Prestress Transfer in NSM CFRP-Strengthened RC Structures Under Curing and Service Temperature Effects: Experimental Validation and Analytical Modeling

Abstract

1. Introduction

2. Experimental Program

2.1. Test Series and Materials Properties

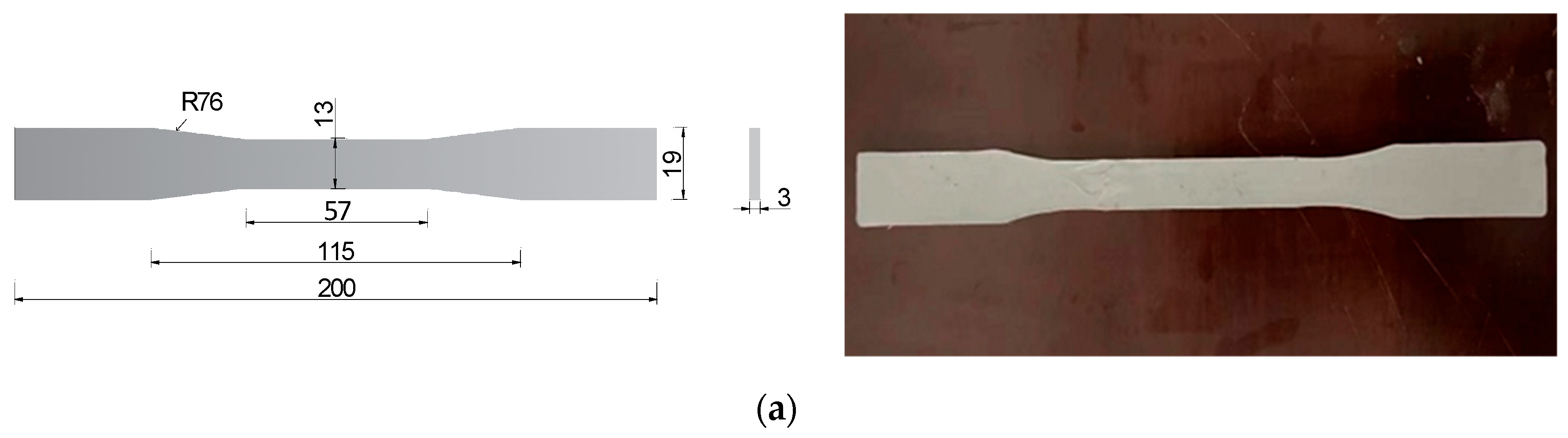

2.2. Specimen Design and Preparation

2.3. Test Setup, Instrumentation and Procedures

3. Results

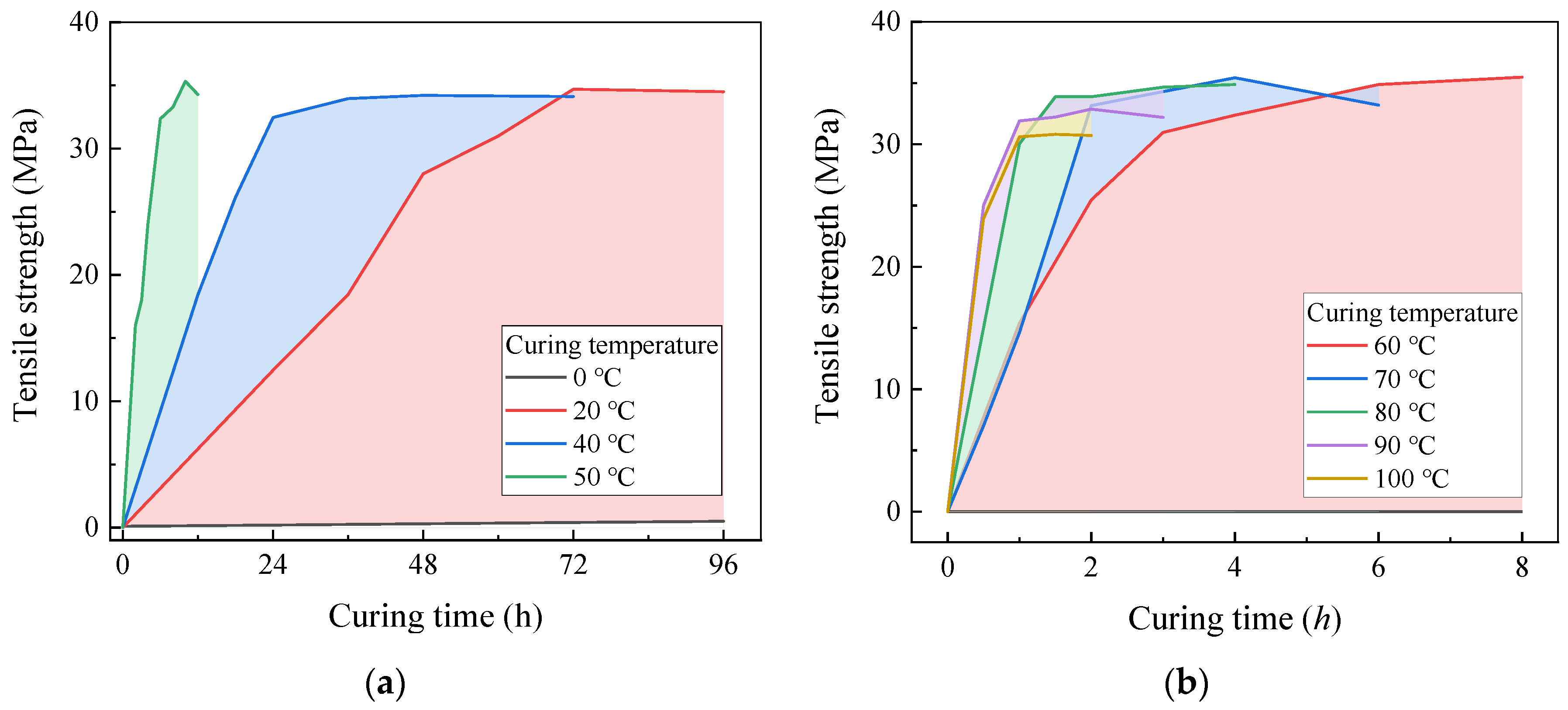

3.1. Effect of Curing Temperature on Tensile Strength and Elasticity

3.2. Effect of Test Temperature on Tensile Properties

