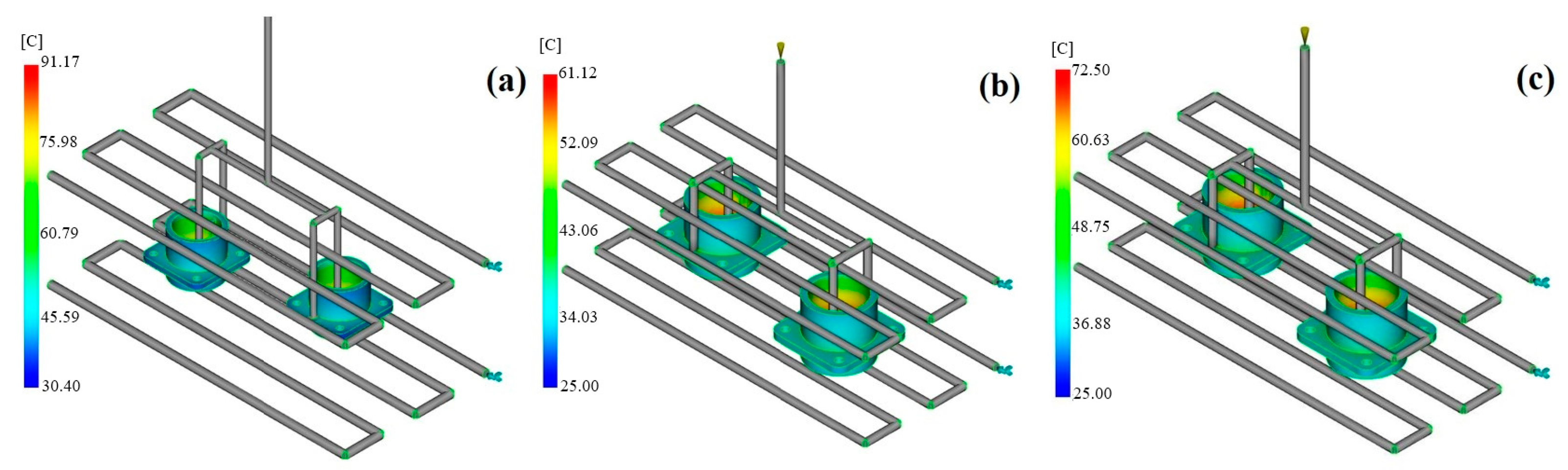

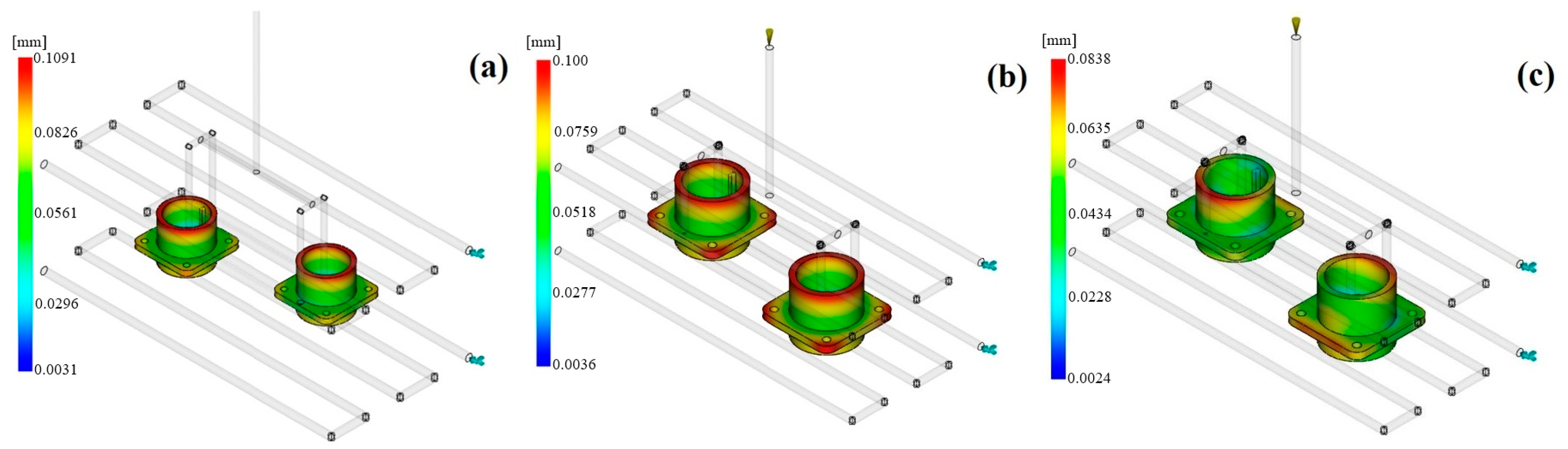

Multi-pin electrical connectors are trusted to deliver highly reliable performance; hence, they are used in defense, aerospace, industrial automation, heavy-duty vehicles, and electronic systems, which require such performance. The manufacturing of parts subject to these conditions necessitates that they not only resist high temperatures and harsh environmental conditions, such as impact, humidity, and vibration, but also have the ability to provide electrical insulation and maintain structural integrity for a long time. Therefore, engineering polymers with high dielectric strength, rather than conventional thermoplastics, should be taken into consideration. Due to their complicated geometries and tight tolerances, manufacturing and quality control should be performed with significant care and precision for connectors of this type. The process of creating such connectors via the injection molding method involves a number of obstacles due to the fact that the materials used are highly viscous, have a narrow thermal processing window, and are very sensitive to temperature changes. Furthermore, the very structure of the multi-pin leads to cooling imbalances, sink marks, residual stress, and warpage, which are typical quality problems. Therefore, a thorough simulation study is necessary at the beginning of the production process to adjust the mold design in a proper way and to increase the reliability of manufacturing. In the literature, injection molding simulation has been widely applied to polymer parts for the automotive, home appliance, and packaging sectors. However, although some studies have addressed the plastic injection process for electrical connectors, no study has directly examined injection molding and the use of dielectric polymers in multi-pin connectors. Thus, special multidimensional analyses of the moldability of high-strength engineering polymers such as PAI, PEI, and PEEK, which require high thermal resistance and superior electrical insulation capacities, are urgently needed.

The quality of injection-molded parts is primarily influenced by the material properties, the mold structure, and the parameters of the molding process. To achieve high appearance quality and accurate dimensional control, it is vital to adjust the process parameters that influence the injection molding quality. In the last decade, thermoplastic polymers have been increasingly gaining ground in the field of high-performance structural materials for various applications due to their low weight, good mechanical properties, and short cycle time in injection molding processes [

