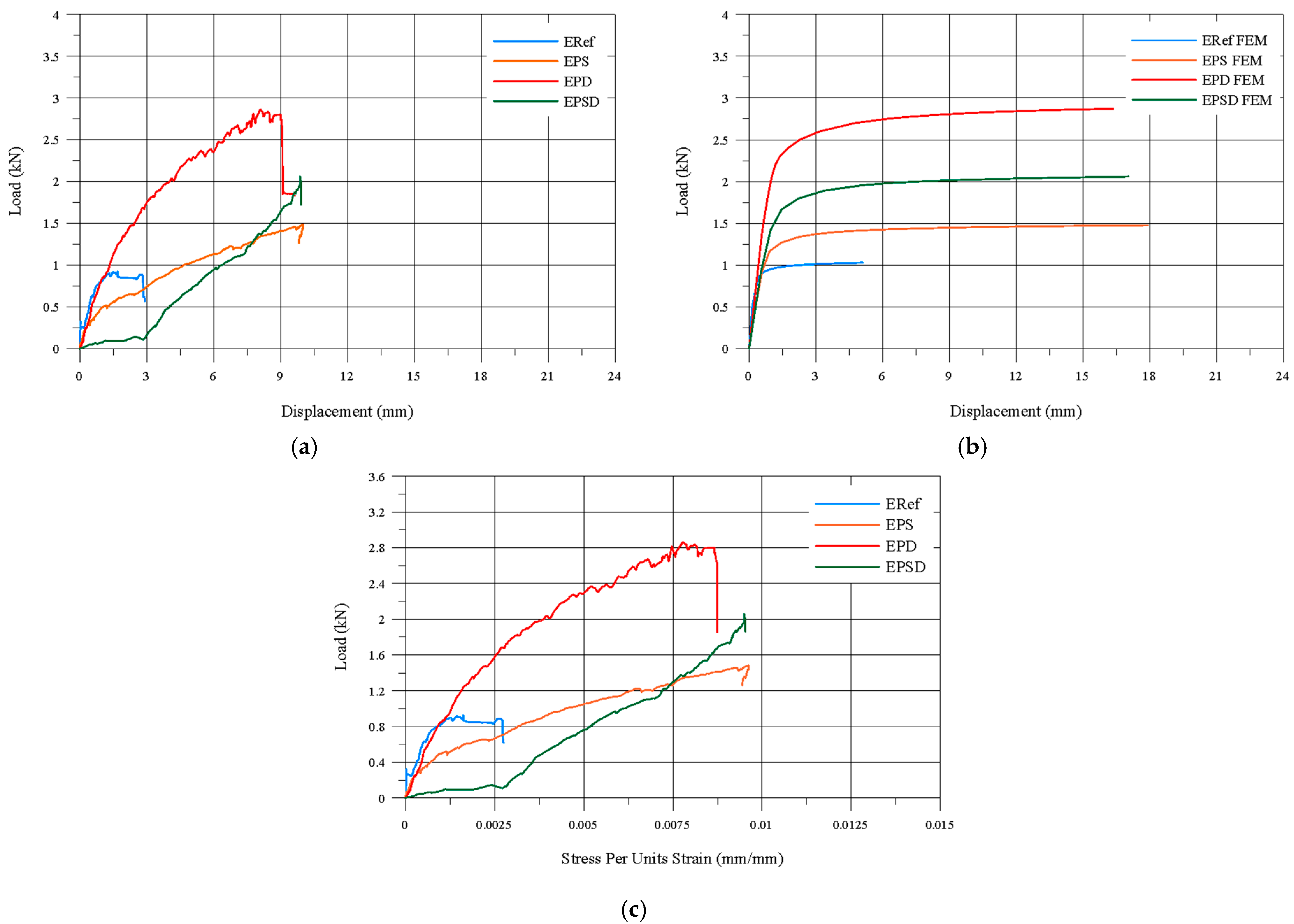

5. Results and Discussion

6. Conclusions

- The analysis showed that the CFRP drum (EPD) specimen carried 1.4 times more of a load than both the CFRP skirt and drum (EPSD) specimen and the CFRP skirt (EPS) specimen. This indicates that CFRP applications are more effective in the drum region and can play a key role in increasing the bearing capacity. In addition, the CFRP reinforcement was found to be more efficient in the angular regions of the dome (drum and skirt) compared to the circular regions (skirt–drum), enhancing the structure’s load-carrying capacity. It was also determined that reinforcing the angular regions is easier and more practical than applying CFRP to the circular regions.

