Crashworthiness Prediction of Perforated Foam-Filled CFRP Rectangular Tubes Crash Box Using Machine Learning

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

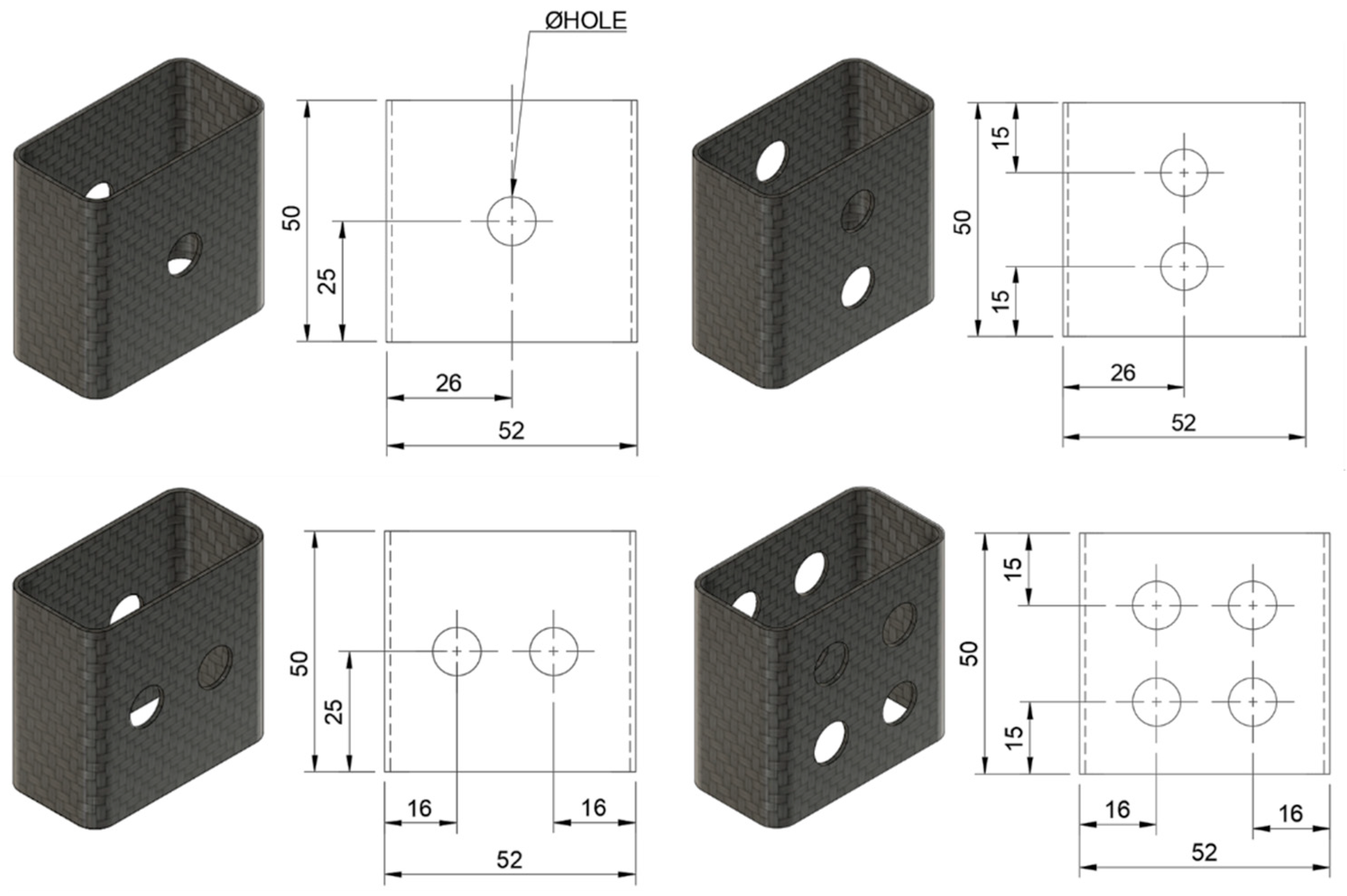

2.2. Experimental Methods

