Rheological and Chemical Effects of Waste Tire Pyrolytic Oil and Its Encapsulation as Rejuvenators on Asphalt Binders

Abstract

1. Introduction

2. Materials and Methods

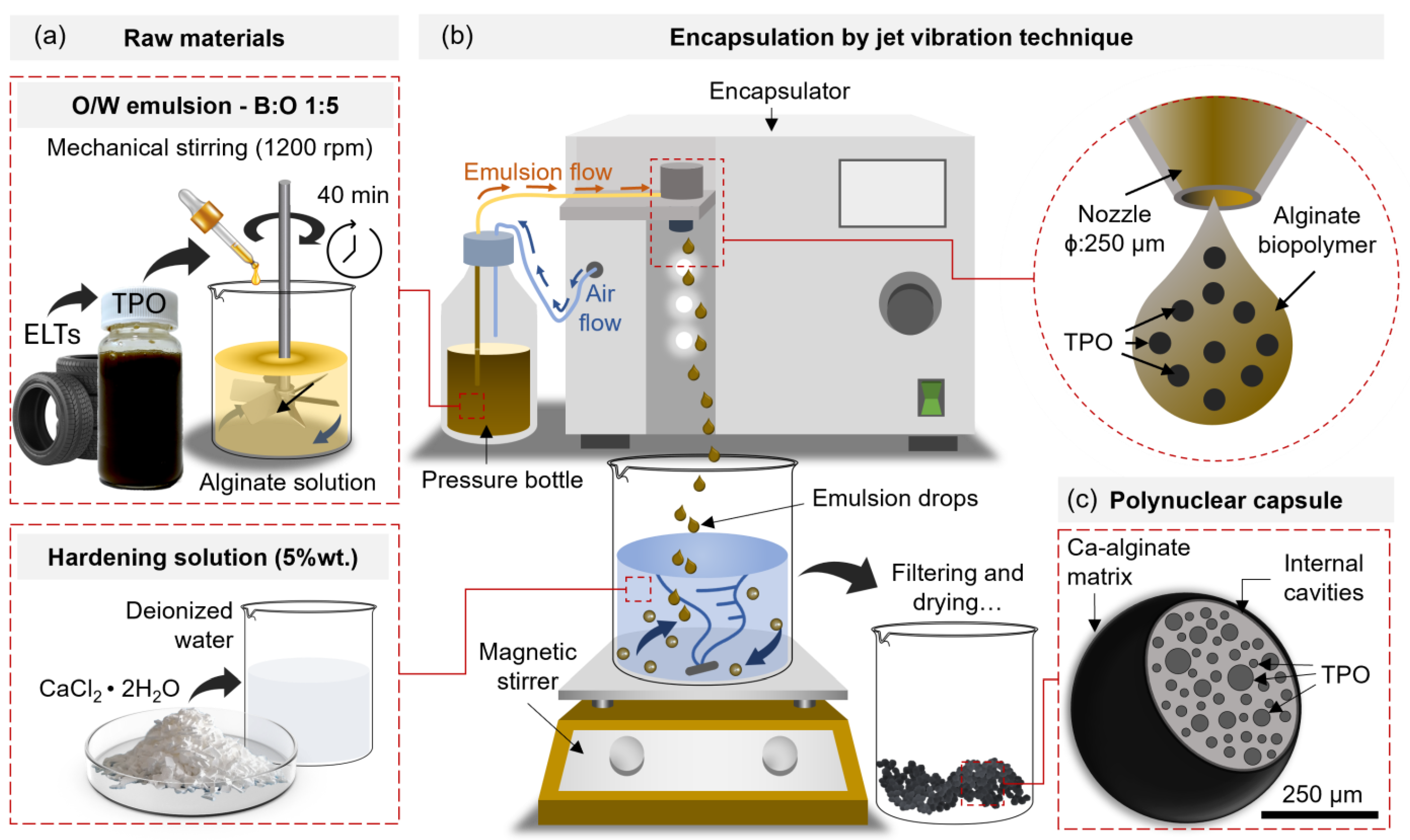

2.1. Asphalt Binder and Additives Based on Pyrolytic Oil

2.2. Evaluation of the Tire Pyrolytic Oil (TPO) and Pyrolytic Oil Capsules (POCs)

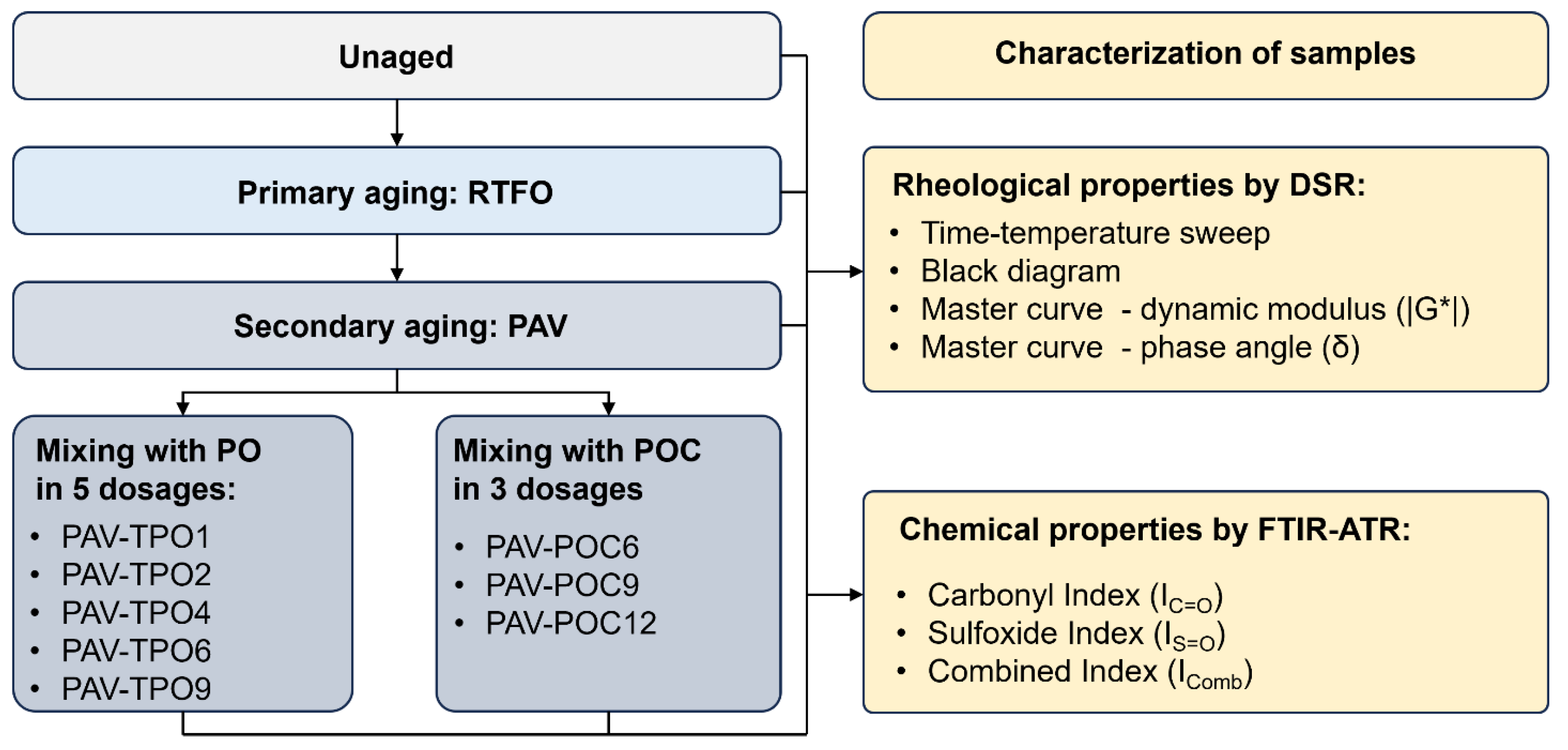

2.3. Aging Process of Asphalt Binders

2.4. Mixing of Asphalt Binder with TPO and POCs

2.5. Rheological Characterization of Aged Asphalt Binders with TPO and POCs

2.6. Characterization of Asphalt Binders by Means of FTIR-ATR

3. Results and Discussion

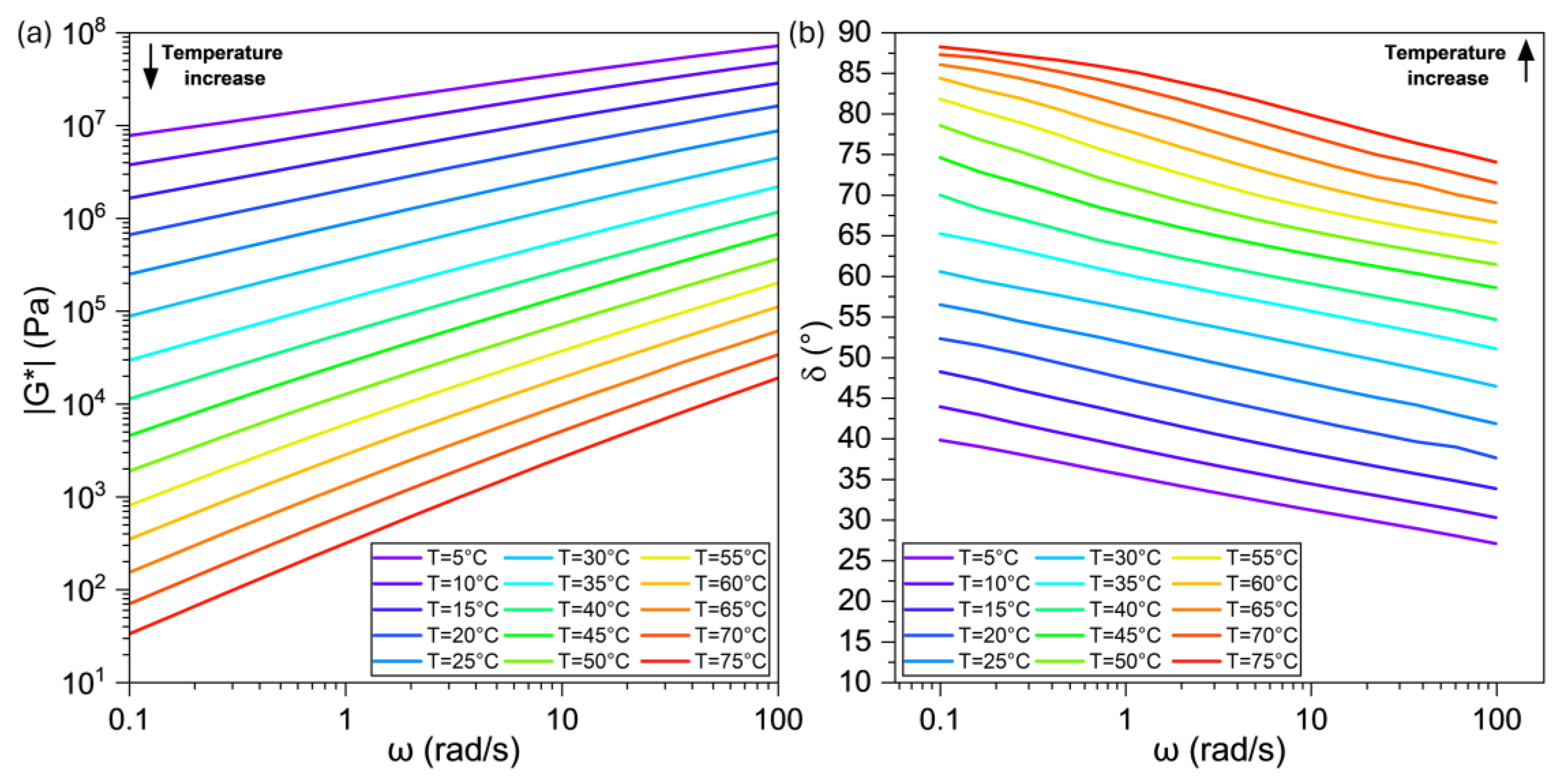

3.1. Rheological Measurements

3.1.1. Master Curves of Dynamic Modulus (|G*|)

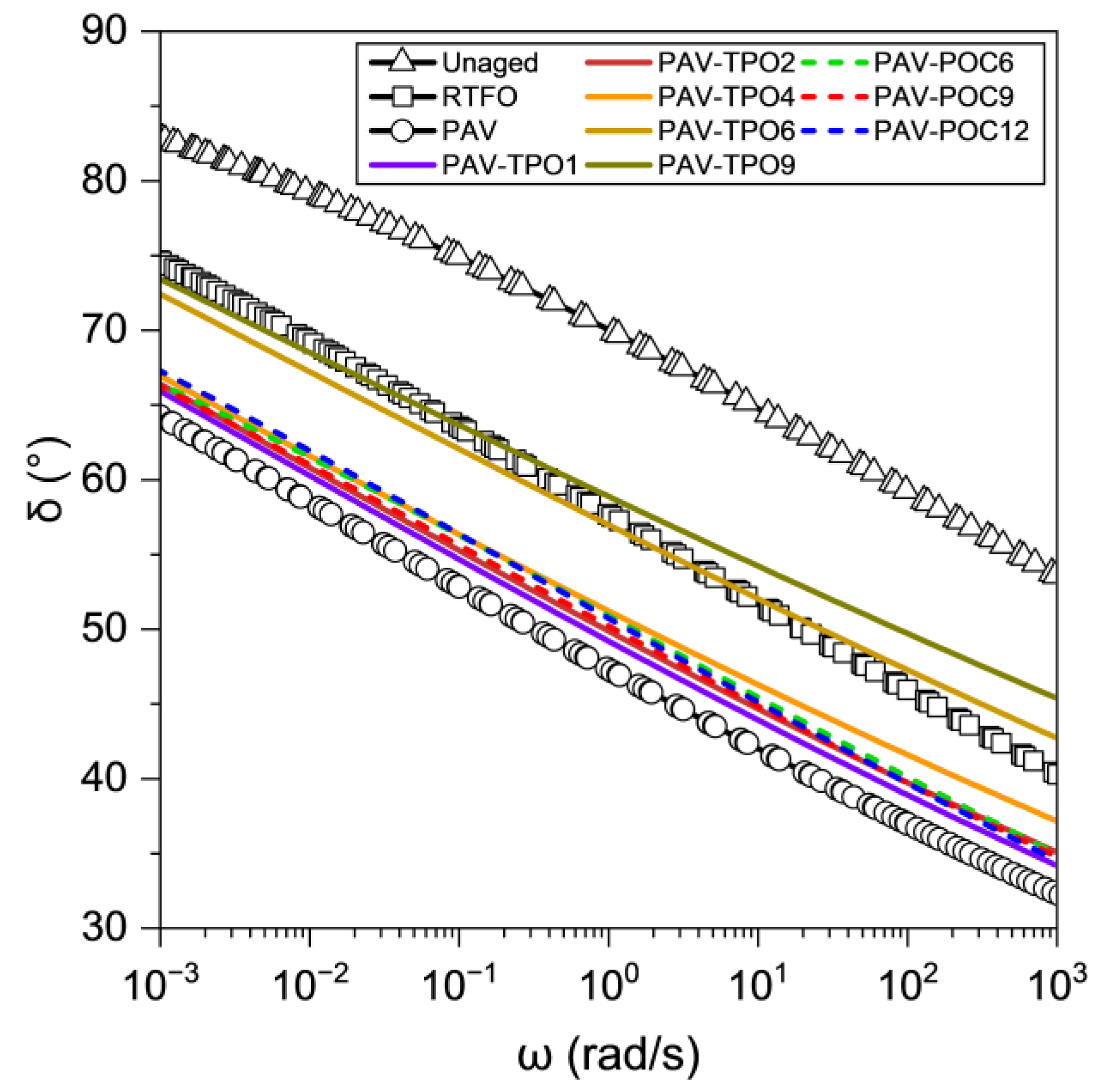

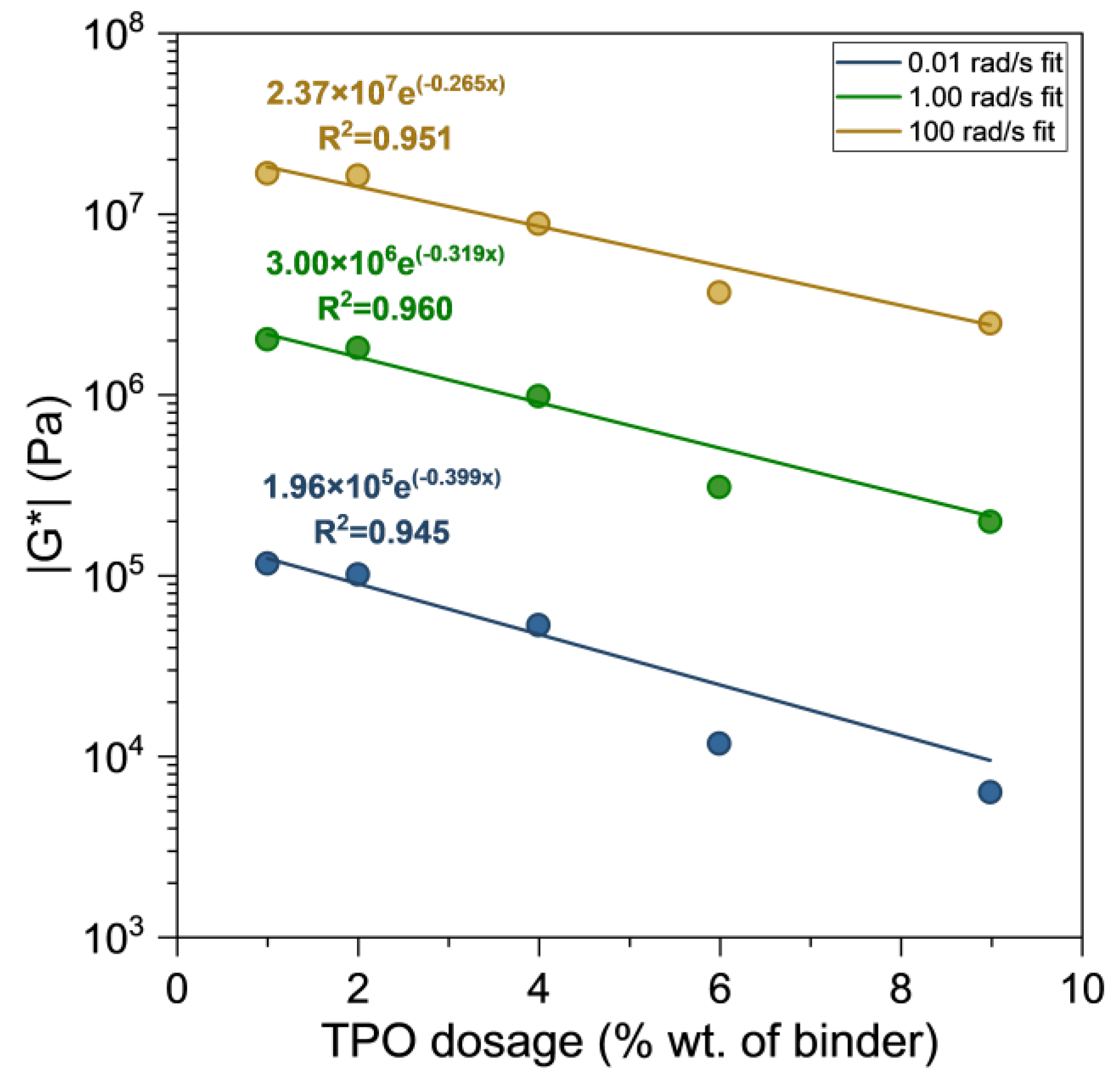

3.1.2. Master Curves of Phase Angle (δ)

3.1.3. Amount of Rejuvenator Released from Capsules During Mixing and Testing

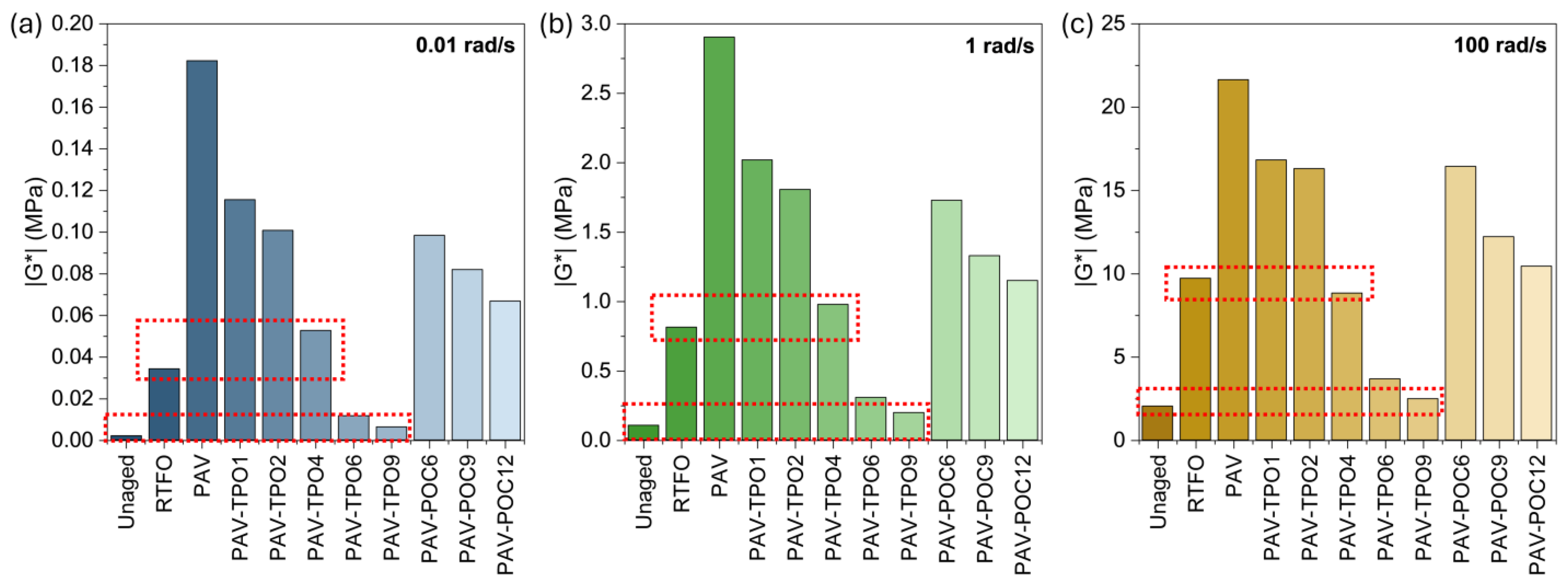

