Strength in Adhesion: A Multi-Mechanics Review Covering Tensile, Shear, Fracture, Fatigue, Creep, and Impact Behavior of Polymer Bonding in Composites

Abstract

1. Introduction

2. Overview of Polymer Adhesives and Characterization of Mechanical Properties

2.1. Overview of Polymer Adhesives in Composites and Bonded Joints

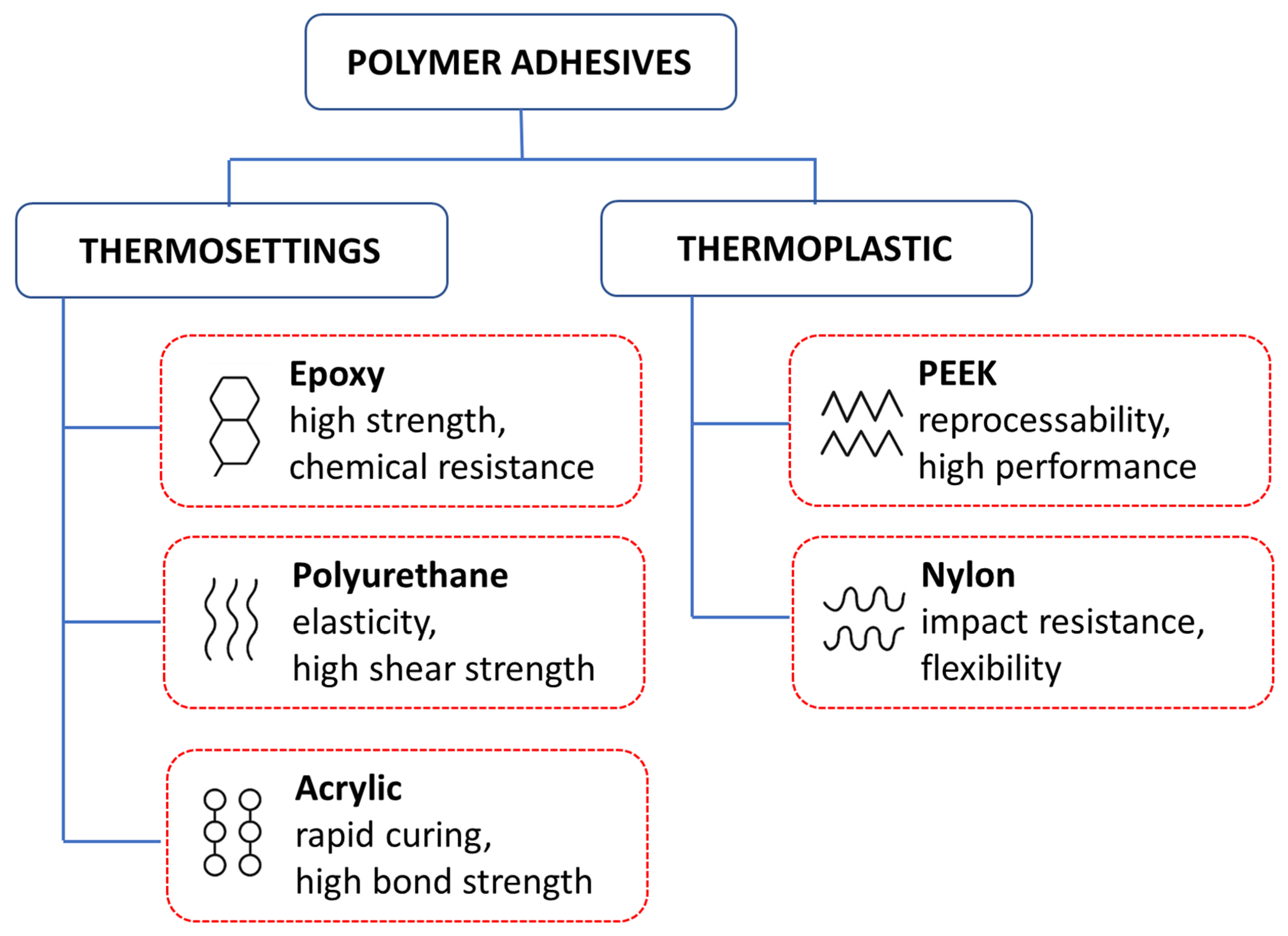

2.1.1. Types of Adhesives Used

- Epoxy adhesives are extensively applied in aerospace, automotive, and construction because of their stiffness, adhesion to metals, ceramics, and composites, and robustness under environmental exposure. Their brittleness, however, limits impact performance, prompting modifications such as rubber or thermoplastic toughening [12]. More recently, formulations designed to maintain performance across wide temperature ranges have expanded their use in extreme environments [13].

- Polyurethane adhesives offer a balance of elasticity and high shear strength, making them suitable for flexible adherends and vibration-damping applications. Their fatigue resistance and toughness make them advantageous where epoxy’s brittleness is problematic. Recent studies on dynamic polymer networks demonstrate potential for recyclable, reprocessable polyurethane adhesives by enabling bond-exchange reactions, though industrial scalability remains a challenge [14].

- Acrylic adhesives combine rapid curing, high bond strength, and ease of processing, which make them attractive in high-volume, cost-sensitive applications such as automotive assembly. Thermosetting acrylics can withstand elevated temperatures and aggressive environments, though they often exhibit lower long-term fatigue resistance than polyurethanes [15]. Cyanoacrylate adhesives cure instantly and bond diverse substrates, from metals and ceramics to biological tissues. However, their brittleness and poor peel/impact resistance limit structural use, confining them to small-area, temporary, or niche applications.

- Polyether ether ketone (PEEK) adhesives combine mechanical strength, chemical resistance, and high-temperature performance. Their dimensional stability and lightweight nature make them suitable for aerospace and electronics, while recent work highlights their potential in biomedical applications due to biocompatibility [16].

- Nylon-based adhesives provide flexibility and impact resistance, performing well in dynamic load conditions. Hot-melt nylon systems show favorable peel strength and fast setting, supporting their use in industrial applications where toughness and wear resistance are essential [17].

2.1.2. Adhesion Mechanisms in Different Applications

| Adhesive Role | Primary Mechanisms | Key Factors and Surface Treatments | Effects on Performance | References |

|---|---|---|---|---|

| Matrix in Fiber-Reinforced Composites | - Chemical bonding (covalent or hydrogen bonds with fiber surface groups) - Mechanical interlocking (infiltration of surface asperities) | - Functional groups on fiber surface (e.g., –OH, –COOH, –NH2) - Use of silane coupling agents for molecular bridging - Surface modifications: plasma treatment, oxidation, grit blasting, chemical etching | - Enhanced stress transfer and interfacial strength - Improved wettability and adhesion strength - Superior mechanical performance of composites | [12,18,20] |

| Bonding Agent in Adhesive Joints | - Surface adhesion (chemical compatibility and surface energy) - Mechanical interlocking (penetration into microscopic irregularities) - Van der Waals forces (secondary molecular attractions) | - Surface treatments: mechanical abrasion, chemical etching, plasma treatment - Laser ablation and nano-patterning for increased anchoring - Surface energy matching between adhesive and substrate | - Improved wetting and adhesion - Enhanced joint strength, especially in composite-to-metal bonds - Complementary van der Waals forces improving durability | [21,22,23,24] |

| Advanced Approaches | - Nano-reinforced adhesives (graphene oxide, carbon nanotubes) | - Nanoparticle incorporation to enhance bonding and fracture toughness | - Increased interfacial bonding and resistance to environmental degradation - Promising for next-generation composite structures | [25] |