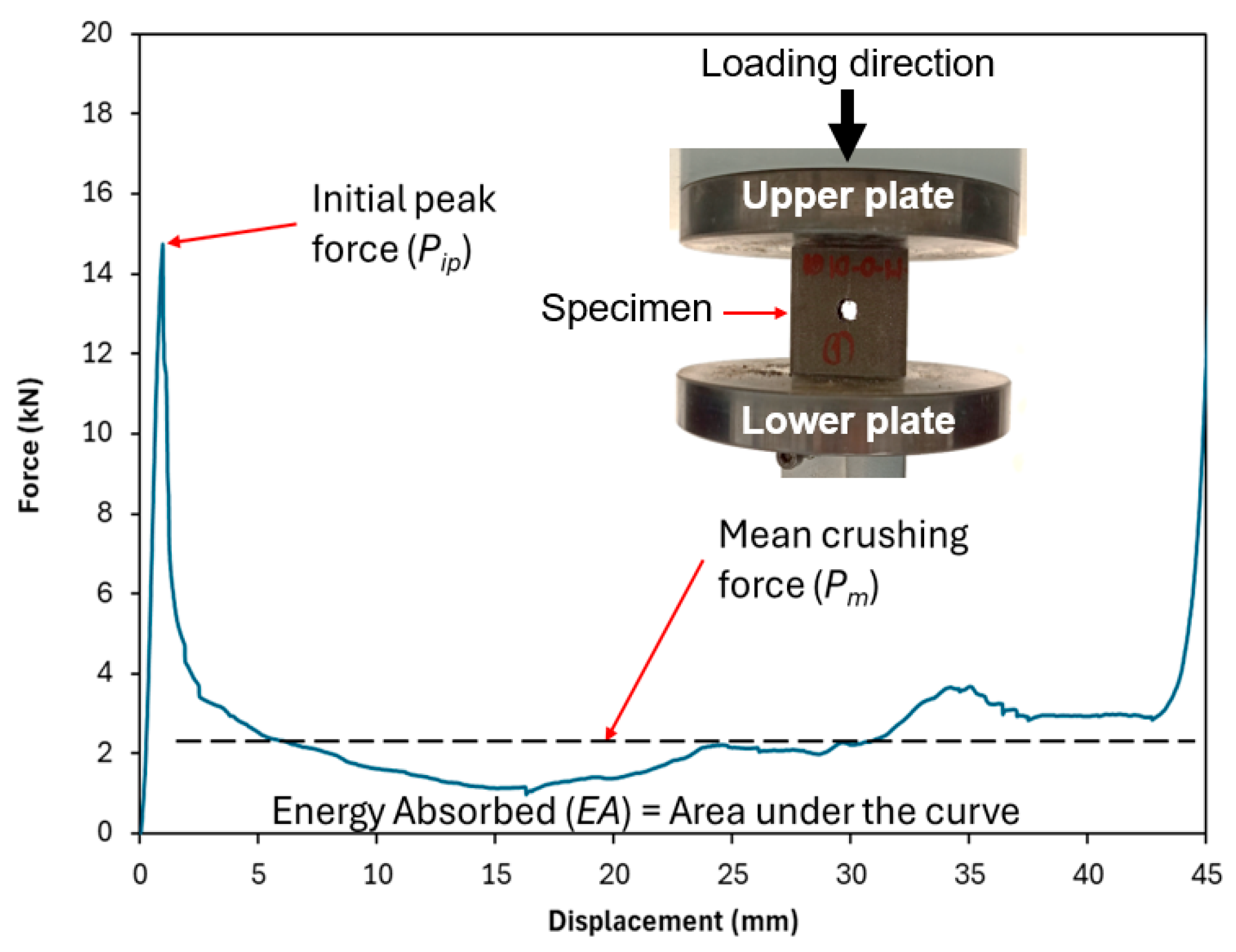

2.3. Crashworthiness Indicators

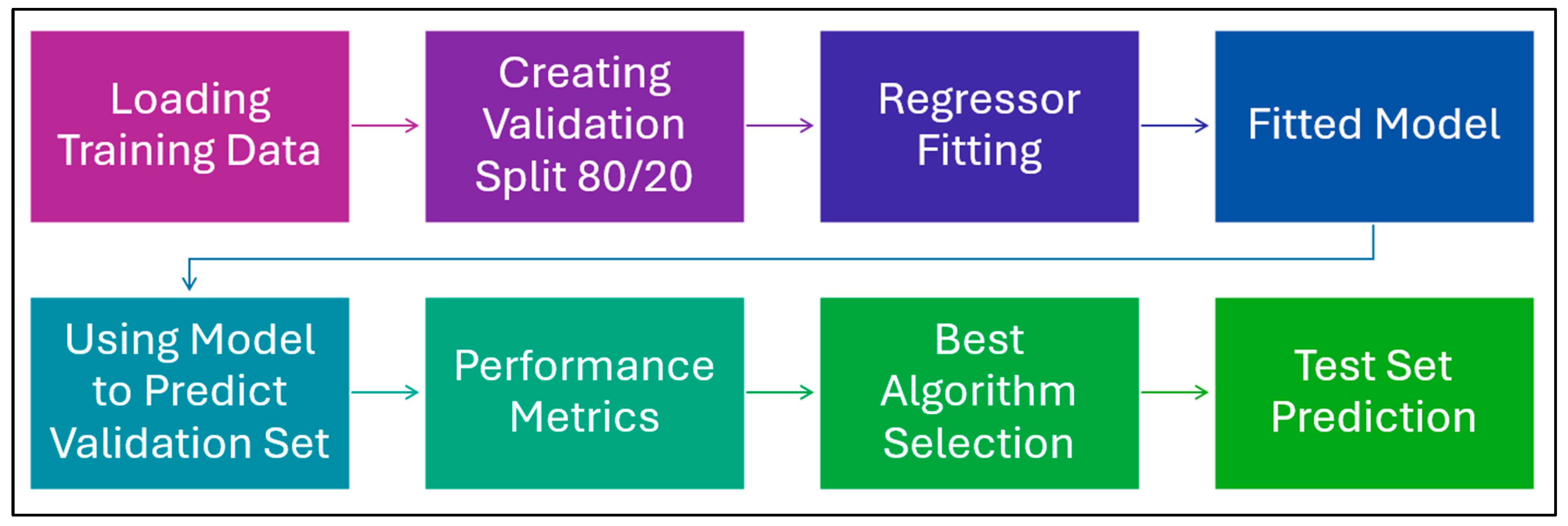

2.4. Machine Learning

2.4.1. Decision Tree Regression

2.4.2. Linear Regression

2.4.3. Ridge Regression

2.4.4. Lasso Regression

