Effect of PEG-600 Incorporation on the Mechanical and Thermal Response of Tunable Fiber-Reinforced Shape Memory Polymer Composites

Abstract

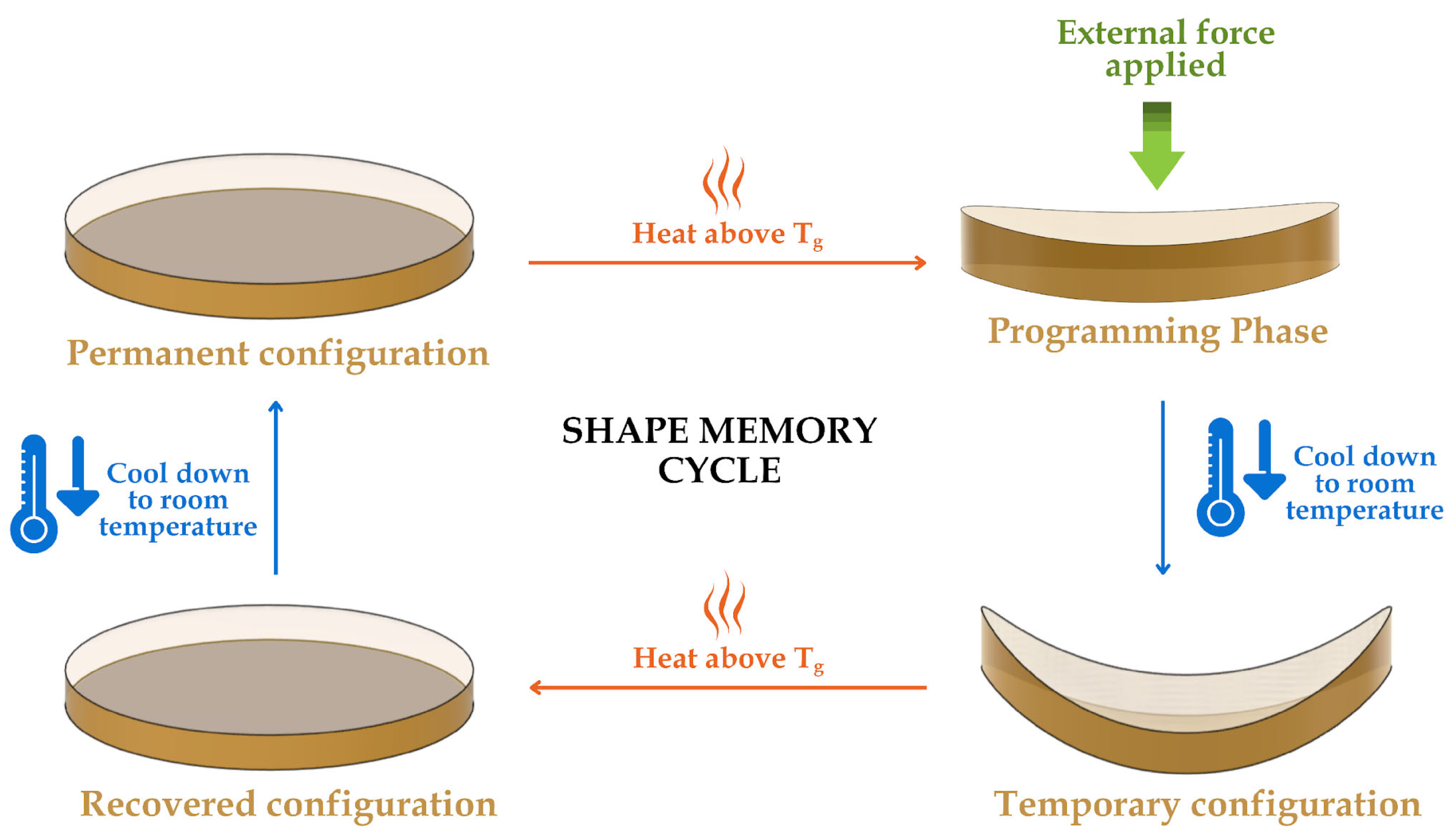

1. Introduction

2. Materials and Methods

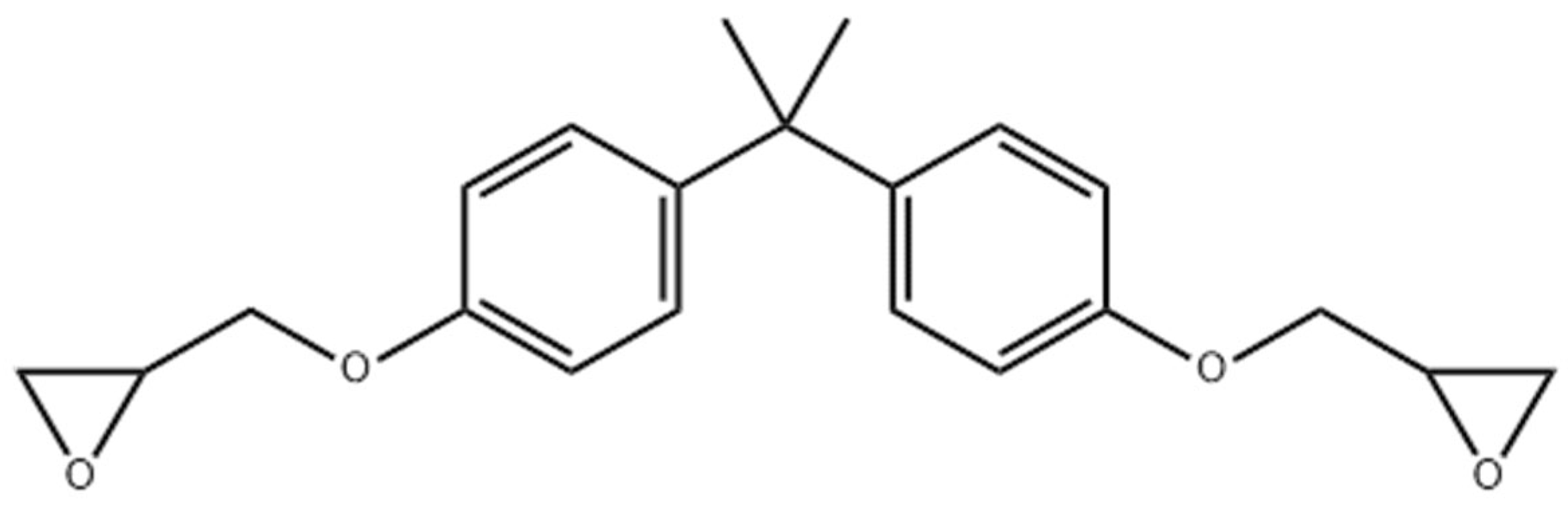

2.1. Material Specifications

2.2. Fabrication of SMPCs

2.2.1. Formation of Sheet-Metal Molds

2.2.2. Preparation of SMP Matrix