2.1.3. Factors Affecting Adhesive Performance

2.2. Characterizing Mechanical Properties

2.2.1. Experimental Methods

2.2.2. Numerical Modeling and Simulation Approaches

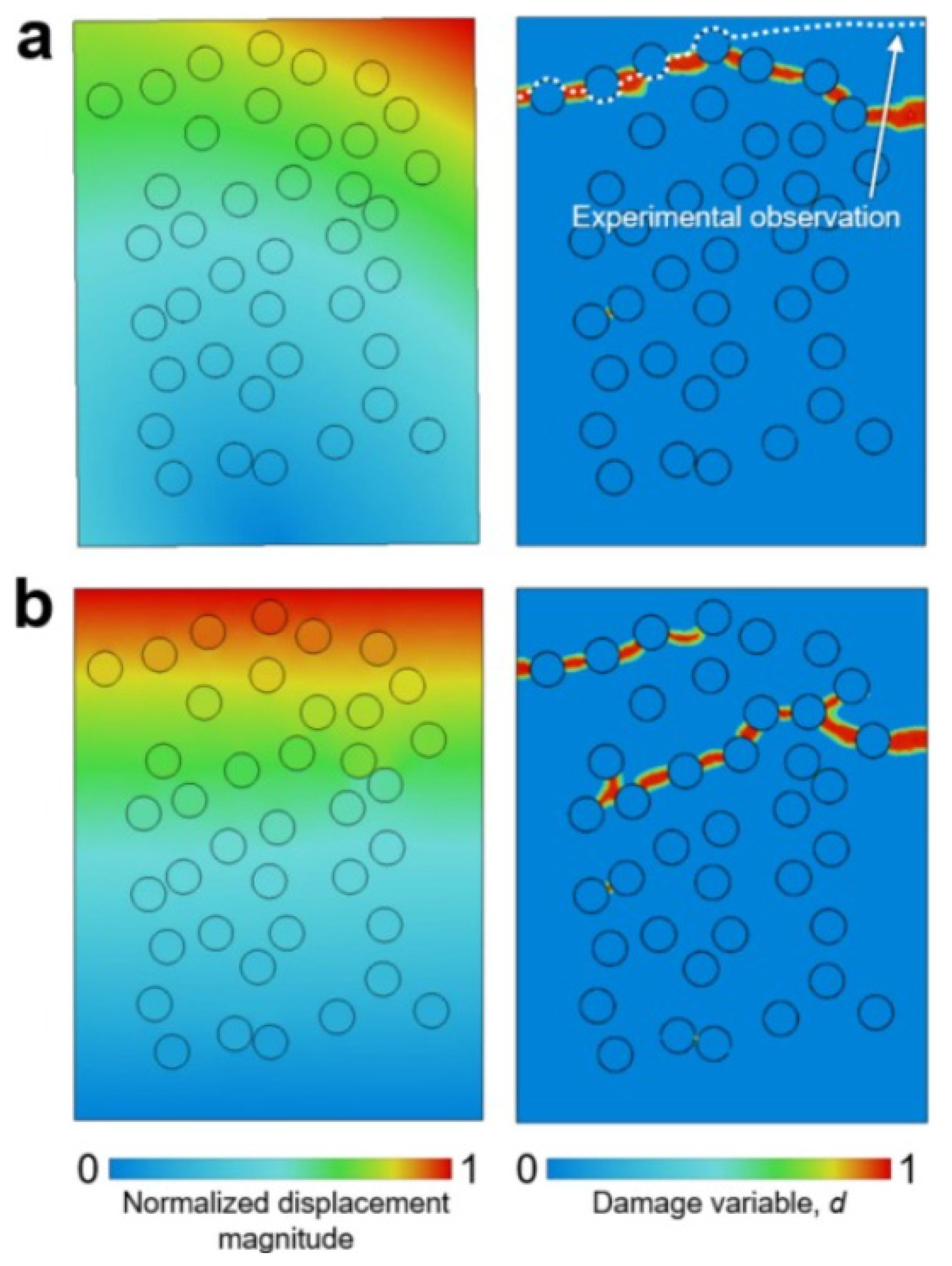

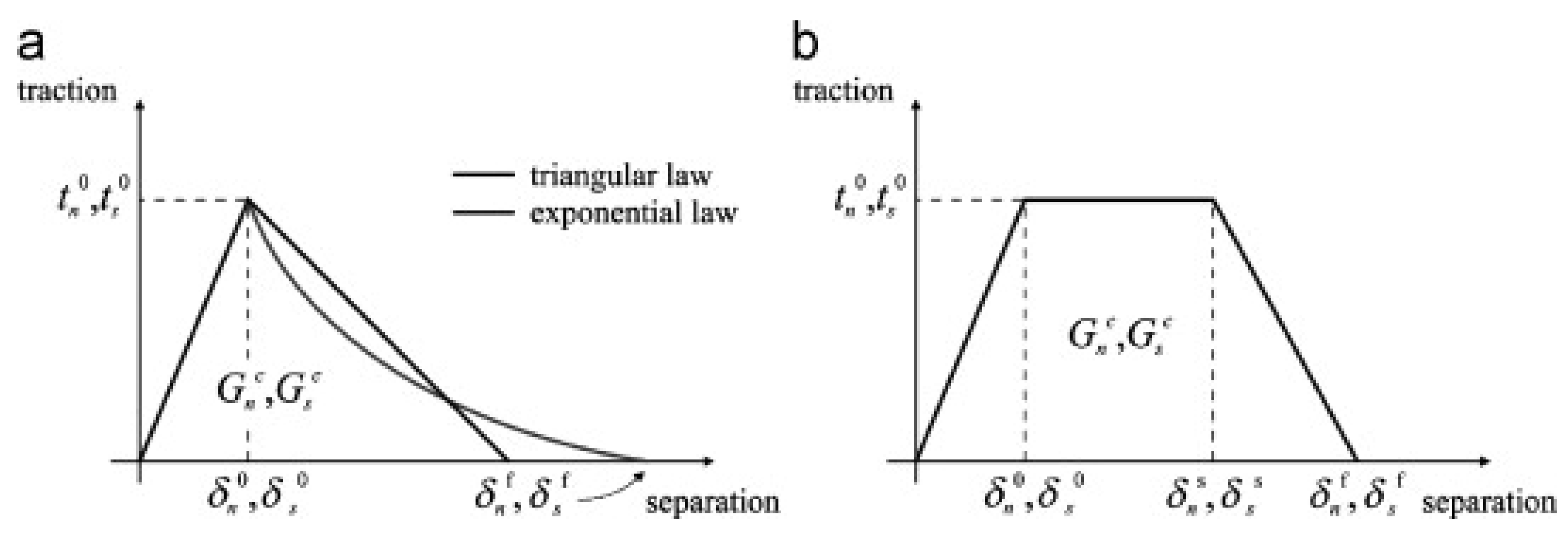

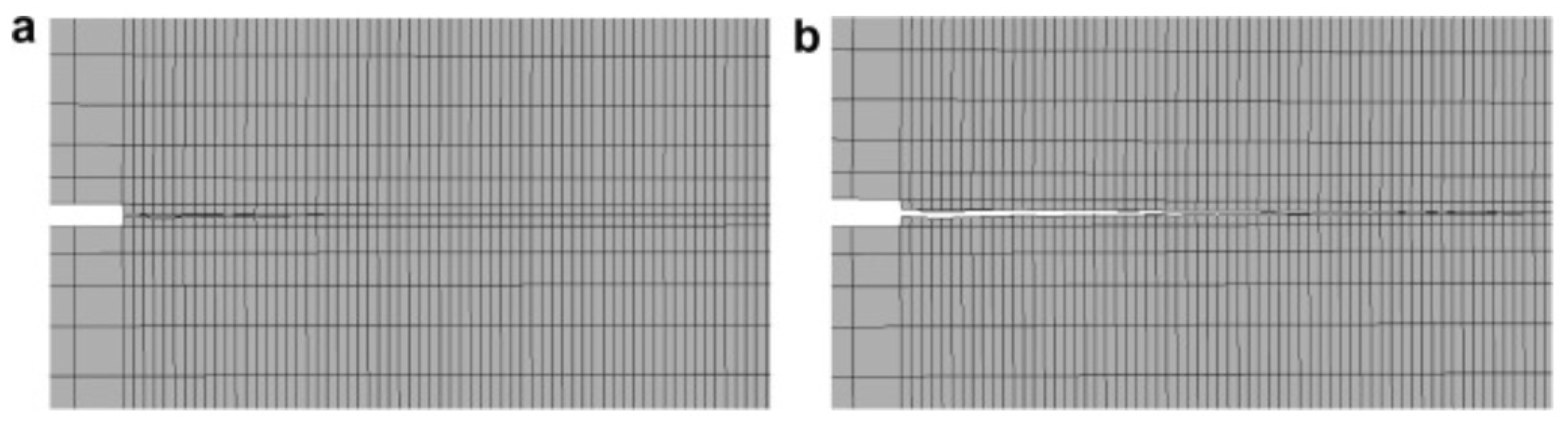

Cohesive Zone Models for Fracture Prediction

Finite Element Analysis (FEA) of Adhesive Joints and Matrices

Multi-Scale Modeling of Adhesives in Composite Laminates

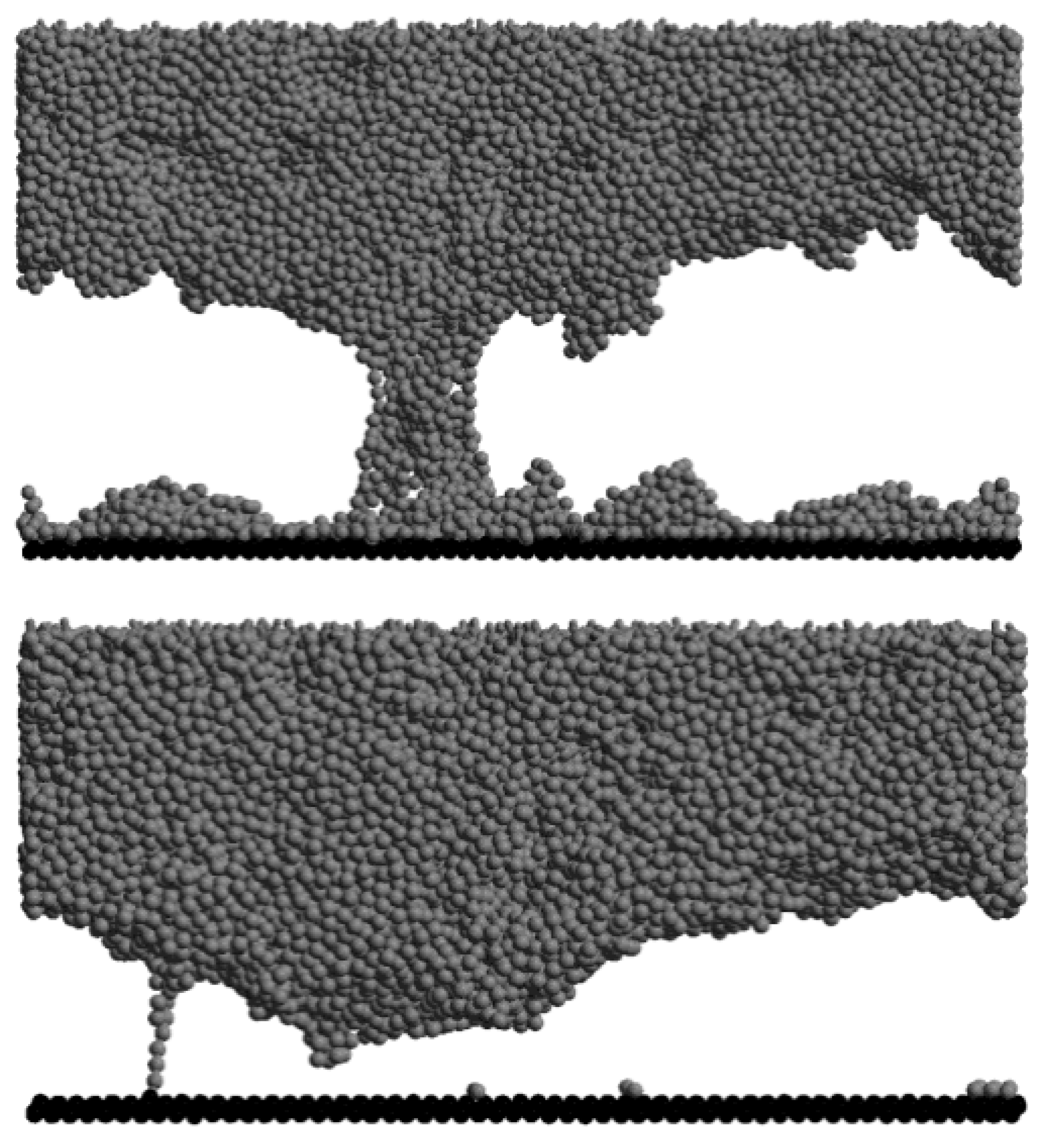

Molecular Dynamics (MD) Simulations

3. Mechanical Properties

3.1. Tensile and Shear Strength

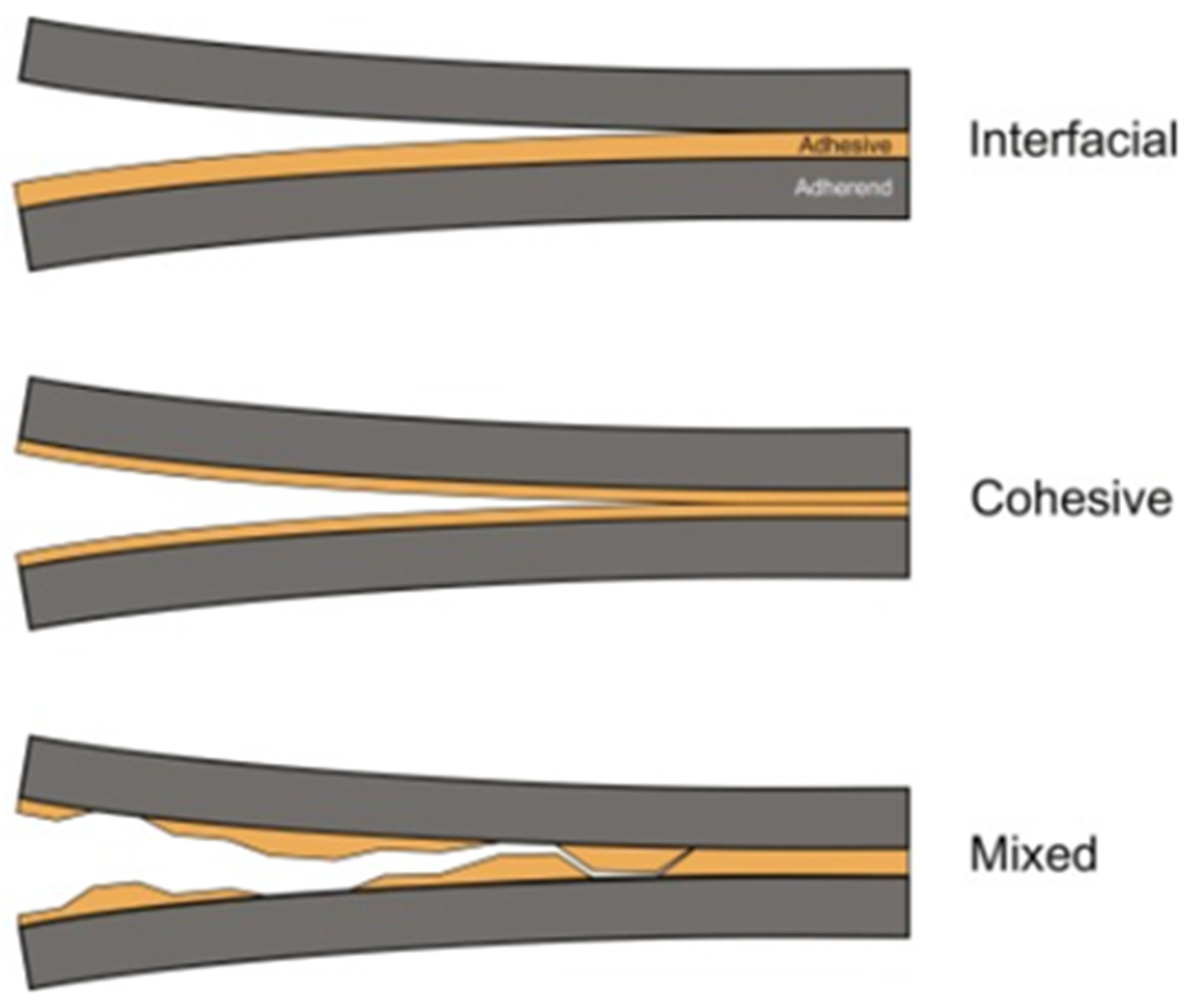

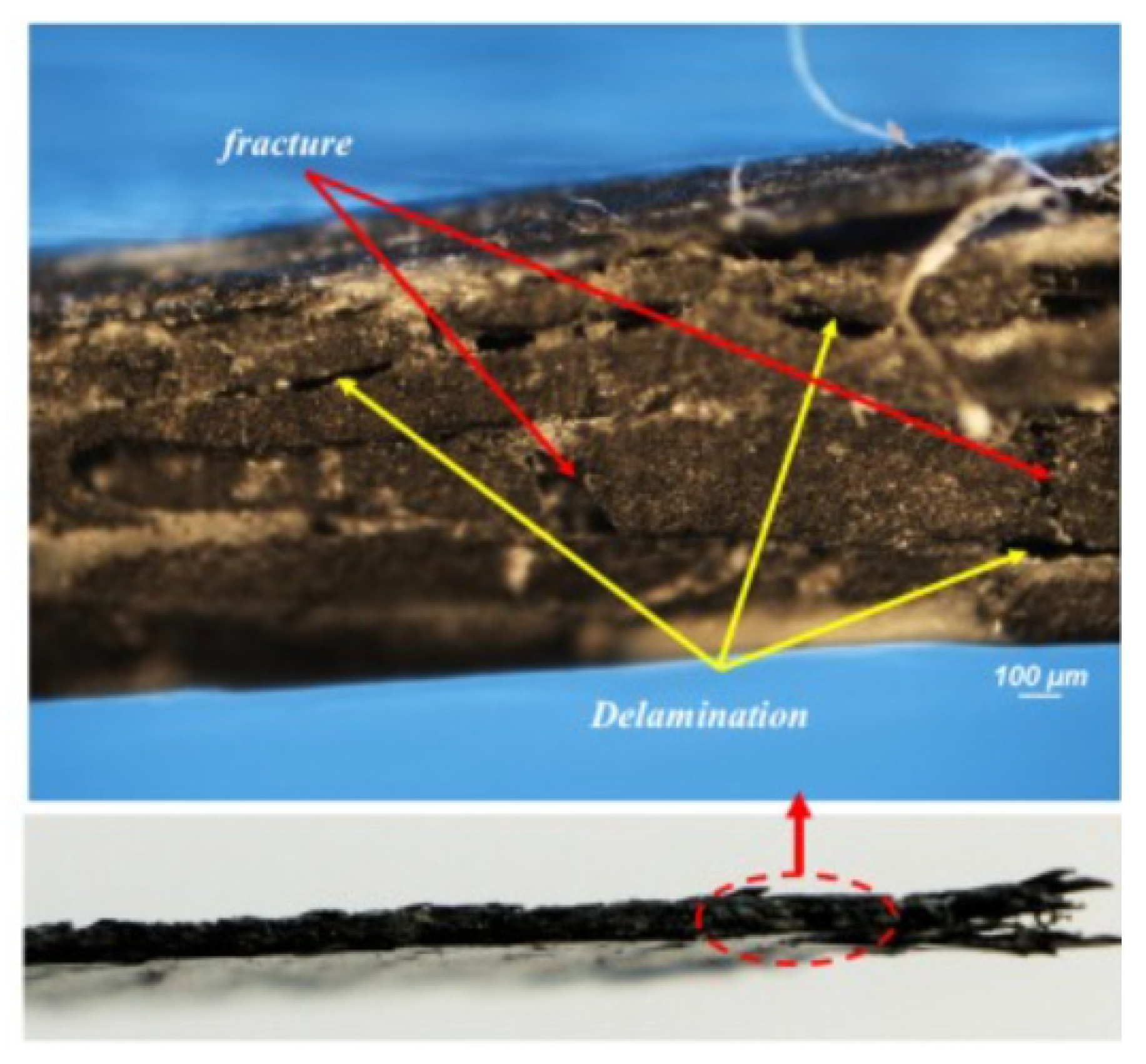

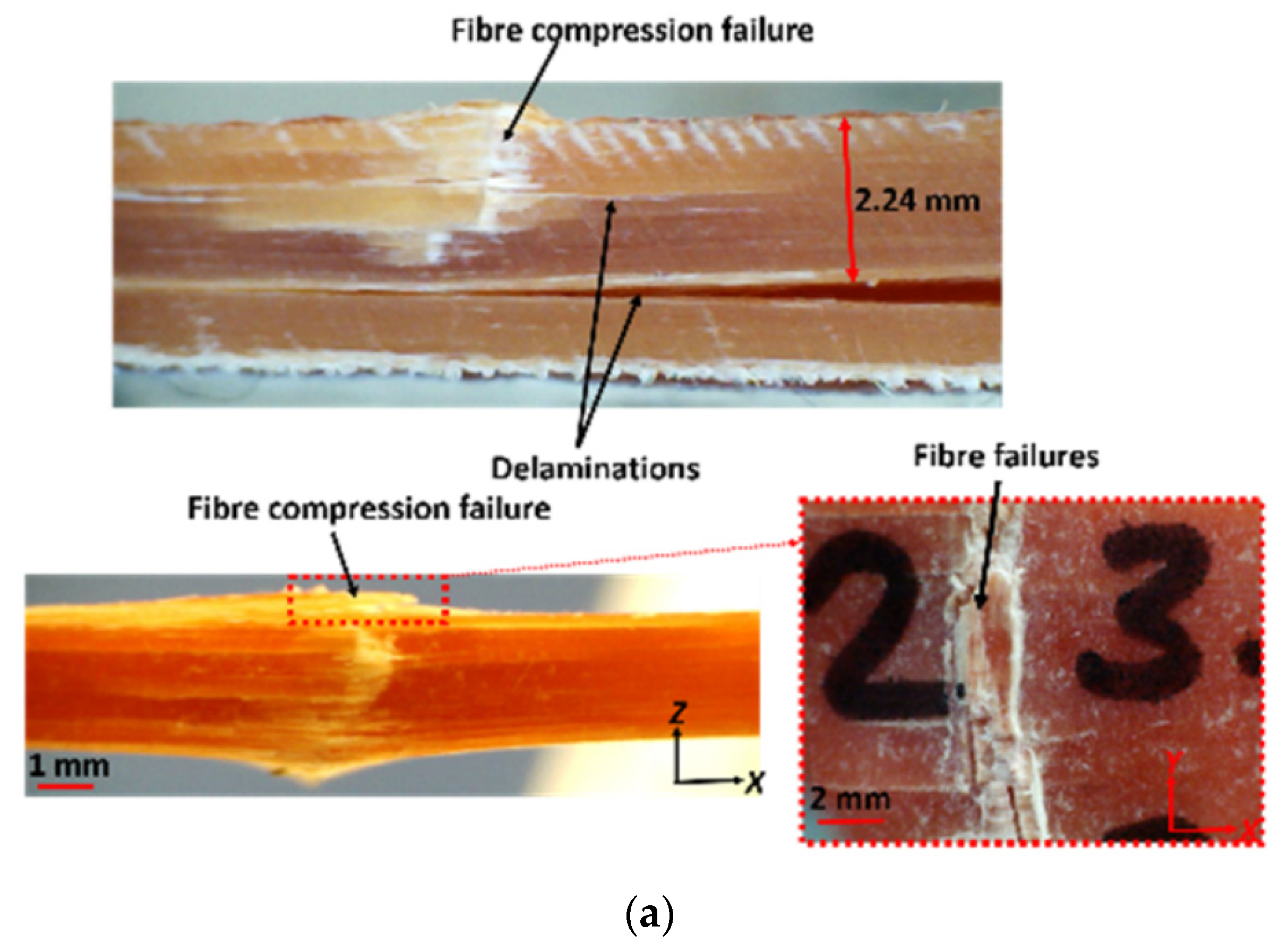

3.2. Fracture Toughness and Crack Propagation

3.3. Fatigue and Long-Term Durability

| Adhesive System | Fatigue Life Range/Key Data | Key Notes and Reference(s) |

|---|---|---|

| Epoxy | ~105–107 cycles under favorable shear/tensile fatigue; significantly reduced life when moisture or environmental degradation is present | Data from a cold-curing structural epoxy investigated under wet/dry fatigue: up to ~10 million cycles in benign conditions, with moisture dramatically reducing fatigue life [141,142,143,144]. |

| Polyurethane (PU) | ~104–106 cycles in normalized cyclic shear/tension conditions; fatigue endurance depends strongly on temperature and environmental conditions | Fatigue design curves and S–N behavior for a one-component PU adhesive show wide cycle ranges and environmental sensitivity [145,146]. |

| Acrylics (MMA/structural acrylics) | ~104–105 cycles in structural adhesive fatigue tests; some data suggest improved endurance for modified formulations | Plexus MA300 methacrylic adhesive fatigue data provide S–N results for a structural acrylic system [147]. |

| PEEK-based systems | ~106–108 cycles. Few direct fatigue data available for adhesive joints; bulk PEEK fatigue studies show endurance, but joint-level fatigue data are scarce | Existing PEEK fatigue studies focus on bulk polymer or composite fatigue, not specifically adhesive joints, so fatigue life in bonding scenarios remains uncertain [148]. |

| Nylon-based adhesives | Very limited fatigue life information for nylon adhesives themselves; fatigue performance is mostly derived from joint-level studies involving polyamide substrates | Systematic data for commercial nylon adhesives under cyclic loading remains scarce. |

3.4. Creep and Viscoelastic Behavior

3.5. Impact and High-Strain-Rate Behavior

4. Applications and Challenges

4.1. Applications

4.2. Challenges

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Maggiore, S.; Banea, M.D.; Stagnaro, P.; Luciano, G. A review of structural adhesive joints in hybrid joining processes. Polymers 2021, 13, 3961. [Google Scholar] [CrossRef]

- Maiti, S.; Islam, M.R.; Uddin, M.A.; Afroj, S.; Eichhorn, S.J.; Karim, N. Sustainable fiber-reinforced composites: A review. Adv. Sustain. Syst. 2022, 6, 2200258. [Google Scholar] [CrossRef]

- Dachev, D.; Kazilas, M.; Alfano, G.; Omairey, S. Towards Reliable Adhesive Bonding: A Comprehensive Review of Mechanisms, Defects, and Design Considerations. Materials 2025, 18, 2724. [Google Scholar] [CrossRef]

- Marques, J.B.; Barbosa, A.Q.; da Silva, C.I.; Carbas, R.J.C.; da Silva, L.F.M. An overview of manufacturing functionally graded adhesives–Challenges and prospects. J. Adhes. 2021, 97, 172–206. [Google Scholar] [CrossRef]

- Stern, T.; Marom, G. Fracture Mechanisms and Toughness in Polymer Nanocomposites: A Brief Review. J. Compos. Sci. 2024, 8, 395. [Google Scholar] [CrossRef]

- Mousavi, S.R.; Estaji, S.; Paydayesh, A.; Arjmand, M.; Jafari, S.H.; Nouranian, S.; Khonakdar, H.A. A review of recent progress in improving the fracture toughness of epoxy-based composites using carbonaceous nanofillers. Polym. Compos. 2022, 43, 1871–1886. [Google Scholar] [CrossRef]

- Kenig, S.; Dodiuk, H.; Otorgust, G.; Gomid, S. Nanocomposite Polymer Adhesives: A Critical Review. Prog. Adhes. Adhes. 2020, 5, 93. [Google Scholar]

- Hussin, M.H.; Abd Latif, N.H.; Hamidon, T.S.; Idris, N.N.; Hashim, R.; Appaturi, J.N.; Kristák, L.; Reh, R.; Lubis, M.A.R.; Savov, V.; et al. Latest advancements in high-performance bio-based wood adhesives: A critical review. J. Mater. Res. Technol. 2022, 21, 3909–3946. [Google Scholar] [CrossRef]

- Oshima, S.; Koyanagi, J. Review on Damage and Failure in Adhesively Bonded Composite Joints: A Microscopic Aspect. Polymers 2025, 17, 377. [Google Scholar] [CrossRef]

- Tserpes, R.V.; Barroso-Caro, A.; Carraro, P.A.; Carrillo Beber, V.; Floros, I.; Gamon, W.; Kozłowski, M.; Santandrea, F.; Shahverdi, M.; Skejić, D.; et al. A review on failure theories and simulation models for adhesive joints. J. Adhes. 2022, 98, 1855–1915. [Google Scholar] [CrossRef]

- Magalhães, S.; Alves, L.; Medronho, B.; Fonseca, A.C.; Romano, A.; Coelho, J.F.J.; Norgren, M. Brief overview on bio-based adhesives and sealants. Polymers 2019, 11, 1685. [Google Scholar] [CrossRef] [PubMed]