2.4.5. Elastic Nets

2.4.6. Multilayer Perceptron

3. Results and Discussion

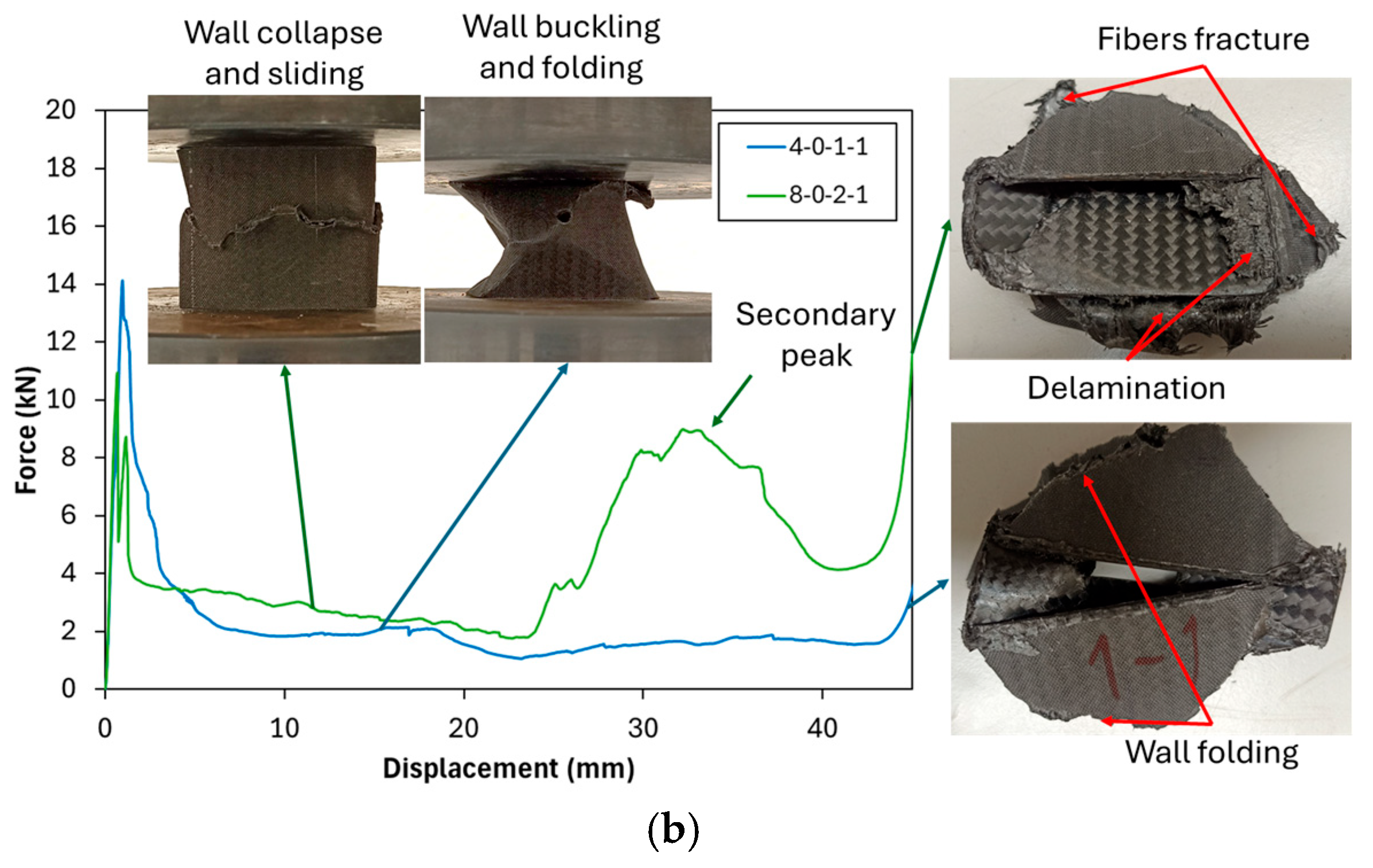

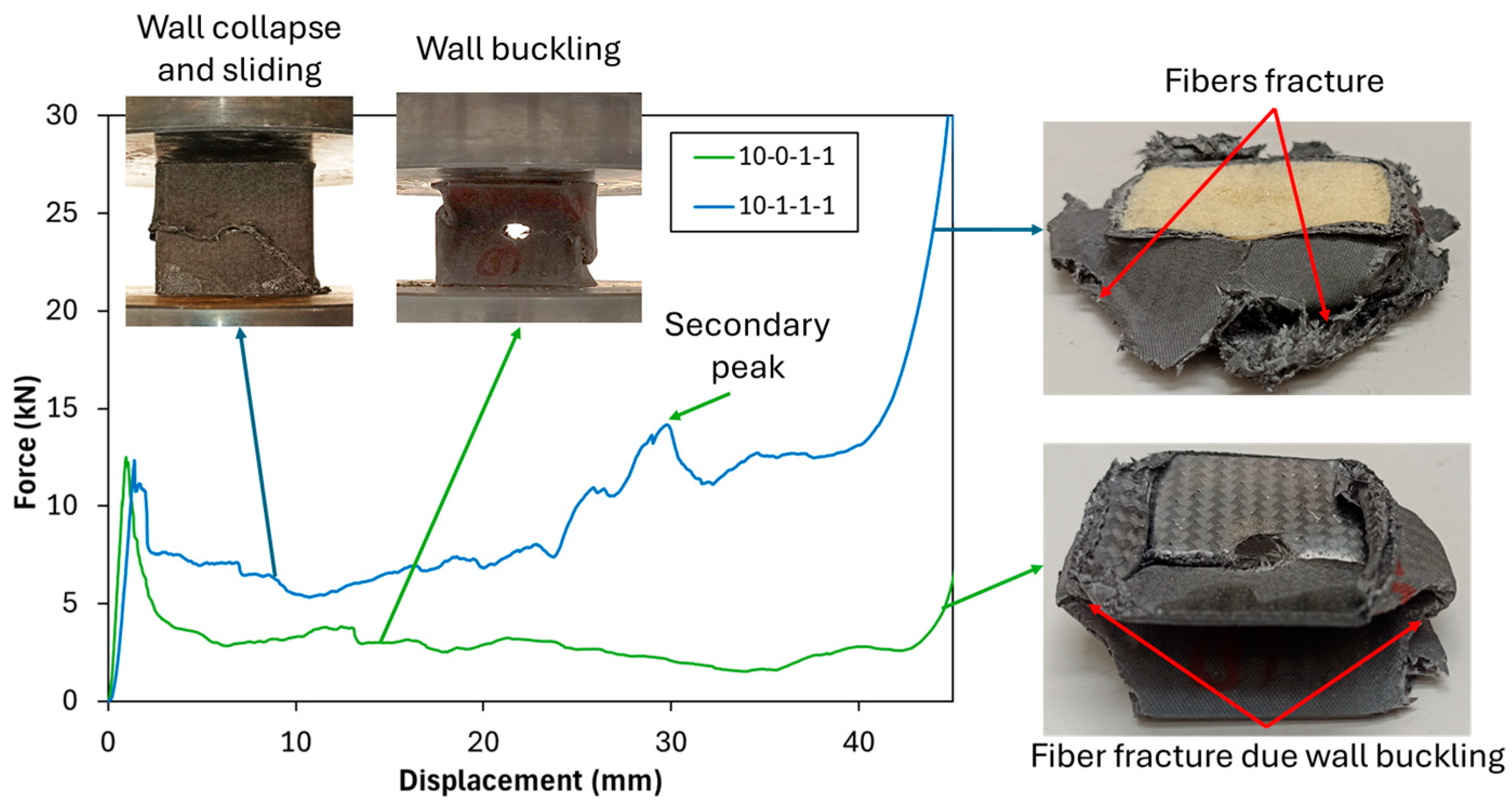

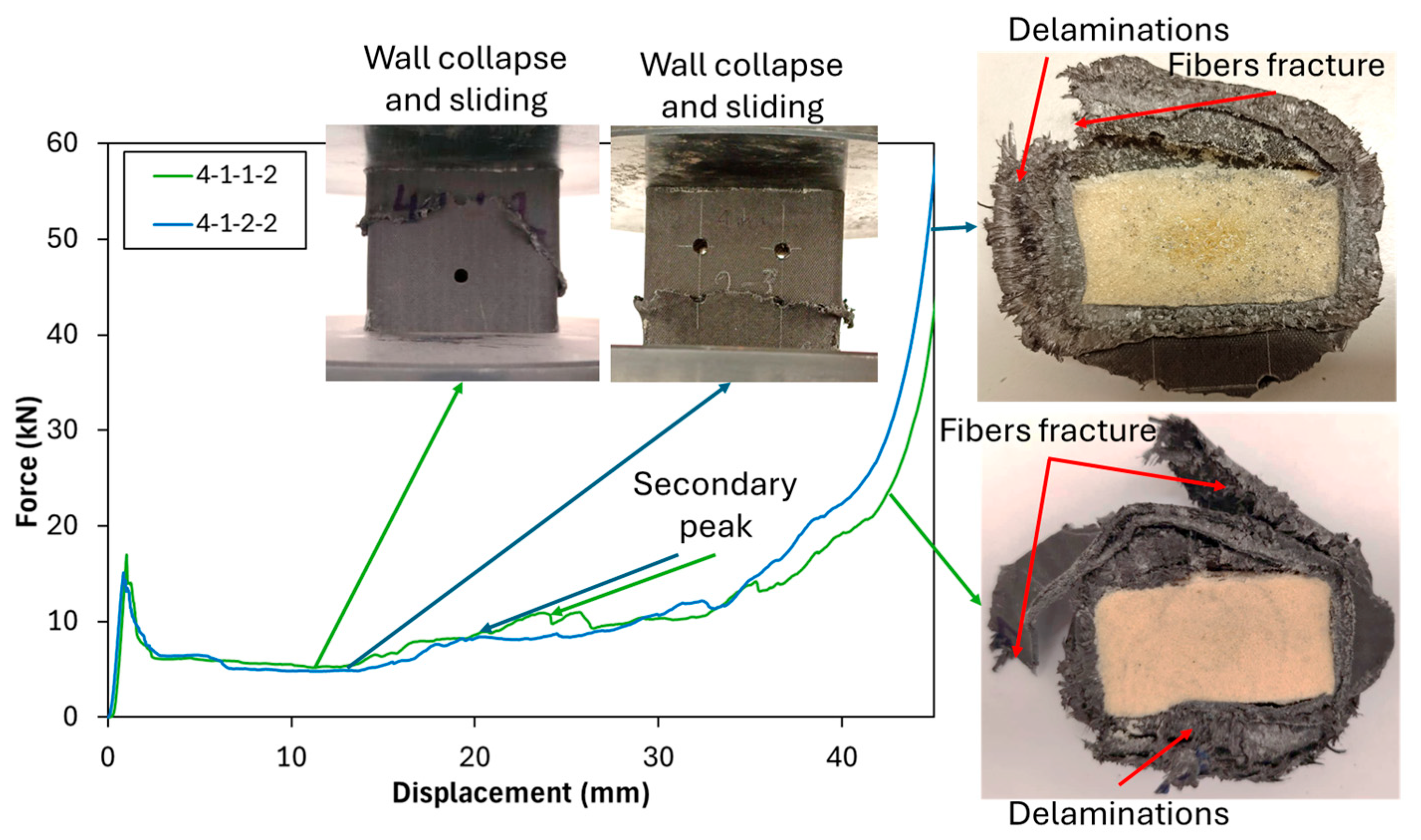

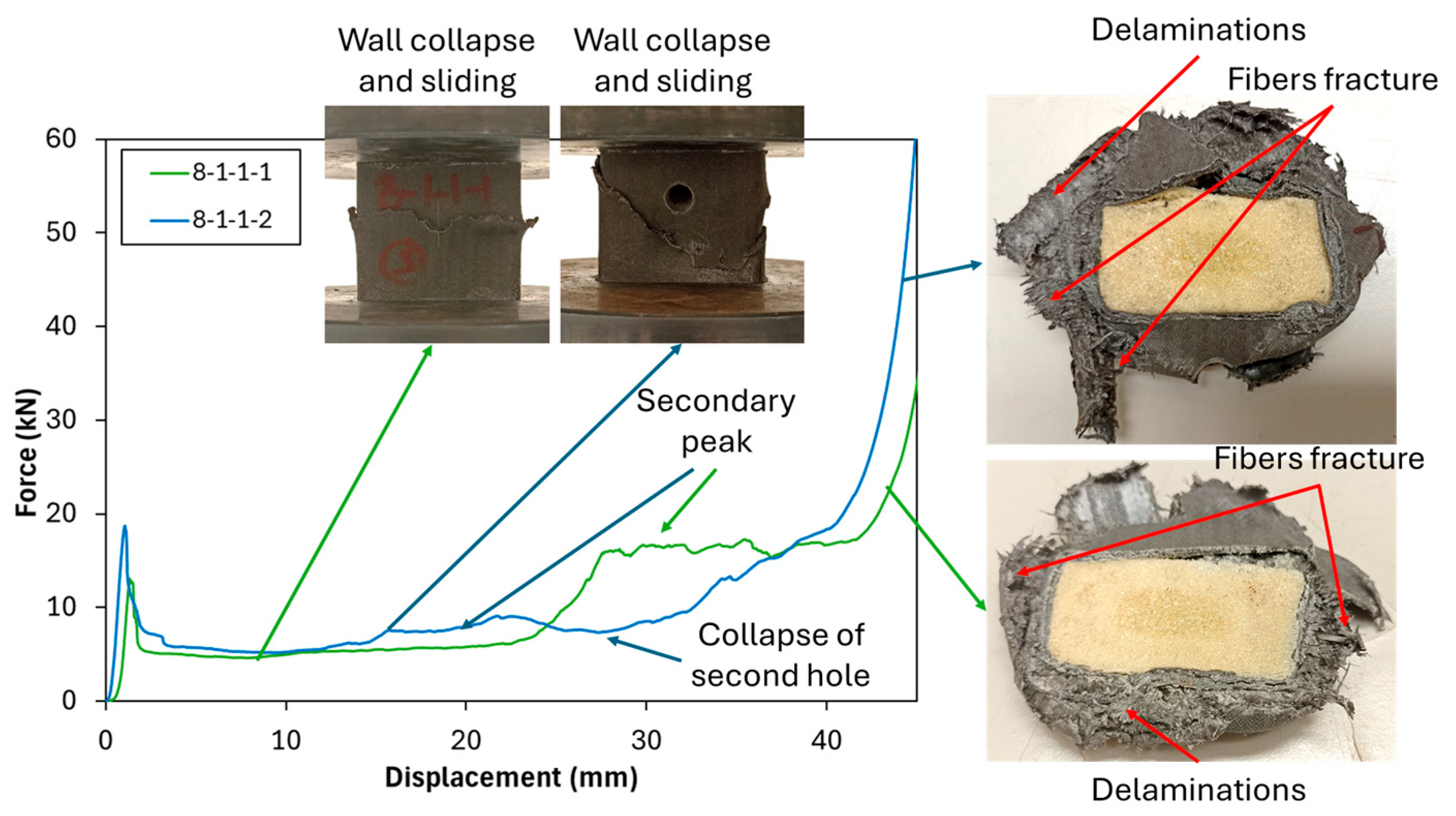

