Study of the Mechanical Recycling on the Properties of Glass Fiber-Reinforced Aliphatic Polyketone Composites

Abstract

1. Introduction

2. Materials

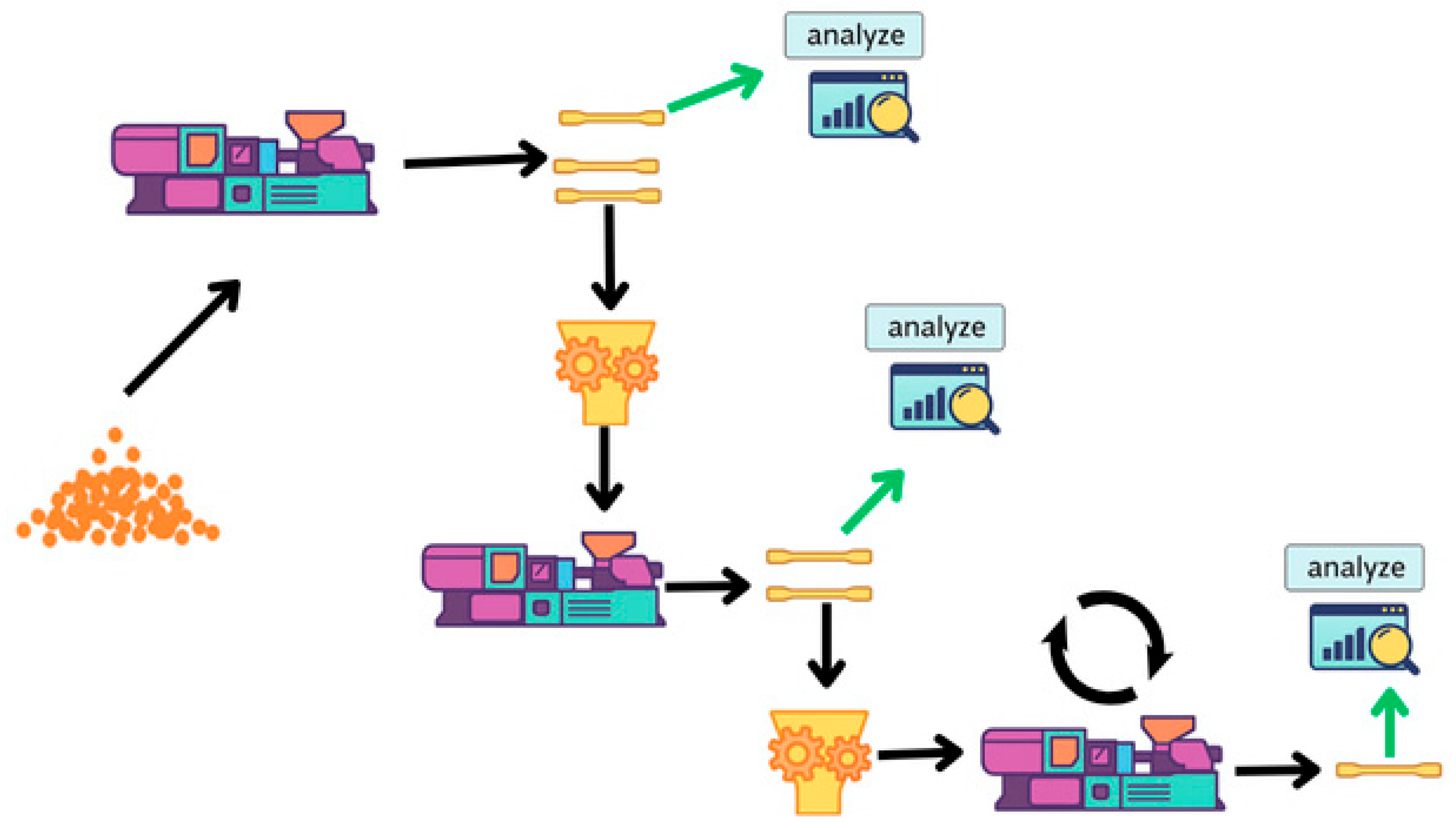

2.1. Preparation of the References and Recycled PK-GF15 and PK-GF30 Composite Samples

2.2. Methods

3. Results and Discussion

3.1. Thermogravimetric Analysis of Virgin and Recycled PK-GF Composites

3.2. Differential Scanning Calorimetry (DSC) of Virgin and Recycled PK-GF Composites