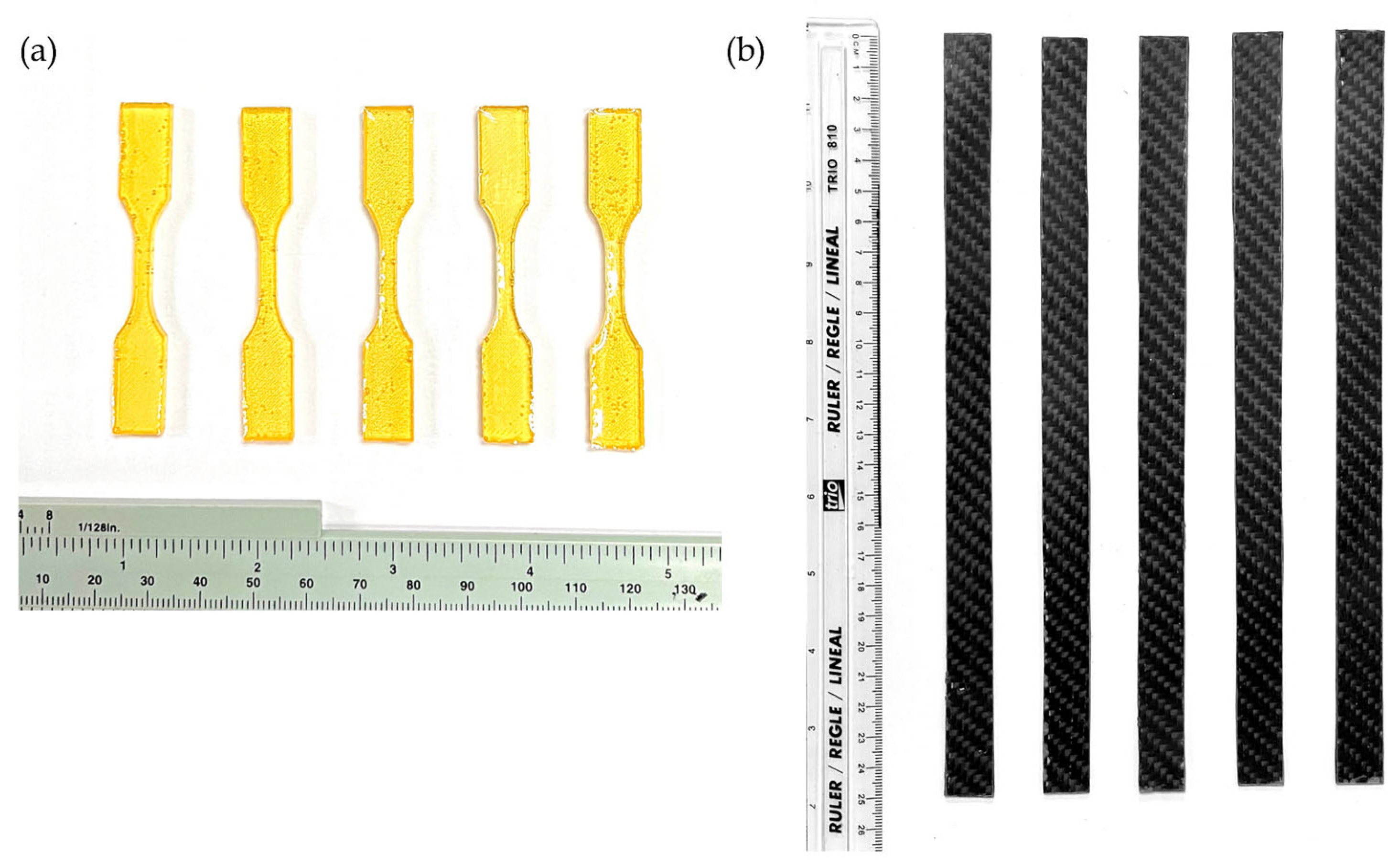

2.2.3. Addition of Carbon–Aramid Fiber Reinforcement

2.2.4. SMPC Curing and Programming

2.3. Material Characterization

2.3.1. Dynamic Mechanical Analysis (DMA)

2.3.2. Fourier Transform Infrared Spectroscopy (FTIR)

2.4. Mechanical Characterization

2.4.1. Uniaxial Tensile Testing

2.4.2. ANSYS Simulations

2.5. Shape Memory Behavior Tests

3. Results and Discussion

