Three-Dimensionally Printed Microstructured Hydrophobic Surfaces: Morphology and Wettability

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of 3D Samples

2.3. Synthesis of Silica Nanoparticles (SiO2 NPs)

2.4. Characterization Methods

3. Results and Discussion

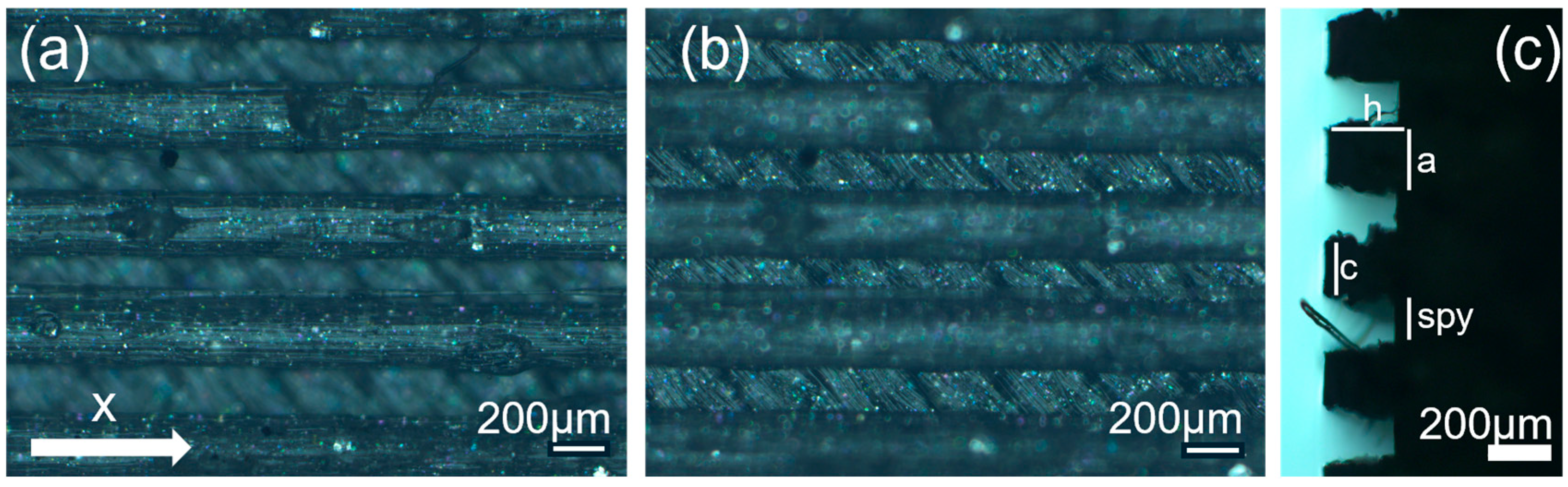

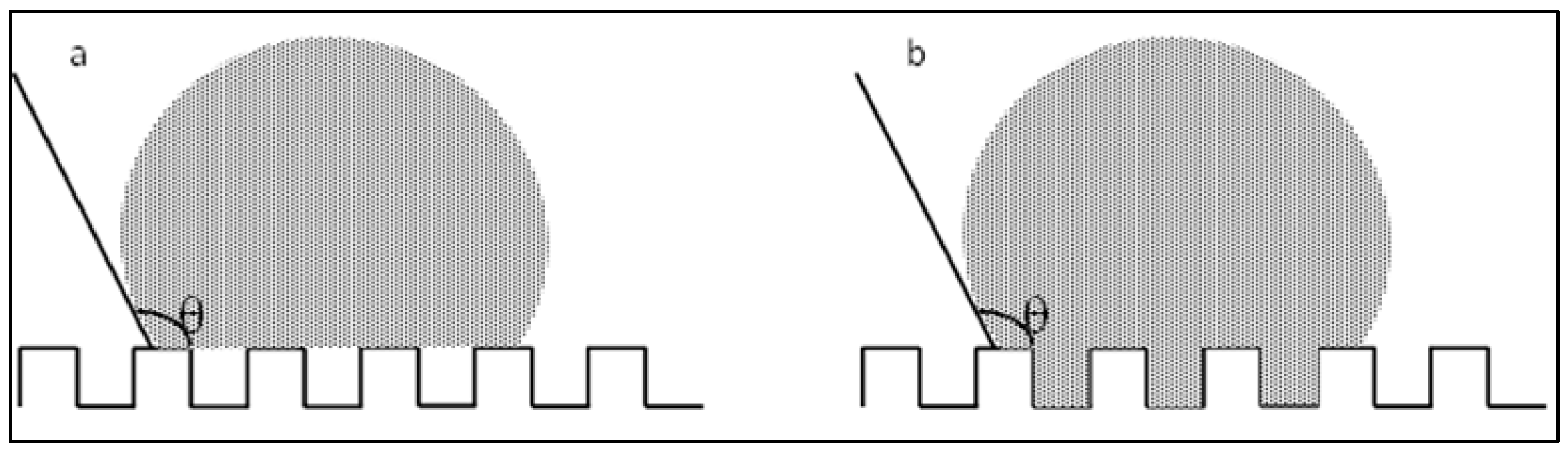

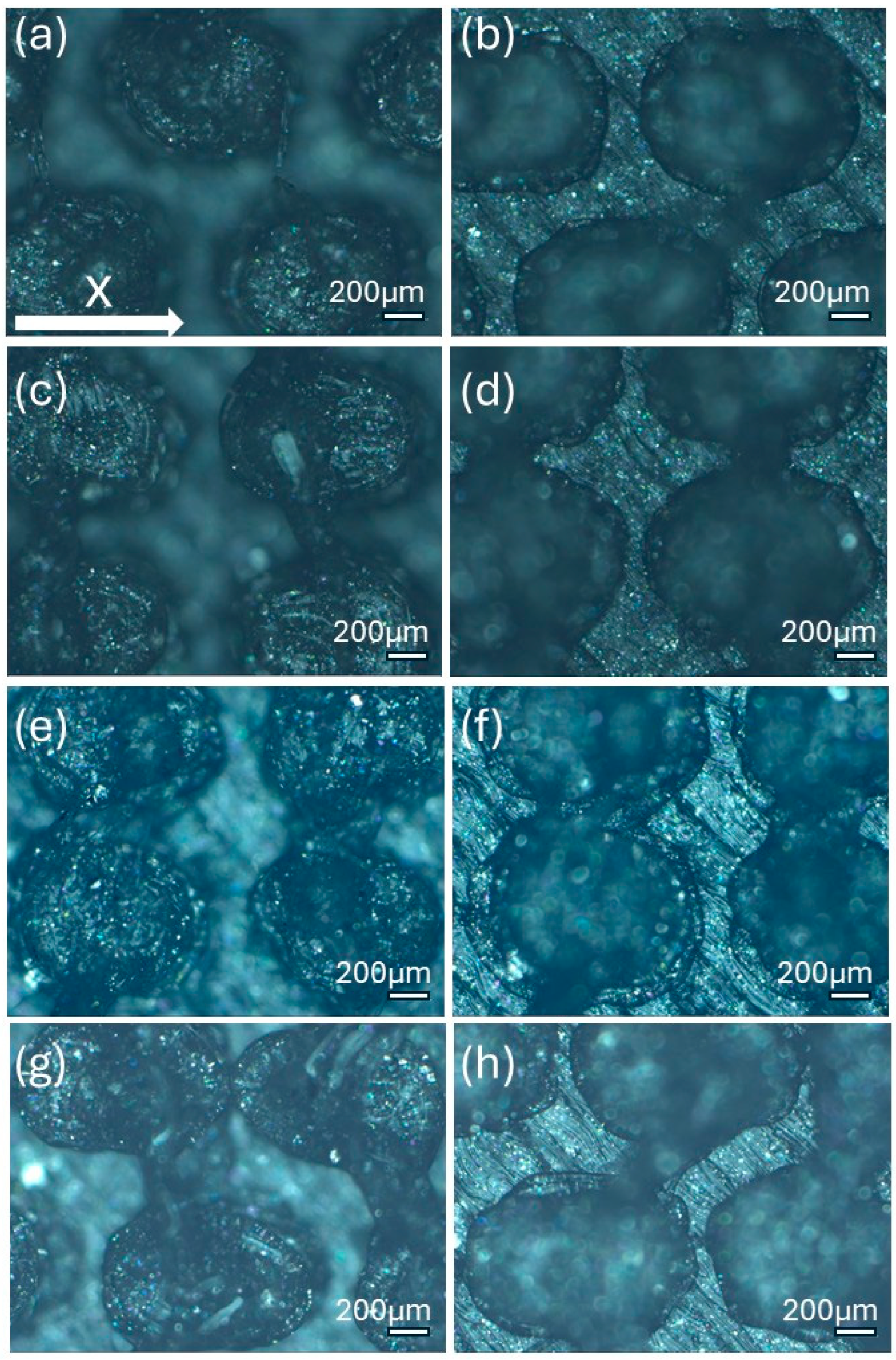

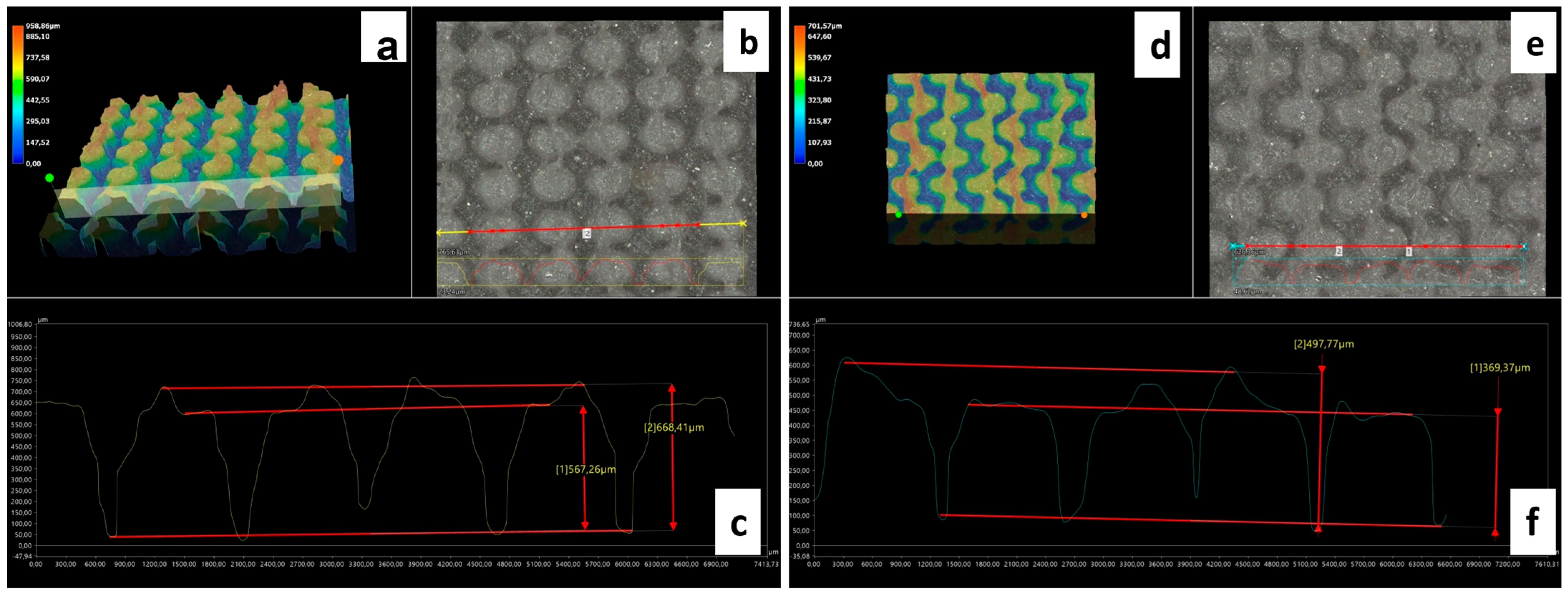

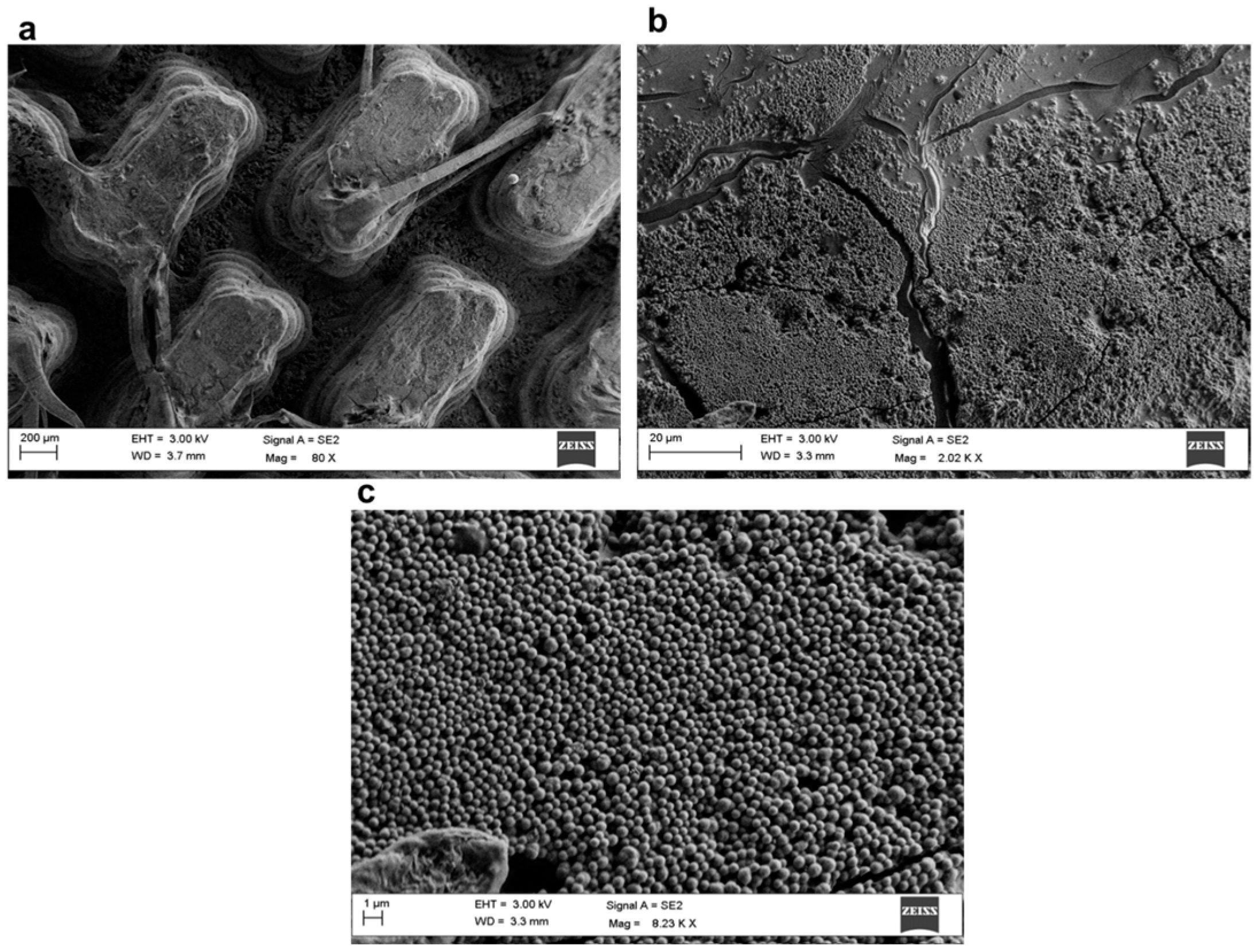

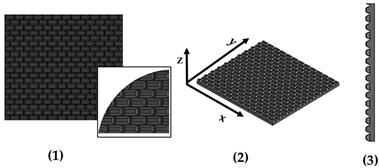

3.1. FFF 3D-Printed Geometries

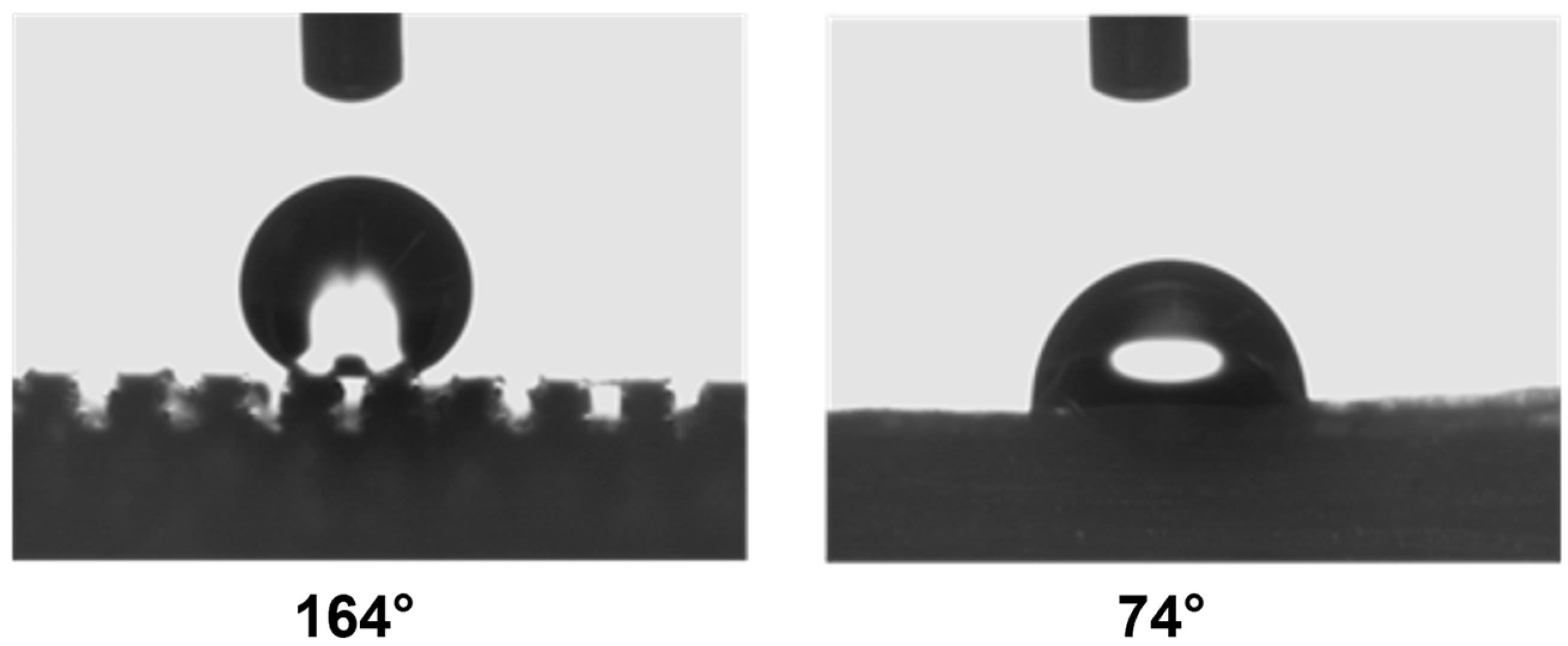

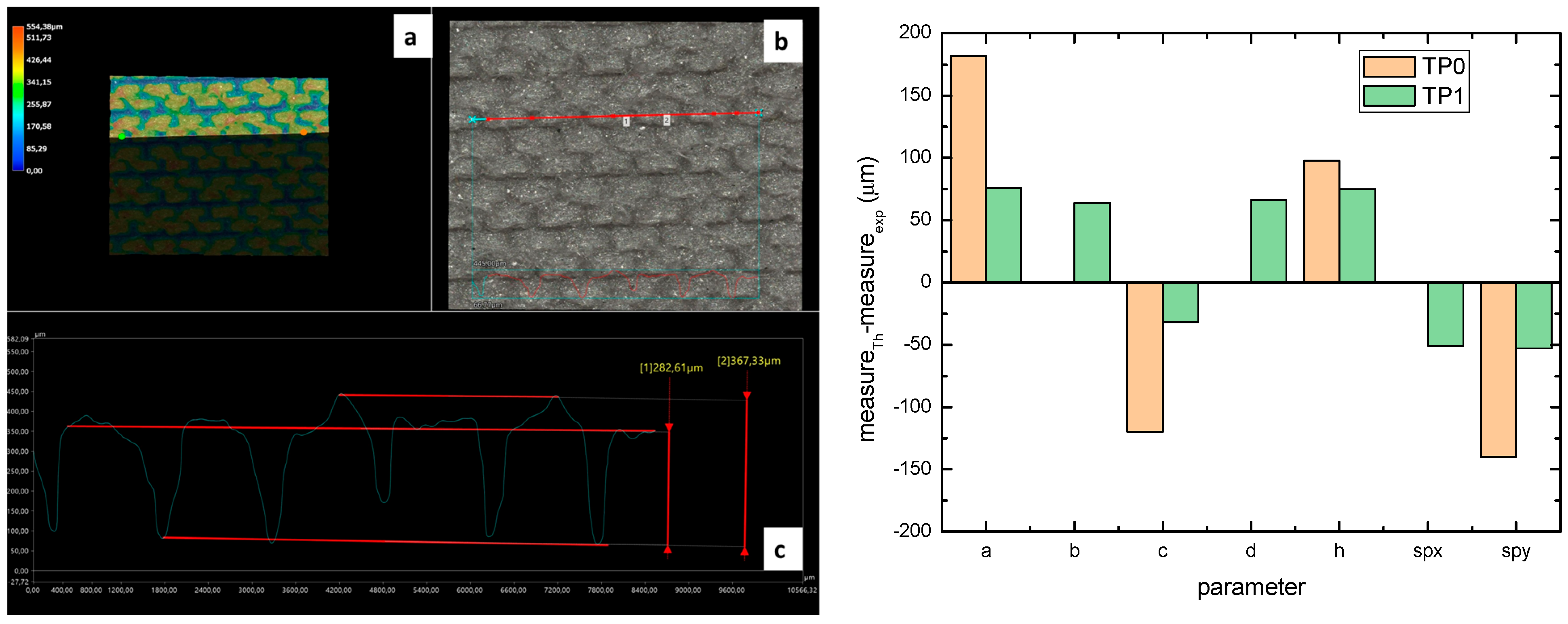

3.2. Characterization

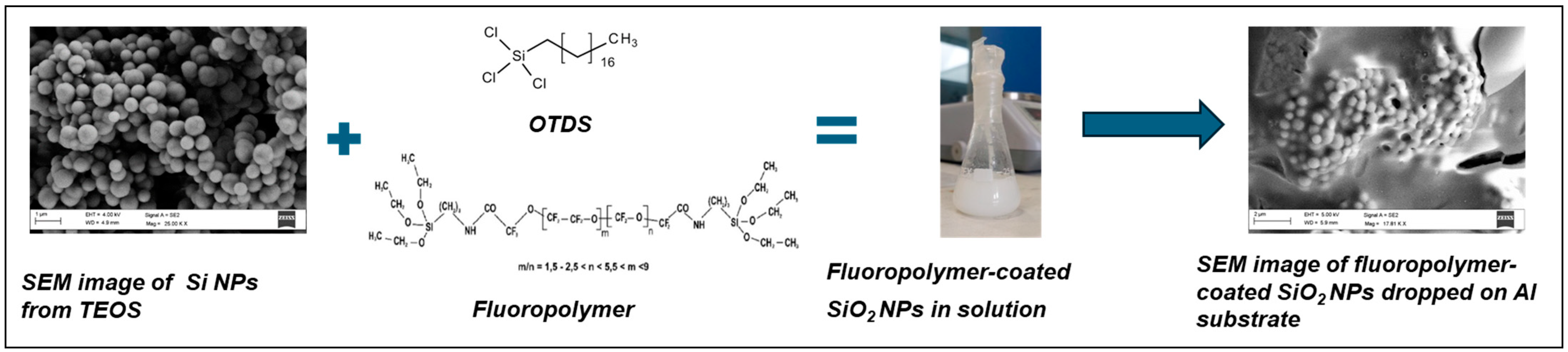

3.3. Chemical Treatment: Surface Deposition of SiO2 Nanoparticles

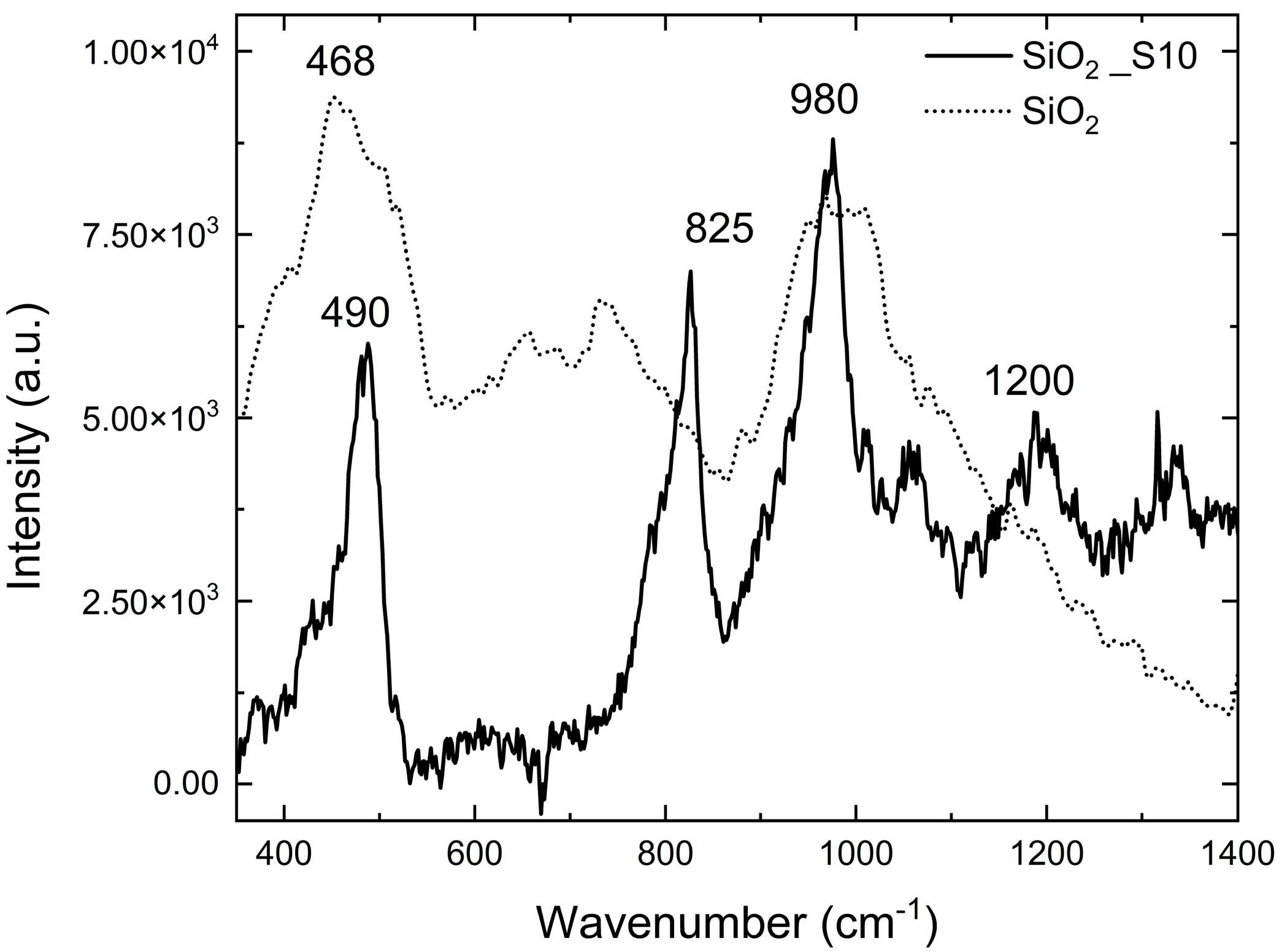

3.3.1. Preparation, Functionalization and Characterization of SiO2 Nanoparticles

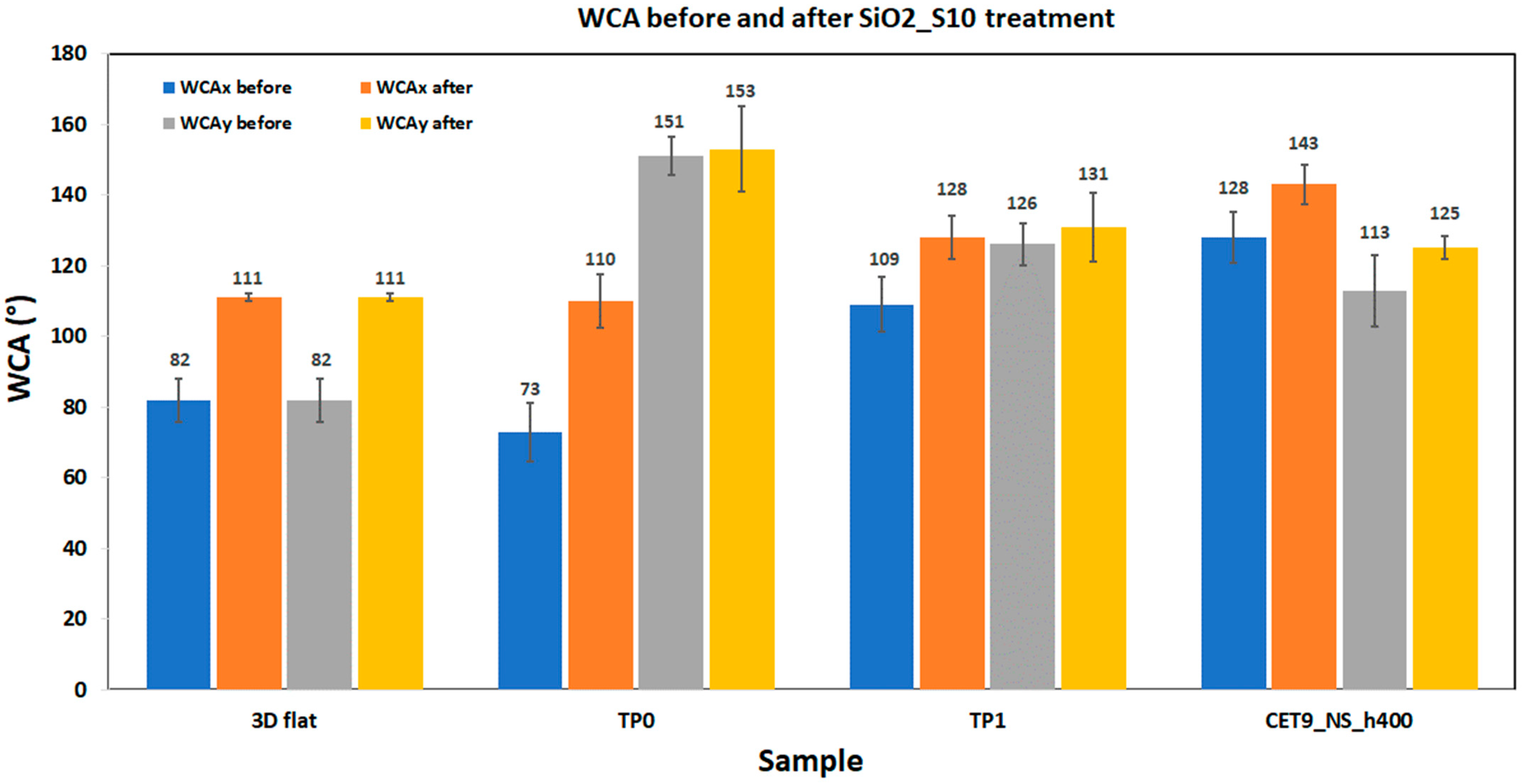

3.3.2. Hydrophobic Coating Deposition

