Fracture Properties of High-Performance High-Ductility Alkali-Activated Concrete Under Thermo-Mechanical Coupling: Effect of Fiber Hybrid Ratio

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Specimen Preparation

2.3. Testing Setup

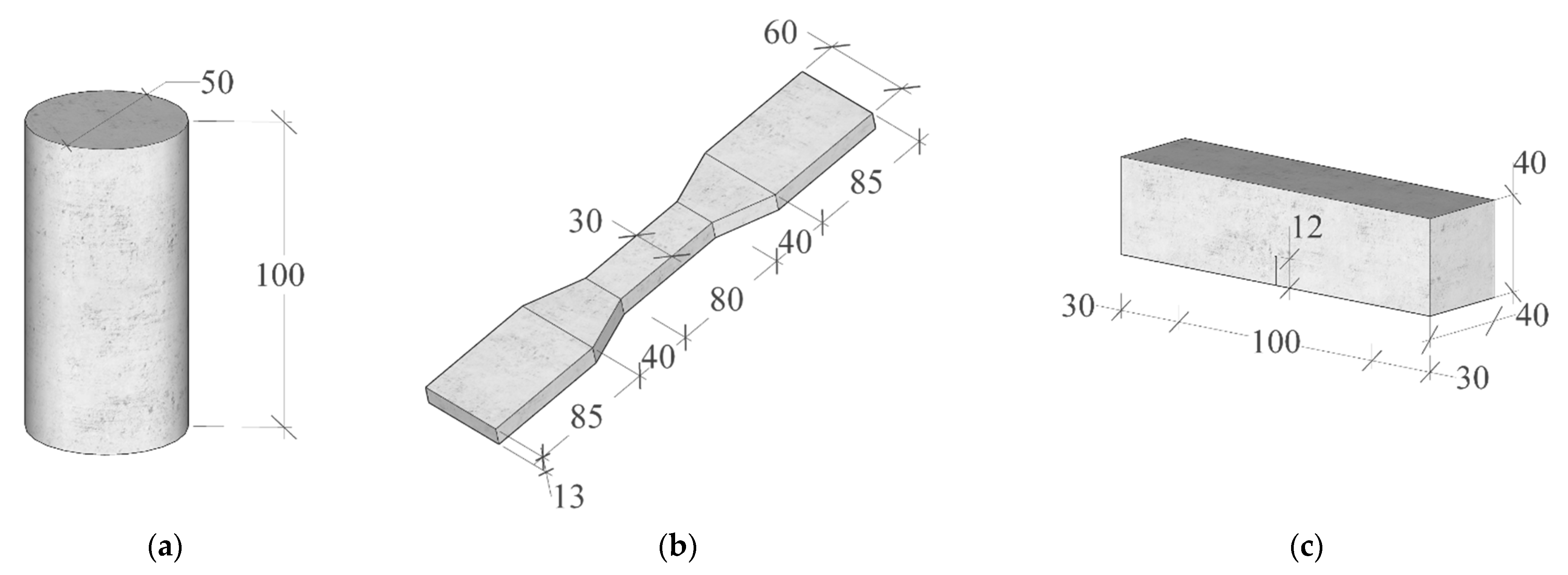

2.3.1. Axial Compressive Test

2.3.2. Axial Tensile Test

2.3.3. Fracture Test

2.4. Two-Way Analysis of Variance

3. Results

3.1. Basic Mechanical Properties of Hybrid PP/PE-HDAAC

3.2. Fracture Properties

3.2.1. Failure Mode

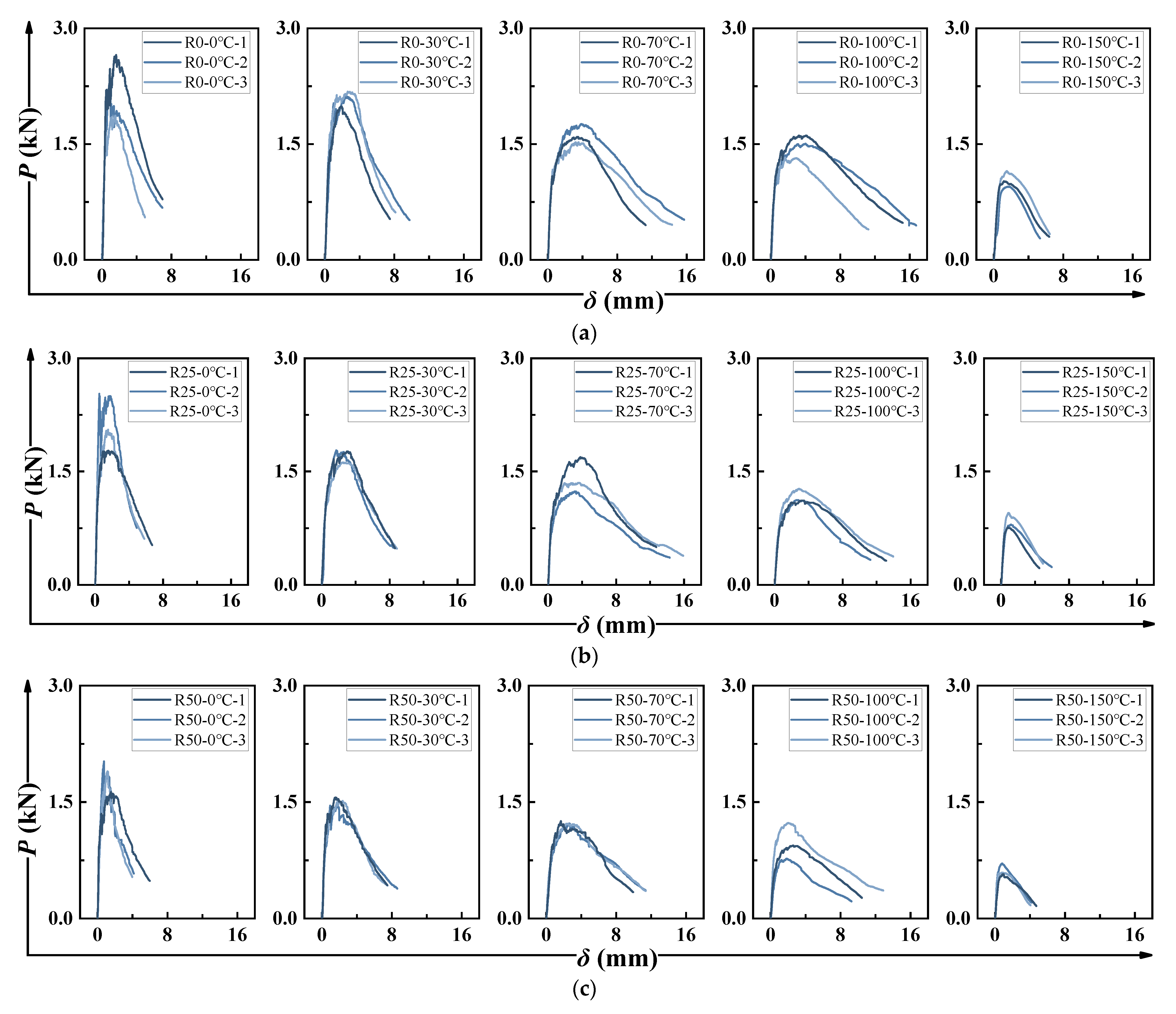

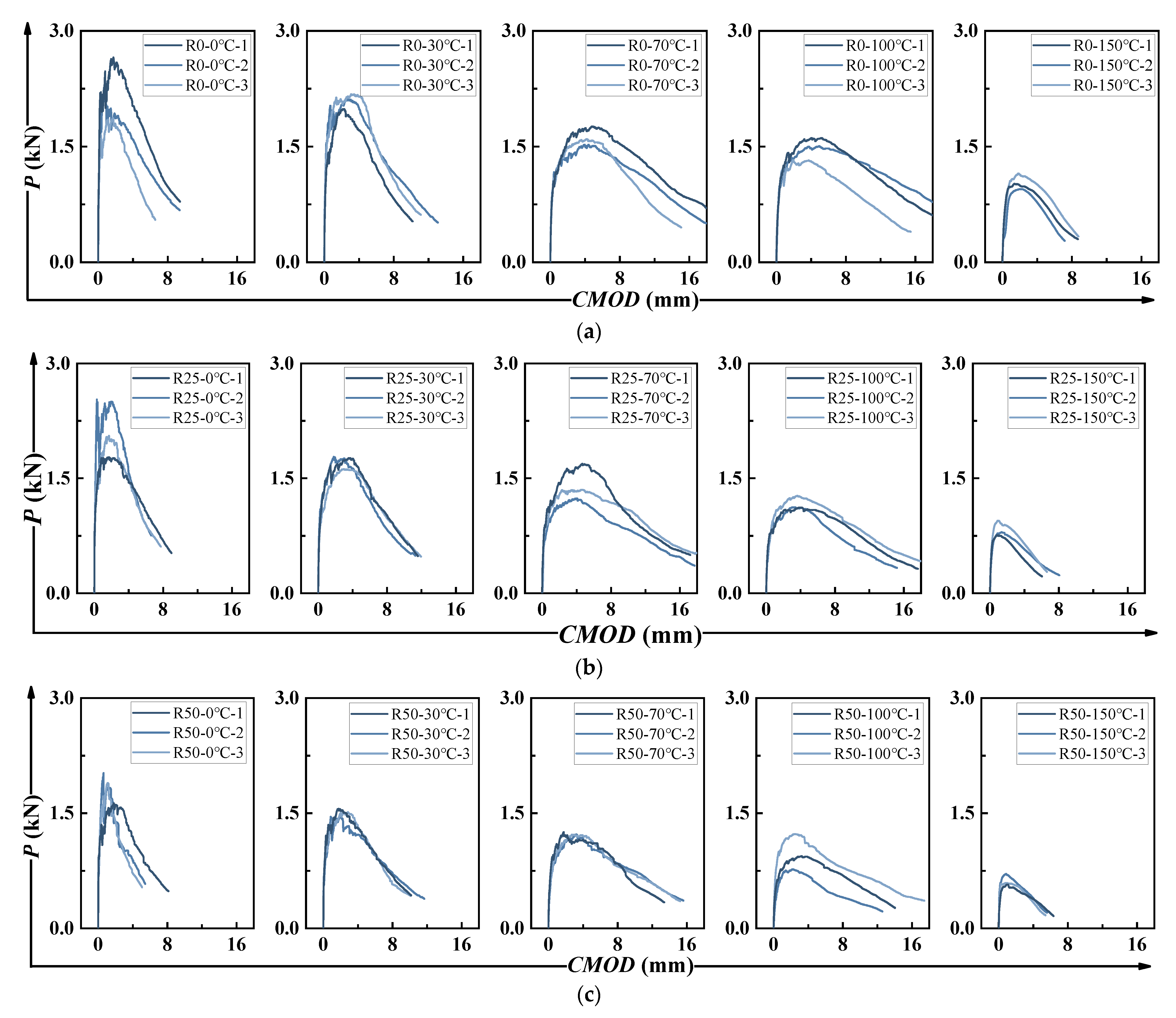

3.2.2. P-δ Curves and P-CMOD Curves

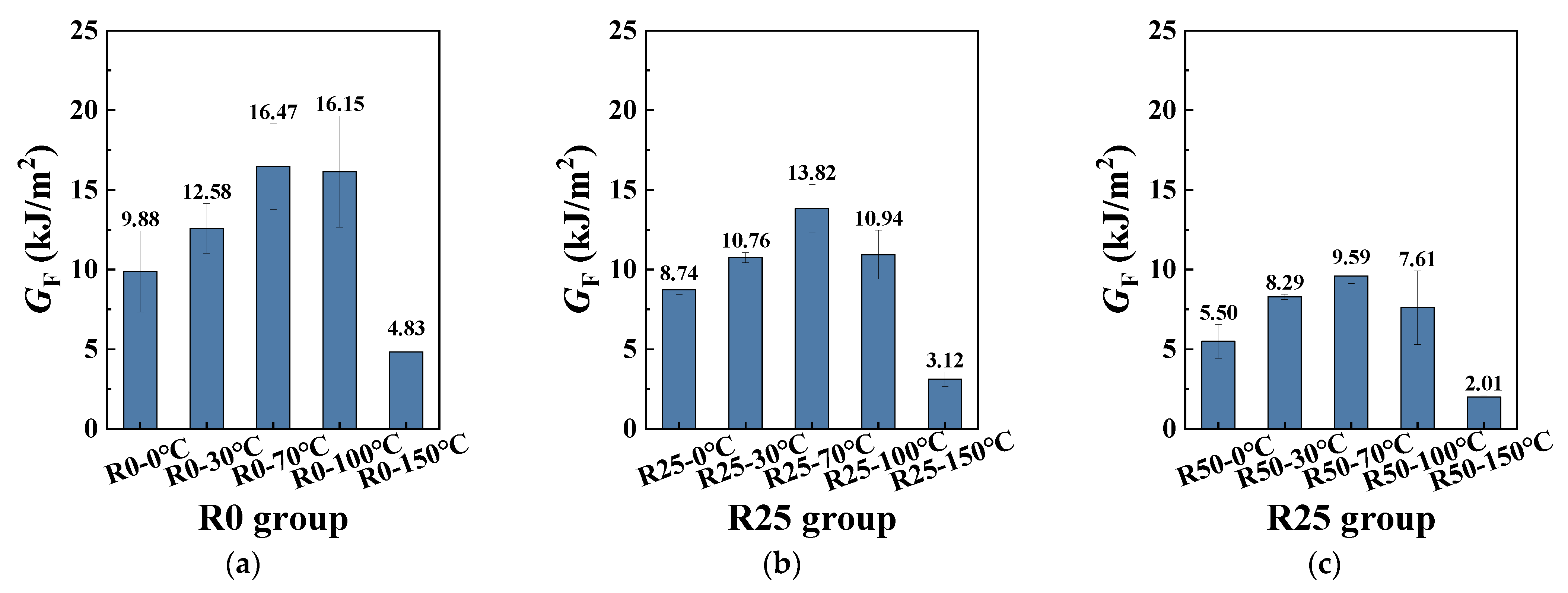

3.2.3. Mode I Fracture Energy of Hybrid PP/PE-HDAAC

3.2.4. Fracture Energy Based on J-Integral Method

3.3. Significance Analysis

4. Discussion

4.1. Basic Mechanical Properties of Hybrid PP/PE-HDAAC Under Ambient Temperature

4.2. Ductile Fracture Phenomenon of Hybrid PP/PE-HDAAC

4.3. Fracture Characteristics of HDAAC Under Thermo-Mechanical Loadings

4.4. Future Research

- (1)

- Cost control and fiber efficiency. Reducing the cost of HDAAC-type composites remains crucial. Advanced fiber hybridization or ultra-low fiber designs can control the material cost, but their effects on performance must be evaluated. For example, Wang, Ma, Ding, Yu and Yu [12] developed an HDAAC with only 0.2% fiber by volume that still achieved high ductility; the low fracture toughness matrix enabled its performance and the embodied cost was only 30% of a conventional high-fiber ECC. Future work should similarly explore hybrid fiber systems and tailor the matrix toughness so as to minimize the fiber content without sacrificing strength or toughness.