3.1. Material Characterization

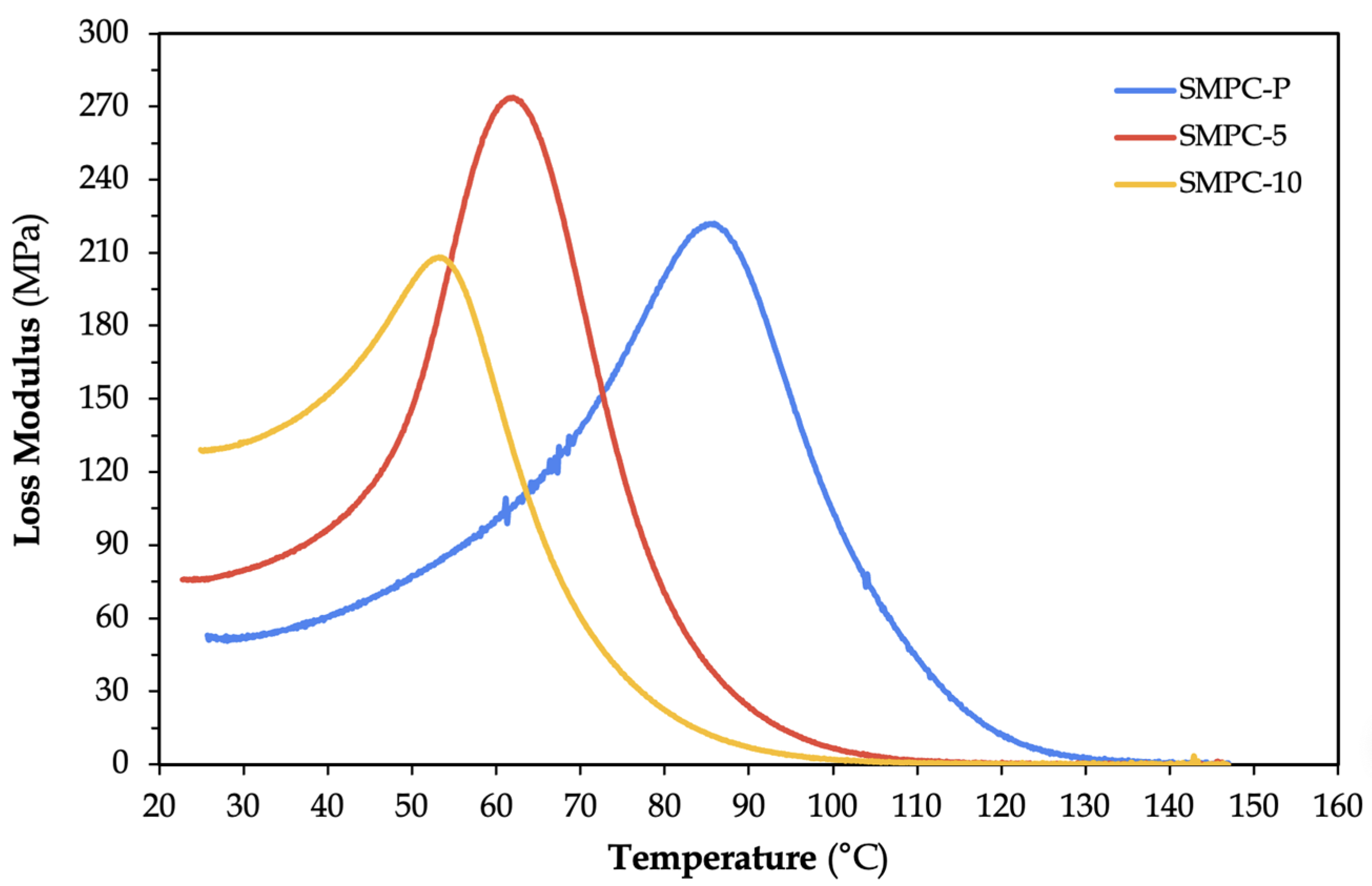

3.1.1. Dynamic Mechanical Analysis (DMA)

3.1.2. Fourier Transform Infrared Spectroscopy (FTIR)

3.2. Mechanical Characterization

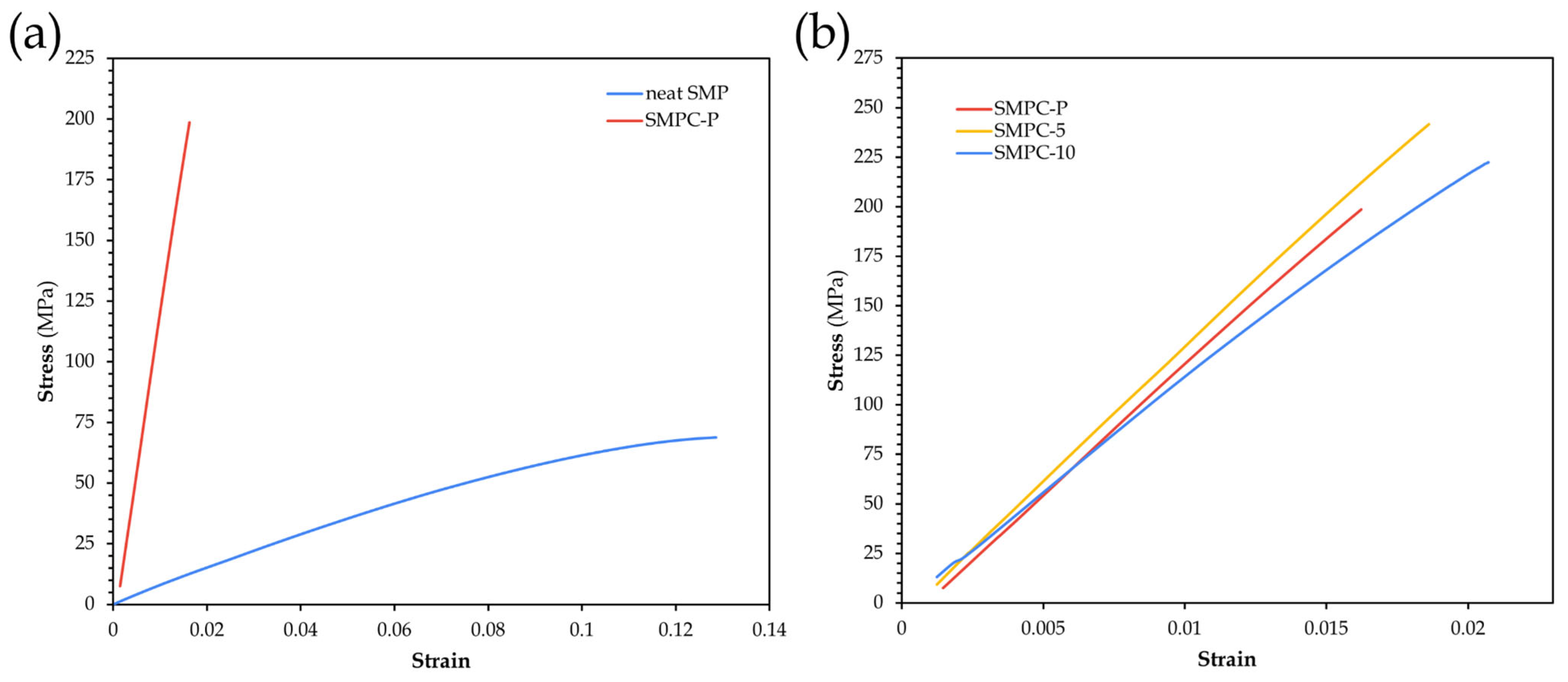

3.2.1. Uniaxial Tensile Tests

Tensile Strength and Stiffness Analysis

Young’s Modulus and Structural Stiffness

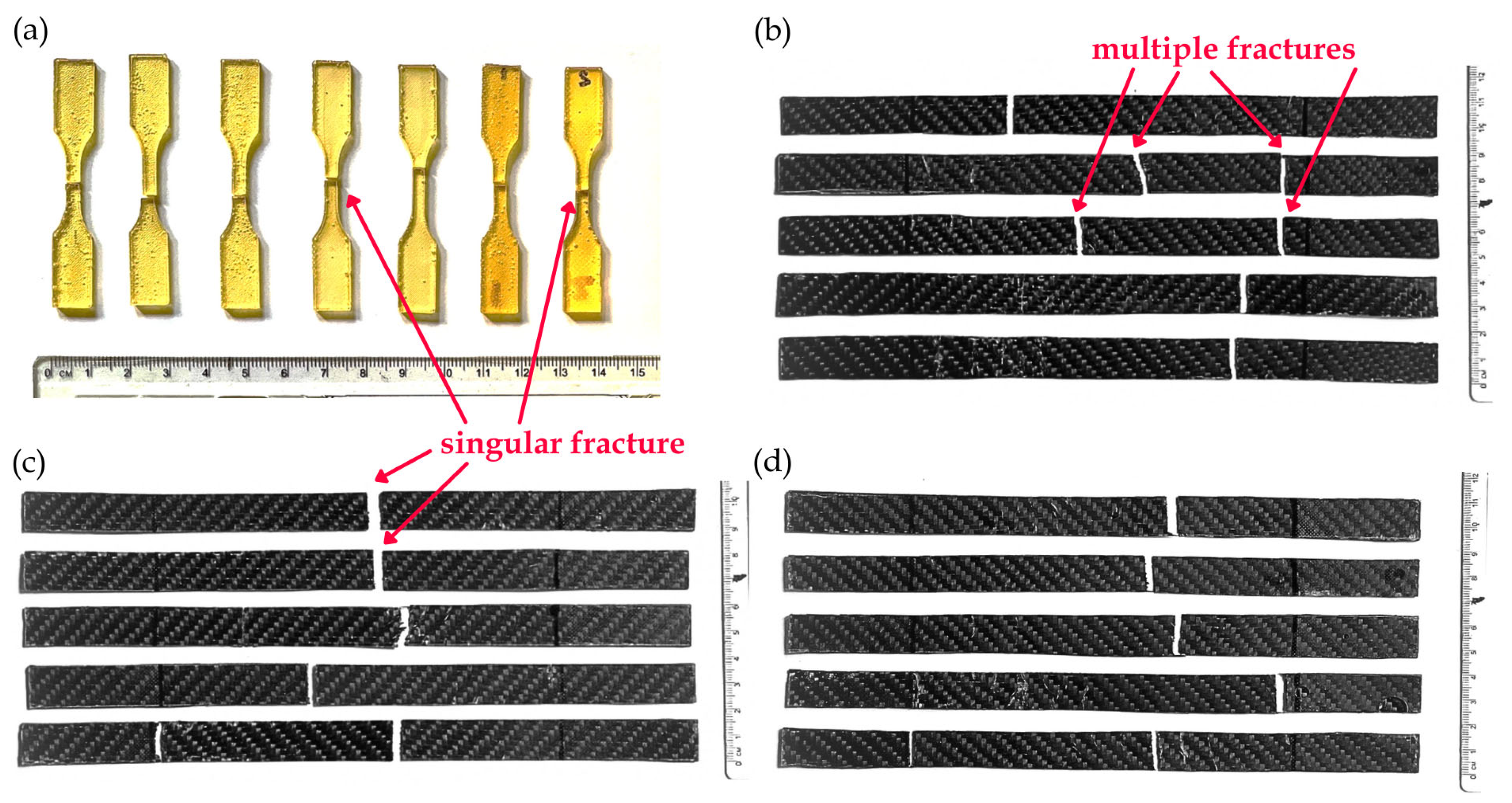

Failure Modes