3.1. Experimental Results

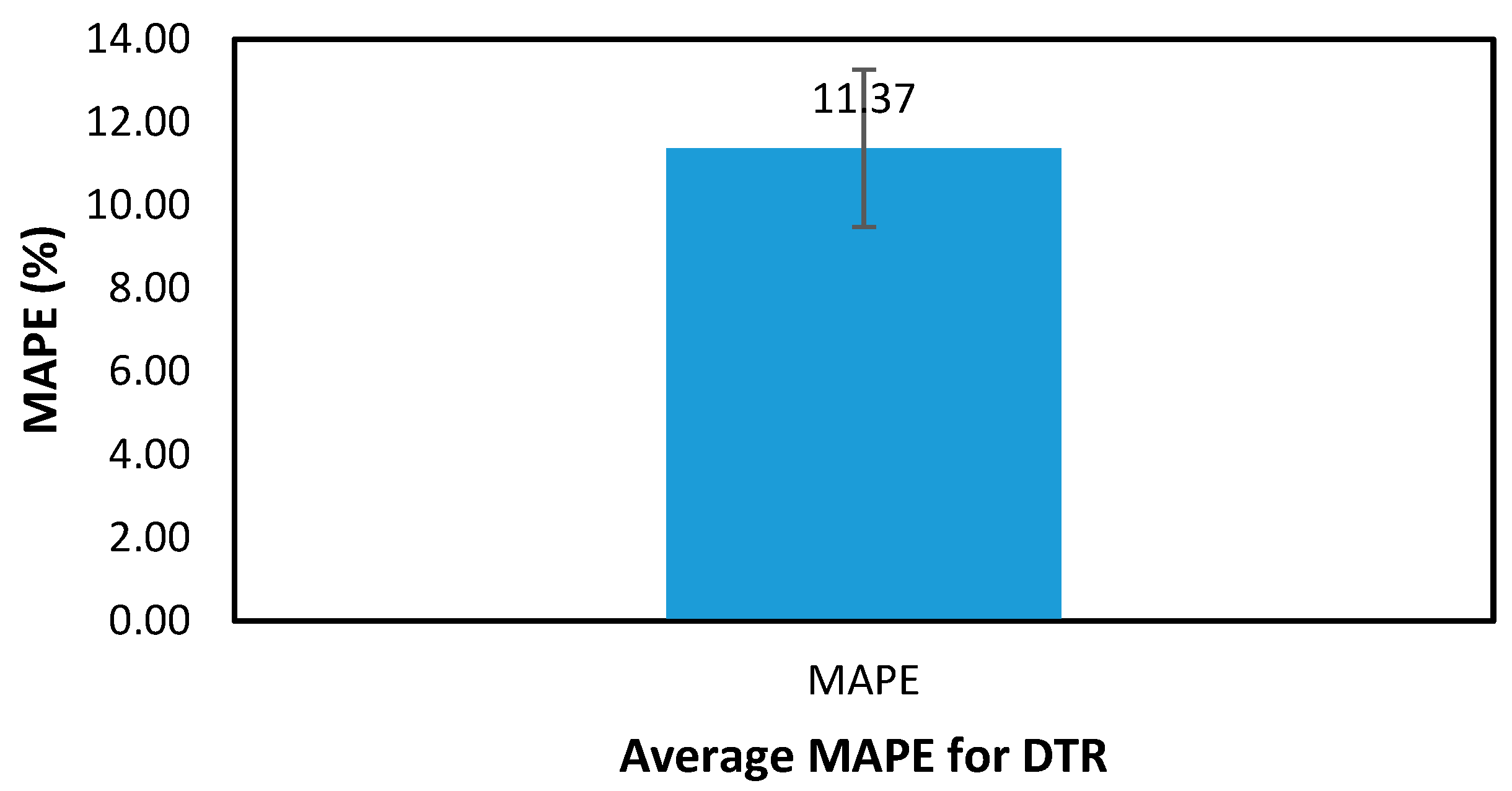

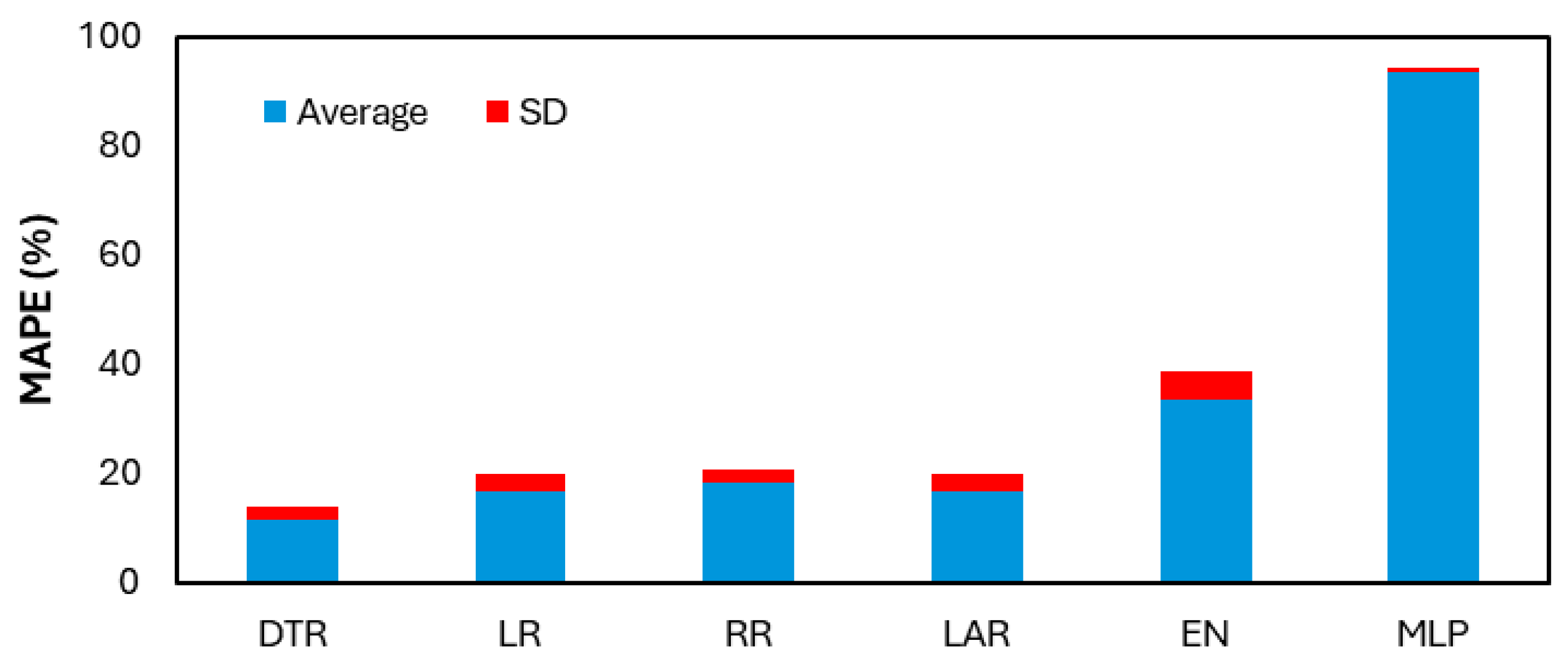

3.2. Machine Learning Prediction

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANN | Artificial Neural Network |

