Abstract

This review presents recent advancements in cold atmospheric pressure (AP) plasma (CAP) processes for the synthesis and surface treatment of polymer films and metal nanoparticles (NPs) in biomedical applications. We discuss the properties and applications of atmospheric pressure plasma (APP) processes, including dielectric barrier discharge (DBD) and plasma jet methods, highlighting their effectiveness in controlling surface characteristics such as wettability and functionalization.

1. Introduction

In general, plasma is a partially ionized state of matter composed of ions, electrons, and neutral particles, and it is classified into two main types: thermal plasma and non-thermal cold plasma (NTCP) [1,2,3,4]. Thermal plasma exists in thermal equilibrium, where the temperature of electrons and ions is comparable, and is primarily employed in high-temperature industrial applications, making it unsuitable for biomedical applications [5]. In contrast, NTCP operates under non-equilibrium conditions, where electron temperatures are significantly higher than ion temperatures [1,2,3,4]. NTCP enables the synthesis and surface treatment of polymers and metal nanoparticles (NPs) at room temperature (RT) through reactions involving energetic electrons during plasma discharge, thereby enhancing properties such as wettability, biocompatibility, antimicrobial resistance, and drug delivery, as well as supporting applications in sterilization, dentistry, dermatology, and implant treatments [6,7,8,9,10,11,12,13]. Atmospheric pressure (AP) –generated NTCP, commonly referred to as cold AP plasma (CAP), produces reactive species including reactive oxygen species (ROS), reactive nitrogen (N2) species (RNS), UV photons, and charged particles, which are highly advantageous for biomedical applications, such as wound healing, decontamination, implant surface treatment, dentistry, sterilization in dermatology, and cancer therapy [14,15,16,17,18]. CAP can be generated under vacuum, low–pressure, or AP plasma (APP). As a result, APP has received significant attention in recent years for plasma synthesis and surface modification of polymer films and metal NPs across various industrial applications. Current research has investigated APP–based plasma synthesis and surface modification of polymers and metal NPs using APP devices such as dielectric barrier discharge (DBD) and plasma jets [15,19,20,21,22,23,24]. Notably, CAP treatment is widely applied using plasma jets under ambient air at room temperature for clinical treatments in plasma biomedicine, including wound healing, tissue treatment, and cancer therapy, as it enables selective targeting of localized areas while minimizing damage to surrounding healthy cells. In direct CAP treatment, reactive oxygen and nitrogen species (RONS), which are radical species, interact directly with biological cells, thereby promoting cell growth, enhancing wound healing, and inducing selective apoptosis in cancer cells [25,26,27,28,29,30]. For desirable clinical treatments, the CAP intensity acting on biological cells needs to be appropriately controlled. Here, CAP intensity is expressed in terms of plasma dosage, which corresponds to the density of RONS formed in the plasma. This plasma dosage depends on various parameters such as plasma source, voltage, current, gas type, gas flow rate, treatment time, and distance between electrodes [31,32,33]. Consequently, CAP processes for plasma synthesis and surface modification are increasingly employed in biomedical applications. This review examines recent studies on polymer films and metal NPs, focusing on CAP–based synthesis and surface modification methods. The objective is to provide a comprehensive reference on recent plasma processes for the synthesis and surface treatment of polymer films and metal NPs in biomedical applications. This review is organized into three sections. Section 2.1 addresses plasma polymer synthesis, Section 2.2 discusses plasma surface modification of polymers, and Section 3 summarizes plasma synthesis and surface treatment of metal NPs. All figures are reproduced with copyright permission from the respective publishers.

2. Plasma Process

2.1. Plasma Synthesis of Polymer Films for Biomedical Applications

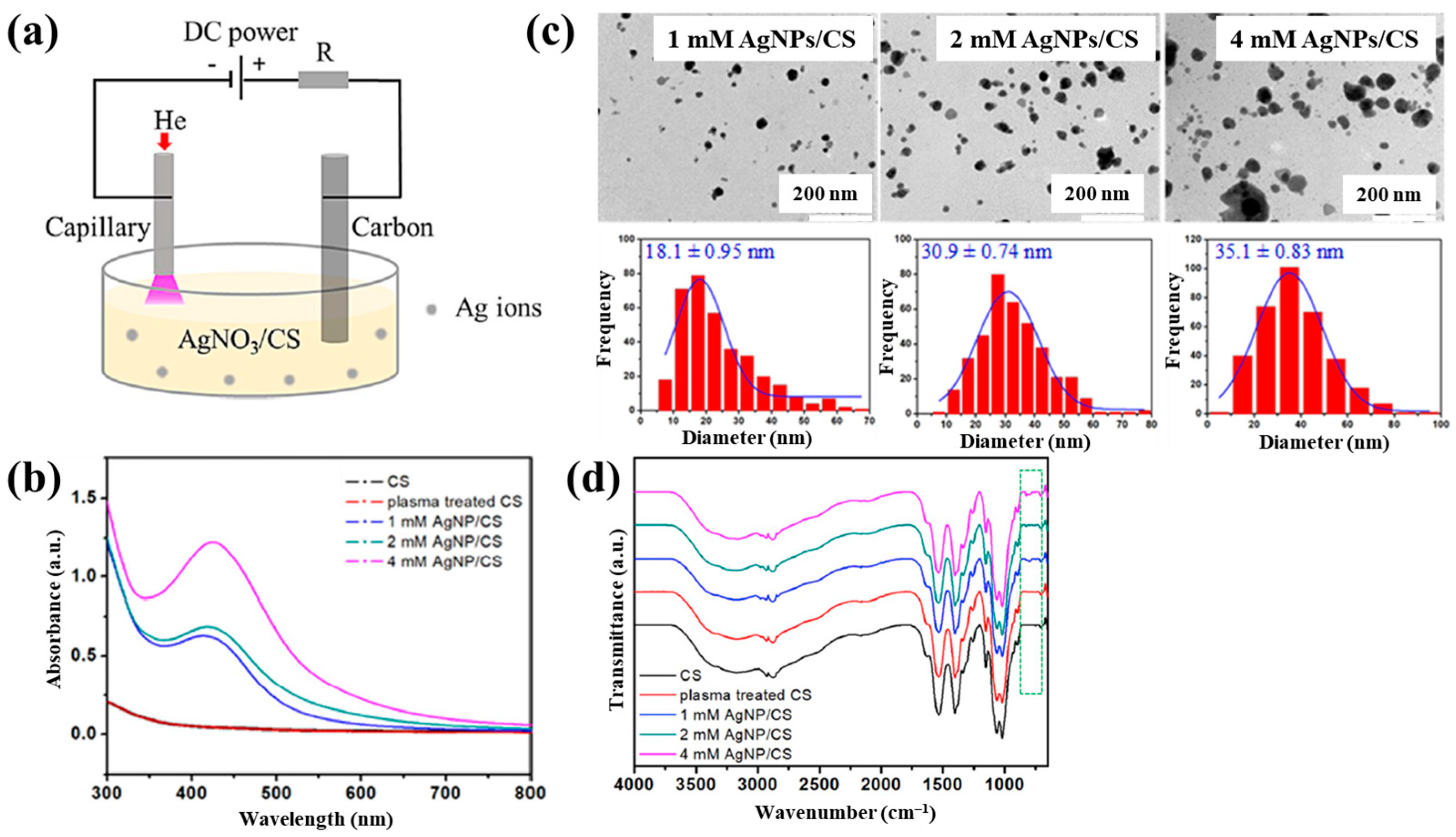

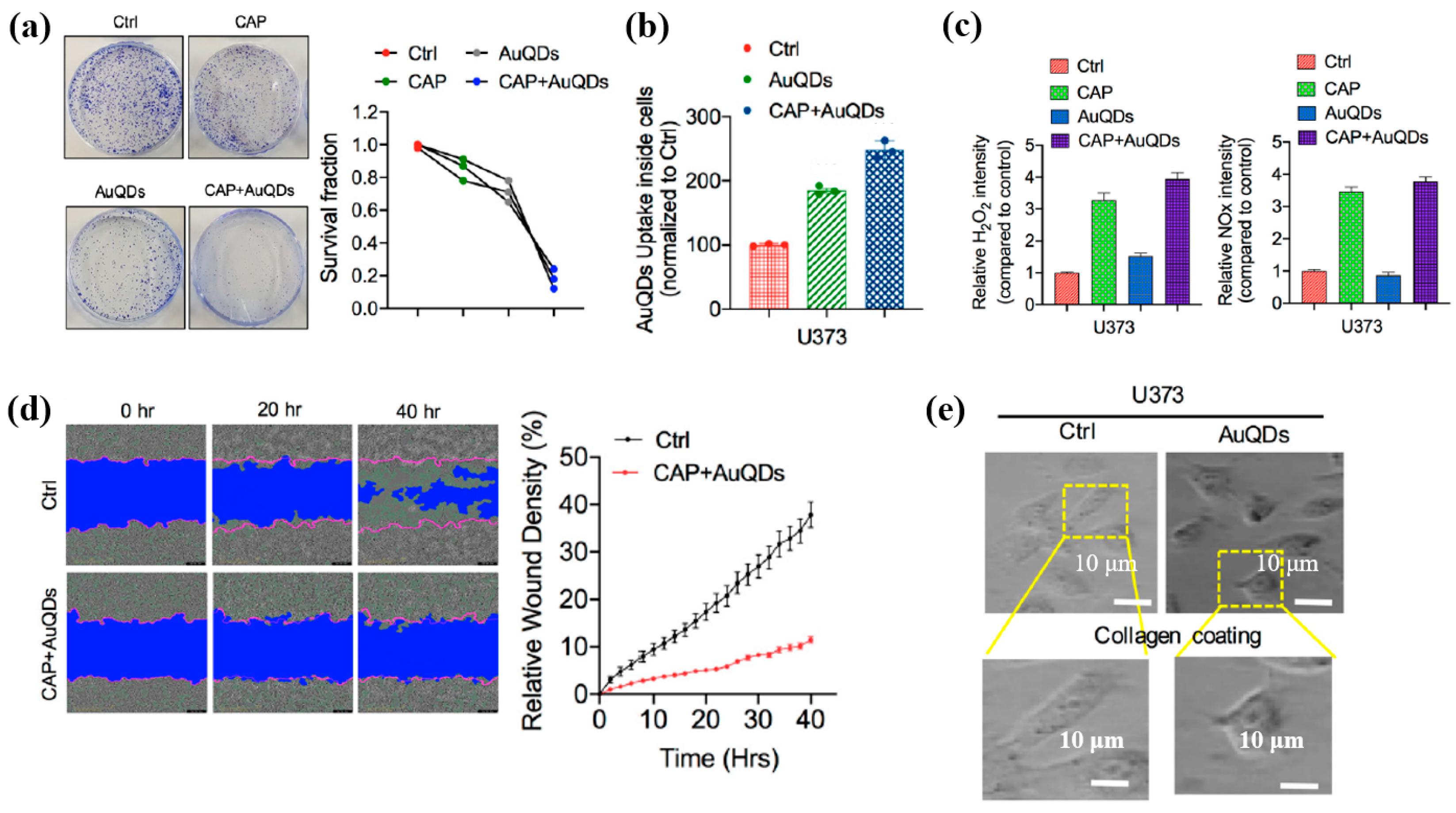

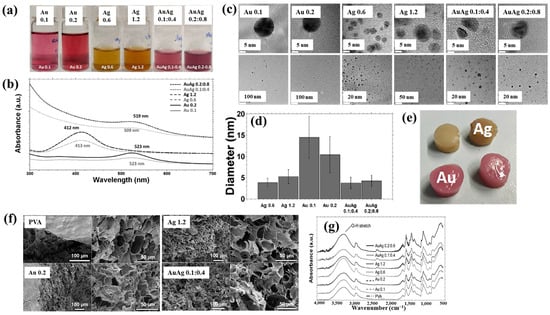

Sun et al. [34] investigated the synthesis of silver NP/chitosan (AgNP/CS) composites for antibacterial applications. Figure 1a shows the experimental setup for the synthesis of AgNP/CS composites using AP microplasma (APM), where a carbon rod served as the anode electrode and was immersed in the AgNO3/CS solution, while a stainless steel capillary with an inner diameter of 250 μm acted as the cathode electrode, positioned 2 mm above the solution surface. Helium (He) gas at a flow rate of 25 sccm was injected through the capillary to initiate plasma discharge. A voltage of 4 kV was applied to the cathode electrode, enabling AgNP/CS composite synthesis in the liquid plasma environment. Upon plasma ignition in the AgNO3/CS solution, the voltage dropped to 2.8 kV, and a discharge current of 5 mA was maintained throughout plasma synthesis for 10 min. The optical properties of plasma-treated solutions were analyzed by UV–Vis spectroscopy. As shown in Figure 1b, no absorption peak was detected in either untreated or plasma-treated CS solutions, despite slight color changes. In contrast, plasma-treated AgNO3/CS solutions exhibited more pronounced color changes, which correlated with increasing AgNO3 concentration. Transmission electron microscopy (TEM) images (Figure 1c) revealed that the synthesized AgNPs were well dispersed and that particle size increased with higher AgNO3 concentrations. The chemical structures of all AgNO3/CS samples were characterized by Fourier-transform infrared (FT–IR) spectroscopy. As shown in Figure 1d, the broad bands at 3200–3500 cm−1 originated from –OH and –NH2 stretching vibrations in the plasma-treated AgNO3/CS samples. The peak at 1647 cm−1 corresponded to C–O stretching of the O–C–NHR amide functional group. During plasma-assisted composite formation, ROS, such as –OH and C–O, were incorporated into the composite. Additional peaks at 2927, 2884, 1411, 1380, 1321, 1260, and 1078 cm−1 were assigned to C–H and N–H vibrations, indicating interactions between AgNPs and CS [34].

Figure 1.

(a) Experimental setup for synthesis of AgNP/chitosan (AgNPs/CS) composites using AP microplasma (APM) by Sun et al. (b) UV–vis spectra of CS and plasma–treated CS. (c) Transmission electron microscopy (TEM) images and size distribution of AgN–/CS composites prepared with 1, 2, and 4 mM AgNO3/CS mixtures. (d) FT–IR spectra of CS, plasma–treated CS, and AgNP/CS composites synthesized with 1, 2, and 4 mM AgNO3/CS mixtures. Reproduced with copyright permission from Ref. [34].

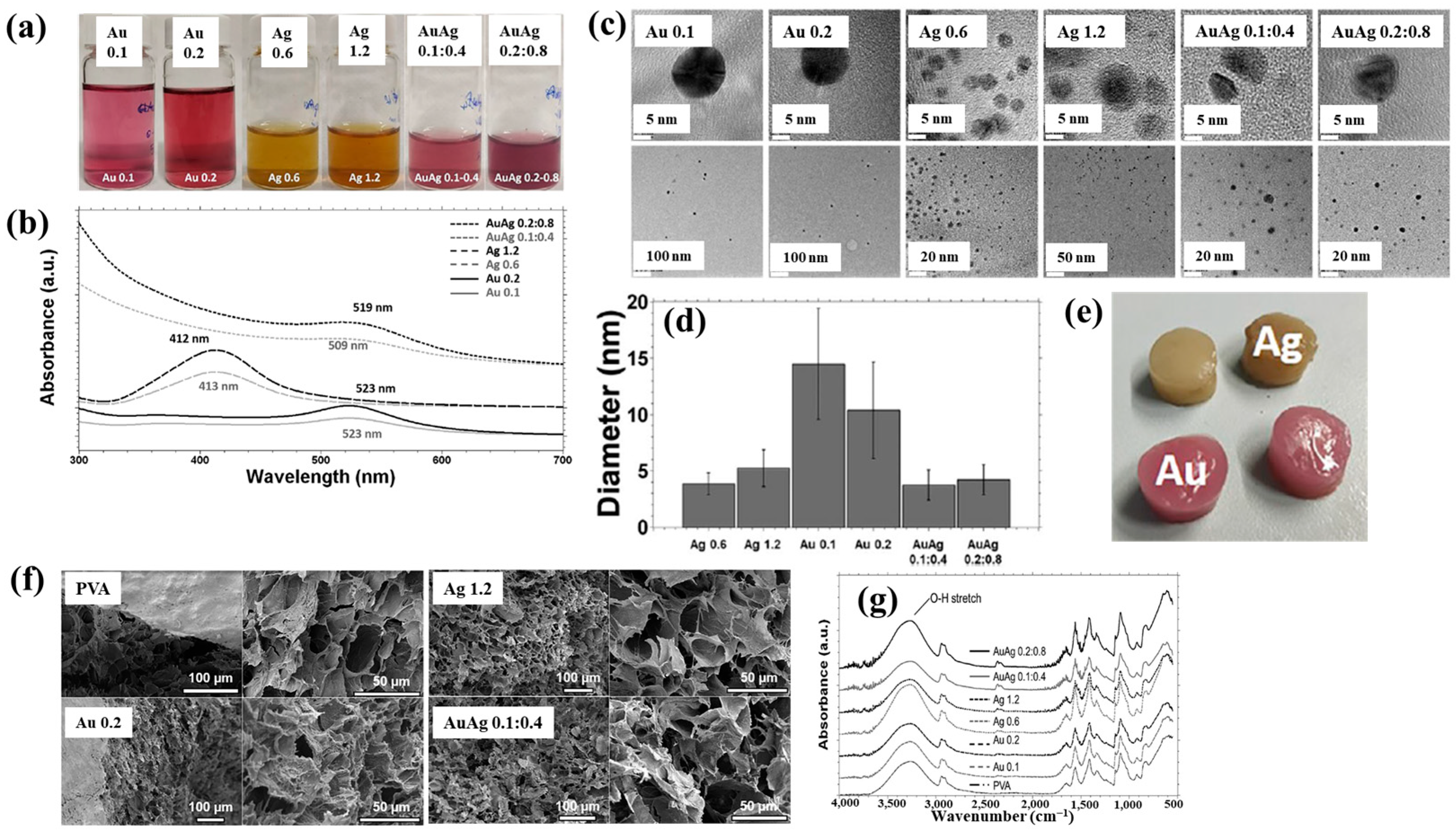

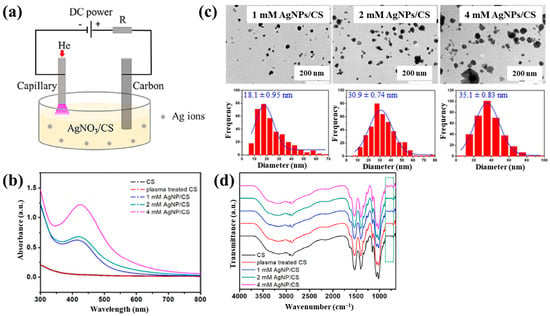

Nolan et al. [35] investigated AuAg NP/polyvinyl alcohol (PVA) hydrogels synthesized via non-thermal APP for antibacterial applications [35]. The hydrogels were synthesized using a similar plasma system (Figure 1a) to that proposed by Sun et al. [34]. For hydrogel synthesis, He gas at a flow rate of 25 sccm was injected through the capillary, which was connected to a power supply via a platinum (Pt) wire acting as the anode in the PVA/salt solution. Plasma discharge was achieved by applying a voltage of 2 kV and a current of 2 mA. As shown in Figure 2a, plasma treatment induced distinct color changes in gold(III) chloroauric acid trihydrate (H[AuCl4]·3H2O)/PVA and AgNO3/PVA solutions. The Ag-treated solution exhibited a yellow color due to colloidal Ag, whereas the plasma-treated H[AuCl4]·3H2O solution shifted to red or purple, indicating AuNP formation. The presence of Au and Ag NPs in plasma-treated solutions was confirmed by UV–vis absorption spectra (Figure 2b). Specifically, plasma-treated H[AuCl4]·3H2O/PVA solutions showed an absorption peak at 523 nm, characteristic of the surface plasmon resonance (SPR) of AuNPs. Similarly, plasma-treated AgNO3/PVA solutions displayed SPR peaks at 413 and 412 nm for Ag 0.6 and Ag 1.2 samples, respectively, confirming AgNP formation. TEM analysis (Figure 2c) revealed that all synthesized metal NPs were well dispersed, spherical, and free from agglomeration. The particle size distributions (Figure 2d) showed the distribution of Ag0.6 and Ag1.2 samples to be 4–5 nm, with Au0.1 and Au0.2 NPs ranging from 10 to 15 nm, and bimetallic AuAg0.1:0.4 and AuAg0.2:0.8 NPs averaging ~4 nm. To evaluate antibacterial performance, NP/PVA hydrogels were fabricated. For AgNO3/PVA hydrogels, AgNO3/PVA solutions were poured into a polytetrafluoroethylene (PTFE) mold, frozen at −20 °C for 14 h, and thawed at 18 °C for 10 h over four freeze–thaw cycles. Figure 2e shows the photographic images of the resulting NP/PVA hydrogels, each with dimensions of 9 × 14 mm. SEM analysis (Figure 2f) revealed that untreated and plasma-treated PVA hydrogels displayed similar morphologies. FT–IR spectra (Figure 2g) confirmed a broad peak at 3300 cm−1 in plasma-treated PVA hydrogels, corresponding to O–H bonds attributed to hydrogen peroxide (H2O2) and ROS radicals (O, H, and OH) generated during plasma treatment. These results demonstrate that AuAg NPs were successfully incorporated into PVA hydrogels by APP, producing composite materials with potential for biomedical applications [35].

Figure 2.

(a) Photographic images and (b) UV–vis absorption spectra of plasma–treated polyvinyl alcohol (PVA) solutions containing AuNPs, AgNPs, and AuAgNPs. (c) TEM images and (d) particle size distribution of synthesized metal NPs. (e) Photographic images, (f) scanning electron microscopy images (SEM), and (g) FT–IR spectra of metal NP/PVA hydrogels prepared under different metal NPs conditions. Reproduced with copyright permission from Ref. [35].

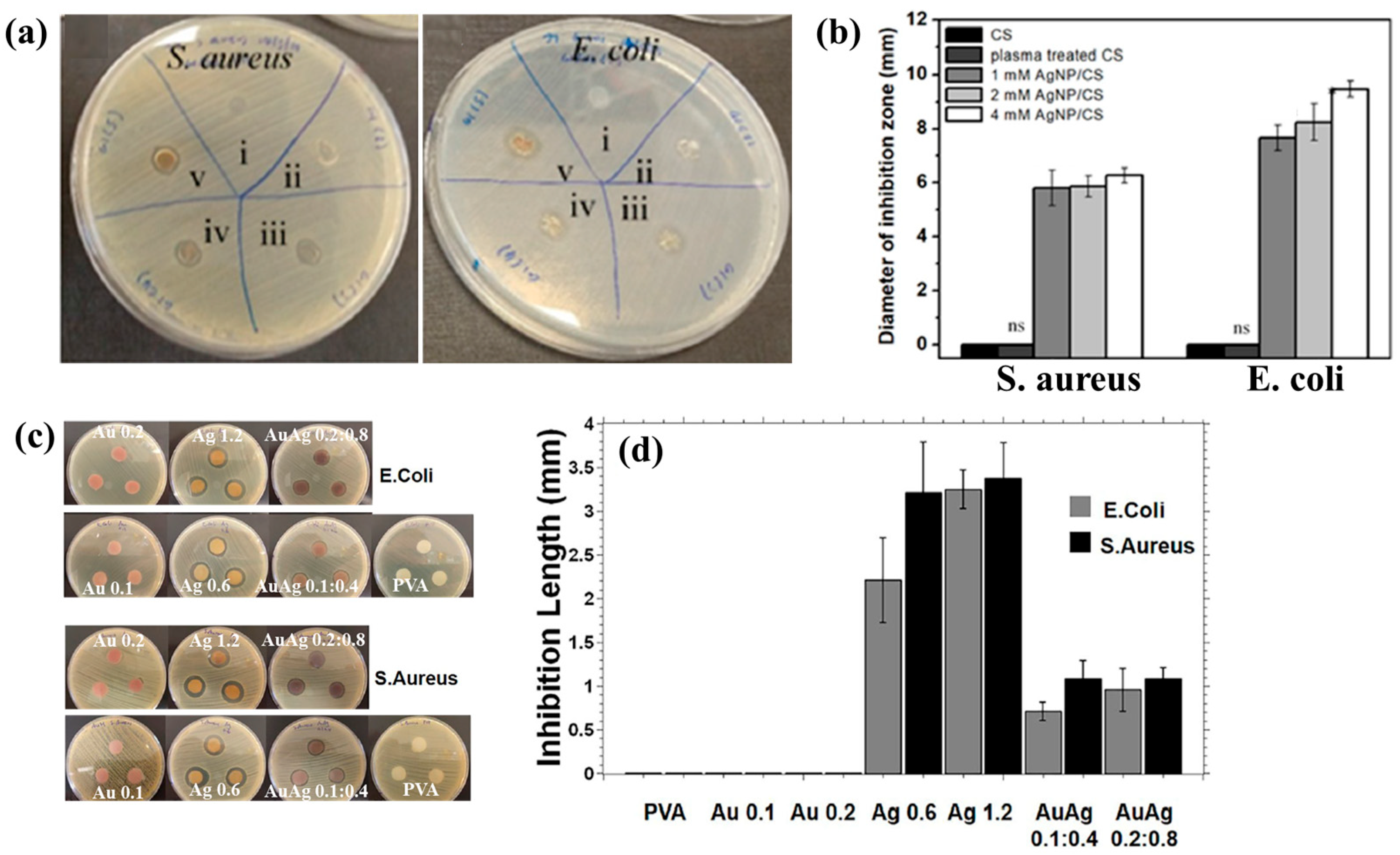

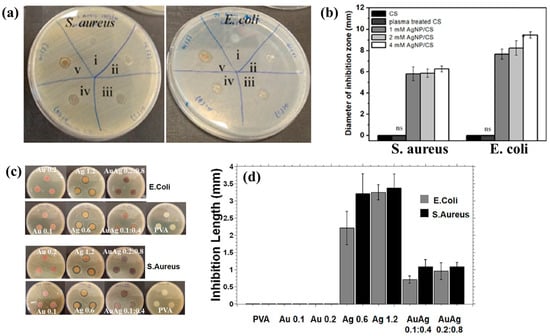

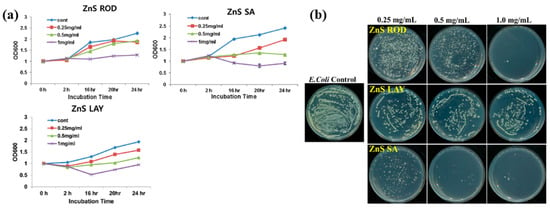

Figure 3a,b illustrate the antibacterial properties and average inhibition zone diameters of two bacterial strains (Escherichia coli (E. coli) and Staphylococcus aureus (S. aureus)), tested with different composite samples: (i) untreated CS, (ii) plasma−treated CS, (iii) 1 mM AgNPs/CS, (iv) 2 mM AgNPs/CS, and (v) 4 mM AgNPs/CS [34]. No antibacterial activity was observed in the untreated or plasma−treated CS samples, whereas all AgNP/CS composites exhibited clear inhibition zones against both bacterial strains. Notably, in the case of E. coli, the inhibition zone diameter increased with higher Ag content. The strong antimicrobial properties of AgNPs are attributed to ROS generated during plasma treatment. When these ROS species interact with bacteria in plasma−treated composite films, they disrupt cellular functions and ultimately induce bacterial death [34].

Figure 3.

(a) Antibacterial effects against S. aureus and E. coli under five conditions: (i) untreated CS, (ii) plasma–treated CS, (iii) 1 mM AgNPs/CS, (iv) 2 mM AgNPs/CS, and (v) 4 mM AgNPs/CS. (b) Comparisons of average inhibition zone diameters against S. aureus and E. coli under five conditions. (c) Antibacterial activity and (d) inhibition zone lengths of AgAu NP/PVA hydrogels against E. coli and S. aureus. Reproduced with copyright permission from Refs. [34,35].

Additionally, Figure 3c,d present the antibacterial activity and inhibition zone lengths of various AuAg metal NP/PVA hydrogels against E. coli and S. aureus. The inhibition zones are most prominent around the AgNP/PVA composite sample, indicating that this sample exhibits superior antibacterial activity. The strong antimicrobial properties of AgNPs are attributed to their enhanced surface electronic property and the generation of ROS induced by plasma treatment. When these ROS interact with bacteria within the plasma-treated composite hydrogels, they disrupt cellular functions and ultimately cause bacterial death [35]. Table 1 summarizes the experimental synthesis and antibacterial results corresponding to Figure 1, Figure 2 and Figure 3 [34,35].

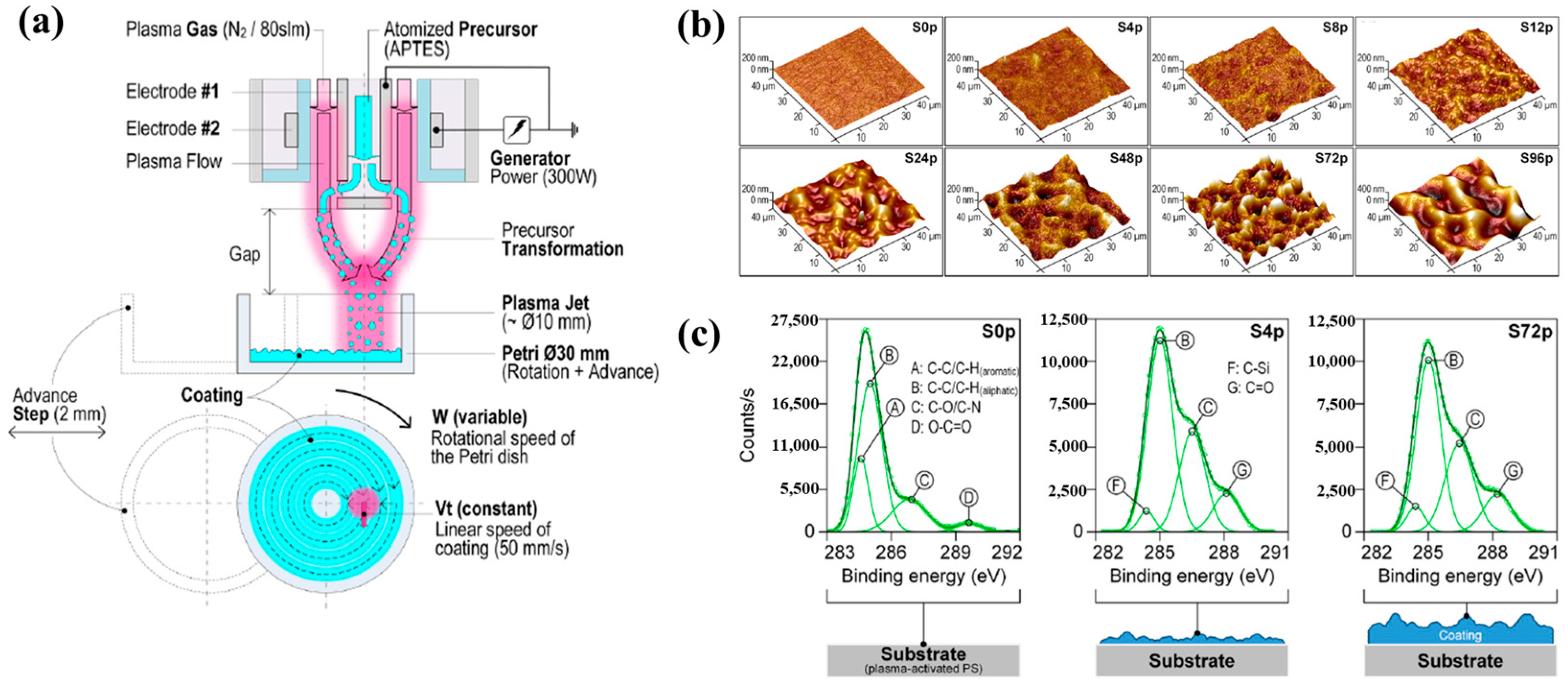

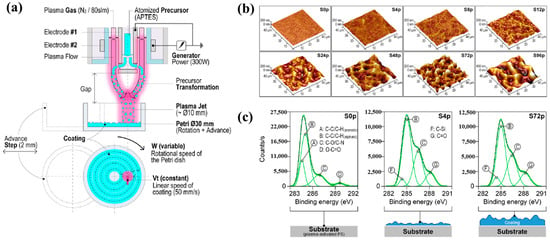

Sainz–García et al. [12] investigated the adhesion of bacterial samples on plasma-polymerized polymer film coatings prepared by using an atmospheric pressure plasma jet (APPJ) on polystyrene (PS) Petri dishes with (3–aminopropyl)triethoxysilane (APTES). Figure 4a illustrates the plasma polymerization process with rotational patterns generated by the APPJ system which consists of two coaxial electrodes. Plasma is generated due to the gas flow between the electrodes, with the internal electrode grounded and the external electrode excited by a high–voltage power source at 68 kHz. The vaporized precursor is injected into the internal electrode within the plasma reactor, where it undergoes plasma-induced reactions and is subsequently deposited as polymer material during multiple plasma passes with APTES. As shown in Figure 4b, increasing the number of plasma polymerization passes transforms the pAPTES film surface morphology from smooth to rough, resulting in a granular topographical pattern with high surface roughness. Figure 4c presents the high–resolution C 1s peaks in the XPS spectra for different polymer films (S0p, S4p, and S72p). For plasma-treated PS surfaces, the uncoated sample (S0p) shows carbon-related functional groups inherent to PS, including C–C, C–H, C–O/C–N, C–O, and O–C=O. In contrast, the plasma–treated PS substrate and plasma-deposited pAPTES films exhibit oxygenated carbon functional groups, namely, C–O, O–C=O, and C=O. Comparison of the XPS spectra confirms that, relative to the uncoated PS Petri dish (S0p), the deposited pAPTES films (S4p, and S72p) introduce additional oxygenated carbon functional groups onto the plasma-treated PS surfaces [12].

Figure 4.

(a) APPJ system for pAPTES polymer film deposition with rotational pattern by Sainz–García et al. (b) AFM images and (c) XPS C 1s high-resolution spectra of prepared samples. Reproduced with copyright permission from Ref. [12].

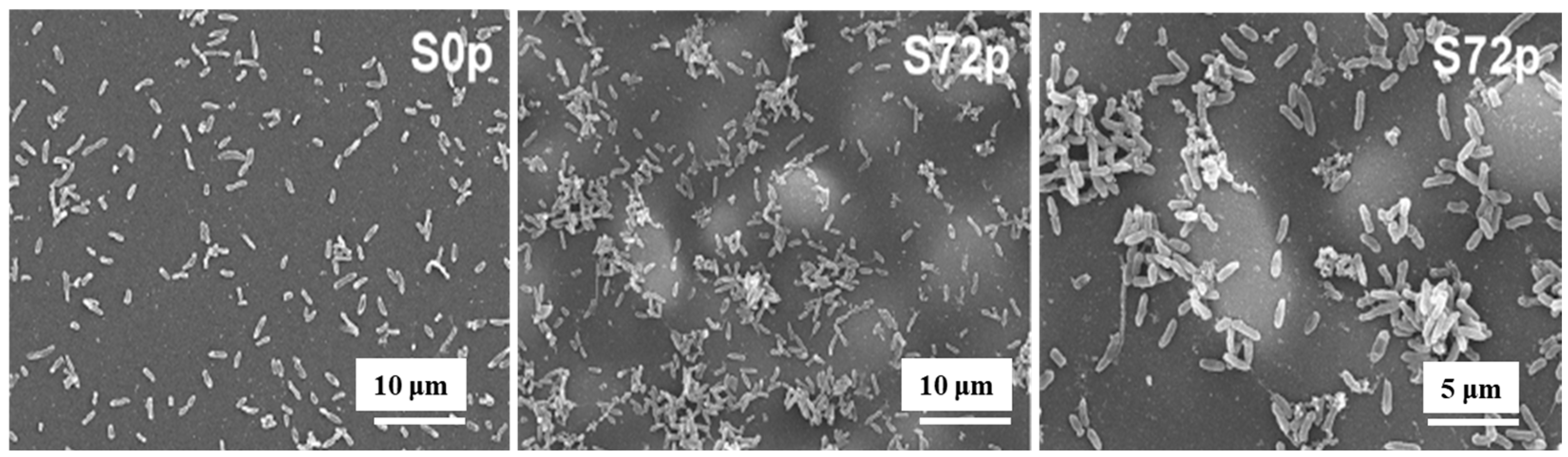

Figure 5 shows SEM images of sessile bacteria on deposited pAPTES film surfaces for different samples (S0p and S72p). When inoculated with the same initial bacterial concentration on uncoated (S0p) and coated (S72p) samples, a higher density of sessile bacteria accumulated in the valley structures of the pAPTES film, which provided a large surface area and rough morphology. Because the plasma-deposited polymer film was formed from an APTES precursor, it contained amine (–NH2) functional groups, which became positively charged due to their ability to accept protons. As a result, negatively charged bacterial (P. aeruginosa) cells were electrostatically attracted to these amine groups and attached to them. Thus, both the chemical functionality and morphological characteristics of plasma–deposited polymer films play a critical role in enhancing high–density bacterial cell adhesion [12]. Table 2 summarizes the experimental plasma synthesis and bacterial results corresponding to Figure 4 and Figure 5.

Figure 5.

SEM images of sessile bacteria on pAPTES film surfaces of samples (S0p and S72p). Reproduced with copyright permission from Ref. [12].