3.3. Dynamic Mechanical Analysis of Virgin and Recycled PK/GF Composites

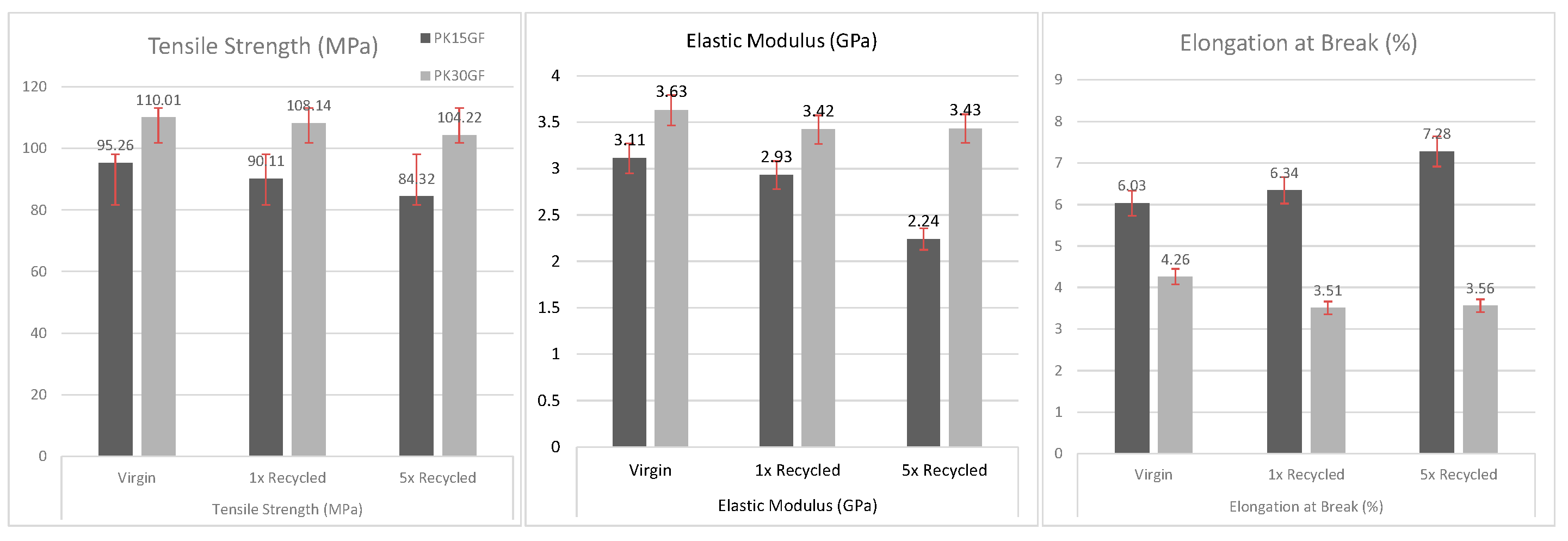

3.4. Mechanical Behavior of Recycled PK-15GF and PK-30GF Composites

3.5. Melt Flow Property of Recycled PK-15GF and PK-30GF

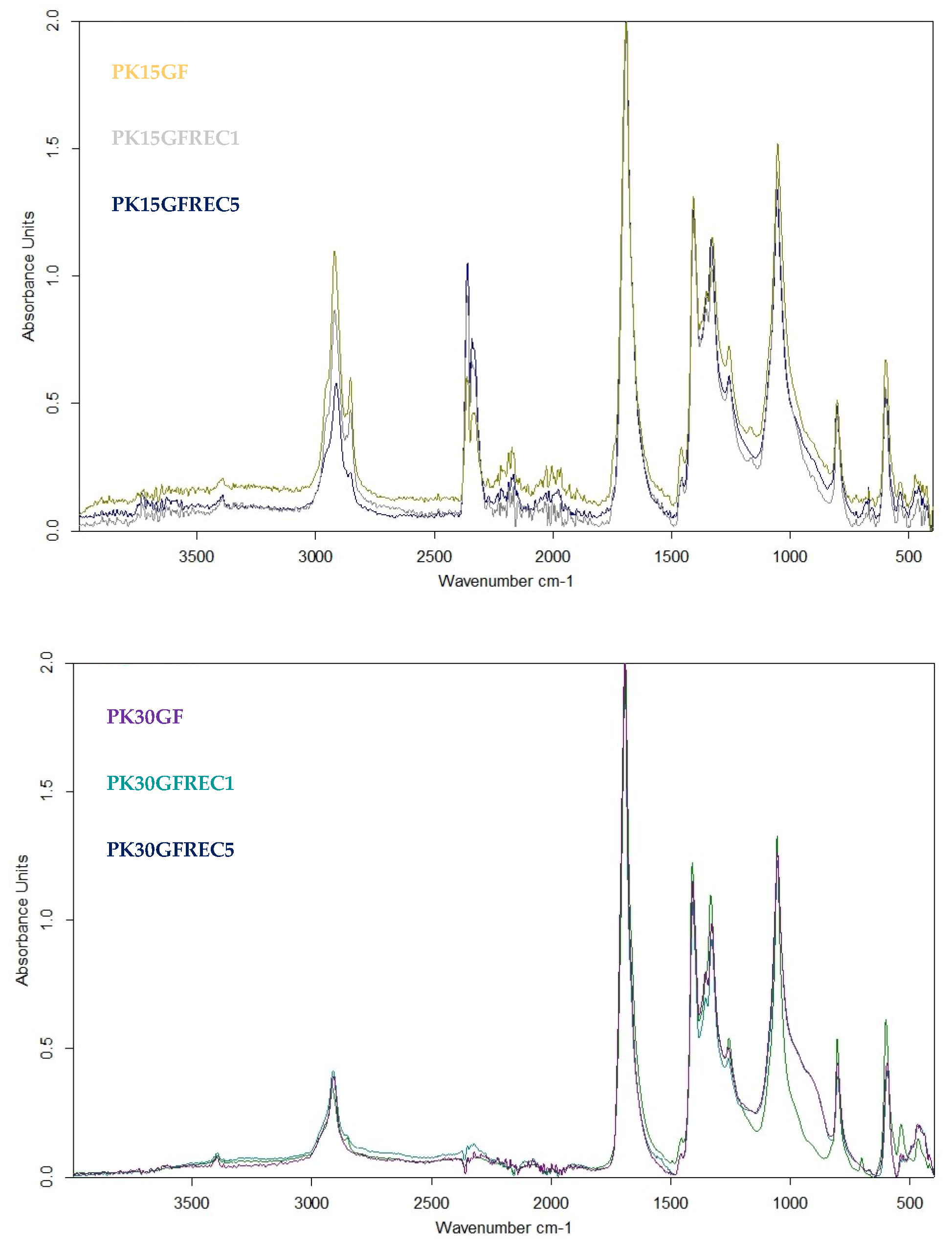

3.6. FT-IR Characterization of PK-15GF and PK-30GF

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- van den Tempel, P.; Picchioni, F. Polymer Recycling: A Comprehensive Overview and Future Outlook. Recycling 2025, 10, 1. [Google Scholar] [CrossRef]

- Lamtai, A.; Elkoun, S.; Robert, M.; Mighri, F.; Diez, C. Mechanical Recycling of Thermoplastics: A Review of Key Issues. Waste 2023, 1, 860–883. [Google Scholar] [CrossRef]

- Zhang, W.; Shen, J.; Guo, X.; Wang, K.; Jia, J.; Zhao, J.; Zhang, J. Comprehensive Investigation into the Impact of Degradation of Recycled Polyethylene and Recycled Polypropylene on the Thermo-Mechanical Characteristics and Thermal Stability of Blends. Molecules 2024, 29, 4499. [Google Scholar] [CrossRef]