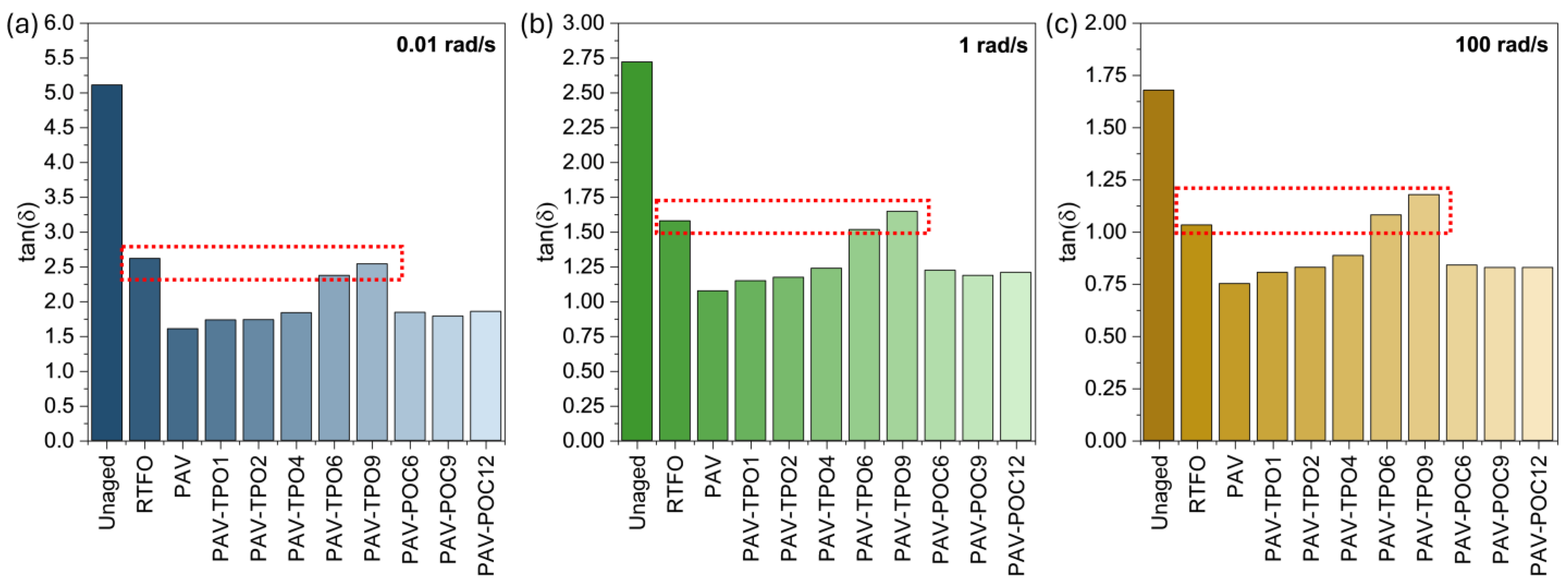

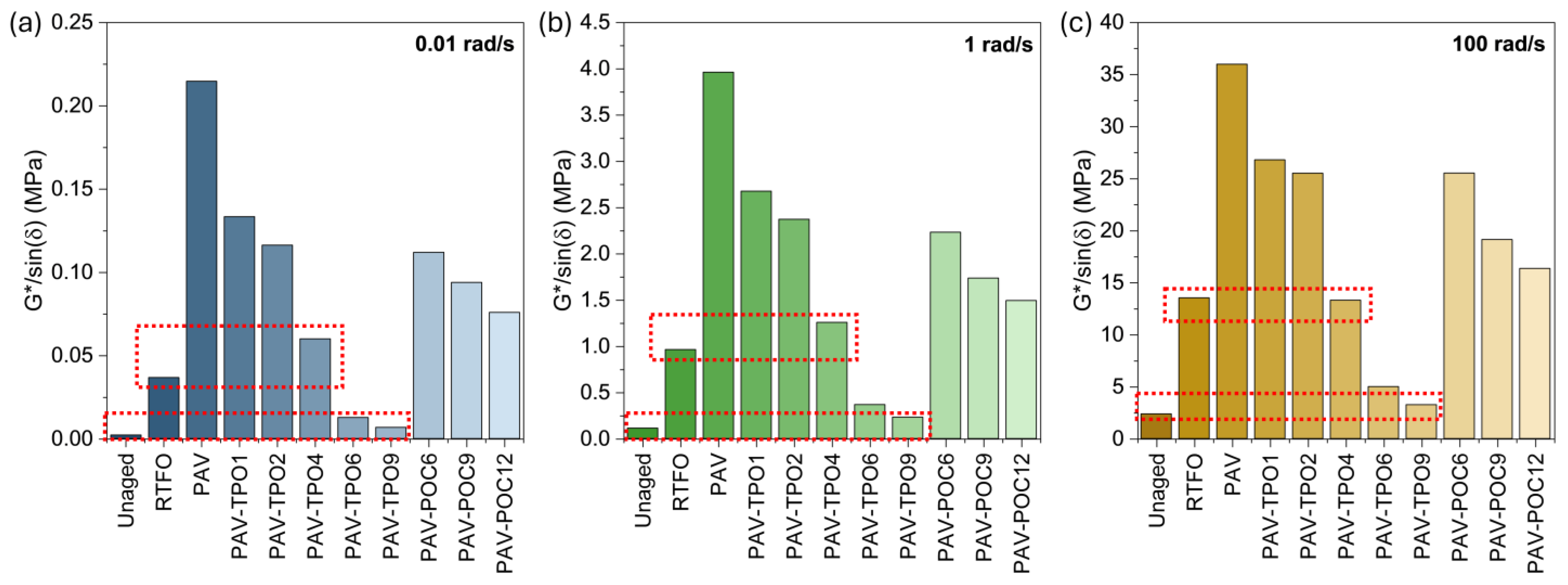

3.1.4. Rheological Properties and Rejuvenator Applications

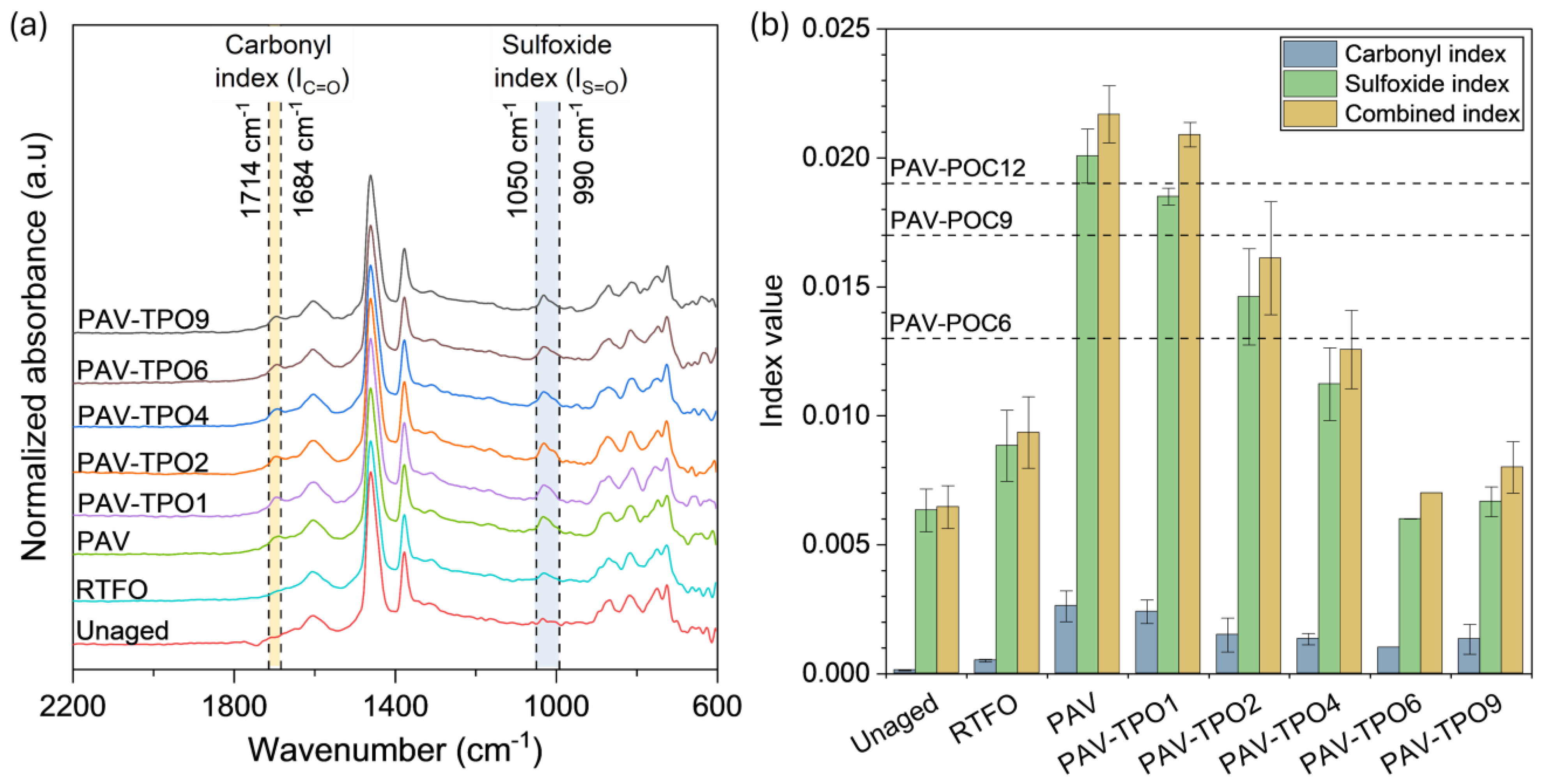

3.2. FTIR-ATR Characterization of the Asphalt Binders

4. Conclusions

- Rejuvenation of aged asphalt binder: Waste tire pyrolytic oil (TPO) effectively rejuvenates aged asphalt binders by reducing stiffness (G*), increasing viscous response (δ), and lowering carbonyl and sulfoxide aging indices of long-term aged binders (PAV). According to FTIR results, carbonyl and sulfoxide indices decreased progressively with TPO dosage, while rheological analysis showed that 4% TPO brought |G*| of the PAV binder to levels comparable to RTFO, and 9% TPO restored stiffness close to the unaged binder. Higher TPO dosages enhance these effects. Additionally, capsules (POC) containing TPO help rejuvenate PAV-aged binders through partial TPO release into the binder.

