Web Crippling of Pultruded GFRP Profiles: A Review of Experimental, Numerical, and Theoretical Analyses

Abstract

1. Introduction

2. Experimental Evidence on Web-Crippling Behavior of Pultruded GFRP Profiles

2.1. Effect of Profile Geometry on Web-Crippling Behavior of Pultruded GFRP Profiles

2.2. Effect of Bearing and Loading on Web Crippling of Pultruded GFRP

2.3. Effect of Thermal Variations on Web Crippling of Pultruded GFRP

3. Numerical and Analytical Modelling Techniques

4. Conclusions, Recommendations, and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vedernikov, A.; Safonov, A.; Tucci, F.; Carlone, P.; Akhatov, I. Pultruded materials and structures: A review. J. Compos. Mater. 2020, 54, 4081–4117. [Google Scholar] [CrossRef]

- Tai, C.; Liu, Z.; Yan, Y.; Shi, S.; Lu, Y. Axial behavior of seawater sea-sand engineered cementitious composites filled I-shaped pultruded profile and GFRP tube stub columns. Constr. Build. Mater. 2025, 493, 143125. [Google Scholar] [CrossRef]

- Bai, H.; Zhang, M.; Wang, D. Ultimate lateral load capacity of FRP tube-confined concrete-encased cross-shaped steel column: Experimental and numerical investigation. Constr. Build. Mater. 2025, 492, 142856. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Gemi, L.; Madenci, E.; Aksoylu, C. Effects of stirrup spacing on shear performance of hybrid composite beams produced by pultruded GFRP profile infilled with reinforced concrete. Arch. Civ. Mech. Eng. 2022, 23, 36. [Google Scholar] [CrossRef]

- García-Espinel, J.D.; Alvarez-García-Lubén, R.; González-Herrero, J.; Castro-Fresno, D. Design and construction methods of caisson-type maritime infrastructures using GFRP. J. Compos. Constr. 2016, 20, 05015002. [Google Scholar] [CrossRef]

- Bazli, M.; Ashrafi, H.; Oskouei, A.V. Effect of harsh environments on mechanical properties of GFRP pultruded profiles. Compos. Part B Eng. 2016, 99, 203–215. [Google Scholar] [CrossRef]

- Saribiyik, A.; Ozturk, O.; Aydin, F.; Ozkilic, Y.O.; Madenci, E. Experimental and analytical study on improvement of flexural strength of polymer concrete filled GFRP box hybrid members. Steel Compos. Struct. 2024, 50, 475. [Google Scholar]

- Correia, J.; Cabral-Fonseca, S.; Branco, F.; Ferreira, J.; Eusébio, M.I.; Rodrigues, M.P. Durability of glass fibre reinforced polyester (GFRP) pultruded profiles used in civil engineering applications. In Proceedings of the Composites in Construction 2005—Third International Conference, Lyon, France, 11–13 July 2005. [Google Scholar]

- Ascione, F.; Maselli, G.; Nesticò, A. Sustainable materials selection in industrial construction: A life-cycle based approach to compare the economic and structural performances of glass fibre reinforced polymer (GFRP) and steel. J. Clean. Prod. 2024, 475, 143641. [Google Scholar] [CrossRef]

- Fernandes, L.A.; Gonilha, J.; Correia, J.R.; Silvestre, N.; Nunes, F. Web-crippling of GFRP pultruded profiles. Part 1: Experimental study. Compos. Struct. 2015, 120, 565–577. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Q.; Long, Y.; Cao, D.; Guo, K. Modelling of Web-Crippling Behavior of Pultruded GFRP I Sections at Elevated Temperatures. Polymers 2022, 14, 5313. [Google Scholar] [CrossRef] [PubMed]

- Aksoylu, C.; Özkılıç, Y.O.; Madenci, E.; Safonov, A. Compressive behavior of pultruded GFRP boxes with concentric openings strengthened by different composite wrappings. Polymers 2022, 14, 4095. [Google Scholar] [CrossRef]

- Madenci, E.; Özkılıç, Y.O.; Aksoylu, C.; Safonov, A. The Effects of Eccentric Web Openings on the Compressive Performance of Pultruded GFRP Boxes Wrapped with GFRP and CFRP Sheets. Polymers 2022, 14, 4567. [Google Scholar] [CrossRef]

