1. Introduction

Among many additive manufacturing (AM) techniques, fused deposition modeling (FDM) method has proved to be one of the most popular techniques over the past few years as it is relatively easy and cost effective, and material selection is easily accessible [

1,

2,

3]. FDM technology manufactures 3D objects using thermoplastic filament that is melted and then deposited by layers according to computer-controlled toolpaths [

4]. FDM has seen drastic improvements in precision, multi-extruder systems for varied materials and improved motion control system to name a few [

5,

6].

The concurrent evolution of compatible materials has proceeded in tandem with technological developments. High-performance engineering polymers represent a significant class of materials for FDM applications, characterized by their superior mechanical properties, thermal stability, and chemical resistance [

7]. Within this category, materials such as polyetheretherketone (PEEK), polyetherimide (ULTEM), and various composite filaments have emerged alongside conventional thermoplastics [

8,

9]. Particularly noteworthy is the development of polycarbonate (PC) filaments, which have garnered attention due to their exceptional tensile strength (approximately 60–70 MPa), remarkable impact resistance, and superior thermal stability compared to analogous thermoplastic materials at elevated temperatures [

10,

11]. This combination of properties positions polycarbonate as a material of significant interest in advanced manufacturing applications requiring both structural integrity and thermal performance [

12]. Research into improved PLA formulations addresses its original limitations while maintaining the material’s ease of biodegradation, making it a better choice for environmentally conscious applications [

13,

14,

15].

Previous studies have reported varying mechanical properties for FDM-printed components, providing important benchmarks for comparison. For polycarbonate, Vidakis et al. [

16] achieved tensile strengths ranging from 55 to 65 MPa with optimized parameters, while Reich et al. [

17] reported values of 45–60 MPa depending on processing conditions. Cantrell et al. [

18] demonstrated that PC specimens could reach up to 68 MPa when printed with optimal orientation and post-processing. For PLA, comparable studies have shown tensile strengths typically ranging from 30 to 50 MPa [

13], with enhanced formulations reaching up to 60 MPa [

14]. Tymrak et al. [

19] reported PLA tensile strengths of 28.5–56.6 MPa across various commercial printers, while Lanzotti et al. [

20] found values of 35–45 MPa with standard parameters. However, direct comparison between studies remains challenging due to variations in test standards, specimen geometry, and specific material grades employed.

The mechanical results from FDM-printed parts show variable outcomes because of their layer-by-layer production method and directional material properties [

21,

22]. Finding out how each printing setting affects mechanical strength remains a key scientific problem, especially when working with functional prototypes and end-use components. The bonding between layers, presence of voids, degree of polymer crystallization, and alignment of polymer chains all influence final part properties in ways not fully predictable through conventional models [

23,

24].

While previous studies have examined individual effects of layer thickness [

25,

26], build orientation [

27,

28,

29], and material selection [

30] on FDM mechanical properties, a critical knowledge gap remains regarding their complex interactions and the underlying mechanisms governing these relationships. Specifically, the conventional assumption that thinner layers invariably produce superior mechanical properties through enhanced interlayer bonding has been challenged by recent observations suggesting that thermal retention dynamics and interface density may create more nuanced relationships [

31]. Similarly, while build orientation effects are well-documented, the interaction between orientation-induced anisotropy and layer thickness remains poorly understood, particularly regarding how these parameters collectively influence polymer chain interdiffusion and failure mechanisms.

Based on preliminary evidence suggesting that thicker layers may enhance interlayer bonding through extended thermal retention, the study hypothesized that increasing layer thickness from 0.2 mm to 0.4 mm would improve ultimate tensile strength via three mechanisms: (1) enhanced thermal retention promoting deeper polymer chain interdiffusion across layer interfaces, (2) reduced interface density minimizing potential failure initiation sites, and (3) improved extrusion consistency reducing flow-related defects. Furthermore, the study hypothesized that these thermal and mechanical advantages would interact with build orientation effects, creating material-specific optimization opportunities not captured in single-parameter studies.

This investigation systematically examines these hypotheses through a full factorial (2

3) experimental design evaluating the interaction effects of material type (PC vs. PLA), layer thickness (0.2 mm vs. 0.4 mm), and build orientation (horizontal vs. vertical) on mechanical properties (

Table 1). The study aims to (1) quantify the relationship between increased layer thickness and mechanical performance, (2) establish how thermal retention mechanisms influence interlayer bonding quality, (3) determine material-specific responses to parameter interactions, and (4) develop an integrated optimization framework that enables simultaneous improvement of mechanical performance and production efficiency.