- Potential for recycling reclaimed asphalt pavement (RAP): The required amount of TPO to rejuvenate a PAV-aged binder to a state similar to its unaged condition was found to be 9% by binder weight. At this dosage, G/sinδ reached values comparable to the unaged binder. This dosage is sufficient for rejuvenating PAV-aged binders in RAP mixtures for reuse in new pavement construction. The dosage was determined by using the rutting parameter (G*/sinδ) and confirmed by FTIR results.

- Amount of rejuvenator released from capsules: It was estimated that capsules (POC) released 27% to 35% of their TPO content during mixing and DSR testing. This conclusion was based on comparisons of G*, δ, and FTIR results between POC capsules and direct TPO applications. For instance, 12% POC showed a softening effect similar to 4% TPO addition, due to the partial rejuvenator released. The capsules are designed for slow release, enabling long-term self-healing in pavements as the remaining TPO is gradually released over time.

- Encapsulated applications: For asphalt pavements with binders in PAV-aging conditions, the amount of TPO released from capsules should not exceed 4% by binder weight within a short period, assuming ideal diffusion. Higher release levels could cause excessive softening, increasing the risk of rutting, as indicated by the G*/sinδ parameter. The required capsule amount depends on their TPO content and release rate over time. In this study, a 12% POC dosage successfully released 4% TPO during mixing and testing of binders, achieving rheological properties comparable to the RTFO-aged condition.

5. Patents

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TPO | Tire Pyrolytic Oil |

| POC | Pyrolytic Oil Capsules |

| RTFO | Rolling Thin Film Oven |

| PAV | Pressure Aging Vessel |

| RAP | Reclaimed Asphalt Pavements |

| MD | Molecular dynamics |

| FTIR | Fourier Transform Infrared spectroscopy |

| GC-MS | Gas Chromatography coupled with Mass Spectrometry |

| ASTM | American Society for Testing and Materials |

| DSR | Dynamic Shear Rheometer |

| ANID | Chilean National Agency for Research and Development |