- Harati Khalilabad, E.; Ruiz Emparanza, A.; De Caso, F.; Roghani, H.; Khodadadi, N.; Nanni, A. Characterization specifications for FRP pultruded materials: From constituents to pultruded profiles. Fibers 2023, 11, 93. [Google Scholar] [CrossRef]

- Wu, C.; Ding, Y.; He, L.; Tam, L.-H. Web crippling of pultruded GFRP built-up sections. Thin-Walled Struct. 2023, 185, 110646. [Google Scholar] [CrossRef]

- Xin, H.; Mosallam, A.; Liu, Y.; Xiao, Y.; He, J.; Wang, C.; Jiang, Z. Experimental and numerical investigation on in-plane compression and shear performance of a pultruded GFRP composite bridge deck. Compos. Struct. 2017, 180, 914–932. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Linul, E. Manufacturing Technologies of Carbon/Glass Fiber-Reinforced Polymer Composites and Their Properties: A Review. Polymers 2021, 13, 3721. [Google Scholar] [CrossRef] [PubMed]

- Correia, J.R. 7—Pultrusion of advanced composites. In Advanced Fiber-Reinforced Polymer (FRP) Composites for Structural Applications, 2nd ed.; Bai, J., Ed.; Woodhead Publishing: Sawston, UK, 2023; pp. 137–177. [Google Scholar]

- Wu, C.; Zhang, L.-T.; Bai, Y.; Zhao, X.-L. Web crippling behavior of pultruded GFRP channel sections under transverse bearing load. Compos. Struct. 2019, 209, 129–142. [Google Scholar] [CrossRef]

- Al-Ezzi, M.J.; Ayamsir, A.; Supian, A.; Beddu, S.; Al-Dala’ien, R.N. Flexural behavior and failure modes of pultruded GFRP tube concrete-filled composite beams: A review of experimental and numerical studies. Buildings 2024, 14, 3966. [Google Scholar] [CrossRef]

- Alhawamdeh, M.; Eayal Awwad, K.; Al-Marafi, M.N.; Al-Rbaihat, R.; Alrsai, M. Cross-sectional optimisation of I-shape pultruded FRP beams using search-adaptive micro-population genetic algorithm. Adv. Struct. Eng. 2025, 28, 1683–1707. [Google Scholar] [CrossRef]

- Estep, D.D.; GangaRao, H.V.; Dittenber, D.B.; Qureshi, M.A. Response of pultruded glass composite box beams under bending and shear. Compos. Part B Eng. 2016, 88, 150–161. [Google Scholar] [CrossRef]

- Madenci, E.; Fayed, S.; Mansour, W.; Özkılıç, Y.O. Buckling performance of pultruded glass fiber reinforced polymer profiles infilled with waste steel fiber reinforced concrete under axial compression. Steel Compos. Struct. 2022, 45, 653–663. [Google Scholar]

- Gonilha, J.A.; Silvestre, N.; Correia, J.R.; Tita, V.; Martins, D. Novel progressive failure model for quasi-orthotropic pultruded FRP structures: Formulation and calibration of parameters (Part I). Compos. Struct. 2021, 255, 112974. [Google Scholar] [CrossRef]

- Gonilha, J.A.; Silvestre, N.; Correia, J.R.; Tita, V.; Almeida-Fernandes, L. Novel progressive failure model for quasi-orthotropic pultruded FRP structures: Application to compact tension and web-crippling case studies (Part II). Compos. Struct. 2021, 255, 112973. [Google Scholar] [CrossRef]

- Costa, D.; Gonilha, J.A.; Silvestre, N. Calibration and validation of a 3D homogenised model to simulate the damage progression of pultruded GFRP composites. Eng. Fail. Anal. 2023, 149, 107261. [Google Scholar] [CrossRef]

- Almeida-Fernandes, L.; Correia, J.R.; Silvestre, N. Effect of fibre layup and bearing length on the web-crippling behaviour of pultruded GFRP profiles. Compos. Struct. 2021, 267, 113884. [Google Scholar] [CrossRef]

- Wu, C.; Ding, Y.; Almeida-Fernandes, L.; Gonilha, J.; Silvestre, N.; Correia, J.R. State-of-the-art review on the web crippling of pultruded GFRP profiles. Thin-Walled Struct. 2023, 192, 111128. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, Y. Tests on GFRP pultruded profiles with channel section subjected to web crippling. Appl. Compos. Mater. 2017, 24, 849–862. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, L.-T.; Tam, L.-h.; Yan, L.; He, L. Effect of bearing length on web crippling behavior of pultruded GFRP channel section. Compos. Struct. 2020, 253, 112810. [Google Scholar] [CrossRef]