3.2.2. ANSYS Simulations

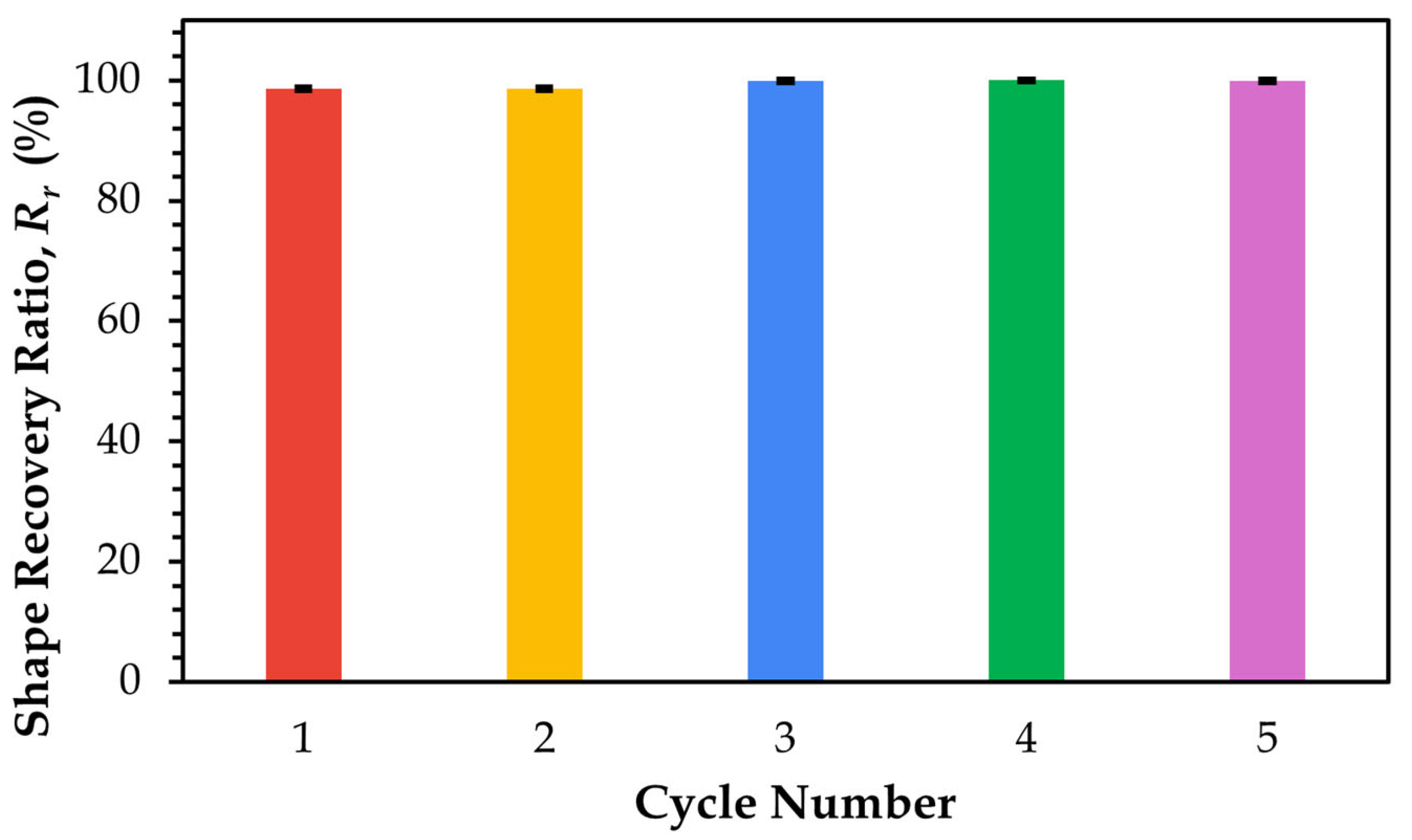

3.3. Shape Fixity and Recovery

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ATR | Attenuated total reflectance |

| DGEBA | Bisphenol A diglycidyl ether |

| DMA | Dynamic mechanical analysis |

| FEA | Finite element analysis |

| FTIR | Fourier Transform Infrared Spectroscopy |

| Tg | Glass transition temperature |

| LVR | Linear viscoelastic region |

| PEG | Polyethylene glycol |

| SMP | Shape memory polymer |

| SMPC | Shape memory polymer composites |

| UTS | Ultimate tensile strength |

| UTM | Universal testing machine |

References

- Dayyoub, T.; Maksimkin, A.V.; Filippova, O.V.; Tcherdyntsev, V.V.; Telyshev, D.V. Shape memory polymers as smart materials: A review. Polymers 2022, 14, 3511. [Google Scholar] [CrossRef]