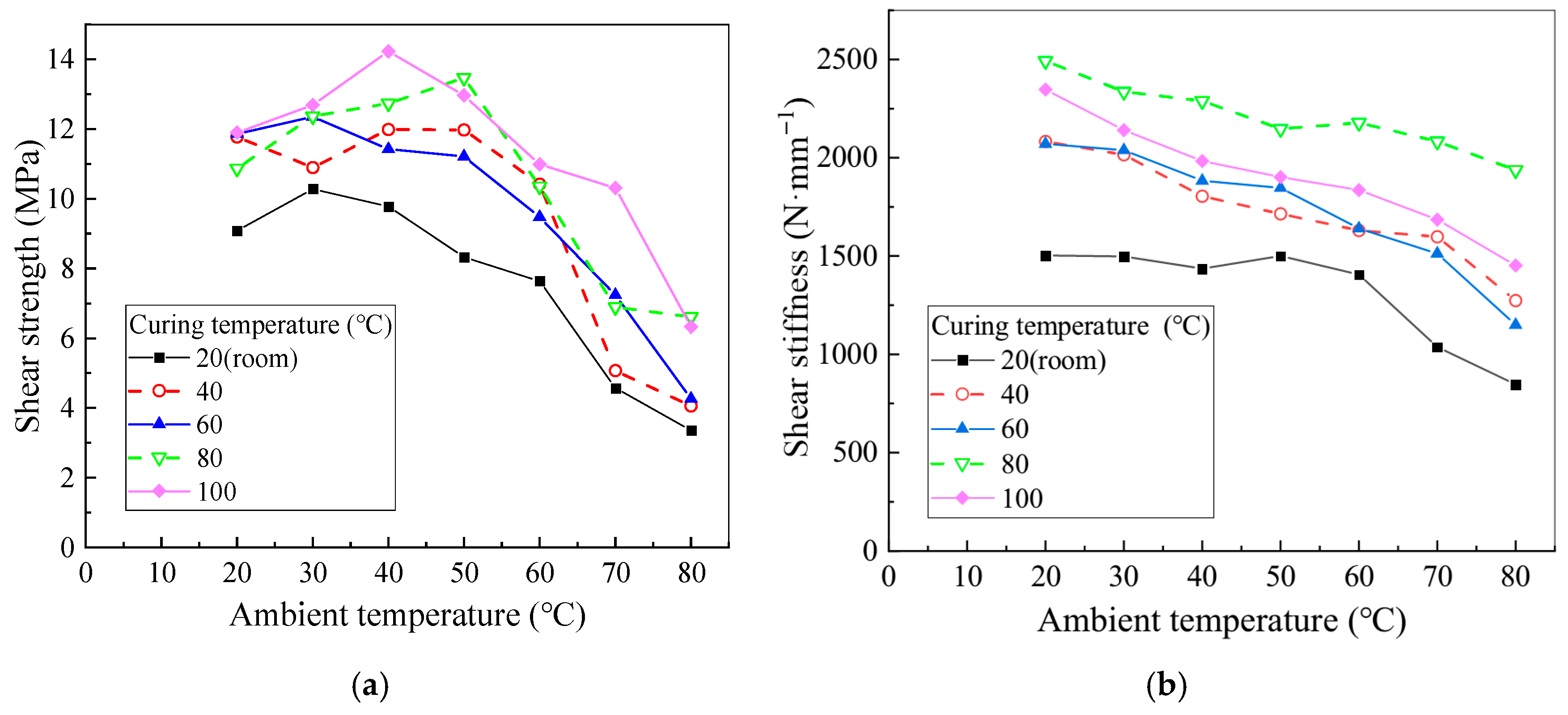

3.3. Effect of Test Ambient Temperature on Shear Properties

4. Prestress Transmission Behavior

4.1. Analytical Approach

- (1)

- All materials behave in a linear elastic and isotropic manner, the strength of CFRP is only considered along the fiber direction;

- (2)

- Perfect bonding exists between the steel bars, CFRP, and surrounding concrete, with no relative slip;

- (3)

- The strain distribution in the concrete, longitudinal steel bars, and CFRP conforms to the plane section assumption.