- Ye, Y.-Y.; Gonilha, J.; Silvestre, N.; Correia, J.R. Web-crippling behavior of pultruded GFRP I-section beams under one-flange loading: Computational modelling and parametric study. Compos. Part B Eng. 2025, 307, 112915. [Google Scholar] [CrossRef]

- Liu, T.; Feng, P.; Bai, Y.; Bai, S.; Yang, J.-Q.; Zhao, F. Flexural performance of curved-pultruded GFRP arch beams subjected to varying boundary conditions. Eng. Struct. 2024, 308, 117962. [Google Scholar] [CrossRef]

- Oskouei, A.V.; Bazli, M.; Ashrafi, H.; Imani, M. Flexural and web crippling properties of GFRP pultruded profiles subjected to wetting and drying cycles in different sea water conditions. Polym. Test. 2018, 69, 417–430. [Google Scholar] [CrossRef]

- Yıldırım, E.G.; Ünal, R. A review on post–buckling behaviors of composites: Crippling phenomenon. J. Aeronaut. Space Technol. 2024, 17, 1–28. [Google Scholar]

- Haloi, J.; Mushahary, S.K.; Borsaikia, A.C.; Singh, K.D. Experimental investigation on the web crippling behaviour of pultruded GFRP wide-flange sections subjected to two-flange loading conditions. Compos. Struct. 2021, 259, 113469. [Google Scholar] [CrossRef]

- Wu, C.; Bai, Y. Web crippling behaviour of pultruded glass fibre reinforced polymer sections. Compos. Struct. 2014, 108, 789–800. [Google Scholar] [CrossRef]

- Nunes, F.; Silvestre, N.; Correia, J.R. Progressive damage analysis of web crippling of GFRP pultruded I-sections. J. Compos. Constr. 2017, 21, 04016104. [Google Scholar] [CrossRef]

- Liu, P.; Zheng, J. Recent developments on damage modeling and finite element analysis for composite laminates: A review. Mater. Des. 2010, 31, 3825–3834. [Google Scholar] [CrossRef]

- David Müzel, S.; Bonhin, E.P.; Guimarães, N.M.; Guidi, E.S. Application of the finite element method in the analysis of composite materials: A review. Polymers 2020, 12, 818. [Google Scholar] [CrossRef] [PubMed]

- Dehshirizadeh, M.; Eslami, A.; Saryazdi, M.K.; Ronagh, H.R. Flexural Behavior of Hollow Pultruded GFRP Box Profiles: An Experimental and Numerical Analysis. Iran. J. Sci. Technol. Trans. Civ. Eng. 2025, 49, 291–303. [Google Scholar] [CrossRef]

- Hakeem, I.Y.; Madenci, E.; Bahrami, A.; Özkılıç, Y.O.; Rizal Muhammad Asyraf, M.; Tawfik, T.A.; Fayed, S. Nonlocal theoretical inquiry into pultruded GFRP plate dynamics: Integrating experimental and numerical analyses. J. Eng. Fibers Fabr. 2024, 19, 1–21. [Google Scholar] [CrossRef]

- Asghar, R.; Javed, M.F.; Ali, M.; Najeh, T.; Gamil, Y. Numerical and artificial intelligence based investigation on the development of design guidelines for pultruded GFRP RHS profiles subjected to web crippling. Sci. Rep. 2024, 14, 10135. [Google Scholar] [CrossRef]

- Yossef, M.; Noureldin, M.; Alqabbany, A. Explainable artificial intelligence framework for FRP composites design. Compos. Struct. 2024, 341, 118190. [Google Scholar] [CrossRef]

- Kim, J.W.; Nam, J.; Kim, G.Y.; Lee, S.W. Artificial intelligence (AI)–based surface quality prediction model for carbon fiber reinforced plastics (CFRP) milling process. Int. J. Precis. Eng. Manuf.-Smart Technol. 2023, 1, 35–47. [Google Scholar] [CrossRef]

- Zhang, H.; Li, F.; Chen, L. Neural network-based prediction of stability coefficients for pultruded Fiber-Reinforced Polymer columns. Comput. Struct. 2025, 316, 107888. [Google Scholar] [CrossRef]