- (2)

- The exploration of fiber surface treatments. Optimizing fiber surface treatment is another promising direction. Treatments (e.g., alkali washes, silane coupling agents, or nanoparticle coatings) can remove impurities and enhance fiber–matrix bonding, which can increase composites’ ductility. Future studies should systematically vary and optimize such treatments (and even develop novel coatings) for the fibers of HDAAC to strengthen the fiber–matrix interface and improve the mechanical properties.

- (3)

- Improve high-temperature resistance. Improving thermal–mechanical performance requires both heat-resistant matrices and fibers. Binders like low-CO2 cements (e.g., LC3 or other blended cements) or alkali-activated materials can be combined with heat-resistant fibers. Promising fiber alternatives include aramid and PBO fibers (as already noted) as well as basalt, carbon, or ceramic fibers [51]. Research should evaluate these and other emerging fibers (and matrix modifications) in HDAAC to extend its service temperature range and fire resistance.

- (4)

- Modeling and simulation approaches. Computational modeling can greatly aid design optimization. Multi-scale numerical methods (e.g., the finite element analysis of the composite specimen or micromechanical models of fiber–matrix cracking) can predict how changes in fiber content, orientation, or interface properties affect behavior. Future work should develop models for HDAAC under combined thermal and mechanical loads, allowing the prediction of ductility, crack patterns, and failure mechanisms without relying solely on experiments.

- (5)

- Durability under cyclic and long-term loading. The long-term reliability of HDAAC under service conditions is still not well understood. Future research should address its fatigue behavior under cyclic and long-term loading, with a particular emphasis on crack evolution, fiber–matrix interface, and the degradation of mechanical properties. Sustained loading effects such as creep and shrinkage-induced cracking also deserve attention, as they directly influence service life and structural safety.

5. Conclusions

- (1)

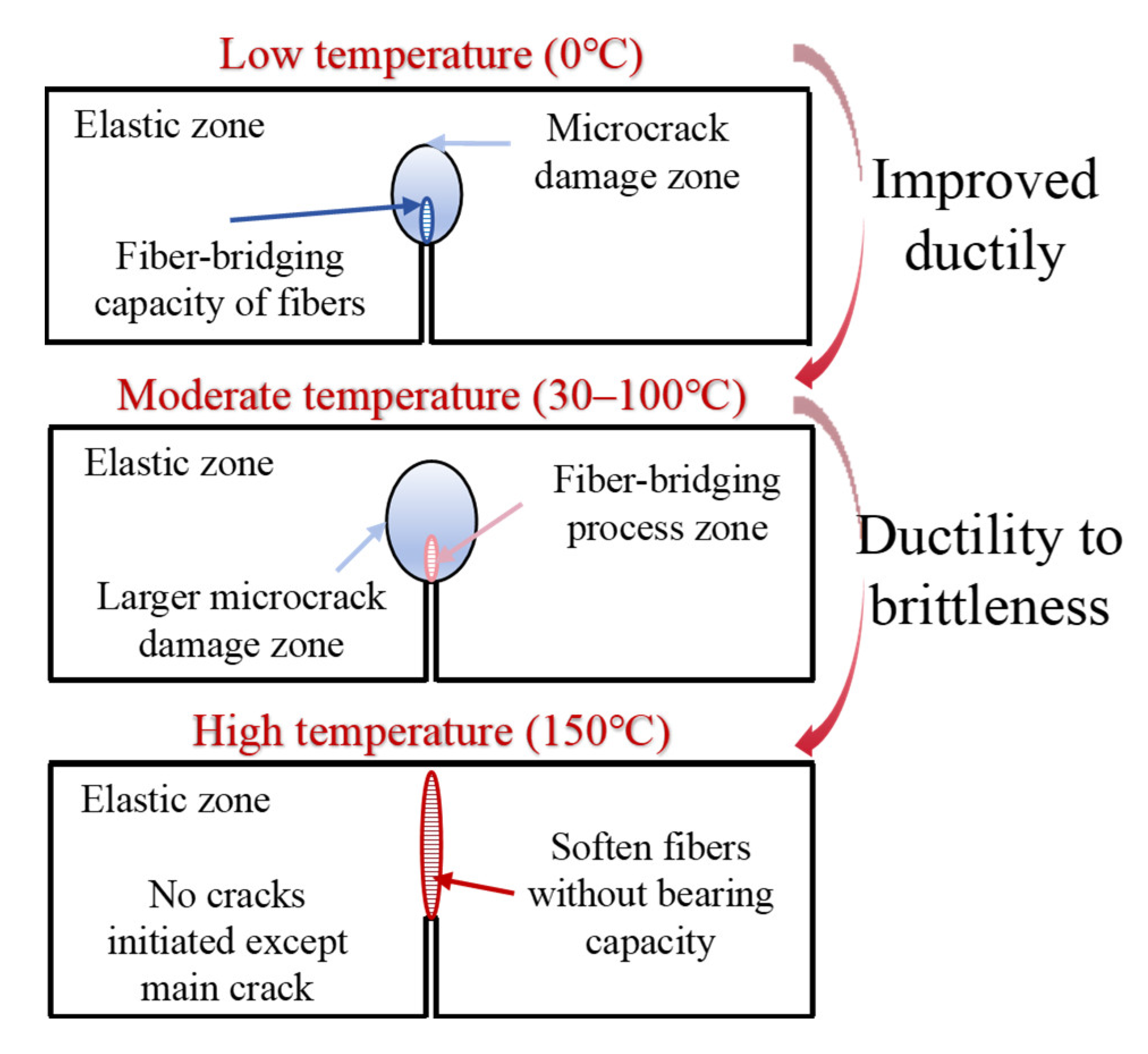

- Overall, except at 150 °C, hybrid PP/PE-HDAAC exhibited a ductile fracture mode under all experimental conditions up to 100 °C. Although the failure mode of the notched beam specimens was still characterized by a primary crack propagating along the notch direction, numerous microcracks developed around the crack tip during the multiple cracking stage of the P-CMOD curve. During this stage, the applied load remained relatively stable.

- (2)

- Under varying thermo-mechanical coupling temperatures, the fracture energy of hybrid PP/PE-HDAAC generally remained high, reaching up to 16.47 kJ/m2, with a sharp decline only at 150 °C, where it dropped to 2.01 kJ/m2. This reduction was attributed to fiber melting at elevated temperatures, which severely compromised the fiber-bridging effect and resulted in a transition from ductile to brittle failure.