- Evaluation of damage formation in the domes showed that cracks in the CFRP-reinforced specimens occurred mainly in the tensile zones. The cracks were particularly concentrated in the skirt region, the upper part of the body wall, and the corners of the domes, with the crack openings varying depending on the reinforcement zone. In this context, the EPSD specimen experienced the least damage, while the EPS specimen showed the highest number of cracks and overall damage. In the EPSD specimen, reinforcing both the skirt and drum regions limited the dome’s tendency to open and provided more effective protection of structural integrity.

- Evaluation of damage in the drum area showed that the cracks in the skirt corners of the EPD specimen were larger and more pronounced compared to the ERD specimen. Conversely, although the crack openings in the upper part of the body wall were larger in the ERD specimen than in the EPD specimen, crack propagation toward the upper parts of the domes was more effectively limited in the ERD specimen. This indicates that not only the crack density and spacing, but also the direction of crack propagation, vary significantly depending on the location of the retrofit application.

- Comparison of the experimental results with the numerical analysis obtained using the finite element method showed that the displacement values increased in parallel with the load in both models. The displacement values, particularly at maximum load levels, were found to be very close. Furthermore, the load–displacement curves from the experimental and numerical analyses largely overlapped, demonstrating that the developed finite element model successfully captured the experimental behavior.

- This study focused on experimental and numerical analyses, but future research should also consider analytical solution methods to provide a more comprehensive evaluation of the effects of different modeling approaches. Additionally, by varying the geometric dimensions of the CFRP materials, the impact of dimensional differences on structural performance can be investigated, allowing for determination of the optimal strengthening parameters for dome behavior.

- While the EPSD strengthening method provided balanced structural improvement, practical factors, such as accessibility, as well as increased labor and material costs, must also be considered in real-world applications.

- While the study confirms the effectiveness of CFRP strengthening of the drum region, limitations, such as scalability to full-scale domes, long-term durability under environmental conditions, and cost implications, should be considered. Further research involving full-scale experiments and long-term monitoring is needed to fully validate the practical application of this method to heritage structures.

- This study highlights the effectiveness of CFRP materials for strengthening historic dome structures, showing that the bearing capacity can be increased by reinforcing the drum region. The results indicate that CFRP applications are particularly efficient in angular regions, providing a reliable solution for strengthening domes. Furthermore, this study offers a solid foundation for future research and serves as a guiding resource for researchers in the field.

- Future research will focus on dynamic testing to evaluate the seismic performance of masonry domes strengthened with CFRP materials. Additionally, hybrid CFRP techniques and regional reinforcement optimization will be explored to identify the most effective strengthening methods. Their long-term durability under environmental conditions will also be assessed to develop sustainable intervention strategies. These efforts aim to contribute significantly to the preservation of historic domes.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Celik, T. Strengthening Methods in Historical Mosque Domes Examination with Experimental Methods. Ph.D. Thesis, Aksaray University, Institute of Science and Technology, Aksaray, Turkey, 2020. Available online: https://hdl.handle.net/20.500.12451/8023 (accessed on 20 September 2025).

- Firat, F.; Ural, A.; Kara, M.E. Sivrice Earthquake and the response of the masonry Haci Yusuf Tas (New) mosque. Earthq. Struct. 2022, 22, 331–343. [Google Scholar] [CrossRef]

- Dollente, I.J.R.; Valerio, D.N.R.; Quiatchon, P.R.J.; Abulencia, A.B.; Villoria, M.B.D.; Garciano, L.E.O.; Ongpeng, J.M.C. Enhancing the mechanical properties of historical masonry using Fiber-Reinforced geopolymers. Polymers 2023, 15, 1017. [Google Scholar] [CrossRef]

- Mercuri, M.; Pathirage, M.; Gregori, A.; Cusatis, G. Masonry vaulted structures under spreading supports: Analyses of fracturing behavior and size effect. J. Build. Eng. 2022, 45, 103396. [Google Scholar] [CrossRef]

- Tanriverdi, S. An experimental and numerical study of the strengthening of masonry brick vaults. Structures 2023, 47, 800–813. [Google Scholar] [CrossRef]

- Latifi, R.; Hadzima-Nyarko, M.; Radu, D.; Rouhi, R. A Brief Overview on Crack Patterns, Repair and Strengthening of Historical Masonry Structures. Materials 2023, 16, 1882. [Google Scholar] [CrossRef]

