Flow-Line-Reducing Tetrahedral Metal Effect Pigments for Injection Molding: A Yield-Rate-Improved Particle Manufacturing Method Based on Soft UVImprint Lithography

Abstract

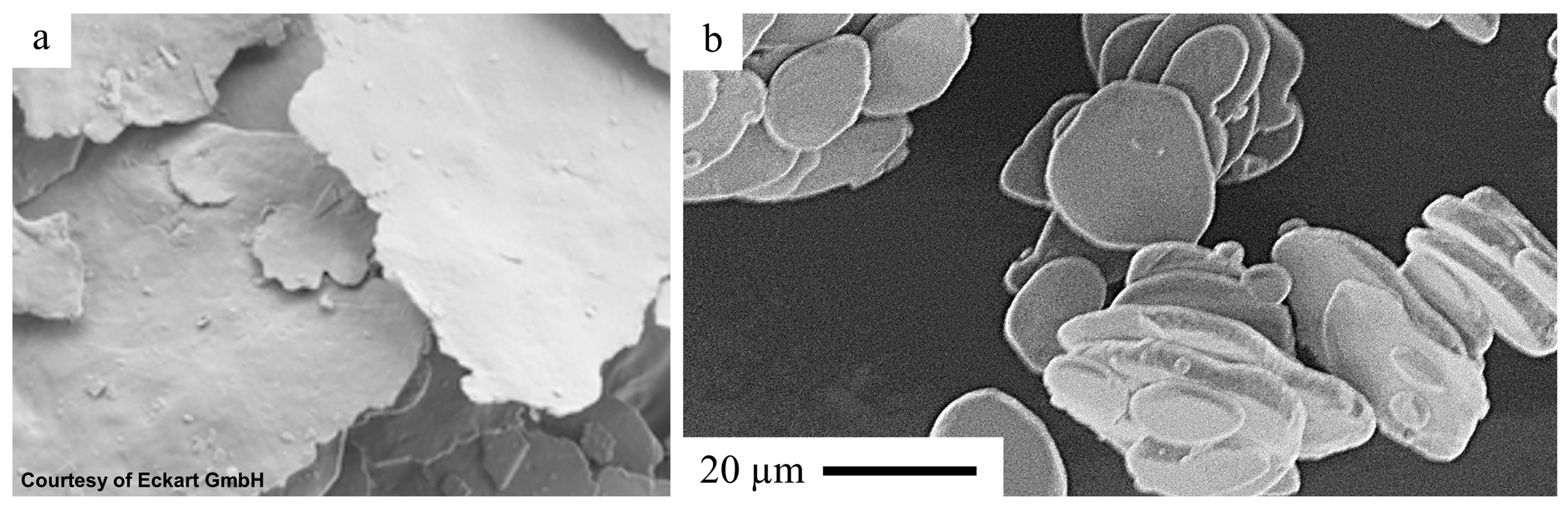

1. Introduction

2. Materials and Methods

2.1. Assessment of THEICTA as a Suitable Material for Particle Manufacturing

2.1.1. Curing Behavior

2.1.2. Glass Transition Temperature

2.1.3. Shear Strength

2.1.4. Yellowing During Curing

2.2. Manufacturing of Tetrahedral Thermoset Particles and Subsequent Injection Molding

| Compound No. | Compound 1 | Compound 2 | Compound 3 | ||

|---|---|---|---|---|---|

| Matrix polymer | PMMA POQ64 | PC Durabio | PMMA POQ64 | ||

| Pigment | Tetrahedral particles | Tetrahedral particles | Reflexal 100 (silver dollar) | ||

