Shrinkage, Degree of Conversion, Water Sorption and Solubility, and Mechanical Properties of Novel One-Shade Universal Composite

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Volumetric Shrinkage

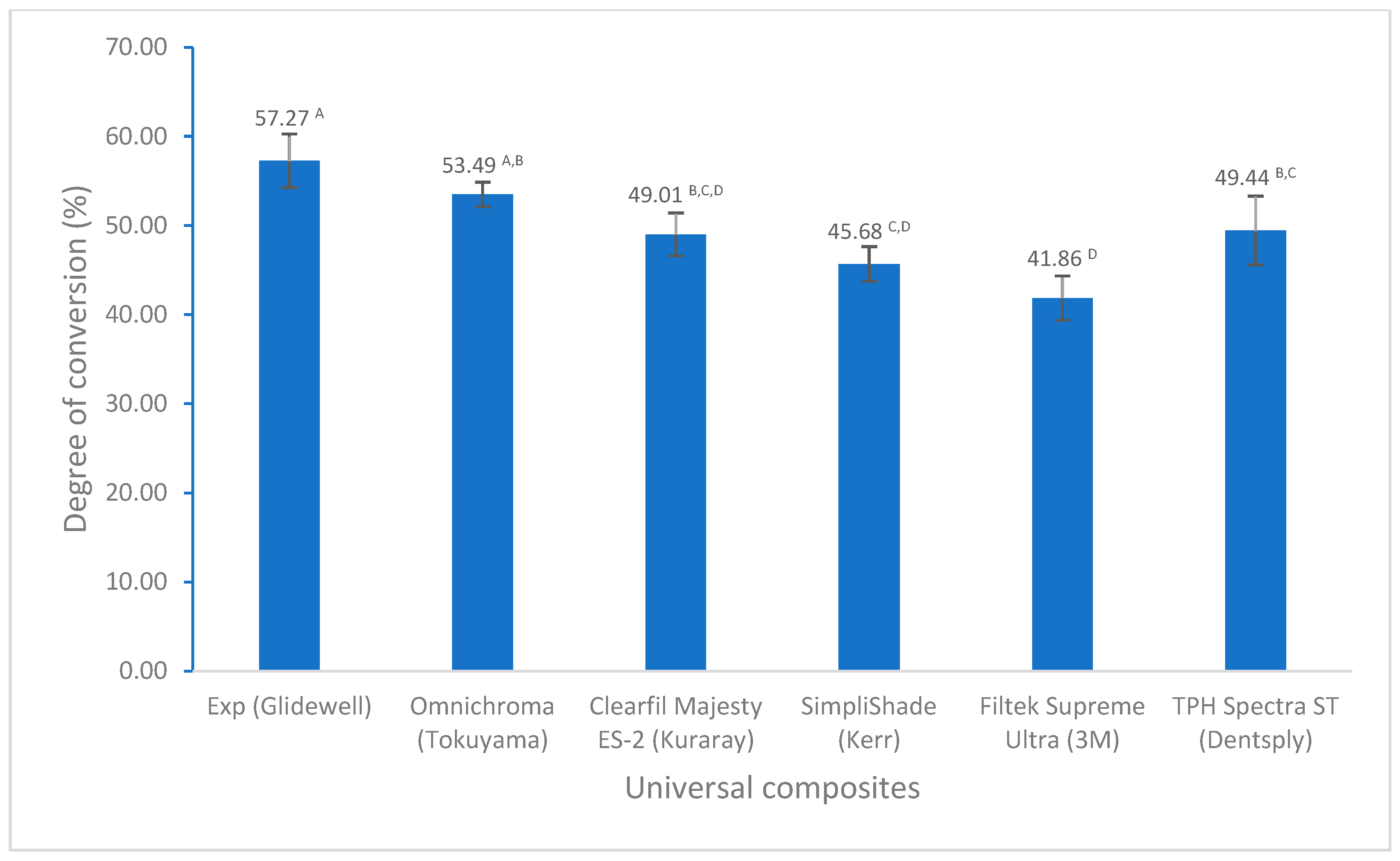

2.3. Degree of Conversion (DC)

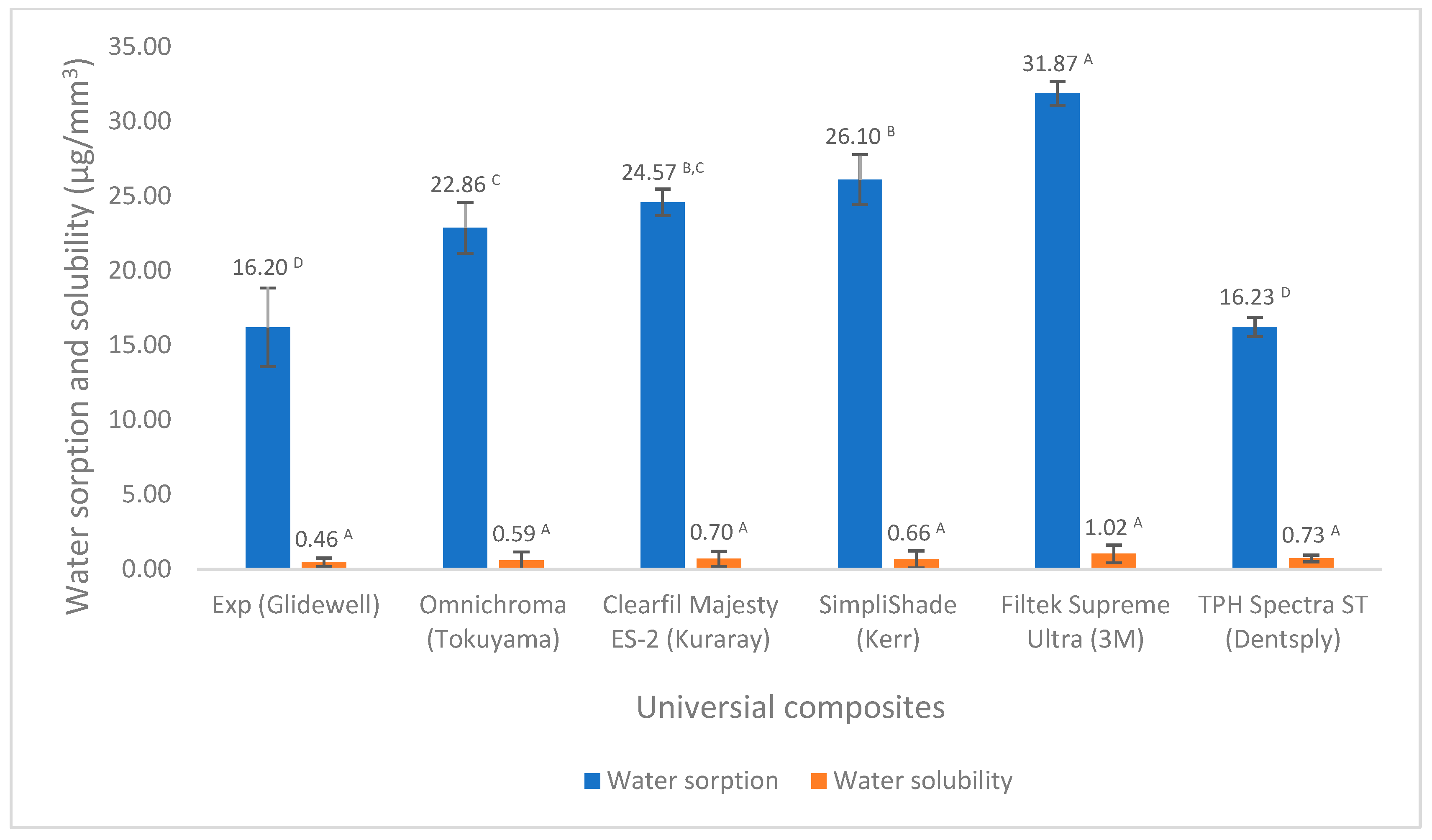

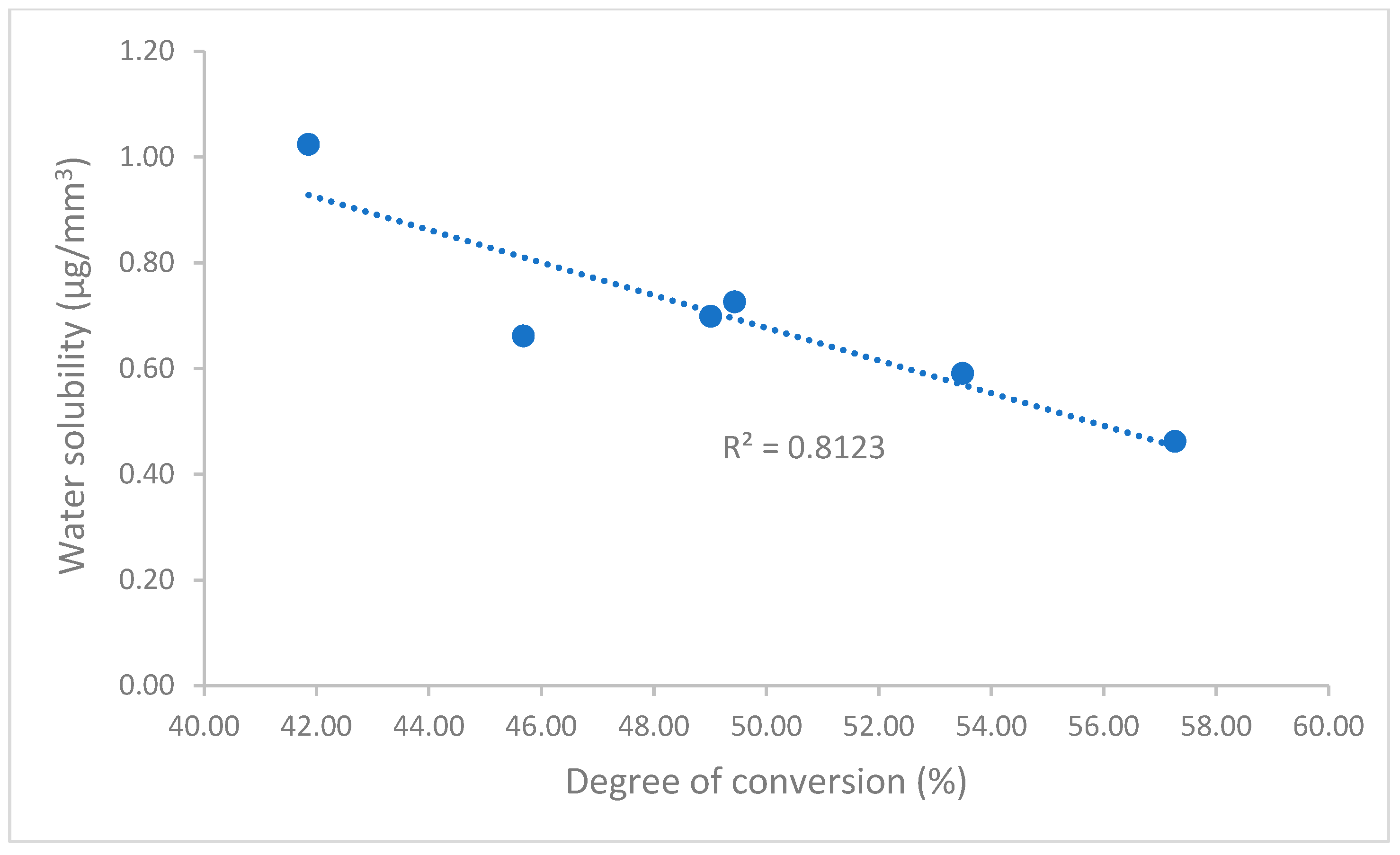

2.4. Water Sorption and Solubility

2.5. Flexural Strength and Flexural Modulus

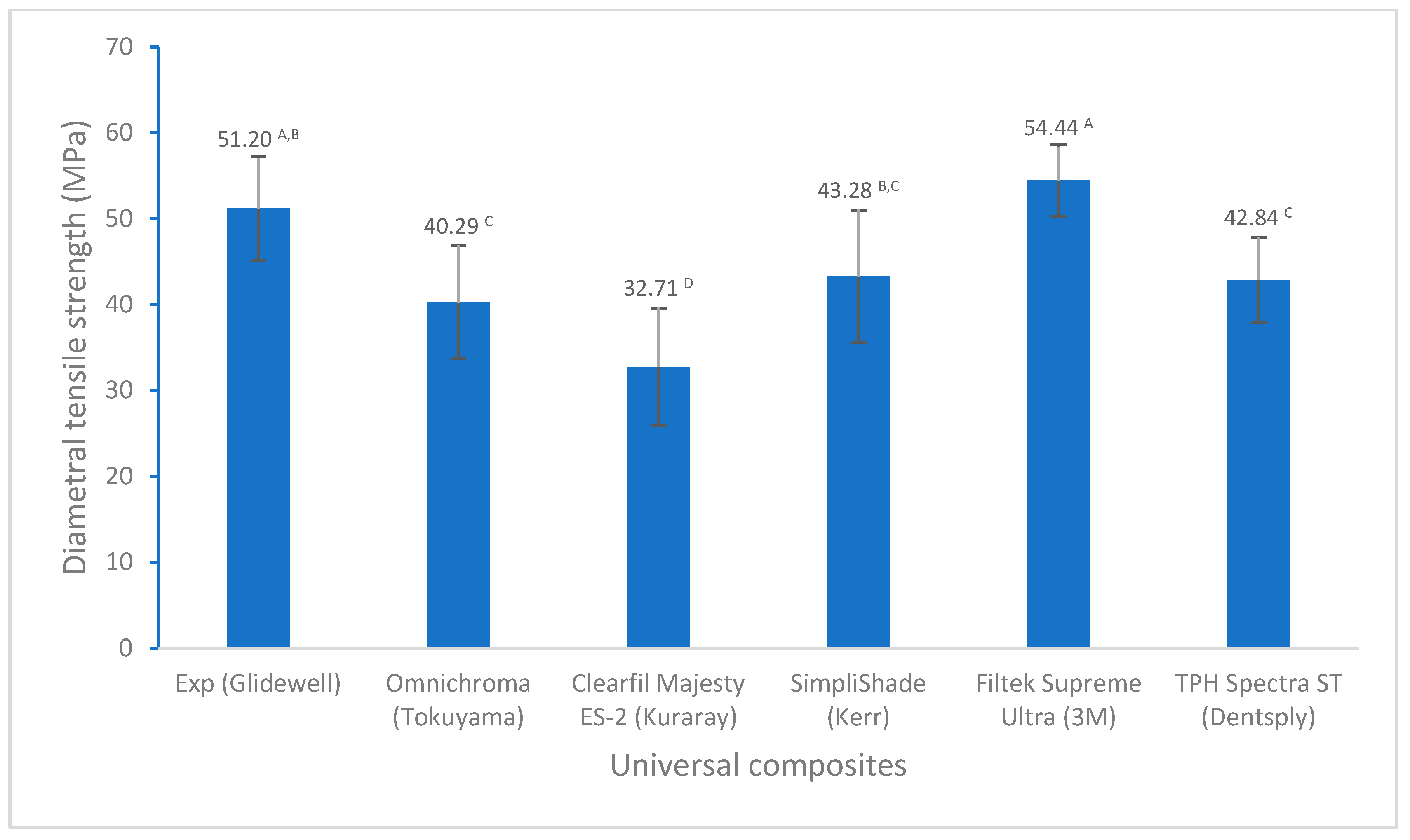

2.6. Diametral Tensile Strength

2.7. Statistical Analysis

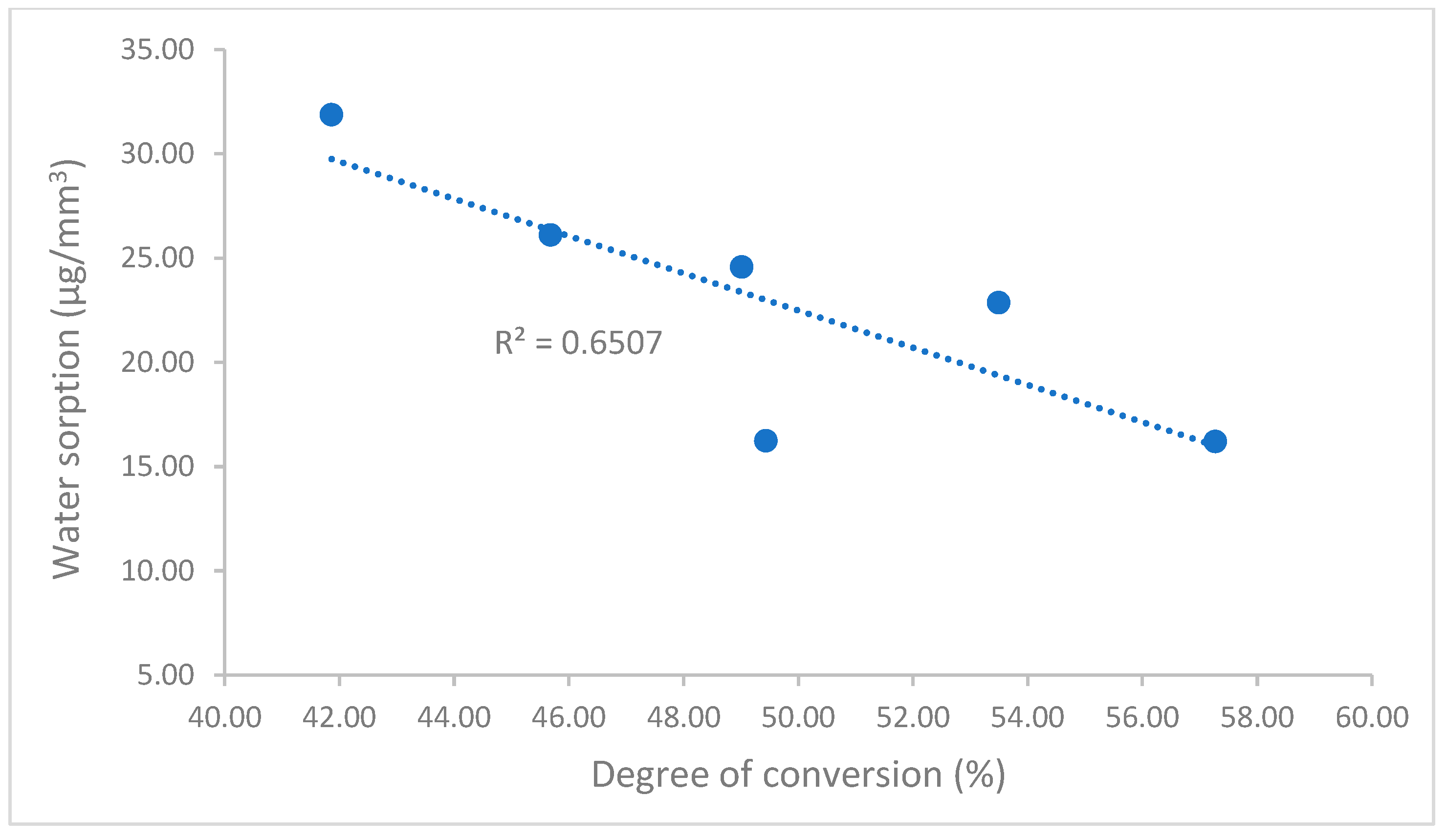

