Abstract

Liquid crystalline block copolymers (LCBCPs) have emerged as an adaptable hybrid class at the intersection of self-assembling block copolymers and liquid crystalline ordering, producing multi-tiered architectures that can be finely programmed for multifunctional performance. This review surveys recent advances in their structure–property relationships and highlights applications spanning nanotechnology, biomedical systems, flexible photonics, stimuli-responsive, energy storage, and soft robotics. Particular emphasis is placed on how molecular design enables precise tuning of structural, optical, mechanical, and stimuli-responsive functions, positioning LCBCPs as strong candidates for next-generation functional materials. We also discuss current challenges, including scalability, phase control, and advanced characterization, and outline promising research directions to accelerate their translation from laboratory concepts to real-world technologies.

1. Introduction

Liquid crystals (LCs) constitute a mesophase—an intermediate state of matter that bridges the characteristics of conventional liquids and crystalline solids. They flow like liquids, yet maintain a degree of molecular alignment reminiscent of solids [1,2,3,4]. Unlike ordinary fluids (exhibiting only short-range disorder) or crystals (with long-range periodic order), LCs preserve orientational order at mesoscopic scales, giving rise to unique anisotropic optical and mechanical properties [3,5,6]. This partial molecular alignment, typically along a preferred direction known as the director, underpins their anisotropic behavior and high responsiveness to external stimuli such as temperature, electric and magnetic fields, or light [2,5,7]. As soft matter, LCs are governed by intermolecular interactions comparable to thermal energy, facilitating abundant structural fluctuations at mesoscopic scales [5,8,9]. These dynamic structures enable LCs to exhibit a broad range of stimuli-responsive functions, which have been effectively harnessed in functional applications [2,10,11,12,13].

Liquid crystal polymers (LCPs) advance the capabilities of LCs by incorporating mesogenic units into polymeric architectures. This design fuses the fluidity and responsiveness of liquid crystals with the mechanical strength and processability of polymers [14,15,16,17]. Based on where the mesogenic units are attached, LCPs can be categorized as main-chain liquid crystal polymers (where mesogens are embedded in the polymer backbone) or side-chain liquid crystal polymers (where mesogens are pendant along a flexible spacer) [18,19,20]. Such structural versatility enables precise tuning of phase transitions, ordering, and functional behaviors, opening pathways to applications including responsive sensors, electromechanical actuators, aerospace fibers, and advanced composites [21,22,23,24,25,26,27].

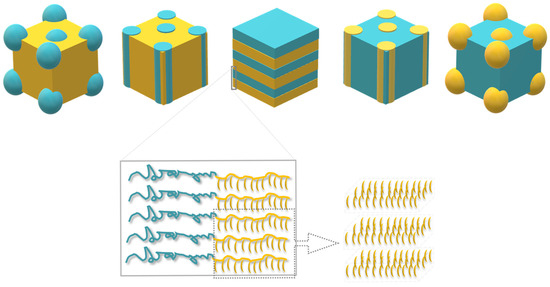

Building on these foundations, liquid crystalline block copolymers (LCBCPs) combine two powerful ordering principles: the microphase separation of block copolymers [28,29,30,31,32,33,34,35,36,37,38,39] and the anisotropic molecular ordering of liquid crystals [2,15,26,40]. In these hybrid macromolecules, chemically distinct polymer blocks—typically one mesogen-containing and the other flexible or amorphous—segregate into nanoscale domains such as lamellae, cylinders, gyroids, or spheres, while mesogenic segments within those domains form ordered LC phases, including nematic, smectic, or cholesteric arrangements (see Scheme 1) [40,41,42,43,44,45,46,47,48,49,50,51,52,53]. This hierarchical organization, spanning nanometers to micrometers, can be tuned by adjusting block volume fraction, mesogen chemistry, and spacer flexibility [54,55,56], enabling precise control over both nanoscale morphology and mesogen alignment [53,57,58].

Scheme 1.

The exceptional nature of LCBCPs comes from their molecular architecture that couples self-assembling polymer blocks with sidechain liquid crystalline mesogens.