| Process temperatures | Screw | Feeding throat [°C] | 19 | 19 | 19 |

| Compression zone [°C] | 265 | 245 | 265 | ||

| Metering zone [°C] | 250 | 245 | 250 | ||

| Plungers | Metering plunger [°C] | 250 | 245 | 250 | |

| Injection plunger [°C] | 250 | 257 | 250 | ||

| Mold | 90 | 80 | 90 | ||

| Speeds | Screw (Ø 14 mm) circumferential speed [mm/s] | 20 | 10 | 20 | |

| Injection speed [cm3 s−1] | 1.96 | 1.96 | 1.96 | ||

2.3. Computer Tomography-Based Observation of the Particles in the FlowLine

3. Results and Discussion

3.1. Results of the Assessment of THEICTA as a Suitable Material for Particle Manufacturing

3.1.1. Results of the Curing Behavior Assessment

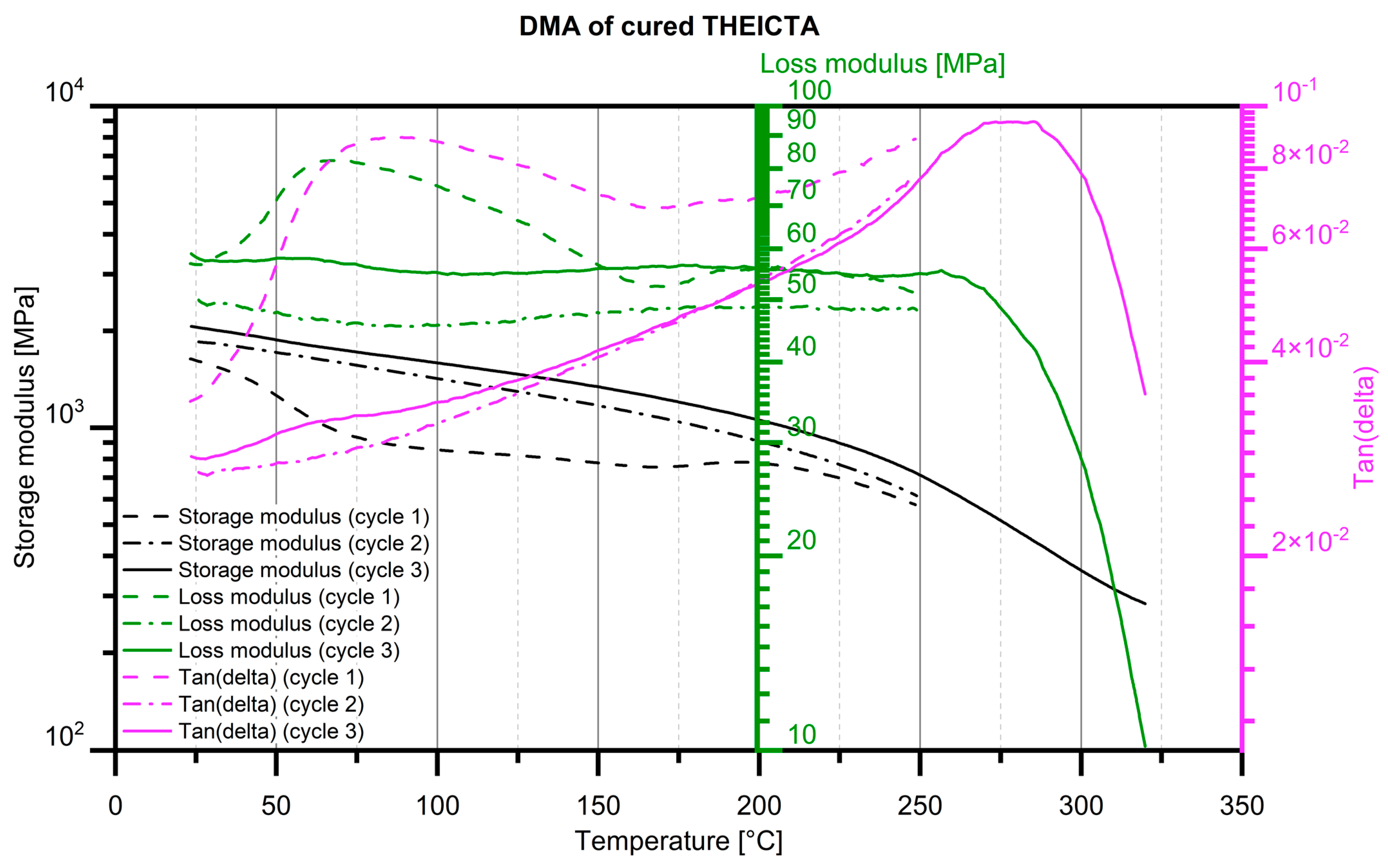

3.1.2. Results of the Assessment of the Glass Transition Temperature

3.1.3. Results of the Shear Strength Assessment