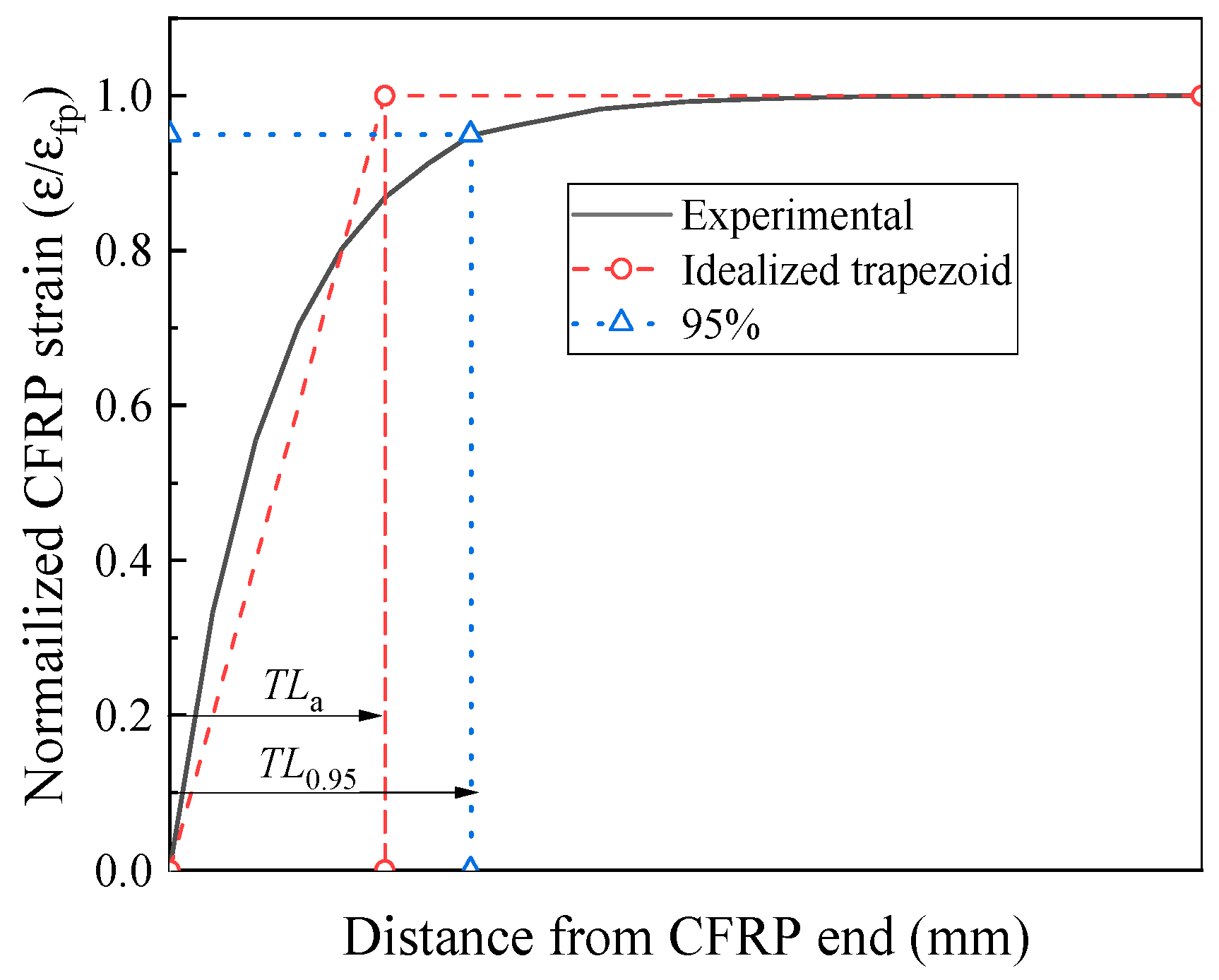

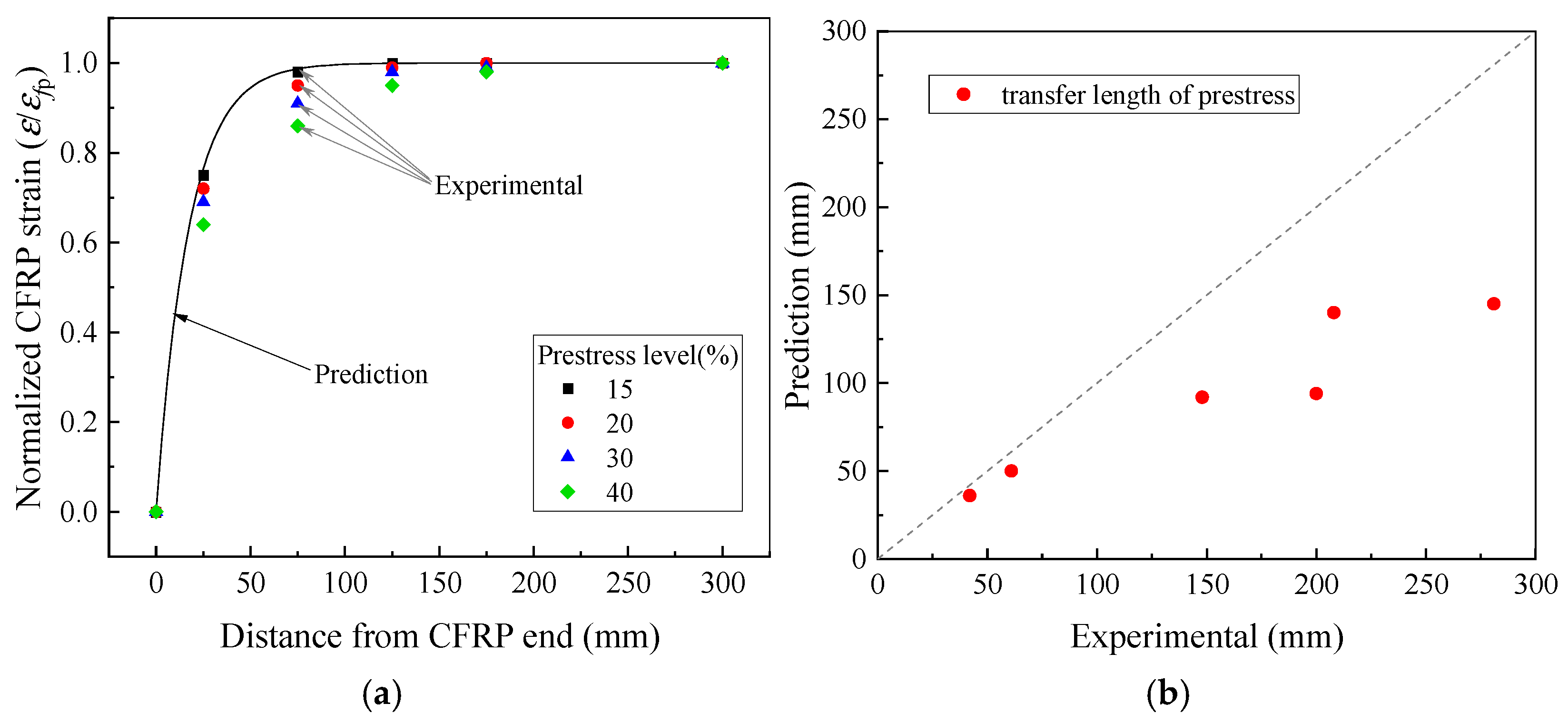

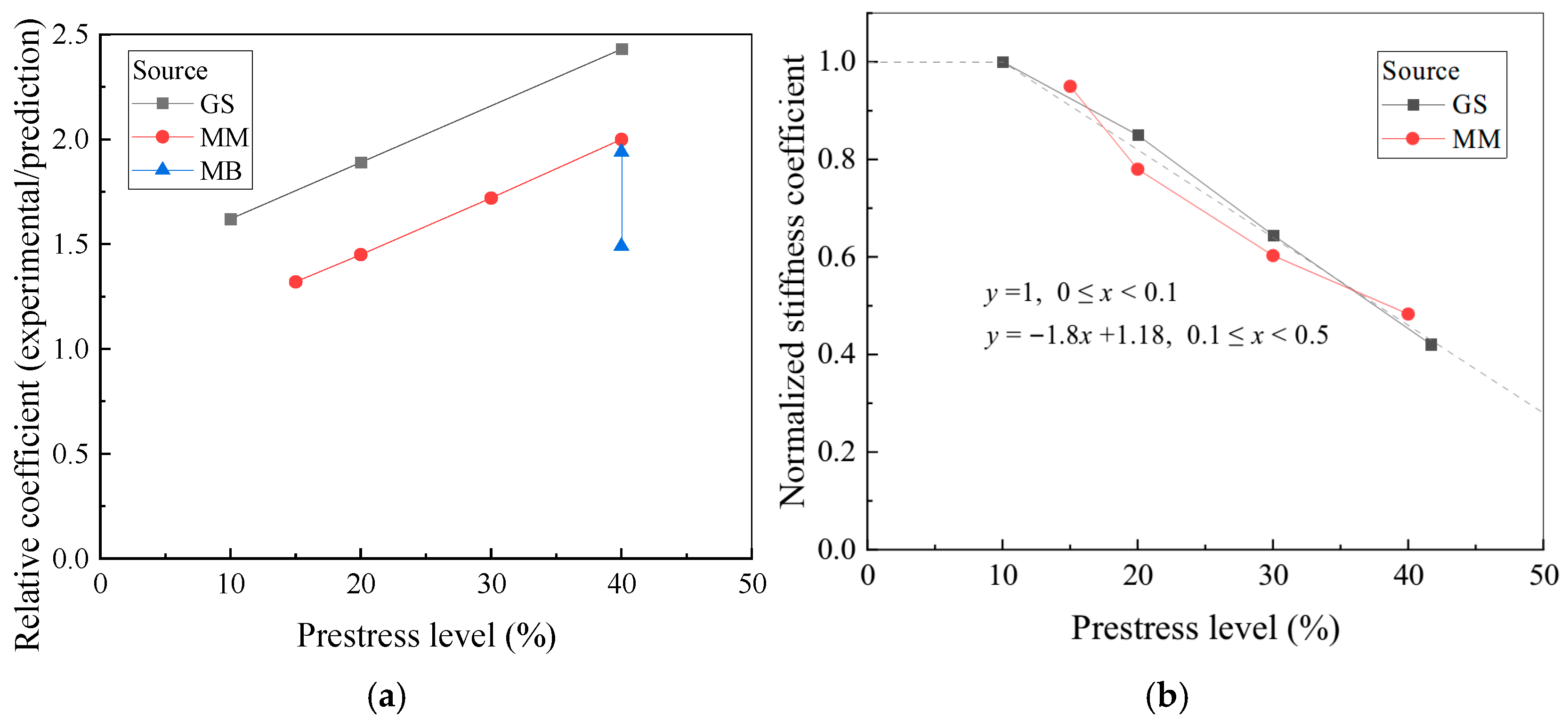

4.2. Prestress Transmission Length

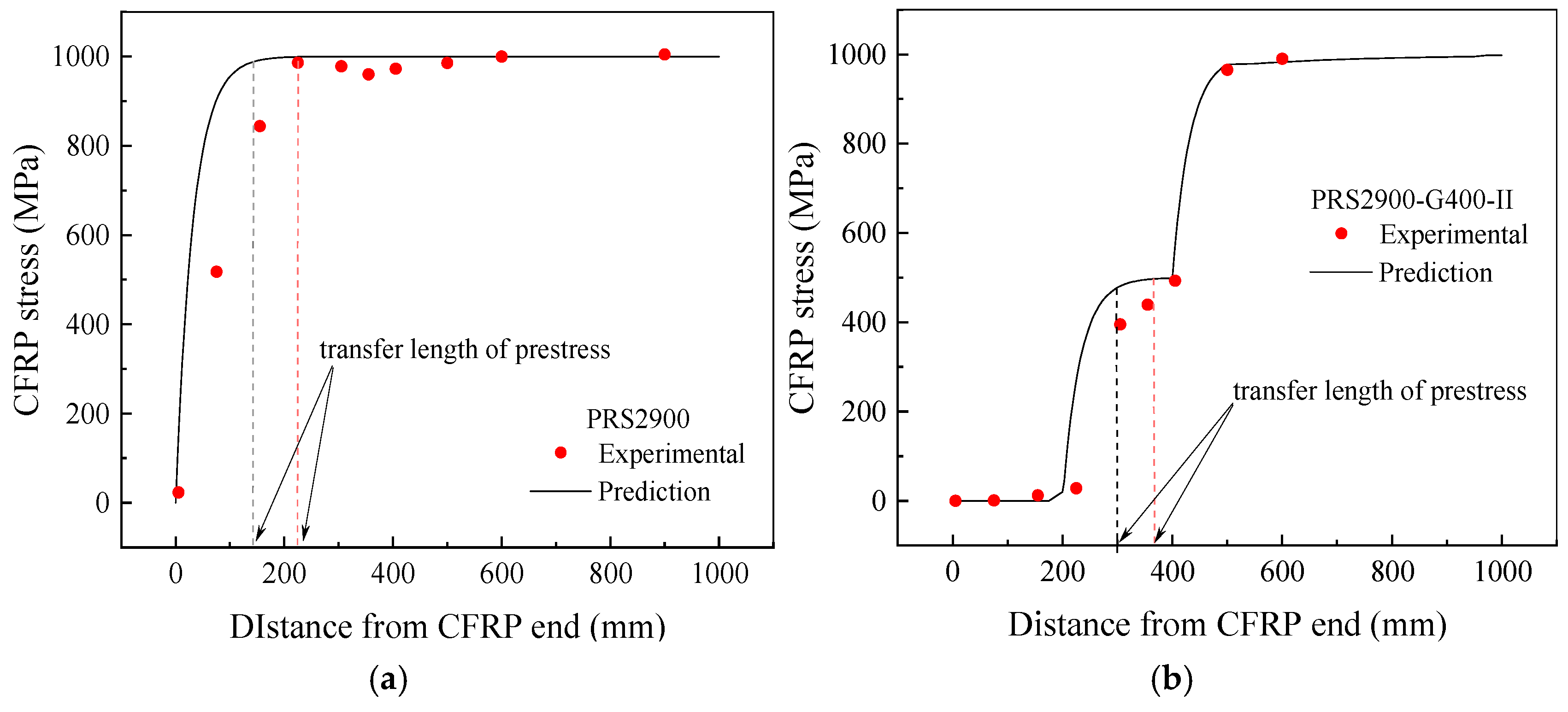

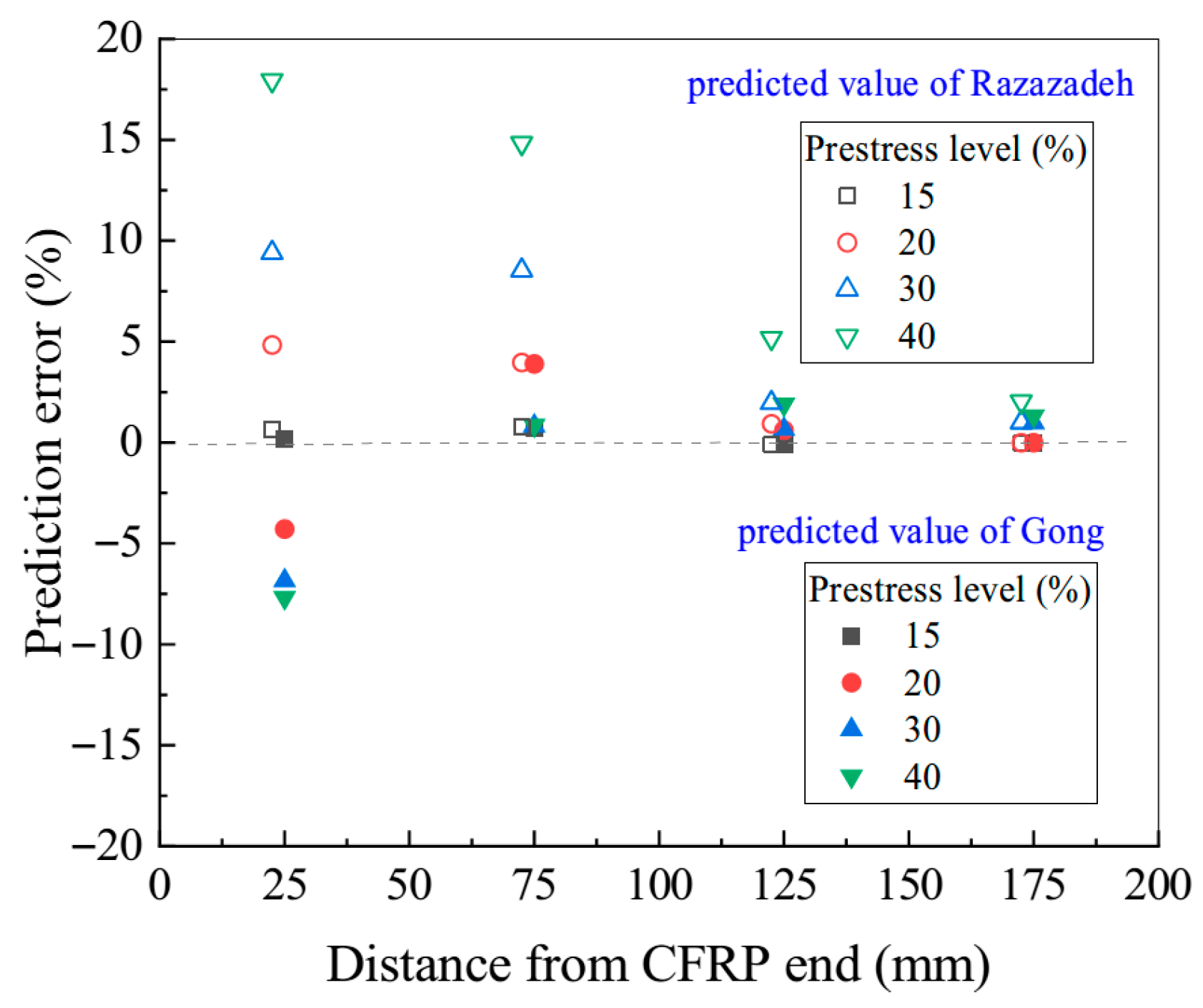

4.3. Prediction Results