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Alzraikat, H.; Burrow, M.F.; Maghaireh, G.A.; Taha, N.A. Nanofilled resin composite properties and clinical performance: A review. Oper. Dent. 2018, 43, E173–E190. [Google Scholar] [CrossRef]

- Yadav, R.; Kumar, M. Dental restorative composite materials: A review. J. Oral Biosci. 2019, 61, 78–83. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, H.; Sun, H.; Liu, Y.; Liu, W.; Su, B.; Li, S. The Development of filler morphology in dental resin composites: A review. Materials 2021, 14, 5612. [Google Scholar] [CrossRef]

- Ilie, N.; Ionescu, A.C.; Diegelmann, J. Characterization of universal chromatic resin-based composites in terms of cell toxicity and viscoelastic behavior. Dent. Mater. 2022, 38, 700–708. [Google Scholar] [CrossRef]

- Ferracane, J.L. A historical perspective on dental composite restorative materials. J Funct Biomater. 2024, 15, 173. [Google Scholar] [CrossRef]

- Tokujama. Technical Report-OMNIchroma. Available online: https://omnichroma.com/us/wp-content/uploads/sites/4/2019/01/OMNI-Tech-Report-Color-Final.pdf (accessed on 7 October 2025).

- de Abreu, J.L.B.; Sampaio, C.S.; Jalkh, E.B.; Hirata, R. Analysis of the color matching of universal resin composites in anterior restorations. J. Esthet. Restor. Dent. 2020, 33, 269–276. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.S.; Huda, N.; Mahendran, S.; Ac, S.A.; Nassar, M.; Rahman, M.M. The blending