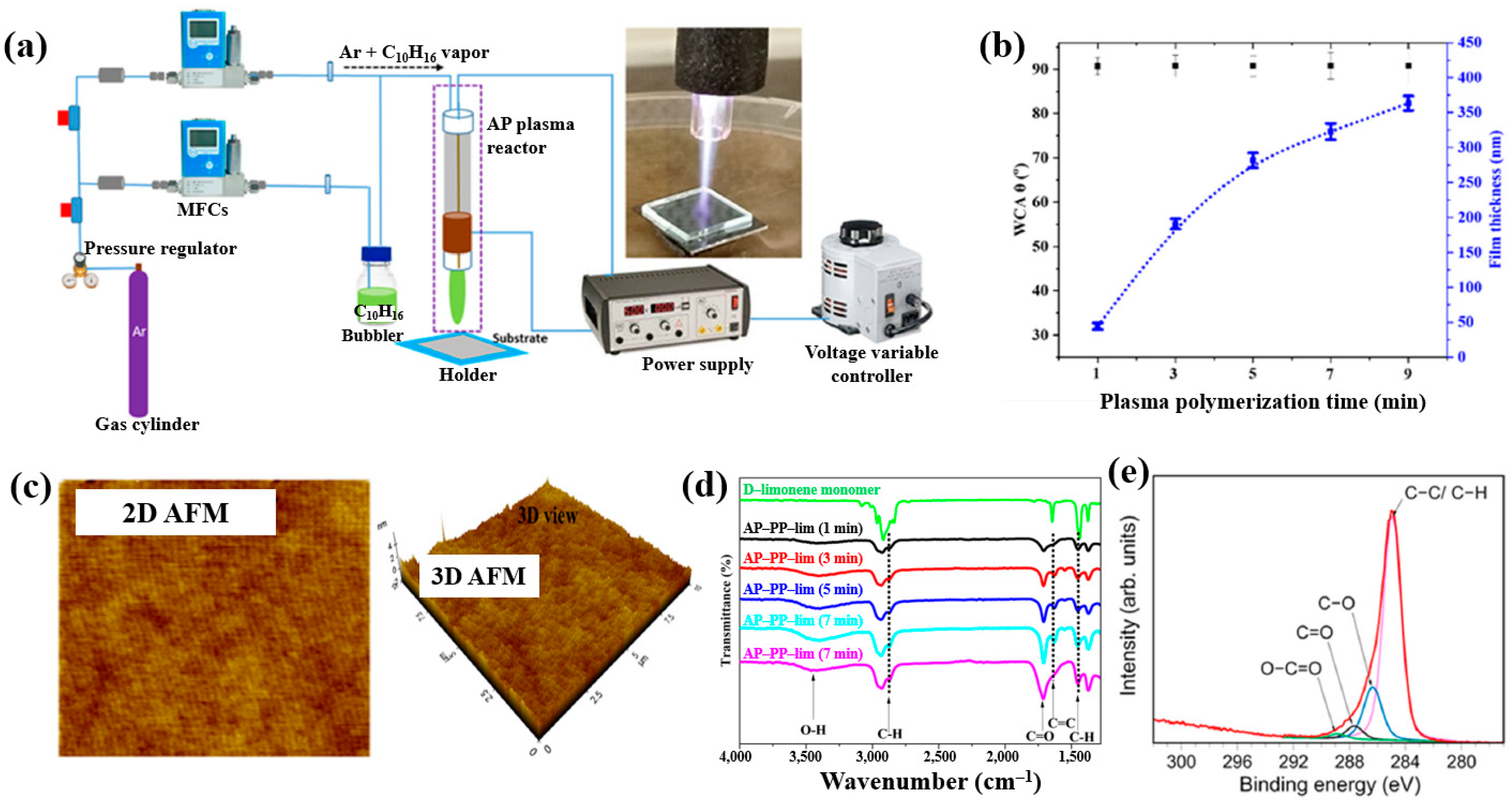

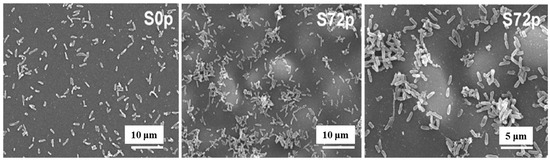

Masood et al. [36] investigated plasma polymerization under AP conditions using a D–limonene monomer to deposit polymer films for antibacterial applications. Figure 6a schematically depicts the AP plasma polymerization system, in which a copper (Cu) rod electrode was inserted into a quartz tube and connected to a high–voltage (HV) supply. A Cu metal ring, serving as the outer electrode, was positioned around the quartz tube and electrically grounded. Plasma discharge within the plasma jet was generated by applying a voltage of 3 kV. The quartz tube had inner and outer diameters of 3.0 mm and 5.0 mm, respectively. The distance between the HV electrode tip and the nozzle was fixed at 20 mm, with the nozzle positioned 15 mm above the glass substrate. AP plasma-polymerized D–limonene (AP–PP–lim) films were deposited on 5 cm × 5 cm glass substrates using vaporized D–limonene carried by argon (Ar) gas at a flow rate of 130 sccm [36]. Figure 6b shows the average water contact angle (WCA) of AP–PP–lim films deposited for different plasma polymerization durations along with images of water droplets on control and coated surfaces. Film thickness measured using a surface profiler increased with plasma exposure times (1, 3, 5, 7, and 9 min), corresponding to a deposition rate of 0.8 nm/s. The control glass substrate exhibited a hydrophilic surface with a very low WCA, whereas all AP–PP–lim–coated samples treated for more than 1 min displayed high WCA values exceeding 90.7°. Notably, the WCA of the AP–PP–lim films remained constant beyond this point [34]. Additionally, the atomic force microscopy (AFM) results in Figure 6c show that an AP–PP–lim film deposited for 1 min exhibited a smooth surface with an average roughness (Ra) of 0.23 nm and a root mean square roughness (Rq) of 0.27 nm. The chemical structure of the D–limonene monomer and AP–PP–lim films was analyzed using FT–IR spectroscopy. As shown in Figure 6d, the FT–IR spectrum of D–limonene displays characteristic peaks corresponding to symmetric C−H stretching (2834 and 2856 cm−1), asymmetric C–H stretching (2920 and 2964 cm−1), unsaturated C–H bonds (3010, 3046, 3072, and 3083 cm−1), C=C stretching (1644 cm−1), asymmetric C–H bending (1436 and 1451 cm−1), symmetric C–H bending (1375 cm−1), and out–of–plane C–H bending (1310 cm−1). These peaks were retained in the AP–PP–lim film; however, peak broadening and the appearance of additional bands indicates cross-linking induced by plasma polymerization relative to the D–limonene monomer. The chemical composition of the AP–PP–lim film was further examined by XPS, and the C 1s spectrum is presented in Figure 6e. The spectrum contains four components: hydrocarbons bonds (C–C/C–H) of polymer chain and oxygenated carbon groups (C–O–H, C–O–C, C–O, C=O, and O–C=O). The presence of these oxygenated carbon groups is attributed to the partial oxidation of the AP–PP–lim film [36].

Figure 6.

(a) Schematic of APP polymerization system by Masood et al. (b) Average water contact angle (WCA) values after different plasma polymerization durations. (c) 2D and 3D atomic force microscopy (AFM) images of AP–PP–lim film deposited for 1 min. (d) FT–IR spectra of D–limonene monomer and AP–PP–lim films deposited for different plasma durations. (e) XPS C 1s high-resolution spectra of AP–PP–lim films. Reproduced with copyright permission from Ref. [36].

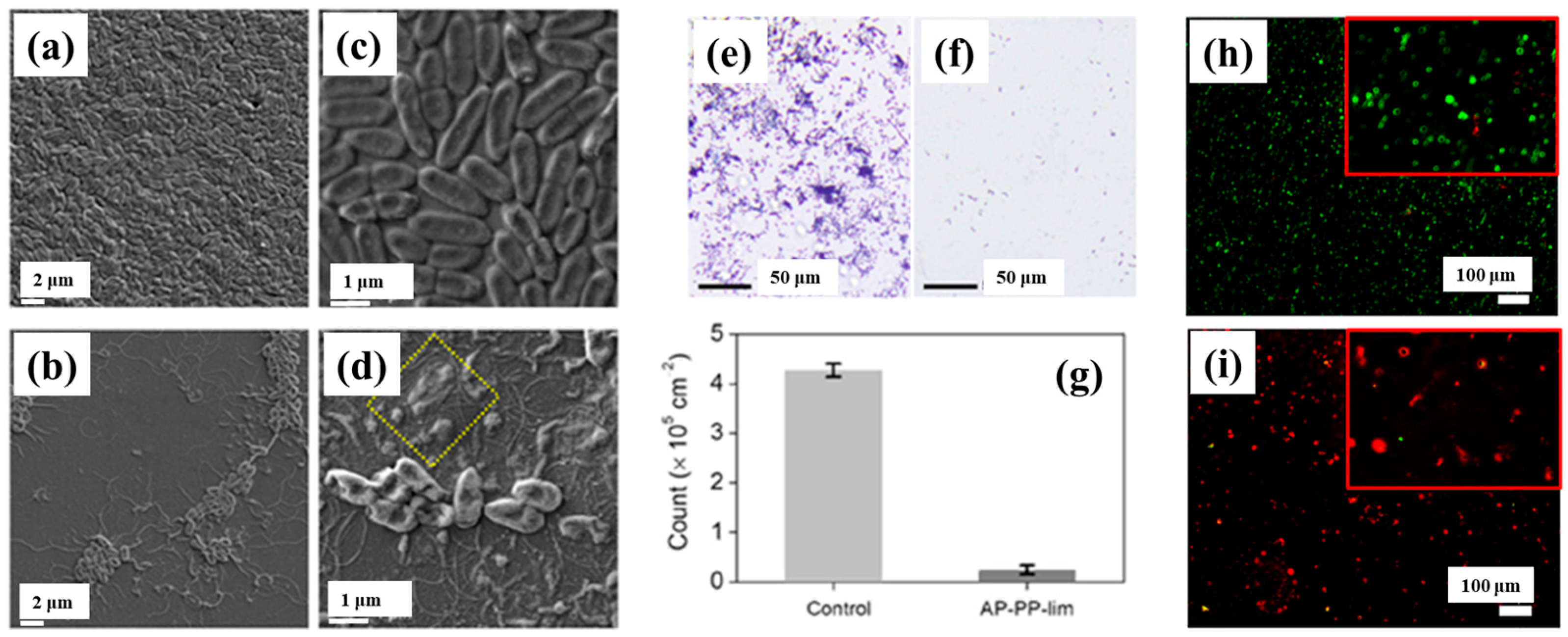

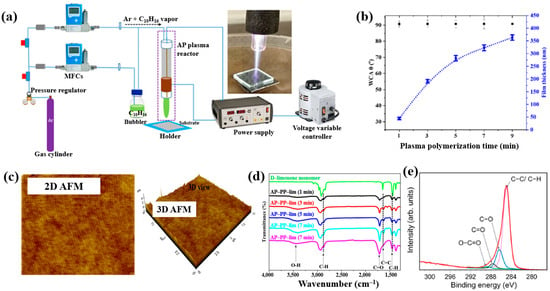

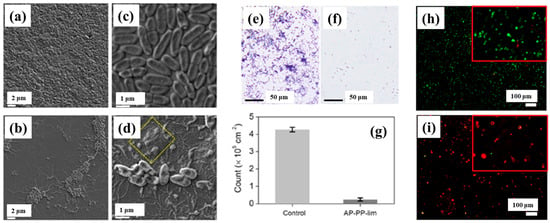

To verify the antibacterial performance of the film, the morphology of E. coli attached to control and AP–PP–lim films was examined using field emission scanning electron microscopy (FE–SEM). Figure 7a–d show FE–SEM images of E. coli on the uncoated sample (control) and AP–PP–lim films [36]. In Figure 7a,c, rod–shaped E. coli with lengths of approximately 2 μm and widths of 0.46 μm are observed on the control sample. In contrast, Figure 7b,d, reveal withered and isolated E. coli on the AP–PP–lim film, with a substantial reduction in bacterial colonies, and dead cells are clearly visible within the yellow box in Figure 7d. The antibacterial effect was further assessed using fluorescence microscopy. Figure 7e,f present fluorescence images of treated E. coli on control and AP–PP–lim films after 24 h of incubation, while Figure 7g quantifies a reduction in bacterial adhesion exceeding 94% on the AP–PP–lim film compared to the control. Likewise, Figure 7h,i show fluorescence images of E. coli attached to a glass substrate and an AP–PP–lim film following 24 h of cultivation, confirming a markedly lower number of attached bacteria on the AP–PP–lim film [36]. The antibacterial properties of plasma–deposited films are attributed primarily to the hydrocarbon groups (C–C, C–H) from the D–limonene monomer and the oxygenated carbon groups (C–O, C=O, and O–C=O) generated through free radical reactions under plasma conditions in ambient air. Table 3 summarizes the experimental synthesis and antibacterial results corresponding to Figure 6 and Figure 7 in this section.

Figure 7.

Antimicrobial performance of E. coli on AP–PP–lim film: (a,c) FE–SEM images of E. coli on control surfaces. (b,d) FE–SEM images on AP–PP–lim films. (e,f) Fluorescence microscopy of crystal violet–stained E. coli on control and AP–PP–lim films. (g) Bacterial counts on control and AP–PP–lim films. (h,i) Live–dead fluorescence assay images of E. coli adhered to glass and AP–PP–lim films. Reproduced with copyright permission from Ref. [36].

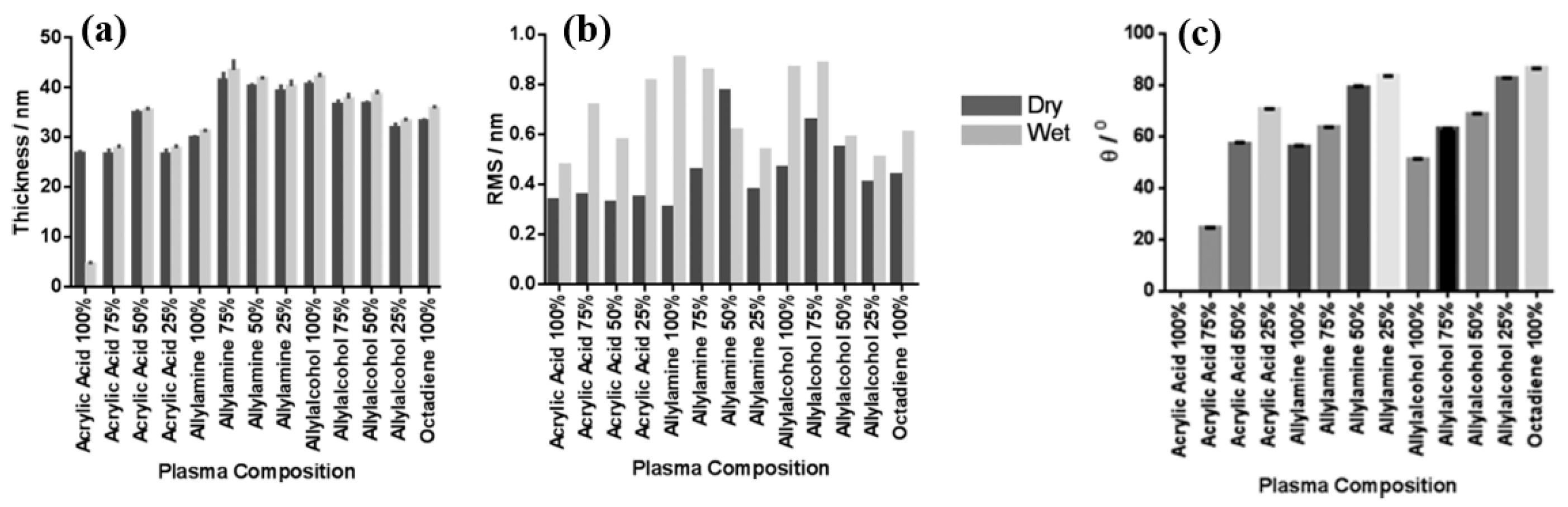

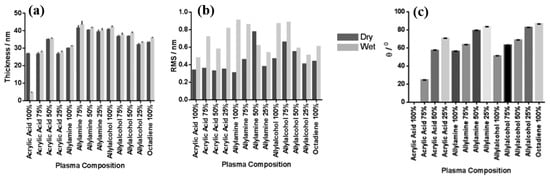

Smith et al. investigated plasma polymerization and copolymerization to prepare plasma polymer (PP) surfaces from four organic monomers: acrylic acid (ppAAc), allyl amine (ppAAm), allyl alcohol (ppAAOH), and copolymers with the diluent hydrocarbon 1, 7, octadiene, (ppOD) [37]. In this study, PP layers of AAc and AAOH were deposited using a radio frequency (13.56 MHz) plasma generator under varying power conditions (3 W for AAc, AAOH, and OD, and 5 W for AAm). All deposited PP layers, except ppAAc, were sufficiently thick [37]. As shown in Figure 8a,b, all monomers exhibited a fast deposition rate and the resulting films displayed smooth surfaces with a roughness (Rq) of less than 1 nm [37]. The thickness of the PP film formed at a deposition rate of 1.3 nm/min using AAc increased with higher concentrations of octadiene in the plasma.

Figure 8.

(a) Film thickness, (b) surface roughness, and (c) WCA of deposited PP films under dry and wet conditions. Reproduced with copyright permission from Ref. [37].

Similarly, the thickness of the PP film formed at a rate of 1 nm/min using AAm also increased with increasing OD content. In contrast, although the initial deposition rate using AAOH was 2 nm/min, the resulting PP film thickness decreased when octadiene was introduced into the plasma. Contact angle measurements (Figure 8c) indicated that the ppAAc–OD film exhibited a hydrophilic surface. When the AAc monomer ratio decreased from 75% to 25%, the contact angle increased from 25° to 72°. Additionally, the contact angles for ppAAm and ppAAOH surfaces were measured at 56° and 51°, respectively. As the octadiene content increased, the PP films became more hydrophobic due to a reduction in hydrophilic functional groups. The pure ppOD polymer film exhibited a hydrophobic surface with a contact angle of 86.5° [37].

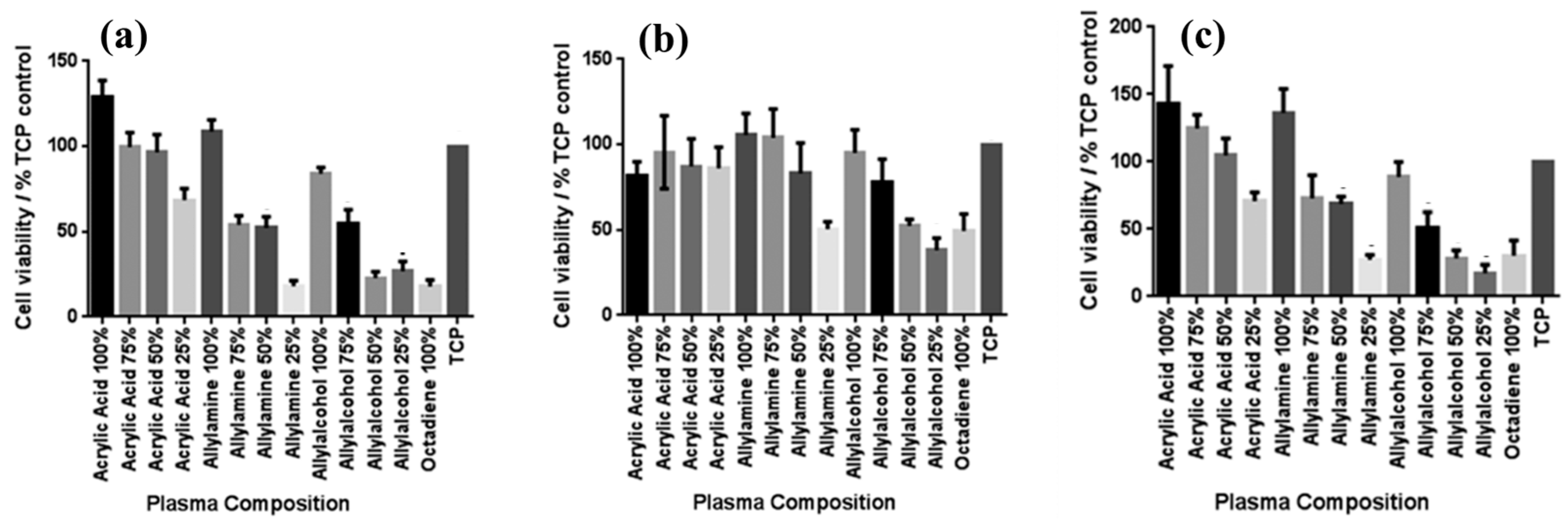

To examine the effect of functional groups and their densities on the viability of various skin cells, including fibroblasts, keratinocytes, and endothelial cells after 4 days in culture, MTT–ESTA assays were performed. The experimental results are presented in Figure 9a–c, showing cell viability on different PP surfaces. In all cases, tissue culture polystyrene (TCP) was used as a reference without a PP layer. As shown in Figure 9a, keratinocyte viability was highest on surfaces with 100% ppAAc and ppAAm. As shown in Figure 9b, fibroblast viability decreased under low functional group concentrations, particularly on 25% ppAAm and ppAAOH surfaces. Similarly, endothelial cells responded in a manner comparable to keratinocytes across the PP surfaces. (Figure 9c), showing improved viability on ppAAc compared with ppAAm and ppAAOH. In cases of high functional group concentrations (100% AAc, 100% AAm, and 100% AAOH), all three cell types exhibited enhanced growth on PP surfaces. Conversely, endothelial cell viability decreased with decreasing functional group concentration [37]. Table 4 summarizes the experimental plasma synthesis parameters and biological results corresponding to Figure 8 and Figure 9 in this section.

Figure 9.

Cell viability on PP surfaces after incubation using the MTT–ESTA assay with (a) keratinocytes, (b) fibroblasts, and (c) endothelial cells. Reproduced with copyright permission from Ref. [37].

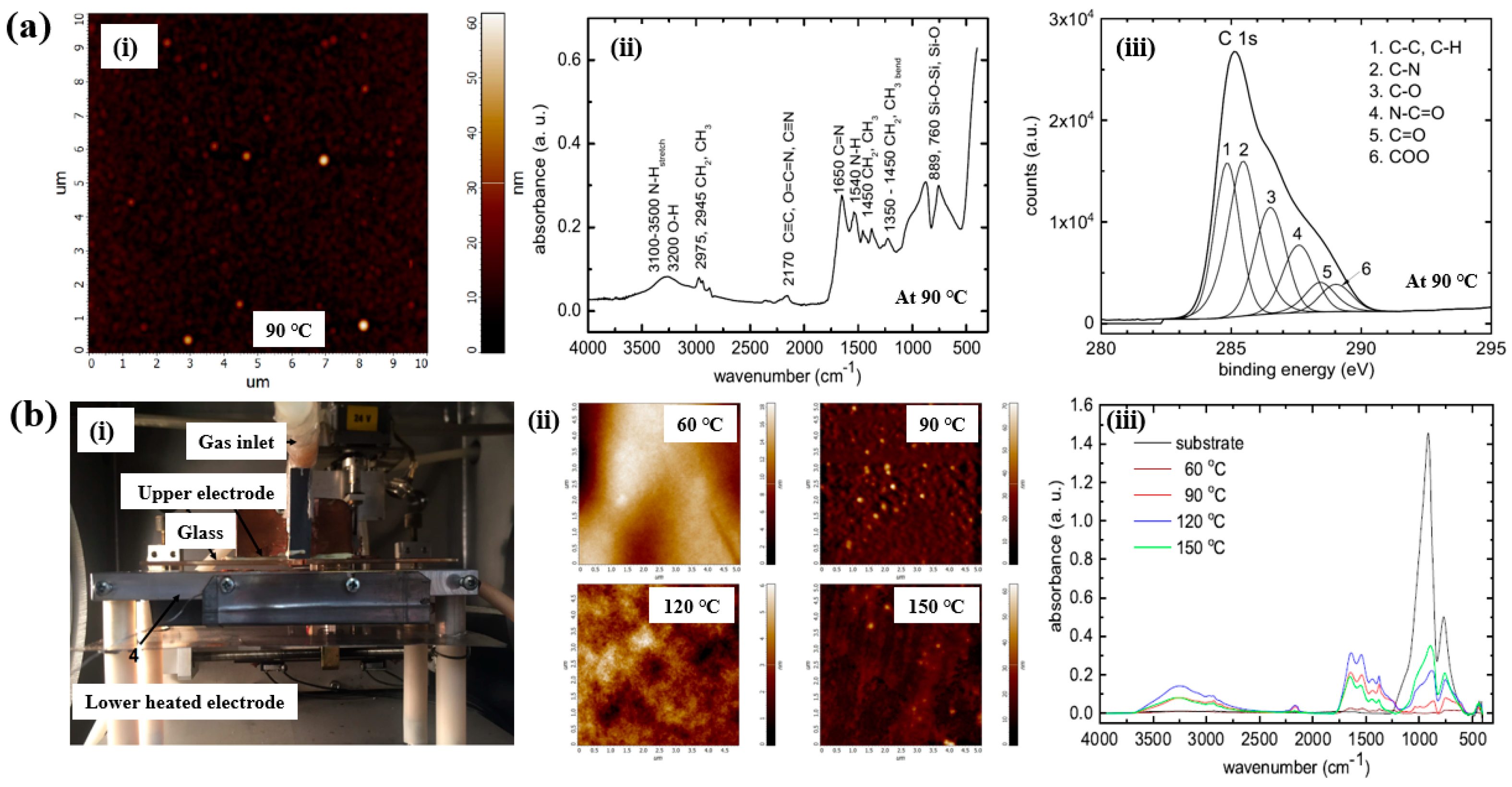

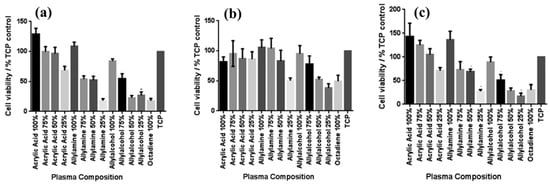

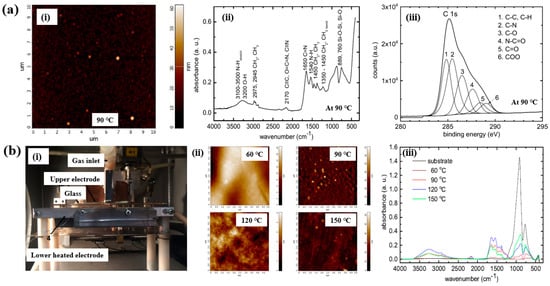

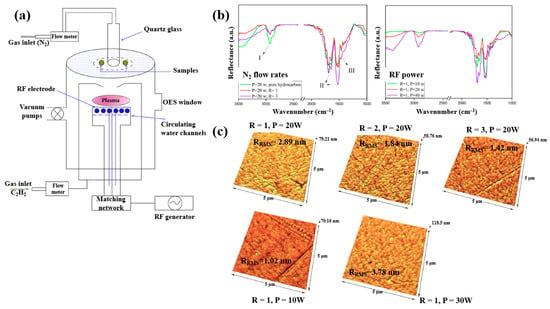

As shown in Figure 10a,b, Mazánková and St’ahel et al. examined polyoxazoline (POx) thin films produced by AP Townsend–like discharge (APTD) polymerization on glass substrates using 2–ethyl–2–oxazoline monomers as precursors [21,38]. The plasma device used by Mazánková and St’ahel et al. for POx deposition is shown in Figure 10b(i). The POx thin films were synthesized via a DBD–type plasma under AP with an N2 gas flow. As shown in Figure 10a(i), the surface roughness (Rq and Ra) of the POx thin films was measured to be approximately 3.2 nm and 2.1 nm, respectively [21]. Figure 10b(ii) shows that the surface morphology of the POx films changed with increasing substrate temperatures (60, 90, 120, and 150 °C) [21]. The FT–IR spectra of the POx films in Figure 10a(i),b(iii) reveal a broad absorption band in the 3000–3600 cm−1 range, corresponding to overlapping signals from OH, NH and NH2 bonds. Peaks at 2975, 2945, 1450, and 1370 cm−1 are associated with CH3 and CH2 stretching and bending vibrations. The peak at 2170 cm−1 is attributed to C≡C, O=C=N, or C≡N functionalities. The absorption band between 1790 and 1590 cm−1 corresponds to the C=N bond of the oxazoline ring, while the peak at approximately 1550 cm−1 indicates N–H bonding. These FT–IR results confirm the formation of various functional groups through fragmentation and recombination reactions of oxazoline monomers during plasma polymerization [21,38]. Furthermore, as shown in Figure 10a(iii), XPS analysis of the POx film revealed six deconvoluted peaks corresponding to the following bonding states: C–C/C–H (284.7 eV), C–N (285.4 eV), C–O (286.3 eV), N–C=O (287.7 eV), C=O (288.2 eV), and COO (289.1 eV) [21].

Figure 10.

(a(i)) AFM image of POx thin film, (a(ii)) FT–IR spectrum, and (a(iii)) high–resolution XPS C 1s spectrum of POx thin films deposited at 90 °C by Mazánková [23]. (b(i)) Photo image of plasma deposition setup; (b(ii)) AFM images; (b(iii)) FT–IR spectra of POx thin films deposited at 60, 90, 120, and 150 °C by St’ahel et al. Reproduced with copyright permission from Refs. [21,38].

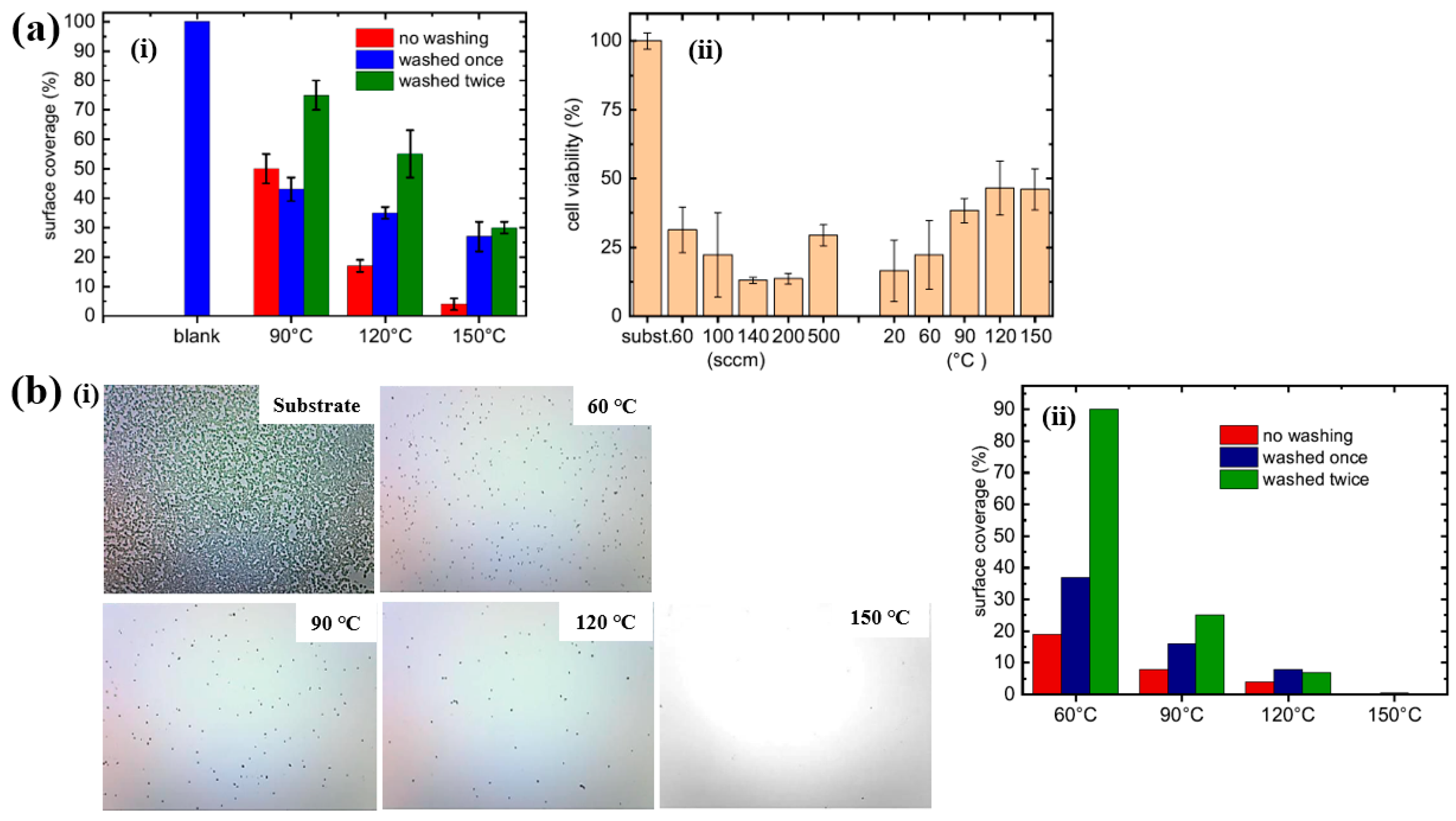

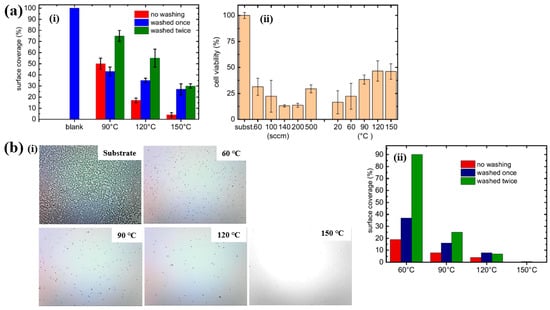

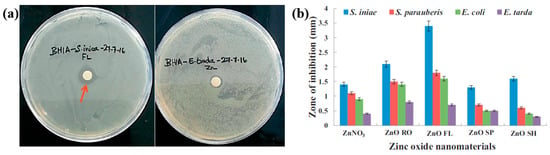

Based on the experimental results in Figure 11a,b, the antibacterial and in vitro cytocompatibility properties of POx thin films were investigated under varying substrate temperatures and monomer vapor flow rates [21,38]. Figure 11a(i) shows that the surface coverage area (%) of S. epidermidis on POx thin films deposited at 90 °C was approximately 50%. In vitro cytocompatibility tests were conducted over 48 h using mouse embryonic fibroblast (NIH/3T3) cells cultured on POx thin films deposited at different substrate temperatures and monomer flow rates. According to Figure 11a(ii), cell viability on POx thin films was significantly lower than that on the pure glass substrate [21].

Figure 11.

(a(i)) Surface coverage (%) of S. epidermidis on POx thin films at different substrate temperatures. (a(ii)) In vitro cytocompatibility for POx thin films prepared under varying substrate temperatures and monomer flow rates by Mazánková et al. [21]. (b(i)) Imges of POx thin films exposed to S. epidermidis. (b(ii)) Surface coverage (%) of S. epidermidis on POx thin films deposited at different substrate temperatures by St’ahel et al. Reproduced with copyright permission from Refs. [21,38].

St’ahel et al. further evaluated the antibacterial performance of POx thin films against S. epidermidis, focusing on the influence of deposition temperature (pure substrate, 60, 90, 120, and 150 °C) [38]. The optical images in Figure 11b(i) reveal that the pure glass substrate was fully covered by bacterial colonies, whereas the POx–coated surfaces exhibited minimal bacterial adhesion, with only isolated cells or small clusters observed. Figure 11b(ii) quantifies the bacterial surface coverage on POx thin films deposited at different substrate temperatures. The POx films deposited at 60 and 90 °C displayed partial water solubility, resulting in reduced antibiofouling performance after water washing. In contrast, POx thin films deposited at 120 and 150 °C were water–insoluble, and their antibiofouling properties remained stable following washing. Furthermore, in vitro cytocompatibility tests were extended to 72 h using NIH/3T3 cells on POx films deposited at various temperatures. The results indicate that oxazoline-based thin films influence cell attachment and that cell viability increases with higher deposition temperatures. Table 5 presents a summary of the plasma synthesis parameters and antibacterial test results corresponding to Figure 10 and Figure 11 in this section.