1,

2]. As the molds, machines, materials, and products are all chosen before processing, the molding process parameters must be carefully adjusted to not only improve efficiency but also avoid or reduce the quality defects, energy consumption, and costs associated with the process [

3]. Earlier investigators employed the Taguchi method and analysis of variance (ANOVA) to explore the impacts of warpage and shrinkage on product characteristics [

4]. Oktem et al. [

5], Tang et al. [

6], Kurt et al. [

7], and Shi et al. [

8] combined neural networks (NNs) and genetic algorithms (GAs), using multi-layer neural networks to estimate the maximum shear stress and GAs to find the best molding process parameters. Ozcelik et al. [

9] first chose key process parameters via ANOVA and then employed NNs and quadratic polynomials to approximate the warpage and determine the best combination of molding process parameters. Zhang et al. [

10] and Deng et al. [

11] utilized mode-pursuing sampling (MPS) algorithms to minimize warpage. In addition, the single-objective search for Simulated Annealing Optimization (SAO) has been confirmed to be a successful method for finding suitable parameters in the injection molding process [

12,

13,

14,

15,

16,

17]. Researchers such as Dimla et al. [

18], Wang et al. [

19], Kitayama et al. [

20,

21,

22,

23], and Guo et al. [

24,

25] have empowered related fields by fusing innovative developments to substantially improve the quality and output of goods. The application of such complex computational methods in the context of PIM involves an ensemble of artificial intelligence networks, operations research, and computational physics. Ouyang Yu et al. [

26] conducted a five-factor and four-level orthogonal experiment to establish the injection molding process of a funboard. With the maximum warpage deformation, volume shrinkage rate, and shrink mark length as the assessment parameters, the signal-to-noise ratio and normalization were used to process the test results. The multi-objective optimization was converted into a single-objective gray correlation degree (GRA) analysis. Another study (Tan and Alkan [

27]) optimized the production efficiency and quality parameters of piezoelectric pumps produced via the microinjection method. An additional investigation was carried out in which the injection molding process parameters were optimized using RSM and GWO methods; it was found that RSM was more efficient, with a 39.4% improvement in the tensile modulus obtained by using 60% fiber reinforcement [