effect of single-shade composite with different shades of conventional resin composites—An in vitro study. Eur. J. Dent. 2023, 17, 342–348. [Google Scholar] [CrossRef] [PubMed]

- Sanchez, N.P.; Powers, J.M.; Paravina, R.D. Instrumental and visual evaluation of the color adjustment potential of resin composites. J. Esthet. Restor. Dent. 2019, 31, 465–470. [Google Scholar] [CrossRef] [PubMed]

- Baghizadeh, S.; Tabari, K.; Abbasi, K.; Farnaz, S.; Tabatabaei, S.F.; Heshmat, H. Assessing shade matching capability of Omnichroma, a single shade composite in posterior restorations: An in vitro study. J. Med. Life 2024, 17, 776–781. [Google Scholar] [CrossRef] [PubMed]

- Lucena, C.; Ruiz-López, J.; Pulgar, R.; Bona, A.D.; Pérez, M.M. Optical behavior of one-shaded resin-based composites. Dent. Mater. 2021, 37, 840–848. [Google Scholar] [CrossRef]

- Anwar, R.S.; Hussein, Y.F.; Riad, M. Optical behavior and marginal discoloration of a single shade resin composite with a chameleon effect: A randomized controlled clinical trial. BDJ Open 2024, 10, 11. [Google Scholar] [CrossRef]

- Kobayashi, S.; Nakajima, M.; Furusawa, K.; Tichy, A.; Hosaka, K.; Tagami, J. Color adjustment potential of single-shade resin composite to various-shade human teeth: Effect of structural color phenomenon. Dent. Mater. J. 2021, 40, 1033–1040. [Google Scholar] [CrossRef]