- Chang, X.; Wang, X.; He, Z.; Ding, L.; Yuan, K.; Noori, M.; Liu, J.; Mujtaba, M.; Wu, Z. Damage identification and localization of pultruded FRP composites based on convolutional recurrent neural network and metaheuristic intelligent algorithms. Polym. Compos. 2025, 46, S356–S382. [Google Scholar] [CrossRef]

- Alhawamdeh, M.; Alajarmeh, O.; Aravinthan, T.; Shelley, T.; Schubel, P.; Mohammed, A.; Zeng, X. Review on Local Buckling of Hollow Box FRP Profiles in Civil Structural Applications. Polymers 2021, 13, 4159. [Google Scholar] [CrossRef]

- Gand, A.; Mohammed, M.H.; Jarrouja, S. Performance of perforated FRP stub beams subject to static transverse actions. Eng. Solid Mech. 2020, 8, 105–118. [Google Scholar] [CrossRef]

- Haloi, J.; Singh, K.D.; Borsaikia, A.C. Effect of web perforation on the performance of pultruded GFRP wide-flange section profile in web crippling under end-two-flange loading configuration. Thin-Walled Struct. 2022, 175, 109187. [Google Scholar] [CrossRef]

- Wu, C.; Tian, J.; Ding, Y.; Feng, P. Axial compression behavior of pultruded GFRP channel sections. Compos. Struct. 2022, 289, 115438. [Google Scholar] [CrossRef]

- Lakhiar, M.T.; Kong, S.Y.; Bai, Y.; Miah, M.J.; Syamsir, A. Web crippling performance of pultruded GFRP C sections strengthened by fibre-reinforced epoxy composite. Compos. Struct. 2023, 316, 117047. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, C. Test on pultruded GFRP I-section under web crippling. Compos. Part B Eng. 2015, 77, 27–37. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, C. Web crippling behavior of pultruded GFRP rectangular hollow sections. Compos. Part B Eng. 2015, 77, 112–121. [Google Scholar] [CrossRef]

- Borowicz, D.T.; Bank, L.C. Behavior of pultruded fiber-reinforced polymer beams subjected to concentrated loads in the plane of the web. J. Compos. Constr. 2011, 15, 229–238. [Google Scholar] [CrossRef]

- Borowicz, D.T. An Investigation into the Behavior of Fiber-Reinforced Polymer (FPR) Beams Subjected to Concentrated Loads in the Plane of the Web. Ph.D. Thesis, The University of Wisconsin, Madison, WI, USA, 2010. [Google Scholar]

- Ashby, M.F.; Jones, D.R.H. Chapter 23—Mechanical behaviour of polymers. In Engineering Materials, 2nd ed.; Ashby, M.F., Jones, D.R.H., Eds.; Butterworth-Heinemann: Oxford, UK, 1998; pp. 238–253. [Google Scholar]

- Correia, J.R.; Bai, Y.; Keller, T. A review of the fire behaviour of pultruded GFRP structural profiles for civil engineering applications. Compos. Struct. 2015, 127, 267–287. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Madenci, E.; Safonov, A.; Gemi, L.; Yazman, Ş. Comprehensive evaluation of tensile properties, damage mechanisms, and predictive modeling of pultruded GFRP after elevated temperatures. Compos. Part B Eng. 2025, 304, 112657. [Google Scholar] [CrossRef]

- Jafari, A.; Ashrafi, H.; Bazli, M.; Ozbakkaloglu, T. Effect of thermal cycles on mechanical response of pultruded glass fiber reinforced polymer profiles of different geometries. Compos. Struct. 2019, 223, 110959. [Google Scholar] [CrossRef]

- Correia, J.R.; Gomes, M.M.; Pires, J.M.; Branco, F.A. Mechanical behaviour of pultruded glass fibre reinforced polymer composites at elevated temperature: Experiments and model assessment. Compos. Struct. 2013, 98, 303–313. [Google Scholar] [CrossRef]

- Bai, Y.; Keller, T.; Correia, J.R.; Branco, F.A.; Ferreira, J.G. Fire protection systems for building floors made of pultruded GFRP profiles—Part 2: Modeling of thermomechanical responses. Compos. Part B Eng. 2010, 41, 630–636. [Google Scholar] [CrossRef]

- Correia, J.R.; Branco, F.A.; Ferreira, J.G.; Bai, Y.; Keller, T. Fire protection systems for building floors made of pultruded GFRP profiles: Part 1: Experimental investigations. Compos. Part B Eng. 2010, 41, 617–629. [Google Scholar] [CrossRef]