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PLA | Polylactic Acid |

| FFF | Fused Filament Fabrication |

| WCA | Water Contact Angle |

| TG | Triangular-based Prism |

| TP | Truncated Pyramid |

| CET | Truncated Ellipsoidal Cone |

| SEM | Scanning Electron Microscopy |

| TEOS | Tetraethyl Orthosilicate |

| OTDS | Trichloro(octadecyl)silane |

| NPs | Nanoparticles |

References

- Antonov, D.V.; Islamova, A.G.; Strizhak, P.A. Hydrophilic and Hydrophobic Surfaces: Features of Interaction with Liquid Drops. Materials 2023, 16, 5932. [Google Scholar] [CrossRef] [PubMed]

- Sotoudeh, F.; Mousavi, S.M.; Karimi, N.; Lee, B.J.; Abolfazli-Esfahani, J.; Manshadi, M.K.D. Natural and synthetic superhydrophobic surfaces: A review of the fundamentals, structures, and applications. Alex. Eng. J. 2023, 68, 587–609. [Google Scholar] [CrossRef]

- Parvate, S.; Dixit, P.; Chattopadhyay, S. Superhydrophobic Surfaces: Insights from Theory and Experiment. J. Phys. Chem. B 2020, 124, 1323–1360. [Google Scholar] [CrossRef]