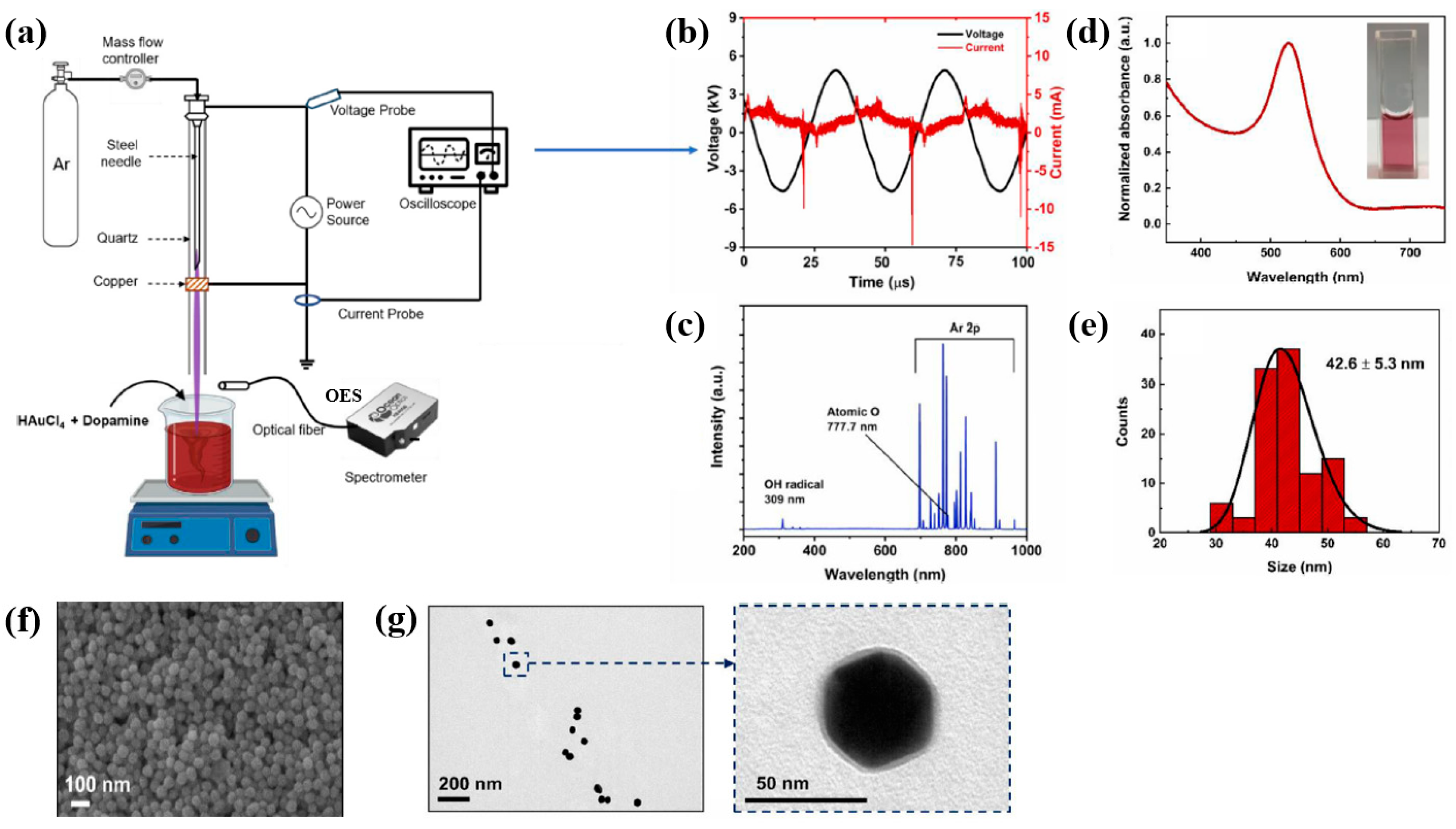

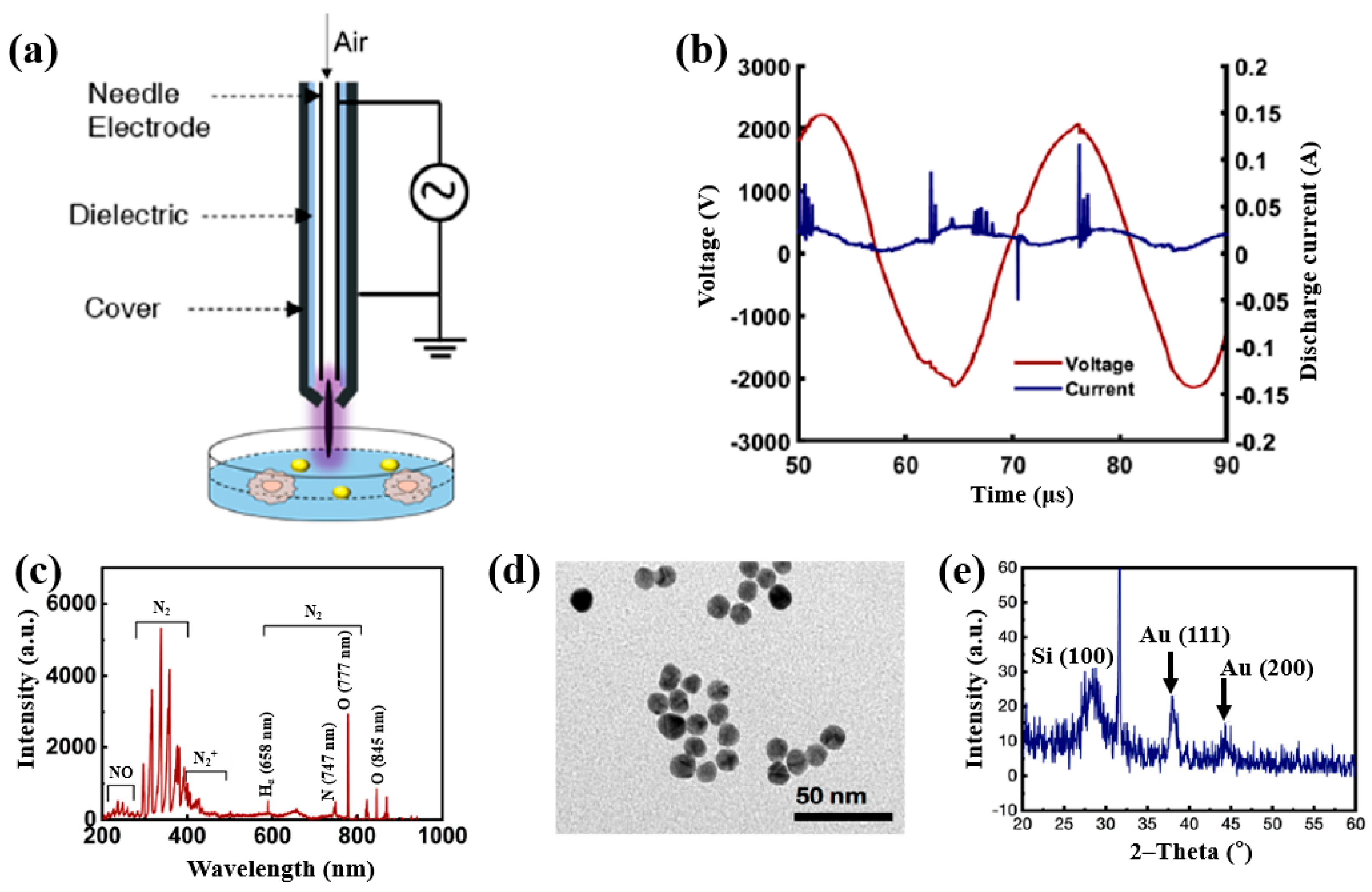

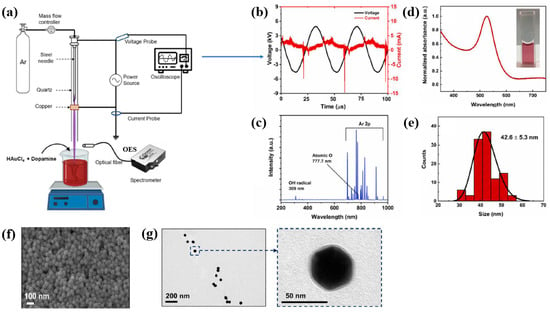

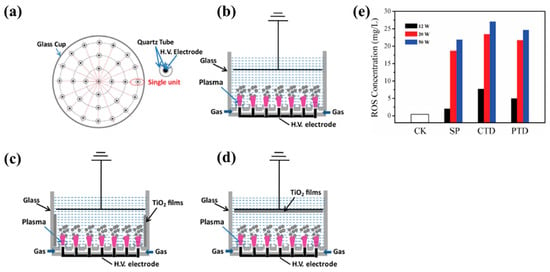

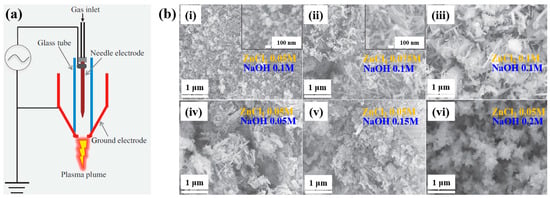

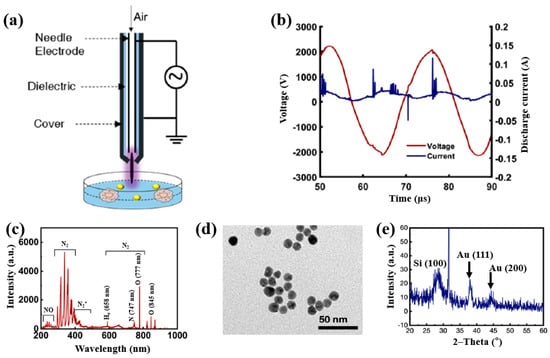

Plasma treatment was conducted using a plasma jet setup consisting of a stainless steel needle electrode and a quartz tube, as illustrated in Figure 12a [39,40]. The 12 cm long needle electrode was centrally positioned within a 20 cm long quartz tube, and a high voltage (HV) was applied. A Cu layer was attached to the exterior of the quartz tube, positioned 1 cm below the needle tip, and grounded for stabilization. Argon (Ar) gas was introduced at a flow rate of 700 sccm to generate plasma discharge. Prior to plasma synthesis, a 2 mL aqueous solution containing 0.2 mM H[AuCl4]·and 0.05 mM dopamine hydrochloride was prepared in deionized water. This solution was exposed to the plasma jet for 5 min, resulting in the formation of Au NPs/polydopamine (PDA) [39,40]. Figure 12b,c show the current–voltage waveform and the optical emission spectroscopy (OES) spectrum recorded during plasma treatment. An alternating current (AC) with a bipolar voltage, a peak amplitude of 4.8 kV, and a frequency of 28 kHz was applied to the needle electrode. The OES spectrum revealed reactive species, including Ar (700–1000 nm), hydroxyl radicals (309 nm), and atomic oxygen (777 nm). These species interacted with the solution surface during plasma exposure, facilitating the formation of Au NPs/PDA. Following plasma treatment, the Au NPs/PDA were collected by centrifugation at 8000 rpm for 10 min and stored at 4 °C. Figure 12d presents the UV–Vis absorbance spectrum of the plasma-treated HAuCl4–DA solution. After 5 min of plasma exposure, the solution color changed from colorless to red wine, indicating the formation of Au NPs/PDA. A strong absorbance peak at approximately 525 nm was observed, corresponding to the SPR of the Au colloids [39]. The average particle size was determined to be 42.6 nm from SEM images using ImageJ software (ver. 1.54) (Figure 12e). The morphology of the synthesized Au NPs/PDA was characterized by SEM and TEM. As shown in Figure 12f, the NPs exhibited spherical morphology, and a 4 nm thick PDA coating layer was observed on the outer shell of each particle (Figure 12g) [39,40].

Figure 12.

(a) Schematic of plasma jet setup for Au NP/polydopamine (PDA) synthesis in liquid solution. (b) Current–voltage profile and (c) optical emission spectroscopy (OES) spectrum of Ar plasma jet. (d) UV–vis absorbance spectrum and (e) size distribution of plasma–treated solution containing Au NPs/PDA. (f) SEM and (g) TEM images of Au NP/PDA nanocomposites. Reproduced with copyright permission from Ref. [39].

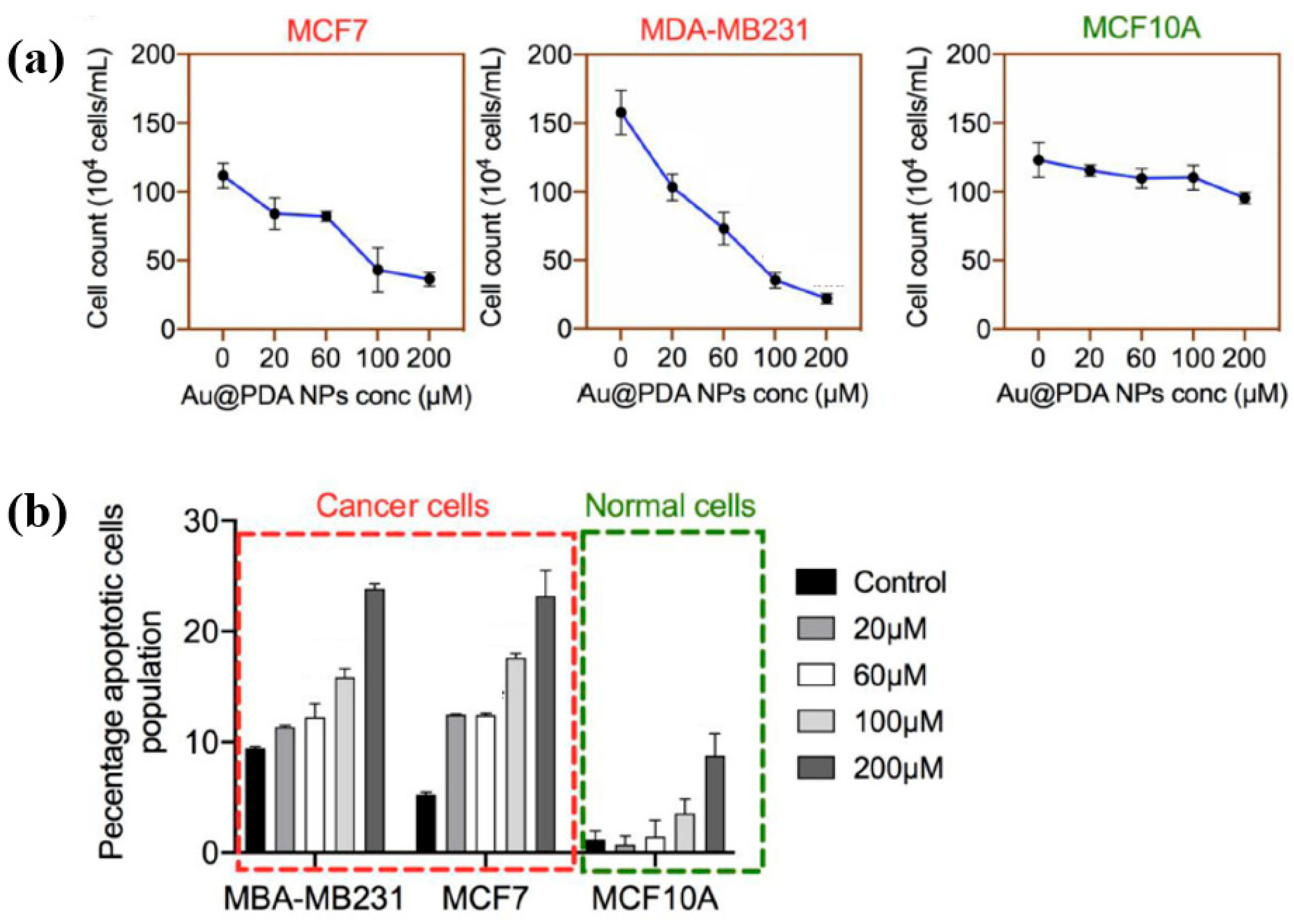

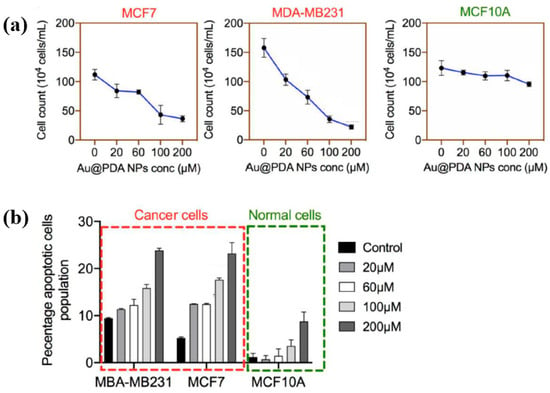

To evaluate the impact of Au NPs/PDA on cancer cell growth inhibition, four concentrations (20, 60, 100, and 200 mM) of the plasma–treated solution were applied to breast cancer cell lines (MCF7 and MDA–MB231) and normal epithelial cells (MCF10A). As shown in Figure 13a, cancer cell viability decreased significantly with increasing concentration, particularly at 200 mM, while the viability of normal cells remained largely unaffected after 48 h of exposure. Additionally, cell death was assessed using annexin–V/propidium iodide (PI) staining across the range of plasma-treated concentrations. As illustrated in Figure 13b, treatment with 200 mM of the plasma-treated solution induced cancer cell death rates of up to 23% and 25% in MCF7 and MDA–MB231 cells, respectively, confirming the cancer cell growth inhibition potential of Au NPs/PDA [39,40]. Table 6 presents a summary of the synthesis conditions and biological results corresponding to Figure 12 and Figure 13 in this section.

Figure 13.

(a) Cell counts of breast cancer and normal cells exposed to plasma–treated Au NP/PDA solutions at 20, 60, 100, and 200 mM. (b) The total apoptotic population in each cell type as a function of plasma–treated solution concentration. Reproduced with copyright permission from Ref. [39].

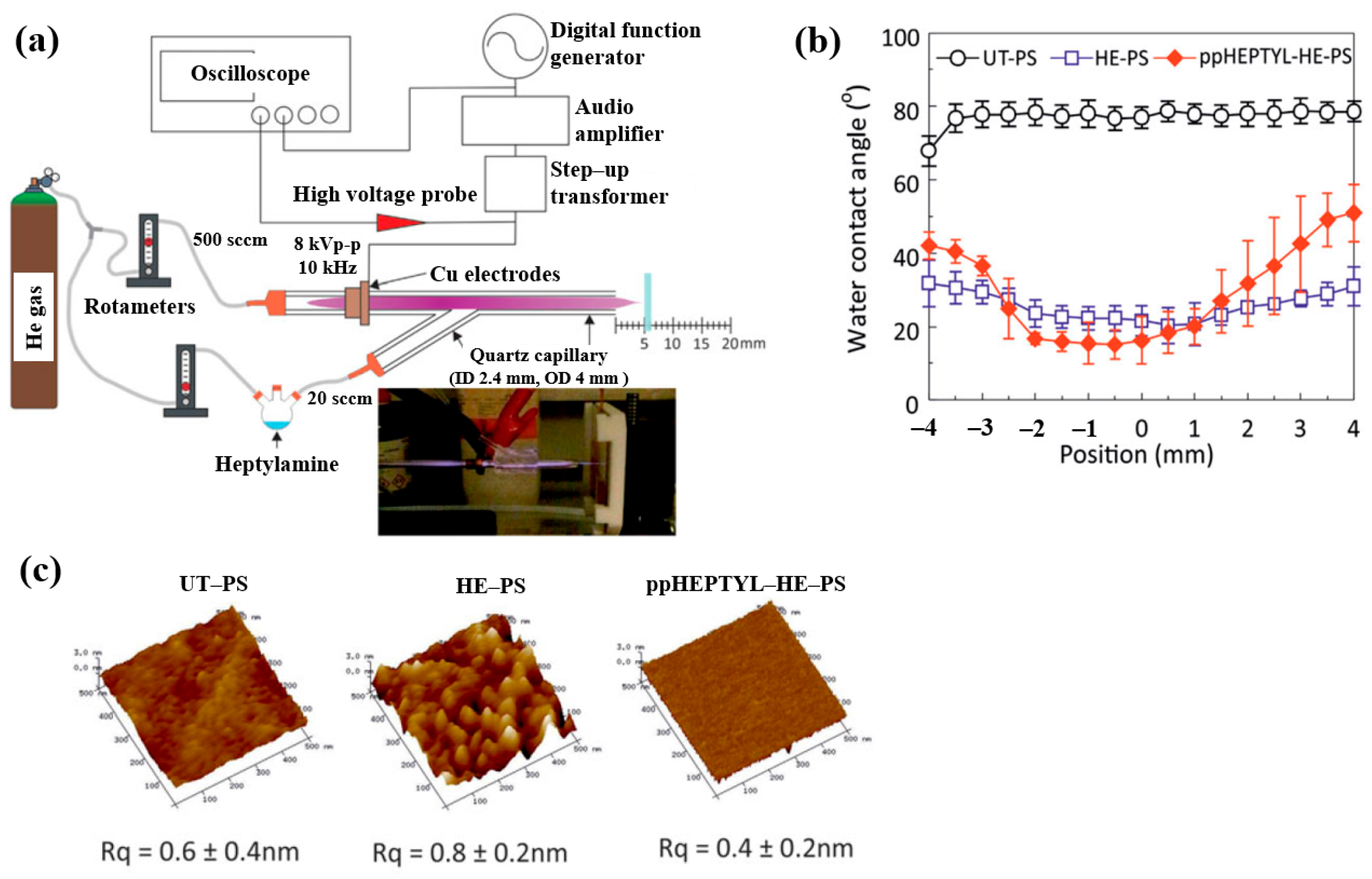

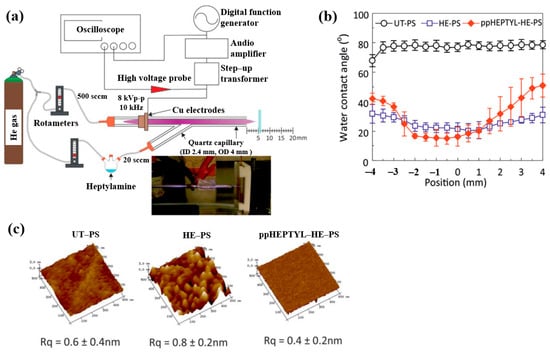

To inject N2 species into a polymer surface for cell growth, this study investigated the plasma polymerization of a heptylamine monomer as a precursor using an APP jet (APPJ) in air [41]. Figure 14a shows the APPJ experimental setup by Doherty et al. [41]. A sinusoidal voltage of 8 kVp–p at a fixed frequency of 10 kHz was applied to the electrode to generate plasma, while He gas was supplied at 500 sccm. The liquid heptylamine was vaporized at RT by a He carrier gas flow of 20–100 sccm and subsequently introduced into the APPJ. A polystyrene (PS) substrate of 10 × 10 mm2 was positioned 5 cm from the nozzle and treated for 10 min under different conditions, such as untreated PS (UT–PS), He-treated PS (HE–PS), and plasma-polymerized heptylamine (ppHEPTYL–HE–PS) on He-treated PS. As shown in Figure 14b, the UT–PS surface exhibited an average water contact angle (WCA) of 77.2°, whereas both HE–PS and ppHEPTYL–HE–PS displayed significantly lower WCA values, ranging from 20.3° to 40° across all measured positions, indicating enhanced hydrophilicity. The surface roughness (Rq) of all samples (UT–PS, HE–PS, and ppHEPTYL–HE–PS) remained comparable, in the range of 0.4 nm to 0.8 nm, as shown in Figure 14c [41].

Figure 14.

(a) Schematic of APPJ experimental setup for heptylamine monomer by Doherty et al. [38]. (b) WCA results and (c) AFM images with surface roughness (Rq) of UT–PS, HE–PS, and ppHEPTYL–HE–PS. Reproduced with copyright permission from Ref. [41].

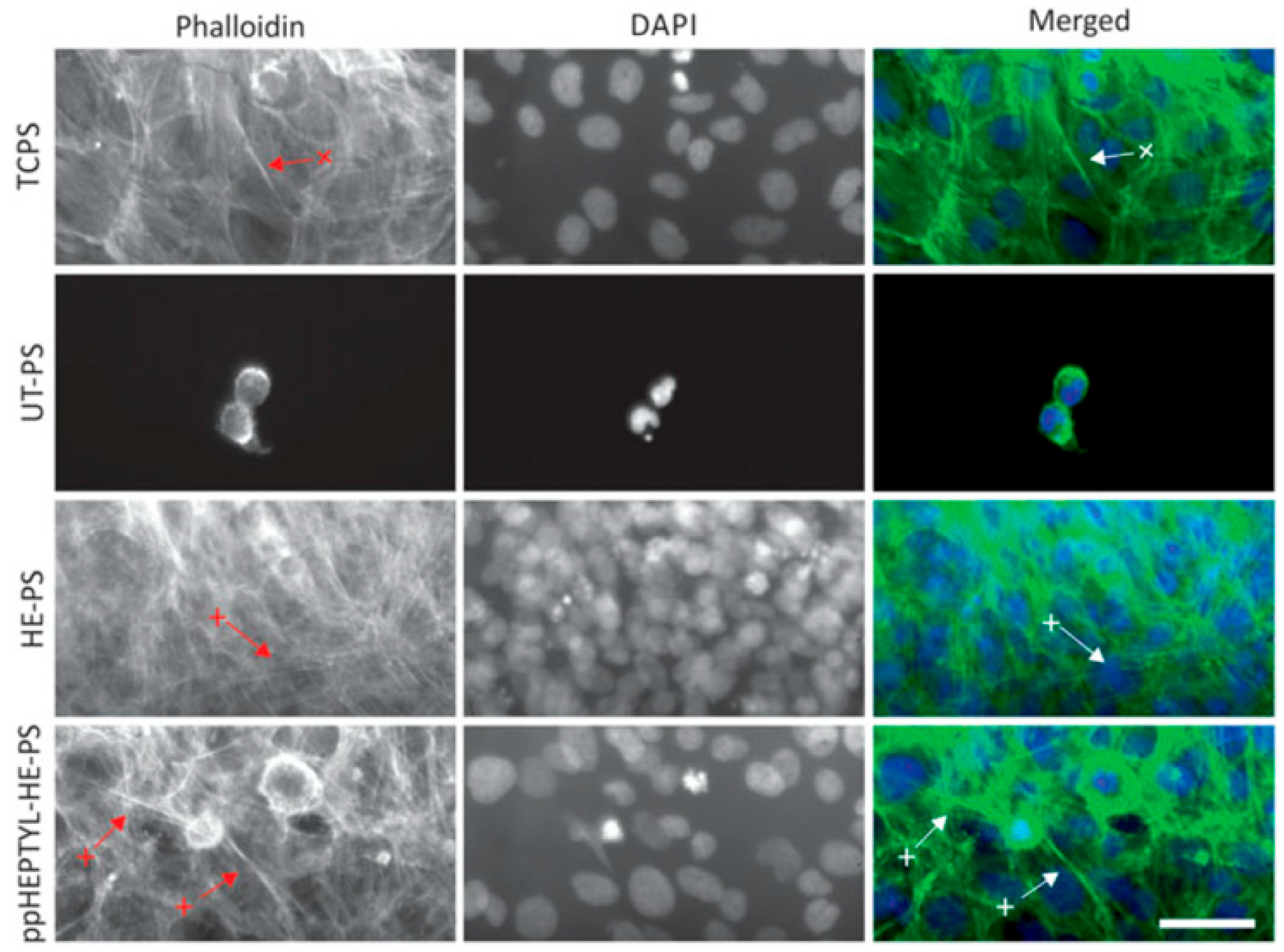

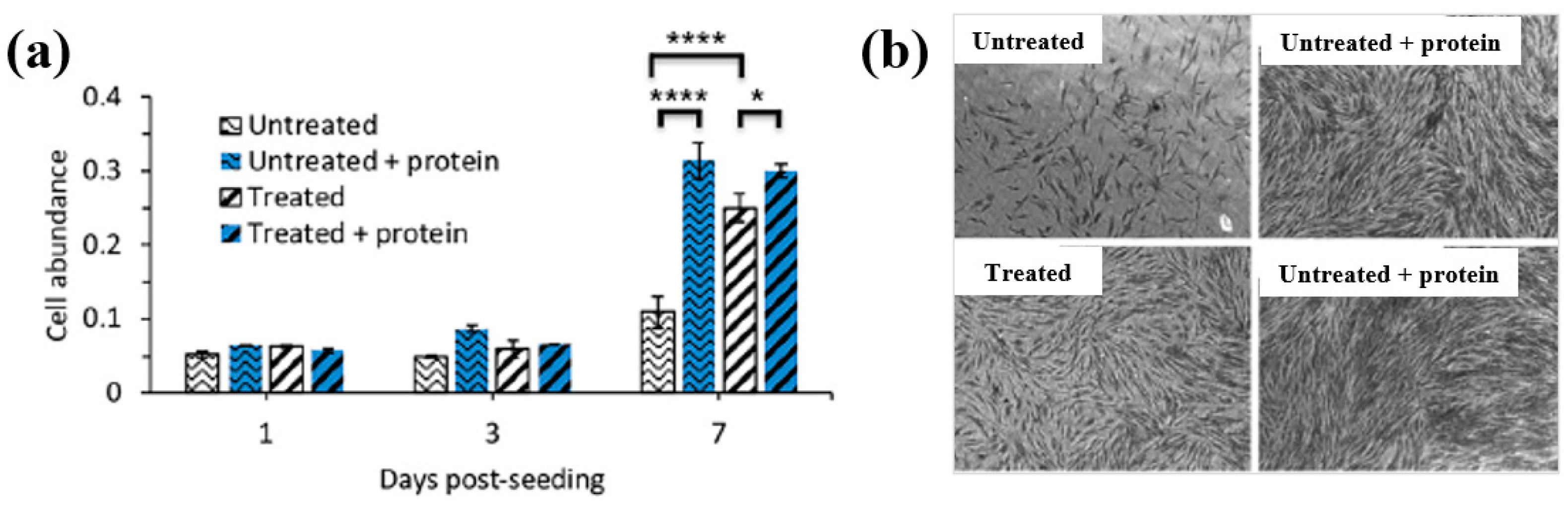

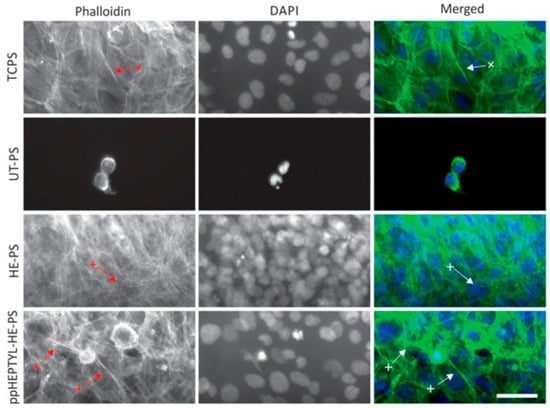

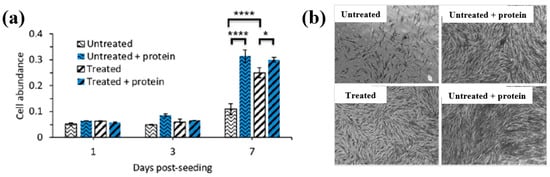

For cell cultivation, human B3 lens epithelial cells (LECs) were grown on various samples, including tissue culture PS (TCPS), UT–PS, HE–PS, and ppHEPTYL–HE–PS. Figure 15 shows optical images of LECs on TCPS, UT–PS, HE–PS, and ppHEPTYL–HE–PS after 7 d. Cells cultured on all samples, except UT–PS, exhibited a fibrotic morphology [41]. Table 7 summarizes the experimental synthesis and biological results corresponding to Figure 14 and Figure 15 in this section.

Figure 15.

Optical images of human B3 lens epithelial cells (LECs) cultured for 7 d on TCPS, UT–PS, He-treated PS, and heptylamine–treated PS. Reproduced with copyright permission from Ref. [41].

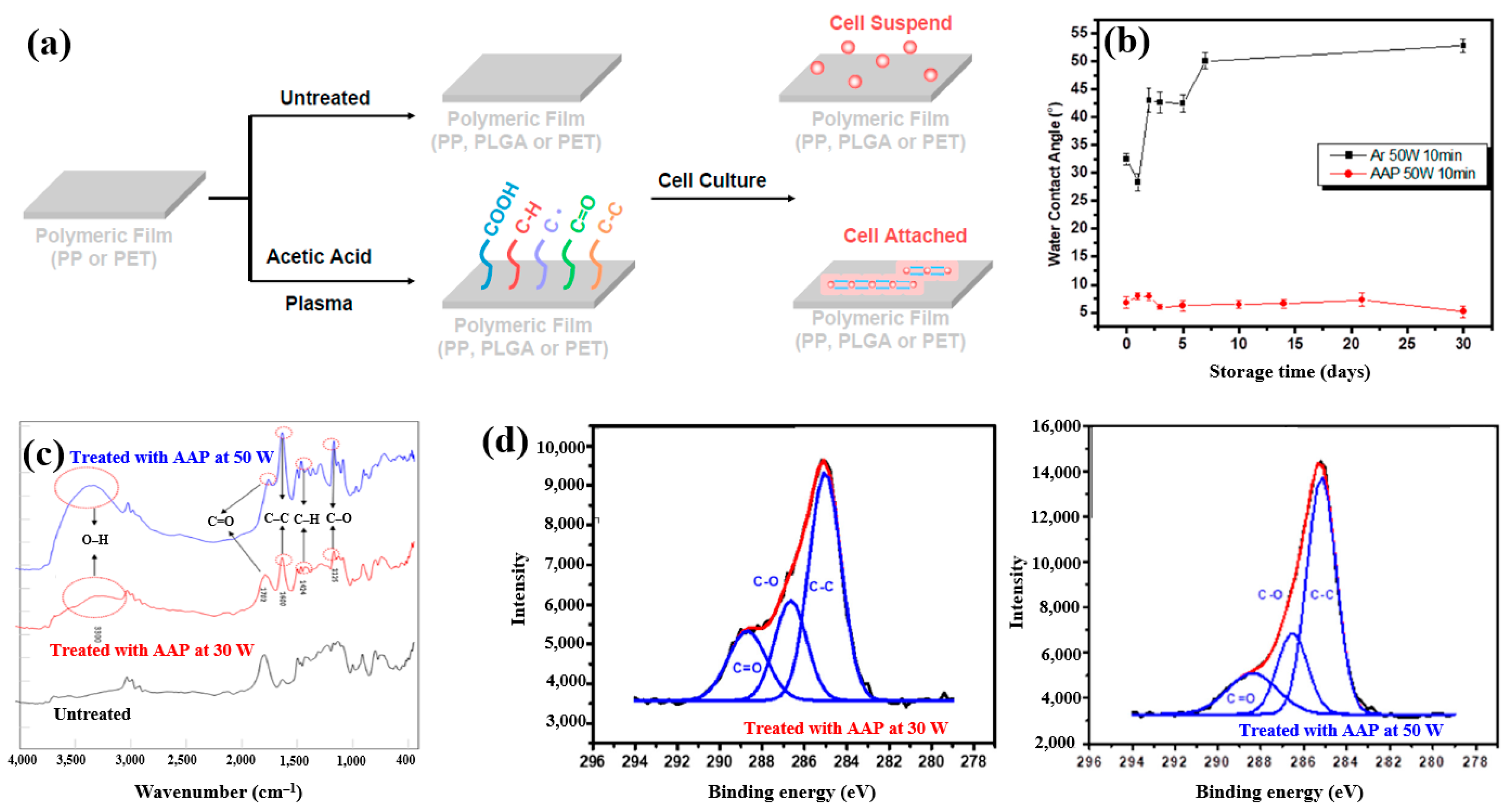

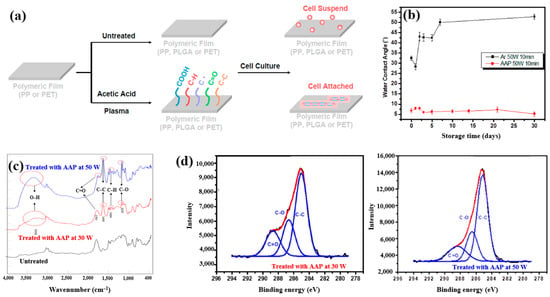

Plasma polymerization was performed in a vacuum chamber using radio frequency (RF) at 13.56 MHz. To introduce carboxylic acid groups onto polyethylene terephthalate (PET), an acetic acid monomer was injected and deposited through CAP proposed by Liao et al. [42]. Figure 16a shows a schematic of polymeric film preparation on plasma-treated PET using acetic acid plasma (AAP), followed by cell cultivation. AAP–deposited films were produced by applying plasma for 10 min at three different powers, namely 10, 30, and 50 W. The untreated PET exhibited an initial WCA of 67.5°. After AAP and Ar plasma treatments at 50 W for 10 min, the WCA decreased to 8.2° for AAP and 32° for Ar. Figure 16b shows the variation in WCA of AAP–deposited poly(DL–lactide–co–glycolide) (PLGA) films with storage time. While the WCA of Ar plasma–deposited films increased over time, that of AAP–deposited PLGA films remained stable. FT–IR spectra of PLGA treated with AAP at 30 and 50 W are shown in Figure 16c, where several peaks associated with acetic acid polymer can be detected. As plasma power increased, the FT–IR peaks corresponding to functional groups in AAP-deposited PLGA films became stronger. Figure 16d presents the XPS high–resolution C 1s spectra of AAP–deposited PLGA films treated for 10 min at 30 and 50 W. In all cases, the spectra consisted of three peaks corresponding to C–C, C–O, and C=O functional groups. Notably, the relative intensity of C=O increased as plasma power decreased [42]. These oxygen–containing functional groups impart hydrophilic properties to the AAP–deposited film surface.

Figure 16.

(a) Schematic of polymeric film preparation on plasma–treated polyethylene terephthalate (PET) using acetic acid plasma (AAP) with poly(DL–lactide–co–glycolide) (PLGA) coating and subsequent cell culture, adapted from Liao et al. [39]. (b) WCA measurements of untreated and AAP–treated films at 30 W and 50 W for 10 min. (c) FT–IR spectra of same films; (d) XPS C 1s high-resolution spectra of AAP–deposited films at 30 W and 50 W for 10 min. Reproduced with copyright permission from Ref. [42].