- Celik, T. Assessment of In Plane Shear Behavior of Historical Andesite Stone–Khorasan Mortar Masonry Walls Strengthened with CFRP Based Techniques and Repair Mortar. Compos. Part B Eng. 2025, 305, 112678. [Google Scholar] [CrossRef]

- Hernoune, H.; Benabed, B.; Abousnina, R.; Alajmi, A.; Alfadhili, A.M.G.; Shalwan, A. Experimental research and numerical analysis of CFRP retrofitted masonry triplets under shear loading. Polymers 2022, 14, 3707. [Google Scholar] [CrossRef]

- Orlando, M.; Becattini, G.; Betti, M. Multilevel structural evaluation and rehabilitation design of an historic masonry fortress. J. Build. Eng. 2023, 63, 105379. [Google Scholar] [CrossRef]

- Koçaman, İ.; Gedik, Y.; Okuyucu, D. Assessment of seismic behavior of historical masonry cupolas: Case of Emir Saltuk Cupola. J. Build. Eng. 2024, 82, 108275. [Google Scholar] [CrossRef]

- Cakiroglu, M.A.; Evci, P.U.; Sever, A.E.; Kaplan, A.N. The Effects of Shotcrete Strengthening on the Seismic Vulnerability of an Existing Masonry Building Damaged in the 6th of February Kahramanmaraş Turkiye Earthquakes. J. Earthq. Tsunami 2025, 19, 2550017. [Google Scholar] [CrossRef]

- Altunişik, A.C.; Sunca, F.; Genç, A.F.; Tavşan, C. Post Earthquake Damage Assessments of Historic Mosques and Effects of Near Fault and Far Fault Ground Motions on Seismic Responses. Int. J. Archit. Herit. 2023, 17, 1043–1078. [Google Scholar] [CrossRef]

- Hejazi, M.; Baranizadeh, S.; Daei, M. Performance of Persian brick masonry single shell domes subjected to uniform pressure and concentrated load. Structures 2021, 34, 1710–1719. [Google Scholar] [CrossRef]

- Uysal, N.; Evci, P.U. Investigation of the dynamic behavior of a registered masonry building in Turkey and strengthening suggestions by CFRP. J. Earthq. Tsunami 2025, 19, 2450012. [Google Scholar] [CrossRef]

- Tanriverdi, S.; Firat, F.K. The Effect of Window Opening Ratio on Dome Behavior in Ottoman Historical Masonry Buildings. Structures 2025, 78, 109253. [Google Scholar] [CrossRef]

- Jasieńko, J.; Raszczuk, K.; Kleszcz, K.; Frąckiewicz, P. Numerical analysis of historical masonry domes: A study of St. Peter’s Basilica dome. Structures 2021, 31, 80–86. [Google Scholar] [CrossRef]

- Celik, T. Strengthening strategies for unreinforced stone masonry walls using FRP and CFM composites. Sci. Rep. 2025, 15, 28167. [Google Scholar] [CrossRef]

- Feizolahbeigi, A.; Ramirez, R.; Lourenço, P.B. Seismic assessment of a dome structure with minarets as secondary elements: The case of Soltaniyeh Dome in Iran. Structures 2024, 63, 106408. [Google Scholar] [CrossRef]

- Foraboschi, P. Resisting system and failure modes of masonry domes. Eng. Fail. Anal. 2014, 44, 315–337. [Google Scholar] [CrossRef]

- Tuhta, S.; Günday, F.; Pehlivan, N.C. Investigation of CFRP retrofitting effect on masonry dome on bending moment using finite element method. Int. J. Innov. Eng. Res. Technol. 2019, 6, 18–22. [Google Scholar]

- Al Saigh, D.; Al Mahaidi, R. Rehabilitation of historic masonry dome of Imam Al Abbas Bin Ali shrine using CFRP systems. In Proceedings of 4th Asia-Pacific Conference on FRP in Structures (APFIS 2013), Melbourne, Australia, 11–13 December 2013. [Google Scholar]

- Hrasnica, M.; Medic, S. Seismic strengthening of historical stone masonry structures in Bosnia Herzegovina. In Proceedings of the 15th World Conference on Earthquake Engineering, Istanbul, Turkey, 24–28 September 2012. [Google Scholar]