- Khayat, W.F. In vitro comparison of optical properties between single-shade and conventional composite resin restorations. Cureus 2024, 16, e57664. [Google Scholar] [CrossRef]

- Durand, L.B.; Ruiz-López, J.; Perez, B.G.; Ionescu, A.M.; Carrillo-Pérez, F.; Ghinea, R.; Pérez, M.M. Color, lightness, chroma, hue, and translucency adjustment potential of resin composites using CIEDE2000 color difference formula. J. Esthet. Restor. Dent. 2021, 33, 836–843. [Google Scholar] [CrossRef]

- Batista, G.R.; Borges, A.B.; Zanatta, R.F.; Pucci, C.R.; Torres, C.R.G. Esthetical properties of single-shade and multishade composites in posterior teeth. Int J Dent. 2023, 2023, 7783321. [Google Scholar] [CrossRef] [PubMed]

- Ling, L.; Taremi, N.; Malyala, R. A novel low-shrinkage resin for 3D printing. J. Dent. 2022, 118, 103957. [Google Scholar] [CrossRef] [PubMed]

- Ling, L.; Chen, Y.; Malyala, R. Assessment of degree of conversion and volumetric shrinkage of novel self-adhesive cement. Polymers 2024, 16, 581. [Google Scholar] [CrossRef]

- Ling, L.; Ma, Y.; Malyala, R. A novel CAD/CAM resin composite block with high mechanical properties. Dent Mater. 2021, 37, 1150–1155. [Google Scholar] [CrossRef] [PubMed]

- ASTM C1327-15; Standard Test Method for Vickers Indentation Hardness of Advanced Ceramics. ASTM International: West Conshohocken, PA, USA, 2019.

- Chung, C.M.; Kim, J.G.; Kim, M.S.; Kim, K.M.; Kim, K.N. Development of a new photocurable composite resin with reduced curing shrinkage. Dent. Mater. 2002, 18, 174–178. [Google Scholar] [CrossRef]

- Weinmann, W.; Thalacker, C.; Guggenberger, R. Siloranes in dental composites. Dent. Mater. 2005, 21, 68–74. [Google Scholar] [CrossRef]

- Venkatesh, A.; Saatwika, L.; Karthick, A.; Subbiya, A. A review on polymerization shrinkage of resin composites. Eur. J. Mol. Clin. Med. 2020, 7, 1245–1250. [Google Scholar]

- Eick, J.D.; Welch, F.H. Polymerization shrinkage of posterior composite resins and its possible influence on postoperative sensitivity. Quintessence Int. 1986, 17, 103–111. [Google Scholar] [PubMed]

- Oberholzer, T.G.; Grobler, S.R.; Pameijer, C.H.; Rossouw, R.J. A modified dilatometer for determining volumetric polymerization shrinkage of dental materials. Meas. Sci. Technol. 2002, 13, 78–83. [Google Scholar] [CrossRef]

- Nitta, K.; Nomoto, R.; Tsubota, Y.; Tsuchikawa, M.; Hayakawa, T. Characteristics of low polymerization shrinkage flowable resin composites in newly developed cavity base materials for bulk filling technique. Dent. Mater. J. 2017, 36, 740–746. [Google Scholar] [CrossRef]

- ISO 17304:2013; Dentistry-Polymerization Shrinkage: Method for Determination of Polymerization Shrinkage of Polymer-Based Restorative Materials. International Organization for Standardization International: Geneva, Switzerland, 2013.

- Sharp, L.J.; Choi, I.B.; Lee, T.E.; Sy, A.; Suh, B.I. Volumetric shrinkage of composites using video imaging. J. Dent. 2003, 31, 97–103. [Google Scholar] [CrossRef]

- Tiba, A.; Charlton, D.G.; Vandewalle, K.S.; Ragain, J.C., Jr. Comparison of two video-imaging instruments for measuring volumetric shrinkage of dental resin components. J. Dent. 2005, 33, 757–763. [Google Scholar] [CrossRef] [PubMed]

- Blackham, J.T.; Vandewalle, K.S.; Lien, W. Properties of hybrid resin composite systems containing prepolymerized filler particles. Oper. Dent. 2009, 34, 697–702. [Google Scholar] [CrossRef]

- Kleverlaan, C.J.; Feilzer, A.J. Polymerization shrinkage and contraction stress of dental resin composites. Dent Mater. 2005, 21, 1150–1157. [Google Scholar] [CrossRef]

- Lim, B.S.; Ferracane, J.F.; Sakaguchi, R.L.; Condon, J.R. Reduction of polymerization contraction stress for dental composites by two-step light-activation. Dent Mater. 2002, 18, 436–444. [Google Scholar] [CrossRef]