- Shubhra, Q.T.H.; Alam, A.; Quaiyyum, M.A. Mechanical properties of polypropylene composites: A review. J. Thermoplast. Compos. Mater. 2013, 26, 362–391. [Google Scholar] [CrossRef]

- Alshammari, B.A.; Alsuhybani, M.S.; Almushaikeh, A.M.; Alotaibi, B.M.; Alenad, A.M.; Alqahtani, N.B.; Alharbi, A.G. Comprehensive Review of the Properties and Modifications of Carbon Fiber-Reinforced Thermoplastic Composites. Polymers 2021, 13, 2474. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.; Ahmed, W.; Arshad, H. Recent trends in recycling and reusing techniques of different plastic polymers and their composite materials. Sustain. Mater. Technol. 2021, 31, e00382. [Google Scholar] [CrossRef]

- Vavasori, A.; Ronchin, L. Polyketones: Synthesis and Applications. In Encyclopedia of Polymer Science and Technology; John Wiley & Sons, Ltd.: London, UK, 2017; pp. 1–41. [Google Scholar] [CrossRef]

- Unni, A.B.; Joseph, T.M. Enhancing Polymer Sustainability: Eco-Conscious Strategies. Polymers 2024, 16, 1769. [Google Scholar] [CrossRef] [PubMed]

- Drent, E.; Van Broekhoven, J.A.M.; Doyle, M.J. Efficient palladium catalysts for the copolymerization of carbon monoxide with olefins to produce perfectly alternating polyketones. J. Organomet. Chem. 1991, 417, 235–251. [Google Scholar] [CrossRef]

- Ohsawa, O.; Lee, K.-H.; Kim, B.-S.; Lee, S.; Kim, I.-S. Preparation and characterization of polyketone (PK) fibrous membrane via electrospinning. Polymer 2010, 51, 2007–2012. [Google Scholar] [CrossRef]

- Xiao, X.; Zheng, H.; Gao, H.; Cheng, Z.; Feng, C.; Yang, J.; Gao, H. Recent Advances in Synthesis of Non-Alternating Polyketone Generated by Copolymerization of Carbon Monoxide and Ethylene. Int. J. Mol. Sci. 2024, 25, 1348. [Google Scholar] [CrossRef]

- Lu, T.; Solis-Ramos, E.; Yi, Y.; Kumosa, M. UV degradation model for polymers and polymer matrix composites. Polym. Degrad. Stab. 2018, 154, 203–210. [Google Scholar] [CrossRef]

- El-Aidy, K.E.; Ellithy, M.; Mahmoud, M.H.; El-Shafiey, T.F. Mechanical and physical properties of eco-friendly recycled plastic concrete (RPC). J. Build. Eng. 2024, 97, 110907. [Google Scholar] [CrossRef]

- Qu, T.; Nan, G.; Ouyang, Y.; Bieketuerxun, B.; Yan, X.; Qi, Y.; Zhang, Y. Structure–Property Relationship, Glass Transition, and Crystallization Behaviors of Conjugated Polymers. Polymers 2023, 15, 4268. [Google Scholar] [CrossRef] [PubMed]

- Gradys, A.; Sajkiewicz, P.; Minakov, A.; Adamovsky, S.; Schick, C.; Hashimoto, T.; Saijo, K. Crystallization of polypropylene at various cooling rates. Mater. Sci. Eng. A 2005, 413–414, 442–446. [Google Scholar] [CrossRef]

- Smaardijk, A.A.; Drent, E. Polyketones: Aliphatic. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P., Eds.; Elsevier: Oxford, UK, 2001; pp. 7194–7196. [Google Scholar] [CrossRef]

- Yang, Y.; Li, S.; Bao, R.; Liu, Z.; Yang, M.; Tan, C.; Yang, W. Progress in polyketone materials: Blends and composites. Polym. Int. 2018, 67, 1478–1487. [Google Scholar] [CrossRef]

- Yıldız, C.; Seki, Y.; Ekti, M.; Aker, S.; Leskeri, B.M.; Sarikanat, M.; Altay, L. Improving Flame Retardant Properties of Aliphatic Polyketone (POK)-Based Composites. ACS Omega 2023, 8, 9415–9422. [Google Scholar] [CrossRef] [PubMed]