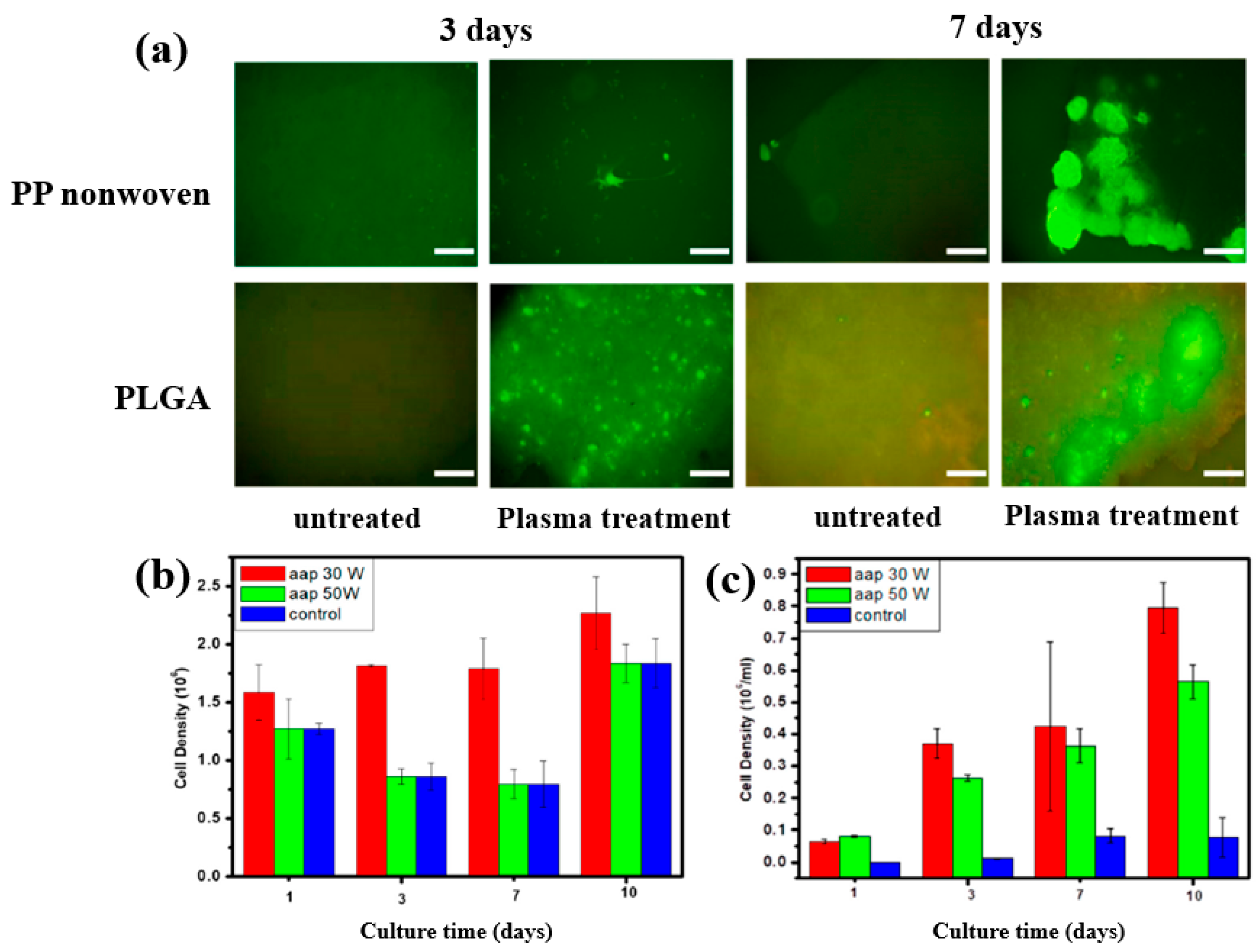

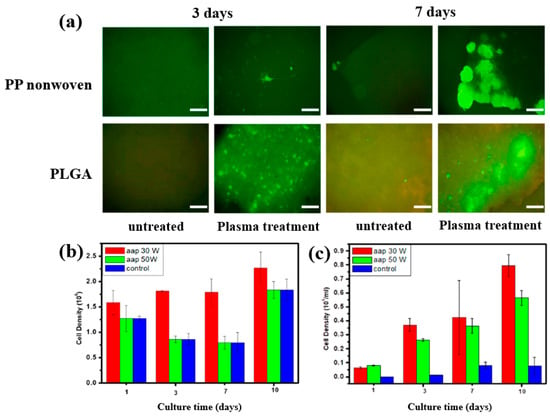

To further investigate cell adhesion on AAP–deposited films, mouse embryonic stem (ES) cells were cultivated for 3 and 7 d on PP nonwoven substrates and AAP–deposited PLGA films. Figure 17a shows fluorescence microscopy images of cells grown on PP and PLGA substrates with and without AAP treatment. ES cells adhered poorly to the untreated PP and PLGA, whereas they exhibited strong adhesion on the AAP–deposited PLGA film. The attached cells were uniformly distributed and proliferated across the PLGA surface. As shown in Figure 17b,c, the measured cell density confirmed significantly higher proliferation on the AAP–deposited PLGA film compared to untreated PP and PLGA substrates [42]. These enhancements in adhesion and proliferation are attributed to increased surface hydrophilicity induced by oxygen–containing functional groups introduced during AAP treatment. Table 8 summarizes the experimental synthesis and biological results corresponding to Figure 16 and Figure 17 in this section.

Figure 17.

(a) Fluorescence microscopy images of embryonic stem (ES) cells cultured for 3 and 7 d on PP nonwoven substrates and AAP–deposited PLGA films with or without AAP treatment. Cell density of ES cells on (b) PP nonwoven substrate and (c) PLGA films treated with 30 and 50 W, evaluated at 1, 3, 7, and 10 d. Reproduced with copyright permission from Ref. [42].

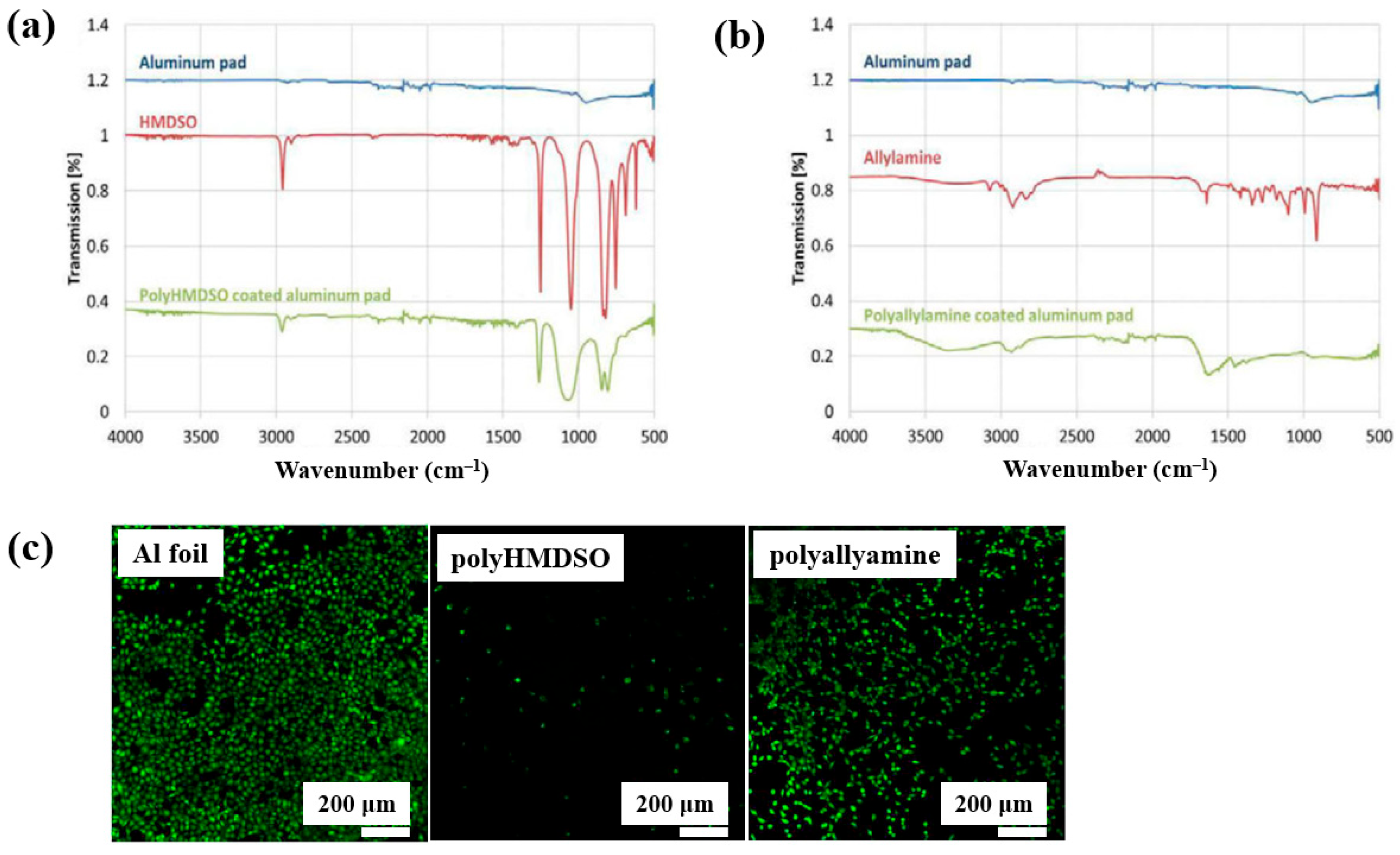

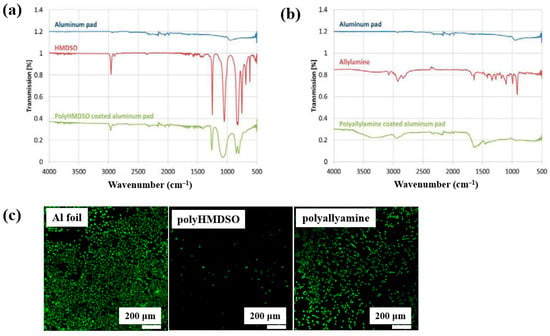

Teske et al. [43] investigated polymer films deposited from allylamine and hexamethyldisiloxane (HMDSO) monomers using plasma–enhanced chemical vapor deposition (PECVD). The films were deposited on aluminum (Al) substrates with an RF generator operating at 13.56 MHz. FT–IR spectra of the polyHMDSO film (Figure 18a) showed characteristic bonding structures in the ranges of 1300–700 and 3000 cm−1, while the polyallylamine film (Figure 18b) displayed peaks associated with allylamine in the ranges of 4200–2800 cm−1 and 1750–1300 cm−1. The adhesion of mouse fibroblast (L929) cells was examined on three samples, namely Al foil, polyHMDSO, and polyallyamine films, using confocal microscopy. As shown in Figure 18c, L929 cells adhered and proliferated on Al foil, while adhesion and growth on polyallyamine films were slightly reduced. In contrast, no cell adhesion was observed on polyHMDSO films [43]. Table 9 summarizes the experimental synthesis and biological results corresponding to Figure 18 in this section.

Figure 18.

FT–IR spectra of plasma–deposited (a) polyHMDSO and (b) polyallylamine films on aluminum (Al) foils. (c) Confocal microscope images of L929 mouse fibroblasts (green fluorescence) cultured on uncoated aluminum (Al) foil, polyHMDSO films, and polyallylamine films. Reproduced with copyright permission from Ref. [43].

Table 9.

Summary of experimental plasma synthesis and antibacterial results corresponding to Figure 18 [43].

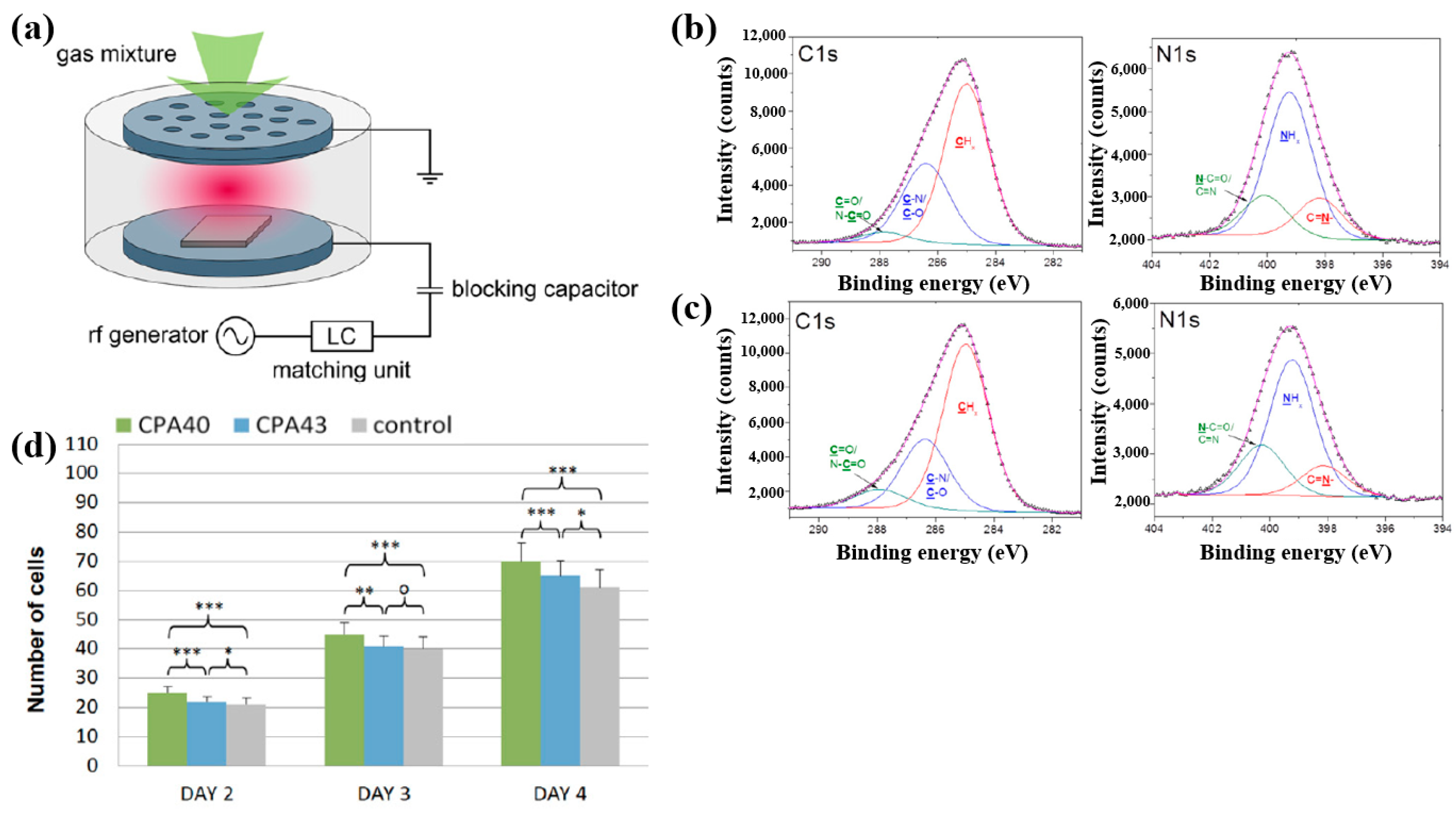

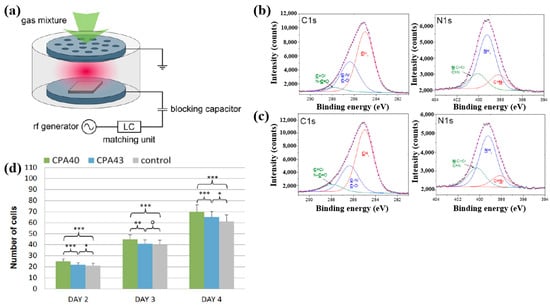

Štrbková et al. [44] investigated the adhesion, viability, and proliferation of cells on amine-rich polymer thin films deposited using RF capacitively coupled plasma with a cyclopropylamine (CPA) precursor, producing films with different N2 and amine group (NHx) concentrations. Figure 19a shows a schematic of the RF capacitively coupled plasma setup for CPA thin-film deposition under low pressure [44]. XPS analysis (Figure 19b,c) revealed that, after soaking in water, the surface composition of CPA films changed slightly. Oxygen concentration in the CPA40 and CPA43 films increased due to N2 loss, leading to enhanced C=O/N–C=O and N–C=O contributions at the expense of C–N/C–O and NHx groups. To assess cell adhesion and growth on plasma-deposited CPA thin films, human dermal fibroblast (HDF) cells were cultured on control, CPA40, and CPA43 samples, and their behavior was observed using coherence-controlled holographic microscopy (CCHM). As shown in Figure 19d, cell adhesion was higher on CPA40 and CPA43 films compared to the control. These results demonstrate that amine-rich CPA thin films are biocompatible, and that cell adhesion and proliferation increase with higher concentrations of amine groups [44]. Table 10 summarizes the experimental synthesis and biological results corresponding to Figure 19a–d in this section.

Figure 19.

(a) Schematic of RF capacitively coupled plasma setup. XPS C 1s and N 1s spectra of CPA40 (b) before and (c) after immersion in water. (d) Cell counts from cultures grown on CPA40, CPA43, and control sample. Reproduced with copyright permission from Ref. [44].

Table 10.

Summary of experimental plasma synthesis and antibacterial results corresponding to Figure 19a–d [44].

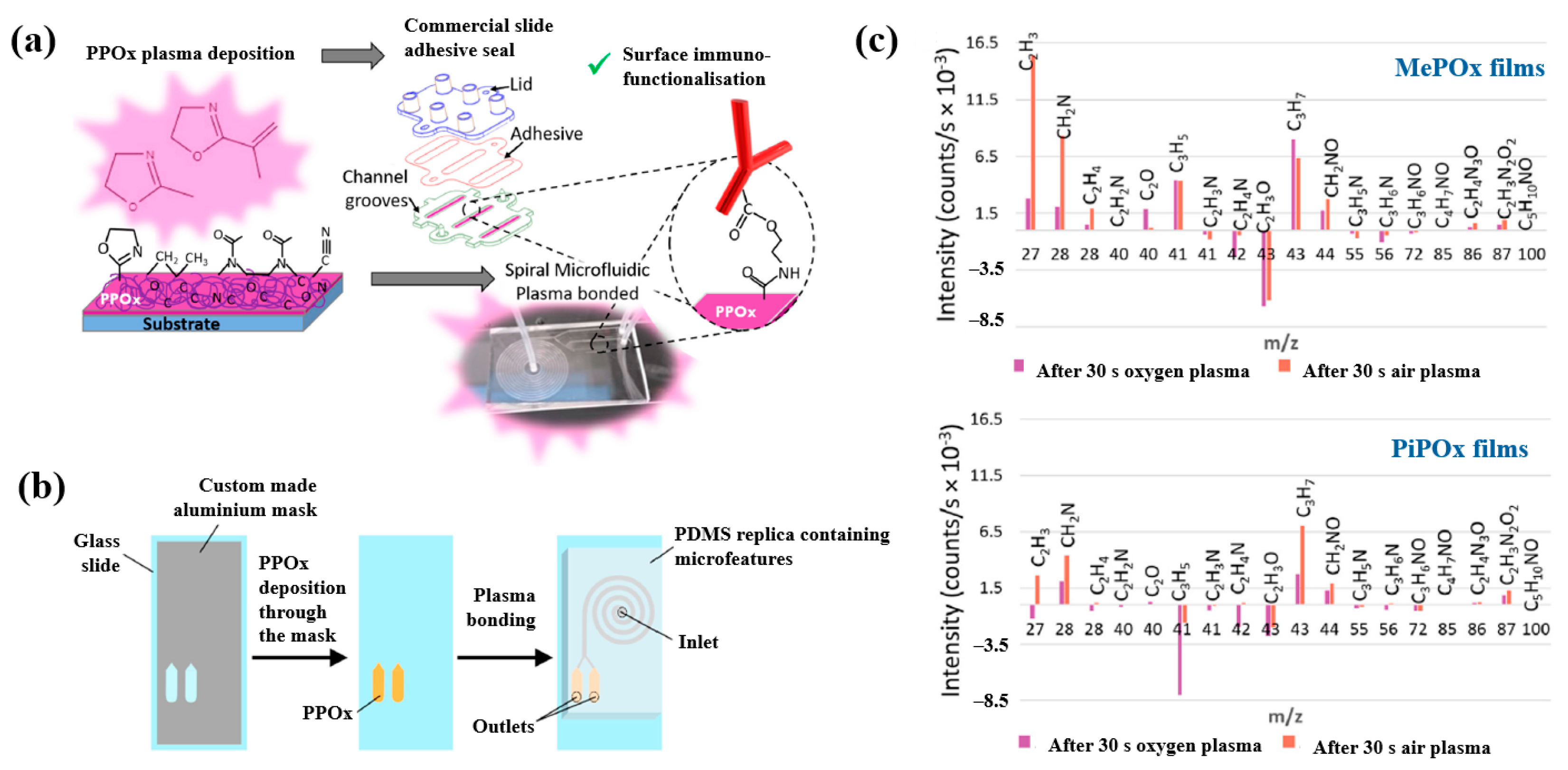

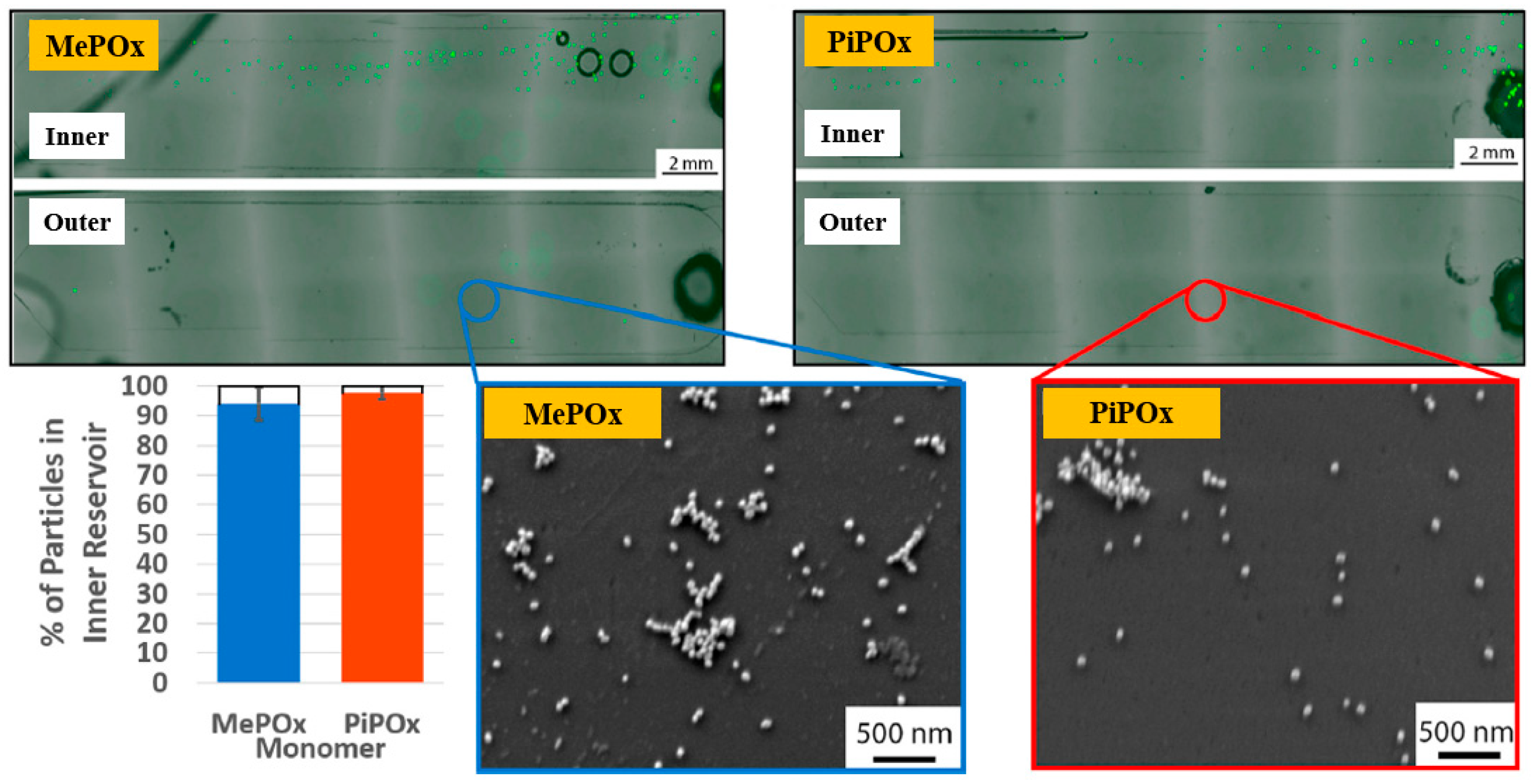

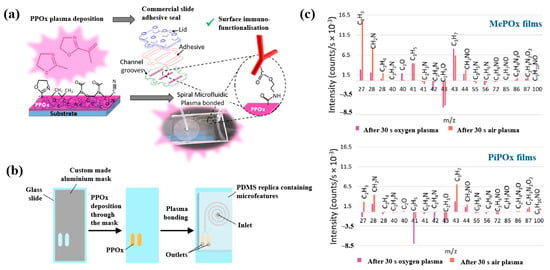

Gheorghiu et al. [45] investigated the chemistry and functionality of plasma–deposited polyoxazoline (POx) films derived from methyl oxazoline (MePOx) and isopropenyl oxazoline (PiPOx), aiming to develop POx–based immunosensors for cancer cell applications. Prior to deposition, substrates were treated with air plasma at 30 W for 3 min. For assembly into spiral microfluidic chips (Figure 20a,b), the POx films were deposited on glass microscope slides at 30 W for 30 and 50 s [45]. The time–of–flight secondary ion mass spectrometry (ToF–SIMS) spectra of MePOx and PiPOx films treated with O2 and air plasma are shown in Figure 20c. All POx films contained higher amounts of aliphatic fragments (C2H3 and C3H7) and lower amounts of heteroatomic fragments (C2H4N and C2H3O). The key distinction between MePOx and PiPOx films was the behavior of the C3H5 fragment, associated with the pendent group in the PiPOx polymer structure. After plasma treatment, the C3H5 fragment decreased more significantly in PiPOx under O2 plasma, indicating that isopropenyl groups on the PiPOx surface were preferentially removed by ROS compared to air plasma.

Figure 20.

Schematic of (a) biosensor fabrication and (b) plasma–deposited polyoxazoline (POx) film and device assembly. (c) ToF–SIMS spectra showing changes in molecular fragments of MePOx and PiPOx films after O2 or air plasma treatment. Reproduced with copyright permission from Ref. [45].

As shown in Figure 21, the reactivity of POx was preserved within the microfluidic reservoirs. Furthermore, both MePOx and PiPOx films directed more than 90% of the microparticles into the inner reservoir [45]. Table 11 summarizes the experimental synthesis and biological results corresponding to Figure 20 and Figure 21 in this section.

Figure 21.

Fluorescence microscopy and SEM images of inner and outer reservoirs functionalized with MePOx and PiPOx films. Reproduced with copyright permission from Ref. [45].

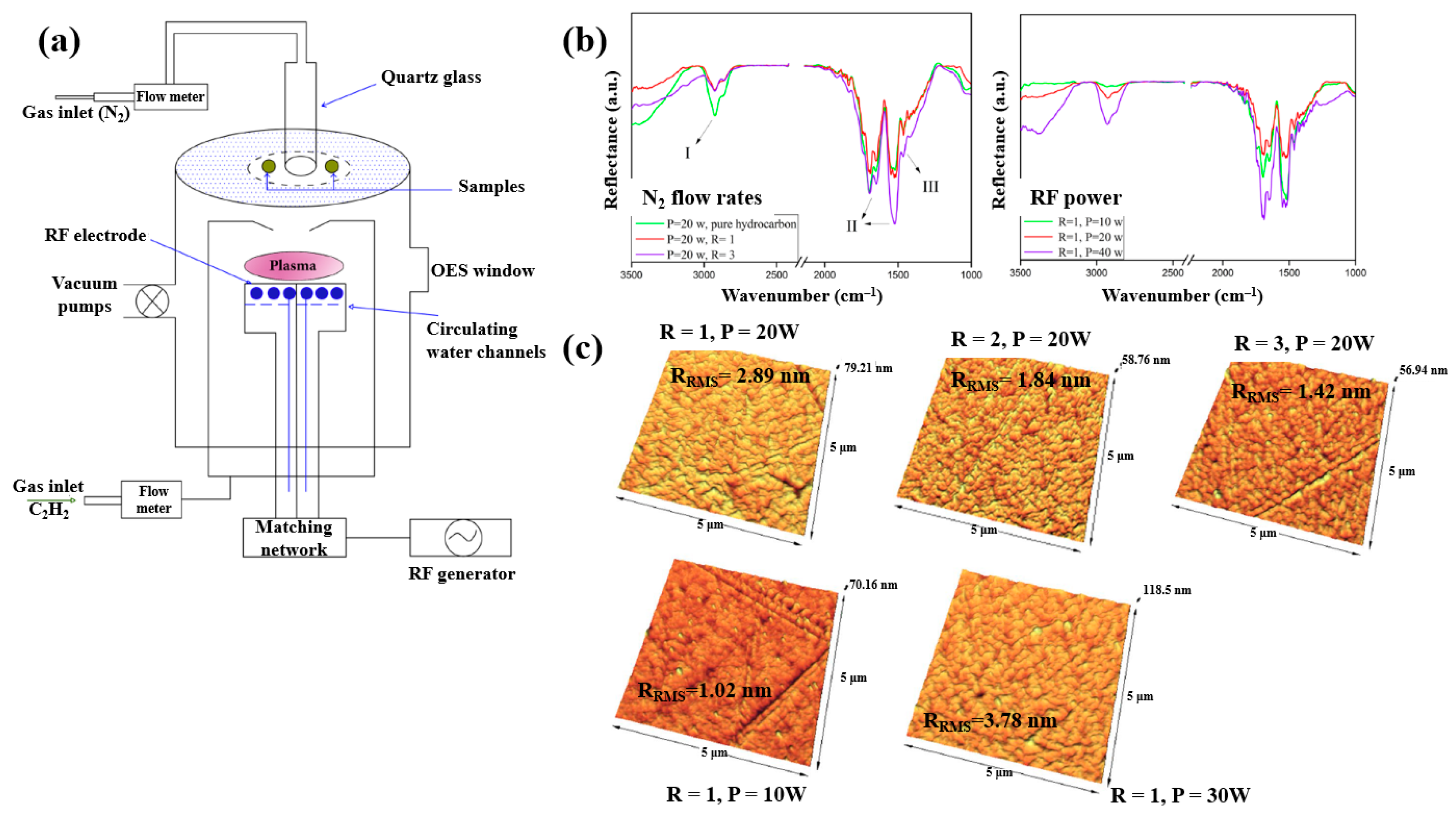

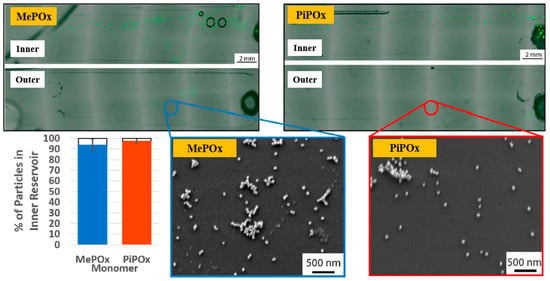

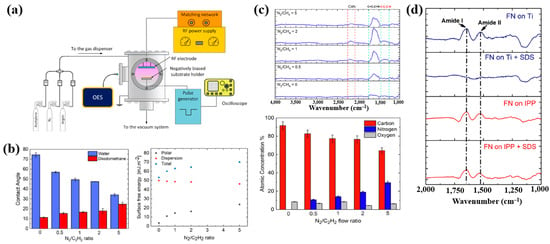

Plasma polymerization was performed in a plasma-enhanced chemical vapor deposition (PE–CVD) reactor with an inductive capacitively coupled electrode by Ghafouri et al., as shown in Figure 22a. The plasma was generated from a mixture of N2 gas and an acetylene monomer using an RF of 13.56 MHz [46]. Figure 22b shows the FT–IR spectra of L–PPA:N films deposited under different conditions of N2 flow and RF power. The spectra indicate that the plasma-deposited L–PPA:N films consist of three bonding structures, namely bond I (3000–2800 cm−1 C–H stretch), II (1800–1500 cm−1 C=C and C=N stretch), and III (1500–1300 cm−1 CH2 and CH3 bending). As shown in Figure 22c, the surface of the L–PPA:N film becomes smoother with increasing N2 flow, whereas the surface roughness increases with increasing RF power from 10 to 30 W due to the etching effect caused by the higher concentration of reactive plasma species [46].

Figure 22.

(a) Schematic of PE–CVD for L–PPA:N film deposition. (b) FT–IR spectra and (c) AFM images of plasma–polymerized films prepared with different N2 flow rates and RF powers. Reproduced with copyright permission from Ref. [46].

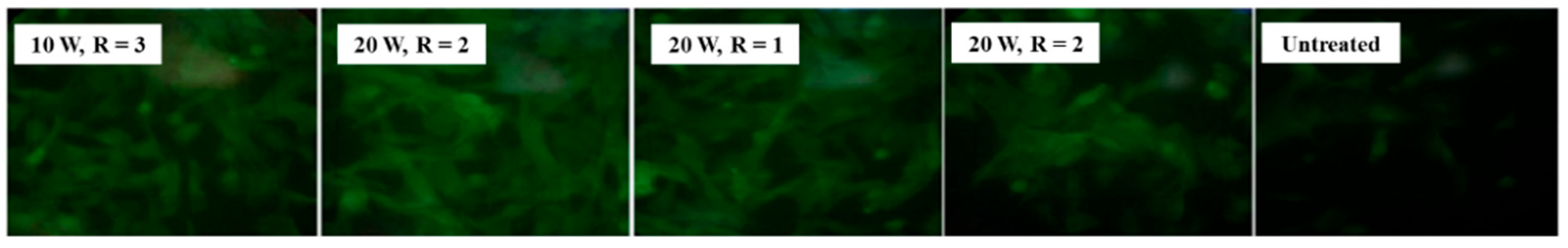

Figure 23 shows fluorescent images of stem cells after 1 week of cultivation on different plasma-treated samples [46]. The cells are well attached and proliferating on the plasma–treated surface compared with the untreated sample. Table 12 summarizes the experimental synthesis conditions and bacterial results corresponding to Figure 22 and Figure 23 in this section.

Figure 23.

Fluorescence images of stem cells after 1 week of cultivation on plasma–treated samples. Reproduced with copyright permission from Ref. [46].

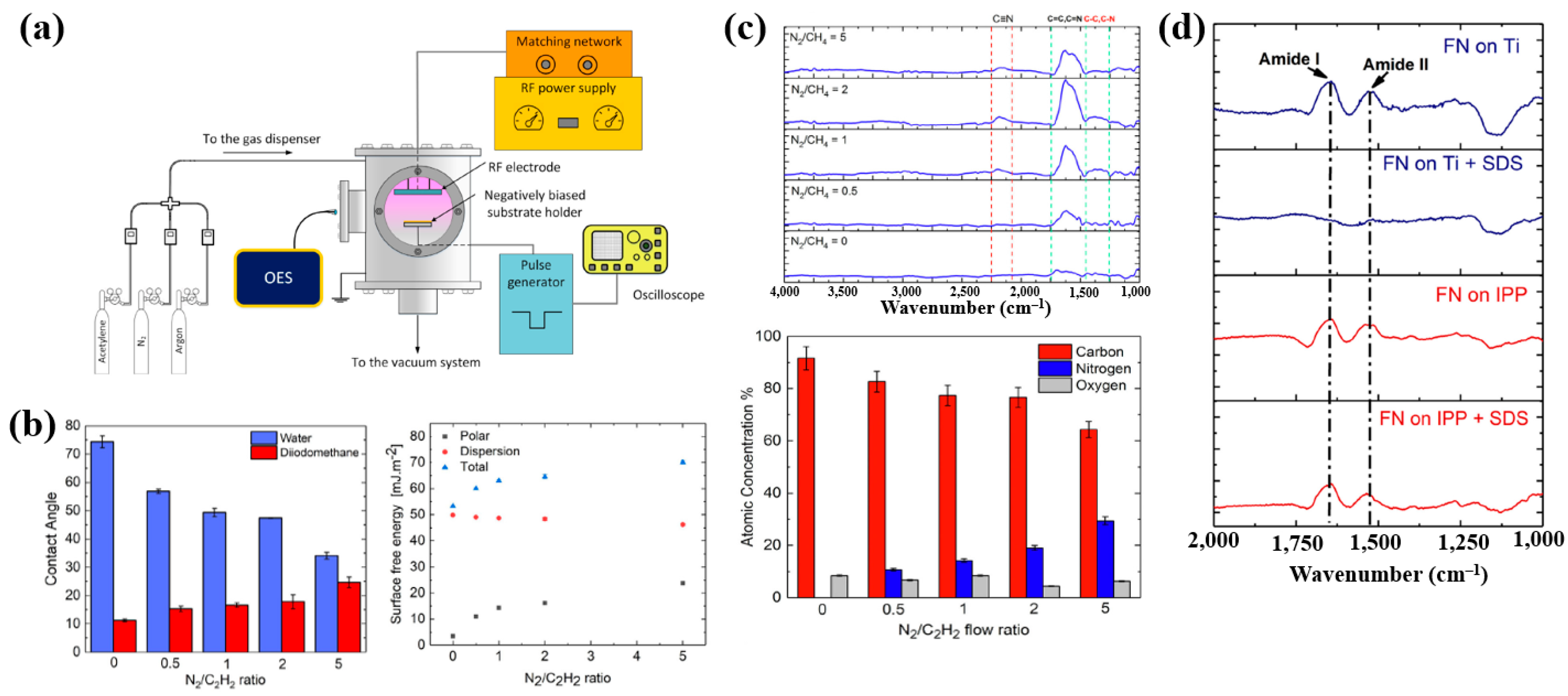

Sharifahmadian et al. [47] investigated ion-assisted plasma polymer (IPP) films containing N2 species for the biofunctionalization of implantable devices. Figure 24a shows the experimental setup for IPP film deposition from a mixture of N2 and acetylene gases. Deposition was carried out at an RF power of 50 W with varying N2 concentrations and N2/C2H2 ratios. As shown in Figure 24b, the WCA decreased with increasing N2/C2H2 gas flow ratio. To evaluate the effect of this ratio on the chemical composition and structure of IPP films, FT–IR and XPS analyses were performed. Figure 24c shows FT–IR spectra with peaks in the ranges of 1200–1500, 1500–1800, and 2100–2250 cm−1. The peak at 1200–1500 cm−1 is attributed to C–C and C–O vibrations, while the broad peak at 1500–1800 cm−1 corresponds to C=C, C=O, C=N, or N–H vibrations, and this band broadened with increasing N2/C2H2 ratio. These spectral changes are attributed to the enhanced formation of CN radicals during plasma deposition under higher N2/C2H2 ratios. The X-ray photoelectron spectroscopy (XPS) results in Figure 24d show that the N2 concentration increased from 0 to 29.4% as the N2/C2H2 ratio increased from 0 to 5, while the carbon concentration decreased from 91.6 to 64.3% [47].