- Sarosi, C.; Moldovan, M.; Soanca, A.; Roman, A.; Gherman, T.; Trifoi, A.; Chisnoiu, A.M.; Cuc, S.; Filip, M.; Gheorghe, G.F.; et al. Effects of monomer composition of urethane methacrylate-based resins on the C=C degree of conversion, residual monomer content and mechanical properties. Polymers 2021, 13, 4415. [Google Scholar] [CrossRef] [PubMed]

- Petronijevic Sarcev, B.; Balos, S.; Markovic, D.; Sarcev, I.; Vukcevic, M.; Labus Zlatanovic, D.; Miletic, V. Effect of the degree of conversion on mechanical properties and monomer elution from self-, dual- and light-cured core composites. Materials 2021, 14, 5642. [Google Scholar] [CrossRef]

- Spahl, W.; Budzikiewicz, H.; Geurtsen, W. Extractable residual monomers from various resin materials-a qualitative study. J Dent. Res. 1994, 73, 295–299. [Google Scholar]

- dos Santos, R.L.; de Sampaio, G.A.; de Carvalho, F.G.; Pithon, M.M.; Guênes, G.M.; Alves, P.M. Influence of degree of conversion on the biocompatibility of different composites in vivo. J. Adhes. Dent. 2014, 16, 15–20. [Google Scholar]

- Ozturk, B.; Cobanoglu, N.; Cetin, A.R.; Gunduz, B. Conversion degrees of resin composites using different light sources. Eur. J. Dent. 2013, 7, 102–109. [Google Scholar]

- Tapety, C.M.C.; Carneiro, Y.K.P.; Chagas, Y.M.; Souza, L.C.; Souza, N.D.O.; Valadas, L.A.R. Degree of conversion and mechanical properties of a commercial composite with an advanced polymerization system. Acta Odontol. Latinoam. 2023, 36, 112–119. [Google Scholar] [CrossRef]

- Atalı, P.Y.; Kaya, B.D.; Özen, A.M.; Tarçın, B.; Şenol, A.A.; Bayraktar, E.T.; Korkut, B.; Göçmen, G.B.; Tağtekin, D.; Türkmen, C. Assessment of Micro-hardness, degree of conversion, and flexural strength for single-shade universal resin composites. Polymers 2022, 14, 4987. [Google Scholar] [CrossRef] [PubMed]

- Ling, L.; Lai, T.; Malyala, R. Mechanical properties and degree of conversion of a novel 3D printing model resin. Polymers 2024, 16, 3562. [Google Scholar] [CrossRef] [PubMed]

- Tserki, S.V.; Papanastasiou, G. Effect of chemical structure on degree of conversion in light-cured dimethacrylate-based dental resins. Biomaterials 2002, 23, 1819–1829. [Google Scholar]

- Ling, L.; Xu, X.; Choi, G.Y.; Billodeaux, D.; Guo, G.; Diwan, R.M. Novel F-releasing composite with improved mechanical properties. J. Dent. Res. 2009, 88, 83–88. [Google Scholar] [CrossRef]

- Misev, L.; Schmid, O.; Udding-Louwrier, S.; Jong, E.S.d.; Bayards, R. Weather stabilization and pigmentation of UV-curable powder coatings. J. Coatings Tech. 1999, 71, 37–44. [Google Scholar] [CrossRef]

- Sideridou, I.D.; Karabela, M.M.; Vouvoudi, E.C. Volumetric dimensional changes of dental light-cured dimethacrylate resins after sorption of water or ethanol. Dent. Mater. 2008, 24, 1131–1136. [Google Scholar] [CrossRef]

- Örtengren, U.; Wellendorf, H.; Karlsson, S.; Ruyter, I.E. Water sorption and solubility of dental composites and identification of monomers released in an aqueous environment. J. Oral Rehabil. 2001, 28, 1106–1115. [Google Scholar] [CrossRef]

- Sideridou, I.; Tserki, V.; Papanastasiou, G. Study of water sorption, solubility and modulus of elasticity of light-cured dimethacrylate-based dental resins. Biomaterials 2003, 24, 655–665. [Google Scholar] [CrossRef]

- Rahim, T.N.A.T.; Mohamad, D.; Akil, H.M.; Rahman, I.A. Water sorption characteristics of restorative dental composites immersed in acidic drinks. Dent. Mater. 2012, 28, e63–e70. [Google Scholar] [CrossRef] [PubMed]

- Pereira, S.G.; Osorio, R.; Toledano, M.; Cabrerizo-Vílchez, M.A.; Nunes, T.G.; Kalachandra, S. Novel light-cured resins and composites with improved physicochemical properties. Dent. Mater. 2007, 23, 1189–1198. [Google Scholar] [CrossRef]