| UTFSM | Universidad Técnica Federico Santa María |

References

- EAPA. Asphalt in Figures 2021. European Asphalt Paving Association, January 2023. [Google Scholar]

- EAPA. European Green Deal: The Asphalt Industry’s Contribution to Climate–Neutrality and Preservation of Europe’s Natural Environment. European Asphalt Paving Association, December 2023. [Google Scholar]

- Hunter, R. Shell Bitumen Handbook, 6th ed.; ICE Publishing: London, UK, 2014. [Google Scholar]

- Airey, G.D. State of the art report on ageing test methods for bituminous pavement materials. Int. J. Pavement Eng. 2003, 4, 165–176. [Google Scholar] [CrossRef]

- Tran, N.; Xie, Z.; Julian, G.; Taylor, A.; Willis, R.; Robbins, M.; Buchanan, S. Effect of a recycling agent on the performance of high-RAP and high-RAS mixtures: Field and lab experiments. J. Mater. Civ. Eng. 2017, 29, 04016178. [Google Scholar] [CrossRef]

- Behnood, A. Application of rejuvenators to improve the rheological and mechanical properties of asphalt binders and mixtures: A review. J. Clean. Prod. 2019, 231, 171–182. [Google Scholar] [CrossRef]

- Ma, Y.; Hu, W.; Polaczyk, P.; Han, B.; Xiao, R.; Zhang, M.; Huang, B. Rheological and aging characteristics of the recycled asphalt binders with different rejuvenator incorporation methods. J. Clean. Prod. 2020, 262, 121249. [Google Scholar] [CrossRef]

- Han, X.; Mao, S.; Zeng, S.; Duan, H.; Liu, Q.; Xue, L.; Yu, J. Effect of reactive flexible rejuvenators on thermal-oxidative aging resistance of regenerated SBS modified asphalt. J. Clean. Prod. 2022, 380, 135027. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Varveri, A.; Khalighi, S.; Jing, R.; Erkens, S. Aging and rejuvenation effects on the rheological response and chemical parameters of bitumen. J. Mater. Res. Technol. 2023, 25, 1289–1313. [Google Scholar] [CrossRef]

- Petersen, J.; Glaser, R. Asphalt oxidation mechanisms and the role of oxidation products on age hardening revisited. Road Mater. Pavement Des. 2011, 12, 795–819. [Google Scholar] [CrossRef]