- Zalucha, D.J.; Abbey, K.J. The chemistry of structural adhesives: Epoxy, urethane, and acrylic adhesives. In Handbook of Industrial Chemistry and Biotechnology; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Aronovich, D.A. A Review of Modern Adhesive Materials Operating in a Wide Temperature Range. Epoxy Adhesives. Polym. Sci. Ser. D 2023, 16, 14–33. [Google Scholar] [CrossRef]

- Bautista-Anguís, D.; Reiner, L.; Röper, F.; Maar, S.; Wolfahrt, M.; Wolfberger, A.; Schlögl, S. Synthesis and Characterization of Rebondable Polyurethane Adhesives Relying on Thermo-Activated Transcarbamoylation. Polymers 2024, 16, 2799. [Google Scholar] [CrossRef]

- Sineokova, O.A.; Khamidulova, Z.S.; Zhdanova, O.G.; Sineokov, A.P. A thermoset structural acryl adhesive. Polym. Sci. Ser. D 2015, 8, 167–170. [Google Scholar] [CrossRef]

- Luo, C.; Liu, Y.; Peng, B.; Chen, M.; Liu, Z.; Li, Z.; Kuang, H.; Gong, B.; Li, Z.; Sun, H. PEEK for Oral Applications: Recent Advances in Mechanical and Adhesive Properties. Polymers 2023, 15, 386. [Google Scholar] [CrossRef]

- Hussey, R.J. Thermoplastic Hot-Melt Adhesives. In Structural Adhesives; Springer: Boston, MA, USA, 1996. [Google Scholar]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Fang, C.; Zhou, Y.; Jia, L.; Yan, R. Interfacial properties of multicomponent plasma-modified high-performance fiber-reinforced composites: A review. Polym. Compos. 2022, 43, 4866–4883. [Google Scholar] [CrossRef]

- Nasreen, A.; Shaker, K.; Nawab, Y. Effect of surface treatments on metal–composite adhesive bonding for high-performance structures: An overview. Compos. Interfaces 2021, 28, 1221–1256. [Google Scholar] [CrossRef]

- Cui, C.; Liu, W. Recent advances in wet adhesives: Adhesion mechanism, design principle and applications. Prog. Polym. Sci. 2021, 116, 101388. [Google Scholar] [CrossRef]

- Wu, L.J.; An, S.L.; Lu, Z.Q.; Ning, S.W.; Ryan, M. Interfacial performance of high-performance fiber-reinforced composites improved by cold plasma treatment: A review. Surf. Interfaces 2021, 24, 101077. [Google Scholar]

- Mandolfino, C.; Leone, P.; Parodi, M.; Giorcelli, C. Laser-induced modification of surface properties by micro-and nano-scale processing. In Laser Micro-and Nano-Scale Processing: Fundamentals and Applications; IOP Publishing: Bristol, UK, 2021; pp. 1–21. [Google Scholar]

- Lin, W.S.; Catchmark, J.M. Development of Sustainable Adhesives Based on Polysaccharide–Polyelectrolyte Complexes for Natural Fiber-Based Materials. ACS Appl. Polym. Mater. 2024, 6, 7947–7955. [Google Scholar] [CrossRef]

- Ogbonna, V.E.; Popoola, A.P.I.; Popoola, O.M.; Adeosun, S.O. A review on the recent advances on improving the properties of epoxy nanocomposites for thermal, mechanical, and tribological applications: Challenges and recommendations. Polym. Plast. Technol. Mater. 2022, 61, 176–195. [Google Scholar] [CrossRef]

- Ravichandran, B.; Balasubramanian, M. Joining methods for Fiber Reinforced Polymer (FRP) composites—A critical review. Compos. Part A Appl. Sci. Manuf. 2024, 186, 108394. [Google Scholar] [CrossRef]

- Jahani, Y.; Baena, M.; Barris, C.; Perera, R.; Torres, L. Influence of curing, post-curing and testing temperatures on mechanical properties of a structural adhesive. Constr. Build. Mater. 2022, 324, 126698. [Google Scholar] [CrossRef]

- Vitale, A.; Trusiano, G.; Bongiovanni, R. UV-curing of adhesives: A critical review. Prog. Adhes. Adhes. 2018, 3, 101–154. [Google Scholar]

- Wei, Y.; Jin, X.; Luo, Q.; Li, Q.; Sun, G. Adhesively bonded joints—A review on design, manufacturing, experiments, modeling and challenges. Compos. Part B Eng. 2024, 276, 111225. [Google Scholar] [CrossRef]

- Zou, X.; Sariyev, B.; Chen, K.; Jiang, M.; Wang, M.; Hua, X.; Zhang, L.; Shan, A. Enhanced interfacial bonding strength between metal and polymer via synergistic effects of particle anchoring and chemical bonding. J. Manuf. Process. 2021, 68, 558–568. [Google Scholar] [CrossRef]

- Zhao, Q.; Lu, Z.; Wu, Y.; Zhao, W. Designing strong interfacial adhesion between carbon fiber and epoxy resin via dopamine towards excellent protection ability under high hydrostatic pressure and severe erosion corrosion condition. Compos. Sci. Technol. 2022, 217, 109090. [Google Scholar] [CrossRef]

- Shu, Y.; Qiang, X.; Jiang, X.; Yang, R.; Li, M. Durability of epoxy adhesives employed in civil engineering under hot/wet environments. J. Build. Eng. 2025, 104, 112366. [Google Scholar] [CrossRef]

- ASTM D1183-01; Standard Test Method for Tensile Properties of Adhesive Bonds. ASTM lnternational: West Conshehoken, PA, USA, 2019; Volume D1183-03, pp. 11–13.

- ISO 9142; Adhesives—Guide to the Selection of Standard Laboratory Ageing Conditions for Testing Bonded Joints. International Organization for Standardization: Geneva, Switzerland, 2003.

- ASTM G154-16; Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Material. ASTM International: West Conshohocken, PA, USA, 2020; pp. 1–11.