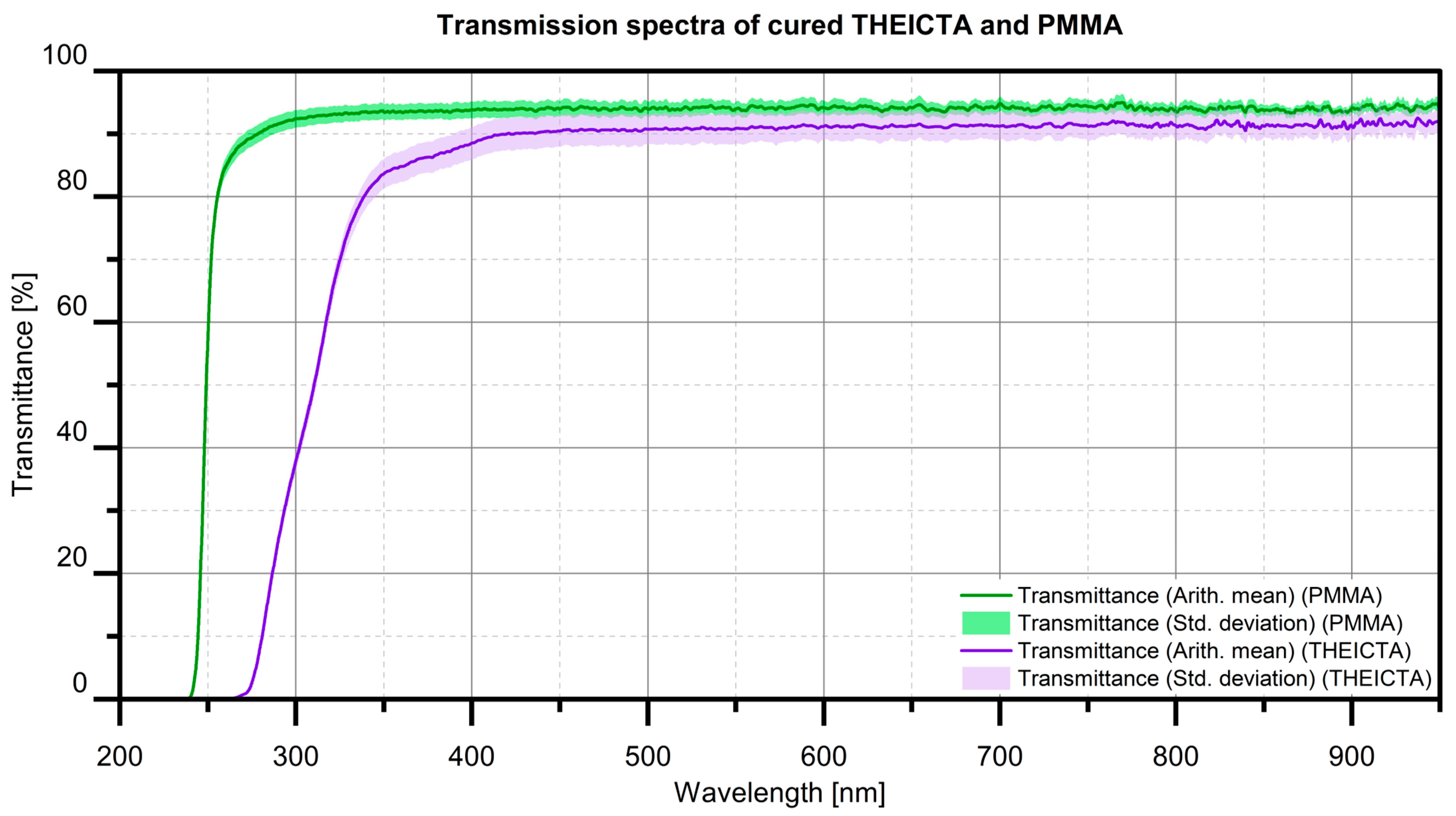

3.1.4. Results of the Assessment of Yellowing During Curing

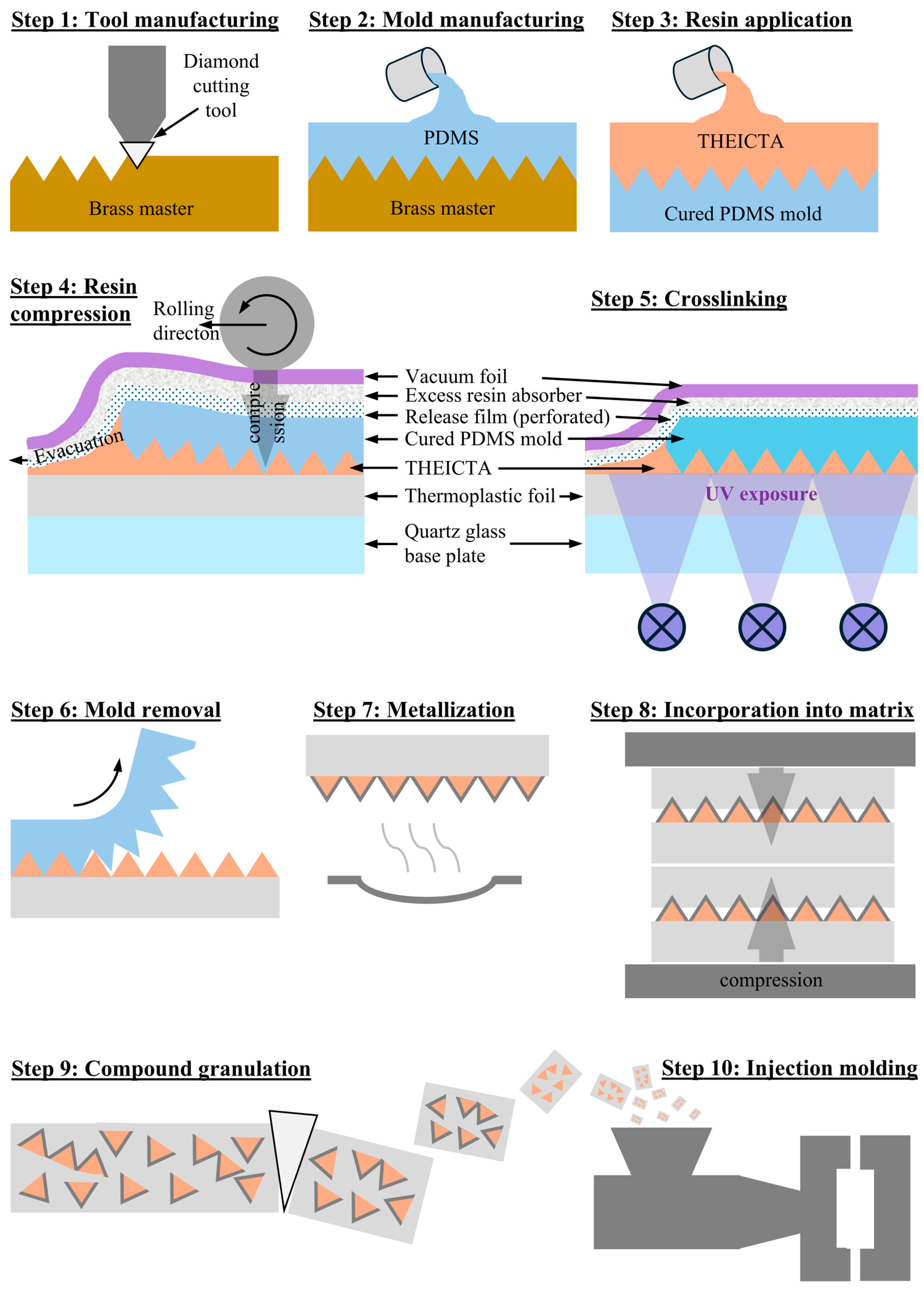

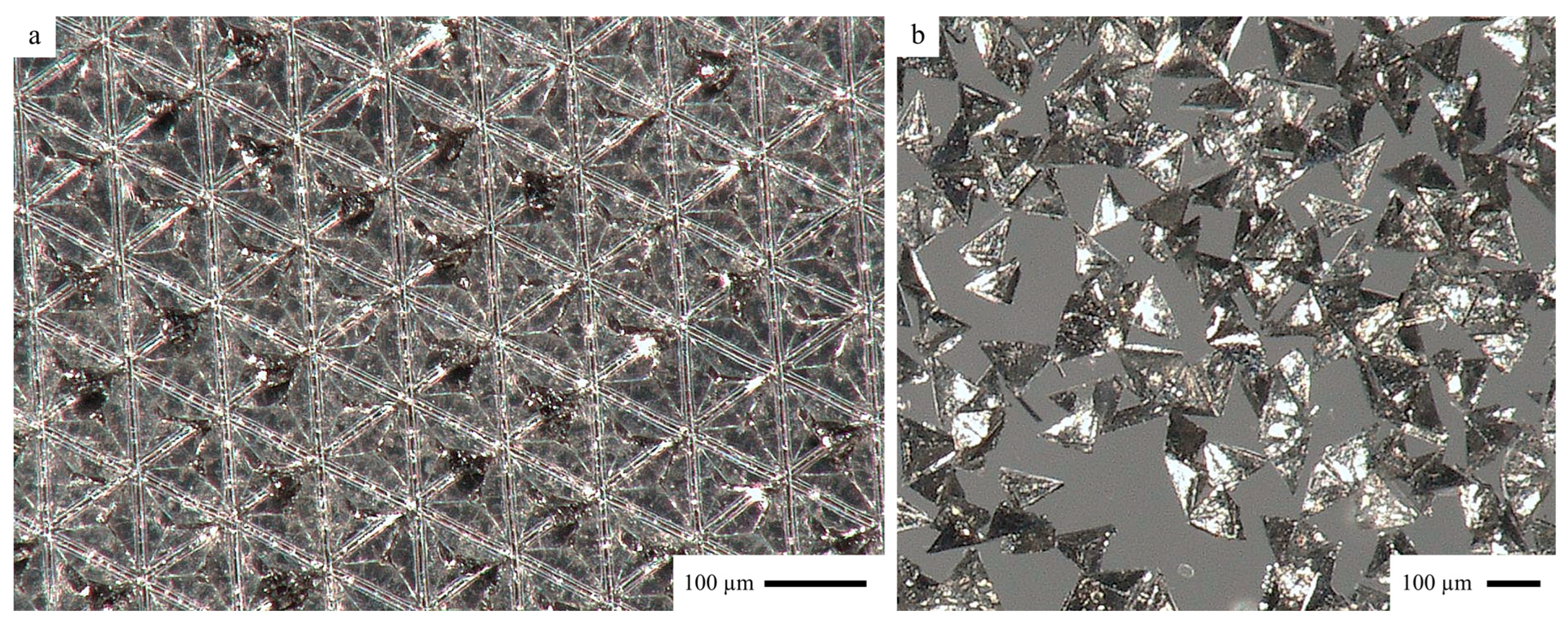

3.1.5. Manufacturing Results

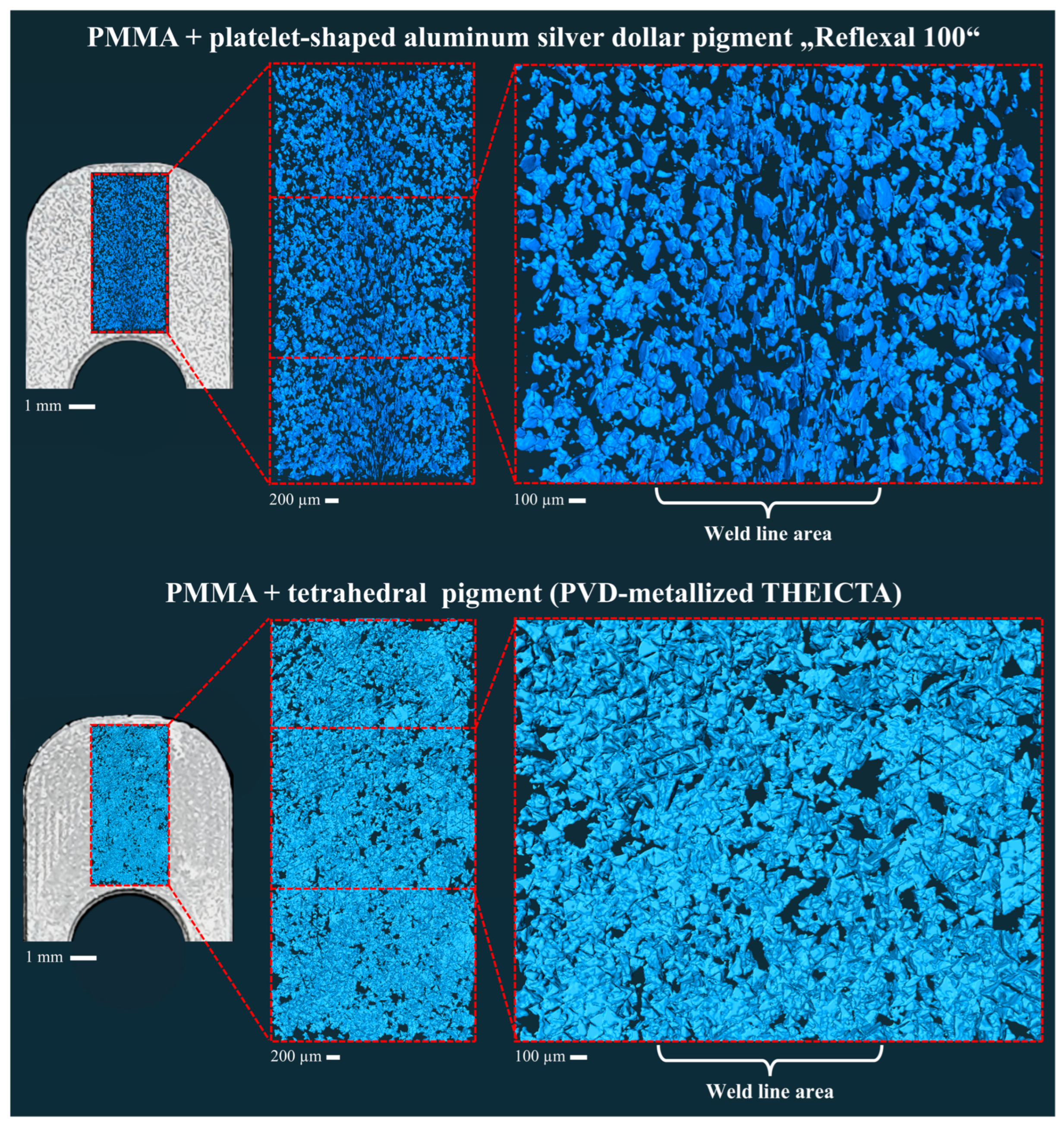

3.2. Results of the FlowLine Visibility inInjection-Molded Parts

3.3. Results of the Computer Tomography-Based Observation of the Particles in the FlowLine

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BSM | Bright Surface Molding (an injection molding process) |