Figure 24.

(a) Experimental setup of ion–assisted plasma polymerization (IPP) system for acetylene polymer film deposition. (b) WCA and surface energy, (c) FT–IR spectra, and (d) XPS composition of IPP films prepared with different N2/C2H2 flow ratios. Reproduced with copyright permission from Ref. [47].

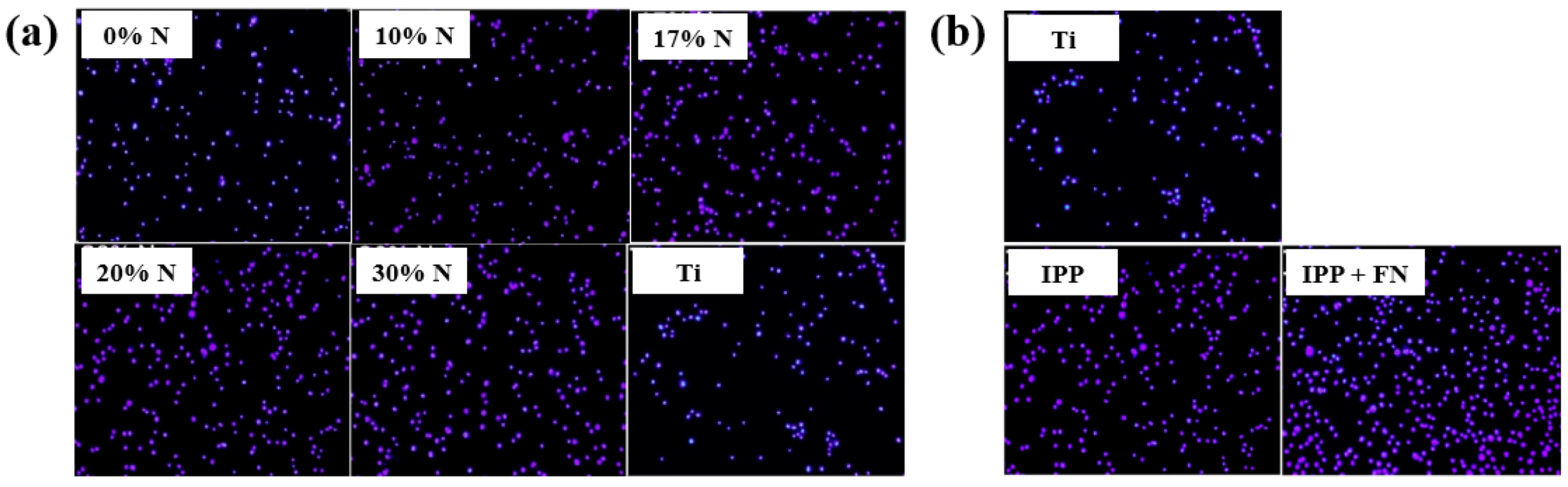

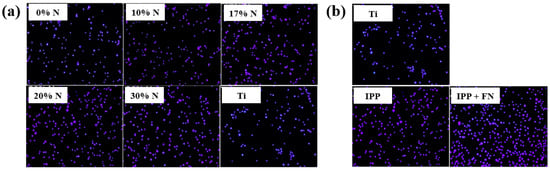

To evaluate cell adhesion on the deposited IPP films, osteoblast cells were seeded onto films prepared with different N2 concentrations and examined by fluorescence optical microscopy. As shown in Figure 25a,b, cell attachment and proliferation were enhanced on both the IPP film and the IPP film with FN compared with the Ti substrate [47]. Table 13 summarizes the experimental synthesis conditions and bacterial results corresponding to Figure 24 and Figure 25 in this section.

Figure 25.

Fluorescence images of osteoblasts on (a) IPP films prepared with different N2 concentrations and (b) after 1 h cultivation on bare Ti, IPP, and IPP with FN films. Reproduced with copyright permission from Ref. [47].

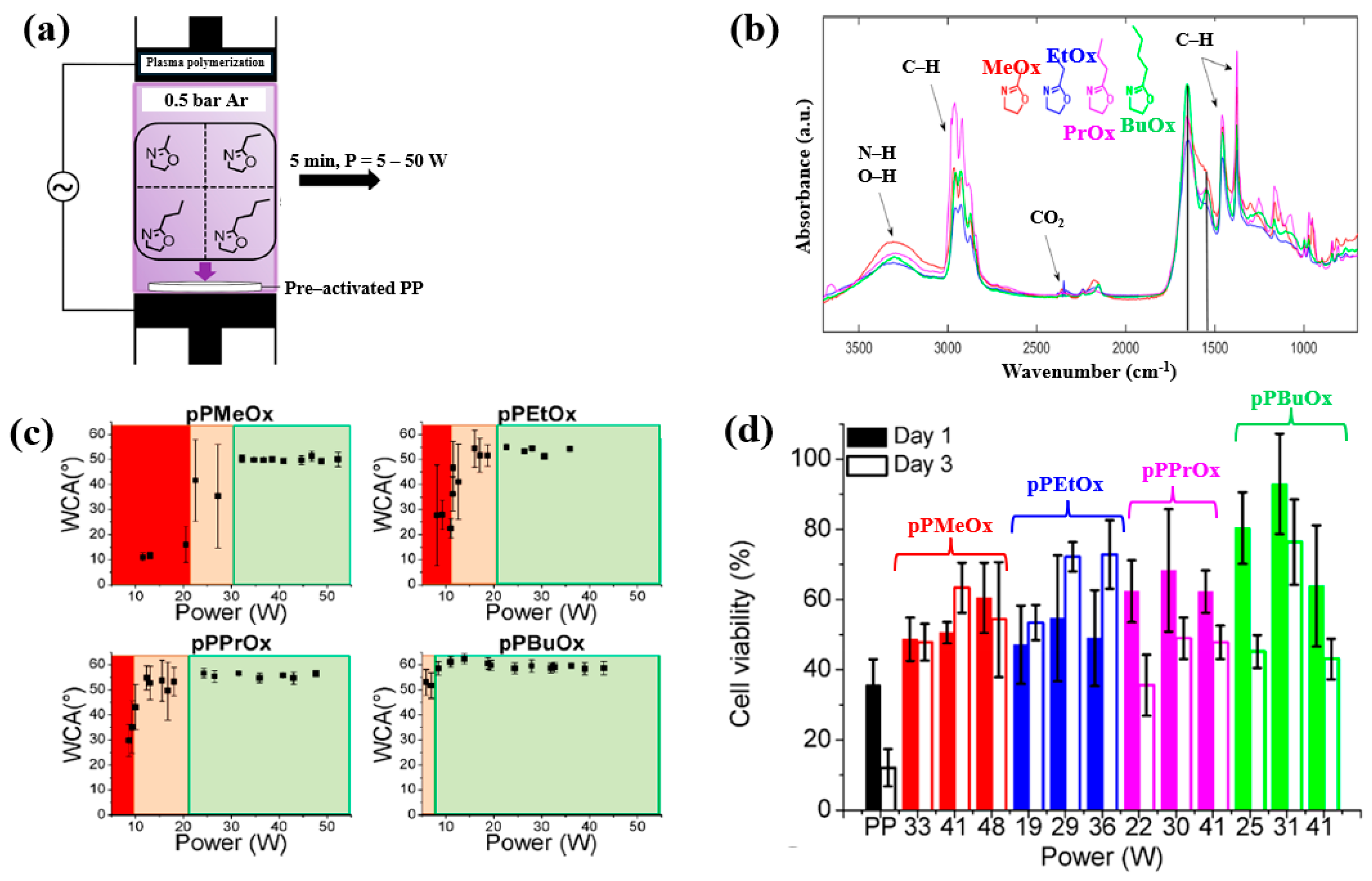

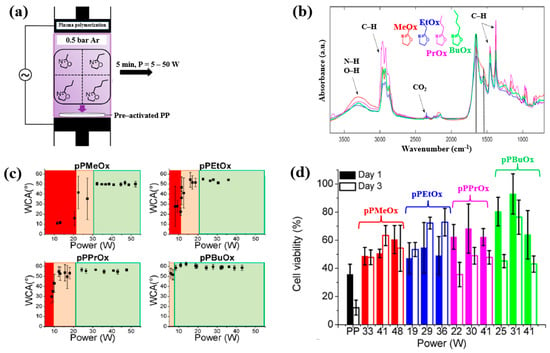

Van Guyse et al. [48] investigated the chemical structure and cell viability of polymer films prepared by using the LPP–DBD plasma process with four monomers, namely 2–methyl–2–oxazoline (MeOx), 2–ethyl–2–oxazoline (EtOx), 2–n–propyl–2–oxazoline (PrOx), and 2–n–butyl–2–oxazoline (BuOx). The plasma polymer films were deposited on polypropylene (PP) substrates in a DBD reactor, as shown in Figure 26a. This cylindrical reactor consists of two electrodes separated by a gap of 8 mm. The bottom Cu electrode is coated with a ceramic material, while the upper electrode is a woven stainless steel electrode. The bottom electrode is connected to a 50 kHz AC power supply, and the upper electrode is grounded [48]. The chemical structure and hydrophilicity of polymer films were investigated by using WCA and FT–IR measurements. As shown in Figure 26b, all polymer films exhibited similar FT–IR peaks at 3500–3000 cm−1 (N−H or O−H stretching), 3000–2800 cm−1 (C−H stretching), and 1700–1500 cm−1 (C=O stretching or N−H bending). Figure 26c shows the WCA results as a function of power for the four monomers. The WCAs were approximately 50° for pPMeOx, 54° for pPEtOx, 56° for pPPrOx, and 60° for pPBuOx. Figure 26d presents the adhesion and viability of human foreskin fibroblast (HFF) cells after 1 and 3 d of cultivation on the four polymer films. The pristine PP substrate exhibited low cell viability, whereas all plasma polymer films enhanced cell adhesion. The results suggest that cell adhesion strength increases with polymer chain length [48]. Table 14 summarizes the experimental synthesis conditions and bacterial results corresponding to Figure 26 in this section.

Figure 26.

(a) Experimental setup of plasma–polymerized film deposition using four monomers (MeOx, EtOx, PrOx, and BuOx). (b) FT–IR spectra and (c) WCA results of four plasma–polymerized films. (d) Cell viability of human foreskin fibroblast (HFF) cells after 1 and 3 d of cultivation on four polymer films. Reproduced with copyright permission from Ref. [48].

Table 14.

Summary of experimental plasma synthesis and antibacterial results corresponding to Figure 26 [48].

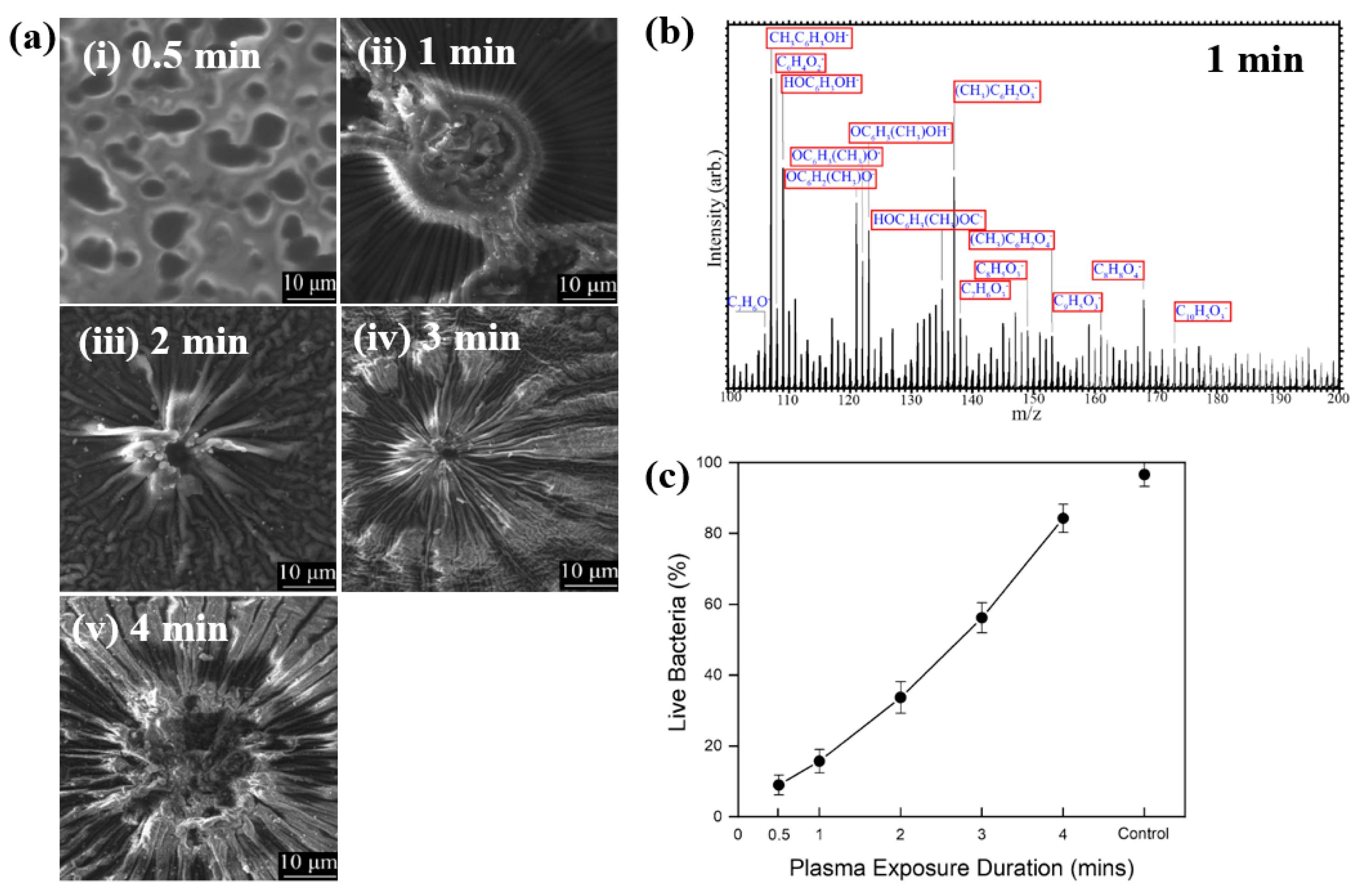

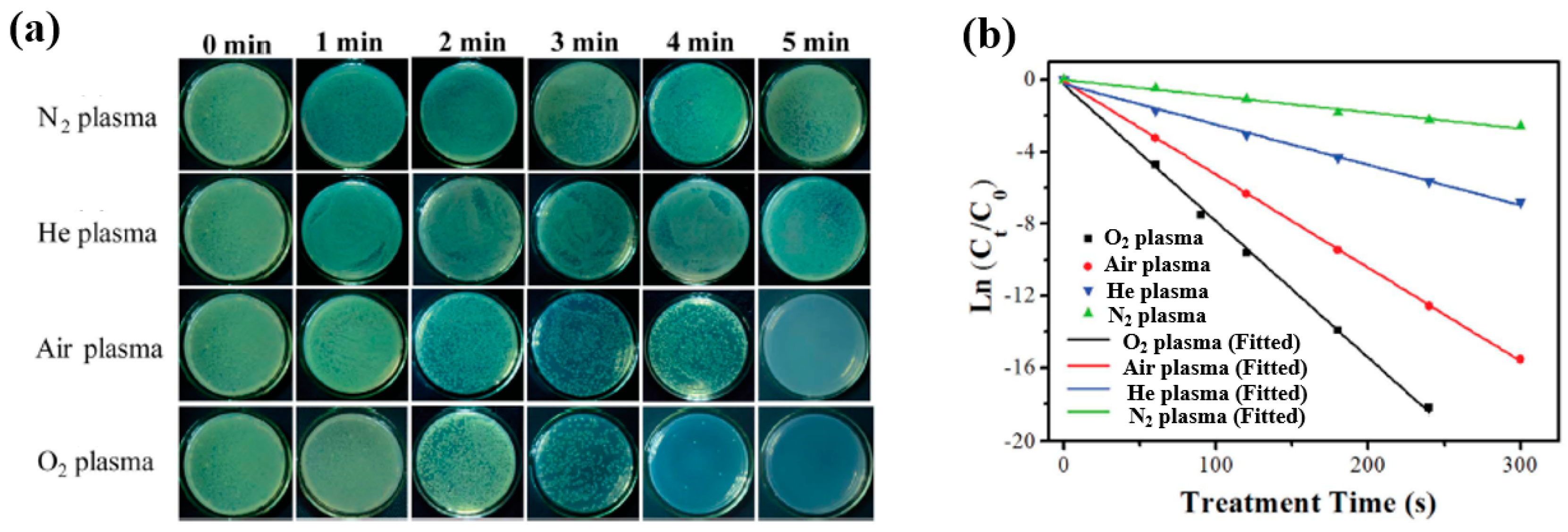

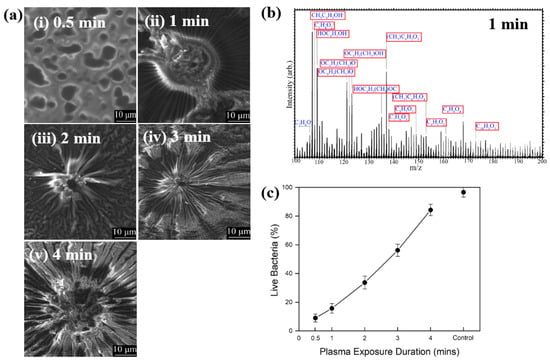

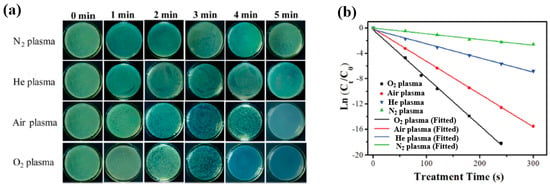

Hartl et al. [49] investigated the structure and bacterial cell response to 3–methylphenol (M–cresol) films prepared by an AP DBD–plasma process on silicon substrates under RT conditions. To form the M–cresol films, the Si (silicon) substrate was positioned 7 mm below the top of the plasma reactor. The films were deposited in open air with plasma exposure times of 0.5, 1, 2, 3, and 4 min. Plasma discharge was applied with a peak–peak voltage of 30 kV at a frequency of 40 kHz. Figure 27a shows FE–SEM images of the deposited M–cresol films on Si wafers after different plasma durations. At 0.5 min, the films exhibited a smooth morphology, whereas with increasing plasma time, a sunburst pattern developed, and the number of sunbursts increased progressively. The chemical composition of the M–cresol film synthesized after 1 min of plasma exposure was analyzed using ToF–SIMS. The spectrum reveals fragment peaks associated with benzene ring, including C7H7O2, C10H5O3, C8H8O4, and C9H5O3. (Figure 27b), suggesting oligomerization or polymerization during plasma synthesis [49].

Figure 27.

(a) FE–SEM images of M–cresol films on Si wafers at plasma exposure times of (i) 0.5, (ii) 1, (iii) 2, (iv) 3, and (v) 4 min. (b) ToF–SIMS spectrum of M–cresol film deposited by plasma for 1 min. (c) Percentage of live E. coli cells on plasma–synthesized M–cresol films with different plasma treatment durations. Reproduced with copyright permission from Ref. [49].

To evaluate antimicrobial properties, M–cresol films were prepared via plasma synthesis, and a pristine Si substrate served as the control. As shown in Figure 27c, E. coli cell survival decreased by approximately 91% after 15 min of seeding on the M–cresol film prepared with 0.5 min plasma treatment. This film exhibited the highest antimicrobial activity, while longer plasma exposure durations resulted in increased survival of live bacterial cells [49]. Table 15 summarizes the experimental synthesis conditions and bacterial results corresponding to Figure 27 in this section.

Table 15.

Summary of experimental synthesis and antibacterial results corresponding to Figure 27 [49].

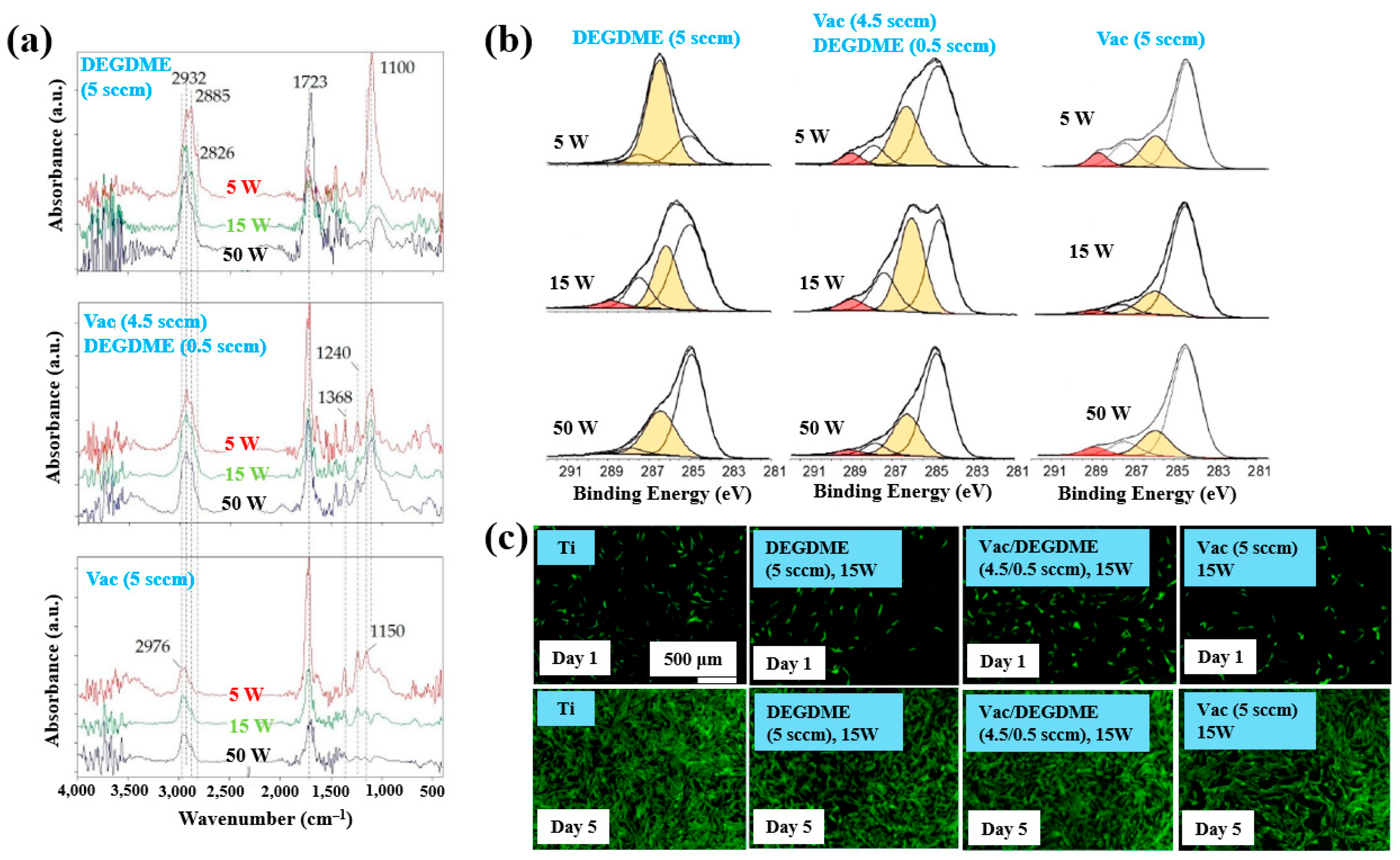

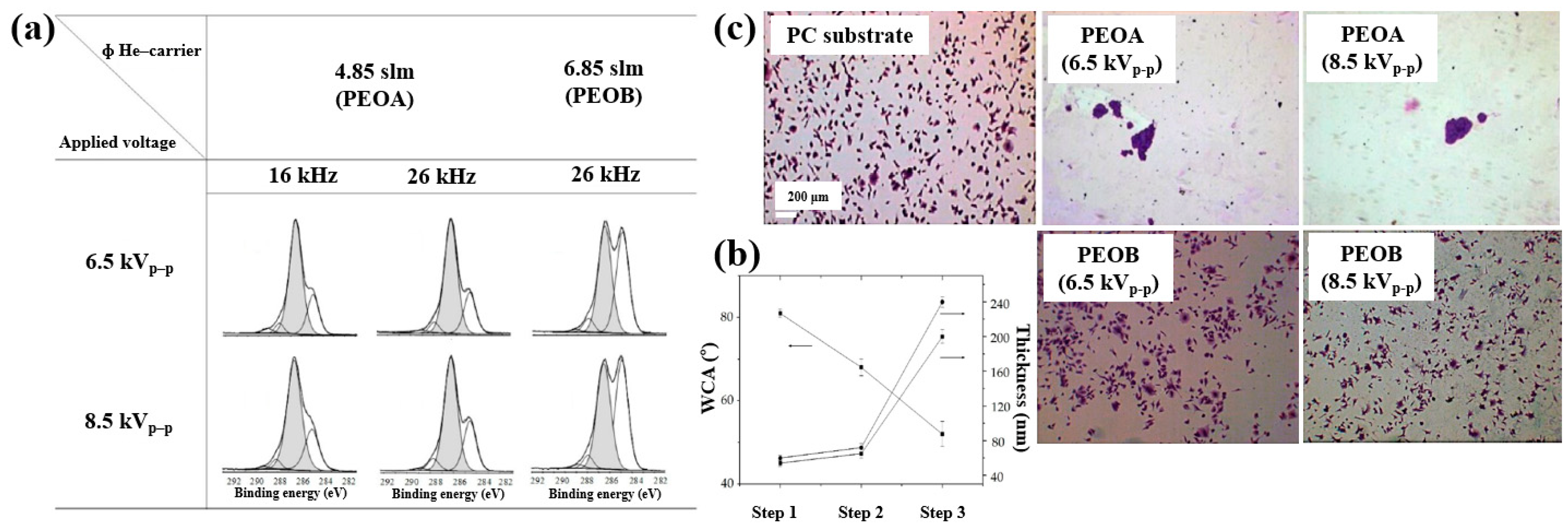

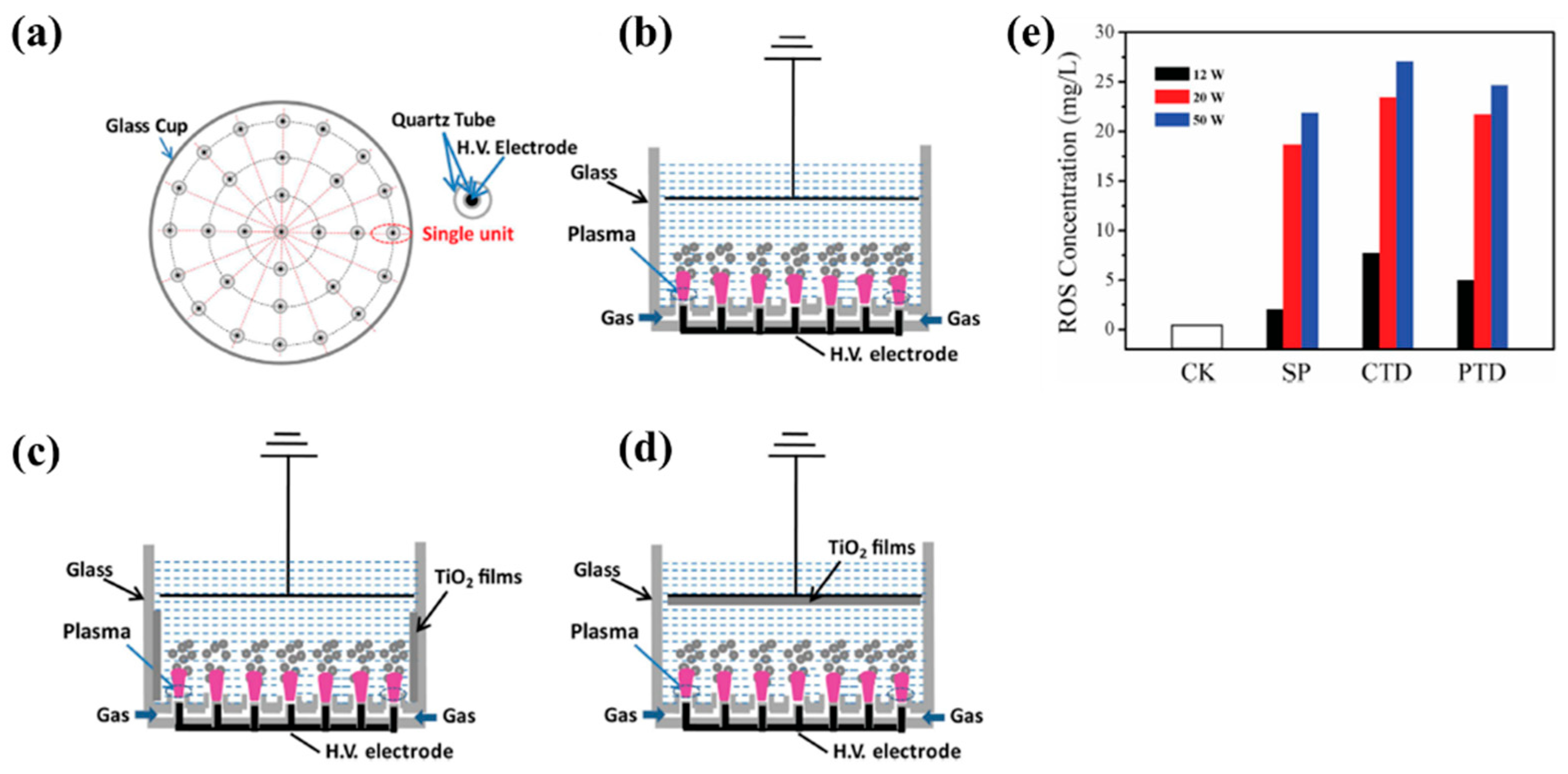

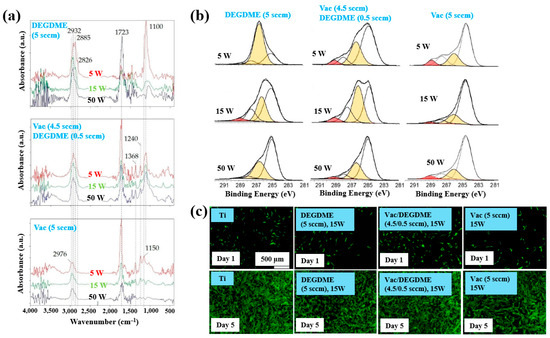

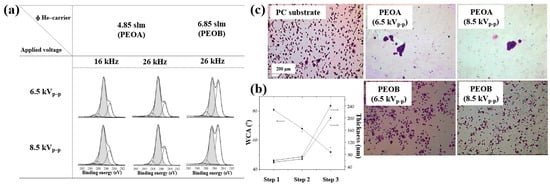

Sardella et al. [50] investigated polyethylene oxide (PEO)–like films deposited via low pressure (LP) and aerosol–assisted APP–enhanced chemical vapor deposition (AP PE–CVD) on titanium (Ti) and polycarbonate (PC) substrates. Figure 28a presents the FT–IR spectra of polymer films deposited using the LP method from DEGDME, VAc, and a mixed solution (Vac/DEGDME = 4.5/0.5) under varying plasma power conditions. Based on the FT–IR spectra in Figure 28a, a peak at 1100 cm−1 corresponding to ether functional groups, characteristic of PEO, can be observed in polymer films deposited from the DEGDME monomer. These films exhibited structural features similar to PEO polymers, including CH2 stretching peaks at 2940–2810 cm−1 and a carbonyl peak at 1723 cm−1. As the plasma power increased from 5 to 50 W, the intensity of the C–O–C ether peak decreased, while the carbonyl peak intensity increased, suggesting fragmentation or inter–chain crosslinking of polymer chains during plasma deposition. Notably, films formed under lower plasma power and retained structures more closely resembling PEO. In contrast, polymer films deposited from the VAc monomer exhibited CH3 peaks at 1240 cm−1 and 1368 cm−1, along with a C=O stretching peak at 1723 cm−1. Films deposited from the mixed monomer solution displayed characteristic peaks of both DEGDME and VAc. As plasma power increased from 5 to 15 W, the intensity of the C=O stretching peak at 1723 cm−1 initially decreased, but increased again at 50 W. The XPS results in Figure 28b show that the chemical composition of the deposited PEO–like polymer films was influenced by plasma power and the monomer feed ratio. A higher plasma power resulted in a decrease in the XPS peak associated with PEO–like functional groups, indicating degradation of PEO–like characteristics under harsher plasma conditions.

Figure 28.

(a) FT–IR spectra and (b) XPS C 1s spectra of polymer films prepared by using LP method. (c) Fluorescence images of NHDF cells attached after 24 h cultivation on bare Ti, DEGDME, VAc, and DEGDME–Vac films. Reproduced with copyright permission from Ref. [50].

To assess biocompatibility, polymer films were deposited onto Ti substrates via the LP method using DEGDME, VAc, and the mixed solution. Figure 28c illustrates cell adhesion and growth behaviors on the three different polymer surfaces. After 1 d of cultivation, minimal cell attachment was observed on all polymer surfaces. However, after 5 d, extensive cell coverage was evident across all polymer film surfaces. This enhanced cell growth is attributed due to the presence of CH2CH2O ester functional groups formed on the surface during LP deposition [50].

Furthermore, the cell adhesion characteristics of polymer samples fabricated by AP PE–CVD were investigated. Cell-repellent films were deposited on PC substrates using aerosol-assisted APP in a DBD reactor, employing a mixture of He and triethylene glycol dimethyl ether (TEGDME). The experiments were conducted using either a single-step or multi-step process to enhance cell adhesion properties. In the single-step process, PEOA was deposited at a He flow rate of 4.85 standard liters per minute (SLM), while PEOB was deposited at a higher He flow rate of 6.85 SLM. In both cases, the He–TEGDME aerosol gas was maintained at 3.15 SLM. The detailed experimental conditions for the three-step AP PE–CVD processes used for PEOA and PEOB deposition are provided in Table 16 [50].

Table 16.

Experimental conditions of AP PE–CVD across three steps for PEOA and PEOB deposition [50].

XPS analysis (Figure 29a) confirmed that the chemical structure of the deposited polymer films varied with He–TEGDME gas flow compared to plasma voltage and frequency conditions. Figure 29b presents the thickness and WCA values of PEOA films under two frequency conditions. In step 1, a polyethylene (PE)–like hydrocarbon film with a thickness of 60 nm was deposited using He and C2H4 precursors, exhibiting hydrophobic properties with a WCA of 81°. In step 2, a 20 nm PE-like film was deposited using TEGDME, He, and C2H4 precursors, yielding a WCA of 68°. Finally, in step 3, a PEOA film with a thickness of 180 nm was deposited, exhibiting enhanced hydrophilicity with a WCA of 53°.

Figure 29.

(a) XPS C 1s spectra of PEOA and PEOB films prepared by AP PE–CVD with three steps at 8.5 kVp–p and frequencies of 16 and 26 kHz. (b) WCA values of PEOA films under same conditions. (c) Fluorescence images of osteoblasts attached to bare PC, PEOA, and PEOB films after 24 h of cultivation. Reproduced with copyright permission from Ref. [50].