- Zuiderduin, W.C.J.; Homminga, D.S.; Huétink, H.J.; Gaymans, R.J. Influence of molecular weight on the fracture properties of aliphatic polyketone terpolymers. Polymer 2003, 44, 6361–6370. [Google Scholar] [CrossRef]

- Cho, J.; Lee, S.-K.; Eem, S.-H.; Jang, J.G.; Yang, B. Enhanced mechanical and thermal properties of carbon fiber-reinforced thermoplastic polyketone composites. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105599. [Google Scholar] [CrossRef]

- You, J.; Lee, Y.M.; Choi, H.-H.; Kim, T.A.; Lee, S.-S.; Park, J.H. Thermally stable and highly recyclable carbon fiber-reinforced polyketone composites based on mechanochemical bond formation. Compos. Part A Appl. Sci. Manuf. 2021, 142, 106251. [Google Scholar] [CrossRef]

- Kovács, A.P.; Hajialilou, S.; Tomin, M.; Minale, Y.F.; Gyore, B.; Szabó, T.J. Investigation of Behavior of Aliphatic Polyketone under the Effects of Recycling and UV. Solid State Phenom. 2025, 371, 25–35. [Google Scholar] [CrossRef]

- Cho, S.; Lee, J.S.; Jang, H.; Park, S.; An, J.H.; Jang, J. Comparative Studies on Crystallinity, Thermal and Mechanical Properties of Polyketone Grown on Plasma Treated CVD Graphene. Polymers 2021, 13, 919. [Google Scholar] [CrossRef] [PubMed]

- ISO 20753:2018; Plastics—Test Specimens. International Organization for Standardization: Geneva, Switzerland, 2018.

- Nurazzi, N.M.; Asyraf, M.R.M.; Rayung, M.; Norrrahim, M.N.F.; Shazleen, S.S.; Rani, M.S.A.; Shafi, A.R.; Aisyah, H.A.; Radzi, M.H.M.; Sabaruddin, F.A.; et al. Thermogravimetric Analysis Properties of Cellulosic Natural Fiber Polymer Composites: A Review on Influence of Chemical Treatments. Polymers 2021, 13, 2710. [Google Scholar] [CrossRef] [PubMed]

- ISO 527-1:2019; Plastics—Determination of Tensile Properties—Part 1: General Principles. International Organization for Standardization (ISO): Geneva, Switzerland, 2019.

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- Yoshida, H. Dynamic analysis of the melting behavior of polymers showing polymorphism observed by simultaneous DSC/X-ray diffraction measurements. Thermochim. Acta 1995, 267, 239–248. [Google Scholar] [CrossRef]

- ISO 1133-1:2022; Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics—Part 1: Standard Method. International Organization for Standardization (ISO): Geneva, Switzerland, 2022.

- Beaumont, J.P. 2—Rheology and Melt Flow in an Injection Mold. In Runner and Gating Design Handbook, 3rd ed.; Beaumont, J.P., Ed.; Hanser: New York, NY, USA, 2019; pp. 7–32. [Google Scholar] [CrossRef]

- Dewi, R.; Sylvia, N.; Zulnazri; Riza, M. Melt flow Index (MFI) analysis of sago based thermoplastic starch blend with polypropylene and polyethylene. Mater. Today Proc. 2023, 87, 396–400. [Google Scholar] [CrossRef]

- Kizil, R.; Irudayaraj, J. Chapter 6—Spectroscopic Technique: Fourier Transform Raman (FT-Raman) Spectroscopy. In Modern Techniques for Food Authentication, 2nd ed.; Sun, D.-W., Ed.; Academic Press: New York, NY, USA, 2018; pp. 193–217. [Google Scholar] [CrossRef]

- Baltes, L.; Costiuc, L.; Patachia, S.; Tierean, M. Differential scanning calorimetry—A powerful tool for the determination of morphological features of the recycled polypropylene. J. Therm. Anal. Calorim. 2019, 138, 2399–2408. [Google Scholar] [CrossRef]