28]. Beyond polymer injection molding, the applicability of RSM has also been validated in different material systems. Shetty et al. examined magnesium AZ31B alloy corrosion protection in a hydrochloric acid medium by employing gelatin as an inhibitor and optimizing the process through RSM. Their results demonstrated that RSM effectively captured the interaction between temperature and the inhibitor concentration, achieving a maximum inhibition efficiency of 86% [

29]. Building on these optimization-focused studies, another study investigated PP, POM, and PBT polymers for implant manufacturing via injection molding. The simulation results showed that PBT exhibited the lowest deformation (1.09 mm) and shrinkage rate (16.76%), along with a favorable stress response (104.2 MPa), making it the most suitable material for biomedical applications [

30]. In addition, Nabudda et al. [

31] employed computational fluid dynamics to optimize degradable polylactic acid (PLA)-based coating materials for sustainable wire manufacturing, demonstrating that the injection angle strongly influences flow dynamics, heat transfer, density distribution, and pressure uniformity. Their findings revealed that a 45° injection angle ensured superior uniformity and structural integrity, further underlining the significance of multi-parameter optimization in injection-based manufacturing processes.

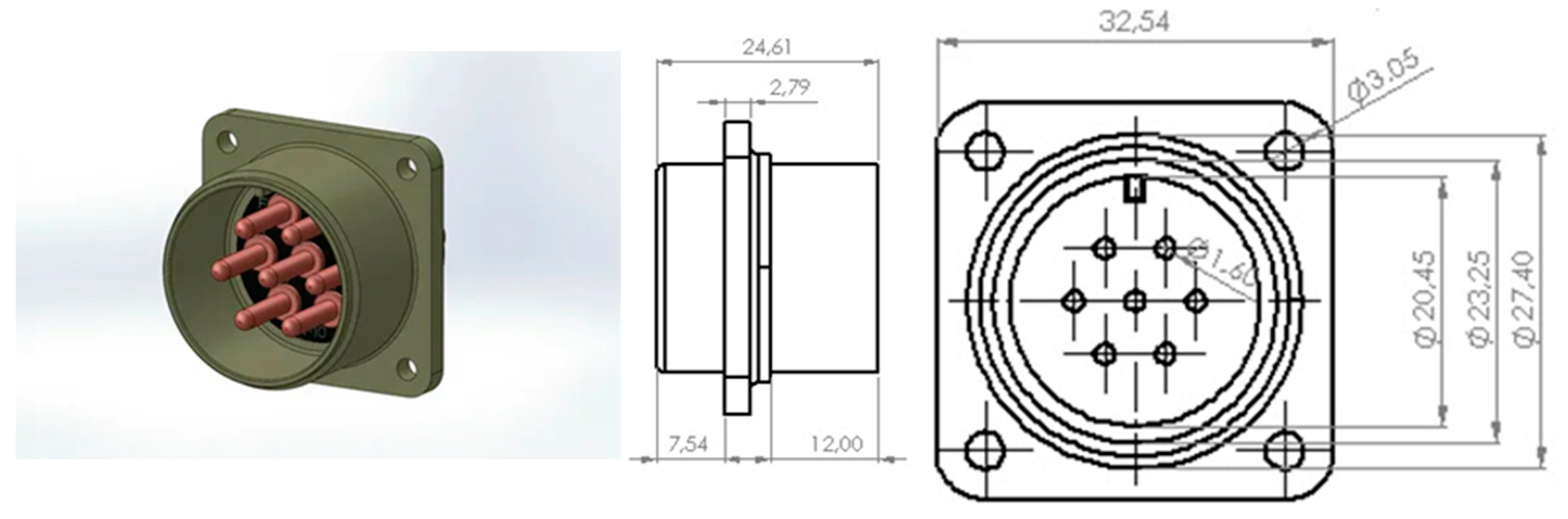

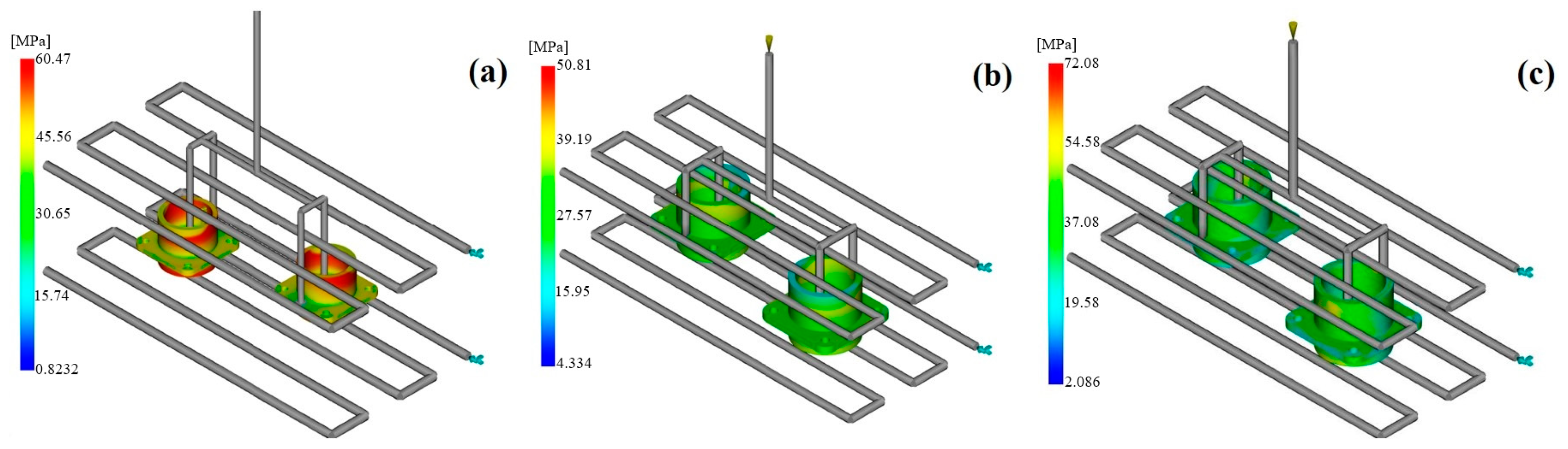

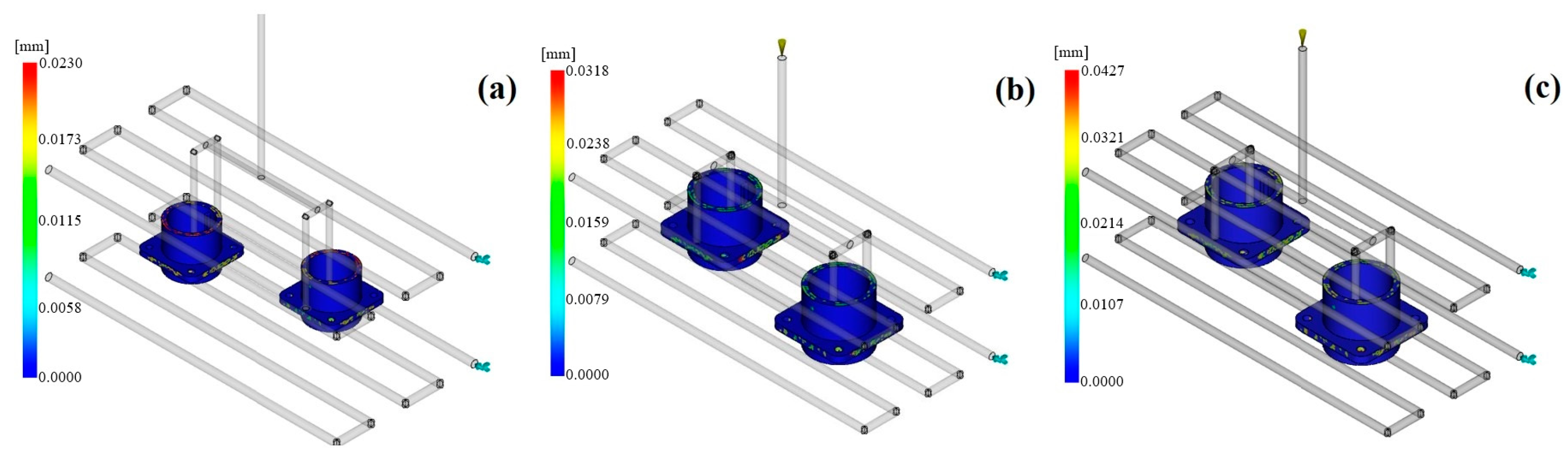

This study focused on examining the moldability and thermomechanical properties of the advanced engineering materials PEEK, PEI, and PAI for the MS3102A 16S-1P type multi-pin electrical connector geometry via Moldflow simulation. Experimental design techniques such as Box–Behnken design and Response Surface Methodology (RSM) were used to establish the effects of some important process parameters; namely, the melt temperature, injection time, and mold open time, on critical quality characteristics. In this way, this study takes a very relevant and practical step towards material identification and process optimization for the manufacturing of high-performance electrical components.