To evaluate cell adhesion on the deposited PEOA and PEOB films, biological experiments were conducted using various fibroblast cell types, including human dermal fibroblasts (HDFs), Saos–2 osteoblast cells, and normal HDFs (NHDFs). These cells were seeded onto the PEOA and PEOB films, and adhesion was assessed using fluorescence optical microscopy. After 24 h of cultivation (Figure 29c), a significant number of osteoblast cells were observed to adhere to the PEOB film surfaces prepared with a low PEOB content (<70%) at a He gas flow rate of 6.85 SLM, showing adhesion levels comparable to those observed on untreated PC substrates [50]. Table 17 summarizes the experimental synthesis conditions and corresponding biological results for Figure 28 and Figure 29 presented in this section.

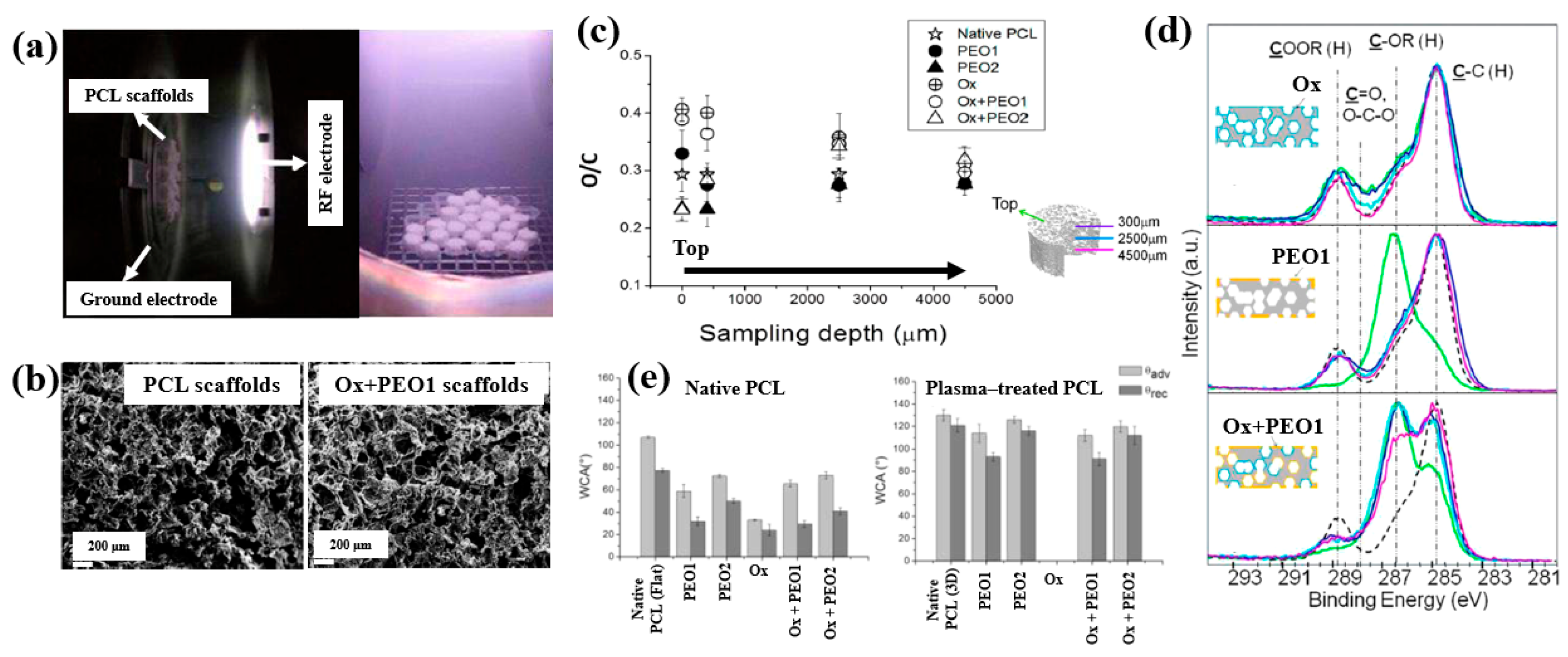

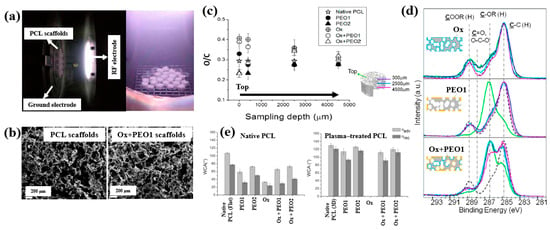

To enhance cell adhesion and proliferation properties, Sardella et al. [51] investigated poly(ethylene oxide) (PEO) coatings deposited on poly–ε caprolactone (PCL) scaffolds using a double-step cold plasma process with Ar and O2 gas mixtures (Figure 30a). The detailed experimental conditions for PEO deposition are summarized in Table 18 [51].

Figure 30.

(a) Photographic image of plasma discharge during deposition in reactor. (b) FE–SEM images of PCL and Ox+PEO 1 scaffolds. (c) O/C ratio of native and plasma–treated PCL and PEO scaffolds. (d) XPS C 1s spectra at different depths for Ox, PEO1, and Ox+PEO1 scaffolds. (e) WCA results of native and plasma–treated PCL and PEO scaffolds. Reproduced with copyright permission from Ref. [51].

Table 18.

Experimental conditions for PEO deposition [51].

According to the FE–SEM results in Figure 30b, both the native PCL and Ox+PEO1 scaffolds exhibited interconnected pore structures with pore sizes ranging from 100 to 300 μm. Furthermore, as shown in Figure 30c, the O/C ratio at a depth of 2500 μm from the surface in plasma–treated scaffolds (PEO2 and PEO1) was similar to that of native PCL, indicating limited oxygen penetration into the scaffold core. However, the XPS results in Figure 30d demonstrate that PEO and Ox+PEO scaffolds possessed uniform oxygen-containing functional groups up to a depth of 3.5 mm along the vertical axis. Figure 30e presents the WCA measurements for native and plasma–treated PCL and PEO scaffolds. The plasma–treated samples exhibited enhanced hydrophilicity compared to the native PCL sample. Among these, PEO2 and Ox+PEO2 showed slightly greater hydrophobic behavior than PEO1 and Ox+PEO1. Notably, the Ox sample exhibited the highest degree of hydrophilicity among all samples tested [51].

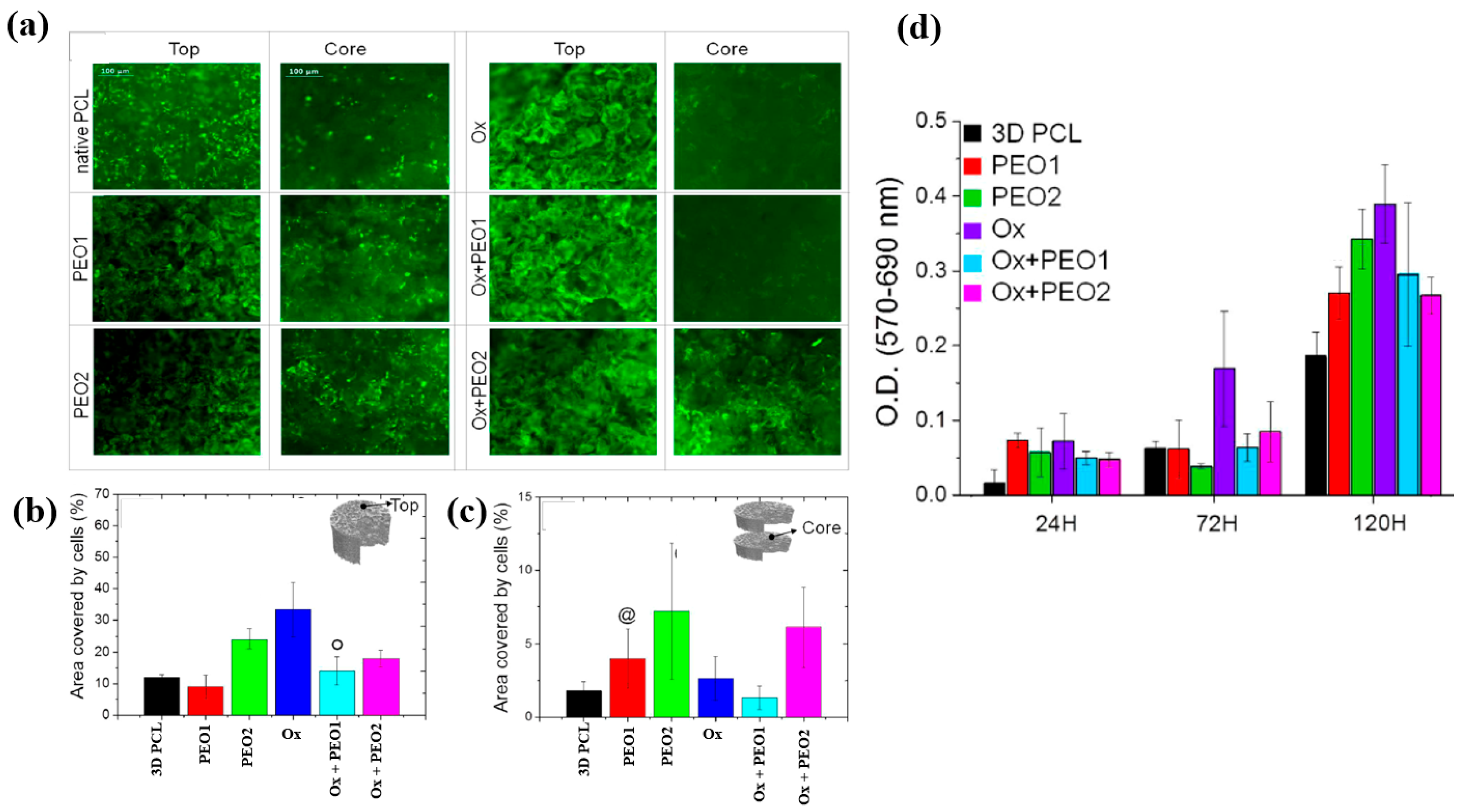

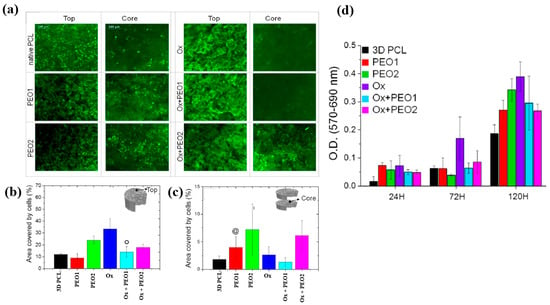

To examine cell adhesion and proliferation on native and plasma–treated PCL scaffolds, human osteoblast cells (Saos–2) were seeded onto the respective scaffolds and evaluated using fluorescence optical microscopy and the MTT colorimetric assay. As shown in Figure 31a, for all scaffolds, the number of cells attached to the scaffold core was lower than that on the top surface [51]. This is likely due to limited cellular diffusion into the interior of the scaffolds. The number of cells adhering to both the top and core regions of the scaffolds was quantified. According to Figure 31b,c, the Ox sample exhibited the highest cell density on the top surface. Additionally, after 120 h of cultivation, the PEO2 scaffold showed a high number of attached cells in both the top and core regions. Cell proliferation on the native and plasma–treated scaffolds was further evaluated using the MTT assay after 24, 72, and 120 h of cultivation. As shown in Figure 31d, no significant difference in cell proliferation was observed among the samples at 24 h. However, at 72 h, a significant increase in cell proliferation was observed only for the Ox sample. By 120 h, all plasma–treated scaffolds exhibited significantly enhanced cell proliferation compared to the native PCL [51]. This improvement in cell adhesion and proliferation is attributed to surface modifications induced by plasma treatment, including increased hydrophilicity and the incorporation of oxygen–containing polar functional groups. Table 19 presents a summary of the experimental synthesis and bacterial results for Figure 30 and Figure 31 in this section.

Figure 31.

(a) Fluorescence images of osteoblasts attached to top and core regions of native and plasma–treated PCL scaffolds after 120 h of cultivation. Area coverage of cells on scaffold (b) top and (c) core regions. (d) MTT assay results for native and plasma–treated PCL and PEO scaffolds after 1, 3, and 5 d of cultivation. Reproduced with copyright permission from Ref. [51].

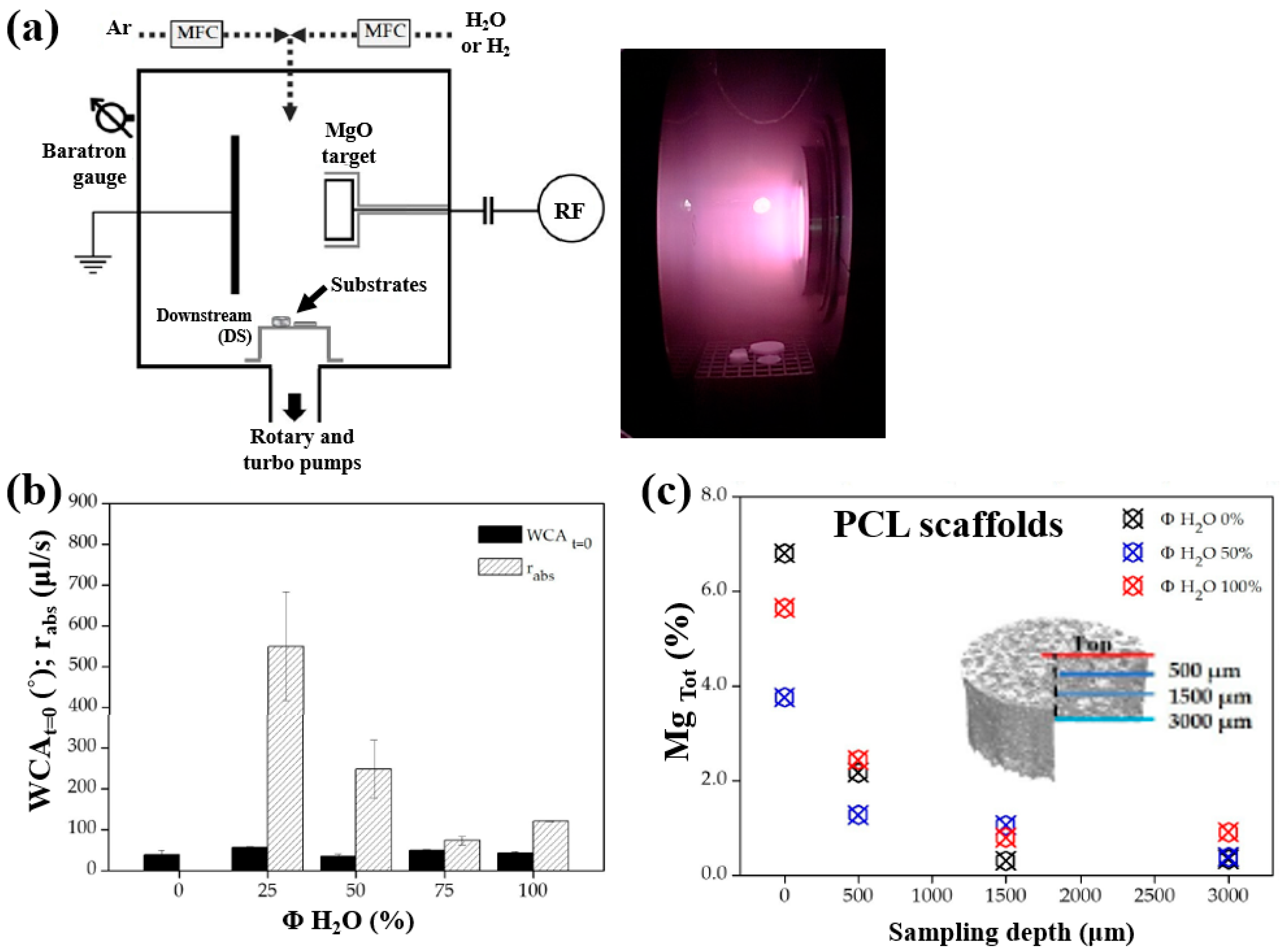

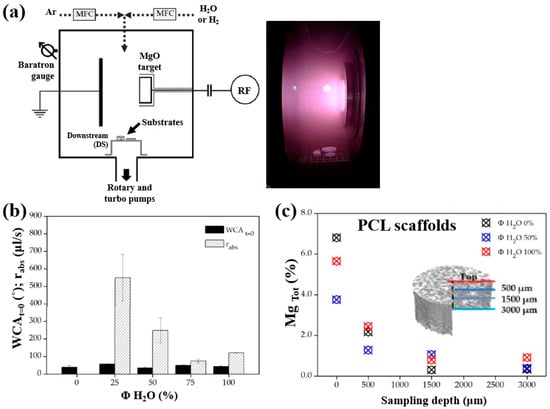

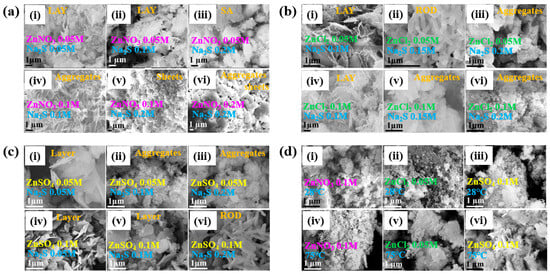

Armenise et al. [52] investigated the surface composition and wettability of poly–ε caprolactone (PCL) scaffolds containing magnesium (Mg), with a particular focus on their influence on cell adhesion. The Mg–containing coatings were prepared using a plasma-assisted technique via RF sputtering. Before MgO deposition, three-dimensional (3D) PCL scaffolds were fabricated using a solvent casting method with a PCL solution composed of chloroform (CHCl3) and NaCl as a porogen. Additionally, two–dimensional (2D) PCL flat samples were prepared by spin–coating using a mixed polymer solution, consisting of 1 g PCL dissolved in 6 mL CHCl3, onto polyethylene terephthalate (PET) substrates. Subsequently, the PCL samples were treated using an RF sputtering plasma–assisted technique, with a magnesium oxide (MgO) target and various injected gas mixtures. Figure 32a illustrates the experimental setup for MgO film deposition using RF sputtering. The plasma reactor was configured with two vertically aligned electrodes spaced 60 mm apart. The MgO target was placed on the powered electrode, while the opposing electrode was grounded. The PCL flat samples and scaffolds were positioned on a stainless steel grid located downstream (DS) from the plasma discharge region. Plasma treatment was conducted for 60 min at a power of 50 W. Figure 32b presents the WCA and water absorption rate of plasma–treated PCL scaffolds under Ar/H2O and pure H2O gas conditions. The results show that the water absorption rate decreased with increasing H2O concentration in the Ar/H2O mixtures. To assess elemental composition across the depth of the 3D–PCL scaffolds, XPS analysis was performed on cross–sections at varying distances from the surface. As shown in Figure 32c, the Mg concentration decreased from the top surface to a depth of 3000 μm, with the highest concentration observed near the surface at a depth of approximately 500 μm [52].

Figure 32.

(a) Schematic of plasma reactor and photographic image of plasma discharge during deposition. (b) Water absorption rate and WCA values of plasma–treated PCL scaffolds with different gas mixtures (Ar, Ar/H2O, and H2O). (c) XPS surface composition of magnesium (Mg) (Mg Tol %) in plasma–treated 3D PCL scaffolds at different surface depths. Reproduced with copyright permission from Ref. [52].

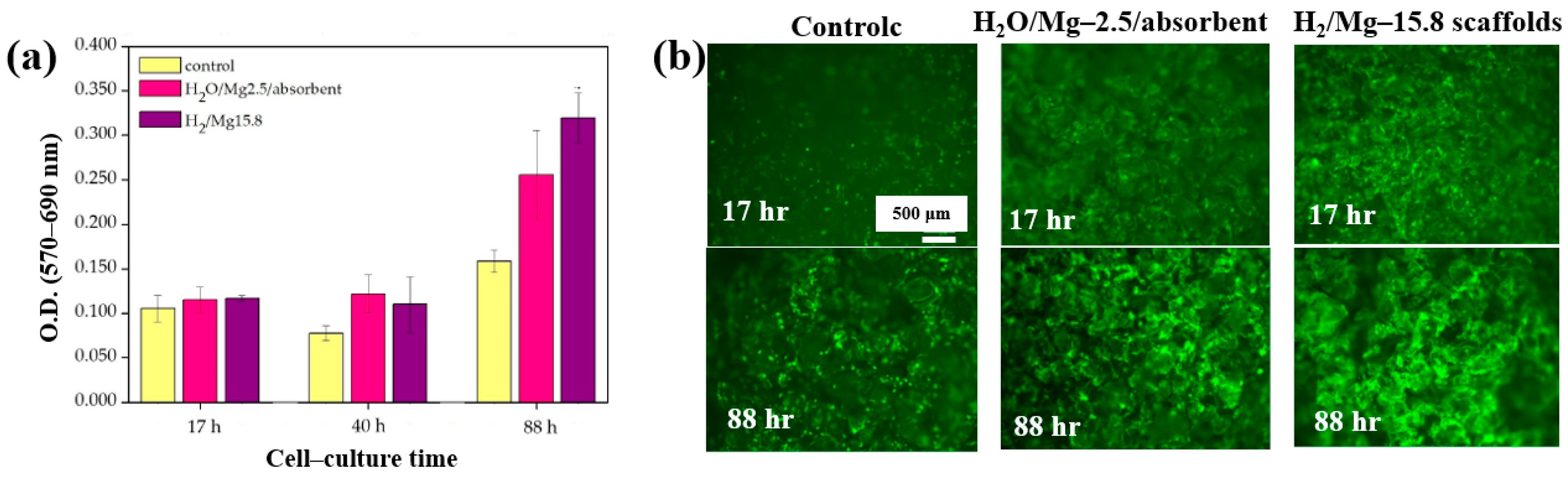

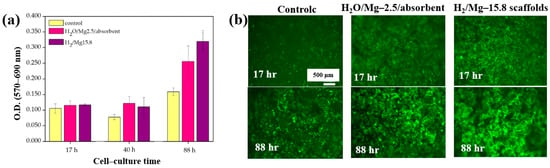

Furthermore, cell adhesion and viability of Saos–2 osteoblast cells cultured on three different PCL scaffolds were assessed at various cultivation times (17, 40, and 88 h) by using fluorescence microscopy. As shown in Figure 33a, no significant differences in cell adhesion or growth were observed after 17 and 40 h of cultivation. However, after 88 h, cell proliferation was evident across all scaffolds. In particular, enhanced adhesion and proliferation were observed on the two 3D–PCL scaffolds, such as on H2O/Mg 2.5/absorbent and H2/Mg 15.8 scaffolds. Fluorescence microscopy images (Figure 33b) further illustrate the adhesion and proliferation behavior of Saos–2 cells after 17 and 88 h of cultivation on these two scaffold types [52]. Table 20 summarizes the experimental synthesis and bacterial assay results corresponding to Figure 32 and Figure 33.

Figure 33.

(a) Cell viability and (b) fluorescence microscopy images of Saos–2 cells on untreated (control) and plasma–treated 3D PCL scaffolds exposed to two gas mixtures (H2O/Mg–2.5/absorbent, H2/Mg–15.8) at cultivation times of 17, 40, and 88 h. Reproduced with copyright permission from Ref. [52].

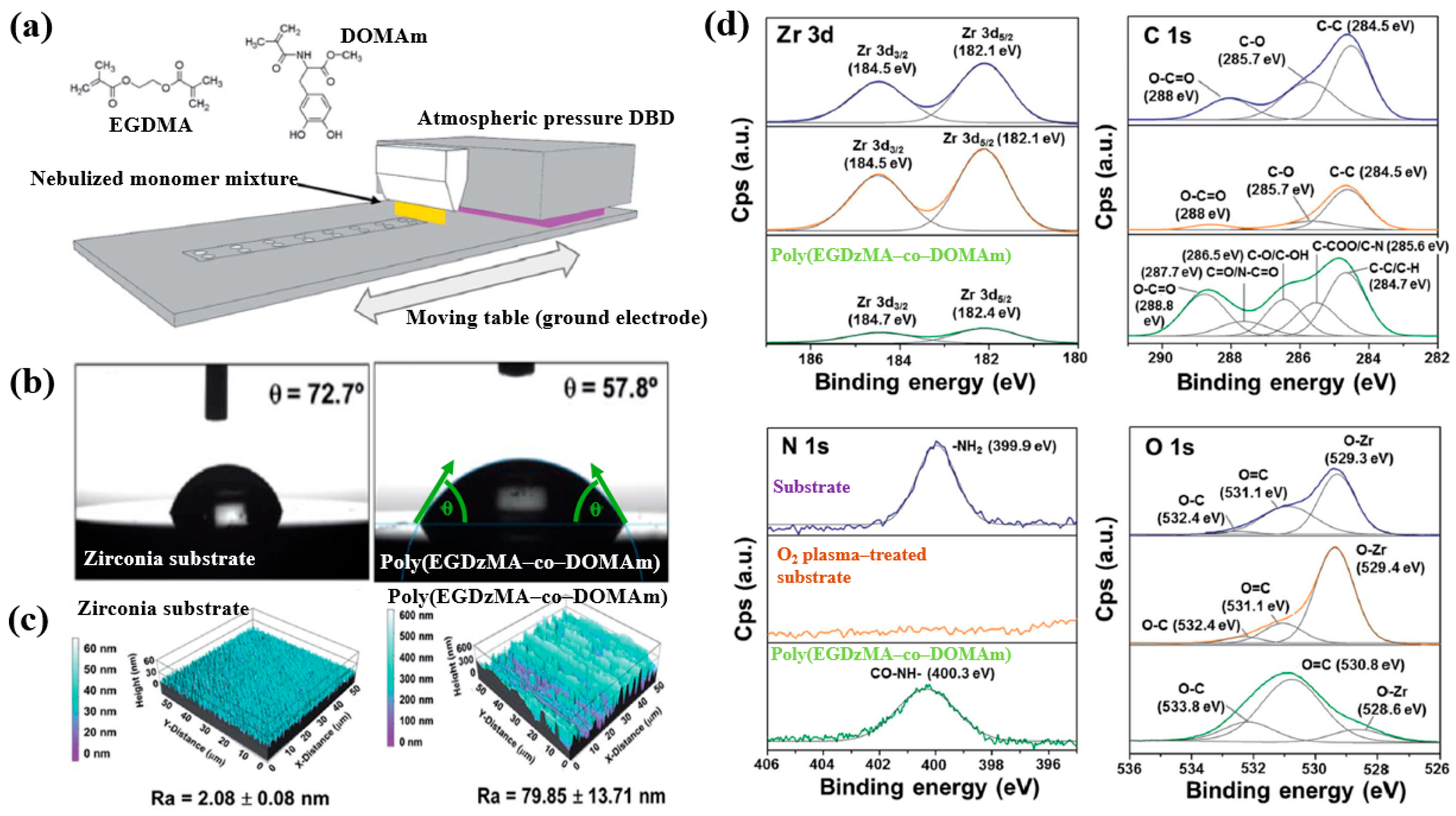

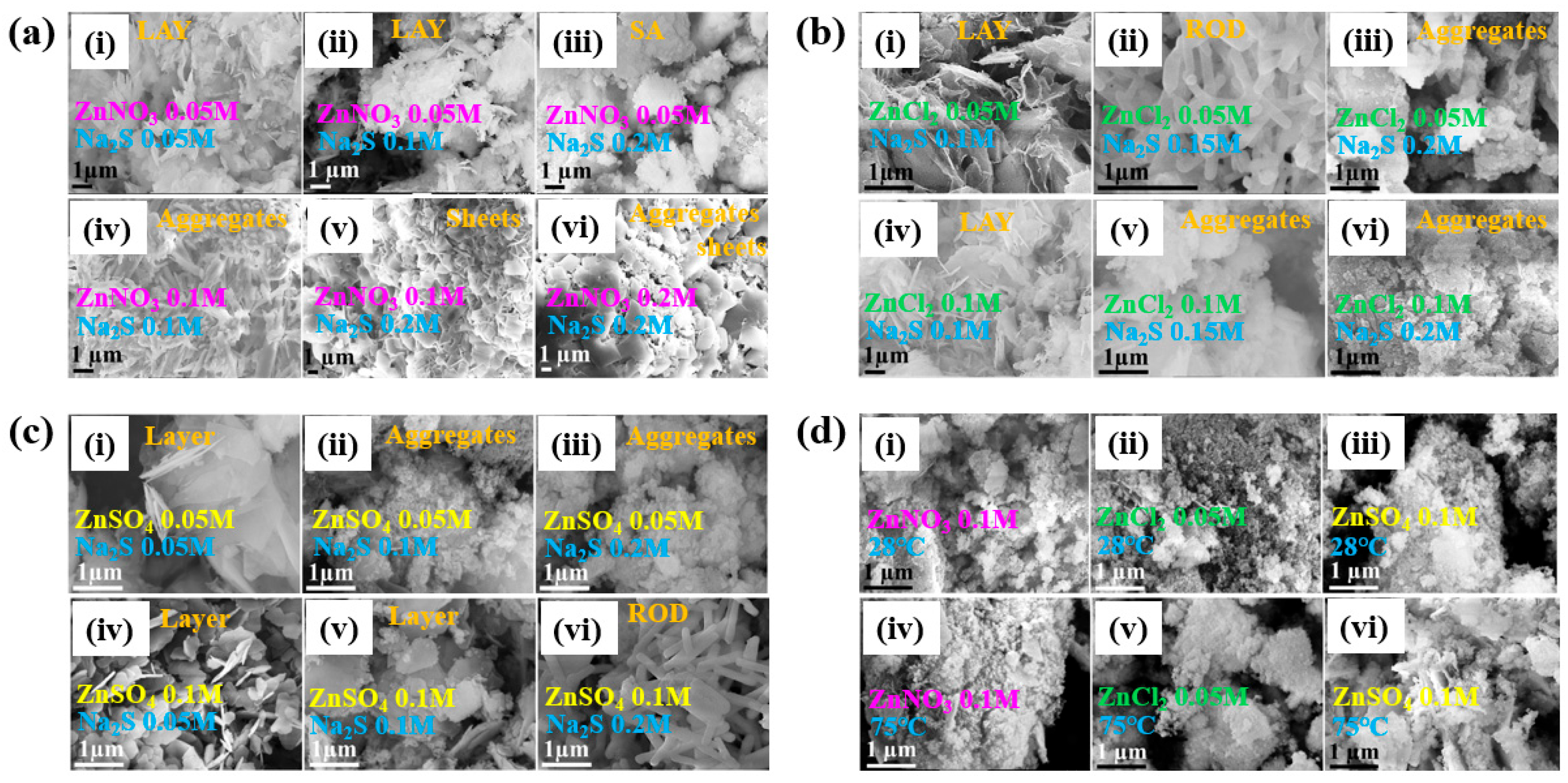

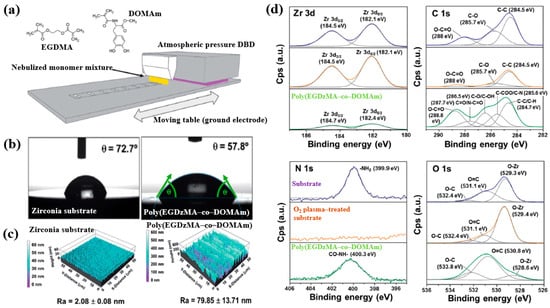

Hod’asov’a et al. [53] investigated the deposition of a poly(EGDMA–co–DOMAm) copolymer film on a zirconia substrate via liquid–assisted APP-induced polymerization (LA–APPiP) using two monomer mixtures of methyl–DOPA methacrylamide (DOMAm), and ethylene glycol dimethacrylate (EGDMA) [53]. The experimental setup for copolymer film deposition is shown in Figure 34a. The film was fabricated in two steps. First, the mixed liquid solutions were sprayed to form a thin liquid layer on the substrate. Then, the layer was polymerized using plasma generated by a sinusoidal waveform at 10 kHz, with an Ar gas flow of 20 SLM. Deposition was carried out for 8 s, resulting in a copolymer film approximately 250 nm thick. As shown in Figure 34b, the WCA value for the zirconia substrate and the copolymer film was 72.7 and 57.8, respectively. Figure 34c presents the AFM images and surface roughness (Ra) values. The untreated zirconia substrate exhibited a low Ra of 2.1 nm, indicating a flat surface. In contrast, after deposition by LA–APPiP, the Ra of the copolymer film increased substantially to 79.9 nm. Figure 34d shows the XPS high-resolution spectra for three samples, namely untreated zirconia, O2 plasma–treated zirconia, and the deposited copolymer film. No significant difference was observed between the untreated and O2 plasma–treated zirconia surfaces. However, new functional groups such as C=O/N–C=O, C–O/C–OH, and C–COO/C–N were detected in the deposited copolymer film [53].

Figure 34.

(a) Schematic of liquid-assisted APP-induced polymerization (LA–APPiP) for poly(EGDMA–co–DOMAm) copolymer deposition. (b) WCA results, (c) AFM images, and roughness (Ra) of zirconia substrate and poly(EGDMA–co–DOMAm) films. (d) XPS high–resolution spectra of untreated zirconia and O2 plasma–treated zirconia and poly(EGDMA–co–DOMAm) copolymer. Reproduced with copyright permission from Ref. [53].

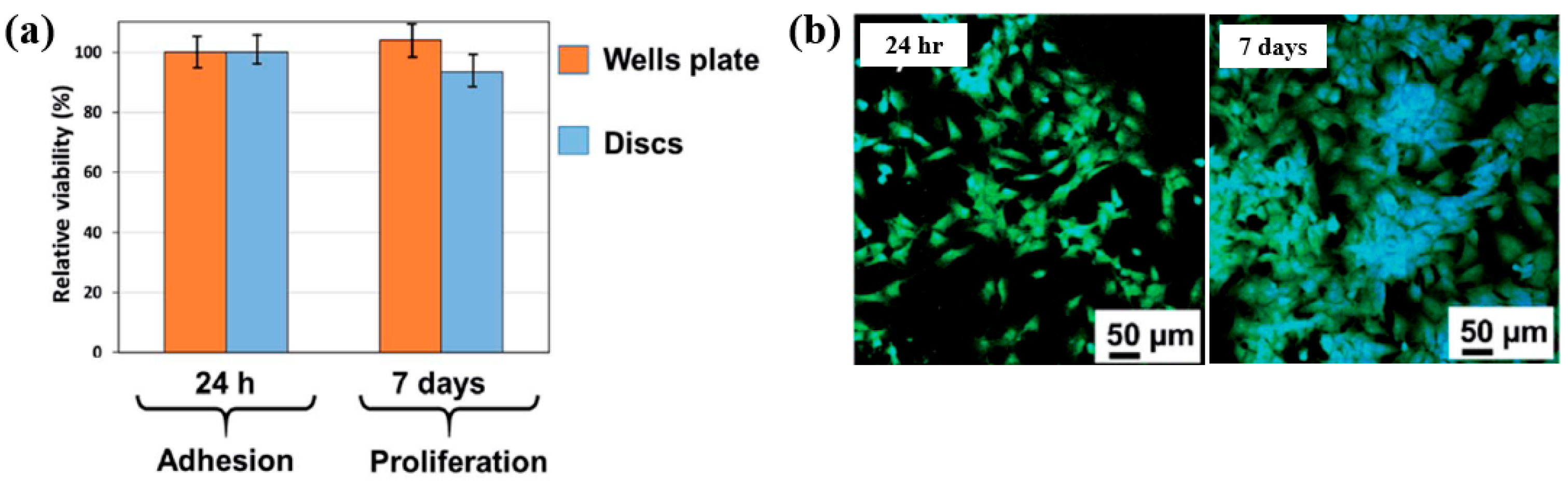

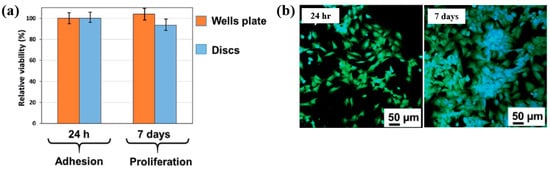

To examine cell adhesion on the poly(EGDMA–co–DOMAm) film, osteoblast-like MG–63 cells were seeded onto the deposited films and analyzed using fluorescence optical microscopy. As shown in Figure 35a,b, cell attachment and proliferation were enhanced on the poly(EGDMA–co–DOMAm) film after 24 h and 7 d of cultivation, respectively [53]. This enhancement is attributed to the presence of functional groups and the increased surface roughness of the plasma-deposited poly(EGDMA–co–DOMAm) copolymer film. Table 21 presents a summary of the experimental synthesis and bacterial assay results corresponding to Figure 34 and Figure 35 in this section.

Figure 35.

(a) Cell viability of MG–63 cells after 24 h and cell proliferation after 7 d. (b) Fluorescence microscopy images of osteogenic MG–63 cells attached to poly(EGDMA–co–DOMAm) films after 24 h and 7 d of cultivation. Reproduced with copyright permission from Ref. [53].