- Chen, M.; Leng, B.; Wu, S.; Sang, Y. Physical, chemical and rheological properties of waste edible vegetable oil rejuvenated asphalt binders. Constr. Build. Mater. 2014, 66, 286–298. [Google Scholar] [CrossRef]

- Campuzano, F.; Martínez, J.; Agudelo, A.; Sarathy, S.; Roberts, W. Pursuing the end-of-life tire circularity: An outlook toward the production of secondary raw materials from tire pyrolysis oil. Energy Fuels 2023, 37, 8836–8866. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Arteaga-Pérez, L.E.; Concha, J.L.; Gonzalez-Torre, I. Pyrolytic oil from waste tyres as a promising encapsulated rejuvenator for the extrinsic self-healing of bituminous materials. Road Mater. Pavement Des. 2021, 22, S117–S133. [Google Scholar] [CrossRef]

- Quezada, G.; Solar, C.; Saavedra, J.; Petit, K.; Martin-Martínez, F.; Arteaga-Pérez, L.; Norambuena-Contreras, J. Operando FTIR-ATR with molecular dynamic simulations to understand the diffusion mechanism of waste tire-derived pyrolytic oil for asphalt self-healing. Fuel 2024, 357, 129834. [Google Scholar] [CrossRef]

- Kumar, A.; Choudhary, R.; Kumar, A. Evaluation of waste tire pyrolytic oil as a rejuvenation agent for unmodified, polymer-modified, and rubber-modified aged asphalt binders. J. Mater. Civ. Eng. 2022, 34, 04022246. [Google Scholar] [CrossRef]

- García, Á.; Schlangen, E.; van de Ven, M.; Sierra-Beltrán, G. Preparation of capsules containing rejuvenators for their use in asphalt concrete. J. Hazard. Mater. 2010, 184, 603–611. [Google Scholar] [CrossRef] [PubMed]

- Norambuena-Contreras, J.; Yalcin, E.; Garcia, A.; Al-Mansoori, T.; Yilmaz, M.; Hudson-Griffiths, R. Effect of mixing and ageing on the mechanical and self-healing properties of asphalt mixtures containing polymeric capsules. Constr. Build. Mater. 2018, 175, 254–266. [Google Scholar] [CrossRef]

- González-Torre, I.; Norambuena-Contreras, J. Recent advances on self-healing of bituminous materials by the action of encapsulated rejuvenators. Constr. Build. Mater. 2020, 258, 119568. [Google Scholar] [CrossRef]

- Kargari, A.; Arabani, M.; Mirabdolazimi, S.M. Effect of palm oil capsules on the self-healing properties of aged and unaged asphalt mixtures gained by resting period and microwave heating. Constr. Build. Mater. 2022, 316, 125901. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Q.; Wu, J.; Wan, P.; Zhao, F. Self-healing performance of asphalt concrete with Ca-alginate capsules under low service temperature conditions. Polymers 2023, 15, 199. [Google Scholar] [CrossRef]

- Zaumanis, M.; Boesiger, L.; Kunz, B.; Cavalli, M.C.; Poulikakos, L. Determining optimum rejuvenator addition location in asphalt production plant. Constr. Build. Mater. 2019, 198, 368–378. [Google Scholar] [CrossRef]

- Xu, S.; Liu, X.; Tabaković, A.; Lin, P.; Zhang, Y.; Nahar, S.; Lommerts, B.J.; Schlangen, E. The role of rejuvenators in embedded damage healing for asphalt pavement. Mater. Des. 2021, 202, 109564. [Google Scholar] [CrossRef]

- Concha, J.; Delgadillo, R.; Arteaga-Pérez, L.; Segura, C.; Norambuena-Contreras, J. Optimised sunflower oil content for encapsulation by vibrating technology as a rejuvenating solution for asphalt self-healing. Polymers 2023, 15, 1578. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Amirkhanian, S.; Tang, B. Effects of rejuvenator on performance-based properties of rejuvenated asphalt binder and mixtures. Constr. Build. Mater. 2007, 21, 958–964. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. Determining optimum rejuvenator dose for asphalt recycling based on Superpave performance grade specifications. Constr. Build. Mater. 2014, 69, 159–166. [Google Scholar] [CrossRef]

- Osmari, P.H.; Aragao, F.T.S.; Leite, L.F.M.; Simao, R.A.; da Motta, L.M.G.; Kim, Y.-R. Chemical, microstructural, and rheological characterizations of binders to evaluate aging and rejuvenation. Transp. Res. Rec. 2017, 2632, 14–24. [Google Scholar] [CrossRef]

- Qurashi, I.A.; Swamy, A.K. Viscoelastic properties of recycled asphalt binder containing waste engine oil. J. Clean. Prod. 2018, 182, 992–1000. [Google Scholar] [CrossRef]

- Lamontagne, J.; Dumas, P.; Mouillet, V.; Kister, J. Comparison by Fourier transform infrared (FTIR) spectroscopy of different ageing techniques: Application to road bitumens. Fuel 2001, 80, 483–488. [Google Scholar] [CrossRef]

- Weigel, S.; Stephan, D. The prediction of bitumen properties based on FTIR and multivariate analysis methods. Fuel 2017, 208, 655–661. [Google Scholar] [CrossRef]

- Jing, R.; Varveri, A.; Liu, X.; Scarpas, A.; Erkens, S. Ageing effect on chemo-mechanics of bitumen. Road Mater. Pavement Des. 2021, 22, 1044–1059. [Google Scholar] [CrossRef]

- ASTM D6373-21A; Standard Specification for Performance-Graded Asphalt Binder. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D6521; Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV). ASTM International: West Conshohocken, PA, USA, 2019.

- Concha, J.; Arteaga-Pérez, L.; Alpizar-Reyes, E.; Segura, C.; Gonzalez-Torre, I.; Kanellopoulos, A.; Norambuena-Contreras, J. Effect of rejuvenating oil type on the synthesis and properties of alginate-based polynuclear capsules for asphalt self-healing. Road Mater. Pavement Des. 2023, 24, 1669–1694. [Google Scholar]

- Cong, P.; Wang, J.; Li, K.; Chen, S. Physical and rheological properties of asphalt binders containing various antiaging agents. Fuel 2012, 97, 678–684. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; You, Z.; Hasan, M. Research on properties of bio-asphalt binders based on time and frequency sweep test. Constr. Build. Mater. 2018, 160, 786–793. [Google Scholar] [CrossRef]

- ASTM D7175; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM International: West Conshohocken, PA, USA, 2015.