- Jeevahan, J.; Chandrasekaran, M.; Joseph, G.B.; Durairaj, R.B.; Mageshwaran, G. Superhydrophobic Surfaces: A Review on Fundamentals, Applications, and Challenges. J. Coat. Technol. Res. 2018, 15, 231–250. [Google Scholar] [CrossRef]

- Amjad, M.; Nguir, M.; Ma, X.; Wen, D. Superhydrophobic 3D-printed microstructures: Applications, challenges, and prospects. Prog. Addit. Manuf. 2025. [CrossRef]

- Nguyen-Tri, P.; Tran, H.N.; Plamondon, C.O.; Tuduri, L.; Vo, D.-V.N.; Nanda, S.; Mishra, A.; Chao, H.-P.; Bajpai, A.K. Recent progress in the preparation, properties and applications of superhydrophobic nano-based coatings and surfaces: A review. Prog. Org. Coat. 2019, 132, 235–256. [Google Scholar] [CrossRef]

- Shekhar, N.; Mondal, A. Synthesis, Properties, Environmental Degradation, Processing, and Applications of Polylactic Acid (PLA): An Overview. Polym. Bull. 2024, 81, 11421–11457. [Google Scholar] [CrossRef]

- Ali, W.; Ali, H.; Gillani, S.; Zinck, P.; Souissi, S. Polylactic Acid Synthesis, Biodegradability, Conversion to Microplastics and Toxicity: A Review. Environ. Chem. Lett. 2023, 21, 1761–1786. [Google Scholar] [CrossRef]

- Sandanamsamy, L.; Harun, W.S.W.; Ishak, I.; Romlay, F.R.M.; Kadirgama, K.; Ramasamy, D.; Idris, S.R.A.; Tsumori, F. A Comprehensive Review on Fused Deposition Modelling of Polylactic Acid. Prog. Addit. Manuf. 2023, 8, 775–799. [Google Scholar] [CrossRef]

- Ramesh, M.; Panneerselvam, K. PLA-Based Material Design and Investigation of Its Properties by FFF. In Advances in Additive Manufacturing and Joining; Lecture Notes on Multidisciplinary Industrial Engineering; Springer: Singapore, 2019; pp. 229–241. [Google Scholar] [CrossRef]

- Jiang, Z.; Sun, Y.; Yan, M.; Qian, B.; Jiang, A.; Zhang, X.; Bi, J.; Tong, Y.; Yu, L.; Li, W. Recent advancements in fabrication strategies and applications of superhydrophobic coatings. J. Mater. Sci. 2025, 60, 7826–7858. [Google Scholar] [CrossRef]