| CFE | Crush force efficiency |

| CFRP | Carbon fiber-reinforced polymer |

| DTR | Decision tree regressor |

| EA | Energy absorption |

| EN | Elastic nets |

| HP | Hyperparameters |

| LAR | Lasso regressor |

| LR | Linear regressor |

| MAPE | Mean absolute percentage error |

| ML | Machine learning |

| MLP | Multi-layer perceptron |

| NSGA-II | Non-dominated sorting genetic algorithm II |

| Pip | Initial peak force |

| Pm | Mean crushing force |

| PUF | Polyurethane foam |

| ReLU | Rectified Linear Unit |

| RL | Reinforcement learning |

| RMSE | Root mean squared error |

| RNN | Recurrent Neural Networks |

| RR | Ridge regressor |

| RSS | Residual sum of squares |

| SEA | Specific absorbed energy |

| Vf | Fiber volume fraction |

References

- Baroutaji, A.; Morris, E.; Olabi, A.G. Quasi-Static Response and Multi-Objective Crashworthiness Optimization of Oblong Tube under Lateral Loading. Thin-Walled Struct. 2014, 82, 262–277. [Google Scholar] [CrossRef]

- Awd Allah, M.M.; Abd El-baky, M.A. Multi-Objective Optimization through Desirability Function Analysis on the Crashworthiness Performance of Thermoplastic/Thermoset Hybrid Structures. Compos. B Eng. 2024, 284, 111742. [Google Scholar] [CrossRef]

- Capretti, M.; Del Bianco, G.; Giammaria, V.; Boria, S. Natural Fibre and Hybrid Composite Thin-Walled Structures for Automotive Crashworthiness: A Review. Materials 2024, 17, 2246. [Google Scholar] [CrossRef]

- Falaschetti, M.P.; Semprucci, F.; Birnie Hernández, J.; Troiani, E. Experimental and Numerical Assessment of Crashworthiness Properties of Composite Materials: A Review. Aerospace 2025, 12, 122. [Google Scholar] [CrossRef]

- Ramalingam, S.K.; Selvan, D.K.; Manoj Mohan Prasath, V.; Suresh Balaji, R.; Loganathan, P.; Naveen Kumar, A. A Crashworthiness Study of Composites for Automobiles. In Sustainable Composites for Automotive Engineering; Elsevier: Amsterdam, The Netherlands, 2026; pp. 489–518. [Google Scholar]

- El-baky, M.A.A.; Allah, M.M.A.; Kamel, M.; Abd-Elaziem, W. Lightweight Cost-Effective Hybrid Materials for Energy Absorption Applications. Sci. Rep. 2022, 12, 21101. [Google Scholar] [CrossRef] [PubMed]

- El-baky, M.A.A.; Allah, M.M.A.; Kamel, M.; Abdel-Aziem, W. Fabrication of Glass/Jute Hybrid Composite over Wrapped Aluminum Cylinders: An Advanced Material for Automotive Applications. Fibers Polym. 2023, 24, 143–155. [Google Scholar] [CrossRef]

- Al Antali, A.; Umer, R.; Zhou, J.; Cantwell, W.J. The Energy-Absorbing Properties of Composite Tube-Reinforced Aluminum Honeycomb. Compos. Struct. 2017, 176, 630–639. [Google Scholar] [CrossRef]

- Allah, M.M.A.; Hegazy, D.A.; Alshahrani, H.; Sebaey, T.A.; El-baky, M.A.A. Fiber Metal Laminates Based on Natural/Synthesis Fiber Composite for Vehicles Industry: An Experimental Comparative Study. Fibers Polym. 2023, 24, 2877–2889. [Google Scholar] [CrossRef]

- Guo, S.; Qi, J.; Wang, Y.; Liu, Z.; Li, J. A Flexible Impact Sensor of Interpenetrating-Phase Composite Architecture with High Mechanical Stability and Energy-Absorbing Capability. Adv. Funct. Mater. 2025, 35, 2419882. [Google Scholar] [CrossRef]

- Awd Allah, M.M.; Shaker, A.; Hassan, M.A.; Abd El-baky, M.A. The Influence of Induced Holes on Crashworthy Ability of Glass Reinforced Epoxy Square Tubes. Polym. Compos. 2022, 43, 8322–8340. [Google Scholar] [CrossRef]

- Ali-Eldin, S.S.; El-Moezz, S.M.A.; Megahed, M.; Abdalla, W.S. Study of Hybridization Effect of New Developed Rice Straw Mat/ Glass Fiber Reinforced Polyester Composite. J. Nat. Fibers 2019, 18, 1194–1206. [Google Scholar] [CrossRef]

- Abd El-Aziz, K.; Megahed, M.; Saber, D. Mechanical Properties and Corrosion Protection Performance of Micro/Nano Alumina Fillers Coated Steel. Polym. Compos. 2024, 45, 989–998. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, F.; Zhai, W.; Cheng, S.; Li, J.; Wang, Y. Unraveling of Advances in 3D-Printed Polymer-Based Bone Scaffolds. Polymers 2022, 14, 566. [Google Scholar] [CrossRef] [PubMed]

- El-Baky, M.A.A.; Allah, M.M.A.; Kamel, M.; Abd-Elaziem, W. Energy Absorption Characteristics of E-Glass/Epoxy over-Wrapped Aluminum Pipes with Induced Holes: An Experimental Research. Sci. Rep. 2022, 12, 21097. [Google Scholar] [CrossRef] [PubMed]

- Somwanshi, A.; Kaware, K.; Sulakhe, V.; Kotambkar, M.; Vasava, A. Advances in Composite Crashworthiness: Material Properties, Failure Mechanisms, and Design Strategies. Eng. Res. Express 2025, 7, 032505. [Google Scholar] [CrossRef]

- Ozkan, D.; Gok, M.S.; Karaoglanli, A.C. Carbon Fiber Reinforced Polymer (CFRP) Composite Materials, Their Characteristic Properties, Industrial Application Areas and Their Machinability; Springer: Cham, Switzerland, 2020. [Google Scholar]

- El Aal, M.I.A.; Allah, M.M.A.; El-baky, M.A.A. Carbon-glass Reinforced Epoxy Hybrid Composites for Crashworthy Structural Applications. Polym. Compos. 2023, 44, 2910–2924. [Google Scholar] [CrossRef]

- Alshahrani, H.; Almeshari, B.; El-baky, M.A.A.; Sebaey, T.A. Crashworthiness Assessment of Foam-Filled Internally Strengthened Carbon Fibre-Reinforced Composite Tubes under Axial Compression. Int. J. Crashworthiness 2024, 29, 142–150. [Google Scholar] [CrossRef]

- Renreng, I.; Djamaluddin, F.; Mar’uf, M.; Li, Q. Optimization of Crashworthiness Design of Foam-Filled Crash Boxes under Oblique Loading for Electric Vehicles. Front. Mech. Eng. 2024, 10, 1449476. [Google Scholar] [CrossRef]