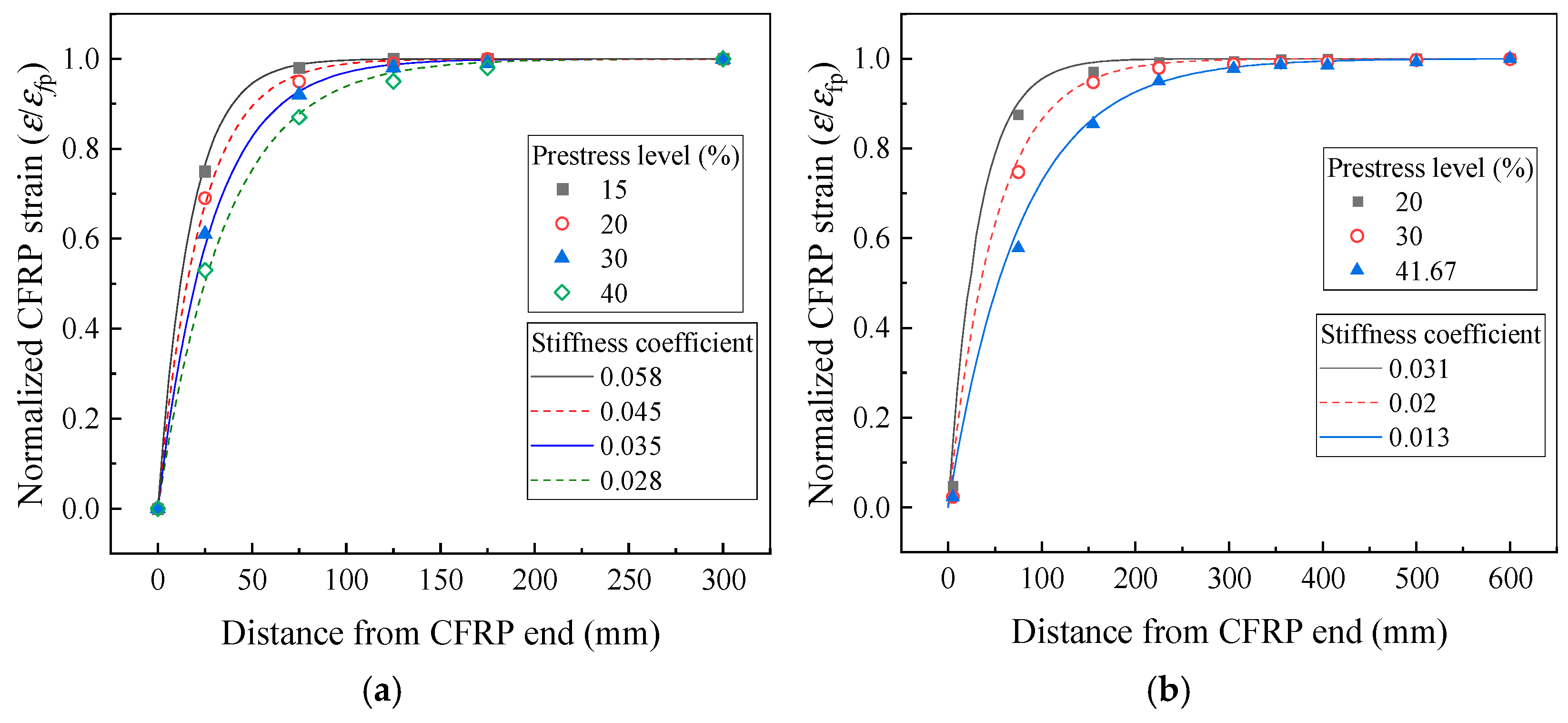

4.4. Parametric Analysis

- (1)

- Material properties

- (2)

- CFRP cross-section and groove dimensions

- (3)

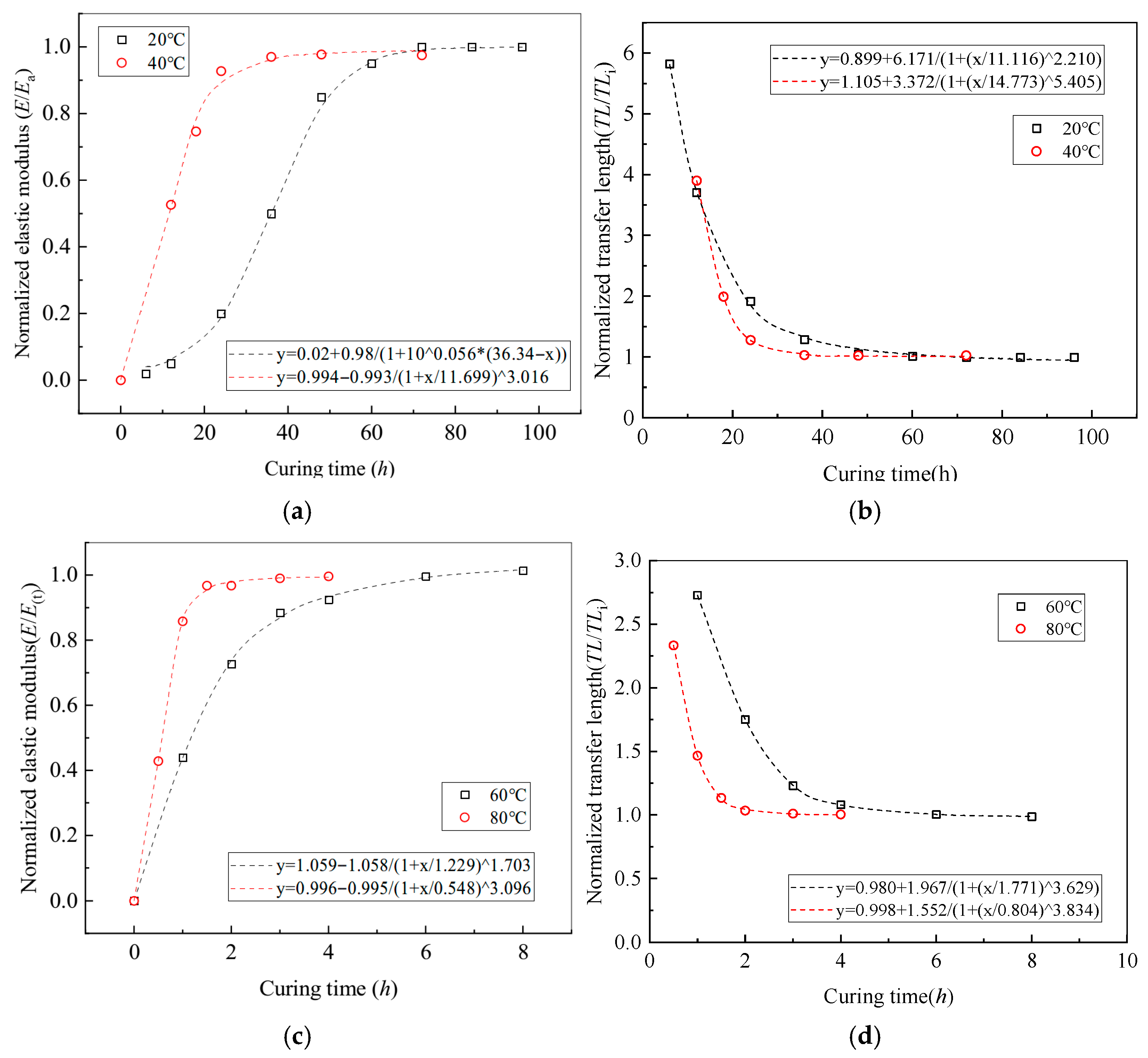

- Degree of adhesive curing

5. Conclusions

- (1)

- The curing time required for epoxy resin to achieve full strength exhibits an inverse exponential relationship with curing temperature. While epoxy performance remains relatively stable across a range of curing temperatures, only a minor reduction (less than 10%) is observed when the temperature exceeds 80 °C. In contrast, service temperature exerts a significant influence: both tensile and shear strengths of the epoxy decrease markedly as ambient temperature increases, with negligible tensile capacity observed above 80 °C.