- Yang, H.; Ji, F.; Li, Z.; Tao, S. Preparation of Hydrophobic Surface on PLA and ABS by Fused Deposition Modeling. Polymers 2020, 12, 1539. [Google Scholar] [CrossRef]

- Borriello, C.; Galvagno, S.; Tammaro, L.; Portofino, S.; Loffredo, F.; De Girolamo Del Mauro, A.; Villani, F.; Pandolfi, G.; Iovane, P.; Tassini, P. Fabrication of 3D Micropatterned Hydrophobic Surfaces by Fused Filament Fabrication Printing Technology. Appl. Res. 2024, 3, e202400003. [Google Scholar] [CrossRef]

- Manabe, K.; Saikawa, M.; Sato, I.; Loo, C.S.; Takashima, K.; Norikane, Y. Biomimetic 3D-Printed Armored Structures for Durable Superhydrophobic Surfaces: Integrating Macroprotection and Nanofunctionality. ACS Appl. Polym. Mater. 2024, 6, 13701–13709. [Google Scholar] [CrossRef]

- Lee, K.-M.; Park, H.; Kim, J.; Chun, D.-M. Fabrication of a Superhydrophobic Surface Using a Fused Deposition Modeling (FDM) 3D Printer with Poly Lactic Acid (PLA) Filament and Dip Coating with Silica Nanoparticles. Appl. Surf. Sci. 2019, 467–468, 979–991. [Google Scholar] [CrossRef]