- Ludwig, C.; Knippers, J.; Hugi, E.; Ghazi Wakili, K. Damage of flexural loaded composite beams subjected to fire. In Proceedings of the 4th International Conference on FRP Composite in Civil Engineering, Zurich, Switzerland, 22–24 July 2008. [Google Scholar]

- Haloi, J. Web Crippling Behaviour of Pultruded Glass Fibre Reinforced Polymer Wide Flange Section Profiles with Web Perforations. Ph.D. Thesis, Indian Institute of Technology Guwahati, Guwahati, India, 2021. [Google Scholar]

- Haloi, J.; Borsaikia, A.C.; Singh, K.D. Web crippling behaviour of web perforated GFRP wide-flange sections subjected to interior-two-flange loading condition. Thin-Walled Struct. 2021, 166, 108072. [Google Scholar] [CrossRef]

- Zhang, L.-T.; Wu, C. Experimental study on the web crippling behaviour of pultruded GFRP channel sections using DIC. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2019. [Google Scholar]

- Pugazhenthi, V.; Gopalakannan, S.; Rajappan, R. Finite element analysis of composite shell structure of aircraft wing using composite structure. In Proceedings of the 2018 IEEE International Conference on System, Computation, Automation and Networking (ICSCA), Pondicherry, India, 6–7 July 2018. [Google Scholar]

- Belytschko, T.; Liu, W.K.; Moran, B.; Elkhodary, K. Nonlinear Finite Elements for Continua and Structures; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Fernandes, L.A.; Nunes, F.; Silvestre, N.; Correia, J.R.; Gonilha, J. Web-crippling of GFRP pultruded profiles. Part 2: Numerical analysis and design. Compos. Struct. 2015, 120, 578–590. [Google Scholar] [CrossRef]

- Nath, A.; Anand, R.; Desai, J.; Sultan, M.; Raj, S.A. Modelling and Finite Element Analysis of an Aircraft Wing using Composite Laminates. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021. [Google Scholar]

- Haloi, J.; Borsaikia, A.C.; Singh, K.D. New design equations for predicting web crippling capacity of pultruded GFRP profile. Structures 2024, 64, 106481. [Google Scholar] [CrossRef]

- European Convention for Constructional Steelwork; Associacao Portuguesa de. Design of Cold-Formed Steel Structures: Eurocode 3: Design of Steel Structures. Part 1–3 Design of Cold-Formed Steel Structures; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- ACI Committee 130. ACI 130R-19 Report on the Role of Materials in Sustainable Concrete Construction; American Concrete Institute: Farmington Hills, MI, USA, 2019. [Google Scholar]

| Reference and Authors | Loading Types | Profile Types | Observed Failures (As Described by Authors) |

|---|---|---|---|

| [37] | ETF, ITF, EG, IG | Square hollow pultruded GFRP sections | Initial web—flange junctions, (Web buckling and web crushing) |