- (3)

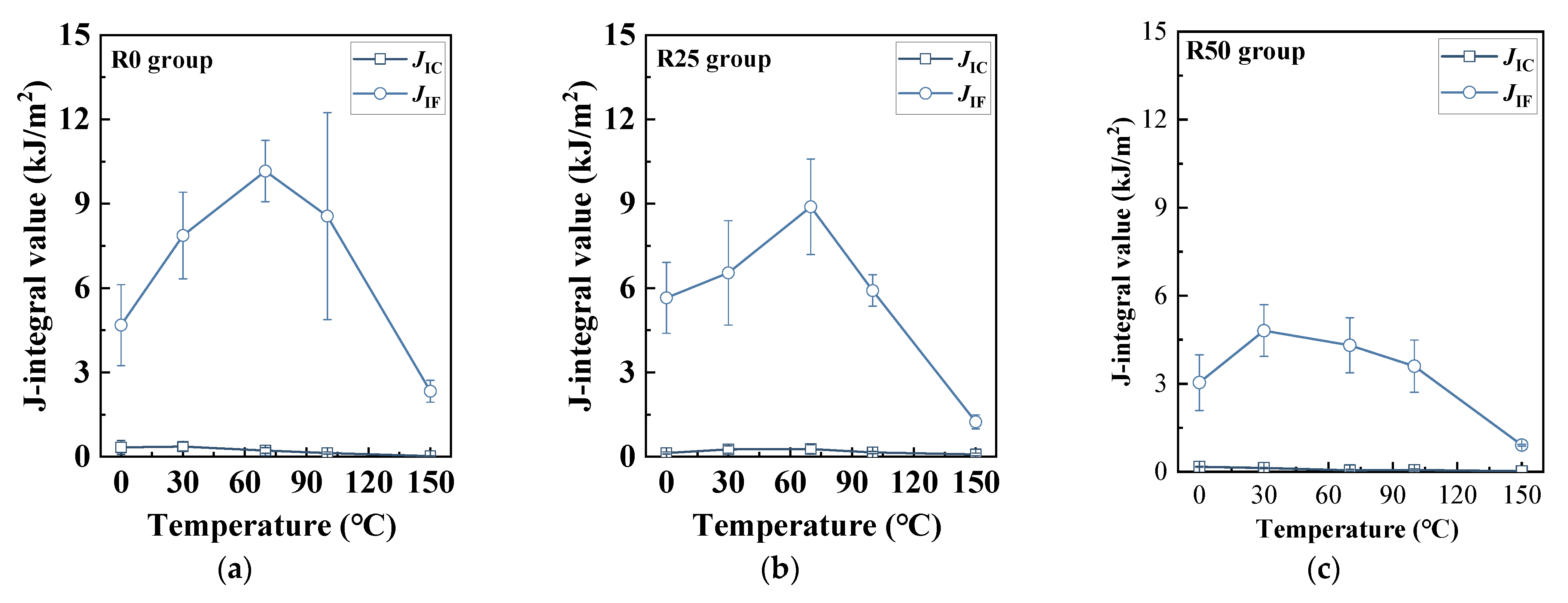

- The JIC remained consistently around 0.1 kJ/m2, showing minimal sensitivity to changes in temperature and fiber replacement ratio. In contrast, the JIF was significantly higher, reflecting the HDAAC’s excellent energy dissipation capacity after crack initiation. This enhanced fracture performance was mainly due to multiple cracking phenomenon around the crack tip and stress redistribution, both of which delayed final failure. JIF reached its maximum at 70 °C (e.g., 10.16 kJ/m2 for the R0 group), but declined sharply at 150 °C, indicating that excessively high temperatures reduced the ability to sustain ductile fracture behavior.

- (4)

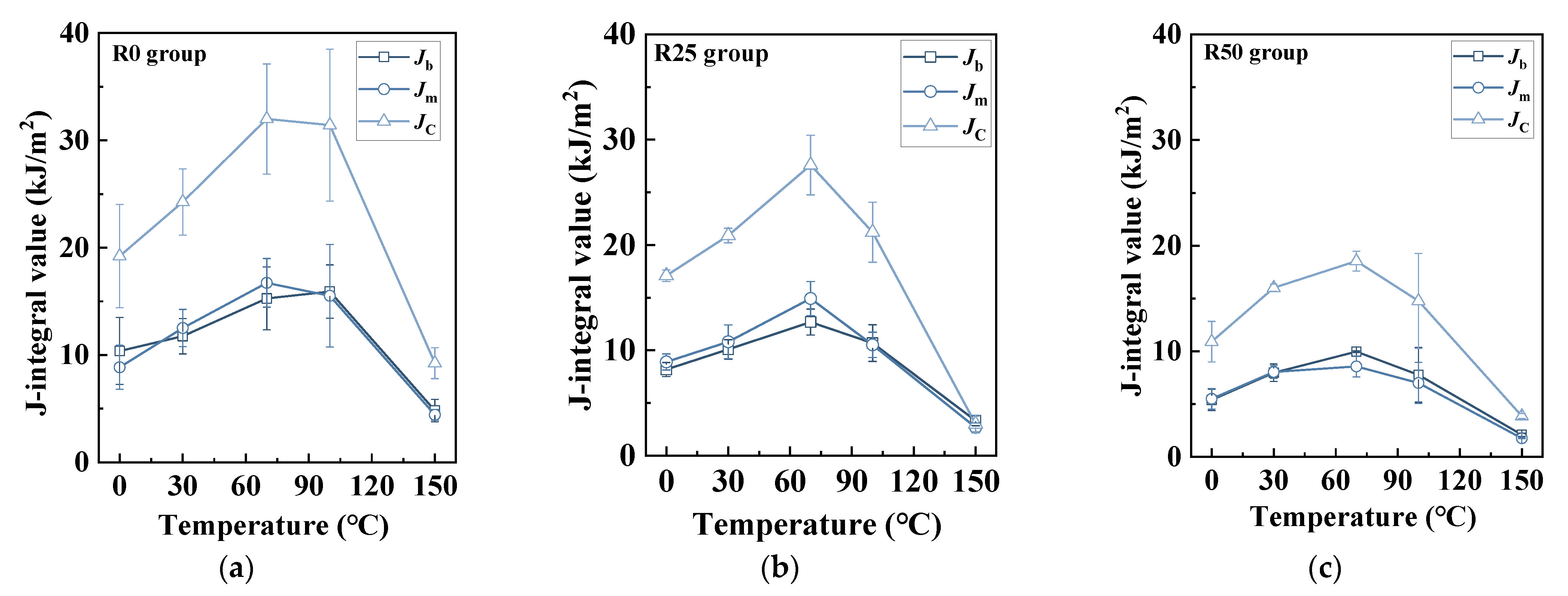

- Both Jm and Jb increased with temperature, peaking at 70 °C, followed by a substantial drop at 150 °C. The ratio Jm/Jc remained relatively stable between 0.4 and 0.5, suggesting that matrix cracking contributed to approximately half of the total fracture energy. This kind of fracture behavior was distinct from that of conventional concrete and typical FRC. Increasing the PP fiber replacement ratio led to a reduction in both Jm and Jb, with the most pronounced decrease observed at the 50% PP fiber replacement ratio. Under thermo-mechanical coupling, fibers were subjected to simultaneous thermal and mechanical loads. Elevated coupled temperatures caused fiber softening or melting, severely diminishing the fiber-bridging capacity. At 150 °C, fibers were no longer able to support the stable growth of matrix cracking, resulting in a transition to brittle failure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, G.; Zheng, D.-P.; Chen, Y.-W.; Lin, J.-X.; Lao, W.-J.; Guo, Y.-C.; Chen, Z.-B.; Lan, X.-W. Development of high performance geopolymer concrete with waste rubber and recycle steel fiber: A study on compressive behavior, carbon emissions and economical performance. Constr. Build. Mater. 2023, 393, 131988. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Kumar, S.; Sekhar Das, C.; Lao, J.; Alrefaei, Y.; Dai, J.-G. Effect of sand content on bond performance of engineered geopolymer composites (EGC) repair material. Constr. Build. Mater. 2022, 328, 127080. [Google Scholar] [CrossRef]