| CT | Computer Tomography |

| DEA | Dielectric Analysis |

| DMA | Dynamic Mechanical Analysis |

| PC | Polycarbonate |

| PDMS | Polydimethylsiloxane |

| PMMA | Polymethylmethacrylate |

| SCORIM | Shear Controlled Orientation Injection Molding (an injection molding process) |

| SEM | Scanning Electron Microscopy |

| THEICTA | Tris(2-hydroxy ethyl) isocyanurate triacrylate |

References

- Demski, N.M.; Lasson, B.; Reinert, K.E.; Kamm, P.H.; Neu, T.R.; García-Moreno, F.; Jagodzinski, M.; Rolón, D.A.; Malcher, M.; Oberschmidt, D. Manufacturing of tetrahedral metal effect pigment particles and analysis of their orientation in polymer melts. Powder Technol. 2022, 408, 117717. [Google Scholar] [CrossRef]

- Demski, N.M.; Jagodzinski, M.; Malcher, M.; Rolón, D.A.; Kamm, P.H.; Neu, T.R.; Garcia-Moreno, F.; Oberschmidt, D. Metal effect pigments for reducing flow-line visibility. In Proceedings of the Euspen’s 20th International Conference & Exhibition, Geneva, Switzerland, 8–12 June 2020. [Google Scholar]

- Park, J.M.; Jeong, S.J.; Park, S.J. Numerical prediction of flake orientation and surface color in injection molding of flake-pigmented thermoplastics. Polym. Compos. 2011, 32, 1297–1303. [Google Scholar] [CrossRef]

- Advani, S.G.; Tucker, C.L. The Use of Tensors to Describe and Predict Fiber Orientation in Short Fiber Composites. J. Rheol. 1987, 31, 751–784. [Google Scholar] [CrossRef]

- Sasayama, T.; Okamoto, H.; Kawada, J.; Sato, N.; Ishibashi, T. Orientation of flake pigments in injection-molded polymer: Numerical simulation and its application to appearance prediction. Powder Technol. 2023, 428, 118848. [Google Scholar] [CrossRef]

- Santos, I.; Pontes, A.J.; Martins, C.I. Optimization of Injection Molding Process of Polypropylene with Aluminum Metallic Pigments; Institute for Polymer and Composites: Madrid, Spain, 2014. [Google Scholar]

- Rawson, K.W.; Allan, P.S.; Bevis, M.J. Controlled orientation of reflective pigment and optical property characterization of injection-molded polypropylene. Polym. Eng. Sci. 1999, 39, 177–189. [Google Scholar] [CrossRef]

- Lim, J.S.; Ban, S.H.; Kim, D.S.; Kwon, K.Y.; Lee, S.H.; Lim, J.K.; Cho, S.H. Development of a noble aluminum-pigmented metallic polymer: Recommendations for visible flow and weld line mitigation. J. Appl. Polym. Sci. 2020, 137, 49084. [Google Scholar] [CrossRef]

- Lim, J.S.; Kwon, K.Y.; Hur, K.B.; Cho, C.H.; Lee, G.C.; Cheon, S.U.; Cho, S.H. Noble aluminum-pigmented metallic polymers II: Effects of inorganic filler on weld- and flow-line visibility. Polym. Test. 2022, 106, 107422. [Google Scholar]

- Demski, N.M.; Oberschmidt, D. Zusammensetzung Enthaltend 3d-Metalleffektpigmente und Verfahren zur Herstellung Derselben. EP3783069B1, 15 December 2021. [Google Scholar]

- Arkema France. SR368 Technical Datasheet; Arkema France: Colombes, France, 2023. [Google Scholar]

- ASTM D732-24; Standard Test Method for Shear Strength of Plastics by Punch Tool. ASTM: West Conshohocken, PA, USA, 2024.