Crucially, the coupling between microphase structure and LC ordering imparts dynamic responsiveness, schematically drawn in Scheme 1: variations in temperature, applied electric or magnetic fields, or light irradiation can reversibly reconfigure both the internal nanostructure and macroscopic behavior in real time [21,41,48,59,60,61,62,63,64,65,66,67,68,69,70]. This combination of tunable multiscale organization, anisotropic functional properties, and adaptive response is rarely achievable in conventional block copolymers or LCPs alone, underscoring the pivotal role of molecular architecture in defining LCBCP performance.

This review paper focuses on publications from peer-reviewed journals, primarily from the last decade (2016–2025), centered around essential keywords: “liquid crystalline block copolymer”, “LCBCP”, “block copolymer self-assembly”, and “liquid crystalline polymers”.

2. Recent Research Fields in LCBCPs

LCBCPs have emerged as a dynamic class of materials, attracting growing interest across diverse research fields due to their unique combination of self-assembly, anisotropic ordering, and stimuli-responsive function. This section highlights recent progress in harnessing LCBCPs for applications spanning nanotechnology, photonics, biomedicine, advanced functional materials, and energy storage, emphasizing their fundamental roles and transformative potential in these domains.

2.1. Nanostructured Materials and Nanotechnology

In nanotechnology, LCBCPs function as highly effective and precise templates for the fabrication of nanostructured materials. Their ability to self-assemble into well-defined morphologies (such as cylindrical, lamellar, or spherical domains) makes them an ideal case for creating ordered nanoscale architectures. These well-defined domains serve as templates for the synthesis of nanoporous membranes and nanostructured inorganic materials through selective etching or infiltration techniques [46,71].

For instance, Houben et al. created mechanically robust, aligned nanoporous smectic LC polymer networks within an anisotropic microporous scaffold. Post-polymerization, the composite membranes featured aligned 2D nanopores capable of rejecting anionic solutes above 322 g/mol, demonstrating their potential for precise molecular sieving

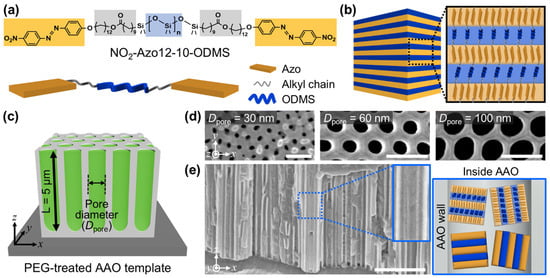

Structural control can be further refined through confinement strategies. In a recent study, Kim et al. [72] examined how nanoconfinement influences the self-assembly and alignment of liquid crystalline block co-oligomers (Azo-LCBCO) within anodic aluminum oxide (AAO) templates (see Figure 1). Using GI-SAXS, they found that reducing pore diameter from 100 nm to 30 nm not only promoted bilayer formation but also introduced interdigitated and monolayer smectic phases, revealing greater structural diversity in tighter confinement. GI-WAXD analysis showed that the proportion of smectic layers aligned parallel to the pore axis increased dramatically from 22% to 93.7%, supported by azimuthal angle evaluation of π–π stacking. These findings demonstrate that nanoscale confinement offers precise control over smectic polymorphism and molecular orientation, providing a versatile strategy for engineering nanostructured soft materials with tunable anisotropic properties.

Figure 1.

(a) Chemical structure and schematic illustration of NO2-Azo12-10-ODMS (Azo-LCBCO). (b) Schematic illustration of the lamellar superstructure comprising smectic layers formed via self-assembly of Azo-LCBCO. (c) Schematic illustration of PEG-treated anodic aluminum oxide (AAO) templates filled with Azo-LCBCO. (d) Top-down SEM (Scanning Electron Microscopy) images of AAO templates with pore diameters (Dpore) of 30, 60, and 100 nm. Scale bars are 200 nm. (e) Cross-sectional SEM image of an AAO template with a Dpore of 60 nm filled with Azo-LCBCO, along with a schematic illustration of the self-assembled lamellar structures within the AAO nanochannel. The scale bar is 500 nm. The figure was reproduced with permission from Ref. [72].