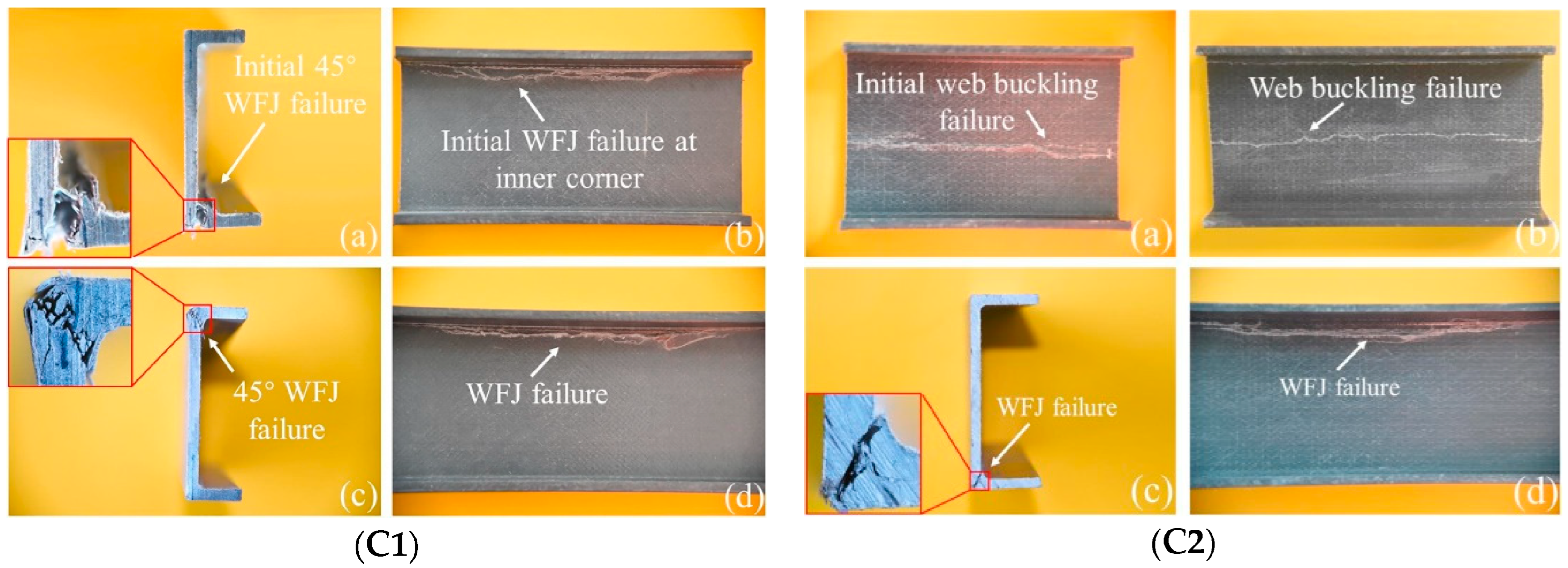

| [15] | ETF, ITF | Pultruded GFRP channel section and built-up sections (I-section) | WFJ failure, Wedge-like cracking, Web cracking |

| [31] | ETF, ITF | GFRP Channel Sections | WFJ failure and WB failure |

| [53] | ETF, ITF, EG, IG | GFRP I-Sections | longitudinal bending cracks, bending wrinkling cracks and shear cracks. |