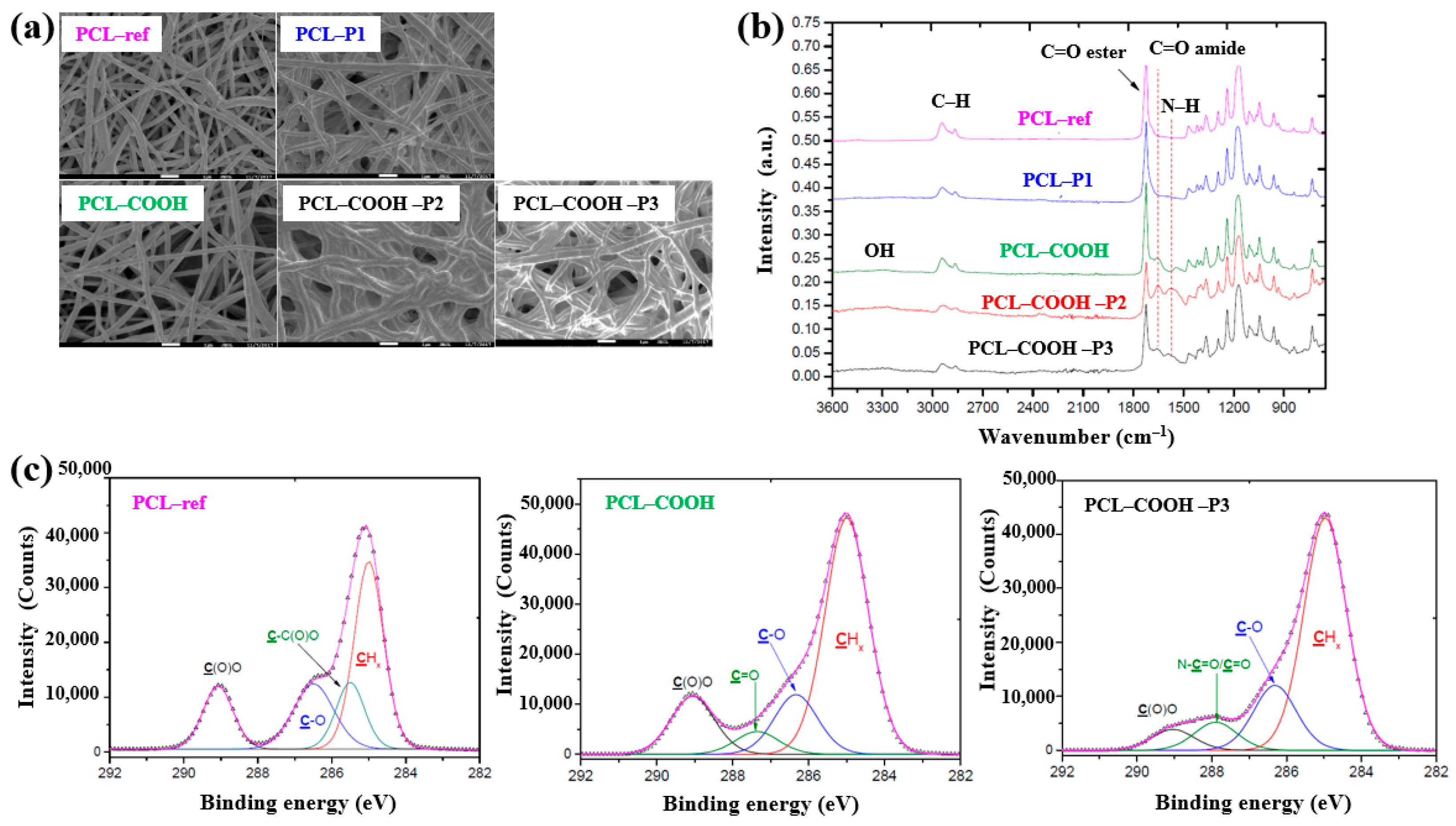

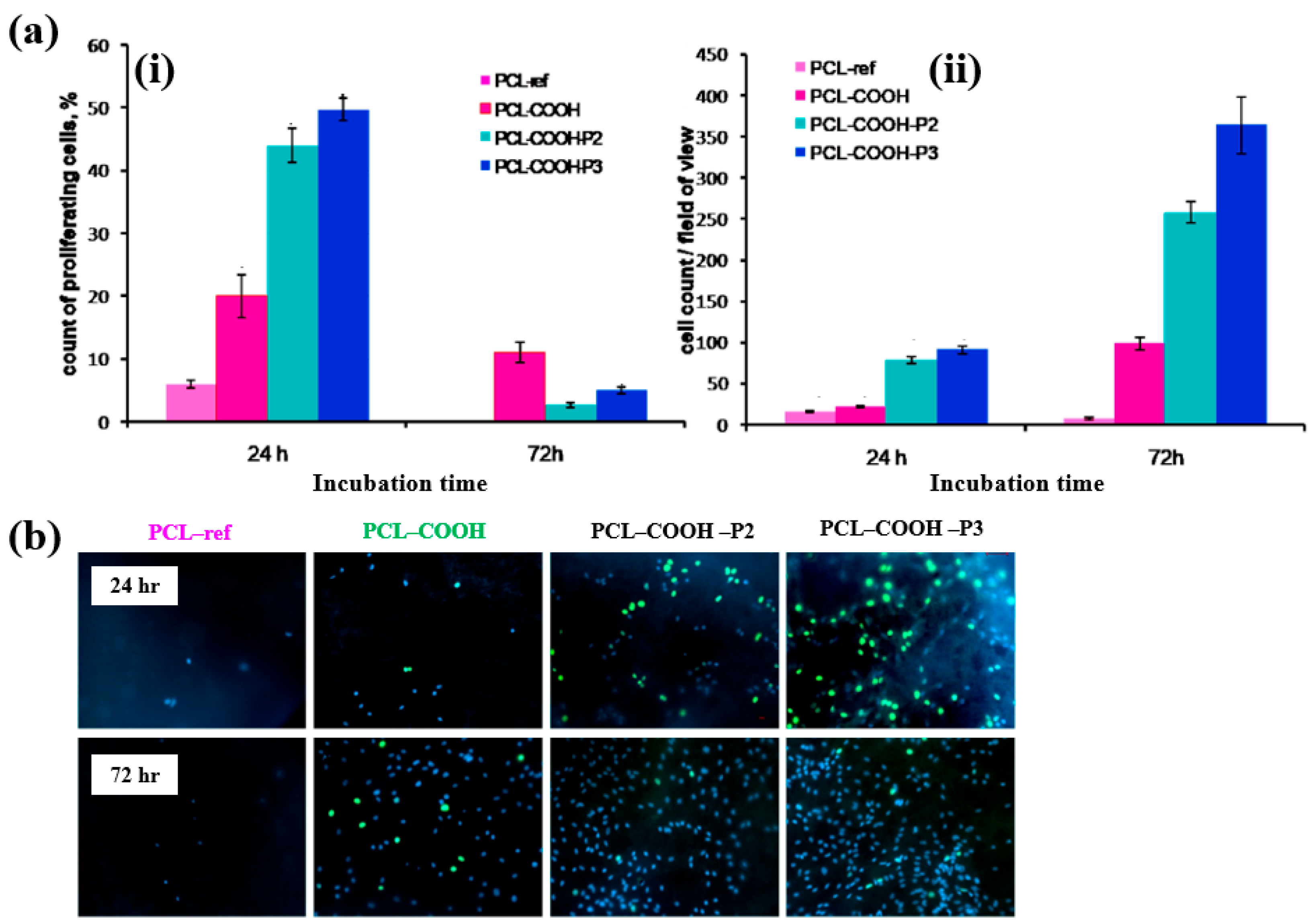

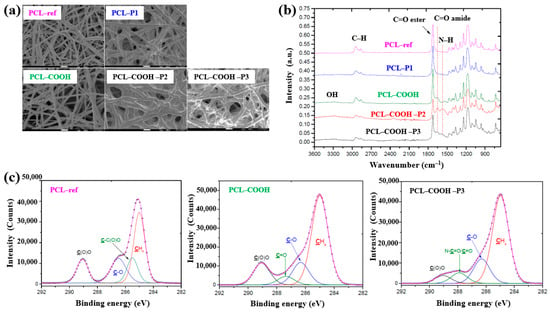

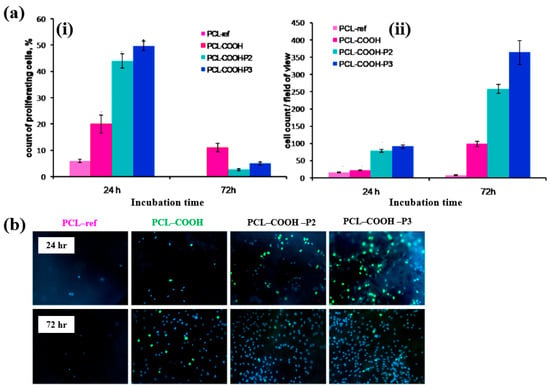

Solovieva et al. [54] investigated the viability and proliferation of mesenchymal stem cells (MSCs) on plasma–deposited polymer films coated on PCL nanofibers (NFs). First, the nanofibers were fabricated by electrospinning using a PCL solution, and the resulting fibers were designated as PCL–ref. A polymer film containing COOH functional groups was then deposited onto the PCL NFs via capacitively coupled RF plasma under vacuum using a precursor gas mixture of Ar, CO2, and C2H4. These plasma–coated nanofibers were designated as PCL–COOH. To evaluate different modes of platelet–rich plasma (PRP) adsorption and bonding on the PCL NFs, three additional treatments were performed. For the physical adsorption of PRP, PCL–ref samples were immersed in PRP solution at RT for 15 min and then rinsed with phosphate-buffered saline (PBS). These samples were designated as PCL–P1. For ionic bonding, PCL–COOH samples were dipped in a PRP solution for 15 min and washed with PBS solution, and designated as PCL–COOH–P2. Finally, for covalent bonding, PCL–COOH samples were treated with N–dicyclohexylcarbodiimide (DCC) solution (2 mg/mL in water) for 15 min, followed by PBS washing. These were designated as PCL–COOH–P3. The detailed identification of all five sample types is provided in Table 22.

Table 22.

Identification of plasma–deposited samples [54].

As shown in the FE–SEM analysis in Figure 36a, the morphology of the PCL–P1 sample was similar to that of PCL–ref, both before and after plasma polymer coating. Additionally, the diameters of all electrospun PCL NF samples were consistently found to be approximately 270 nm. The FT–IR spectra in Figure 36b reveal new peaks at 1652 and 1598 cm−1, corresponding to C=O stretching and the NH2 bond of amide groups, respectively, on the surface of the plasma polymer-coated PCL NFs. These peaks are attributed to the introduction of COOH functional groups from the plasma polymer layer and the presence of molecules containing peptide bonds. Furthermore, XPS analysis (Figure 36c) shows that PCL–COOH consisted of 72.1 at% carbon and 27.9 at% oxygen. After immobilization with PRP via ionic bonding, PCL–COOH–P2 exhibited a composition of 70.5 at% carbon, 18.8 at% oxygen, and 10.7 at% N2. Similarly, PCL–COOH–P3, treated for covalent immobilization of PRP, showed a comparable elemental composition. Notably, in the C1s spectrum of PCL–COOH–P3 NFs, a shift in the carbon peak was observed after PRP immobilization. The intensity of the C(O)O peak decreased, while a new peak corresponding to amide groups (N–C=O) emerged [54].

Figure 36.

(a) FE–SEM images and (b) FT–IR spectra of polymer samples, namely polycaprolactone nanofibers (PCL–ref), PCL–P1, PCL–COOH, PCL–COOH–P2, and PCL–COOH–P3. (c) XPS C 1s high-resolution spectra of PCL–ref, PCL–COOH, and PCL–COOH–P3. Reproduced with copyright permission from Ref. [54].

To evaluate cell adhesion and proliferation of human bone marrow (BM) mesenchymal stromal cells (MSCs) on various plasma polymer-coated PCL NFs, human MSCs were seeded onto the coated NFs and analyzed using fluorescence optical microscopy. As shown in Figure 37a,b, the PCL–COOH sample exhibited limited cell adhesion, with cells displaying a smaller spreading area compared to the PCL–ref sample. In contrast, the PCL–COOH–P2 and PCL–COOH–P3 samples showed uniformly attached cells with high density. Furthermore, after 72 h of cultivation, the attached cells remained viable, and cell proliferation was notably enhanced [54]. Table 23 presents a summary of the experimental synthesis and bacterial assay results corresponding to Figure 36 and Figure 37.

Figure 37.

(a(i)) Count percentage and (a(ii)) average number of proliferating cells after 24 and 72 h of cultivation with different plasma polymer-coated PCL nanofibers (NFs). (b) Fluorescence images of human MSCs on plasma polymer–coated PCL NFs after 24 and 72 h of cultivation. Reproduced with copyright permission from Ref. [54].

Furthermore, additional information related to plasma synthesis and biomedical experiments from published papers without copyright permission approval is summarized and presented in Table 24 [55,56,57,58].

Table 24.

Summary of plasma synthesis and biomedical experiments reported in recent studies without copyright permission approval [55,56,57,58].

Table 25 summarizes the plasma-based synthesis of polymer films for biomedical applications discussed in this section.

Table 25.

Summary of plasma-based synthesis methods for polymer films for biomedical applications.

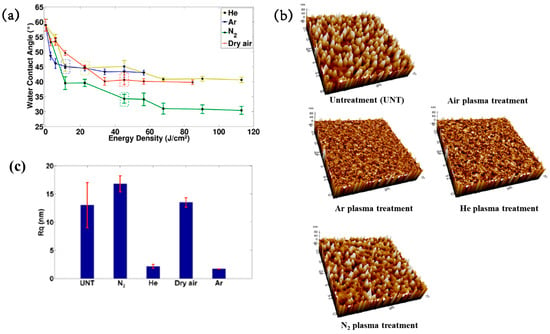

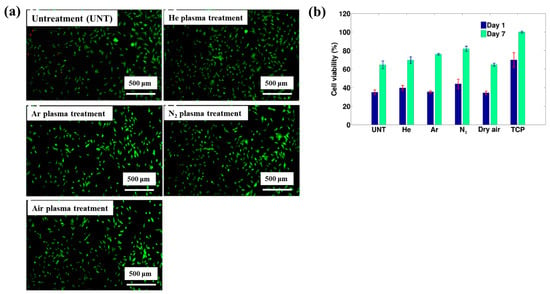

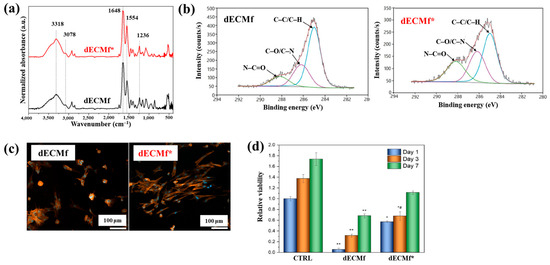

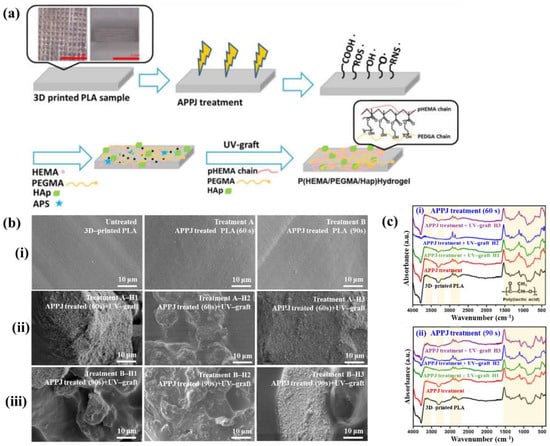

2.2. Plasma Surface Treatment of Polymer Films for Biomedical Applications

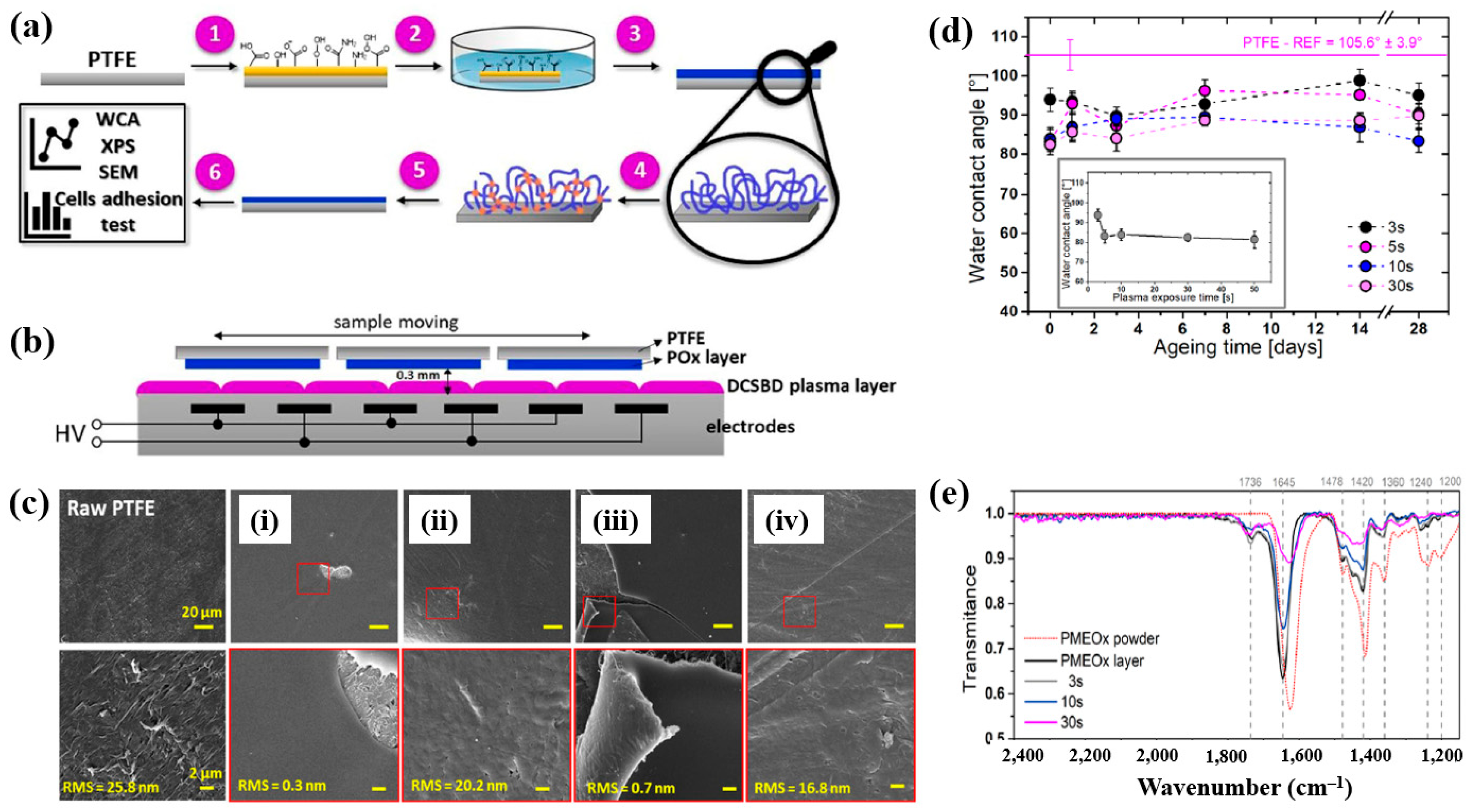

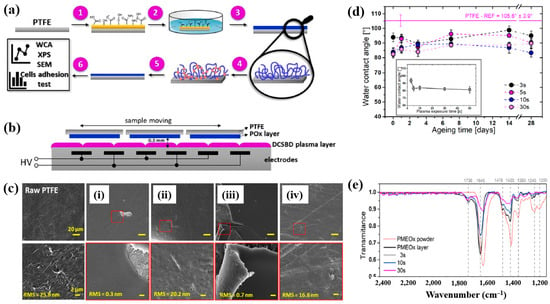

To deposit the PMEOx layer, the polytetrafluoroethylene (PTFE) surface must first be modified with reactive functional groups. Figure 38a,b illustrate the experimental procedures for the plasma deposition of poly(2–oxazolines) (POx) films and the surface treatment of PTFE using a diffuse coplanar surface barrier discharge (DCSBD) device based on DBD technology [59]. Both the pre–treatment of PTFE and the post–treatment of the deposited poly(2–methyl–2–oxazoline)–stat–(2–(3–butenyl)–2–oxazoline) (PMEOx) layer were carried out using the DCSBD system. The DCSBD apparatus comprises 16 pairs of parallel-aligned Ag electrodes embedded in 0.6 mm thick alumina ceramics, operating at a peak–to–peak voltage (Vp-p) of 20 kV and a frequency of 15 kHz. This configuration enables the generation of a uniform plasma across a flat dielectric ceramic surface between the electrodes. Initially, the PTFE substrate was treated with ambient air plasma using a sinusoidal voltage for varying durations (3, 5, 10, 30, and 50 s). Following plasma activation, the samples were immersed in a mixed solution of chloroform and 5 wt% PMEOx for 1 min via dip–coating. After removal from the solution, the samples were dried for 24 h under ambient conditions. Subsequently, the PMEOx–coated PTFE underwent a 3 s post-plasma treatment in ambient air at 15 kHz. During this process, the sample was placed in a holder mounted on a moving stage within the DCSBD chamber. Before plasma activation, the chamber was pumped and purged with Ar gas at a flow rate of 1.0 L·min−1 for 5 min [59]. The surface morphology and roughness were analyzed using atomic force microscopy (AFM) and scanning electron microscopy (SEM). The untreated PTFE exhibited a rough surface with a roughness of 25.8 nm (Figure 38c) [59]. In contrast, the PMEOx-deposited surface was notably smoother, with a roughness of 0.3 nm (Figure 38c(i)). After air plasma treatment, the surface roughness slightly increased to 0.7 nm, indicating minor surface modification compared to the untreated PMEOx layer (Figure 38c(iii)). Evidence of plasma–induced surface damage was observed on the air plasma–treated PMEOx layer (Figure 38c(i,iii). Despite plasma exposure and subsequent washing, both pristine and air plasma–treated PMEOx layers remained well adhered to the PTFE substrate, as shown in Figure 38c(ii,iv)) [59]. The raw PTFE exhibited high hydrophobicity due to the strong electronegativity of fluorine atoms, with a WCA of 105.6°. To facilitate PMEOx deposition, plasma treatment was applied to introduce reactive functional groups onto the PTFE surface. After 3 s of air plasma treatment, the WCA decreased from 105.6° to 93.9° (Figure 38d). With extended plasma exposure beyond 50 s, the WCA further decreased to 81.5°, the lowest observed value (Figure 38c). This reduction in WCA is attributed to the DCSBD system, which promotes surface functionalization by generating reactive species that disrupt chemical bonds, thereby forming new functional groups on the PTFE surface. The chemical structures of both the raw PMEOx powder and the air plasma-treated PMEOx film were analyzed using FT–IR spectroscopy. As shown in Figure 38e, the raw PMEOx powder displays a broad peak at 1624 cm−1 corresponding to amide functional groups and a peak at 1478 cm−1 associated with CH2 deformations within the polymer backbone. Additional features include a broad shoulder at 1450 cm−1 and a peak at 1360 cm−1, corresponding to asymmetric and symmetric CH3 deformations, respectively, along with a broad peak in the 1240–1200 cm−1 range attributed to C–N stretching vibrations. In the deposited PMEOx film, the amide peak shifts to 1645 cm−1, and a new peak at 1736 cm−1 appears, corresponding to C=O bonds. The POx film also exhibits new functional groups, such as isocyanates (2170 cm−1) and nitriles (2250 cm−1). As plasma treatment time increases, the intensity of these FT–IR peaks decreases, indicating that the upper layer of the PMEOx film undergoes etching during plasma exposure [59]. Consequently, plasma treatment not only modifies the chemical structure of the PMEOx film but also enables the formation of new functional groups on the underlying PTFE surface, enhancing its chemical reactivity and suitability for subsequent coating applications.

Figure 38.

(a) Experimental setup for PMEOx film plasma deposition and PTFE surface treatment. (b) Side view of DCSBD plasma device. (c) SEM images of (i) raw PTFE, (ii) PMEOx deposited on pre–treated PTFE, (iii) PMEOx on pre–treated PTFE post washing, and (iv) air plasma–treated PMEOx post washing. (d) WCA results of air plasma–treated PTFE after 28 d of storage. (e) FT–IR spectra of PMEOx powder, untreated PMEOx layer, and plasma–treated PMEOx layer after 3, 10, and 30 s exposure without washing. Reproduced with copyright permission from Ref. [59].

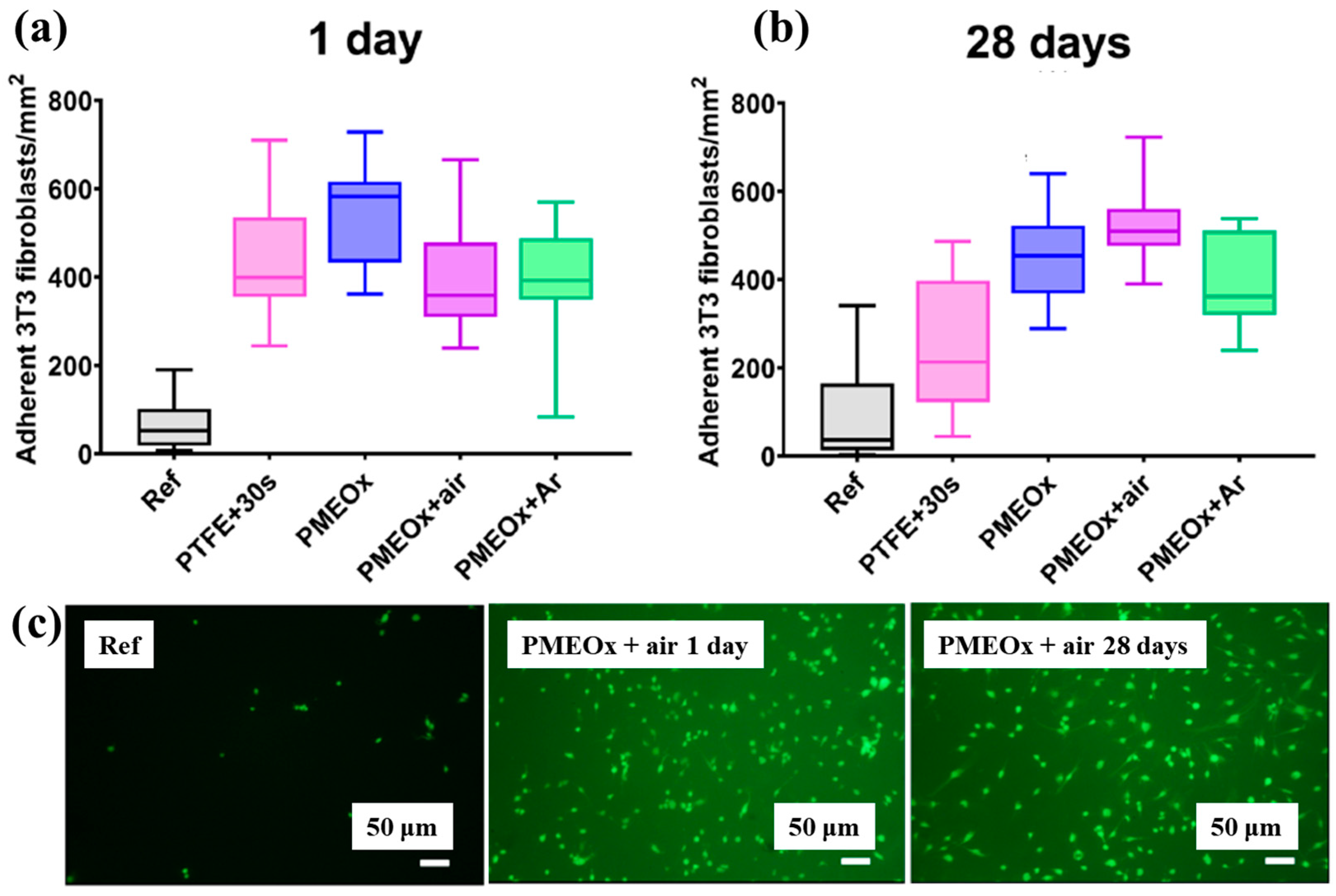

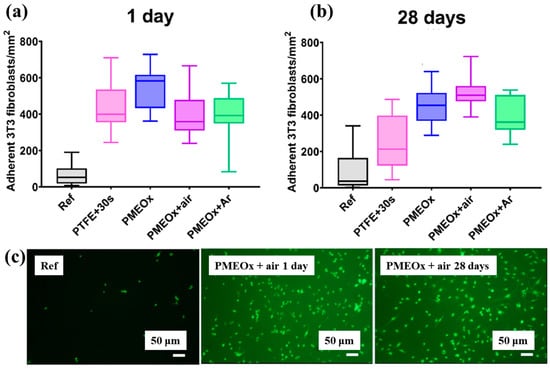

To assess biomaterial properties, this study examined the adhesion of mouse fibroblast cells (3T3). As shown in Figure 39a, the number of adherent fibroblasts after 1 d was relatively low on the untreated PTFE surface, with a median of 69 cells mm−2 [59]. In contrast, the air plasma–treated PTFE surface exhibited significantly enhanced adhesion, reaching 434 cells·mm−2, attributed to the introduction of polar functional groups via plasma treatment. After 28 d of storage, fibroblast adhesion further increased across all POx–coated samples, as illustrated in Figure 39b. To validate these adhesion properties, fluorescence imaging of adherent cells was conducted. Figure 39c confirms that, even after 28 d of storage, the cell–adhesive properties remained stable, owing to the durable formation of the POx layer on the air plasma-treated PTFE surface [59]. Table 26 summarizes the experimental surface treatments and bacterial results presented in Figure 38 and Figure 39.

Figure 39.

Adhesion of fibroblasts (3T3) on PTFE and POx surfaces after 1 d of incubation. Density of adherent cells (a) 1 d post preparation and (b) after 30 d of aging. (c) Fluorescence images of adherent cells stained with FDA (scale bar: 50 μm). Reproduced with copyright permission from Ref. [59].