- Kang, B.; Sung, J.; So, H. Realization of Superhydrophobic Surfaces Based on Three-Dimensional Printing Technology. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 6, 743–751. [Google Scholar] [CrossRef]

- Amin, M.; Singh, M.; Ravi, K.R. Fabrication of Superhydrophobic PLA Surfaces by Tailoring FDM 3D Printing and Chemical Etching Process. Appl. Surf. Sci. 2023, 616, 157217. [Google Scholar] [CrossRef]

- Konieczna, R.; Przekop, R.E.; Pakuła, D.; Głowacka, J.; Ziętkowska, K.; Kozera, R.; Sztorch, B. Functional Silsesquioxanes—Tailoring Hydrophobicity and Anti-Ice Properties of Polylactide in 3D Printing Applications. Materials 2024, 17, 4850. [Google Scholar] [CrossRef]

- Bañón-García, F.; Bermudo Gamboa, C.; López-Fernández, J.A.; Trujillo-Vilches, F.J.; Martín-Béjar, S. Correlation between Surface Texture, Wettability and Mechanical Strength of Polylactic Acid Parts Fabricated by Fused Filament Fabrication. Coatings 2024, 14, 1033. [Google Scholar] [CrossRef]

- Khan, M.Z.; Militky, J.; Petru, M.; Tomkovà, B.; Ali, A.; Toren, E.; Perveen, S. Recent advances in superhydrophobic surfaces for practical applications: A review. Eur. Polym. J. 2022, 178, 111481. [Google Scholar] [CrossRef]

- Kwon, J.; Jung, H.; Jung, H.; Lee, J. Micro/Nanostructured Coating for Cotton Textiles That Repel Oil, Water, and Chemical Warfare Agents. Polymers 2020, 12, 1826. [Google Scholar] [CrossRef] [PubMed]

- Cassie, A.B.D.; Baxter, S. Wettability of Porous Surfaces. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Dey, A.; Yodo, N. A Systematic Survey of FDM Process Parameter Optimization and Their Influence on Part Characteristics. J. Manuf. Mater. Process. 2019, 3, 64. [Google Scholar] [CrossRef]

- Hashmi, A.W.; Mali, H.S.; Meena, A. The Surface Quality Improvement Methods for FDM Printed Parts: A Review. In Fused Deposition Modeling Based 3D Printing. Materials Forming, Machining and Tribology; Dave, H.K., Davim, J.P., Eds.; Springer: Cham, Switzerland, 2021; pp. 167–194. [Google Scholar]

- Buscarino, G.; Ardizzone, V.; Vaccaro, G.; Agnello, S.; Gelardi, F.M. Atomic force microscopy and Raman investigation on the sintering process of amorphous nanoparticles. J. Appl. Phys. 2010, 108, 074314. [Google Scholar] [CrossRef]

- Alessi, A.; Agnello, S.; Buscarino, G.; Gelardi, F.M. Structural properties of core and surface of silica nanoparticles investigated by Raman spectroscopy. J. Raman Spectrosc. 2013, 44, 810–816. [Google Scholar] [CrossRef]

- Radice, S.; Tommasini, M.; Castiglioni, C. Two-dimensional correlation Raman spectroscopy of perfluoropolyethers: Effect of peroxide groups. J. Mol. Struct. 2010, 974, 73–79. [Google Scholar] [CrossRef]

| Filament | Material | Nozzle Diameter (mm) | Nozzle Temperature (°C) | Bed Temperature (°C) | Infill Type | Printing Speed (mm/s) | Layer Thickness (mm) | Infill Density (%) |

|---|---|---|---|---|---|---|---|---|

| Galaxy silver Prusa | PLA | 0.2 | 215 | 60 | linear | 25 | 0.2 first layer 0.05 other layers | 100 |

| Sample | Surface Morphology | CAD Design | Dimension (μm) |

|---|---|---|---|

| F | Without patterns |  | Flat surface |

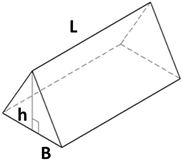

| TG | Triangular prism |  | L: specimens’ length B: 400 h: 400 spy: 0 NS |

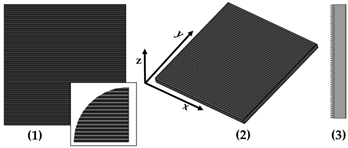

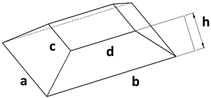

| TP0 | Truncated pyramid |  | a: 800 b: specimens’ length c: 400 d: specimens’ length h: 400 spy: 0 NS |

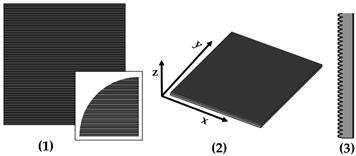

| TP1 | Truncated pyramid |  | a: 800 b: 1500 c: 400 d: 1100 h: 400 spx, spy: 100 S |

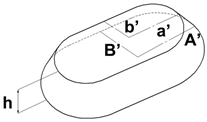

| CET9_NS_h400 | Truncated cone |  | A′: 600 B′: 450 a′: 450 b′: 300 h: 400 spx, spy: 100 NS |

| Legend | |||

| TG: Triangular prism L: length of the prism B: bottom edge of the base triangle h: height of the base triangle | ||

| TP: Truncated pyramid a: shorter side of the lower base b: longer side of the lower base c: shorter side of the upper base d: longer side of the upper base h: truncated height | ||

| CET: Truncated ellipsoidal cone A′: semi-major axis of the bottom base B′: semi-minor axis of the bottom base a′: semi-major axis of the top base b′: semi-minor axis of the top base h: truncated height | ||

| spx: spacing between patterns along x-axis spy: spacing between patterns along y-axis S: sequence of staggered structures NS: sequence of non-staggered structures | |||

| Sample | a (µm) | c (µm) | h (µm) | Spy (µm) | CAD Model (Black) Print Geometry (White) Scale 25:1 | Axis View | |

|---|---|---|---|---|---|---|---|

| TG | th | 400 | 0 | 400 | 0 |  | y |

| exp | 262 ± 16 | 202 ± 11 | 255 ± 4 | 134 ± 15 |

| Sample | a (µm) | b (µm) | c (µm) | d (µm) | h (µm) | spx (µm) | spy (µm) | CAD Model (Black) Print Geometry (White). Scale 10:1 | Axis View | |

|---|---|---|---|---|---|---|---|---|---|---|

| TP0 | th | 800 | sp length | 400 | sp length | 400 | / | 0 |  | y |

| exp | 618 ± 54 | sp length | 520 ± 27 | sp length | 302 ± 3 | / | 140 ± 17 | |||

| TP1 | th | 800 | 1500 | 400 | 1100 | 400 | 100 | 100 |  | x y |

| exp | 724 ± 22 | 1436 ± 21 | 432 ± 29 | 1034 ± 85 | 325 ± 42 | 151 ± 20 | 153 ± 14 |