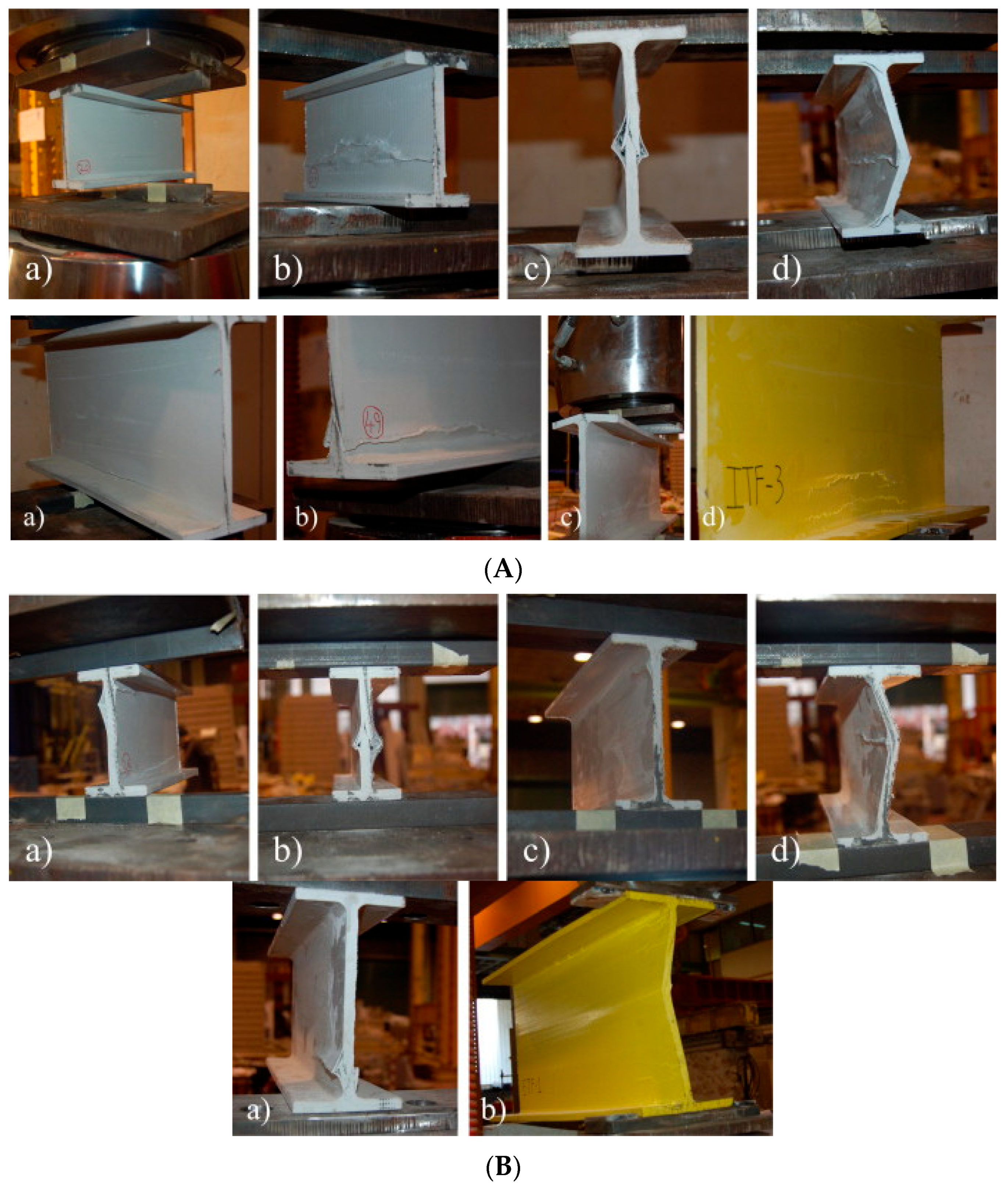

| [10] | ITF, ETF | GFRP I-Sections | Web crushing and Web buckling |

| [30] | ETF, ITF, EG, IG | GFRP Channel Sections | Bending main crack (on the web). |

| [54] | ETF, ITF, EG, IG | Rectangular hollow pultruded GFRP sections | WFJ failures, Bending crack (web bucking), longitudinal wrinkling cracks |

| [55] | Three-Point Bending | GFRP I-Sections | Wedge-like shear failure at the top web-flange junction, longitudinal cracking. |

| [56] | Three-Point Bending | GFRP I and W Section | Web-flange junction, Web bucking, Longitudinal cracking, web crushing. |

| [36,65] | ETF, ITF | GFRP Wide-Flange Sections | Material wrinkling, web–flange junction, Wedge shear failure, cracks longitudinal, web crushing. |

| [66] | ITF | GFRP Wide-Flange Sections | WJF failure, Wedge shear failure, longitudinal crack, shear crack. |

| [50] | ETF | GFRP Wide-Flange Sections | WJF failure, Wedge shear failure, longitudinal crack, shear crack, web crushing |

| [28] | ETF, ITF | GFRP Profiles with Various Fiber Layups | Web crushing and web buckling. |