Parallel to the influence of confinement, compositional design strategies have also been used to tune nanostructure and functional performance in LCBCPs. In a recent study, Zhou et al. [73] synthesized a block copolymer (BCP) combining an LC azobenzene polymer with an ionized polymeric ionic liquid, showing that its nanostructure changes with composition and temperature. Notably, the material’s ionic conductivity improved markedly at higher temperatures, highlighting its promise as a solid polymer electrolyte [73].

Similarly, targeted molecular design of LCBCPs can enable precise control over microphase-separated morphologies and LC alignment. In 2023, Takahashi et al. [74] synthesized novel smectic LC diblock copolymers, poly(methacrylate) featuring side chains terminated with cyano-functionalized phenyl benzoate mesogens, called PEO-b-PM6BACP, using atom transfer radical polymerization, ATRP. These BCPs featured sidechain cyano-terminated phenyl benzoate mesogens and formed hexagonally packed cylindrical microphase-separated structures with lattice periods around 18 nm. The LC behavior and molecular alignment within the PEO-b-PM6BACP system indicated precise control over morphology via LC incorporation in block frameworks [74].

In a striking demonstration of self-assembly’s precision, Luo et al. [75] reported a one-step assembly pathway in which a liquid crystalline block copolymer formed uniform cylindrical micelles that spontaneously coupled end-to-end into hierarchical supramicellar nanofibrils. By tuning nucleation and aggregation tendencies through controlled assembly conditions, the length of individual cylinders and the overall fibril morphology could be precisely adjusted. The liquid-crystalline ordering of the micellar core facilitated this sequential coupling, enabling the creation of both homogeneous and heterogeneous segmented fibrils. This work underscores how LCBCP self-assembly can be directed toward highly ordered, multi-level nanostructures with tunable dimensions and rigidity [75].

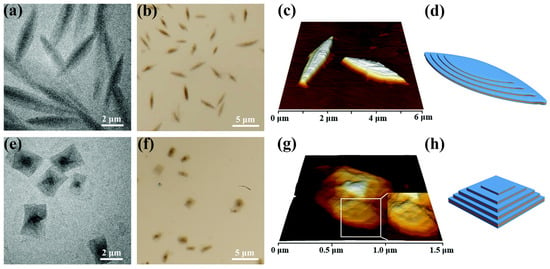

Beyond microphase separation control, recent studies have pushed toward the hierarchical assembly of complex, multi-dimensional architectures. Hierarchical assembly of complex nanostructures is critical for creating advanced artificial systems, yet controlling 2D and 3D morphologies with LCBCPs remains difficult. Sun et al. [76] demonstrated that an azobenzene-containing liquid-crystalline diblock copolymer, PEG-b-PAzoMA, undergoes a rich sequence of morphological transformations during thermal annealing in ethanol. At moderate concentrations, the copolymer initially forms stacked leaf-shaped platelets (Figure 2). With increasing concentration, these evolve into cross-shaped and ultimately flower-like hierarchical platelets, a progression indicative of concentration-mediated nucleation and aggregation control. Moreover, slow cooling promotes a transition from 2D leaf platelets into 3D rectangular platelets, revealing that annealing kinetics critically influence domain geometry. Adding an extra dimension to this self-assembly, the photoactive azobenzene cores enable UV-induced trans–cis isomerization, which in turn triggers reversible morphological reconfiguration of the platelet structures. Together, these capabilities illustrate how tuning solution conditions and thermal protocol, in combination with molecular photo-responsiveness, enables the fabrication of hierarchically structured, stimuli-adaptive nanomaterials, a promising foundation for applications in templating, sensing, photonic modulation, and beyond.

Figure 2.