- ASTM B-117; Standard Practice for Operating Salt Spray (Fog) Apparatus. ASTM: West Conshehoken, PA, USA, 2024.

- ISO 9227:2017; Corrosion Tests in Artificial Atmospheres—Salt Spray Tests. International Organization for Standardization: Geneva, Switzerland, 2017.

- Ye, J.; Zhang, Z.; Huang, S.; Liu, Y.; Wen, W.; Xiang, H. UV-Curing Silicone-Based Adhesives with Improved Adhesion Strength and Aging Resistance. Ind. Eng. Chem. Res. 2024, 63, 21300–21311. [Google Scholar] [CrossRef]

- Buran, E.; Şişmanoğlu, S.; Çavdar, A.; Belkuyu, E.N. Effect of UV and Hydrothermal Artificial Aging on Mechanical, Thermal and Morphological Properties of Epoxy and Green Chemistry Synthesized Fe2O3 Nanoparticle Filled Epoxy Composites. Polym. Compos. 2025. [Google Scholar] [CrossRef]

- Gupta, A.; Maiti, S.; Saini, P.; Srivastava, S.; Kausley, S.; Rai, B. Combined concurrent Physical and Chemical model for accelerated weathering damages of polyurethane-based coatings. arXiv 2024, arXiv:2410.19797. [Google Scholar]

- Aronovich, D.A.; Boinovich, L.B. Structural acrylic adhesives: A critical review. Prog. Adhes. Adhes. 2021, 6, 651–708. [Google Scholar]

- Zhao, Y.; Zhang, H.; Zhu, X.; Wang, M.; Shen, D.; Fu, C.; Ma, J. Stable waterborne epoxy resins: Impact of toughening agents on coating properties. Smart Mater. Manuf. 2025, 3, 100079. [Google Scholar] [CrossRef]

- Savage, G. Failure prevention in bonded joints on primary load bearing structures. Eng. Fail. Anal. 2007, 14, 321–348. [Google Scholar] [CrossRef]

- ASTM D1002-10; Standard Test Method for Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens by Tension Loading (Metal-to-Metal). ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D5656-04; Standard Test Method for Thick-Adherend Metal Lap-Shear Joints for Determination of the Stress-Strain Behavior of Adhesives in Shear by Tension Loading. ASTM International: West Conshohocken, PA, USA, 2004.

- Shishesaz, M.; Hosseini, M. Effects of joint geometry and material on stress distribution, strength and failure of bonded composite joints: An overview. J. Adhes. 2020, 96, 1053–1121. [Google Scholar] [CrossRef]

- Goglio, L.; Peroni, L.; Peroni, M.; Rossetto, M. High strain-rate compression and tension behaviour of an epoxy bi-component adhesive. Int. J. Adhes. Adhes. 2008, 28, 329–339. [Google Scholar] [CrossRef]

- Ling, Q.; Ke, T.; Liu, W.; Ren, Z.; Zhao, L.; Gu, H. Tough, repeatedly adhesive, cyclic compression-stable, and conductive dual-network hydrogel sensors for human health monitoring. Ind. Eng. Chem. Res. 2021, 60, 18373–18383. [Google Scholar]

- ASTM D5528; Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. ASTM: West Conshohocken, PA, USA, 2021.

- Morimoto, T.; Katoh, H.; Ishida, Y.; Hara, E.; Kusano, M.; Naito, K.; Watanabe, M.; Takagi, K.; Arai, K.; Hasegawa, K. Modified double cantilever beam test method for mode-I energy release rate of elastic adhesive layers. Eng. Fract. Mech. 2024, 307, 110320. [Google Scholar] [CrossRef]

- Valoroso, N.; Sessa, S.; Lepore, M.; Cricri, G. Identification of mode-I cohesive parameters for bonded interfaces based on DCB test. Eng. Fract. Mech. 2013, 104, 56–79. [Google Scholar] [CrossRef]

- ASTM D7905; Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. Annual Book ASTM Standard: West Conshohocken, PA, USA, 2014; pp. 1–18.

- Rahman, S.A.; Subhani, M.; Ashraf, M. Mode-II progressive fracture of sawn timber and timber-adhesive bond: Experimental evaluation of end notched flexure (ENF) testing using DIC. Eur. J. Wood Wood Prod. 2023, 81, 1437–1453. [Google Scholar] [CrossRef]

- Pérez-Galmés, M.; Renart, J.; Sarrado, C.; Brunner, A.J.; Rodríguez-Bellido, A. Towards a consensus on mode II adhesive fracture testing: Experimental study. Theor. Appl. Fract. Mech. 2018, 98, 210–219. [Google Scholar] [CrossRef]

- Kumar, A.; Saikia, P.J.; Narayanan, R.G.; Muthu, N. Experimental and numerical analysis of mixed mode bending of adhesive-bonded and hybrid honeycomb core sandwich structures. Int. J. Solids Struct. 2025, 309, 113177. [Google Scholar] [CrossRef]

- ASTM D3479; Standard Test Method for Tension-Tension Fatigue of Polymers Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D3166; Standard Test Method for Fatigue Properties of Adhesives in Shear by Tension Loading (Metal/Metal). ASTM International: West Conshohocken, PA, USA, 2020.

- Sousa, F.C.; Akhavan-Safar, A.; Carbas, R.J.; Marques, E.A.; Barbosa, A.Q.; da Silva, L.F. Experimental study on the influence of environmental conditions on the fatigue behaviour of adhesive joints. Int. J. Fatigue 2023, 175, 107752. [Google Scholar] [CrossRef]

- Jones, R.; Kinloch, A.J.; Michopoulos, J.; Iliopoulos, A.P. Crack growth in adhesives: Similitude and the Hartman-Schijve equation. Compos. Struct. 2021, 273, 114260. [Google Scholar] [CrossRef]

- He, Z.; Luo, Q.; Li, Q.; Zheng, G.; Sun, G. Fatigue behavior of CFRP/Al adhesive joints—Failure mechanisms study using digital image correlation (DIC) technique. Thin-Walled Struct. 2022, 174, 109075. [Google Scholar] [CrossRef]

- Owens, A.T.; Tippur, H.V. Measurement of mixed-mode fracture characteristics of an epoxy-based adhesive using a hybrid digital image correlation (DIC) and finite elements (FE) approach. Opt. Lasers Eng. 2021, 140, 106544. [Google Scholar] [CrossRef]

- Nazari, R.; Khoramishad, H.; Hakimi, R. The effect of abrading treatment method on the bonding surface characteristics and fracture behavior of glass fiber-epoxy composite adhesive joints. J. Adhes. Sci. Technol. 2024, 38, 2405. [Google Scholar] [CrossRef]

- Ramić, B.D.; Stojanac, I.L.; Drobac, M.R.; Kantardžić, I.R.; Maletin, A.Z.; Cvjetićanin, M.T.; Otašević, K.S.; Petrović, L.M. Application of Scanning Electron Microscopy in the observation of dentin-adhesive interface. Microsc. Res. Tech. 2021, 84, 602–607. [Google Scholar] [CrossRef]

- Kumpati, R.; Skarka, W.; Ontipuli, S.K. Current trends in integration of nondestructive testing methods for engineered materials testing. Sensors 2021, 21, 6175. [Google Scholar] [CrossRef]

- Guin, R.S.; Bhowmik, J.; Verghese, T.; Anand, N.; Narayanasamy, N.; Thiyagarajan, A.; Wang, E. Characterization of fracture behavior in adhesively bonded joints with porosity in the adhesive layer using X-ray computed tomography. Compos. Sci. Technol. 2025, 261, 111025. [Google Scholar] [CrossRef]

- Petreanu, I.; Niculescu, V.-C.; Stanica, S.; Enache, C.; Iacob, C. Structural characterization of silica and amino-silica nanoparticles by Fourier transform infrared (FTIR) and raman spectroscopy. Anal. Lett. 2023, 56, 390–403. [Google Scholar] [CrossRef]

- Alhenaki, A.M.; Attar, E.A.; Alshahrani, A.; Farooq, I.; Vohra, F.; Abduljabbar, T. Dentin bond integrity of filled and unfilled resin adhesive enhanced with silica nanoparticles—An SEM, EDX, micro-raman, FTIR and micro-tensile bond strength study. Polymers 2021, 13, 1093. [Google Scholar] [CrossRef]

- De Pasquale, G.; Altunok, F.E. Multiphase modeling of matrix/fiber-related damaging mechanism in multimaterial additively manufactured joints with 3D interlocking. Eng. Fail. Anal. 2025, 170, 109272. [Google Scholar] [CrossRef]

- Cheng, Z.Q.; Liu, H.; Tan, W. Advanced computational modelling of composite materials. Eng. Fract. Mech. 2024, 305, 110120. [Google Scholar] [CrossRef]

- Campilho, R.D.; Banea, M.D.; Neto, J.A.B.P.; da Silva, L.F. Modelling adhesive joints with cohesive zone models: Effect of the cohesive law shape of the adhesive layer. Int. J. Adhes. Adhes. 2013, 44, 48–56. [Google Scholar] [CrossRef]

- de Castro Saiki, L.E.; Gomes, G.F. Understanding and mitigating delamination in composite materials: A comprehensive review. Mech. Adv. Mater. Struct. 2024, 31, 13147–13167. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, L.; Liu, Z.; Qi, S.; Zhu, Y.; Zhu, P. Numerical analysis of hybrid (bonded/bolted) FRP composite joints: A review. Compos. Struct. 2021, 262, 113606. [Google Scholar] [CrossRef]

- Alshoaibi, A.M.; Fageehi, Y.A. Advances in Finite Element Modeling of Fatigue Crack Propagation. Appl. Sci. 2024, 14, 9297. [Google Scholar] [CrossRef]

- Benyettou, M.; Madani, K.; Djebbar, S.C.; Amin, H.; Belhouari, M.; Elajrami, M.; Feaugas, X.; Campilho, R.D.S.G. Analysis of load-displacement curves of an adhesive-reinforced composite patch repaired plate using the combination of XFEM and CZM techniques. Int. J. Adhes. Adhes. 2025, 136, 103885. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G.; Banea, M.D.; Chaves, F.J.P.; Da Silva, L.F.M. eXtended Finite Element Method for fracture characterization of adhesive joints in pure mode I. Comput. Mater. Sci. 2011, 50, 1543–1549. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.D. Reviewing the integrated design approach for augmenting strength and toughness at macro-and micro-scale in high-performance advanced composites. Materials 2023, 16, 5745. [Google Scholar] [CrossRef]

- Adediran, I.; Fritz, J.; Truster, T. Comparative Analysis of Different Adhesive Model Representations in Single Lap Joints Using Finite Element Analysis. Appl. Sci. 2025, 15, 2661. [Google Scholar] [CrossRef]

- Ebrahimi, S.; Behjat, B.; Kouhi, M. The effect of loading rate on mixed mode I/II fracture behavior of adhesively bonded joints: Experimental and numerical approach. Theor. Appl. Fract. Mech. 2024, 131, 104420. [Google Scholar] [CrossRef]

- Rafiee, R.; Sahraei, M. Characterizing delamination toughness of laminated composites containing carbon nanotubes: Experimental study and stochastic multi-scale modeling. Compos. Sci. Technol. 2021, 201, 108487. [Google Scholar] [CrossRef]

- Pizzorni, M.; Parmiggiani, A.; Prato, M. Adhesive bonding of a mixed short and continuous carbon-fiber-reinforced Nylon-6 composite made via fused filament fabrication. Int. J. Adhes. Adhes. 2021, 107, 102856. [Google Scholar] [CrossRef]

- Cheng, J.; Xu, Y.; Zhang, W.; Liu, W. A review on the multi-scale simulation of Z-pinned composite laminates. Compos. Struct. 2022, 295, 115834. [Google Scholar] [CrossRef]

- Koohbor, B.; Hazaveh, Z.; Doitrand, A.; Girard, H. Fiber–matrix interface debonding and transverse cracking in macro fiber composites. Eng. Fract. Mech. 2025, 325, 111345. [Google Scholar] [CrossRef]

- Jandaghian, M.H.; Kazerooni, H. Performance of polyurea formulations against impact loads: A molecular dynamics and mechanical simulation approach. J. Appl. Polym. Sci. 2021, 138, 50309. [Google Scholar] [CrossRef]

- Zhai, D.; Sun, Q. Molecular dynamics and experimental study of the interfacial adhesion mechanism of polyurethane-based repair materials. Constr. Build. Mater. 2025, 459, 139796. [Google Scholar] [CrossRef]

- Tsige, M.; Stevens, M.J. Effect of cross-linker functionality on the adhesion of highly cross-linked polymer networks: A molecular dynamics study of epoxies. Macromolecules 2024, 37, 630–637. [Google Scholar] [CrossRef]

- Wu, R.; Wang, X.Q.; Zhao, D.; Hou, J.A.; Wu, C.; Lau, D.; Tam, L.H. Degradation of fiber/matrix interface under various environmental and loading conditions: Insights from molecular simulations. Constr. Build. Mater. 2023, 390, 13110. [Google Scholar] [CrossRef]

- Manolis, G.D.; Dineva, P.S.; Rangelov, T.; Sfyris, D. Mechanical models and numerical simulations in nanomechanics: A review across the scales. Eng. Anal. Bound. Elem. 2021, 128, 149–170. [Google Scholar] [CrossRef]

- Kadioglu, F.; Demiral, M.; El Zaroug, M. Effects of overlap length on the strength of bolted, bonded and hybrid single lap joints with different adherend materials and thicknesses. J. Adhes. Sci. Technol. 2019, 33, 2191–2206. [Google Scholar] [CrossRef]

- Goda, I.; Padayodi, E.; Raoelison, R.N. Enhancing fiber/matrix interface adhesion in polymer composites: Mechanical characterization methods and progress in interface modification. J. Compos. Mater. 2024, 58, 3077–3110. [Google Scholar] [CrossRef]

- Malekinejad, H.; Carbas, R.J.; Akhavan-Safar, A.; Marques, E.A.; Castro Sousa, F.; da Silva, L.F. Enhancing fatigue life and strength of adhesively bonded composite joints: A comprehensive review. Materials 2023, 16, 6468. [Google Scholar] [CrossRef]