- Lee, S.K.; Oh, T.; Banthia, N.; Yoo, D.-Y. Optimization of fiber aspect ratio for 90 MPa strain-hardening geopolymer composites (SHGC) with a tensile strain capacity over 7.5%. Cem. Concr. Compos. 2023, 139, 105055. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M. Engineered geopolymer composites: A state-of-the-art review. Cem. Concr. Compos. 2023, 135, 104850. [Google Scholar] [CrossRef]

- Nguyễn, H.H.; Lương, Q.-H.; Choi, J.-I.; Ranade, R.; Li, V.C.; Lee, B.Y. Ultra-ductile behavior of fly ash-based engineered geopolymer composites with a tensile strain capacity up to 13.7%. Cem. Concr. Compos. 2021, 122, 104133. [Google Scholar] [CrossRef]

- Yang, Z.-M.; Pan, H.-S.; Jiang, Z.-X.; Lv, J.-H.; Ruan, G.-W.; Lai, H.-M.; Lin, J.-X. Pseudo strain-hardening alkali-activated composites with up to 100% rubber aggregate: Static mechanical properties analysis and constitutive model development. Constr. Build. Mater. 2024, 439, 137338. [Google Scholar] [CrossRef]

- Li, V.C.; Leung, C.K.Y. Steady State and Multiple Cracking of Short Random Fiber Composites. J. Eng. Mech. 1992, 118, 2246–2264. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.X.; Wu, C. Tensile strain-hardening behavior of polyvinyl alcohol engineered cementitious composite (PVA-ECC). ACI Mater. J. 2001, 98, 483–492. [Google Scholar] [CrossRef]

- Maras, M.M. Tensile and flexural strength cracking behavior of geopolymer composite reinforced with hybrid fibers. Arab. J. Geosci. 2021, 14, 2258. [Google Scholar] [CrossRef]

- Yu, J.; Yao, J.; Lin, X.; Li, H.; Lam, J.Y.K.; Leung, C.K.Y.; Sham, I.M.L.; Shih, K. Tensile performance of sustainable Strain-Hardening Cementitious Composites with hybrid PVA and recycled PET fibers. Cem. Concr. Res. 2018, 107, 110–123. [Google Scholar] [CrossRef]

- Wang, F.; Ma, J.; Ding, Y.; Yu, J.; Yu, K. Engineered geopolymer composite (EGC) with ultra-low fiber content of 0.2%. Constr. Build. Mater. 2024, 411, 134626. [Google Scholar] [CrossRef]

- Huang, Z.; Liang, T.; Huang, B.; Zhou, Y.; Ye, J. Ultra-lightweight high ductility cement composite incorporated with low PE fiber and rubber powder. Constr. Build. Mater. 2021, 312, 125430. [Google Scholar] [CrossRef]

- Alrefaei, Y.; Dai, J.-G. Tensile behavior and microstructure of hybrid fiber ambient cured one-part engineered geopolymer composites. Constr. Build. Mater. 2018, 184, 419–431. [Google Scholar] [CrossRef]

- Pakravan, H.R.; Jamshidi, M.; Latifi, M. Study on fiber hybridization effect of engineered cementitious composites with low- and high-modulus polymeric fibers. Constr. Build. Mater. 2016, 112, 739–746. [Google Scholar] [CrossRef]

- Zhang, X.; Ling, Y.; Wu, Y.; Lai, H.; Wang, Y.; Chen, Z. Comprehensive Analysis of Mechanical, Economic, and Environmental Characteristics of Hybrid PE/PP Fiber-Reinforced Engineered Geopolymer Composites. Buildings 2024, 14, 1094. [Google Scholar] [CrossRef]

- Deshpande, A.A.; Kumar, D.; Ranade, R. Influence of high temperatures on the residual mechanical properties of a hybrid fiber-reinforced strain-hardening cementitious composite. Constr. Build. Mater. 2019, 208, 283–295. [Google Scholar] [CrossRef]

- Ling, Y.; Zhang, X.; Wu, Y.; Zou, W.; Wang, C.; Li, C.; Li, W. Evaluation of Bonding Behavior between Engineered Geopolymer Composites with Hybrid PE/PVA Fibers and Concrete Substrate. Materials 2024, 17, 3778. [Google Scholar] [CrossRef]

- Lin, J.-X.; Chen, G.; Pan, H.-S.; Wang, Y.-C.; Guo, Y.-C.; Jiang, Z.-X. Analysis of Stress-Strain Behavior in Engineered Geopolymer Composites Reinforced with Hybrid PE-PP Fibers: A Focus on Cracking Characteristics. Compos. Struct. 2023, 323, 117437. [Google Scholar] [CrossRef]

- Cai, Z.-T. Experimental Study on Fracture Properties of Steel-PE Fiber High Ductile Geopolymer Composites. Master’s Thesis, Guangdong University of Technology, Guangdong, China, 2023. [Google Scholar]

- Xu, L.-Y.; Lao, J.-C.; Qian, L.-P.; Khan, M.; Xie, T.-Y.; Huang, B.-T. Low-carbon high-strength engineered geopolymer composites (HS-EGC) with full-volume fly ash precursor: Role of silica modulus. J. CO2 Util. 2024, 88, 102948. [Google Scholar] [CrossRef]

- Xu, S.; Reinhardt, H.W. A simplified method for determining double-K fracture parameters for three-point bending tests. Int. J. Fract. 2000, 104, 181–209. [Google Scholar] [CrossRef]

- Ouldboukhitine, S.-E.; Belarbi, R.; Jaffal, I.; Trabelsi, A. Assessment of green roof thermal behavior: A coupled heat and mass transfer model. Build. Environ. 2011, 46, 2624–2631. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Kodur, V.; Wu, B.; Cao, L.; Qi, S.L. Comparative Thermal and Mechanical Performance of Geopolymers derived from Metakaolin and Fly Ash. J. Mater. Civ. Eng. 2016, 28, 04015092. [Google Scholar] [CrossRef]

- Ruan, G.-W.; Luo, R.-H.; Liao, Z.-K.; Qu, C.-Y.; Jiang, Z.-X.; Yang, Z.-M.; Lin, J.-X. Residual mechanical properties and spalling behavior of seawater coral sand powder engineered cementitious composites under high-temperature exposure. Constr. Build. Mater. 2025, 492, 142978. [Google Scholar] [CrossRef]

- Lee, N.K.; Koh, K.T.; An, G.H.; Ryu, G.S. Influence of binder composition on the gel structure in alkali activated fly ash/slag pastes exposed to elevated temperatures. Ceram. Int. 2017, 43, 2471–2480. [Google Scholar] [CrossRef]

- Liu, X.; Yu, W. Evaluation of the tensile properties and thermal stability of ultrahigh-molecular-weight polyethylene fibers. J. Appl. Polym. Sci. 2005, 97, 310–315. [Google Scholar] [CrossRef]