- (2)

- Introducing the concept of effective bond stiffness enables accurate characterization of adhesive–concrete bonding performance and facilitates precise simulation of shear stress distribution at the CFRP–concrete interface under prestress. The proposed prestress reduction coefficient further extends the model’s applicability, enabling analysis of structures with varying prestress levels and gradually anchored prestressed strengthening systems.

- (3)

- Parametric analyses demonstrate that the elastic modulus of CFRP exerts the greatest influence on shear stress distribution, with prestress transfer length increasing proportionally with the modulus. For a constant strengthening ratio, CFRP sections with larger bonding areas provide superior interfacial performance, whereas increasing adhesive layer thickness reduces effective bond stiffness and diminishes the overall performance of the bonding interface.

- (4)

- The prestress transfer behavior under varying curing temperatures and durations is governed by changes in the adhesive’s elastic modulus. As curing temperature increases and curing time extends, the effective bond stiffness of the adhesive increases accordingly, while the degree of prestress transfer decreases, both following an exponential trend.

- (5)

- Based on the validated model and experimental data, the following concise design recommendations are proposed: limit service temperature to ≤60 °C (short-term exposure up to 80 °C is permissible only if prestress is reduced or a higher-Tg adhesive is employed); provide an adhesive layer thickness of at least 2 mm; ensure full cure (≥96 h at 20 °C or 22 h at 40 °C); limit prestress to 50% of the CFRP ultimate strength; and provide mechanical anchorage if higher prestress levels are required. Wide, thin rectangular NSM strips are recommended when the cross-sectional area is fixed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Frhaan, W.K.M.; Bakar, B.H.A.; Hilal, N.; Al-Hadithi, A.I. CFRP for strengthening and repairing reinforced concrete: A review. Innov. Infrastruct. Solut. 2021, 6, 49. [Google Scholar] [CrossRef]

- Naser, M.Z.; Hawileh, R.A.; Abdalla, J.A. Fiber-reinforced polymer composites in strengthening reinforced concrete structures: A critical review. Eng. Struct. 2019, 198, 109542. [Google Scholar] [CrossRef]

- Nuaimi, N.A.; Sohail, M.G.; Hawileh, R.; Abdalla, J.A.; Douier, K. Durability of Reinforced Concrete Beams Externally Strengthened with CFRP Laminates under Harsh Climatic Conditions. J. Compos. Constr. 2021, 25, 04021005. [Google Scholar] [CrossRef]

- Teng, J. New-material hybrid structures. China Civ. Eng. J. 2018, 51, 11. [Google Scholar]

- Zhang, S.S.; Yu, T.; Chen, G.M. Reinforced concrete beams strengthened in flexure with near-surface mounted (NSM) CFRP strips: Current status and research needs. Compos. Part B Eng. 2017, 131, 30–42. [Google Scholar] [CrossRef]

- Biscaia, H.C. The influence of temperature variations on adhesively bonded structures: A non-linear theoretical perspective. Int. J. Non-Linear Mech. 2019, 113, 67–85. [Google Scholar] [CrossRef]

- Kim, Y.J.; Yoshitake, I.; Yang, M. A predictive investigation associated with design recommendations for CFRP-confined concrete in aggressive service environments—ScienceDirect. Constr. Build. Mater. 2013, 43, 69–79. [Google Scholar] [CrossRef]

- Yoshitake, I.; Tsuda, H.; Itose, J.; Hisabe, N. Effect of discrepancy in thermal expansion coefficients of CFRP and steel under cold temperature. Constr. Build. Mater. 2014, 59, 17–24. [Google Scholar] [CrossRef]

- Al-Saadi, N.T.K.; Mohammed, A.; Al-Mahaidi, R.; Sanjayan, J. A state-of-the-art review: Near-surface mounted FRP composites for reinforced concrete structures. Constr. Build. Mater. 2019, 209, 748–769. [Google Scholar] [CrossRef]

- De Lorenzis, L.; Teng, J.G. Near-surface mounted FRP reinforcement: An emerging technique for strengthening structures. Compos. Part B Eng. 2007, 38, 119–143. [Google Scholar] [CrossRef]

- Parvin, A.; Syed Shah, T. Fiber Reinforced Polymer Strengthening of Structures by Near-Surface Mounting Method. Polymers 2016, 8, 298. [Google Scholar] [CrossRef] [PubMed]

- Gong, S.; Su, M.; Zhang, J.; Peng, H. Flexural behavior of reinforced concrete beams strengthened with gradually prestressed near surface mounted carbon fiber-reinforced polymer strips under static and fatigue loading. Adv. Struct. Eng. 2024, 27, 1234–1250. [Google Scholar] [CrossRef]

- Nordin, H.; Täljsten, B. Concrete beams strengthened with prestressed near surface mounted CFRP. J. Compos. Constr. 2006, 10, 60–68. [Google Scholar] [CrossRef]

- Peng, H.; Zhang, J.; Cai, C.; Liu, Y. An experimental study on reinforced concrete beams strengthened with prestressed near surface mounted CFRP strips. Eng. Struct. 2014, 79, 222–233. [Google Scholar] [CrossRef]

- Gong, S.; Su, M.; Yoshitake, I.; Zhu, C.; Peng, H. Factors affecting flexural properties of RC beams strengthened with gradually prestressed NSM CFRP strips. Eng. Struct. 2024, 306, 117865. [Google Scholar] [CrossRef]

- Kotynia, R.; Walendziak, R.; Stoecklin, I.; Meier, U. RC slabs strengthened with prestressed and gradually anchored CFRP strips under monotonic and cyclic loading. J. Compos. Constr. 2011, 15, 168–180. [Google Scholar] [CrossRef]