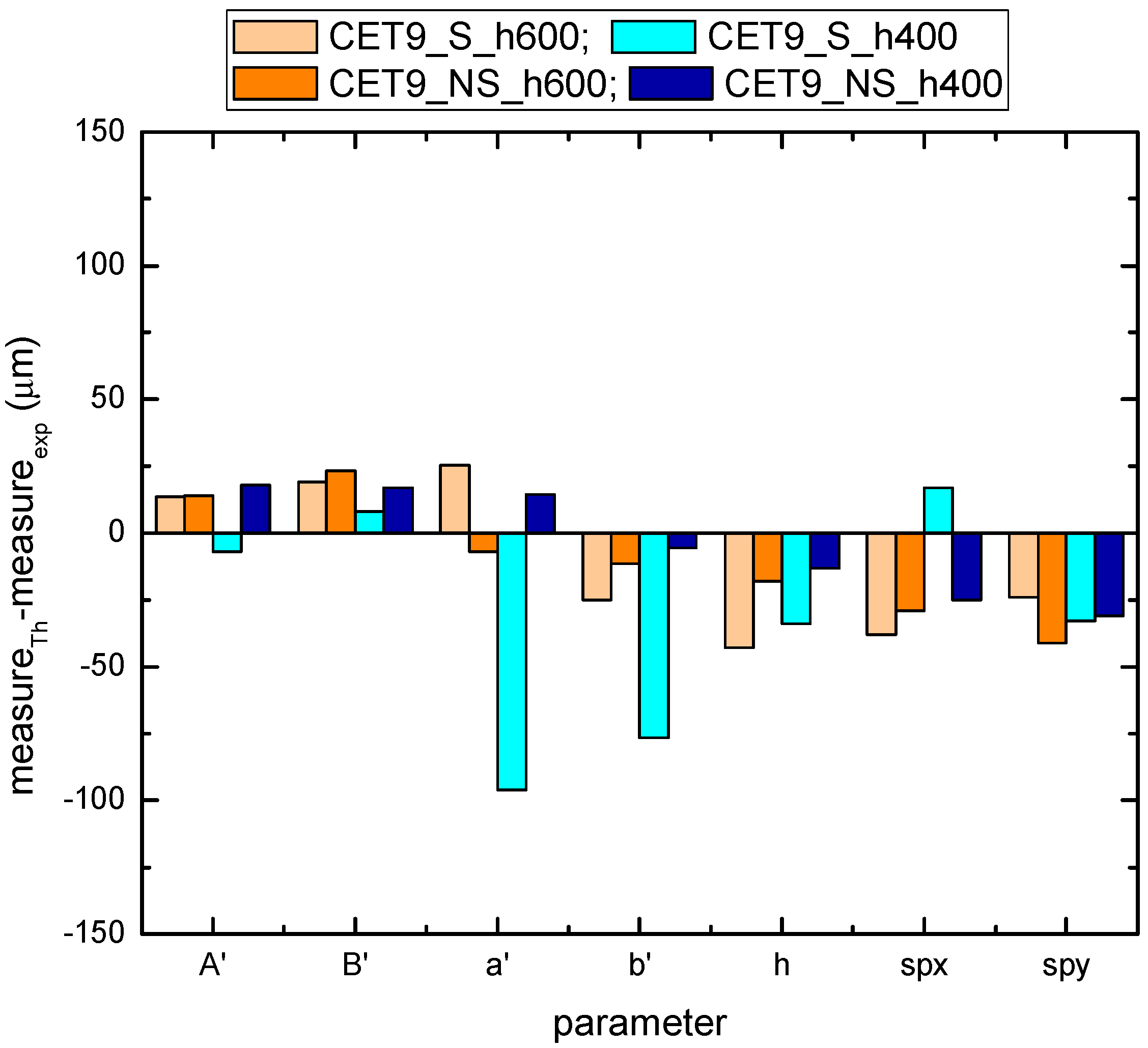

| Sample | 2 *A′ (µm) | 2 *B′ (µm) | 2 *a′ (µm) | 2 *b’ (µm) | h (µm) | spx (µm) | spy (µm) | CAD Model (Black) Print Geometry (White) Scale 10:1 | Axis View | |

|---|---|---|---|---|---|---|---|---|---|---|

| CET9_S_h600 | th | 1200 | 900 | 900 | 600 | 600 | 100 | 100 |  | x |

| exp | 1173 ± 26 | 862 ± 22 | 849 ± 51 | 650 ± 46 | 643 ± 57 | 138 ± 26 | 124 ± 30 |  | y | |

| CET9_NS_h600 | th | 1200 | 900 | 900 | 600 | 600 | 100 | 100 |  | x |

| exp | 1172 ± 34 | 853 ± 30 | 914 ± 81 | 623 ± 47 | 618 ± 50 | 129 ± 32 | 141 ± 14 |  | y | |

| CET9_NS_h400 | th | 1200 | 900 | 900 | 600 | 400 | 100 | 100 |  | x |

| exp | 1164 ± 39 | 866 ± 16 | 871 ± 30 | 611 ± 40 | 413 ± 34 | 125 ± 23 | 131 ± 20 |  | y | |

| CET9_S_h400 | th | 1200 | 900 | 900 | 600 | 400 | 100 | 100 |  | x |

| exp | 1214 ± 62 | 884 ± 33 | 1092 ± 48 | 753 ± 52 | 434 ± 64 | 83 ± 34 | 133 ± 32 |  | y |