- Park, S.M.; Jang, J.G.; Lee, N.K.; Lee, H.K. Physicochemical properties of binder gel in alkali-activated fly ash/slag exposed to high temperatures. Cem. Concr. Res. 2016, 89, 72–79. [Google Scholar] [CrossRef]

- Aygörmez, Y.; Canpolat, O.; Al-mashhadani, M.M.; Uysal, M. Elevated temperature, freezing-thawing and wetting-drying effects on polypropylene fiber reinforced metakaolin based geopolymer composites. Constr. Build. Mater. 2020, 235, 117502. [Google Scholar] [CrossRef]

- Chen, Z.-B.; Su, J.-Y.; Luo, R.-H.; Lin, J.-X.; Chen, X.-F.; Huang, P.-Y.; Guo, Y.-C. Experimental investigation on fracture behavior of rubberized engineered cementitious composites under thermo-mechanical loadings. Eng. Fract. Mech. 2025, 315, 110838. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Silva, F.d.A.; Müller, S.; Jun, P.; Filho, R.D.T. Coupled strain rate and temperature effects on the tensile behavior of strain-hardening cement-based composites (SHCC) with PVA fibers. Cem. Concr. Res. 2012, 42, 1417–1427. [Google Scholar] [CrossRef]

- Constâncio Trindade, A.C.; Liebscher, M.; Curosu, I.; de Andrade Silva, F.; Mechtcherine, V. Influence of elevated temperatures on the residual and quasi in-situ flexural strength of strain-hardening geopolymer composites (SHGC) reinforced with PVA and PE fibers. Constr. Build. Mater. 2022, 314, 125649. [Google Scholar] [CrossRef]

- Wang, Y.; Chan, C.L.; Leong, S.H.; Zhang, M. Engineering properties of strain hardening geopolymer composites with hybrid polyvinyl alcohol and recycled steel fibres. Constr. Build. Mater. 2020, 261, 120585. [Google Scholar] [CrossRef]

- Choi, J.-I.; Lee, B.Y.; Ranade, R.; Li, V.C.; Lee, Y. Ultra-high-ductile behavior of a polyethylene fiber-reinforced alkali-activated slag-based composite. Cem. Concr. Compos. 2016, 70, 153–158. [Google Scholar] [CrossRef]

- Meng, F.; Luo, S.; Sun, J.; Zhang, C.; Xu, L.; Du, Y.; Zeng, J.; Guo, Y. Compressive and Tensile Behavior of High-Ductility Alkali-Activated Composites with Polyethylene Terephthalate Powder. Buildings 2024, 14, 1399. [Google Scholar] [CrossRef]

- Lao, J.-C.; Huang, B.-T.; Fang, Y.; Xu, L.-Y.; Dai, J.-G.; Shah, S.P. Strain-hardening alkali-activated fly ash/slag composites with ultra-high compressive strength and ultra-high tensile ductility. Cem. Concr. Res. 2023, 165, 107075. [Google Scholar] [CrossRef]

- Chen, G.; Liu, L.-Y.; Li, J.-F.; Lin, J.-X.; Guo, Y.-C. In-situ tensile behavior of hybrid PE/PP fibers reinforced strain-hardening alkali-activated composites (H-SHAAC) subjected to different temperatures. J. Build. Eng. 2024, 98, 111332. [Google Scholar] [CrossRef]

- ASTM C469/C469M-22; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2022. Available online: https://store.astm.org/standards/c469 (accessed on 20 June 2023).

- Yokota, H.; Rokugo, K.; Sakata, N. JSCE Recommendations for design and construction of high performance fiber reinforced cement composite with multiple fine cracks. In Concrete Engineering Series 82; Springer: Tokyo, Japan, 2007; Available online: https://www.jsce.or.jp/committee/concrete/e/hpfrcc_JSCE.pdf (accessed on 15 October 2023).

- JCI-S-001-2003; Method of Test for Fracture Energy of Concrete by Use of Notched Beam. Japan Concrete Institute: Tokyo, Japan, 2003. Available online: https://www.jci-net.or.jp/j/publish/standard/jci_standard/JCI-S-001-2003-e.pdf (accessed on 7 December 2023).

- Ayatollahi, M.R.; Bahrami, B.; Mirzaei, A.M.; Yazid Yahya, M. Effects of support friction on mode I stress intensity factor and fracture toughness in SENB testing. Theor. Appl. Fract. Mech. 2019, 103, 102288. [Google Scholar] [CrossRef]

- Liu, W.; Xu, S.; Li, Q. Experimental study on fracture performance of ultra-high toughness cementitious composites with J-integral. Eng. Fract. Mech. 2012, 96, 656–666. [Google Scholar] [CrossRef]

- Gao, S.; Qi, L.; Zhu, Y.; Wang, W. Effect of notch depth ratio on mode I and mixed mode I-II fracture properties of engineered cementitious composites (ECC). Int. J. Solids Struct. 2022, 236–237, 111363. [Google Scholar] [CrossRef]

- Marshall, D.B.; Cox, B.N. A J-integral method for calculating steady-state matrix cracking stresses in composites. Mech. Mater. 1988, 7, 127–133. [Google Scholar] [CrossRef]

- Su, J.-Y.; Luo, R.-H.; Chen, Z.-B.; Lin, J.-X.; Huang, P.-Y.; Guo, Y.-C. Experimental study on the fracture performance of rubberized high strength-high ductility concrete with J-integral method. Constr. Build. Mater. 2024, 421, 135668. [Google Scholar] [CrossRef]

- Ding, Y.; Shi, C.-J.; Li, N. Fracture properties of slag/fly ash-based geopolymer concrete cured in ambient temperature. Constr. Build. Mater. 2018, 190, 787–795. [Google Scholar] [CrossRef]

- Li, V.; Hashida, T. Engineering ductile fracture in brittle-matrix composites. J. Mater. Sci. Lett. 1993, 12, 898–901. [Google Scholar] [CrossRef]

- Bashar, I.I.; Alengaram, U.J.; Jumaat, M.Z.; Islam, A.; Santhi, H.; Sharmin, A. Engineering properties and fracture behaviour of high volume palm oil fuel ash based fibre reinforced geopolymer concrete. Constr. Build. Mater. 2016, 111, 286–297. [Google Scholar] [CrossRef]

- Li, V.C.; Mishra, D.K.; Wu, H.-C. Matrix design for pseudo-strain-hardening fibre reinforced cementitious composites. Mater. Struct. 1995, 28, 586–595. [Google Scholar] [CrossRef]

- Pan, H.; Yang, Z.; Xue, M.; Su, J.; Yan, X.; Chen, Z.; Lin, J.; Guo, Y. Fracture properties and sustainability assessment of strain-hardening alkali activated composites of up to 100% rubber aggregate. Structures 2025, 81, 110221. Available online: https://www.sciencedirect.com/science/article/abs/pii/S2352012425020363?dgcid=author (accessed on 26 July 2025).