- Akbari, P.; Zamani, M.; Mostafaei, A. Machine Learning Prediction of Mechanical Properties in Metal Additive Manufacturing. Addit. Manuf. 2024, 91, 104320. [Google Scholar] [CrossRef]

- Mobarak, M.H.; Mimona, M.A.; Islam, M.A.; Hossain, N.; Zohura, F.T.; Imtiaz, I.; Rimon, M.I.H. Scope of Machine Learning in Materials Research—A Review. Appl. Surf. Sci. Adv. 2023, 18, 100523. [Google Scholar] [CrossRef]

- Kazi, M.-K.; Eljack, F.; Mahdi, E. Design of Composite Rectangular Tubes for Optimum Crashworthiness Performance via Experimental and ANN Techniques. Compos. Struct. 2022, 279, 114858. [Google Scholar] [CrossRef]

- Borse, A.; Gulakala, R.; Stoffel, M. Machine Learning Enhanced Optimisation of Crash Box Design for Crashworthiness Analysis. PAMM 2023, 23, e202300145. [Google Scholar] [CrossRef]

- Liang, R.; Tang, X.; Huang, J.; Bastien, C.; Zhang, C.; Tuo, W. A Machine Learning-Based Crashworthiness Optimization for a Novel Pine Cone-Inspired Multi-Cell Tubes under Bending. Heliyon 2024, 10, e37828. [Google Scholar] [CrossRef]

- Sorour, S.S.; Saleh, C.A.; Shazly, M. A Review on Machine Learning Implementation for Predicting and Optimizing the Mechanical Behaviour of Laminated Fiber-Reinforced Polymer Composites. Heliyon 2024, 10, e33681. [Google Scholar] [CrossRef]

- Arnold, S.M.; Mital, S.K.; Hearley, B.L. Stiffness and Fatigue Life Estimator for Polymer Composite Laminates Using Machine Learning. In Proceedings of the American Society for Composites (ASC) 38th Annual Technical Conference, Boston, MA, USA, 17–20 September 2023. [Google Scholar]

- Chowdhury, S.A.; Nelon, C.; Li, S.; Myers, O.; Hall, A. Quantification of the Out-of-Plane Loading Fatigue Response of Bistable CFRP Laminates Using a Machine Learning Approach. Mech. Adv. Mater. Struct. 2025, 32, 217–232. [Google Scholar] [CrossRef]

- Osa-uwagboe, N.; Udu, A.G.; Ghalati, M.K.; Silberschmidt, V.V.; Aremu, A.; Dong, H.; Demirci, E. A Machine Learning-Enabled Prediction of Damage Properties for Fiber-Reinforced Polymer Composites under out-of-Plane Loading. Eng. Struct. 2024, 308, 117970. [Google Scholar] [CrossRef]

- Allah, M.M.A.; El-Halim, M.F.A.; Aal, M.I.A.E.; El-baky, M.A.A. Picking Up the Optimum Triggering Combinations of Crashworthy 3D-Printed Sustainable Structures: An Experimental Study in Al-Kharj Governorate, KSA. Fibers Polym. 2024, 25, 3911–3930. [Google Scholar] [CrossRef]

- John, K.M.; Thirumalai Kumaran, S. Backup Support Technique towards Damage-Free Drilling of Composite Materials: A Review. Int. J. Lightweight Mater. Manuf. 2020, 3, 357–364. [Google Scholar] [CrossRef]

- Alshahrani, H.; Sebaey, T.A.; Awd Allah, M.M.; Abd El-baky, M.A. Multi-Response Optimization of Crashworthy Performance of Perforated Thin Walled Tubes. J. Compos. Mater. 2023, 57, 1579–1597. [Google Scholar] [CrossRef]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V. Scikit-Learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Van Rossum, G.; Drake, F.L. Python 3 Reference Manual: (Python Documentation Manual Part 2); Documentation for Python; CreateSpace Independent Publishing Platform: Paramount, CA, USA, 2009; ISBN 9781441412690. [Google Scholar]

- Harris, C.R.; Millman, K.J.; van der Walt, S.J.; Gommers, R.; Virtanen, P.; Cournapeau, D.; Wieser, E.; Taylor, J.; Berg, S.; Smith, N.J.; et al. Array Programming with NumPy. Nature 2020, 585, 357–362. [Google Scholar] [CrossRef]

- Haruna, S.I.; Ibrahim, Y.E.; Umar, I.K. Machine Learning Approach for Prediction and Reliability Analysis of Failure Strength of U-Shaped Concrete Samples Joined with UHPC and PUC Composites. J. Compos. Sci. 2025, 9, 23. [Google Scholar] [CrossRef]

- Shaikh, A.A.; Raheman, M.A.; Hrairi, M.; Baig, M. Improving the Performance of Damage Repair in Thin-Walled Structures with Analytical Data and Machine Learning Algorithms. Frat. Integrità Strutt. 2024, 18, 310–324. [Google Scholar] [CrossRef]

- Haruna, S.I.; Ibrahim, Y.E.; Ahmed, O.S.; Farouk, A.I.B. Impact Strength Properties and Failure Mode Classification of Concrete U-Shaped Specimen Retrofitted with Polyurethane Grout Using Machine Learning Algorithms. Infrastructures 2024, 9, 150. [Google Scholar] [CrossRef]

- Thomas, T.; Vijayaraghavan, A.P.; Emmanuel, S. Machine Learning Approaches in Cyber Security Analytics; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- James, G.; Witten, D.; Hastie, T.; Tibshirani, R.; Taylor, J. Statistical Learning; Springer: Cham, Switzerland, 2023; pp. 15–67. [Google Scholar]

- Rajan, M.P. An Efficient Ridge Regression Algorithm with Parameter Estimation for Data Analysis in Machine Learning. SN Comput. Sci. 2022, 3, 171. [Google Scholar] [CrossRef]

- Sivakumar, N.K.; Palaniyappan, S.; Bodaghi, M.; Azeem, P.M.; Nandhakumar, G.S.; Basavarajappa, S.; Pandiaraj, S.; Hashem, M.I. Predictive Modeling of Compressive Strength for Additively Manufactured PEEK Spinal Fusion Cages Using Machine Learning Techniques. Mater. Today Commun. 2024, 38, 108307. [Google Scholar] [CrossRef]

- Malashin, I.P.; Tynchenko, V.S.; Nelyub, V.A.; Borodulin, A.S.; Gantimurov, A.P. Estimation and Prediction of the Polymers’ Physical Characteristics Using the Machine Learning Models. Polymers 2023, 16, 115. [Google Scholar] [CrossRef]

- Chan, K.Y.; Abu-Salih, B.; Qaddoura, R.; Al-Zoubi, A.M.; Palade, V.; Pham, D.-S.; Ser, J.D.; Muhammad, K. Deep Neural Networks in the Cloud: Review, Applications, Challenges and Research Directions. Neurocomputing 2023, 545, 126327. [Google Scholar] [CrossRef]

- Ataabadi, P.B.; Karagiozova, D.; Alves, M. Crushing and Energy Absorption Mechanisms of Carbon Fiber-Epoxy Tubes under Axial Impact. Int. J. Impact Eng. 2019, 131, 174–189. [Google Scholar] [CrossRef]

- Aboudi, J.; Gilat, R. The Effect of Local and Random Fiber Waviness on the Microbuckling of Composite Materials. Int. J. Solids Struct. 2022, 254–255, 111862. [Google Scholar] [CrossRef]

- Mamalis, A.; Robinson, M.; Manolakos, D.; Demosthenous, G.; Ioannidis, M.; Carruthers, J. Crashworthy Capability of Composite Material Structures. Compos. Struct. 1997, 37, 109–134. [Google Scholar] [CrossRef]