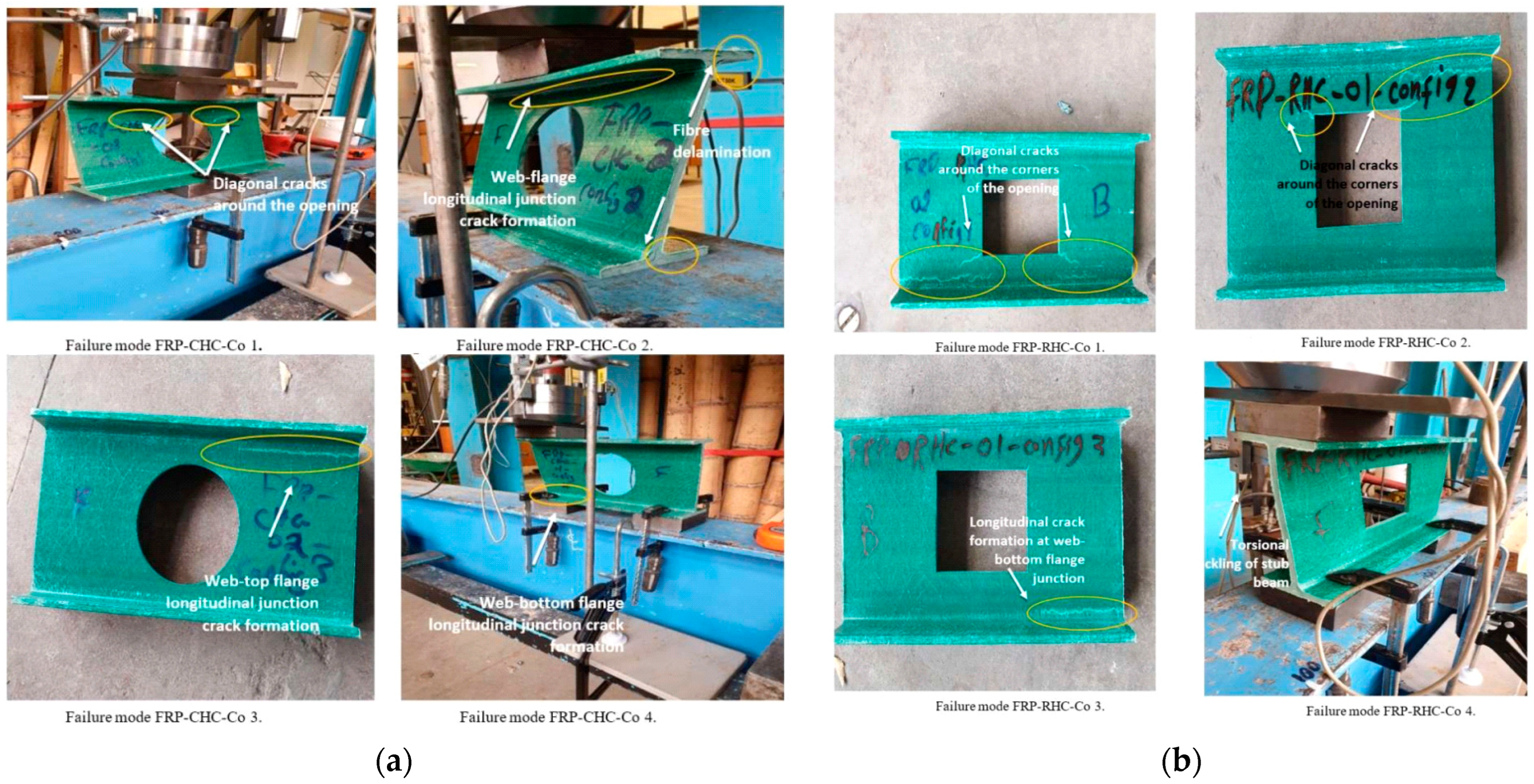

| [49] | ETF, ITF, EG, IG | GFRP I-Sections with holes | Web–flange junction failure for circular holes; diagonal cracks for rectangular holes. |

| [11] | ETF, EG | GFRP I-Sections at elevated temperatures | Web–flange junction failure, longitudinal cracking at WFJ. |

| [67] | ETF, ITF | PGFRP Channel sections | Web—flange junction initial crack |

| For EG loading condition | |

| For ETF loading condition | |

| For IG loading condition | |

| For ITF loading condition |

| Based on: | P in ETF Loading Condition | P in ITF Loading Condition |

|---|---|---|

| EC 3 | ||

| NAS | ||

| Fernandes et al. [70] |

| For EG loading conditions | |

| For IG loading conditions | |

| For ETF loading conditions | |

| For ITF loading conditions |

| For EG loading condition | |

| For ETF loading condition | |

| For IG loading condition | |

| For ITF loading condition |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soumbourou, M.A.; Aksoylu, C.; Madenci, E.; Özkılıç, Y.O. Web Crippling of Pultruded GFRP Profiles: A Review of Experimental, Numerical, and Theoretical Analyses. Polymers 2025, 17, 2746. https://doi.org/10.3390/polym17202746

Soumbourou MA, Aksoylu C, Madenci E, Özkılıç YO. Web Crippling of Pultruded GFRP Profiles: A Review of Experimental, Numerical, and Theoretical Analyses. Polymers. 2025; 17(20):2746. https://doi.org/10.3390/polym17202746

Chicago/Turabian StyleSoumbourou, Mohamed Ahmed, Ceyhun Aksoylu, Emrah Madenci, and Yasin Onuralp Özkılıç. 2025. "Web Crippling of Pultruded GFRP Profiles: A Review of Experimental, Numerical, and Theoretical Analyses" Polymers 17, no. 20: 2746. https://doi.org/10.3390/polym17202746

APA StyleSoumbourou, M. A., Aksoylu, C., Madenci, E., & Özkılıç, Y. O. (2025). Web Crippling of Pultruded GFRP Profiles: A Review of Experimental, Numerical, and Theoretical Analyses. Polymers, 17(20), 2746. https://doi.org/10.3390/polym17202746