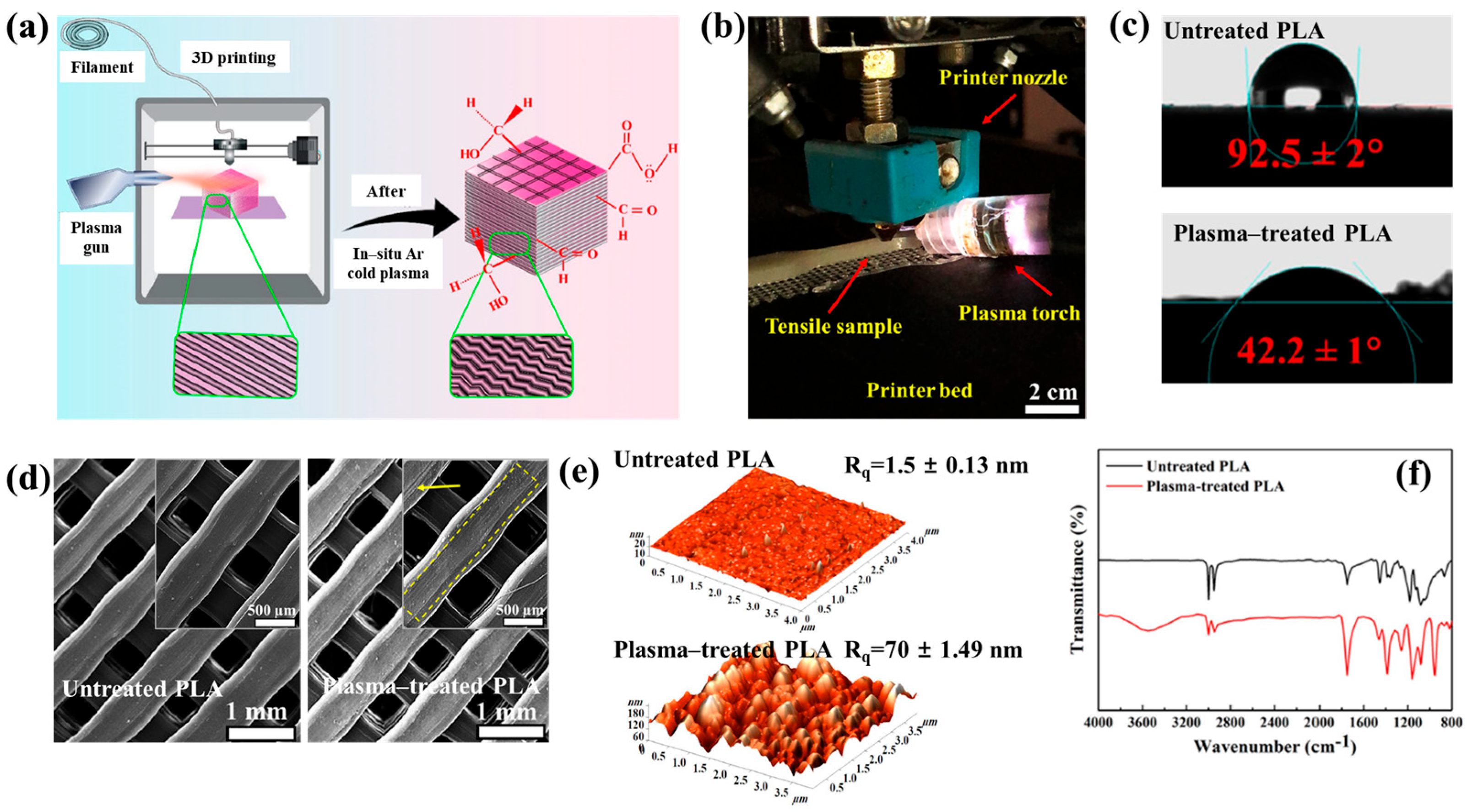

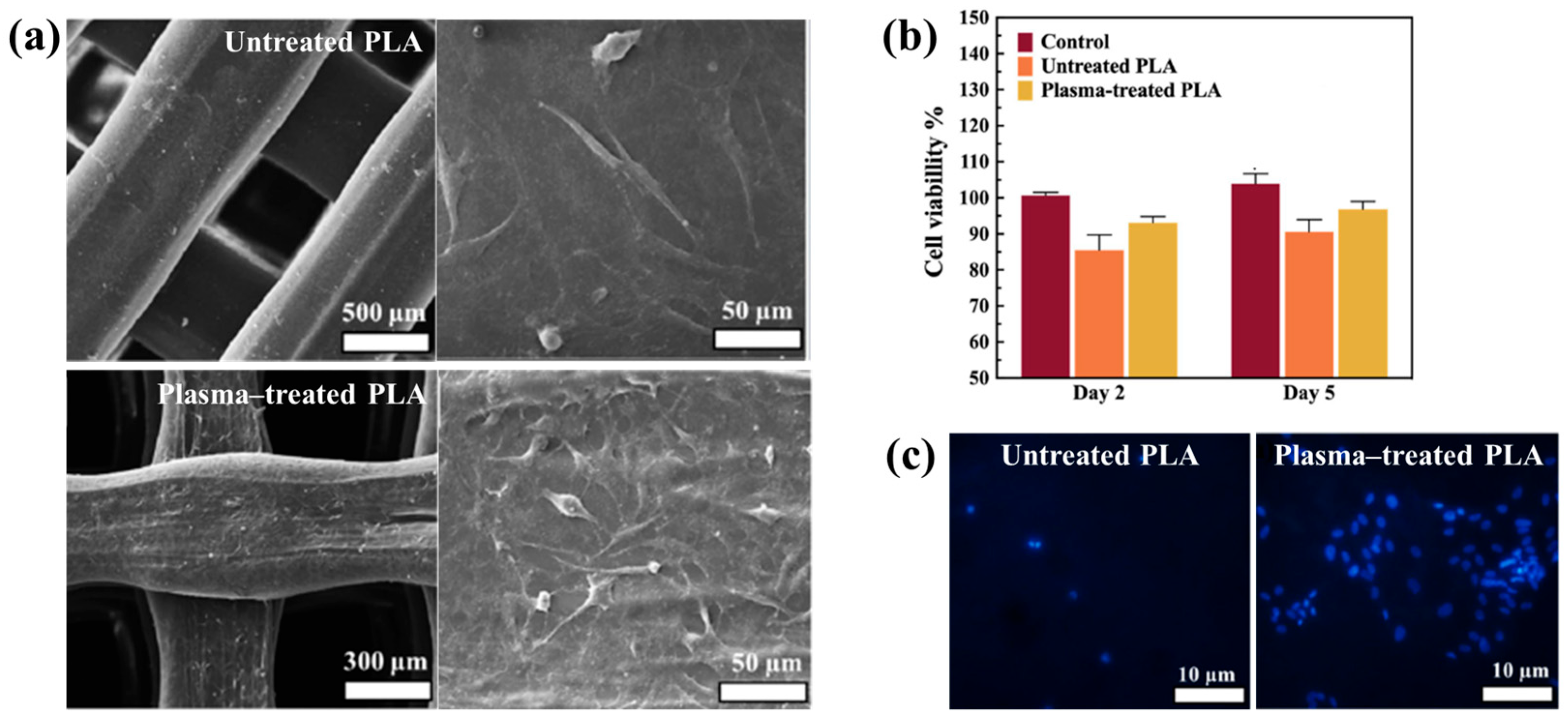

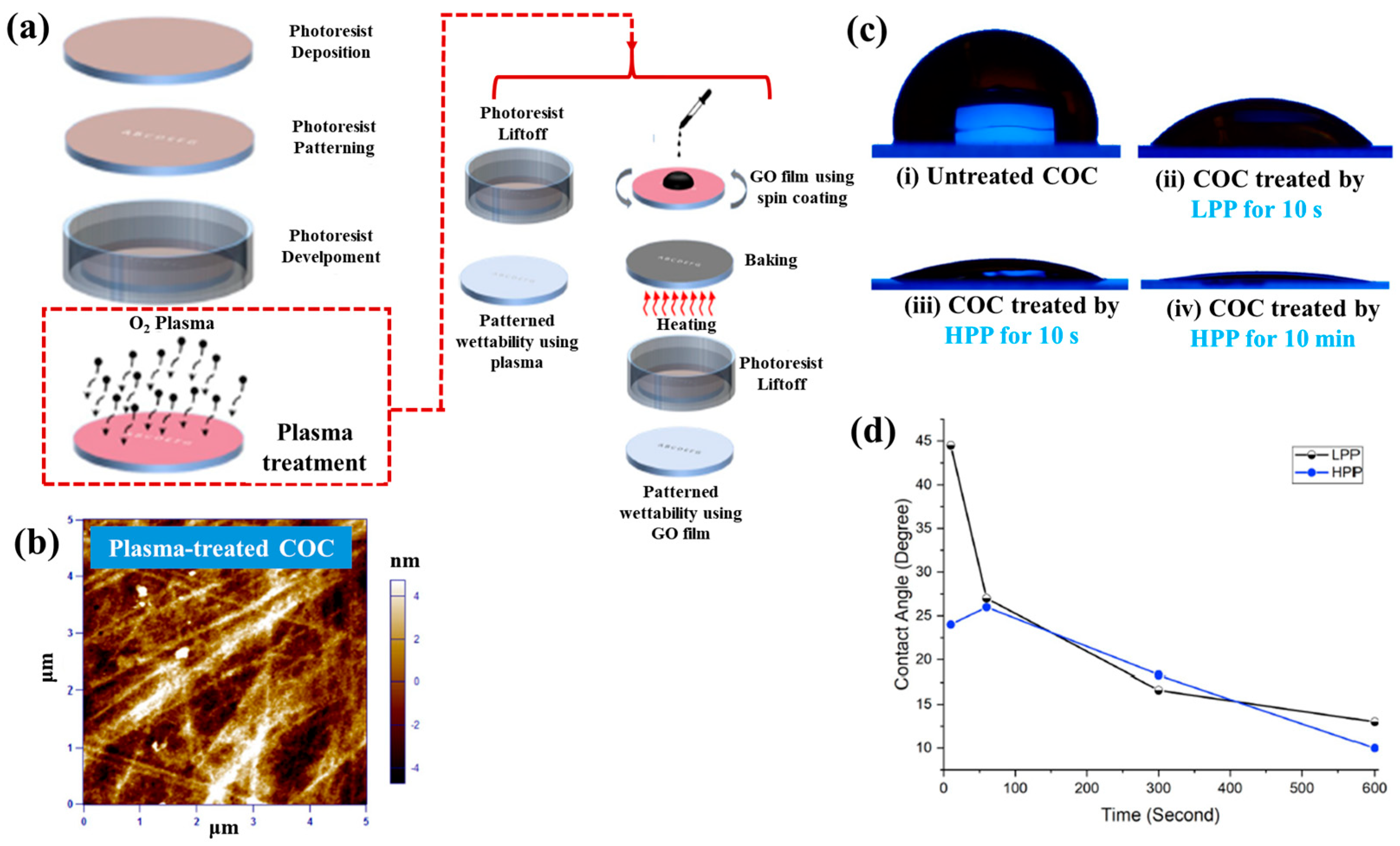

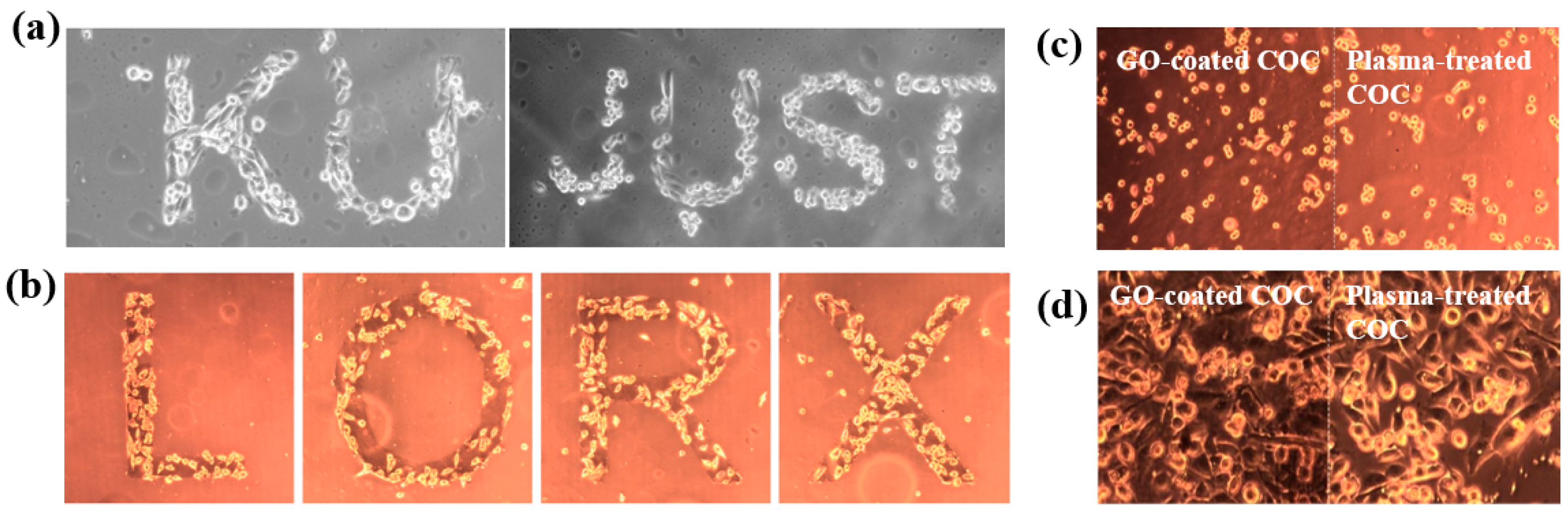

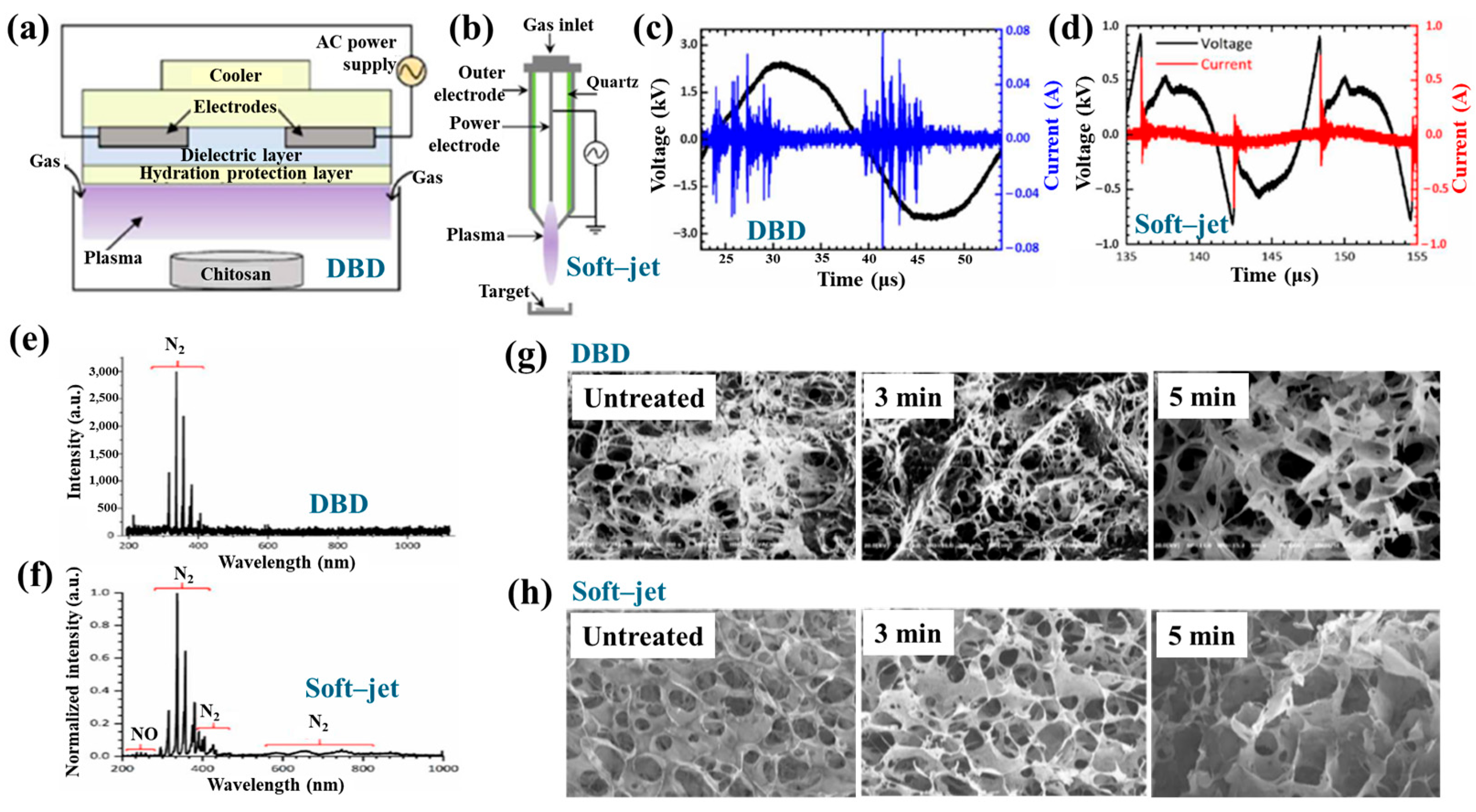

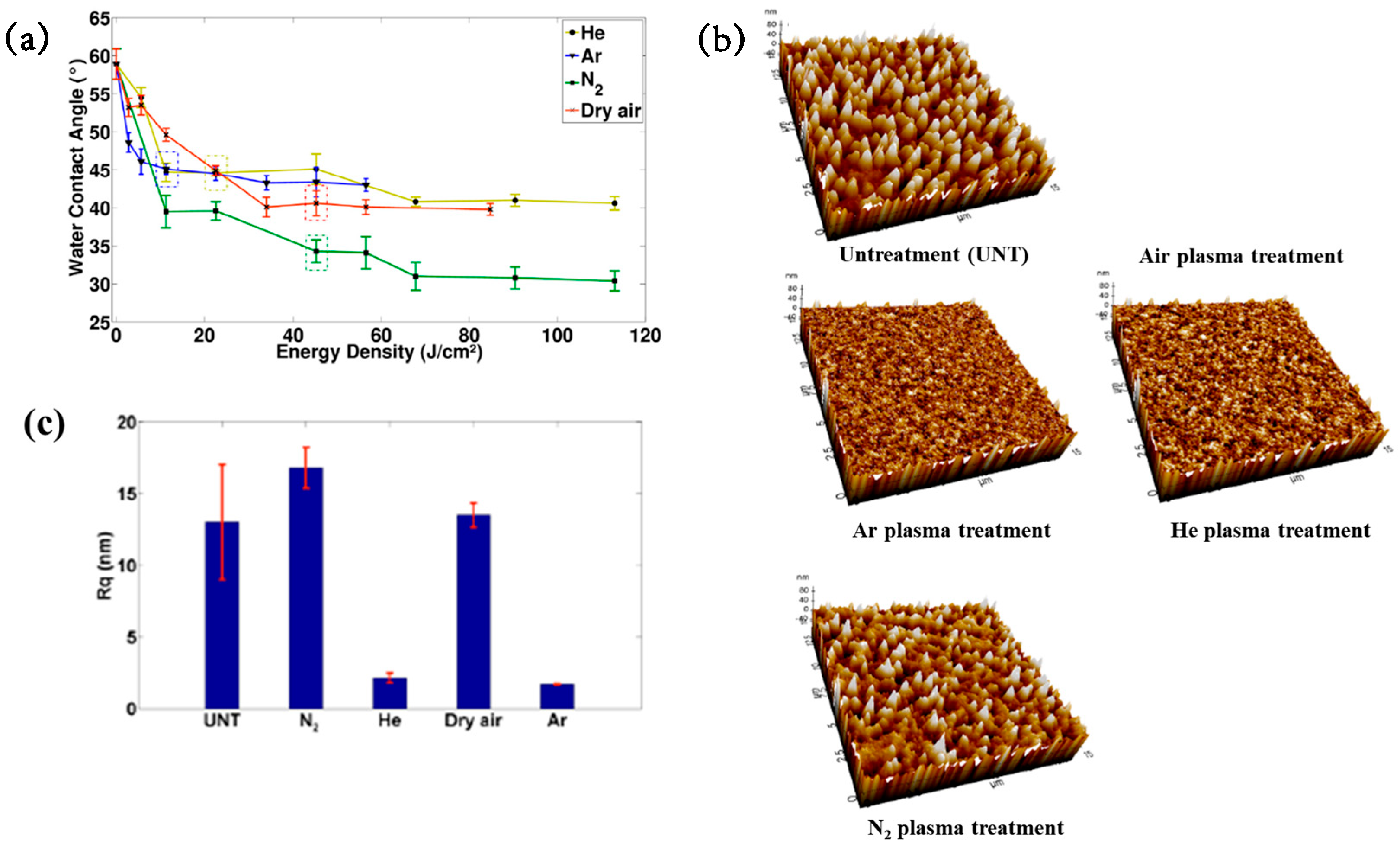

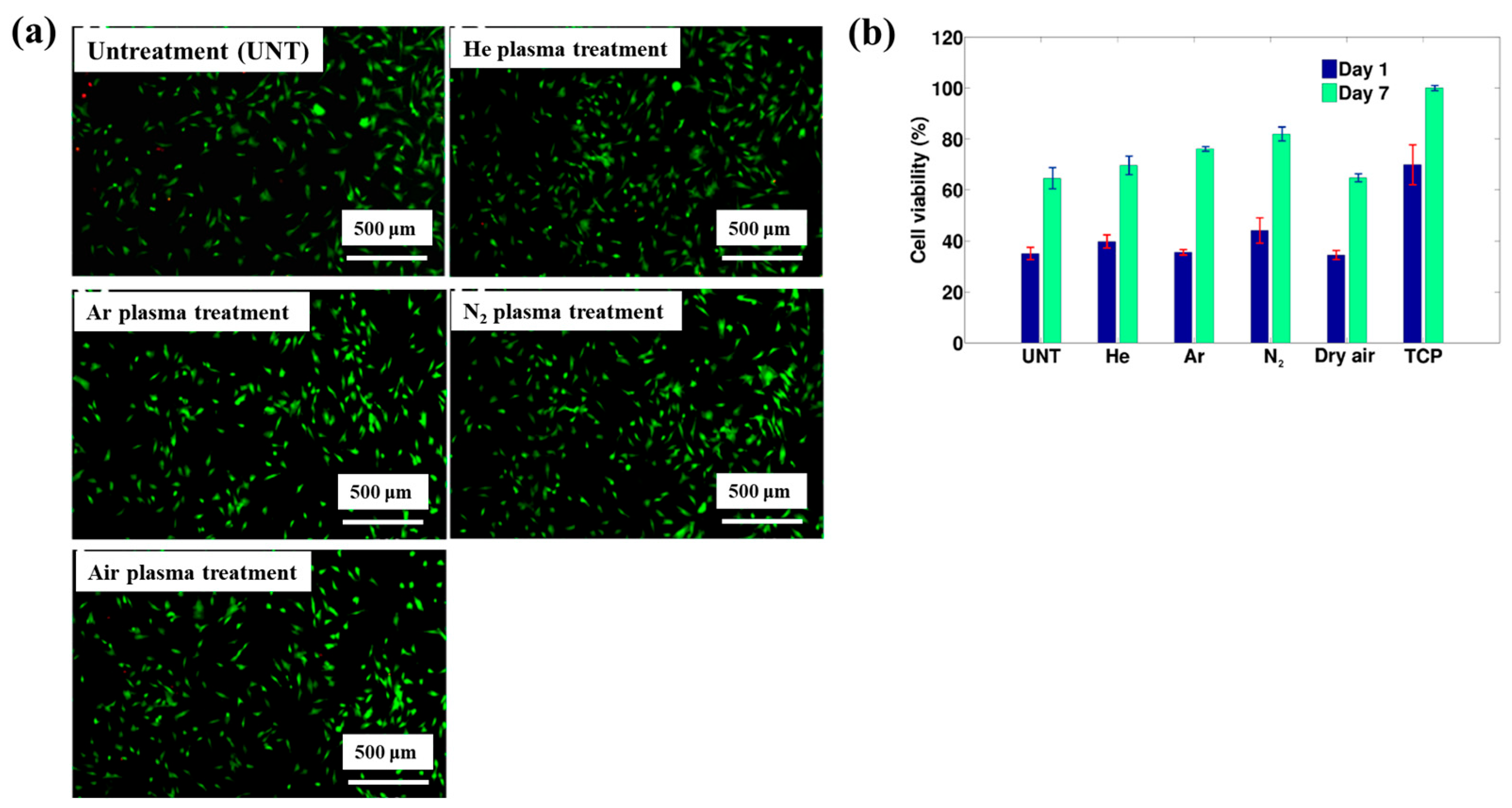

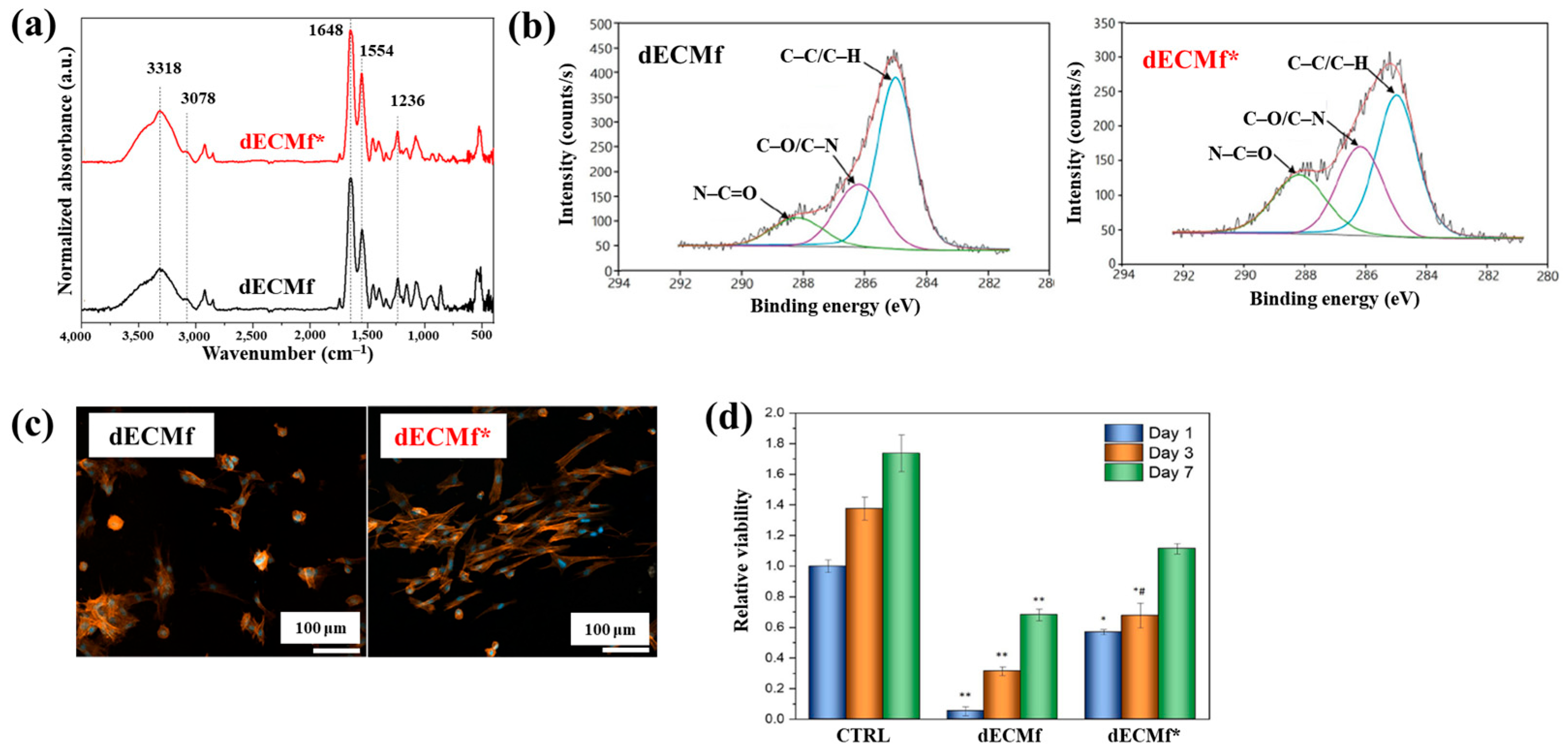

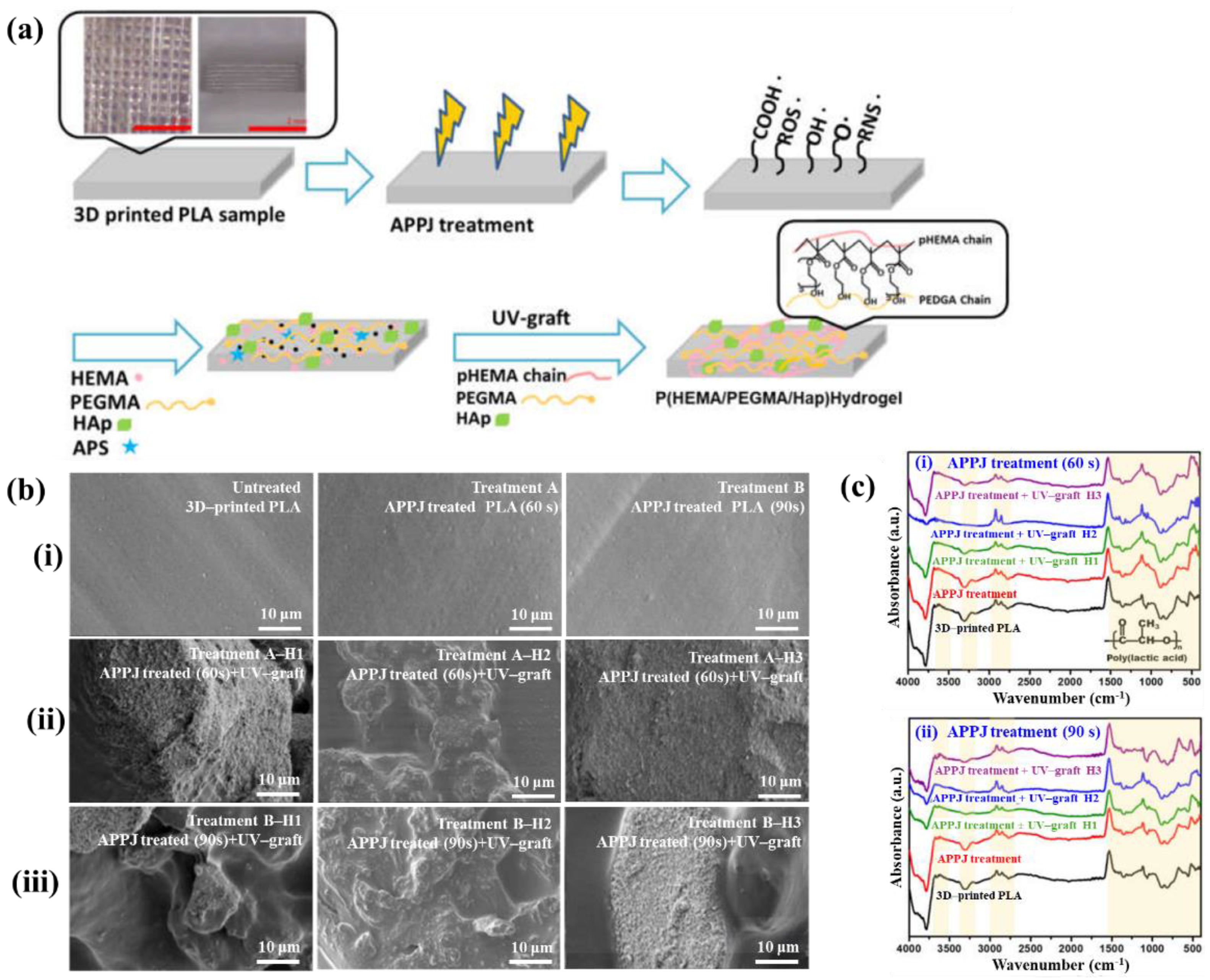

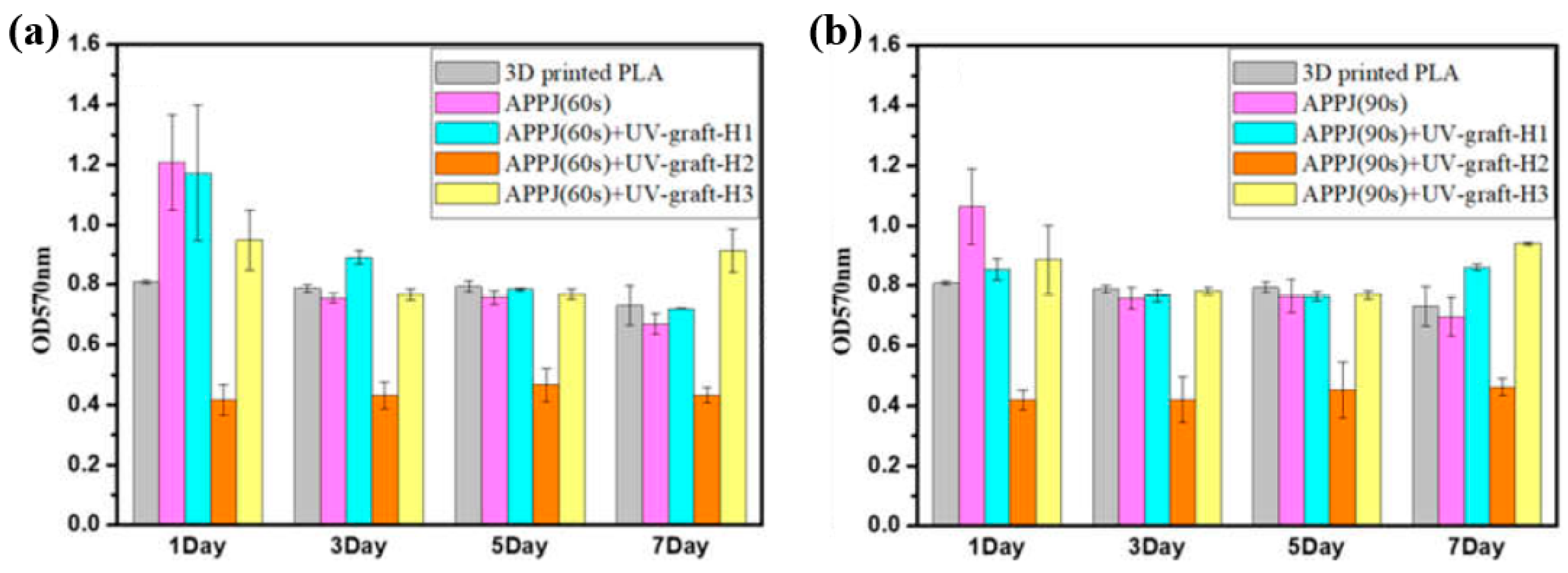

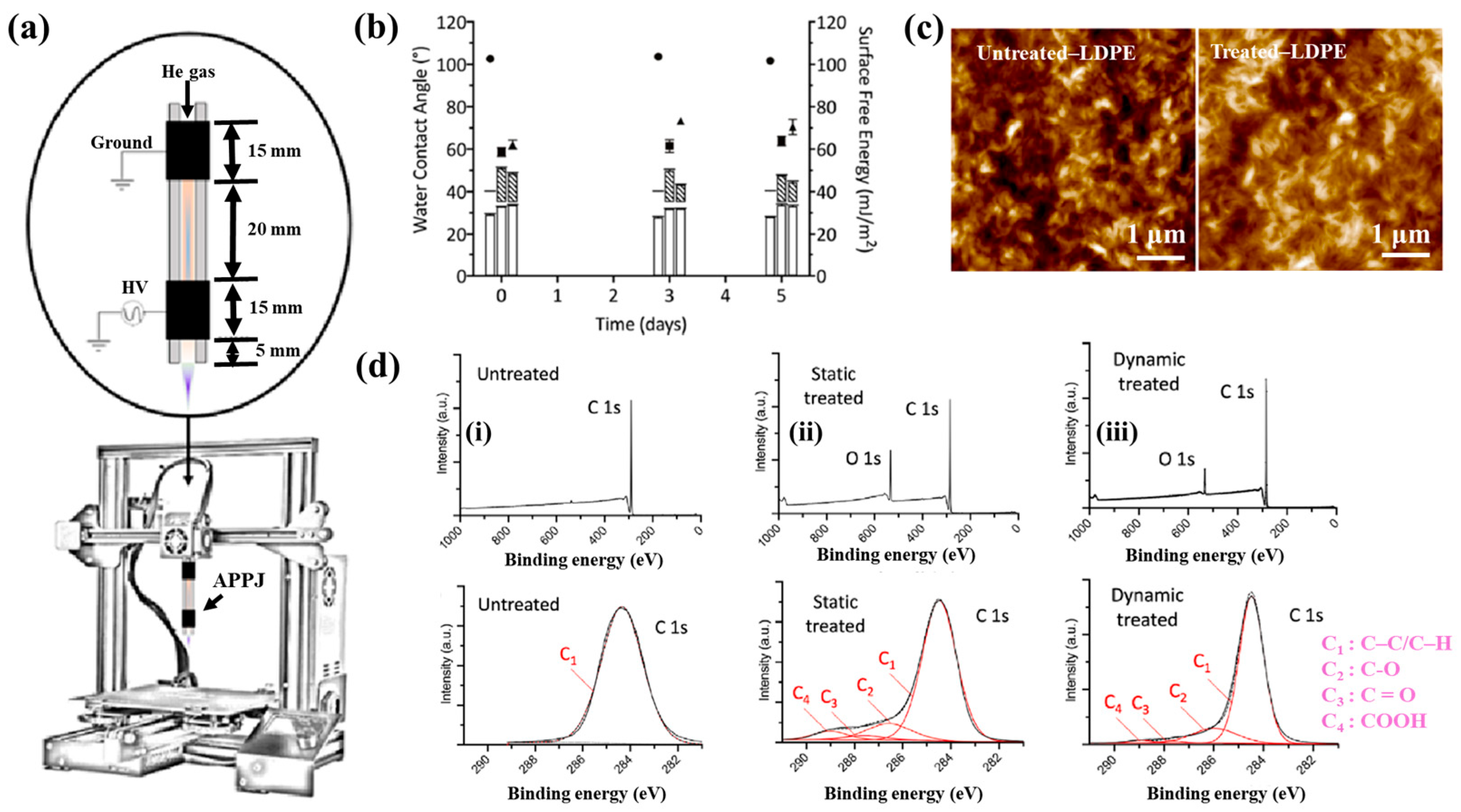

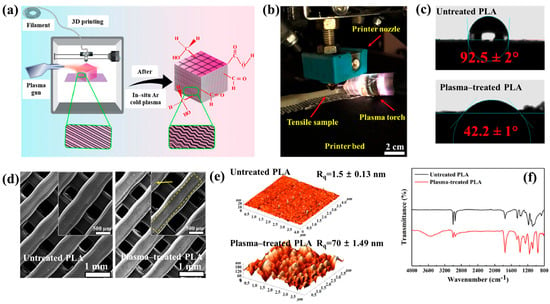

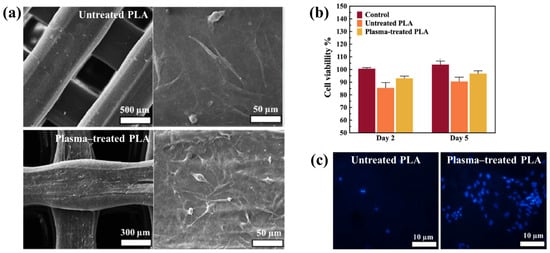

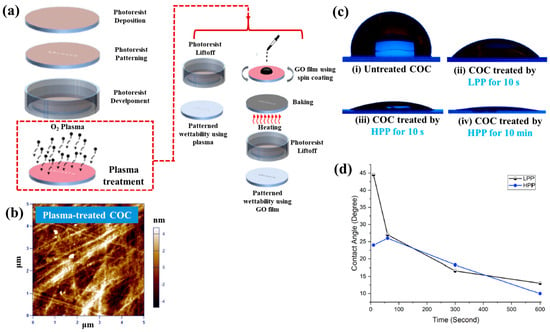

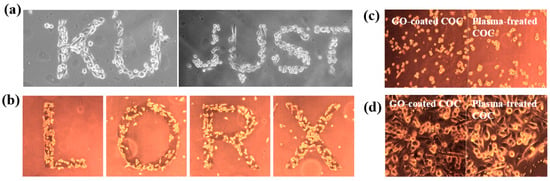

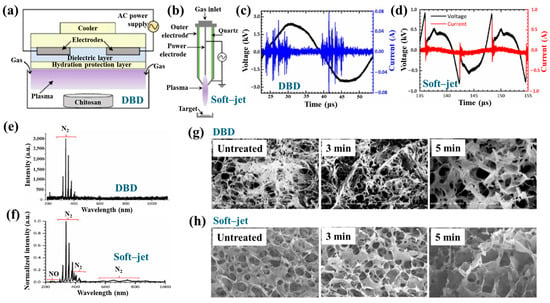

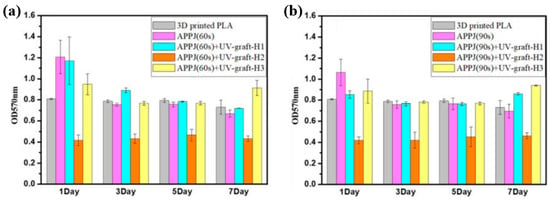

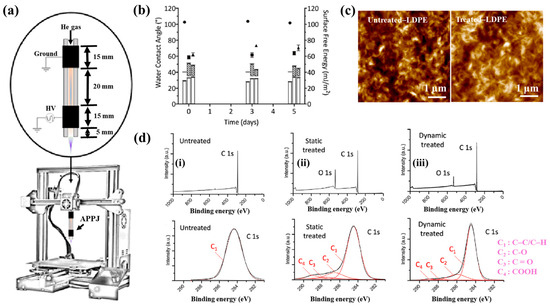

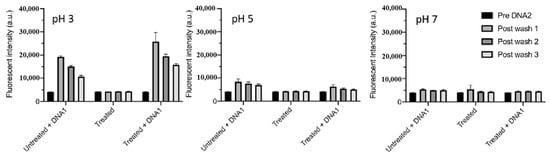

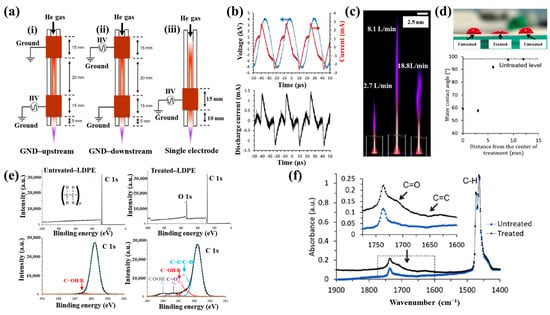

Figure 40a,b present a schematic diagram and photograph of 3D-printed polylactic acid (PLA) treated using an in situ Ar APP system developed by Zarei et al. [60].

Figure 40.

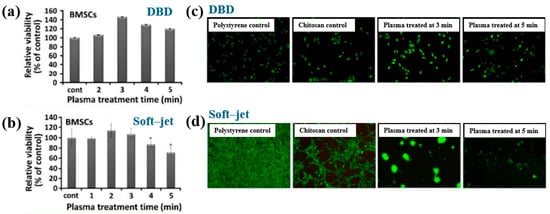

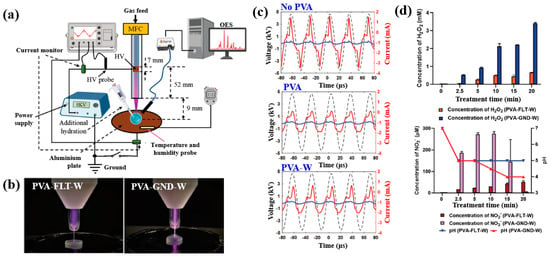

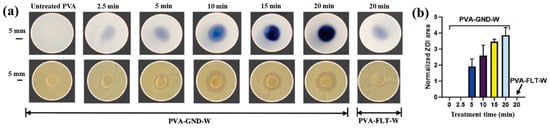

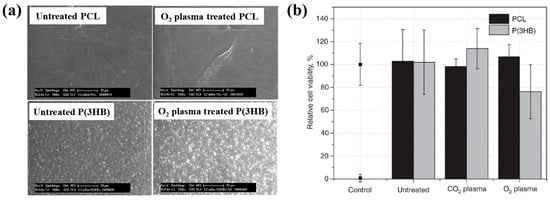

(a) Schematic of 3D–printed PLA scaffold treatment with in situ Ar APP system, adapted from Zarei et al. (b) Photographic image of plasma–treated scaffold. (c) WCA, (d) FE–SEM images, (e) AFM images, and (f) FT–IR spectra of untreated and plasma–treated PLA scaffolds. Reproduced with copyright permission from Ref. [60].