- Awd Allah, M.M.; El-Halim, A.; Mahmoud, F.; Abbas, M.A.; Almuflih, A.S.; Saleh, D.I.; El-baky, A.; Marwa, A. Discovering the Impact of Printing Parameters on the Crashworthiness Performance of 3D-Printed Cellular Structures. Fibers Polym. 2025, 26, 297–315. [Google Scholar] [CrossRef]

| No. | Configuration | Hole Diameter (mm) | PUF-Filled | Number of Holes on x-Direction | Number of Holes on y-Direction |

|---|---|---|---|---|---|

| 1 | 0-0-0-0 | 0 | 0 | 0 | 0 |

| 2 | 0-1-0-0 | 0 | 1 | 0 | 0 |

| 3 | 4-0-1-1 | 4 | 0 | 1 | 1 |

| 4 | 4-1-1-1 | 4 | 1 | 1 | 2 |

| 5 | 4-1-2-2 | 4 | 1 | 2 | 2 |

| 6 | 6-0-1-2 | 6 | 0 | 1 | 2 |

| 7 | 6-0-2-2 | 6 | 0 | 2 | 2 |

| 8 | 6-1-2-1 | 6 | 1 | 2 | 1 |

| 9 | 8-0-2-1 | 8 | 0 | 2 | 1 |

| 10 | 8-1-1-1 | 8 | 1 | 1 | 1 |

| 11 | 8-1-1-2 | 8 | 1 | 1 | 2 |

| 12 | 10-0-1-1 | 10 | 0 | 1 | 1 |

| 13 | 10-0-2-2 | 10 | 0 | 2 | 2 |

| 14 | 10-1-1-1 | 10 | 1 | 1 | 1 |

| Configuration | Hole Diameter (mm) | PUF-Filled | Number of Holes on x-Direction | Number of Holes on y-Direction |

|---|---|---|---|---|

| 4-0-1-2 | 4 | 0 | 1 | 2 |

| 4-0-2-1 | 4 | 0 | 2 | 1 |

| 4-0-2-2 | 4 | 0 | 2 | 2 |

| 6-0-1-1 | 6 | 0 | 1 | 1 |

| 6-0-2-1 | 6 | 0 | 2 | 1 |

| 8-0-1-1 | 8 | 0 | 1 | 1 |

| 8-0-1-2 | 8 | 0 | 1 | 2 |

| 8-0-2-2 | 8 | 0 | 2 | 2 |

| 10-0-2-1 | 10 | 0 | 2 | 1 |

| 10-0-1-2 | 10 | 0 | 1 | 2 |

| 4-1-2-1 | 4 | 1 | 2 | 1 |

| 4-1-1-1 | 4 | 1 | 1 | 1 |

| 6-1-1-1 | 6 | 1 | 1 | 1 |

| 6-1-1-2 | 6 | 1 | 1 | 2 |

| 6-1-2-2 | 6 | 1 | 2 | 2 |

| 8-1-2-1 | 8 | 1 | 2 | 1 |

| 8-1-2-2 | 8 | 1 | 2 | 2 |

| 10-1-2-2 | 10 | 1 | 2 | 2 |

| 10-1-2-1 | 10 | 1 | 2 | 1 |

| 10-1-1-2 | 10 | 1 | 1 | 2 |

| DTR | LR | RR | LAR | EN | MLP | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| HP | Value | HP | Value | HP | Value | HP | Value | HP | Value | HP | Value |

| Criterion | Squared error | Fit intercept | True | Fit intercept | True | Fit intercept | True | Fit intercept | True | Hidden layers | 1 |

| Splitter | Best | Tol | 0.000001 | Tol | 0.0001 | Tol | 0.0001 | Tol | 0.0001 | Tol | 0.0001 |

| Min samples split | 2 | Copy X | True | Copy X | True | Copy X | True | Copy X | True | Neurons | 100 |

| Min samples leaf | 1 | Positive | False | Positive | False | Positive | False | Positive | False | Activation | ReLu |

| Solver | Auto | Selection | Cyclic | Selection | Cyclic | Solver | Adam | ||||

| Alpha | 1 | Alpha | 1 | Alpha | 1 | beta_1 | 0.9 | ||||

| L1 ratio | 0.5 | beta_2 | 0.999 | ||||||||

| Configuration * | Hole Diameter (mm) | PUF-Filled | Number of Holes on x-Direction | Number of Holes on y-Direction | Initial Peak Load, Pip (N) | Crushing Mean Load, Pm (N) | Energy Absorption, EA (J) |

|---|---|---|---|---|---|---|---|

| 0-0-0-0 | 0 | 0 | 0 | 0 | 16,700 | 3313 | 141 |

| 0-0-0-0 | 0 | 0 | 0 | 0 | 15,305 | 3307 | 142 |

| 0-0-0-0 | 0 | 0 | 0 | 0 | 16,735 | 3274 | 142 |

| 0-1-0-0 | 0 | 1 | 0 | 0 | 19,490 | 11,066 | 442 |

| 0-1-0-0 | 0 | 1 | 0 | 0 | 21,480 | 11,080 | 439 |

| 0-1-0-0 | 0 | 1 | 0 | 0 | 19,075 | 11,392 | 450 |

| 4-0-1-1 | 4 | 0 | 1 | 1 | 14,120 | 1926 | 96 |

| 4-0-1-1 | 4 | 0 | 1 | 1 | 12,470 | 2742 | 119 |

| 4-0-1-1 | 4 | 0 | 1 | 1 | 14,100 | 2819 | 124 |

| 4-1-1-2 | 4 | 1 | 1 | 2 | 17,875 | 6848 | 278 |

| 4-1-1-2 | 4 | 1 | 1 | 2 | 17,000 | 9178 | 366 |

| 4-1-1-2 | 4 | 1 | 1 | 2 | 15,275 | 10,126 | 402 |

| 4-1-2-2 | 4 | 1 | 2 | 2 | 15,125 | 9134 | 363 |

| 4-1-2-2 | 4 | 1 | 2 | 2 | 16,825 | 8993 | 359 |

| 4-1-2-2 | 4 | 1 | 2 | 2 | 12,915 | 7116 | 283 |

| 6-0-1-2 | 6 | 0 | 1 | 2 | 14,340 | 3757 | 162 |

| 6-0-1-2 | 6 | 0 | 1 | 2 | 15,465 | 4898 | 207 |

| 6-0-1-2 | 6 | 0 | 1 | 2 | 15,025 | 4853 | 203 |

| 6-0-2-2 | 6 | 0 | 2 | 2 | 10,900 | 3275 | 144 |

| 6-0-2-2 | 6 | 0 | 2 | 2 | 12,420 | 2860 | 135 |

| 6-0-2-2 | 6 | 0 | 2 | 2 | 14,560 | 3071 | 139 |

| 6-1-2-1 | 6 | 1 | 2 | 1 | 13,165 | 9356 | 367 |

| 6-1-2-1 | 6 | 1 | 2 | 1 | 18,440 | 9941 | 396 |

| 6-1-2-1 | 6 | 1 | 2 | 1 | 18,670 | 9565 | 383 |

| 8-0-2-1 | 8 | 0 | 2 | 1 | 10,935 | 4266 | 199 |

| 8-0-2-1 | 8 | 0 | 2 | 1 | 11,165 | 5245 | 239 |

| 8-0-2-1 | 8 | 0 | 2 | 1 | 13,450 | 6780 | 311 |

| 8-1-1-1 | 8 | 1 | 1 | 1 | 13,070 | 9497 | 416 |

| 8-1-1-1 | 8 | 1 | 1 | 1 | 11,840 | 9428 | 425 |

| 8-1-1-1 | 8 | 1 | 1 | 1 | 13,505 | 9800 | 443 |

| 8-1-1-2 | 8 | 1 | 1 | 2 | 18,725 | 8581 | 398 |

| 8-1-1-2 | 8 | 1 | 1 | 2 | 15,185 | 9441 | 416 |

| 8-1-1-2 | 8 | 1 | 1 | 2 | 18,065 | 8310 | 383 |

| 10-0-1-1 | 10 | 0 | 1 | 1 | 13,970 | 2274 | 109 |

| 10-0-1-1 | 10 | 0 | 1 | 1 | 14,730 | 2164 | 109 |

| 10-0-1-1 | 10 | 0 | 1 | 1 | 12,515 | 2788 | 132 |

| 10-0-2-2 | 10 | 0 | 2 | 2 | 9440 | 3167 | 155 |

| 10-0-2-2 | 10 | 0 | 2 | 2 | 7285 | 2794 | 134 |

| 10-0-2-2 | 10 | 0 | 2 | 2 | 9430 | 3838 | 165 |

| 10-1-1-1 | 10 | 1 | 1 | 1 | 12,350 | 8977 | 372 |

| 10-1-1-1 | 10 | 1 | 1 | 1 | 12,905 | 7953 | 333 |

| 10-1-1-1 | 10 | 1 | 1 | 1 | 14,440 | 9853 | 407 |

| Algorithm | DTR | LR | RR | LAR | EN | MLP | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample | RMSE | MAPE | RMSE | MAPE | RMSE | MAPE | RMSE | MAPE | RMSE | MAPE | RMSE | MAPE |