- Garces Arguello, I.T. Shape Memory Polymers and Their Composites: Towards Field Applications via Production, Characterization and Modelling. Ph.D. Thesis, The University of Alberta, Edmonton, AB, Canada, 2021. [Google Scholar]

- Mu, T.; Liu, L.; Lan, X.; Liu, Y.; Leng, J. Shape memory polymers for composites. Compos. Sci. Technol. 2018, 160, 169–198. [Google Scholar] [CrossRef]

- Melly, S.K.; Liu, L.; Liu, Y.; Leng, J. Active composites based on shape memory polymers: Overview, fabrication methods, applications, and future prospects. J. Mater. Sci. 2020, 55, 10975–11051. [Google Scholar] [CrossRef]

- Hu, J.; Chen, W.; Fan, P.; Gao, J.; Fang, G.; Cao, Z.; Peng, F. Epoxy shape memory polymer (SMP): Material preparation, uniaxial tensile tests and dynamic mechanical analysis. Polym. Test. 2017, 62, 335–341. [Google Scholar] [CrossRef]

- Luo, L.; Zhang, F.; Leng, J. Shape memory epoxy resin and its composites: From materials to applications. Research 2022, 2022, 9798431. [Google Scholar] [CrossRef]

- Xia, Y.; He, Y.; Zhang, F.; Liu, Y.; Leng, J. A review of shape memory polymers and composites: Mechanisms, materials, and applications. Adv. Mater. 2021, 33, 2000713. [Google Scholar] [CrossRef]

- Liang, C.; Rogers, C.A.; Malafeew, E. Investigation of shape memory polymers and their hybrid composites. J. Intell. Mater. Syst. Struct. 1997, 8, 380–386. [Google Scholar] [CrossRef]

- Li, F.; Liu, Y.; Leng, J. Progress of shape memory polymers and their composites in aerospace applications. Smart Mater. Struct. 2019, 28, 103003. [Google Scholar] [CrossRef]

- Mohammed, M.I.; El-Sayed, F. PEG’s impact as a plasticizer on the PVA polymer’s structural, thermal, mechanical, optical, and dielectric characteristics. Opt. Quant. Electron. 2023, 55, 1141. [Google Scholar] [CrossRef]

- Li, Z.; Yang, Y.; Ma, L.; Liu, H.; Zhang, X. Shape memory epoxy resin and its composite with good shape memory performance and high mechanical strength. Polym. Bull. 2023, 80, 1641–1655. [Google Scholar] [CrossRef]

- ASTM D4065-01; Standard Practice for Plastics: Dynamic Mechanical Properties: Determination and Report of Procedures. ASTM International: West Conshohocken, PA, USA, 2001.

- Tensile Test Methods for Plastics: ASTM D638—Specs. Available online: https://www.shimadzu.com/an/products/materials-testing/uni-ttm-system/tensile-test-methods-for-plastics-astm-d638/spec.html (accessed on 17 August 2025).

- Jia, X.; Zhu, Y.; Zhang, H.; Li, Y. Structural Design and Performance Testing of SMPC Deployable Hinge. J. Intell. Mater. Syst. Struct. 2019, 30, 1946–1955. [Google Scholar] [CrossRef]

- Margoy, D.; Gouzman, I.; Grossman, E.; Bolker, A.; Eliaz, N.; Verker, R. Epoxy-Based Shape Memory Composite for Space Applications. Acta Astronaut. 2021, 178, 908–919. [Google Scholar] [CrossRef]

- Bellisario, D.; Quadrini, F.; Iorio, L.; Santo, L.; Zhang, Z.; Li, X.; Dong, H.; Semitekolos, D.; Konstantopoulos, G.; Charitidis, C.A. Microscopic Testing of Carbon Fiber Laminates with Shape Memory Epoxy Interlayer. Mater. Today Commun. 2022, 32, 103854. [Google Scholar] [CrossRef]

- Kumar, S.S.; Akmal, J.S.; Salmi, M. 4D Printing of Shape Memory Polymer with Continuous Carbon Fiber. Prog. Addit. Manuf. 2024, 9, 1985–1995. [Google Scholar] [CrossRef]

- Tang, Z.; Zhao, L.; Liu, Y.; Zhang, Y. Molecular design of environmental friendly green plasticizers. Chin. Sci. Bull. 2022, 67, 2835–2847. [Google Scholar] [CrossRef]

- Jayalath, H.T.S.; Herath, M.; Epaarachchi, J. Cyanate esters as a high performing shape memory polymer: A review. Mater. Today Proc. 2022, 57, 693–700. [Google Scholar] [CrossRef]

- Chai, Q.; Huang, Y.; Ayres, N. Shape memory biomaterials prepared from polyurethane/ureas containing sulfated glucose. J. Polym. Sci. A Polym. Chem. 2015, 53, 2252–2257. [Google Scholar] [CrossRef]

- Jayalath, S.; Herath, M.; Epaarachchi, J.; Trifoni, E.; Gdoutos, E.E.; Samarasekara, B. Cyanate ester and polyethylene glycol based high temperature resistant shape memory polymer development for space applications. React. Funct. Polym. 2024, 201, 105949. [Google Scholar] [CrossRef]

- Uyan, M.; Celiktas, M.S. New approach to shape memory polymer composite production using alkaline lignin-reinforced epoxy-based shape memory polymers. ACS Omega 2023, 8, 15003–15016. [Google Scholar] [CrossRef]