- Amor, I.B.; Klinkova, O.; Baklouti, M.; Elleuch, R.; Tawfiq, I. Mechanical Recycling and Its Effects on the Physical and Mechanical Properties of Polyamides. Polymers 2023, 15, 4561. [Google Scholar] [CrossRef]

- Diego, S.; Casado, J.; Carrascal, I.; Sainz-Aja, J.; Ferreño, D. Mechanical Performance of Recycled Reinforced Polyamide from Rejected Railway Fastenings Flanged Plates. Polymers 2022, 14, 4940. [Google Scholar] [CrossRef]

- Lin, H.; Pearson, A.; Kazemi, Y.; Kakroodi, A.; Hammami, A.; Heydrich, M.; Xu, B.; Naguib, H.E. Influence of hygrothermal conditioning on the chemical structure and thermal mechanical properties of aliphatic polyketone. Polym. Degrad. Stab. 2020, 179, 109260. [Google Scholar] [CrossRef]

| Sample Code | Material Content and Description |

|---|---|

| PK15GF | Original virgin granules of polyketone with 15% glass fiber content |

| PK15REC1 | 100% 1 cycled recycled polyketone with 15% glass fiber content |

| PK15REC5 | 100% 5 cycled recycled polyketone with 15% glass fiber content |

| PK30GF | Original virgin granules of polyketone with 30% glass fiber content |

| PK30REC1 | 100% 1 cycled recycled polyketone with 30% glass fiber content |

| PK30REC5 | 100% 5 cycled recycled polyketone with 30% glass fiber content |

| Sample | T5 a (°C) | T10 b (°C) | T50 c (°C) | Tmax (°C) | d Char Residue |

|---|---|---|---|---|---|

| PK15GF | 374.16 | 382.25 | 456.22 | 410.81 | 55.62 |

| PK15GFREC1 | 372.33 | 382.72 | - | 402.37 | 44.15 |

| PK15GFREC5 | 369.73 | 379.24 | 552.13 | 397.96 | 52.83 |

| PK30GF | 372.21 | 384.75 | - | 405.65 | 45.61 |

| PK30GFREC1 | 365.82 | 379.81 | - | 382.61 | 43.44 |

| PK30GFREC5 | 358.34 | 371.50 | 444.21 | 397.63 | 62.42 |

| Sample | Tm (°C) | ΔHm (J·g−1) | Xc (%) |

|---|---|---|---|

| PK15GF | 217.98 | 117.60 | 58.80 |

| PK15GF1REC | 214.97 | 60.18 | 30.09 |

| PK15GF5REC | 212.26 | 48.35 | 24.18 |

| PK30GF | 218.28 | 45.14 | 22.57 |

| PK30GF1REC | 215.36 | 43.28 | 21.64 |

| PK30GF5REC | 211.35 | 31.21 | 15.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kovács, A.P.; Firew Minale, Y.; Hegedűs, M.É.; Szabó, T.J. Study of the Mechanical Recycling on the Properties of Glass Fiber-Reinforced Aliphatic Polyketone Composites. Polymers 2025, 17, 2743. https://doi.org/10.3390/polym17202743

Kovács AP, Firew Minale Y, Hegedűs MÉ, Szabó TJ. Study of the Mechanical Recycling on the Properties of Glass Fiber-Reinforced Aliphatic Polyketone Composites. Polymers. 2025; 17(20):2743. https://doi.org/10.3390/polym17202743

Chicago/Turabian StyleKovács, Annamária Polyákné, Yitbarek Firew Minale, Mariann Éva Hegedűs, and Tamás József Szabó. 2025. "Study of the Mechanical Recycling on the Properties of Glass Fiber-Reinforced Aliphatic Polyketone Composites" Polymers 17, no. 20: 2743. https://doi.org/10.3390/polym17202743

APA StyleKovács, A. P., Firew Minale, Y., Hegedűs, M. É., & Szabó, T. J. (2025). Study of the Mechanical Recycling on the Properties of Glass Fiber-Reinforced Aliphatic Polyketone Composites. Polymers, 17(20), 2743. https://doi.org/10.3390/polym17202743