To evaluate mechanical integrity, the study conducts standardized tensile testing according to ASTM D638 [

32], complemented by detailed fractographic analysis to understand failure mechanisms and validate the proposed thermal retention hypothesis. This comprehensive approach allows accurate measurement of specimen response under loading while providing mechanistic insights into the structure–property relationships governing FDM-printed components.

2. Experimental Methodology

2.1. Materials Selection and Characterization

This investigation employed two industrially significant thermoplastic materials: Polycarbonate (PC) and Polylactic Acid (PLA). PC was selected for its superior mechanical strength (60–70 MPa), impact resistance, and thermal stability (Tg ≈ 147 °C), making it suitable for engineering applications. PLA offered complementary properties with excellent printability at lower temperatures (180–220°C), biodegradability, and dimensional stability, albeit with reduced impact resistance. Both materials were procured as 1.75 mm diameter filaments from a single manufacturer (MatterHackers, Lake Forest, CA, USA) to minimize variability. Prior to fabrication, PC filaments were desiccated at 70 °C for 6 h, while PLA filaments underwent conditioning at 45 °C for 4 h to mitigate hygroscopic effects that could compromise print quality and mechanical integrity.

2.2. Experimental Design and Parameter Selection

Build Orientation Specification: Build orientation was precisely defined relative to both the printer coordinate system and the subsequent tensile loading direction to ensure reproducible results and clear interpretation of anisotropic effects.

Horizontal Orientation: Specimens were printed with their length axis parallel to the printer’s X-Y plane, with layer deposition occurring in the Z-direction perpendicular to the specimen’s major axis. The 100% rectilinear infill pattern was implemented with alternating 0°/90° raster angles relative to the specimen’s length axis, meaning adjacent layers alternated between filament deposition parallel to (0°) and perpendicular to (90°) the tensile loading direction. This configuration creates maximum reliance on interlayer bonding strength, as tensile loading occurs perpendicular to the primary layer interfaces.

Vertical Orientation: Specimens were printed with their length axis parallel to the printer’s Z-axis (build direction), with layer deposition occurring perpendicular to the specimen’s major axis. Each layer represented a cross-sectional slice through the specimen geometry, with the 100% rectilinear infill deposited at 0°/90° angles relative to the specimen’s width. In this configuration, tensile loading occurs parallel to the filament deposition direction within each layer, leveraging the inherent strength of continuous polymer chains rather than interlayer bonding.

Raster Pattern Specification: All specimens utilized 100% rectilinear infill with a 0.4 mm line width matching the nozzle diameter. The raster pattern consisted of parallel lines deposited with 0.1 mm spacing (line overlap), alternating between 0° and 90° orientations on successive layers. This pattern ensures complete volume filling while maintaining consistent extrusion parameters across both orientations.

Layer Thickness Selection Rationale: The selection of 0.2 mm and 0.4 mm layer heights represents the practical processing extremes for the 0.4 mm nozzle diameter (50% and 100% ratios, respectively). This binary approach was chosen to maximize the thermal contrast necessary for testing the thermal retention hypothesis while maintaining a manageable 23 factorial design. Layer heights below 0.2 mm typically suffer from inconsistent extrusion and poor interlayer adhesion, while heights above 0.4 mm create geometric limitations leading to void formation and dimensional instability.

2.3. Specimen Fabrication

Specimens conforming to ASTM D638 [

32] Type I geometry were fabricated using a FlashForge Creator Pro (Zhejiang Flashforge 3D Technology Co., Ltd., Jinhua, China) equipped with a 0.4 mm hardened steel nozzle (

Figure 1). The printer was operated according to manufacturer specifications with routine maintenance including bed leveling verification and nozzle cleaning between material changes.

Horizontal Specimens: Printed flat on the build plate with the gauge section aligned parallel to the X-axis. Layer height was controlled at 0.2 mm or 0.4 mm as specified, with each layer deposited as parallel lines alternating between 0° (parallel to gauge length) and 90° (perpendicular to gauge length) raster angles. Support material was not required for this orientation.

Vertical Specimens: Printed standing upright with the gauge section parallel to the Z-axis (build direction). Soluble support material (HIPS for PC, PVA for PLA) was used to support the specimen geometry during printing. The grip sections required support structures that were removed via dissolution in d-limonene (for HIPS) or water (for PVA) followed by mechanical cleaning.