- Douglas, P.; Albadarin, A.B.; Sajjia, M.; Mangwandi, C.; Kuhs, M.; Collins, M.N.; Walker, G.M. Effect of poly (ethylene glycol) on the mechanical and thermal properties of bioactive poly(ε-caprolactone) melt extrudates for pharmaceutical applications. Int. J. Pharm. 2016, 500, 179–186. [Google Scholar] [CrossRef]

- Stukalin, E.B.; Douglas, J.F.; Freed, K.F. Plasticization and antiplasticization of polymer melts diluted by low molar mass species. J. Chem. Phys. 2010, 132, 084504. [Google Scholar] [CrossRef]

- Singh, A.; Chamola, R.; Goyat, M.S.; Paul, B.; Das, S. Effect of polyethylene glycol on rheological, thermo-mechanical, and tribological behavior of epoxy. Polym. Eng. Sci. 2025, 65, 1433–1447. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- Feng, Q.; Yang, J.; Liu, Y.; Xiao, H.; Fu, S. Simultaneously enhanced cryogenic tensile strength, ductility and impact resistance of epoxy resins by polyethylene glycol. J. Mater. Sci. Technol. 2014, 30, 90–96. [Google Scholar] [CrossRef]

- Yoshida, S. Quantitative evaluation of an epoxy resin dispersion by infrared spectroscopy. Polym. J. 2014, 46, 430–434. [Google Scholar] [CrossRef]

- Jayan, J.S.; Saritha, A.; Deeraj, B.D.S.; Joseph, K. Modelling of the Rheological Behaviour of Epoxy–Polyethylene Glycol-1000 Blends. Top. Catal. 2022, 65, 1733–1744. [Google Scholar] [CrossRef]

- Tavadi, A.; Basheer, D.; Melese, K.G.; Kumaresan, K.; Mohan, N.; Kerur, M.R.H.; Shashidhara, L. Experimental analysis of mechanical properties and FTIR analysis of areca fiber-reinforced epoxy composites incorporating Al2O3. J. Ind. Text. 2025, 55, 1–23. [Google Scholar] [CrossRef]

- Tsuji, Y.; Kitamura, Y.; Someya, M.; Takano, T.; Yaginuma, M.; Nakanishi, K.; Yoshizawa, K. Adhesion of epoxy resin with hexagonal boron nitride and graphite. ACS Omega 2019, 4, 4491–4504. [Google Scholar] [CrossRef]

- Sundararajan, S.; Kumar, A.; Chakraborty, B.C.; Samui, A.B.; Kulkarni, P.S. Poly (ethylene glycol) (PEG)-modified epoxy phase-change polymer with dual properties of thermal storage and vibration damping. Sustain. Energy Fuels 2018, 2, 688–697. [Google Scholar] [CrossRef]

- Xiao, Y.; E, Y.; Gao, H.; Li, H.; Xu, G.; Qiang, X. Mechanical properties of aramid fiber fabrics and composites enhanced by phthalic anhydride catalyzed with anhydrous aluminum chloride. Appl. Sci. 2024, 14, 3800. [Google Scholar] [CrossRef]

- Kosmachev, P.V.; Stepanov, D.Y.; Tyazhev, A.V.; Vinnik, A.E.; Eremin, A.V.; Tolbanov, O.P.; Panin, S.V. Radiographic inspection of carbon fiber-reinforced polymer composites (laminates) with epoxy and PEEK binders after impact and subsequent compression loading. Polymers 2024, 16, 3262. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.S.; Satish Kumar, D.; Arvind, M. Investigation on the tensile strength of epoxy (wt 75%) reinforced with stranded mat glass fibre (wt 25%) and unreinforced epoxy—A novel approach. In Proceedings of the 2022 14th International Conference on Mathematics, Actuarial Science, Computer Science and Statistics (MACS), Karachi, Pakistan, 12–13 November 2022; pp. 1–5. [Google Scholar]

- Pincheira, G.; Canales, C.; Medina, C.; Fernández, E.; Flores, P. Influence of aramid fibers on the mechanical behavior of a hybrid carbon–aramid–reinforced epoxy composite. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2015, 232, 58–66. [Google Scholar] [CrossRef]

- Eremin, A.; Burkov, M.; Luybutin, P.; Kononova, A. Mechanical behavior of carbon and aramid fiber reinforced composites with various layups under tension. Procedia Struct. Integr. 2023, 50, 65–72. [Google Scholar] [CrossRef]

- Sakhawat, H.; Anwar, M.S.; Islam, M.S.; Arifuzzaman, M. Effect of fiber orientation and volume fraction on Young’s modulus for unidirectional carbon fiber reinforced composites: A numerical investigation. Malays. J. Compos. Sci. Manuf. 2024, 13, 45–54. [Google Scholar]

- Homsi, L.; Noels, L. A discontinuous Galerkin method for non-linear electro-thermo-mechanical problems: Application to shape memory composite materials. Meccanica 2018, 53, 1357–1401. [Google Scholar] [CrossRef]