- Fonseca, A.S.Q.S.; Moreira, A.D.L.; de Albuquerque, P.P.A.C.; de Menezes, L.R.; Pfeifer, C.S.; Schneider, L.F.J. Effect of monomer type on the CC degree of conversion, water sorption and solubility, and color stability of model dental composites. Dent. Mater. 2017, 33, 394–401. [Google Scholar] [CrossRef] [PubMed]

- Ling, L.; Ma, Y.; Chen, Y.; Malyala, R. Physical, mechanical and adhesive properties of novel self-adhesive resin cement. Int. J. Dent. 2022, 2022, 4475394. [Google Scholar] [CrossRef] [PubMed]

- Mizutani, K.; Takamizawa, T.; Ishii, R.; Shibasaki, S.; Kurokawa, H.; Suzuki, M.; Tsujimoto, A.; Miyazaki, M. Flexural properties and polished surface characteristics of a structural colored resin composite. Oper. Dent. 2021, 46, E117–E131. [Google Scholar] [CrossRef]

- Barszczewska-Rybarek, I.M. Structure-property relationships in dimethacrylate networks based on Bis-GMA, UDMA and TEGDMA. Dent. Mater. 2009, 25, 1082–1089. [Google Scholar] [CrossRef]

- Alrahlah, A.; Khan, R.; Al-Odayni, A.B.; Saeed, W.S.; Bautista, L.S.; Alnofaiy, I.A.; De Vera, M.A.T. Advancing dimethacrylate dental composites by synergy of pre-polymerized TEGDMA co-filler: A physio-mechanical evaluation. Biomimetics 2023, 8, 577. [Google Scholar] [CrossRef]

- Shibasaki, S.; Takamizawa, T.; Nojiri, K.; Imai, A.; Tsujimoto, A.; Endo, H.; Suzuki, S.; Suda, S.; Barkmeier, W.W.; Latta, M.A. Miyazaki. M. Polymerization behavior and mechanical properties of high-viscosity bulk fill and low shrinkage resin composites. Oper. Dent. 2017, 42, E177–E187. [Google Scholar] [CrossRef] [PubMed]

| Universal Composite | Manufacturer | Shade | Resin | Filler | Filler Content (w%) |

|---|---|---|---|---|---|

| Exp | Glidewell | One | BisGMA, BisEMA, UDMA, TEGDMA, | Nano-silica and micro-barium glass, Ytterbium fluoride | 78 |

| OmniChroma | Tokuyama | One | UDMA, TEGDMA | Spherical nano-silica-zirconia | 79 |

| Clearfil Majesty ES2 | Kuraray | One (Posterior) | BisGMA, Aromatic- and Aliphatic-dimethacrylates | Barium glass, Pre-polymerized organic filler | 78 |

| SimpliShade | Kerr | Three | BisEMA, TEGDMA | Zirconium oxide, Silicon dioxide, Ytterbium Fluoride | 81 |

| Filtek Spreme Ultra | 3M ESPE | Multiple | BisGMA, UDMA, BisEMA(6), TEGDMA | Nano-zirconia and nano-silica and zirconia/silica cluster | 78.5 |

| TPH Spectra ST(HV) | Dentsply | Multiple | Poly-UDMA, BisEMA, TEGDMA, Methacrylic polysiloxane | Barium glass, Pre-poly-merized filler, Ytterbium fluoride | 79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ling, L.; Lai, T.; Chung, P.-T.; Malyala, R. Shrinkage, Degree of Conversion, Water Sorption and Solubility, and Mechanical Properties of Novel One-Shade Universal Composite. Polymers 2025, 17, 2728. https://doi.org/10.3390/polym17202728

Ling L, Lai T, Chung P-T, Malyala R. Shrinkage, Degree of Conversion, Water Sorption and Solubility, and Mechanical Properties of Novel One-Shade Universal Composite. Polymers. 2025; 17(20):2728. https://doi.org/10.3390/polym17202728

Chicago/Turabian StyleLing, Long, Theresa Lai, Pei-Ting Chung, and Raj Malyala. 2025. "Shrinkage, Degree of Conversion, Water Sorption and Solubility, and Mechanical Properties of Novel One-Shade Universal Composite" Polymers 17, no. 20: 2728. https://doi.org/10.3390/polym17202728

APA StyleLing, L., Lai, T., Chung, P.-T., & Malyala, R. (2025). Shrinkage, Degree of Conversion, Water Sorption and Solubility, and Mechanical Properties of Novel One-Shade Universal Composite. Polymers, 17(20), 2728. https://doi.org/10.3390/polym17202728