TEM (a), OM (b), and 3D AFM (Atomic Force Microscopy) (c) images of stacked leaf-shaped platelets self-assembled from PEG45-b-PAzoMA180 upon natural cooling within 1 h. TEM (e), OM (f), and 3D AFM (g) images of stacked rectangular platelets self-assembled from PEG45-b-PAzoMA180 upon gradient cooling within 7 h. (d,h) are the corresponding schematic diagrams. The images were reproduced with permission from Ref. [76].

2.2. Light–Matter Interaction and Photonic Functionality in LCBCPs

Beyond structural control for nanoscale templating and hierarchical assembly, the self-assembly principles of LCBCPs can also be exploited to manipulate light–matter interactions. This capability makes them highly attractive for photonic applications, where their ordered morphologies and tunable optical properties enable the formation of photonic bandgap structures. Such structures underpin advanced devices including optical filters, waveguides, and tunable lasers [41,77].

Recent research has focused on exploiting this optical tunability through advanced molecular designs and self-assembly pathways. In their 2024 study, Yang et al. [78] synthesized an LCBCP featuring a discotic triphenylene (HAT) mesogen block and explored its solution-state self-assembly driven by strong π–π stacking interactions. They reported a profound sequence of morphological transformations: starting with spherical micelles, the LCBCP evolves through worm-like and tubular structures, then forms vesicular aggregates and ultimately assembles into thin fibrillar networks. These transitions occur spontaneously over extended aging periods, reflecting a subtle but powerful LC ordering effect. Remarkably, the introduction of small-molecule dopants shifts the self-assembly mechanism from intramolecular rearrangement to a nucleation-growth mode, enabling controlled formation of uniform fibrils and organo-gels via end-to-end coupling. This tunable assembly underscores the potential of discotic LCBCPs for crafting optoelectronic nanofibrils with organized π–stacked architectures, valuable in photonic and electronic applications [78].

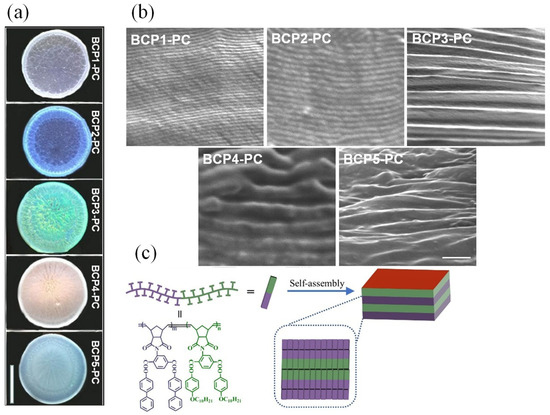

While discotic LCBCPs demonstrate the power of π-stacking-driven morphologies, other approaches leverage lamellar architectures to achieve photonic functionality. Ji et al. [79] reported mesogens-jacketed liquid-crystal-like block copolymers (MJ-LCBCPs) that self-assemble into lamellar structures functioning as 1D photonic crystal (PC) thin films (see Figure 3). The mesogens-jacketed rod block, based on benzene terephthalate derivatives, provided a high refractive index, while the coil block maintained processability. Spin-coated films exhibited well-ordered lamellae, confirmed by SAXS and cross-sectional SEM, producing strong Bragg reflections tunable from the UV to near-IR by varying the degree of polymerization. This molecular-weight-dependent periodicity allowed precise control over the stop-band position, enabling color tuning without post-processing. The modular synthesis and robust LC ordering of MJ-LCBCPs highlight their potential for optical coatings, sensors, and photonic device applications.

Figure 3.

(a) Optical photographs (scale bar = 1 cm); (b) cross-sectional SEM images (scale bar = 1 μm); (c) schematic illustration of 1D PC thin films prepared by the self-assembly of mesogen-jacketed liquid crystals like PBNM-b-PDNM BCPs (adapted with permission from Ref. [79]).