Build Platform Preparation: The build platform was prepared with appropriate adhesion methods: glass bed with PEI coating for PC specimens (heated to 100 °C), and glass bed with blue painter’s tape for PLA specimens (heated to 60 °C). All specimens were printed with 3-perimeter shells, 100% rectilinear infill, and material-specific thermal profiles.

Quality Control Measures: Each specimen underwent dimensional verification using digital calipers before testing. Specimens with dimensional deviations exceeding ±0.2 mm from ASTM D638 [

32] specifications were excluded from analysis. This tolerance reflects the combined uncertainty of the printing process and measurement equipment rather than absolute dimensional precision.

Detailed Raster and Perimeter Specification:

(1) Perimeter Configuration: All specimens utilized 3 perimeter layers with raster direction determined by specimen contour geometry:

Horizontal specimens: Perimeter layers oriented parallel to specimen length (0° relative to loading direction);

Vertical specimens: Perimeter layers oriented perpendicular to specimen length (90° relative to loading direction).

(2) Infill Pattern Details:

Pattern: 100% rectilinear infill with alternating layer orientations;

Raster angles: 0° and 90° relative to specimen length axis on alternating layers;

Line width: 0.4 mm (matching nozzle diameter);

Line spacing: 0.4 mm (100% infill density).

Critical Design Limitation: The perimeter orientation varies between build orientations, creating a confounding variable where horizontal specimens benefit from load-aligned perimeters while vertical specimens have load-perpendicular perimeters. This geometric constraint of FDM printing makes it impossible to maintain constant perimeter orientation across different build orientations while preserving specimen geometry.

Specimen Geometry Verification and Dimensional Analysis

While specimens were designed according to ASTM D638 [

32] Type I geometry, actual printed dimensions deviated from nominal specifications due to FDM process limitations (

Figure 2 and

Table 2). Dimensional measurements of the gauge section were conducted on all specimens prior to testing using digital calipers at three locations along the gauge length. Vertical orientation specimens showed systematic dimensional reduction due to layer compression effects and support material removal requirements. Cross-sectional areas ranged from 31.3 to 39.4 mm

2, representing 75-95% of the nominal ASTM D638 [

32] Type I area (41.6 mm

2).

2.4. Mechanical Testing and Analysis

Tensile testing was conducted using an Instron 5969 universal testing machine (Instron Corporation, Norwood, MA, USA) with a 5 kN load cell at 5 mm/min crosshead speed (

Figure 3a,b). Specimens were secured with pneumatic grips (150 psi, serrated faces) over 100 mm grip separation. Engineering strain was calculated from crosshead displacement without extensometry or machine compliance corrections. Engineering strain calculations were based on crosshead displacement rather than direct gauge length measurement using extensometry. This approach assumes uniform deformation occurs within the 100 mm grip separation distance, which includes both the 50 mm gauge section and portions of the transition regions. The calculated elastic modulus represents an apparent modulus that includes machine compliance effects (estimated at ~0.1 mm/kN for the Instron 5969 frame) and deformation outside the gauge section. The assumption of uniform strain over the 100 mm grip distance underestimates actual gauge section strain, particularly at higher stress levels where deformation concentrates in the necked region. Grip slippage was minimized through proper specimen preparation and grip pressure, but no independent monitoring of grip displacement was conducted. The grip section geometry (wider than gauge section) provided mechanical anti-slip features according to ASTM D638 [

32] design.