- Curosu, I.; Liebscher, M.; Mechtcherine, V.; Bellmann, C.; Michel, S. Tensile behavior of high-strength strain-hardening cement-based composites (HS-SHCC) made with high-performance polyethylene, aramid and PBO fibers. Cem. Concr. Res. 2017, 98, 71–81. [Google Scholar] [CrossRef]

| CaO | SiO2 | Al2O3 | SO3 | Fe2O3 | MgO | TiO2 | Other | LOI (%) | |

|---|---|---|---|---|---|---|---|---|---|

| GGBS | 34.0 | 34.5 | 17.7 | 1.64 | 1.03 | 6.01 | / | 5.12 | 0.840 |

| FA | 4.01 | 54.8 | 31.2 | 2.20 | 4.16 | 1.01 | 1.13 | 2.37 | 4.60 |

| Fiber Type | Length (mm) | Diameter (um) | Strength (MPa) | Density (g/cm3) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|

| PP | 12.0 | 100.0 | 400 | 0.910 | 13.5 |

| PE | 12.0 | 20.0 | 3000 | 0.970 | 120 |

| Group | FA 1 | GGBS 2 | QS 3 | AAS 4 | Water | BaCl2 | Volume Dosage (Vol. %) | |

|---|---|---|---|---|---|---|---|---|

| PE | PP | |||||||

| R0 | 0.70 | 0.30 | 0.20 | 0.40 | 0.06 | 0.01 | 2.0 | 0 |

| R25 | 0.70 | 0.30 | 0.20 | 0.40 | 0.06 | 0.01 | 1.5 | 0.5 |

| R50 | 0.70 | 0.30 | 0.20 | 0.40 | 0.06 | 0.01 | 1.0 | 1.0 |

| Group | Specimen IDs | Temperature (°C) | Number | Compressive Test | Tensile Test | Fracture Test |

|---|---|---|---|---|---|---|

| R0 | R0-0 °C * | 0 | 3 | × | × | √ |

| R0-30 °C | 30 | 3 | √ | √ | √ | |

| R0-70 °C | 70 | 3 | × | × | √ | |

| R0-100 °C | 100 | 3 | × | × | √ | |

| R0-150 °C | 150 | 3 | × | × | √ | |

| R25 | R25-0 °C | 0 | 3 | × | × | √ |

| R25-30 °C | 30 | 3 | √ | √ | √ | |

| R25-70 °C | 70 | 3 | × | × | √ | |

| R25-100 °C | 100 | 3 | × | × | √ | |

| R25-150 °C | 150 | 3 | × | × | √ | |

| R50 | R50-0 °C | 0 | 3 | × | × | √ |

| R50-30 °C | 30 | 3 | √ | √ | √ | |

| R50-70 °C | 70 | 3 | × | × | √ | |

| R50-100 °C | 100 | 3 | × | × | √ | |

| R50-150 °C | 150 | 3 | × | × | √ |

| Specimen IDs | Compressive Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|

| R0-30 °C | 100.5 ± 3.9 | 18.7 ± 0.6 |

| R25-30 °C | 102.8 ± 3.6 | 19.4 ± 0.0 |

| R50-30 °C | 82.4 ± 5.6 | 18.1 ± 0.5 |

| Specimen IDs | Initial Cracking Strength (MPa) | Tensile Strength (Mpa) | Ultimate Tensile Strain (%) |

|---|---|---|---|

| R0-30 °C | 4.4 (0.3) | 7.7 (0.2) | 5.5 (0.5) |

| R25-30 °C | 3.5 (0.2) | 7.3 (0.2) | 7.4 (0.3) |

| R50-30 °C | 2.7 (0.8) | 7.7 (0.2) | 5.3 (0.5) |

| Mix IDs | m (kg) | CMOD0 (mm) | W0 (kN·mm) | W1 (kN·mm) | GF (kJ/m2) |

|---|---|---|---|---|---|

| R0-0 °C | 0.485 ± 0.010 | 8.46 ± 1.34 | 12.62 ± 3.25 | 0.023 ± 0.004 | 9.88 ± 2.54 a, a |

| R0-30 °C | 0.504 ± 0.001 | 11.46 ± 1.21 | 16.06 ± 2.00 | 0.032 ± 0.004 | 12.58 ± 1.56 a, a |

| R0-70 °C | 0.491 ± 0.004 | 18.63 ± 2.61 | 21.01 ± 3.43 | 0.051 ± 0.007 | 16.47 ± 2.69 a, b |

| R0-100 °C | 0.498 ± 0.006 | 19.49 ± 2.97 | 20.61 ± 4.47 | 0.054 ± 0.008 | 16.15 ± 3.50 a, c |

| R0-150 °C | 0.501 ± 0.012 | 8.21 ± 0.73 | 6.15 ± 0.96 | 0.023 ± 0.002 | 4.83 ± 0.76 a, d |

| R25-0 °C | 0.489 ± 0.012 | 7.78 ± 0.96 | 11.16 ± 0.39 | 0.021 ± 0.003 | 8.74 ± 0.31 b, a |

| R25-30 °C | 0.487 ± 0.005 | 11.61 ± 0.27 | 13.73 ± 0.41 | 0.031 ± 0.001 | 10.76 ± 0.32 b, a |

| R25-70 °C | 0.492 ± 0.004 | 18.23 ± 1.11 | 17.62 ± 1.95 | 0.050 ± 0.003 | 13.82 ± 1.52 b, b |

| R25-100 °C | 0.491 ± 0.012 | 17.34 ± 1.63 | 13.95 ± 1.97 | 0.047 ± 0.004 | 10.94 ± 1.54 b, c |

| R25-150 °C | 0.492 ± 0.006 | 6.91 ± 0.85 | 3.97 ± 0.58 | 0.019 ± 0.002 | 3.12 ± 0.45 b, d |

| R50-0 °C | 0.472 ± 0.006 | 6.22 ± 1.36 | 7.02 ± 1.36 | 0.016 ± 0.004 | 5.50 ± 1.07 c, a |

| R50-30 °C | 0.471 ± 0.002 | 10.65 ± 0.73 | 10.57 ± 0.22 | 0.028 ± 0.002 | 8.29 ± 0.17 c, a |

| R50-70 °C | 0.481 ± 0.010 | 14.75 ± 0.96 | 12.2 ± 0.59 | 0.039 ± 0.003 | 9.59 ± 0.46 c, b |

| R50-100 °C | 0.498 ± 0.006 | 14.68 ± 2.03 | 9.69 ± 2.95 | 0.040 ± 0.006 | 7.61 ± 2.31 c, c |

| R50-150 °C | 0.490 ± 0.010 | 5.78 ± 0.40 | 2.55 ± 0.15 | 0.016 ± 0.001 | 2.01 ± 0.12 c, d |

| Mix IDs | JIC (kJ/m2) | JIF (kJ/m2) | Jc (kJ/m2) | Jb (kJ/m2) | Jm (kJ/m2) | Jm/Jc |

|---|---|---|---|---|---|---|

| R0-0 °C | 0.33 ± 0.25 a, a | 4.68 ± 1.44 a, a | 19.21 ± 4.81 a, c | 10.37 ± 3.12 a, b | 8.85 ± 2.04 a, b | 0.47 ± 0.06 |

| R0-30 °C | 0.36 ± 0.16 a, a | 7.87 ± 1.54 a, a | 24.26 ± 3.09 a, bc | 11.75 ± 1.65 a, ab | 12.51 ± 1.74 a, ab | 0.52 ± 0.03 |

| R0-70 °C | 0.22 ± 0.10 a, a | 10.16 ± 1.09 a, b | 31.99 ± 5.13 a, a | 15.27 ± 2.93 a, a | 16.72 ± 2.27 a, a | 0.53 ± 0.02 |

| R0-100 °C | 0.13 ± 0.04 a, a | 8.56 ± 3.68 a, a | 31.42 ± 7.07 a, ab | 15.91 ± 2.49 a, a | 15.51 ± 4.78 a, a | 0.48 ± 0.06 |