- Bayraktar, A.; Bayraktar, S.; Hökelekli, E. Strengthening techniques for masonry domes: A review. Int. J. Space Struct. 2023, 38, 30–39. [Google Scholar] [CrossRef]

- Gandolfi, A.; Pingaro, N.; Milani, G. Simple nonlinear numerical modeling for unreinforced and FRP reinforced masonry domes. Buildings 2024, 14, 166. [Google Scholar] [CrossRef]

- Fraternali, F.; Carpentieri, G.; Modano, M.; Fabbrocino, F.; Skelton, R.E. A tensegrity approach to the optimal reinforcement of masonry domes and vaults through fiber reinforced composite materials. Compos. Struct. 2015, 134, 247–254. [Google Scholar] [CrossRef]

- Lin, B.; Chun, Q.; Ma, Y. Seismic Behavior of Historical Masonry Arched Walls Reinforced with Novel Hybrid FRPs. Structures 2025, 71, 107987. [Google Scholar] [CrossRef]

- Dan, S.; Herban, S.; Ionescu, D. Structural rehabilitation of historical masonry buildings in Romania. In Proceedings of the 4th International Conference Contemporary Achievements in Civil Engineering, Subotica, Serbia, 22 April 2016; pp. 155–161. [Google Scholar] [CrossRef]

- Gupta, T.; Dubey, K.; Panwar, G.; Singh, S. Numerical Modeling of Retrofitted Structures. In Proceedings of the International Conference on Intelligent Engineering and Management (ICIEM), London, UK, 17–19 June 2020; pp. 431–436. [Google Scholar] [CrossRef]

- Buyukkaragoz, A.; Kopraman, Y. In plane behaviour of masonry brick walls strengthened with mortar from two sides. Structures 2021, 29, 1627–1639. [Google Scholar] [CrossRef]

- Hamdy, G.; Kamal, O.; Al Hariri, O.; El Salakawy, T. Plane and vaulted masonry elements strengthened by different techniques–Testing, numerical modeling and nonlinear analysis. J. Build. Eng. 2018, 15, 203–217. [Google Scholar] [CrossRef]

- EN 12390-3; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. Turkish Standards Institution (TSE): Ankara, Turkey, 2019.

- EN 12390-6; Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens. Turkish Standards Institution (TSE): Ankara, Turkey, 2010.

- EN 772-1:2011+A1; Methods of Test for Masonry Units—Part 1: Determination of Compressive Strength. Turkish Standards Institution (TSE): Ankara, Turkey, 2015.

- EN 772-6; Methods of Test for Masonry Units—Part 6: Determination of Bending Tensile Strength of Aggregate Concrete Masonry Units. Turkish Standards Institution (TSE): Ankara, Turkey, 2004.

- Fırat, F.K.; Eren, A. Investigation of frp effects on damaged arches in historical masonry structures. J. Fac. Eng. Archit. Gazi Univ. 2015, 30, 659–670. [Google Scholar]

- TS EN 1052-1:2000; Methods of Test for Masonry—Part 1: Determination of Compressive Strength. Turkish Standards Institution (TSE): Ankara, Turkey, 2000.

- TS EN 1996-1-1:2005+A1; Design of Masonry Structures—Part 1-1: General Rules for Buildings—Rules for Reinforced and Unreinforced Masonry. Turkish Standards Institution (TSE): Ankara, Turkey, 2005.

- Firat, F.K.; Tanriverdi, S. The investigation of drum height effects on masonry domes. Struct. Eng. Mech. 2025, 94, 113–127. [Google Scholar] [CrossRef]

- FEA Ltd. LUSAS Finite Element Analysis Software Products; Finite Element System: Kingston upon Thames, UK, 2020. [Google Scholar]

- Paulo, B.L. Computations on historic masonry structures. Prog. Struct. Eng. Mater. 2002, 4, 301–319. [Google Scholar] [CrossRef]

- Usta, P.; Karimzadeh, S.; Lourenço, P.B. Seismic fragility assessment of historical Khan structures in Izmir (Türkiye). Structures 2025, 81, 110208. [Google Scholar] [CrossRef]