| 0 | 1269.87 | 12.49 | 1591.08 | 13.15 | 1653.99 | 15.66 | 1591.93 | 13.19 | 2266.92 | 29.44 | 9616.76 | 92.48 |

| 1 | 1015.81 | 6.90 | 1202.08 | 12.97 | 1186.86 | 14.37 | 1200.75 | 12.90 | 1699.13 | 30.23 | 9853.45 | 93.78 |

| 2 | 1168.14 | 11.58 | 1557.40 | 19.07 | 1540.39 | 20.53 | 1557.17 | 19.05 | 1946.74 | 33.24 | 9636.33 | 94.38 |

| 3 | 1293.61 | 16.39 | 1539.34 | 22.69 | 1493.15 | 22.24 | 1539.61 | 22.60 | 1825.48 | 27.86 | 9793.56 | 93.46 |

| 4 | 1308.96 | 10.25 | 1179.65 | 14.17 | 1199.65 | 16.27 | 1179.07 | 14.07 | 1892.59 | 36.57 | 9349.70 | 93.27 |

| 5 | 1202.65 | 14.09 | 1459.19 | 16.51 | 1519.12 | 19.11 | 1459.66 | 16.80 | 2173.42 | 34.03 | 9836.02 | 94.17 |

| 6 | 1245.53 | 9.86 | 1306.97 | 16.55 | 1361.01 | 18.53 | 1307.18 | 16.44 | 2043.18 | 38.04 | 9770.82 | 92.64 |

| 7 | 1791.48 | 10.98 | 1716.62 | 19.77 | 1717.78 | 19.64 | 1716.11 | 19.29 | 2146.00 | 36.65 | 9460.42 | 92.80 |

| 8 | 978.11 | 9.13 | 1447.69 | 13.73 | 1460.02 | 14.88 | 1447.92 | 13.60 | 1970.49 | 25.89 | 9513.69 | 94.34 |

| 9 | 1240.50 | 12.06 | 1455.12 | 17.10 | 1463.56 | 19.23 | 1455.30 | 17.05 | 1982.90 | 42.01 | 9123.99 | 93.72 |

| Average | 1251.47 | 11.37 | 1445.51 | 16.57 | 1459.55 | 18.05 | 1445.47 | 16.50 | 1994.68 | 33.39 | 9595.48 | 93.50 |

| SD | 220.30 | 2.65 | 171.73 | 3.21 | 172.35 | 2.61 | 172.02 | 3.16 | 170.21 | 5.05 | 236.68 | 0.70 |

| Actual | Predicted | ||||

|---|---|---|---|---|---|

| Actual Initial Peak Force, Fip (N) | Actual Crushing Mean Force, Fm (N) | Actual Energy Absorption, EA (J) | Predicted Initial Peak Force, Pip (N) | Predicted Crushing Mean Force, Pm (N) | Predicted Energy Absorption, EA (J) |

| 19,490 | 11,066 | 442 | 20,277.5 | 11,236 | 444.5 |

| 16,735 | 3274 | 142 | 16,002.5 | 3310 | 141.5 |

| 18,670 | 9565 | 383 | 15,802.5 | 9648.5 | 381.5 |

| 12,350 | 8977 | 372 | 13,672.5 | 8903 | 370 |

| 15,025 | 4853 | 203 | 14,902.5 | 4327.5 | 184.5 |

| 13,505 | 9800 | 443 | 12,455 | 9462.5 | 420.5 |

| 12,420 | 2860 | 135 | 12,730 | 3173 | 141.5 |

| 12,515 | 2788 | 132 | 14,350 | 2219 | 109 |

| 15,185 | 9441 | 416 | 18,395 | 8445.5 | 390.5 |

| Configuration | Hole Diameter (mm) | PUF-Filled | Number of Holes in the x Direction | Number of Holes in the y Direction | Initial Peak Force, Pip (N) | Crushing Mean Force, Pm (N) | Energy Absorption, EA (J) |

|---|---|---|---|---|---|---|---|

| 4-0-1-2 | 4 | 0 | 1 | 2 | 14,903 | 4339 | 184 |

| 4-0-2-1 | 4 | 0 | 2 | 1 | 12,387 | 3378 | 154 |

| 4-0-2-2 | 4 | 0 | 2 | 2 | 12,820 | 3069 | 139 |

| 6-0-1-1 | 6 | 0 | 1 | 1 | 13,755 | 2729 | 122 |

| 6-0-2-1 | 6 | 0 | 2 | 1 | 12,387 | 3378 | 154 |

| 8-0-1-1 | 8 | 0 | 1 | 1 | 13,870 | 2611 | 124 |

| 8-0-1-2 | 8 | 0 | 1 | 2 | 14,313 | 4344 | 186 |

| 8-0-2-2 | 8 | 0 | 2 | 2 | 12,034 | 4828 | 222 |

| 10-0-2-1 | 10 | 0 | 2 | 1 | 9209 | 3626 | 165 |

| 10-0-1-2 | 10 | 0 | 1 | 2 | 14,192 | 4135 | 178 |

| 4-1-2-1 | 4 | 1 | 2 | 1 | 16,127 | 9352 | 371 |

| 4-1-1-1 | 4 | 1 | 1 | 1 | 15,623 | 9354 | 385 |

| 6-1-1-1 | 6 | 1 | 1 | 1 | 15,636 | 9625 | 395 |

| 6-1-1-2 | 6 | 1 | 1 | 2 | 16,729 | 8988 | 359 |

| 6-1-2-2 | 6 | 1 | 2 | 2 | 15,394 | 8711 | 347 |

| 8-1-2-1 | 8 | 1 | 2 | 1 | 13,917 | 9607 | 416 |

| 8-1-2-2 | 8 | 1 | 2 | 2 | 15,283 | 8547 | 359 |

| 10-1-2-2 | 10 | 1 | 2 | 2 | 14,625 | 8542 | 356 |

| 10-1-2-1 | 10 | 1 | 2 | 1 | 13,452 | 9004 | 372 |

| 10-1-1-2 | 10 | 1 | 1 | 2 | 15,675 | 8752 | 384 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Junaedi, H.; Akkad, K.; Khan, T.; Abd El-baky, M.A.; Awd Allah, M.M.; Sebaey, T.A. Crashworthiness Prediction of Perforated Foam-Filled CFRP Rectangular Tubes Crash Box Using Machine Learning. Polymers 2025, 17, 2887. https://doi.org/10.3390/polym17212887

Junaedi H, Akkad K, Khan T, Abd El-baky MA, Awd Allah MM, Sebaey TA. Crashworthiness Prediction of Perforated Foam-Filled CFRP Rectangular Tubes Crash Box Using Machine Learning. Polymers. 2025; 17(21):2887. https://doi.org/10.3390/polym17212887

Chicago/Turabian StyleJunaedi, Harri, Khaled Akkad, Tabrej Khan, Marwa A. Abd El-baky, Mahmoud M. Awd Allah, and Tamer A. Sebaey. 2025. "Crashworthiness Prediction of Perforated Foam-Filled CFRP Rectangular Tubes Crash Box Using Machine Learning" Polymers 17, no. 21: 2887. https://doi.org/10.3390/polym17212887

APA StyleJunaedi, H., Akkad, K., Khan, T., Abd El-baky, M. A., Awd Allah, M. M., & Sebaey, T. A. (2025). Crashworthiness Prediction of Perforated Foam-Filled CFRP Rectangular Tubes Crash Box Using Machine Learning. Polymers, 17(21), 2887. https://doi.org/10.3390/polym17212887