- Teymourpour, P.; Hanz, A.; Mandal, T.; Bahia, H.; Rizzutto, S. Effect of parallel plate gap height on repeatability in DSR measurements of crumb-rubber modified binders. J. Mater. Civ. Eng. 2016, 28, 04016047. [Google Scholar] [CrossRef]

- Papagiannakis, A.T.; Masad, E.A.P.E.; Wiley, J. Pavement Design and Materials; John Wiley & Sons: Hoboken, NJ, USA, 2024. [Google Scholar]

- Pipintakos, G.; Soenen, H.; Ching, H.Y.V.; Velde, C.V.; Van Doorslaer, S.; Lemière, F.; Varveri, A.; Van den bergh, W. Exploring the oxidative mechanisms of bitumen after laboratory short-and long-term ageing. Constr. Build. Mater. 2021, 289, 123182. [Google Scholar] [CrossRef]

- Ferry, J. Viscoelastic Properties of Polymers; John Wiley & Sons: Hoboken, NJ, USA, 1980. [Google Scholar]

- Malinowski, S.; Wróbel, M.; Bandura, L.; Woszuk, A.; Franus, W. Use of new green bitumen modifier for asphalt mixtures recycling. Materials 2022, 15, 6070. [Google Scholar] [CrossRef]

- Little, D.; Bhasin, A. Exploring mechanism of H ealing in asphalt mixtures and quantifying its impact. In Self Healing Materials: An Alternative Approach to 20 Centuries of Materials Science; Springer: Dordrecht, The Netherlands, 2007; pp. 205–218. [Google Scholar]

- Norambuena-Contreras, J.; Concha, J.L.; Valdes-Vidal, G.; Wood, C. Optimised biopolymer-based capsules for enhancing the mechanical and self-healing properties of asphalt mixtures. Mater. Struct. 2024, 57, 236. [Google Scholar] [CrossRef]

- Mirwald, J.; Werkovits, S.; Camargo, I.; Maschauer, D.; Hofko, B.; Grothe, H. Investigating bitumen long-term-ageing in the laboratory by spectroscopic analysis of the SARA fractions. Constr. Build. Mater. 2020, 258, 119577. [Google Scholar] [CrossRef]

- Ma, F.; Wang, Y.; Fu, Z.; Tang, Y.; Dai, J.; Li, C.; Dong, W. Thermal ageing mechanism of a natural rock-modified asphalt binder using Fourier Transform Infrared Spectroscopy analysis. Constr. Build. Mater. 2022, 335, 127494. [Google Scholar] [CrossRef]

| Property | Value | Standard |

|---|---|---|

| Density | 1.04 g/cm3 | ASTM D70/D70M-21 |

| Penetration @ 25 °C | 53 dmm | ASTM D946/D946M-20 |

| Softening Point | 52.2 °C | ASTM D36/D36M-12 |

| G*/sin(δ) @ 64 °C (Unaged) | >1 kPa | ASTM D6373-21A |

| G*/sin(δ) @ 64 °C (RTFO-aged) | >2.2 kPa | ASTM D6373-21A |

| G*·sin(δ) @ 25 °C (PAV-aged) | 5976 | ASTM D6373-21A |

| S @-12 °C | 222 MPa | ASTM D6373-21A |

| m @-12 °C | 0.36 | ASTM D6373-21A |

| ω [rad/s] | PAV-POC6 | PAV-POC9 | PAV-POC12 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A: TPO Released (*) | B: Total TPO Content | A/B: Fraction Released | A: TPO Released (*) | B: Total TPO Content | A/B: Fraction Released | A: TPO Released (*) | B: Total TPO Content | A/B: Fraction Released | |

| 0.01 | 1.73% | 5% | 0.35 | 2.19% | 7.5% | 0.29 | 2.70% | 10% | 0.27 |

| 1 | 1.73% | 5% | 0.35 | 2.55% | 7.5% | 0.34 | 3.01% | 10% | 0.30 |

| 100 | 1.38% | 5% | 0.28 | 2.50% | 7.5% | 0.33 | 3.09% | 10% | 0.31 |

| Wavelength (cm−1) | Assigned Vibration (*) | Functional Group |

|---|---|---|

| 720 | ρ(CH2)n | Alkyls |

| 748 | γCHaro | Aromatic |

| 810 | γCHaro | Aromatic |

| 869 | γCHaro | Aromatic |

| - | δ(CH) | Alkene |

| 1027 | νS=O | Sulfoxides |

| 1160 | νSO2 (in-phase) | Sulfones |

| 1375 | δsCH2/CH3 | Alkyls |

| 1455 | δasCH2/CH3 | Alkyls |

| 1600 | νC=C | Aromatic |

| 1710 | νC=O | Ketone |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Delgadillo, R.; González, A.; Marzal, I.; Concha, J.L.; Segura, C.; Arteaga-Pérez, L.E.; Norambuena-Contreras, J. Rheological and Chemical Effects of Waste Tire Pyrolytic Oil and Its Encapsulation as Rejuvenators on Asphalt Binders. Polymers 2025, 17, 2449. https://doi.org/10.3390/polym17182449

Delgadillo R, González A, Marzal I, Concha JL, Segura C, Arteaga-Pérez LE, Norambuena-Contreras J. Rheological and Chemical Effects of Waste Tire Pyrolytic Oil and Its Encapsulation as Rejuvenators on Asphalt Binders. Polymers. 2025; 17(18):2449. https://doi.org/10.3390/polym17182449

Chicago/Turabian StyleDelgadillo, Rodrigo, Araceli González, Ixa Marzal, Jose L. Concha, Cristina Segura, Luis E. Arteaga-Pérez, and Jose Norambuena-Contreras. 2025. "Rheological and Chemical Effects of Waste Tire Pyrolytic Oil and Its Encapsulation as Rejuvenators on Asphalt Binders" Polymers 17, no. 18: 2449. https://doi.org/10.3390/polym17182449

APA StyleDelgadillo, R., González, A., Marzal, I., Concha, J. L., Segura, C., Arteaga-Pérez, L. E., & Norambuena-Contreras, J. (2025). Rheological and Chemical Effects of Waste Tire Pyrolytic Oil and Its Encapsulation as Rejuvenators on Asphalt Binders. Polymers, 17(18), 2449. https://doi.org/10.3390/polym17182449