- Sharafi, S.; Santare, M.H.; Gerdes, J.; Advani, S.G. A review of factors that influence the fracture toughness of extrusion-based additively manufactured polymer and polymer composites. Addit. Manuf. 2021, 38, 101830. [Google Scholar] [CrossRef]

- Guo, J.; Zhan, L.; Ma, B.; Zhang, D.; Fan, Y.; Yao, S.; Feng, J. A review on failure mechanism and mechanical performance improvement of FRP-metal adhesive joints under different temperature-humidity. Thin-Walled Struct. 2023, 188, 110788. [Google Scholar] [CrossRef]

- Ribas, M.; Oliveira, H.; Akhavan-Safar, A.; Carbas, R.; Marques, E.; Wenig, S.; Silva, L. Characterization of the mechanical properties of a polyurethane adhesive: Tensile strength and Fracture tests. Eng. Manuf. Lett. 2024, 2, 14–22. [Google Scholar] [CrossRef]

- Xi, J.; Wang, N. Synthesis of high mechanical strength and thermally recyclable and reversible polyurethane adhesive by Diels–Alder Reaction. Macromol. Chem. Phys. 2024, 225, 2400199. [Google Scholar] [CrossRef]

- Qiao, C.; Jian, X.; Gao, Z.; Ban, Q.; Zhang, X.; Wang, H.; Zheng, Y. Tough polyurethane elastomers with high strength and rapid healing ability. Mater. Adv. 2023, 4, 1711–1719. [Google Scholar] [CrossRef]

- Daissè, G.; Abali, B.E.; Wan-Wendner, R. Tensile and shear creep behavior of structural adhesives: Experiments and modeling. Appl. Compos. Mater. 2024, 31, 739–764. [Google Scholar] [CrossRef]

- Rodrigues, V.C.M.B.; Marques, E.A.S.; Carbas, R.J.C.; Youngberg, M.; Dussaud, A.; Beygi, R.; da Silva, L.F.M. Development and study of a new silane based polyurethane hybrid flexible adhesive—Part 1: Mechanical characterization. Materials 2023, 16, 7299. [Google Scholar] [CrossRef]

- Giv, A.N.; Fu, Q.; Yan, L.; Kasal, B. The effect of adhesive amount and type on failure mode and shear strength of glued timber-concrete joints. Constr. Build. Mater. 2022, 345, 128375. [Google Scholar] [CrossRef]

- Qin, Q.; Wei, D.; Gan, J.; Gong, Y.; Jin, T. Preparation of environmental-benign castor oil-derived polyurethane thermal conductive structural adhesives with superior strength. Polymer 2024, 298, 126831. [Google Scholar] [CrossRef]

- Gupta, S.K.; Shukla, D.K.; Kaustubh Ravindra, D. Effect of nanoalumina in epoxy adhesive on lap shear strength and fracture toughness of aluminium joints. J. Adhes. 2021, 97, 117–139. [Google Scholar]

- Bernaczyk, A.; Wagenführ, A.; Terfloth, C.; Lincke, J.; Krystofiak, T.; Niemz, P. Investigations into the influence of temperature on the tensile shear strength of various adhesives. Materials 2023, 16, 6173. [Google Scholar] [CrossRef]

- Guo, L.; Liu, J.; Xia, H.; Li, X.; Zhang, X.; Yang, H.; Yang, Y. Effects of loading rate, temperature, and thickness on the tensile strength of precision adhesive joints. Polym. Test. 2022, 109, 107528. [Google Scholar] [CrossRef]

- Zhao, K.; Hu, Z.; Wang, B.; Li, Q.; Xu, Y. Effect of roughness and adhesive on the strength of concrete-to-concrete interfaces cast from 3D-printed prefabricated plastic formworks. Constr. Build. Mater. 2023, 368, 130423. [Google Scholar] [CrossRef]

- Farzanehfar, N.; Taheri, A.; Rafiemanzelat, F.; Jazani, O.M. High-performance epoxy nanocomposite adhesives with enhanced mechanical, thermal and adhesion properties based on new nanoscale ionic materials. Chem. Eng. J. 2023, 471, 144. [Google Scholar] [CrossRef]

- Yamazaki, T.; Ikeda, K.; Sekiguchi, Y.; Sato, C. Experimental investigation of adhesive joint strength and stress-based criteria under tensile/compression–shear stress state using a developed fixture. J. Adhes. 2025, 1, 22. [Google Scholar] [CrossRef]

- Atahan, M.G.; Apalak, M.K. Loading-rate effect on tensile and bending strength of 3D-printed polylactic acid adhesively bonded joints. J. Adhes. Sci. Technol. 2022, 36, 317–344. [Google Scholar]

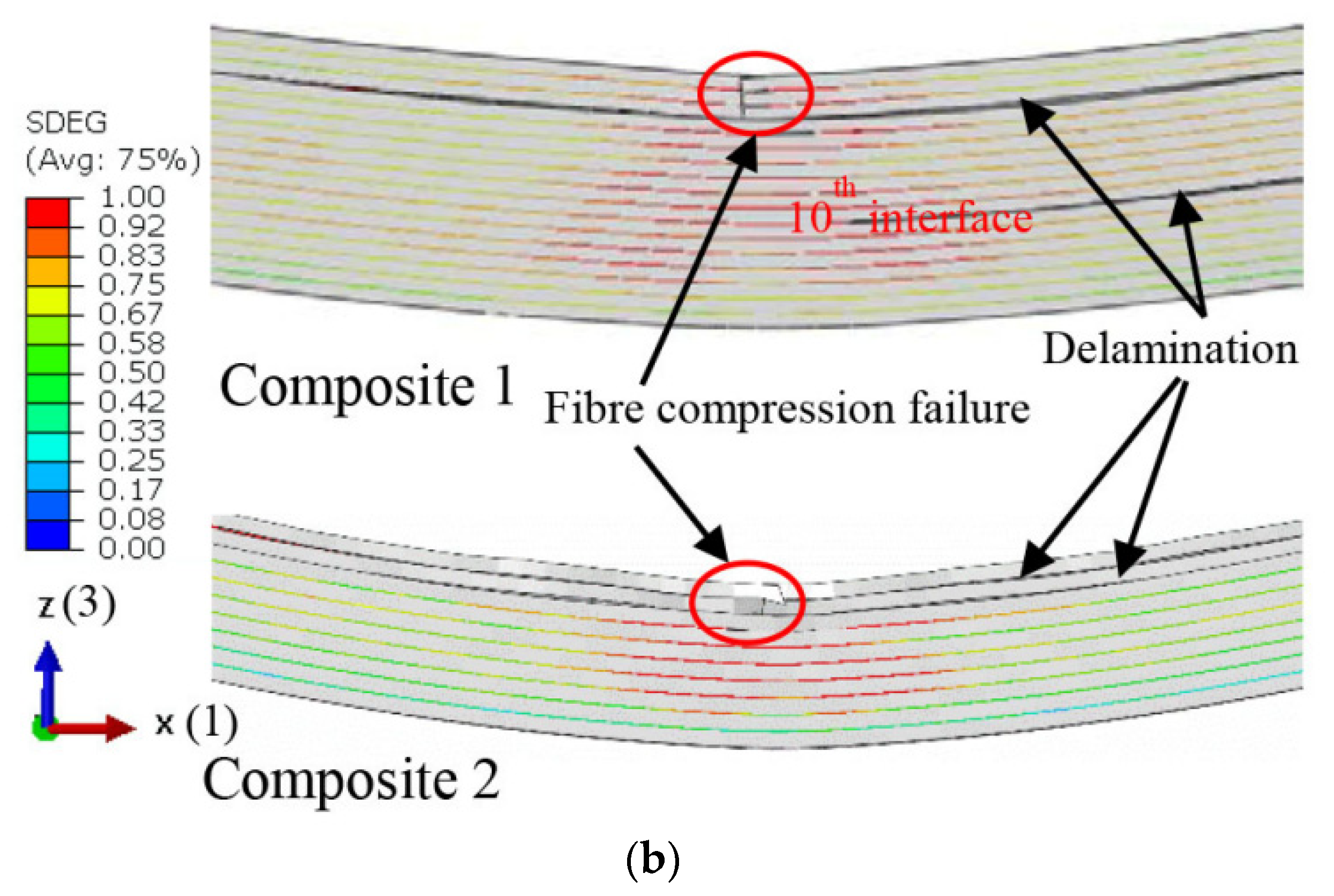

- Jebri, L.; Abbassi, F.; Demiral, M.; Soula, M.; Ahmad, F. Experimental and numerical analysis of progressive damage and failure behavior of carbon Woven-PPS. Compos. Struct. 2020, 243, 112234. [Google Scholar] [CrossRef]

- Demiral, M.; Kadioglu, F.; Silberschmidt, V.V. Size effect in flexural behaviour of unidirectional GFRP composites. J. Mech. Sci. Technol. 2020, 34, 5053–5061. [Google Scholar] [CrossRef]

- Akpinar, S.; Kilbas, M.; Demiral, M. Structural tuning of single-lap joints with thin-walled inserts and nanomodified adhesives for superior flexural performance. Eng. Fract. Mech. 2025, 328, 111529. [Google Scholar] [CrossRef]

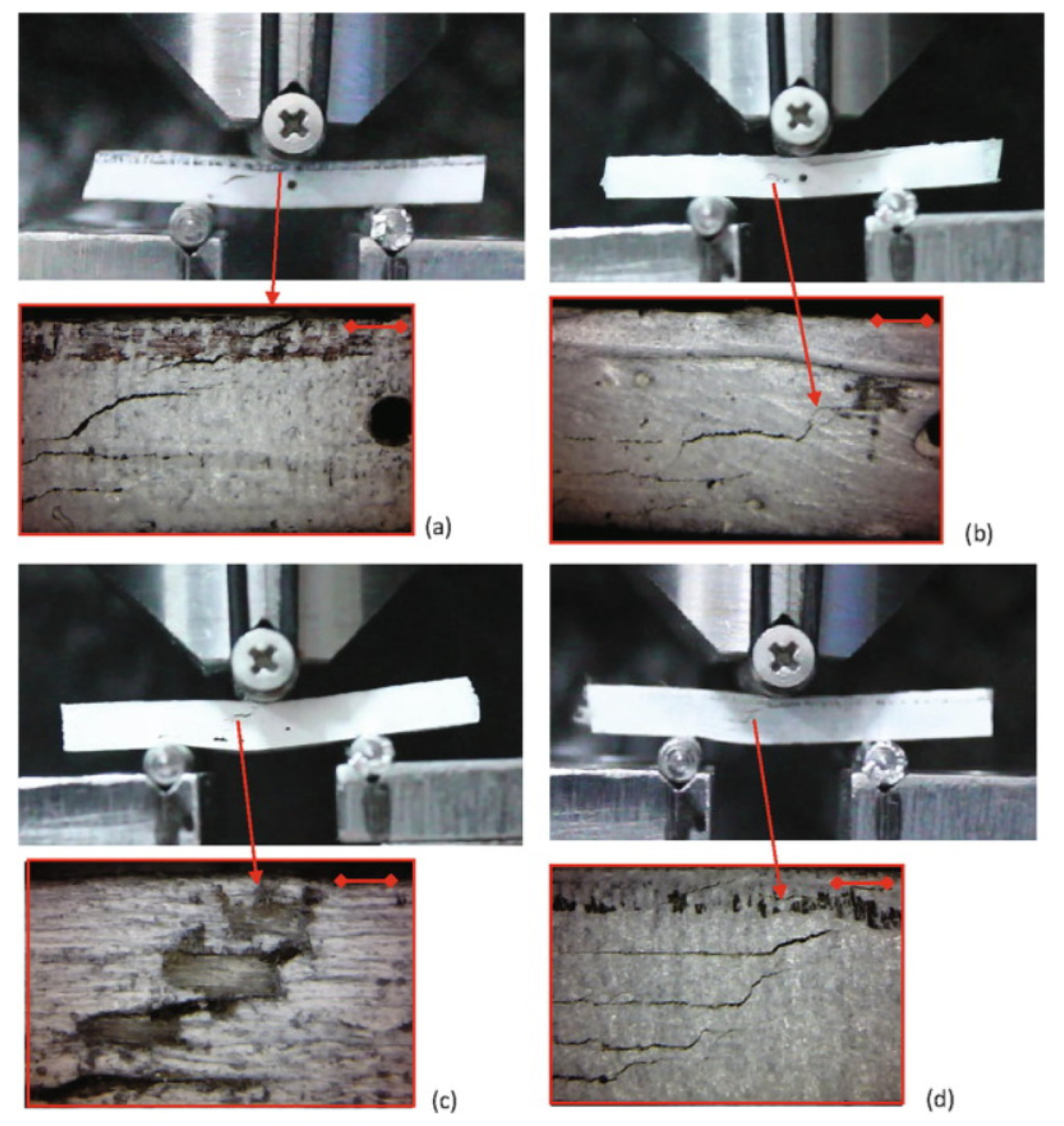

- Kadioglu, F.; Demiral, M. Failure behaviour of the single lap joints of angle-plied composites under three point bending tests. J. Adhes. Sci. Technol. 2020, 34, 531–548. [Google Scholar] [CrossRef]

- Demiral, M.; Tanabi, H.; Sabuncuoglu, B. Experimental and numerical investigation of transverse shear behavior of glass-fibre composites with embedded vascular channel. Compos. Struct. 2020, 252, 112697. [Google Scholar] [CrossRef]

- Li, Z.Y.; Zhang, W.M.; Zou, S.; Wang, X.T.; Ma, L.; Wu, L.Z.; Hu, H. Quasi-static uniaxial compression and low-velocity impact properties of composite auxetic CorTube structure. Thin-Walled Struct. 2024, 202, 112059. [Google Scholar] [CrossRef]

- Yousefi Kanani, A.; Green, S.; Hou, X.; Ye, J. Hybrid and adhesively bonded joints with dissimilar adherends: A critical review. J. Adhes. Sci. Technol. 2021, 35, 1821–1859. [Google Scholar]

- Demiral, M.; Kadioglu, F. Failure behaviour of the adhesive layer and angle ply composite adherends in single lap joints: A numerical study. Int. J. Adhes. Adhes. 2018, 87, 181–190. [Google Scholar] [CrossRef]

- Kadioglu, F.; Demiral, M. Design of Adhesively-Bonded Single Lap Joints for Automotive Applications Under Compressive Loading. Results Eng. 2025, 25, 104176. [Google Scholar] [CrossRef]