- Boin, M.; Apel, D.; García-Moreno, F.; Genzel, C.; Kamm, P.; Klaus, M.; Mainz, R.; Wagener, G.; Wimpory, R. (Eds.) Operating Liquid MetalJet X-ray Sources for Materials Research; JACoW Publishing: Geneva, Switzerland, 2024. [Google Scholar]

- Paganin, D.; Mayo, S.C.; Gureyev, T.E.; Miller, P.R.; Wilkins, S.W. Simultaneous phase and amplitude extraction from a single defocused image of a homogeneous object. J. Microsc. 2002, 206, 33–40. [Google Scholar] [CrossRef] [PubMed]

- Feldkamp, L.A.; Davis, L.C.; Kress, J.W. Practical cone-beam algorithm. J. Opt. Soc. Am. A 1984, 1, 612. [Google Scholar] [CrossRef]

| Specimen | No. 1 | No. 2 | No. 3 | No. 4 | No. 5 | Arith. Mean | Std. dev. |

|---|---|---|---|---|---|---|---|

| Shear strength PMMA [MPa] | 67.11 | 66.38 | 67.09 | 68.02 | 62.10 | 66.14 | 2.09 |

| Shear strength THEICTA untempered [MPa] | 48.69 | 42.35 | 69.01 | 98.09 | 85.98 | 68.83 | 21.25 |

| Shear strength THEICTA tempered [MPa] | 73.73 | 100.84 | 82.98 | 84.48 | 154.27 | 99.25 | 28.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Demski, N.M.; Seidlitz, H.; Kuke, F.; Dorn, O.N.; Zoglauer, J.; Hückstaedt, T.; Kamm, P.H.; García-Moreno, F.; Kremp, N.; Dreyer, C.; et al. Flow-Line-Reducing Tetrahedral Metal Effect Pigments for Injection Molding: A Yield-Rate-Improved Particle Manufacturing Method Based on Soft UVImprint Lithography. Polymers 2025, 17, 2708. https://doi.org/10.3390/polym17192708

Demski NM, Seidlitz H, Kuke F, Dorn ON, Zoglauer J, Hückstaedt T, Kamm PH, García-Moreno F, Kremp N, Dreyer C, et al. Flow-Line-Reducing Tetrahedral Metal Effect Pigments for Injection Molding: A Yield-Rate-Improved Particle Manufacturing Method Based on Soft UVImprint Lithography. Polymers. 2025; 17(19):2708. https://doi.org/10.3390/polym17192708

Chicago/Turabian StyleDemski, Nils Maximilian, Holger Seidlitz, Felix Kuke, Oliver Niklas Dorn, Janina Zoglauer, Tobias Hückstaedt, Paul Hans Kamm, Francisco García-Moreno, Noah Kremp, Christian Dreyer, and et al. 2025. "Flow-Line-Reducing Tetrahedral Metal Effect Pigments for Injection Molding: A Yield-Rate-Improved Particle Manufacturing Method Based on Soft UVImprint Lithography" Polymers 17, no. 19: 2708. https://doi.org/10.3390/polym17192708

APA StyleDemski, N. M., Seidlitz, H., Kuke, F., Dorn, O. N., Zoglauer, J., Hückstaedt, T., Kamm, P. H., García-Moreno, F., Kremp, N., Dreyer, C., & Oberschmidt, D. (2025). Flow-Line-Reducing Tetrahedral Metal Effect Pigments for Injection Molding: A Yield-Rate-Improved Particle Manufacturing Method Based on Soft UVImprint Lithography. Polymers, 17(19), 2708. https://doi.org/10.3390/polym17192708