- Reza Aram, M.; Czaderski, C.; Motavalli, M. Effects of gradually anchored prestressed CFRP strips bonded on prestressed concrete beams. J. Compos. Constr. 2008, 12, 25–34. [Google Scholar] [CrossRef]

- Badawi, M.; Wahab, N.; Soudki, K. Evaluation of the transfer length of prestressed near surface mounted CFRP rods in concrete. Constr. Build. Mater. 2011, 25, 1474–1479. [Google Scholar] [CrossRef]

- Hong, S.; Park, S.-K. Effect of prestress and transverse grooves on reinforced concrete beams prestressed with near-surface-mounted carbon fiber-reinforced polymer plates. Compos. Part B Eng. 2016, 91, 640–650. [Google Scholar] [CrossRef]

- Rezazadeh, M. Innovative Methodologies for the Enhancement of the Flexural Strengthening Performance of NSM CFRP Technique for RC Beams. Ph.D. Thesis, Universidade do Minho, Braga, Portugal, 2015. [Google Scholar]

- Jafari, A.; Shahmansouri, A.A.; Bengar, H.A.; Naser, M.Z. Post-heating flexural behavior of steel fiber reinforced SCC beams strengthened with NSM-CFRP strips: Experimentation and analytical modeling. Constr. Build. Mater. 2024, 451, 138846. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: Conshohocken, PA, USA, 2017.

- GB 50728-2011; Code for Acceptance of Construction Quality of Concrete Structure Works. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2011.

- ASTM D638-10; Standard Test Method for Tensile Properties of Plastics. ASTM International: Conshohocken, PA, USA, 2010.

- GB/T 7124-2008; Adhesives—Determination of Tensile Shear Strength (Rigid-to-Rigid Materials). Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- Gong, S.; Lin, F.; Su, M.; Zhang, J.; Peng, H. Effect of curing and ambient temperature on properties of epoxy resin and bond behavior of near-surface-mounted CFRP-concrete interface. Acta Mater. Compos. Sin. 2022, 39, 5512–5524. [Google Scholar]

- Esposito, L.; Sorrentino, L.; Penta, F.; Bellini, C. Effect of curing overheating on interlaminar shear strength and its modelling in thick FRP laminates. Int. J. Adv. Manuf. Technol. 2016, 87, 2213–2220. [Google Scholar] [CrossRef]

- Firmo, J.P.; Roquette, M.G.; Correia, J.R.; Azevedo, A.S. Influence of elevated temperatures on epoxy adhesive used in CFRP strengthening systems for civil engineering applications. Int. J. Adhes. Adhes. 2019, 93, 102333. [Google Scholar] [CrossRef]

- Dai, J.; Ueda, T.; Sato, Y. Development of the nonlinear bond stress–slip model of fiber reinforced plastics sheet–concrete interfaces with a simple method. J. Compos. Constr. 2005, 9, 52–62. [Google Scholar] [CrossRef]

- Gong, S.; Deng, X.; Song, Z.; Yuan, B.; Dai, L.; Peng, H. Analytical Model for Concrete Cover Separation in Prestressed Near-Surface-Mounted Carbon Fiber-Reinforced Polymer-Strengthened Reinforced Concrete Beams. Buildings 2025, 15, 600. [Google Scholar] [CrossRef]

- Rezazadeh, M.; Barros, J.; Costa, I. Analytical approach for the flexural analysis of RC beams strengthened with prestressed CFRP. Compos. Part B Eng. 2015, 73, 16–34. [Google Scholar] [CrossRef]

- Rezazadeh, M.; Barros, J. A new hybrid methodology according to near surface mounted carbon fiber reinforced polymer technique for the flexural strengthening of reinforced concrete beams. J. Reinf. Plast. Compos. 2014, 33, 1993–2009. [Google Scholar] [CrossRef]

- Chou, J.; Liu, Y.; Guo, H.; Zhang, J.; Peng, H. Fatigue behavior of reinforced concrete beams strengthened with prestressed near-surface-mounted carbon-fiber-reinforced polymer strips. Compos. Struct. 2023, 308, 116689. [Google Scholar] [CrossRef]

- Lv, Y.; Wu, P.; Chou, J.; Han, W.; Su, M.; Peng, H. An experimental study on the interfacial bonding performance of horizontally embedded CFRP strips to concrete. Constr. Build. Mater. 2023, 369, 130514. [Google Scholar] [CrossRef]

| Materials | Tensile Strength/MPa | Compressive Strength/MPa | Elongation/% | Elastic Modulus/GPa |

|---|---|---|---|---|

| CFRP strip | 2561.1 | - | 1.96 | 142.2 |

| Epoxy resin | 31.9 | - | 1.47 | 11.2 |

| C40 concrete | 41.9 | - | 33.5 | |

| HRB400 steel bar | 540 | 442 | 16 | 201.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, S.; He, P.; Wang, R.; Li, J.; Liu, J.; Su, M. Prestress Transfer in NSM CFRP-Strengthened RC Structures Under Curing and Service Temperature Effects: Experimental Validation and Analytical Modeling. Polymers 2025, 17, 2492. https://doi.org/10.3390/polym17182492

Gong S, He P, Wang R, Li J, Liu J, Su M. Prestress Transfer in NSM CFRP-Strengthened RC Structures Under Curing and Service Temperature Effects: Experimental Validation and Analytical Modeling. Polymers. 2025; 17(18):2492. https://doi.org/10.3390/polym17182492

Chicago/Turabian StyleGong, Shuang, Peiqi He, Ruogu Wang, Junjin Li, Jun Liu, and Miao Su. 2025. "Prestress Transfer in NSM CFRP-Strengthened RC Structures Under Curing and Service Temperature Effects: Experimental Validation and Analytical Modeling" Polymers 17, no. 18: 2492. https://doi.org/10.3390/polym17182492

APA StyleGong, S., He, P., Wang, R., Li, J., Liu, J., & Su, M. (2025). Prestress Transfer in NSM CFRP-Strengthened RC Structures Under Curing and Service Temperature Effects: Experimental Validation and Analytical Modeling. Polymers, 17(18), 2492. https://doi.org/10.3390/polym17182492