- Centelles, X.; Castro, J.R.; Cabeza, L.F. Double-lap shear test on laminated glass specimens under diverse ageing conditions. Constr. Build. Mater. 2020, 249, 118784. [Google Scholar] [CrossRef]

- Barcikowski, M.; Rybka, K. Mode II fracture characterization of toughened epoxy resin composites. Int. J. Fract. 2022, 234, 223–233. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, W.; He, Q.; Chen, C.; Zhang, M.; Huang, Z.; Zhou, H. Enhanced interlaminar fracture toughness of CF/PEEK laminates by interleaving CNT-decorated PEEK films. Polym. Test. 2023, 126, 108159. [Google Scholar]

- Karthikeyan, L.; Robert, T.M.; Mathew, D.; Suma, D.D.; Thomas, D. Novel epoxy resin adhesives toughened by functionalized poly (ether ether ketone) s. Int. J. Adhes. Adhes. 2021, 106, 102816. [Google Scholar] [CrossRef]

- Lesiuk, G.; Sawicka, A.; Correia, J.A.F.O.; Frątczak, R. Fracture resistance analysis of PEEK-polymer. Eng. Struct. Technol. 2017, 9, 207–213. [Google Scholar] [CrossRef]

- Kim, M.H.; Ri, U.I.; Hong, H.S.; Kim, Y.C. Comparative study of failure models for prediction of mixed-mode failure characteristics in composite adhesively bonded joint with brittle/Quai-brittle adhesive using finite element analysis. Int. J. Adhes. Adhes. 2021, 109, 102911. [Google Scholar] [CrossRef]

- Eghbalpoor, R.; Akhavan-Safar, A.; Jalali, S.; Ayatollahi, M.R.; Da Silva, L.F.M. A progressive damage model to predict the shear and mixed-mode low-cycle impact fatigue life of adhesive joints using cohesive elements. Finite Elem. Anal. Des. 2023, 216, 103894. [Google Scholar] [CrossRef]

- Liu, Y.; Gu, Z.; Hughes, D.J.; Ye, J.; Hou, X. Understanding mixed mode ratio of adhesively bonded joints using genetic programming (GP). Compos. Struct. 2021, 258, 113389. [Google Scholar] [CrossRef]

- Wen, L.; Dong, Z.; Wang, R. The Effect of Low-Temperature Plasma Treatment on the Adhesive Bonding Performance of CF/PEKK Surfaces. Surfaces 2025, 8, 41. [Google Scholar] [CrossRef]

- Peng, H.; Zhou, T.; Shangguan, L.; Cheng, R. Effect of temperature and humidity coupling on the ageing failure of carbon fiber composite/Titanium bonded joints. Polymers 2024, 16, 952. [Google Scholar] [CrossRef]

- Carolan, D.; He, S.; Taylor, A.C. Advances in toughening strategies for structural adhesives. In Advances in Structural Adhesive Bonding; Woodhead Publishing: Cambridge, UK, 2023; pp. 251–286. [Google Scholar]

- Oliveira, J.; Xavier, J.; Pereira, F.; Morais, J.; de Moura, M. Direct evaluation of mixed mode I+ II cohesive laws of wood by coupling MMB test with DIC. Materials 2021, 14, 374. [Google Scholar] [CrossRef] [PubMed]

- Karthikeyan, N.; Naveen, J. Progress in adhesive-bonded composite joints: A comprehensive review. J. Reinf. Plast. Compos. 2024, 07316844241248236. [Google Scholar] [CrossRef]

- Wagih, A.; Lubineau, G. Enhanced mode II fracture toughness of secondary bonded joints using tailored sacrificial cracks inside the adhesive. Compos. Sci. Technol. 2021, 204, 108605. [Google Scholar] [CrossRef]

- Wagih, A.; Tao, R.; Lubineau, G. Bio-inspired adhesive joint with improved interlaminar fracture toughness. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106530. [Google Scholar] [CrossRef]

- Tao, R.; Li, X.; Yudhanto, A.; Alfano, M.; Lubineau, G. Toughening adhesive joints through crack path engineering using integrated polyamide wires. Compos. Part A Appl. Sci. Manuf. 2022, 158, 106954. [Google Scholar] [CrossRef]

- Delzendehrooy, F.; Beygi, R.; Akhavan-Safar, A.; Da Silva, L.F.M. Fracture energy assessment of adhesives part II: Is GIIc an adhesive material property? (a neural network analysis). J. Adv. Join. Process. 2021, 3, 100049. [Google Scholar] [CrossRef]

- Sekiguchi, Y.; Sato, C. Experimental investigation of the effects of adhesive thickness on the fracture behavior of structural acrylic adhesive joints under various loading rates. Int. J. Adhes. Adhes. 2021, 105, 102782. [Google Scholar] [CrossRef]

- Sekiguchi, Y.; Sato, C. Effect of bond-line thickness on fatigue crack growth of structural acrylic adhesive joints. Materials 2021, 14, 1723. [Google Scholar] [CrossRef]

- Saleh, M.N.; Tomić, N.Z.; Marinković, A.; de Freitas, S.T. The effect of modified tannic acid (TA) eco-epoxy adhesives on mode I fracture toughness of bonded joints. Polym. Test. 2021, 96, 107122. [Google Scholar] [CrossRef]

- Houjou, K.; Sekiguchi, Y.; Shimamoto, K.; Akiyama, H.; Sato, C. Energy release rate and crack propagation rate behaviour of moisture-deteriorated epoxy adhesives through the double cantilever beam method. J. Adhes. 2023, 99, 1016–1030. [Google Scholar] [CrossRef]

- Shakil, U.A.; Hassan, S.A.; Yahya, M.Y.; San, K.P.; Wahit, M.U. Electrospun nanofiber interleaving through double infusion method to induce pseudo-ductile damage resistance response in carbon/epoxy composites. Polym. Compos. 2024, 45, 570. [Google Scholar] [CrossRef]

- Wang, Z.; Lai, Y.; Xu, P.; Ma, J.; Xu, Y.; Yang, X. Synergistic Effects of Liquid Rubber and Thermoplastic Particles for Toughening Epoxy Resin. Polymers 2024, 16, 2775. [Google Scholar] [CrossRef]

- Olajide, S.O.; Arhatari, B.D. Recent progress on damage mechanisms in polymeric adhesively bonded high-performance composite joints under fatigue. Int. J. Fatigue 2017, 95, 45–63. [Google Scholar] [CrossRef]

- Ramírez, F.M.; de Moura, M.F.; Moreira, R.D.; Silva, F.G. A review on the environmental degradation effects on fatigue behaviour of adhesively bonded joints. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 1307–1326. [Google Scholar] [CrossRef]

- Antelo, J.; Akhavan-Safar, A.; Carbas, R.J.C.; Marques, E.A.S.; Goyal, R.; da Silva, L.F.M. Fatigue life evaluation of adhesive joints in a real structural component. Int. J. Fatigue 2021, 153, 106504. [Google Scholar] [CrossRef]

- Vigón, P.; Viña, J.; Lozano, M.; Argüelles, A. Impact of adverse environmental conditions on the fatigue behavior of carbon epoxy adhesive joints under mode II fracture. Sci. Rep. 2025, 15, 27735. [Google Scholar] [CrossRef]

- Argüelles, A.; Viña, I.; Vigón, P.; Lozano, M.; Viña, J. Study of the fatigue delamination behaviour of adhesive joints in carbon fibre reinforced epoxy composites, influence of the period of exposure to saline environment. Sci. Rep. 2022, 12, 19789. [Google Scholar] [CrossRef]

- Castro Sousa, F.; Akhavan-Safar, A.; Rakesh, G.; Da Silva, L.F.M. Fatigue life estimation of adhesive joints at different mode mixities. J. Adhes. 2022, 98, 1–23. [Google Scholar] [CrossRef]

- Boutar, Y.; Naïmi, S.; Mezlini, S.; Carbas, R.J.; da Silva, L.F.; Ali, M.B.S. Cyclic fatigue testing: Assessment of polyurethane adhesive joints’ durability for bus structures’ aluminium assembly. J. Adv. Join. Process. 2021, 3, 10. [Google Scholar] [CrossRef]

- Fernandes, P.H.E.; Nagel, C.; Wulf, A.; Beber, V.C.; Mayer, B. Compliance-Based Determination of Fatigue Design Curves for Elastomeric Adhesive Joints. Eng 2023, 4, 2615–2639. [Google Scholar] [CrossRef]

- Maćkowiak, P. Fatigue Properties of Methacrylic Adhesive Plexus MA300. Materials 2025, 18, 2127. [Google Scholar] [CrossRef]

- Rendas, P.; Imperadeiro, A.; Martins, R.F.; Soares, B.A. High-cycle fatigue behaviour of polyetheretherketone (PEEK) produced by additive manufacturing. Polymers 2023, 16, 18. [Google Scholar] [CrossRef]

- Stape, T.H.S.; Tulkki, O.; Salim, I.A.; Jamal, K.N.; Mutluay, M.M.; Tezvergil-Mutluay, A. Composite repair: On the fatigue strength of universal adhesives. Dent. Mater. 2022, 38, 231–241. [Google Scholar] [CrossRef]

- Kasper, Y.; Albiez, M.; Ummenhofer, T.; Mayer, C.; Meier, T.; Choffat, F.; Ciupack, Y.; Pasternak, H. Application of toughened epoxy-adhesives for strengthening of fatigue-damaged steel structures. Constr. Build. Mater. 2021, 275, 121579. [Google Scholar] [CrossRef]

- Stape, T.H.S.; Viita-Aho, T.; Sezinando, A.; Wik, P.; Mutluay, M.; Tezvergil-Mutluay, A. To etch or not to etch, Part I: On the fatigue strength and dentin bonding performance of universal adhesives. Dent. Mater. 2021, 37, 949–960. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Zheng, C.; Lu, Y.; Yue, Y.; Yang, W.; Mei, C.; Xu, X.; Xiao, H.; Han, J. Mussel-adhesive chemistry inspired conductive hydrogel with self-adhesion, biocompatibility, self-recovery and fatigue-resistance performances as flexible sensing electronics. Compos. Part A Appl. Sci. Manuf. 2024, 185, 108330. [Google Scholar] [CrossRef]

- Bhagavathi, L.R.; Deshpande, A.P.; Ram, G.J.; Panigrahi, S.K. Hygrothermal aging, fatigue and dynamic mechanical behavior of cellulosic particles reinforced one-component moisture curable polyurethane adhesive joints. Int. J. Adhes. Adhes. 2021, 105, 102771. [Google Scholar] [CrossRef]

- Shi, J.W.; Wu, Q.Q.; Li, B.; Liu, Y.; Cao, W.H.; Wang, H.T. Fatigue bond behavior of FRP-to-concrete joints with various bonding adhesives. Eng. Struct. 2024, 301, 117311. [Google Scholar] [CrossRef]

- Tian, G.; Zhu, M.; Chen, J.; Liang, C.; Zhao, Q.; Yang, D.; Liu, Y.; Tang, S.; Huang, J.; Liu, Z.; et al. Anti-fatigue adhesive non-swelling hydrogel constructed by covalent topological structure and micro-nano gel for stretchable bioelectronics. Bioact. Mater. 2025, 53, 178–187. [Google Scholar] [CrossRef] [PubMed]

- Yao, C.; Xia, Y.; Yang, Z.; Zhu, Z.; Li, Z.; Jiang, H. Fatigue failure of soft adhesive systems: A state-of-the-art review. Giant 2024, 19, 100292. [Google Scholar] [CrossRef]

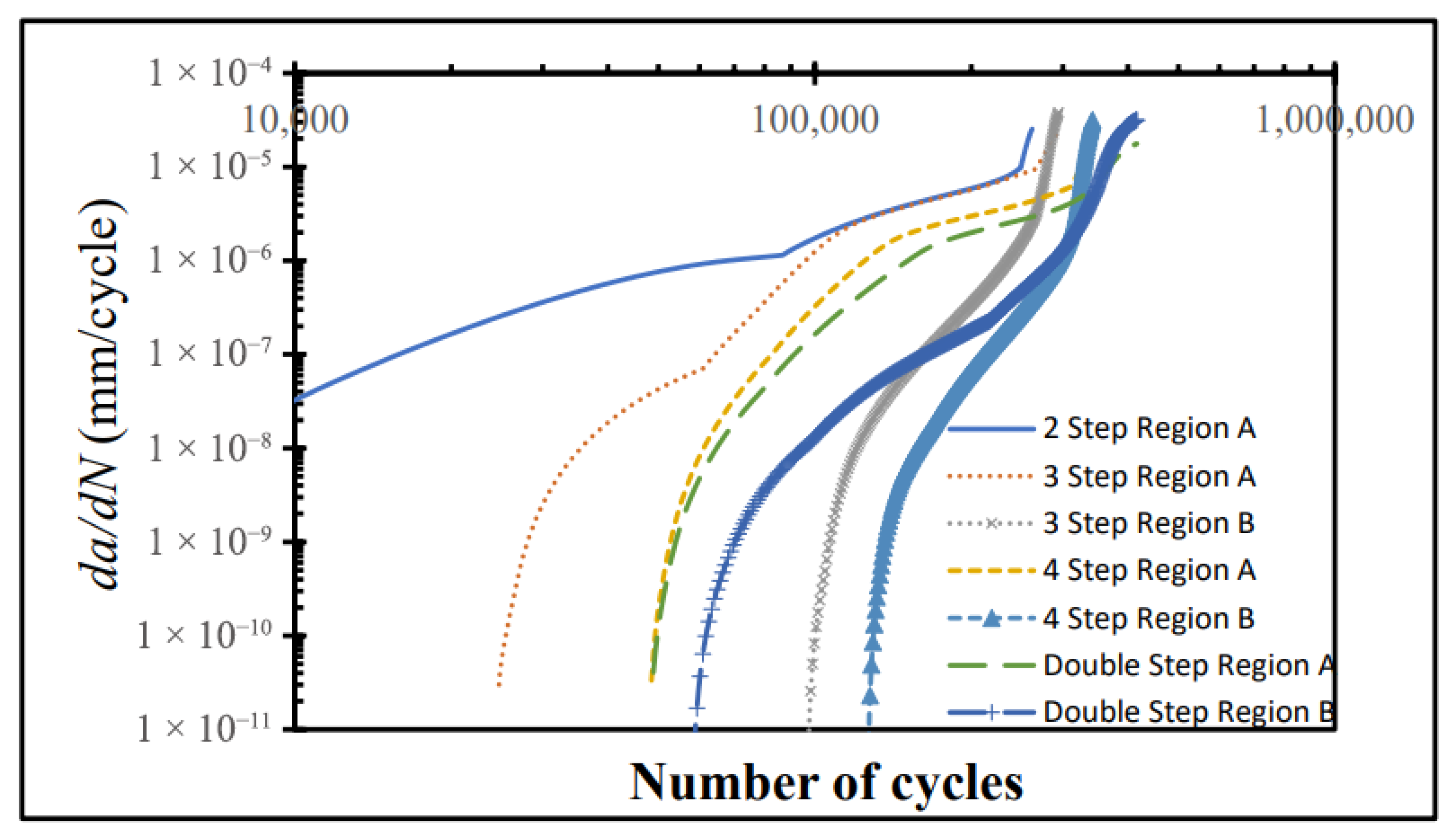

- Demiral, M.; Abbassi, F.; Zahedi, A.; Akpinar, S. Critical assessment of the bonded single lap joint exposed to cyclic tensile loading. Aerospace 2023, 10, 454. [Google Scholar] [CrossRef]