- Hollaway, L.C.; Teng, J.G. Strengthening and Rehabilitation of Civil İnfrastructures Using Fibre-Reinforced Polymer (FRP) Composites; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

| Series | Maximum Loading (kN) | Compressive Strength (N/mm2) | Series | Maximum Loading (kN) | Flexural Tensile Strength (N/mm2) |

|---|---|---|---|---|---|

| KC1 | 5.45 | 2.18 | KT1 | 0.35 | 0.88 |

| KC2 | 5.07 | 2.03 | KT2 | 0.30 | 0.75 |

| KC3 | 4.79 | 1.92 | KT3 | 0.28 | 0.70 |

| KC4 | 5.25 | 2.10 | KT4 | 0.34 | 0.85 |

| KC5 | 4.87 | 1.95 | KT5 | 0.30 | 0.75 |

| KC6 | 5.17 | 2.07 | KT6 | 0.33 | 0.83 |

| Mean | 5.10 | 2.04 | 0.32 | 0.79 | |

| ±SD | 0.25 | 0.10 | 0.027 | 0.07 |

| Series | Maximum Loading (kN) | Compressive Strength (N/mm2) | Series | Maximum Loading (kN) | Flexural Tensile Strength (N/mm2) |

|---|---|---|---|---|---|

| AC1 | 18.34 | 7.34 | AT1 | 6.15 | 15.38 |

| AC2 | 18.21 | 7.28 | AT2 | 5.87 | 14.68 |

| AC3 | 18.17 | 7.27 | AT3 | 5.65 | 14.13 |

| AC4 | 17.79 | 7.12 | AT4 | 5.18 | 12.95 |

| AC5 | 17.52 | 7.01 | AT5 | 5.12 | 12.80 |

| AC6 | 16.91 | 6.76 | AT6 | 4.85 | 12.13 |

| Mean | 17.82 | 7.13 | 5.47 | 13.68 | |

| ±SD | 0.54 | 0.22 | 0.50 | 1.25 |

| System | Thickness (t), mm | Yield Strength (MPa) | Strain at Ultimate (µ-Strain) | Modulus of Elasticity, GPa |

|---|---|---|---|---|

| CFRP (Unidirectional) | 0.131 | 4300 | 0.018 | 234 |

| Epoxy | - | 12,500 | 0.009 | 3.8 |

| Specimens | Max. Load, V (kN) | Compressive Strength, f (MPa) | Young’s Modulus, E (MPa) | Ratio, E/f |

|---|---|---|---|---|

| MW1 | 81.80 | 4.09 | 2038 | 582 |

| MW2 | 70.60 | 3.53 | 1947 | 556 |

| MW3 | 87.80 | 4.39 | 1514 | 433 |

| Mean | 80.07 | 4.00 | 1833 | 524 |

| ±SD | 8.73 | 0.44 | 279.97 | 79.57 |

| Materials | Properties | Values |

|---|---|---|

| Masonry Wall | Elasticity module (MPa) | 1850 |

| Poisson’s ratio | 0.2 | |

| Cohesion (MPa) | 2.5 | |

| Internal friction angle | 25 | |

| Plastic deformation | 0.001 | |

| CFRP + Epoxy | Elasticity module (MPa) | 234,000 |

| Poisson’s ratio | 0.3 | |

| Uniaxial yield stress (MPa) | 4300 | |

| Plastic deformation | 0.018 |

| Experiment Name | Max. Load (kN) | Increase a (%) | Displacement (mm) | Stress per Unit Strain (mm/mm) |

|---|---|---|---|---|

| ERef Experiment | 0.92 | 0 | 5.08 | 0.00265 |

| EPS Experiment | 1.48 | 160.87 | 17.49 | 0.00956 |

| EPD Experiment | 2.86 | 310.87 | 16.03 | 0.00927 |

| EPSD Experiment | 2.06 | 223.91 | 17.05 | 0.00949 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Celik, T.; Ural, A. Effect of Strengthening Location on Seismic Performance of Masonry Domes Retrofitted with Composite Material. Polymers 2025, 17, 2921. https://doi.org/10.3390/polym17212921

Celik T, Ural A. Effect of Strengthening Location on Seismic Performance of Masonry Domes Retrofitted with Composite Material. Polymers. 2025; 17(21):2921. https://doi.org/10.3390/polym17212921

Chicago/Turabian StyleCelik, Tulin, and Ali Ural. 2025. "Effect of Strengthening Location on Seismic Performance of Masonry Domes Retrofitted with Composite Material" Polymers 17, no. 21: 2921. https://doi.org/10.3390/polym17212921

APA StyleCelik, T., & Ural, A. (2025). Effect of Strengthening Location on Seismic Performance of Masonry Domes Retrofitted with Composite Material. Polymers, 17(21), 2921. https://doi.org/10.3390/polym17212921