- Yadav, M.K.; Kumar, B.R.; Stephen, D.S.; Vikas, G.; Swetha, J. Structural analysis of Kevlar-49 fiber reinforcement composite material using FEM. Int. Res. J. Eng. Technol. 2022, 9, 1550–1554. [Google Scholar]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

| Properties | Component A (Resin) | Component B (Hardener) |

|---|---|---|

| Specific gravity (at 30 °C) | 1.08 gm/ml | 0.915 gm/ml |

| Density (at 25 °C) | 1.16 g/cm3 | - |

| Boiling point | >100 °C | |

| Shore D Hardness | 83 | |

| Tensile strength of cured epoxy resin | 6500–8000 psi | |

| Flexural strength of cured epoxy resin | 13,500–15,500 psi | |

| Properties | Aramid (Primary Fiber) | Carbon (Secondary Fiber) |

|---|---|---|

| Weave pattern | 2 × 2 Twill | |

| Fiber orientation | 0°/90° | |

| Areal density | 238 g/m2 | |

| Thickness | 0.43 mm | |

| Tensile strength | 424 ksi | 512 ksi |

| Tensile modulus | 10.2 msi | 33.4 msi |

| Strain to failure | 3.6% | 1.5% |

| Density | 1.44 kg/L | 1.80 kg/L |

| Sample | Storage Modulus, E′ (MPa) | Peak Loss Modulus, E″ (MPa) | Glass Transition Temperature, Tg (°C) | ∆Tg |

|---|---|---|---|---|

| SMPC-P | 2253 | 222.0 | 89.79 | - |

| SMPC-5 | 2444 | 273.8 | 70.28 | 19.51 |

| SMPC-10 | 2226 | 208.1 | 59.34 | 30.45 |

| Sample | Corresponding Functional Groups to Identified Peaks (cm−1) | ||||

|---|---|---|---|---|---|

| Hydroxyl (-O-H) | Aliphatic C-H (Asymmetric) | Aliphatic C-H (Symmetric) | Carbonyl (C=O) | -C-O- and -C-O-C- Stretching | |

| SMP | 3312.52 | 2918.22 | 2849.04 | Absent | Similar peaks (1600–500 cm−1) |

| SMPC-P | 3359.77 | 2916.52 | 2848.38 | 1736.61 | |

| SMPC-5 | 3355.21 | 2916.90 | 2848.61 | 1735.77 | |

| SMPC-10 | 3360.43 | 2917.04 | 2848.76 | 1736.29 | |

| Sample | Elongation (%) | Strain at Break |

|---|---|---|

| SMP Pure | 11.225 ± 1.386 | 0.112 ± 0.014 |

| SMPC-P | 1.618 ± 0.263 | 0.016 ± 0.003 |

| SMPC-5 | 1.560 ± 0.183 | 0.016 ± 0.002 |

| SMPC-10 | 2.068 ± 0.232 | 0.021 ± 0.002 |

| Material Specification | Carbon Fiber | Aramid Fiber |

|---|---|---|

| Young’s Modulus X Direction | 23714.533 MPa | 15,856.043 MPa |

| Young’s Modulus Y Direction | 23714.533 MPa | 15,856.043 MPa |

| Young’s Modulus Z Direction | 843.9524828 MPa | 842.4665459 MPa |

| Poisson’s Ratio XY | 0.3406 | 0.2654 |

| Poisson’s Ratio YZ | 0.335 | 0.215 |

| Poisson’s Ratio XZ | 0.335 | 0.215 |

| Shear Modulus XY | 1172.026168 MPa | 7584.973166 MPa |

| Shear Modulus YZ | 1169.529598 MPa | 6746.189024 MPa |

| Shear Modulus XZ | 1169.529598 MPa | 6746.189024 MPa |

| Cycle No. | Radius of Curvature, rnl (cm) | Bending Curvature, knl (cm−1) | Shape Fixity Ratio 1, Rf (%) |

|---|---|---|---|

| 1 | 0.645 | 1.5504 | 98.45 |

| 2 | 0.645 | 1.5504 | 98.45 |

| 3 | 0.650 | 1.5385 | 97.69 |

| 4 | 0.670 | 1.4925 | 94.78 |

| 5 | 0.710 | 1.4085 | 89.44 |

| Average Rf | 95.76 ± 3.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De la Cruz, M.T.; Gamboa, R.G.P.; Raguindin, R.K.M.; Dalisay, J.D.E.; Magdaluyo, E.R., Jr. Effect of PEG-600 Incorporation on the Mechanical and Thermal Response of Tunable Fiber-Reinforced Shape Memory Polymer Composites. Polymers 2025, 17, 2742. https://doi.org/10.3390/polym17202742

De la Cruz MT, Gamboa RGP, Raguindin RKM, Dalisay JDE, Magdaluyo ER Jr. Effect of PEG-600 Incorporation on the Mechanical and Thermal Response of Tunable Fiber-Reinforced Shape Memory Polymer Composites. Polymers. 2025; 17(20):2742. https://doi.org/10.3390/polym17202742

Chicago/Turabian StyleDe la Cruz, Marylen T., Riana Gabrielle P. Gamboa, Ricky Kristan M. Raguindin, Jon Dewitt E. Dalisay, and Eduardo R. Magdaluyo, Jr. 2025. "Effect of PEG-600 Incorporation on the Mechanical and Thermal Response of Tunable Fiber-Reinforced Shape Memory Polymer Composites" Polymers 17, no. 20: 2742. https://doi.org/10.3390/polym17202742

APA StyleDe la Cruz, M. T., Gamboa, R. G. P., Raguindin, R. K. M., Dalisay, J. D. E., & Magdaluyo, E. R., Jr. (2025). Effect of PEG-600 Incorporation on the Mechanical and Thermal Response of Tunable Fiber-Reinforced Shape Memory Polymer Composites. Polymers, 17(20), 2742. https://doi.org/10.3390/polym17202742