- Demiral, M.; Mamedov, A. Fatigue performance of a step-lap joint under tensile load: A numerical study. Polymers 2023, 15, 1949. [Google Scholar] [CrossRef]

- Akkasali, N.K.; Biswas, S.; Sen, S.; Anitha, S. A state-of-the-art review on adhesively bonded joints of similar and dissimilar materials. J. Adhes. Sci. Technol. 2024, 38, 4317–4371. [Google Scholar] [CrossRef]

- Carneiro Neto, R.M.; Akhavan-Safar, A.; Sampaio, E.M.; Simões, B.D.; Vignoli, L.L.; da Silva, L.F.M. Creep behaviour of adhesively bonded joints: A comprehensive review. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2024, 238, 1625–1650. [Google Scholar] [CrossRef]

- Simões, B.D.; Fernandes, É.M.; Marques, E.A.; Carbas, R.J.; Maul, S.; Stihler, P.; Weißgraeber, P.; da Silva, L.F. An exploratory study on determining and modeling the creep behavior of an acrylic pressure-sensitive adhesive. Materials 2023, 16, 2029. [Google Scholar] [CrossRef]

- Guchait, A.; Saxena, A.; Chattopadhyay, S.; Mondal, T. Influence of nanofillers on adhesion properties of polymeric composites. ACS Omega 2022, 7, 3844–3859. [Google Scholar] [CrossRef]

- Gonçalves, F.A.; Santos, M.; Cernadas, T.; Alves, P.; Ferreira, P. Influence of fillers on epoxy resins properties: A review. J. Mater. Sci. 2022, 57, 15183–15212. [Google Scholar] [CrossRef]

- Simões, B.D.; Fernandes, É.M.; Marques, E.A.; Carbas, R.J.; Maul, S.; Stihler, P.; Weißgraeber, P.; da Silva, L.F. Development of a Cyclic Creep Testing Station Tailored to Pressure-Sensitive Adhesives. Machines 2024, 12, 76. [Google Scholar] [CrossRef]

- Eslami, G.; Movahedi-Rad, A.V.; Keller, T. Viscoelastic adhesive modeling of ductile adhesive-composite joints during cyclic loading. Int. J. Adhes. Adhes. 2022, 119, 103241. [Google Scholar] [CrossRef]

- Guder, M.; Günther, R.; Bremgartner, K.; Senn, N.; Brändli, C. Revealing the Impact of Viscoelastic Characteristics on Performance Parameters of UV-Crosslinked Hotmelt Pressure-Sensitive Adhesives: Insights from Time–Temperature Superposition Analysis. Polymers 2024, 16, 2123. [Google Scholar] [CrossRef]

- Chen, Y.; Smith, L.V. A nonlinear viscoelastic–viscoplastic constitutive model for adhesives under creep. Mech. Time-Depend. Mater. 2022, 26, 663–681. [Google Scholar] [CrossRef]

- Feng, W.; He, J.; Dai, Z.; Chang, X.; Shi, X.; Xu, F.; Liu, B. Creep behavior of epoxy adhesives subjected to different hygrothermal aging conditions—Nanoindentation creep tests and theoretical study. Polym. Degrad. Stab. 2024, 229, 1109. [Google Scholar] [CrossRef]

- Śliwa-Wieczorek, K.; Szeptyński, P.; Kozik, T.; Gubert, M. Creep behavior of CLT beams with finite thickness layers of flexible adhesives. Materials 2023, 16, 4484. [Google Scholar] [CrossRef]

- Fernandes, É.M.; Simoes, B.D.; Marques, E.A.; Carbas, R.J.; Maul, S.; Stihler, P.; Weißgraeber, P.; da Silva, L.F. Analytical model for static and cyclic creep behavior of pressure-sensitive adhesives. Mech. Adv. Mater. Struct. 2024, 31, 9426–9439. [Google Scholar] [CrossRef]

- Ernault, E.; Diani, J.; Schmid, Q. Single-lap joint creep behaviour of two soft adhesives. J. Adhes. 2023, 99, 1282–1298. [Google Scholar] [CrossRef]

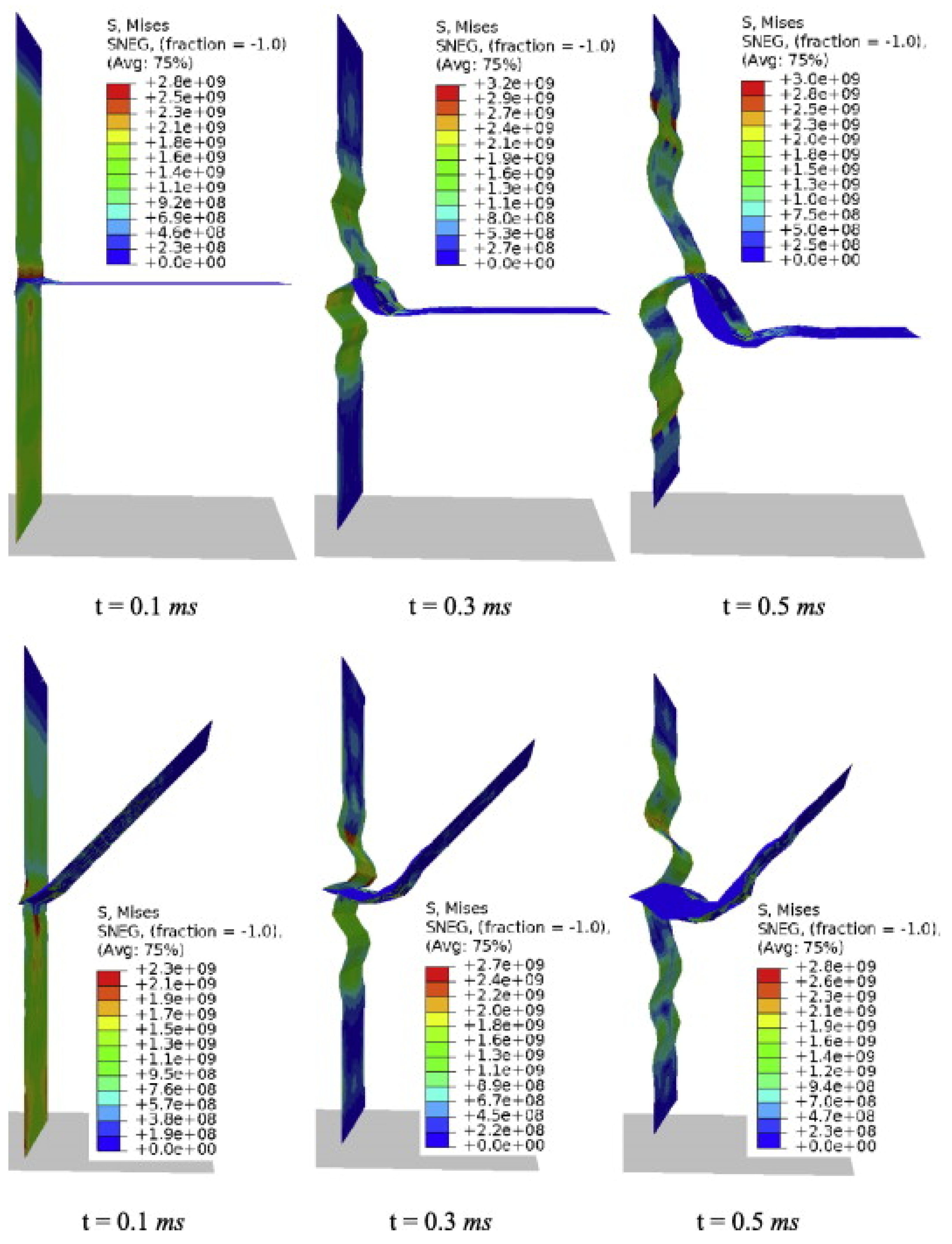

- Demiral, M.; Kadioglu, F. Residual strength and failure evolution of adhesively bonded joints under successive ballistic impacts. Eng. Fail. Anal. 2025, 182, 110021. [Google Scholar] [CrossRef]

- Yang, S.; Li, R.; Zhu, H.; Qin, Y.; Huang, C. Review of the state-of-the-art techniques for enhancing the toughness of thermosetting epoxy asphalt. Constr. Build. Mater. 2024, 449, 137660. [Google Scholar] [CrossRef]

- Çakır, M.V. The synergistic effect of hybrid nano-silica and GNP additives on the flexural strength and toughening mechanisms of adhesively bonded joints. Int. J. Adhes. Adhes. 2023, 122, 103333. [Google Scholar] [CrossRef]

- Zuo, P.; Vassilopoulos, A.P. Review of fatigue of bulk structural adhesives and thick adhesive joints. Int. Mater. Rev. 2021, 66, 313–338. [Google Scholar] [CrossRef]

- Perry, J.I.; Walley, S.M. Measuring the effect of strain rate on deformation and damage in fibre-reinforced composites: A review. J. Dyn. Behav. Mater. 2022, 8, 178–213. [Google Scholar] [CrossRef]

- Irzhak, V. Epoxy Nanocomposites with Carbon Fillers. Rev. Adv. Chem. 2022, 12, 22–56. [Google Scholar] [CrossRef]

- Nunes, P.D.P.; Marques, E.A.S.; Carbas, R.J.C.; Akhavan-Safar, A.; Da Silva, L.F.M. DCB tests at constant strain rate using crash-resistant epoxy adhesives: A numerical and experimental approach. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 235, 3234–3242. [Google Scholar] [CrossRef]

- Rezaei, M.; Arezoo, B.; Ziaei-Rad, S. Redesign an aircraft windshield to improve its mechanical resistance against simultaneous bird impacts. Int. J. Impact Eng. 2024, 184, 104811. [Google Scholar] [CrossRef]

- Moreno, M.S.; Cela, J.L.; Vicente, J.M.; Vecino, J.G. Adhesively bonded joints as a dissipative energy mechanism under impact loading. Appl. Math. Model. 2015, 39, 3496–3505. [Google Scholar] [CrossRef]

- Pai, A.; Kini, C.R.; Shenoy, S. Development of materials and structures for shielding applications against Blast and Ballistic impact: A Detailed Review. Thin-Walled Struct. 2022, 179, 109664. [Google Scholar] [CrossRef]

- Ramalho, L.D.C.; Sánchez-Arce, I.J.; Gonçalves, D.C.; Belinha, J.; Campilho, R.D.S.G. Numerical analysis of the dynamic behaviour of adhesive joints: A review. Int. J. Adhes. Adhes. 2022, 118, 103219. [Google Scholar] [CrossRef]

- Houjou, K.; Shimamoto, K.; Akiyama, H.; Sato, C. Experimental investigations on the effect of a wide range of strain rates on mechanical properties of epoxy adhesives, and prediction of creep and impact strengths. J. Adhes. 2022, 98, 449–463. [Google Scholar] [CrossRef]

- Ribas, M.; Akhavan-Safar, A.; Adam-Cottard, P.; Carbas, R.; Marques, E.A.S.; Wenig, S.; da Silva, L.F.M. Exploring strain rate variation in the adhesive layer during constant speed mode I fracture tests: Loading speed and test temperature effects. Theor. Appl. Fract. Mech. 2024, 130, 104274. [Google Scholar] [CrossRef]

- Ribas, M.J.; Akhavan-Safar, A.; Pigray, N.; Carbas, R.J.; Marques, E.A.; Borges, C.S.; Wenig, S.; da Silva, L.F. From high strain rates to elevated temperatures: Investigating mixed-mode fracture behaviour in a polyurethane adhesive. Polymers 2023, 15, 2675. [Google Scholar] [CrossRef]

- Okumura, R.; Shimamoto, K.; Sekiguchi, Y.; Kimura, K.; Kageyama, H.; Yamamoto, Y.; Matsuki, Y.; Sato, C. Effects of low temperatures and high strain rates on the tensile properties of polyurethane polymers for adhesives. J. Adhes. 2023, 99, 2238–2259. [Google Scholar] [CrossRef]

- Han, J.; Yin, Z.Y.; Dano, C.; Hicher, P.Y. Effect of strain rate on the adhesive bond shearing resistance of stiff clay. Transp. Geotech. 2021, 27, 100479. [Google Scholar] [CrossRef]

- Feng, H.; Luo, G.; Li, J.; Wei, J.; Zhang, R.; Zhang, J.; Shen, Q. Adhesion enhancement in Al/PMMA joints under dynamic loading: Effects of adhesive thickness and strain rate. J. Reinf. Plast. Compos. 2025, 07316844251352914. [Google Scholar] [CrossRef]

- Wetta, M.; Kopp, J.B.; Le Barbenchon, L.; Viot, P. Strain rate effect on the compressive behaviour of a thick cellular structural adhesive. Mater. Lett. 2024, 356, 135573. [Google Scholar] [CrossRef]

- Sassi, S.; Tarfaoui, M. Dynamic properties and plastic dissipative mechanisms of polymeric adhesive under dynamic compression at various strain rates. J. Compos. Mater. 2024, 58, 569–581. [Google Scholar] [CrossRef]