| Sample | CAD Model (Black) vs. Print Geometry (White) Scale 25:1 | Axis View |

|---|---|---|

| TG |  | x |

| TP0 |  | x |

| TP1 |  | x |

| y | |

| CET9_NS_h400 |  | x |

| y |

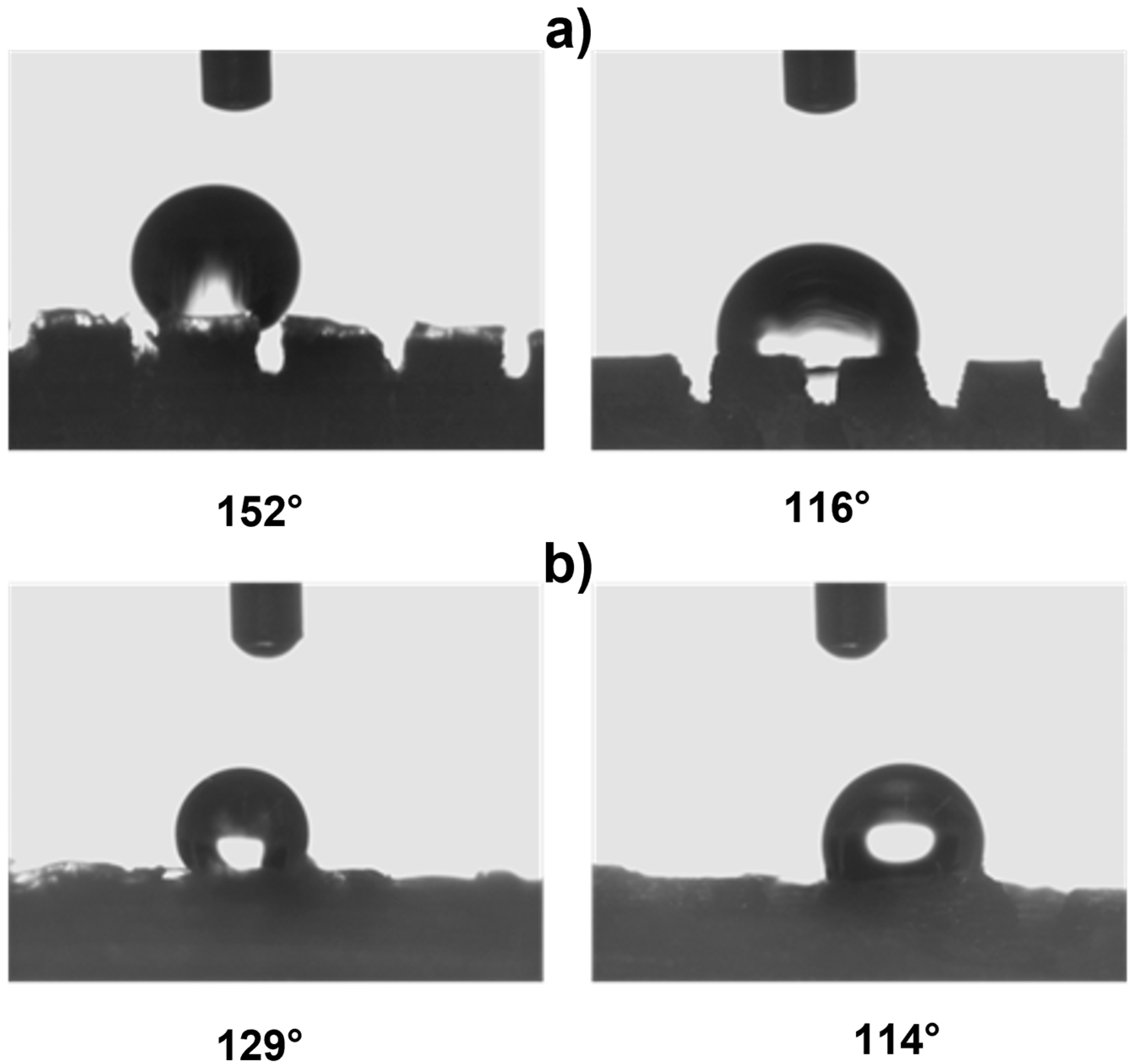

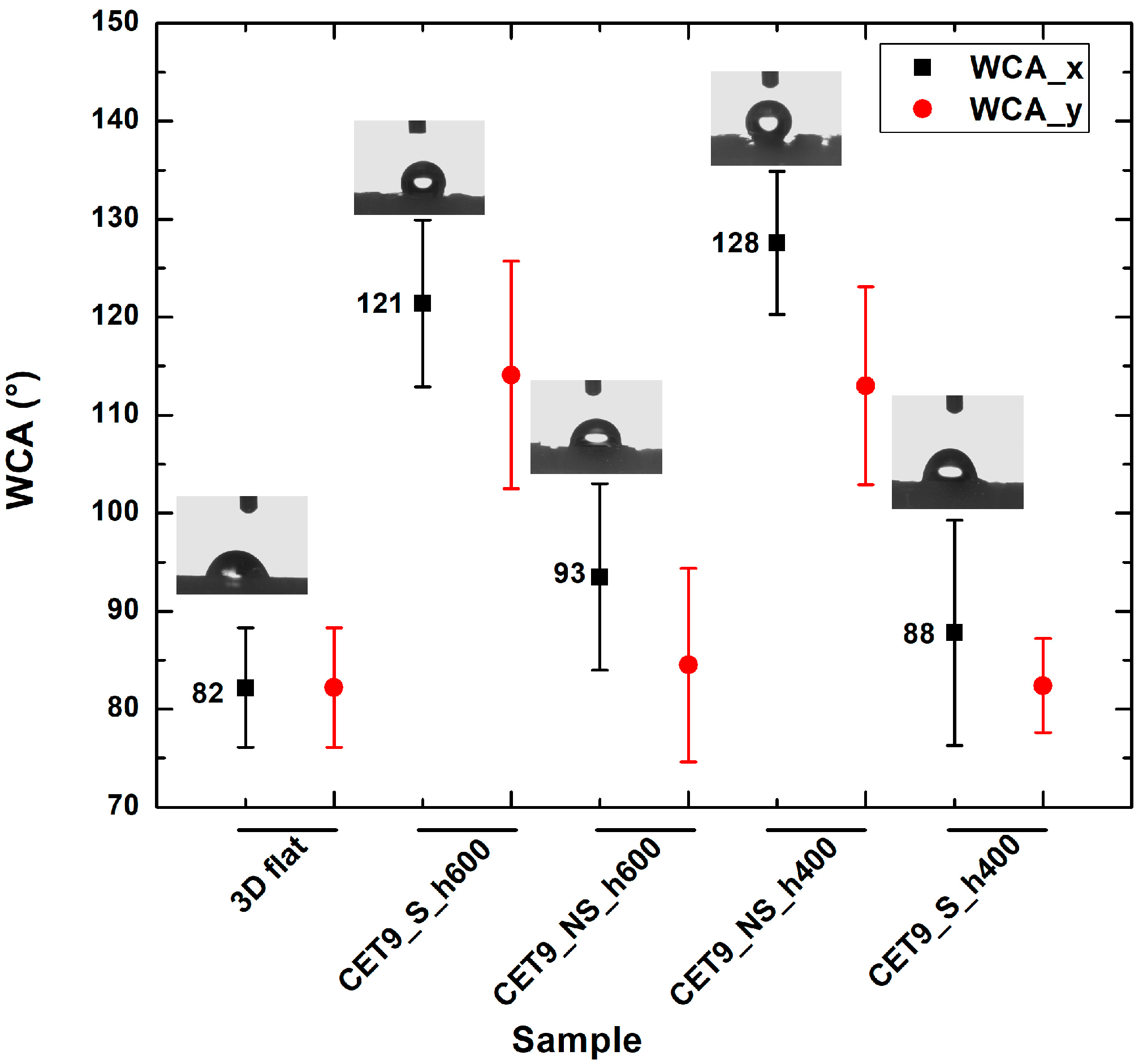

| Sample | WCAx (°) | WCAy (°) |

|---|---|---|

| CET9_S_h600 | 121.4 ± 8.5 | 114.1 ± 11.6 |

| CET9_NS_h600 | 93.5 ± 9.5 | 84.5 ± 9.9 |

| CET9_NS_h400 | 127.6 ± 7.3 | 113.0 ± 10.1 |

| CET9_S_h400 | 87.8 ± 11.5 | 82.4 ± 4.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tammaro, L.; Galvagno, S.; Pandolfi, G.; Loffredo, F.; Villani, F.; De Girolamo Del Mauro, A.; Iovane, P.; Portofino, S.; Tassini, P.; Borriello, C. Three-Dimensionally Printed Microstructured Hydrophobic Surfaces: Morphology and Wettability. Polymers 2025, 17, 2570. https://doi.org/10.3390/polym17192570

Tammaro L, Galvagno S, Pandolfi G, Loffredo F, Villani F, De Girolamo Del Mauro A, Iovane P, Portofino S, Tassini P, Borriello C. Three-Dimensionally Printed Microstructured Hydrophobic Surfaces: Morphology and Wettability. Polymers. 2025; 17(19):2570. https://doi.org/10.3390/polym17192570

Chicago/Turabian StyleTammaro, Loredana, Sergio Galvagno, Giuseppe Pandolfi, Fausta Loffredo, Fulvia Villani, Anna De Girolamo Del Mauro, Pierpaolo Iovane, Sabrina Portofino, Paolo Tassini, and Carmela Borriello. 2025. "Three-Dimensionally Printed Microstructured Hydrophobic Surfaces: Morphology and Wettability" Polymers 17, no. 19: 2570. https://doi.org/10.3390/polym17192570

APA StyleTammaro, L., Galvagno, S., Pandolfi, G., Loffredo, F., Villani, F., De Girolamo Del Mauro, A., Iovane, P., Portofino, S., Tassini, P., & Borriello, C. (2025). Three-Dimensionally Printed Microstructured Hydrophobic Surfaces: Morphology and Wettability. Polymers, 17(19), 2570. https://doi.org/10.3390/polym17192570