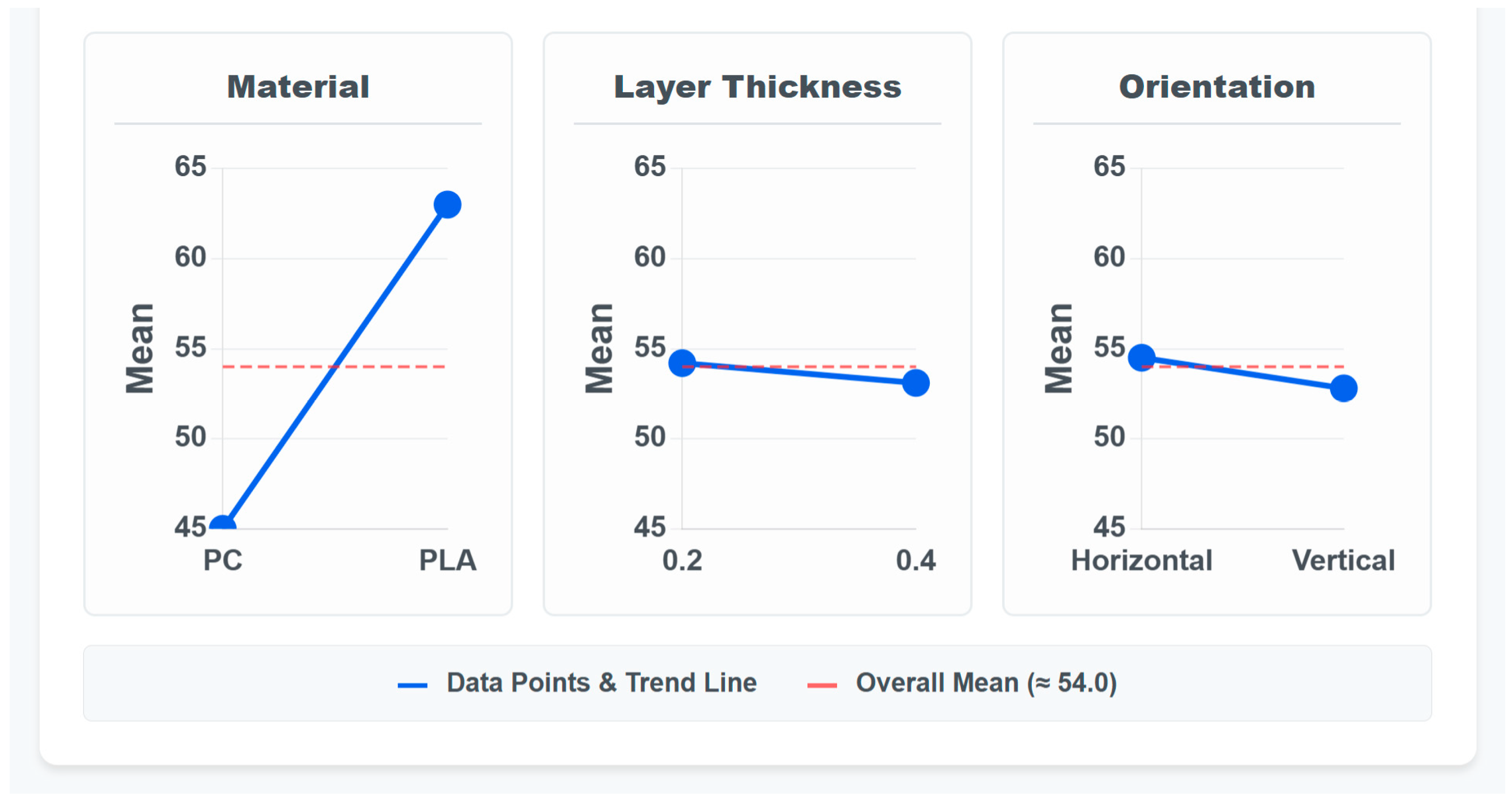

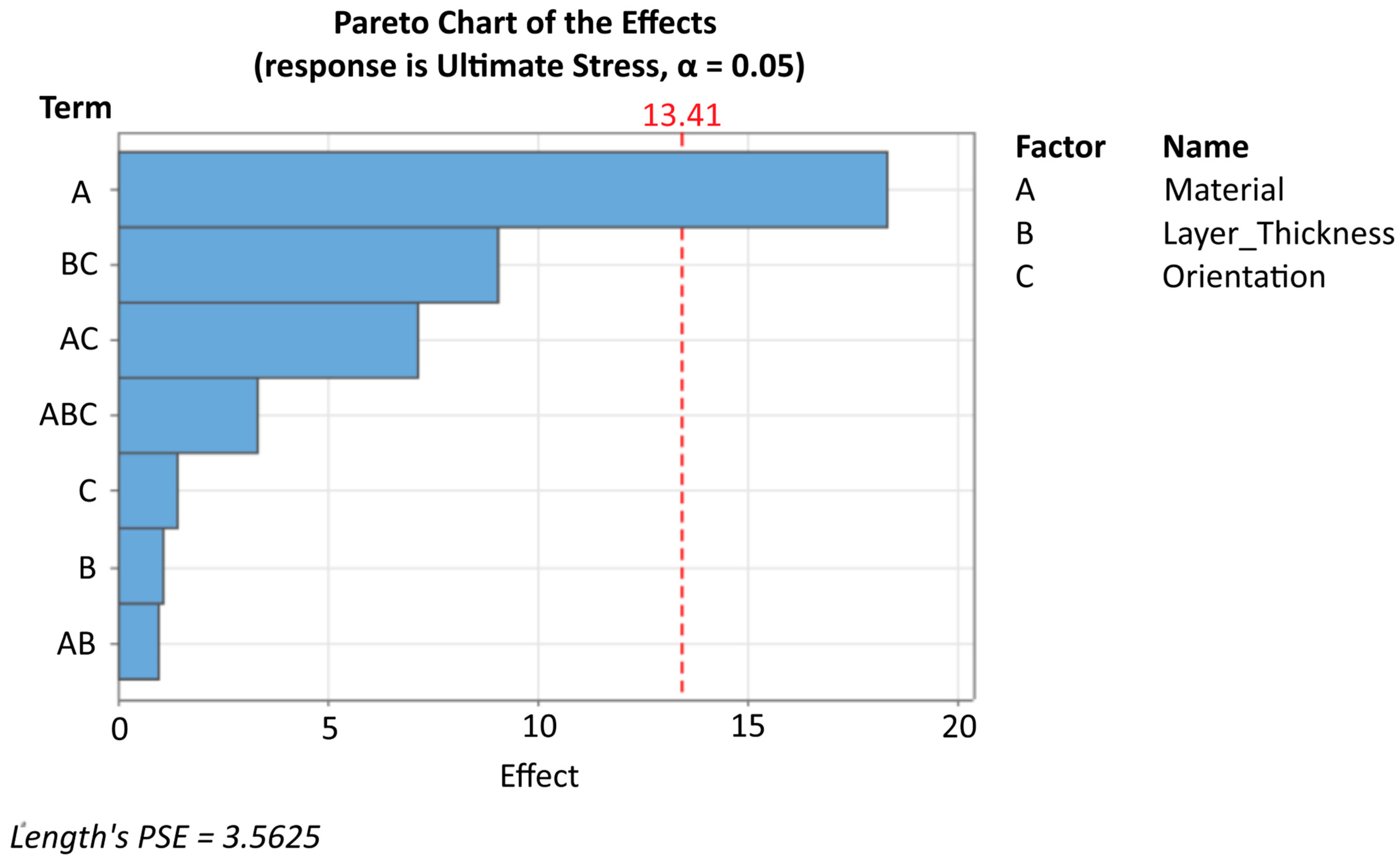

2.5. Statistical Methods

Statistical analysis employed Analysis of Variance (ANOVA) with significance level α = 0.05 to determine factor significance for the primary mechanical properties. A first-order multiple regression analysis was developed to produce predictive models for ultimate tensile strength, with model quality assessed through R-squared values. Main effects were visualized through plots to illustrate the individual impact of each factor, while potential parameter interactions were examined using interaction plots. Parameter significance was further evaluated through Pareto analysis of standardized effects to identify the most influential factors affecting mechanical performance. This statistical framework enabled systematic evaluation of the relationships between processing parameters and mechanical outcomes, facilitating the translation of experimental findings into practical manufacturing guidelines for application-specific optimization. Statistical coding employed effects coding (±1) rather than dummy coding (0,1) to enable proper interpretation of main effects in the presence of interactions.

4. Conclusions

This exploratory investigation establishes preliminary trends in FDM parameter optimization that provide direction for future adequately powered studies. The single-specimen experimental design (n = 1 per condition) successfully mapped the parameter space but limits statistical conclusions due to insufficient power for effect detection.

Key Findings and Statistical Context: Material selection emerged as the only statistically significant factor (p = 0.039), with PC demonstrating superior strength characteristics (maximum 67.5 MPa) compared to PLA, though PLA offered enhanced ductility (up to 22.4% strain). This significance reflects both large effect sizes and the relatively high statistical power (92%) for material comparisons.

Build orientation showed substantial practical trends, with vertical specimens demonstrating up to 64.7% higher tensile strength than horizontal builds, accompanied by significant reductions in ductility. However, these effects did not achieve statistical significance (p = 0.825) due to inadequate statistical power (8%). Post hoc power analysis indicates that 8-12 specimens per condition would be required to establish statistical significance for orientation effects.

Layer thickness trends suggest that thicker layers (0.4 mm) may improve ultimate strength by up to 36.2% while reducing production time by 50%. These findings contribute to growing evidence questioning traditional assumptions about layer thickness optimization, though statistical validation requires adequate replication (estimated 15–20 specimens per condition for 80% power).