| R0-150 °C | 0.02 ± 0.01 a, b | 2.33 ± 0.39 a, c | 9.24 ± 1.44 a, d | 4.82 ± 1.05 a, c | 4.42 ± 0.51 a, c | 0.48 ± 0.05 |

| R25-0 °C | 0.13 ± 0.04 ab, a | 5.65 ± 1.26 a, a | 17.09 ± 0.55 b, c | 8.18 ± 0.66 b, b | 8.90 ± 0.76 b, b | 0.52 ± 0.04 |

| R25-30 °C | 0.26 ± 0.13 ab, a | 6.54 ± 1.86 a, a | 20.90 ± 0.69 b, bc | 10.09 ± 0.92 b, ab | 10.81 ± 1.60 b, ab | 0.52 ± 0.06 |

| R25-70 °C | 0.27 ± 0.16 ab, a | 8.89 ± 1.70 a, b | 27.59 ± 2.83 b, a | 12.68 ± 1.23 b, a | 14.92 ± 1.62 b, a | 0.54 ± 0.01 |

| R25-100 °C | 0.15 ± 0.04 ab, a | 5.91 ± 0.56 a, a | 21.21 ± 2.85 b, ab | 10.69 ± 1.74 b, a | 10.52 ± 1.20 b, a | 0.50 ± 0.02 |

| R25-150 °C | 0.08 ± 0.05 ab, b | 1.24 ± 0.25 a, c | 3.00 ± 0.85 b, d | 3.32 ± 0.47 b, c | 2.68 ± 0.42 b, c | 0.45 ± 0.02 |

| R50-0 °C | 0.17 ± 0.01 b, a | 3.04 ± 0.95 b, a | 10.91 ± 1.92 c, c | 5.40 ± 1.01 c, b | 5.50 ± 0.98 c, b | 0.51 ± 0.03 |

| R50-30 °C | 0.13 ± 0.02 b, a | 4.81 ± 0.88 b, a | 16.01 ± 0.35 c, bc | 7.97 ± 0.83 c, ab | 8.04 ± 0.60 c, ab | 0.50 ± 0.04 |

| R50-70 °C | 0.05 ± 0.03 b, a | 4.31 ± 0.94 b, b | 18.54 ± 0.94 c, a | 9.97 ± 0.07 c, a | 8.57 ± 0.99 c, a | 0.46 ± 0.03 |

| R50-100 °C | 0.06 ± 0.03 b, a | 3.60 ± 0.89 b, a | 14.77 ± 4.50 c, ab | 7.77 ± 2.59 c, a | 7.00 ± 1.95 c, a | 0.48 ± 0.02 |

| R50-150 °C | 0.02 ± 0.00 b, b | 0.91 ± 0.03 b, c | 3.87 ± 0.23 c, d | 2.10 ± 0.17 c, c | 1.77 ± 0.05 c, c | 0.46 ± 0.01 |

| Source | A × B | A | B |

|---|---|---|---|

| GF (F, p, η2) | 1.125, 0.375, 0.231 | 26.661, <0.001 ***, 0.640 | 33.037, <0.001 ***, 0.815 |

| JIC (F, p, η2) | 1.007, 0.451, 0.212 | 4.159, 0.025 *, 0.217 | 4.145, 0.009 **, 0.356 |

| JIF (F, p, η2) | 1.284, 0.289, 0.255 | 14.493, <0.001 ***, 0.491 | 16.787, <0.001 ***, 0.691 |

| Jc (F, p, η2) | 1.214, 0.325, 0.245 | 26.510, <0.001 ***, 0.639 | 33.756, <0.001 ***, 0.818 |

| Jb (F, p, η2) | 0.810, 0.599, 0.178 | 21.716, <0.001 ***, 0.591 | 27.503, <0.001 ***, 0.786 |

| Jm (F, p, η2) | 1.495, 0.201, 0.285 | 23.016, <0.001 ***, 0.605 | 29.206, <0.001 ***, 0.796 |

| Comparison | GF | JIC | JIF | Jc | Jb | Jm |

|---|---|---|---|---|---|---|

| R0–R25 | 0.005 | 0.723 | 0.233 | 0.008 | 0.004 | 0.044 |

| R0–R50 | <0.001 | 0.024 | <0.001 | <0.001 | <0.001 | <0.001 |

| R25–R50 | 0.001 | 0.125 | 0.003 | 0.001 | 0.011 | <0.001 |

| Comparison | GF | JIC | JIF | Jc | Jb | Jm |

|---|---|---|---|---|---|---|

| 0–30 °C | 0.089 | 0.943 | 0.156 | 0.113 | 0.291 | 0.098 |

| 0–70 °C | <0.001 | 0.990 | 0.003 | 0.000 | 0.000 | 0.000 |

| 0–100 °C | 0.007 | 0.474 | 0.344 | 0.008 | 0.010 | 0.030 |

| 0–150 °C | <0.001 | 0.050 | 0.010 | 0.000 | 0.001 | 0.001 |

| 30–70 °C | 0.052 | 0.743 | 0.475 | 0.035 | 0.066 | 0.059 |

| 30–100 °C | 0.819 | 0.141 | 0.990 | 0.792 | 0.533 | 0.983 |

| 30–150 °C | <0.001 | 0.008 | 0.000 | 0.000 | 0.000 | 0.000 |

| 70–100 °C | 0.389 | 0.757 | 0.238 | 0.322 | 0.745 | 0.176 |

| 70–150 °C | <0.001 | 0.133 | 0.000 | 0.000 | 0.000 | 0.000 |

| 100–150 °C | <0.001 | 0.725 | 0.000 | 0.000 | 0.000 | 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, T.; Huang, B.-Y.; Zhan, Z.-F.; Huang, Y.-W.; Wang, L.; Li, M.; Xie, Z.-H.; Li, J.-F.; Su, J.-Y. Fracture Properties of High-Performance High-Ductility Alkali-Activated Concrete Under Thermo-Mechanical Coupling: Effect of Fiber Hybrid Ratio. Polymers 2025, 17, 2568. https://doi.org/10.3390/polym17192568

Huang T, Huang B-Y, Zhan Z-F, Huang Y-W, Wang L, Li M, Xie Z-H, Li J-F, Su J-Y. Fracture Properties of High-Performance High-Ductility Alkali-Activated Concrete Under Thermo-Mechanical Coupling: Effect of Fiber Hybrid Ratio. Polymers. 2025; 17(19):2568. https://doi.org/10.3390/polym17192568

Chicago/Turabian StyleHuang, Tao, Bo-Yuan Huang, Zhi-Feng Zhan, Yu-Wen Huang, Lei Wang, Meng Li, Zhi-Hong Xie, Jian-Fa Li, and Jia-Ying Su. 2025. "Fracture Properties of High-Performance High-Ductility Alkali-Activated Concrete Under Thermo-Mechanical Coupling: Effect of Fiber Hybrid Ratio" Polymers 17, no. 19: 2568. https://doi.org/10.3390/polym17192568

APA StyleHuang, T., Huang, B.-Y., Zhan, Z.-F., Huang, Y.-W., Wang, L., Li, M., Xie, Z.-H., Li, J.-F., & Su, J.-Y. (2025). Fracture Properties of High-Performance High-Ductility Alkali-Activated Concrete Under Thermo-Mechanical Coupling: Effect of Fiber Hybrid Ratio. Polymers, 17(19), 2568. https://doi.org/10.3390/polym17192568