- Davies, P.; Sohier, L.; Cognard, J.Y.; Bourmaud, A.; Choqueuse, D.; Rinnert, E.; Créac’hcadec, R. Influence of adhesive bond line thickness on joint strength. Int. J. Adhes. Adhes. 2009, 29, 724–736. [Google Scholar] [CrossRef]

- Viana, G.M.S.O.; Costa, M.; Banea, M.D.; da Silva, L.F. A review on the temperature and moisture degradation of adhesive joints. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2017, 231, 488–501. [Google Scholar] [CrossRef]

- Peng, H.; Zhou, T.; Fan, Y.; Shangguan, L.; Zhang, N. Recent Advances in Aluminum Alloy Surface Treatment Technology and Bonding Properties. Phys. Status Solidi 2025, 222, 2400715. [Google Scholar] [CrossRef]

- Wen, L.; Xu, X.; Qin, L. Effect of low-temperature plasma surface treatment on bonding properties of single-lap joint of thermosetting composites. Polymers 2023, 15, 1631. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.; Min, J.; Lin, J.; Wan, H. Effect of atmospheric pressure plasma treatment on adhesive bonding of carbon fiber reinforced polymer. Polymers 2019, 11, 139. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Rossi, D.; Guo, Y.; Wan, Q.G.; Chen, X.; Mohler, C.E.; Kuo, T.C.; Chen, Z. Effect of Corona Treatment on the Adhesion between a Two-Component Polyurethane Adhesive and Polypropylene. Macromolecules 2024, 57, 6646–6656. [Google Scholar] [CrossRef]

- Chomiak, M.; Sałaciński, M.; Gołębiowski, F.; Broda, P. Durability and corrosion resistance test of adhesive joints using two adherence promoters for the connection of aerospace aluminum alloys. Materials 2022, 15, 8733. [Google Scholar] [CrossRef] [PubMed]

- Ozturk, F.; Cobanoglu, M.; Ece, R.E. Recent advancements in thermoplastic composite materials in aerospace industry. J. Thermoplast. Compos. Mater. 2024, 37, 3084–3116. [Google Scholar] [CrossRef]

- Zheng, Y.; Cui, T.; Wang, J.; Ge, H.; Gui, Z. Unveiling innovative design of customizable adhesive flexible devices from self-healing ionogels with robust adhesion and sustainability. Chem. Eng. J. 2023, 471, 144617. [Google Scholar] [CrossRef]

- Wang, B.; Li, Z.; Liu, X.; Li, L.; Yu, J.; Li, S.; Guo, G.; Gao, D.; Dai, Y. Preparation of epoxy resin with disulfide-containing curing agent and its application in self-healing coating. Materials 2023, 16, 4440. [Google Scholar] [CrossRef]

- Sáiz, L.M.; Prolongo, M.G.; Bonache, V.; Jiménez-Suárez, A.; Prolongo, S.G. Self-healing materials based on disulfide bond-containing acrylate networks. Polym. Test. 2023, 117, 107832. [Google Scholar] [CrossRef]

- Niu, P.; Zhao, Z.; Zhu, J.; Zhang, Z.; Sun, A.; Wei, L.; Li, Y. Epoxy-based multifunctional re-bondable polymer with self-healing, shape memory and superb bonding properties. J. Colloid Interface Sci. 2025, 678, 30–39. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J.; Sun, Z. Aromatic Biobased Polymeric Materials Using Plant Polyphenols as Sustainable Alternative Raw Materials: A Review. Polymers 2024, 16, 2752. [Google Scholar] [CrossRef]

- Serrano-Martínez, V.M.; Hernández-Fernández, C.; Pérez-Aguilar, H.; Carbonell-Blasco, M.P.; García-García, A.; Orgilés-Calpena, E. Development and application of a lignin-based polyol for sustainable reactive polyurethane adhesives synthesis. Polymers 2024, 16, 1928. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, Y.; Yang, X.; Liu, L.; Guo, H.; Xie, L.; Chai, X.; Xu, K.; Du, G.; Zhang, L. Development of a boiling water resistant, flame retardant, and mildew resistant multifunctional adhesive cross-linked with chitosan and biomass polyester. ACS Sustain. Chem. Eng. 2024, 12, 12341–12353. [Google Scholar] [CrossRef]

- Jafarypouria, M.; Mahato, B.; Abaimov, S.G. Real-time cure monitoring via carbon nanotube networks enables mechanical property optimization in post-cured epoxy resins. Carbon Lett. 2025, 1–15. [Google Scholar] [CrossRef]

- Wang, S.; Xu, Z.; Stratford, T.; Li, B.; Zeng, Q.; Su, J. Machine learning approach for analysing and predicting the modulus response of the structural epoxy adhesive at elevated temperatures. J. Adhes. 2023, 99, 2280–2298. [Google Scholar] [CrossRef]

- Jang, H.; Ryu, D.; Lee, W.; Park, G.; Kim, J. Machine learning-based epoxy resin property prediction. Mol. Syst. Des. Eng. 2024, 9, 959–968. [Google Scholar] [CrossRef]

- Zhao, S.; An, T.; Wang, Q.; Qin, F. Using machine learning and finite element analysis to extract traction-separation relations at bonding wire interfaces of insulated gate bipolar transistor modules. Materials 2024, 17, 1002. [Google Scholar] [CrossRef] [PubMed]

- Ramian, A.; Elhajjar, R. Machine Learning Algorithms for Prediction and Characterization of Cohesive Zone Parameters for Mixed-Mode Fracture. J. Compos. Sci. 2024, 8, 326. [Google Scholar] [CrossRef]

- Son, D.; Liimatainen, V.; Sitti, M. Machine learning-based and experimentally validated optimal adhesive fibril designs. Small 2021, 17, 2102867. [Google Scholar] [CrossRef] [PubMed]

- Chenani, H.; Razaghi, Z.; Saeidi, M.; Aghaii, A.H.; Rastkhiz, M.A.; Orouji, M.; Ekrami, A.; Simchi, A. A stretchable, adhesive, and wearable hydrogel-based patches based on a bilayer PVA composite for online monitoring of sweat by artificial intelligence-assisted smartphones. Talanta 2025, 287, 127640. [Google Scholar] [CrossRef]

- Shojaeifard, M.; Ferraresso, M.; Lucantonio, A.; Bacca, M. Machine learning-based optimal design of fibrillar adhesives. J. R. Soc. Interface 2025, 22, 20240636. [Google Scholar] [CrossRef]

| Category | Methods/Tests | Purpose, Key Insights, and Application to Composite–Adhesive Systems | References |

|---|---|---|---|

| 4.1 Mechanical Testing Approaches | Tensile Testing (UTMs) | Measures tensile strength, modulus of elasticity, and elongation at break. In composite–adhesive joints, direct tensile tests are less common due to stress concentrations; results are mainly used to characterize bulk adhesive properties rather than joint performance. Generates stress–strain curves to assess load-bearing capacity and deformation behavior. Limitations: Stress concentrations often cause premature failure at the grips, making results less representative of in-joint performance. | [43] |

| Shear Testing (Lap Shear: ASTM D1002, D5656) | Evaluates shear resistance, joint strength, and load transfer efficiency. ASTM D1002 [44] is most relevant for single-lap joints with thin adhesives (<0.25 mm) and is widely used for metal–composite bonding, whereas ASTM D5656 [45] uses thick adherends to minimize bending effects and is preferred for composite–composite joints. Failure mode analysis (cohesive vs. adhesive) helps optimize surface preparation and curing parameters. Limitations: Lap shear results are highly geometry-dependent, and peel stresses may overshadow shear, limiting their predictive capability for real joints. | [10,46] | |

| Compression Testing | Determines compressive strength, modulus, and failure strain. Important for bonded composite assemblies subjected to through-thickness compression or impact loads. Special fixturing is needed to avoid buckling of composite adherends. Limitations: Edge effects and buckling of adherends often interfere, making reproducibility a challenge. | [47,48] | |

| 4.2 Fracture and Fatigue Testing Methods | Mode I (DCB Test) | Assesses crack opening resistance (Mode I fracture toughness). Standardized by ASTM D5528 [49] for composite laminates; applicable to adhesively bonded joints when crack growth occurs along the bondline. Provides critical strain energy release rate GICG_{IC} used in CZM calibration. Limitations: Pre-crack insertion methods influence results, and fiber bridging in composites can artificially elevate toughness values. | [50,51] |

| Mode II (ENF Test) | Evaluates shear-driven crack growth resistance. ASTM D7905 [52] is typically used; data is crucial for bonded composite joints under in-plane shear loading. Helps identify weak interfaces and interfacial toughness improvements after surface treatment. Limitations: Test setup is sensitive to loading asymmetry, and frictional effects at the crack tip can distort measured toughness. | [53,54] | |

| Mixed Mode Bending (MMB) | Combines Mode I and II loading to replicate real-world multiaxial stress states in joints. Useful for automotive/aerospace joints subjected to peel + shear; enables derivation of mixed-mode interaction criteria for CZM. Limitations: Accurate control of mode mixity is difficult; results are highly sensitive to fixture alignment. | [53,55] | |

| Fatigue Crack Growth Tests | Examines long-term durability under cyclic loads. ASTM D3479 [56] and D3166 [57] can be adapted for bonded joints; results reveal growth rates da/dN vs. ΔG, informing service-life predictions for composite structures. Limitations: Time-intensive testing, high scatter in fatigue data, and strong sensitivity to environmental conditions. | [58,59] | |

| Digital Image Correlation (DIC) | Non-contact optical technique for real-time strain mapping and crack growth monitoring. Particularly valuable for composite–adhesive joints, as it captures strain localization near the bondline and validates FE models under complex loading. Limitations: Requires high-quality surface preparation, is sensitive to lighting, and typically limited to surface strain fields rather than subsurface mechanisms. | [60,61] | |

| 4.3 Microscopic and Spectroscopic Failure Analysis | Scanning Electron Microscopy (SEM) | Examines fracture surfaces at high magnification. Used to distinguish cohesive, adhesive, and interfacial failures in composite joints; reveals fiber bridging, resin remnants, and failure initiation sites. Limitations: Requires destructive sample preparation and only provides post-mortem analysis. | [62,63] |

| X-ray Computed Tomography (XCT) | Non-destructive 3D imaging to detect voids, porosity, and microcracks within adhesive layers. Especially relevant for thick composite joints where internal defects affect load transfer and fatigue resistance. Limitations: Limited spatial resolution for thin bondlines and relatively high cost/time per scan. | [64,65] | |

| Spectroscopy (FTIR, Raman) | Analyzes chemical composition, curing reactions, and degradation mechanisms. Useful for verifying surface treatments (e.g., plasma or primer presence), degree of cure, and tracking adhesive aging in service. Limitations: Typically requires small-scale samples; depth penetration is limited, making it difficult to assess bulk adhesive chemistry in joints. | [66,67] |

| Adhesive System | Tensile Strength (MPa) | Shear Strength (MPa) | Notes/Variability Sources |

|---|---|---|---|

| Epoxy | 30–85 | 15–35 | High strength and stiffness; brittleness remains an issue; toughening via rubber particles, thermoplastics, or nanofillers (graphene, alumina) significantly improves toughness; curing time and temperature strongly influence performance. |

| Polyurethane | 14–92 | 7–25 | Wide variability: conventional PU adhesives show low strength (~14 MPa); advanced Diels–Alder cross-linked PU and disulfide-bonded PU report tensile strengths equal to or surpassing epoxies (60–92 MPa). Highly flexible, good for dynamic and harsh environments. |

| Acrylics | 20–55 | 10–25 | Moderate strength, relatively easy to use; toughness and performance highly dependent on curing conditions and substrates; bridge gap between strength and processability. |

| PEEK (Polyether ether ketone) | 70–100 | 20–40 | High-performance thermoplastic with excellent mechanical stability; often used as a matrix or surface-modified for adhesion; adhesion strength depends strongly on surface treatment (plasma, chemical etching). |

| Nylon (Polyamide) | 40–80 | 15–30 | Strong hydrogen bonding capacity but moisture sensitivity reduces performance; adhesion often enhanced via surface functionalization or coupling agents. Used as matrix in fiber composites or as adhesive in structural plastics. |

| Adhesive System | Typical GIc Range (J/m2) | Typical GIIc Range (J/m2) | Remarks |

|---|---|---|---|

| Epoxy | 200–800 (toughened: up to 1500) | 1000–2500 | Aerospace/automotive standard; toughened epoxies with rubber/nanofillers achieve very high toughness |

| Polyurethane (PU) | 300–1200 | 1500–3000 | High toughness and flexibility; excellent under impact and fatigue loading |

| Acrylics (MMA, Cyanoacrylate, etc.) | 200–600 (toughened: up to ~1000) | 800–2000 | Fast-curing structural systems; unmodified forms brittle, but toughened grades show significant improvement |

| PEEK-based adhesives | 400–1200 | 1200–2500 | High-performance thermoplastic adhesives; retain toughness at elevated temperatures |

| Nylon-based adhesives | 300–900 | 1000–2200 | Good toughness and flexibility; sensitive to moisture uptake, which may affect long-term durability |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Demiral, M. Strength in Adhesion: A Multi-Mechanics Review Covering Tensile, Shear, Fracture, Fatigue, Creep, and Impact Behavior of Polymer Bonding in Composites. Polymers 2025, 17, 2600. https://doi.org/10.3390/polym17192600

Demiral M. Strength in Adhesion: A Multi-Mechanics Review Covering Tensile, Shear, Fracture, Fatigue, Creep, and Impact Behavior of Polymer Bonding in Composites. Polymers. 2025; 17(19):2600. https://doi.org/10.3390/polym17192600

Chicago/Turabian StyleDemiral, Murat. 2025. "Strength in Adhesion: A Multi-Mechanics Review Covering Tensile, Shear, Fracture, Fatigue, Creep, and Impact Behavior of Polymer Bonding in Composites" Polymers 17, no. 19: 2600. https://doi.org/10.3390/polym17192600

APA StyleDemiral, M. (2025). Strength in Adhesion: A Multi-Mechanics Review Covering Tensile, Shear, Fracture, Fatigue, Creep, and Impact Behavior of Polymer Bonding in Composites. Polymers, 17(19), 2600. https://doi.org/10.3390/polym17192600