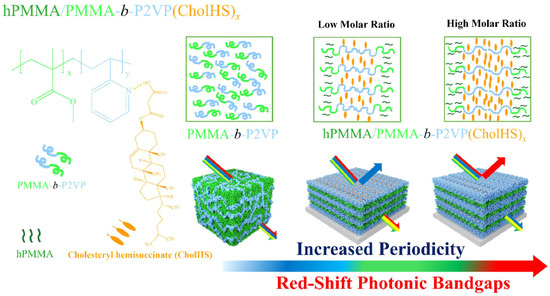

Expanding on this lamellar-based photonic design, recent research has shifted toward scalable, non-labor-intensive processing routes that preserve or even improve structural order in liquid-crystalline block copolymer (LCBCP) systems. In 2025, AboElsood et al. [80] reported a rapid solution-casting strategy in which coincident augmentation (growth of lamellar domain size) and alignment occur synergistically during solvent evaporation (Figure 4). This method exploits the interplay between solvent–polymer interactions and evaporation-induced flow fields to promote both the lateral expansion of lamellae and the in-plane orientation of their stacking direction. Remarkably, the films, comprising solid-state block copolymer photonic crystals, exhibit intense, angle-dependent structural coloration with composition-tunable reflection peaks spanning the visible spectrum. The entire fabrication process is completed within minutes, requiring no post-processing such as thermal annealing or shear alignment, while still achieving optical performance comparable to more energy- and time-intensive methods. The approach is also compatible with large-area casting, indicating strong potential for scalable manufacturing of structurally colored films. Collectively, such advances demonstrate how careful molecular design of LCBCP lamellae, combined with process-driven structural control, can deliver precisely tuned photonic responses for applications in optical coatings, sensors, anti-counterfeiting devices, and display technologies.

Figure 4.

Schematic representation of the rapid fabrication of hPMMA/PMMA-b-P2VP(CholHS)x supramolecular assemblies, in which the lamellar periodicity and microstructural orientation are simultaneously controlled. The periodicity, governed by the stretching of the P2VP chains in the host block copolymer, is tuned through hydrogen bonding with guest CholHS molecules. By varying the amount of CholHS, both the lamellar spacing and the resulting photonic bandgap can be precisely adjusted. Concurrently, the liquid-crystalline nature of CholHS promotes the alignment of parallel lamellar domains, enabling well-ordered photonic structures. The schematic drawing was reproduced with permission from Ref. [80].

2.3. Biomedical Applications

LCBCPs can be engineered for biomedical use by incorporating biocompatible segments, such as polyethylene glycol or cholesterol, while retaining mesogen-driven order and stimuli-responsiveness, enabling multifunctional carriers and scaffolds with precisely tunable structure–function relationships [81,82,83].

One promising direction in this context is the development of biomimetic scaffolds that replicate the structural cues of native tissues. LCBCs can form scaffolds with ordered nanostructures that mimic biological tissues, supporting cell growth and differentiation. Prévôt et al. [82] reported LCBCP-derived foams prepared by crosslinking star block copolymers bearing cholesteryl side groups, producing interconnected, brain-like porous scaffolds with SmA ordering. These scaffolds supported high cell viability and promoted contact guidance along anisotropic LC cues; their mechanical properties and biodegradation profile were tailored to mimic soft neural tissue [82].

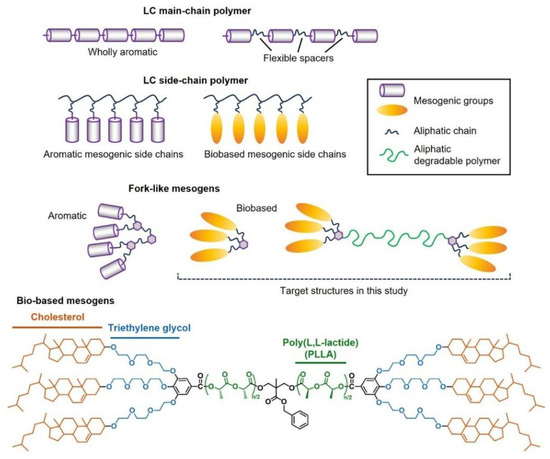

Expanding beyond specific scaffold systems, the broader family of LC polymers offers valuable architectural insights for biomedical LCBCP design. In 2025, as illustrated in Figure 5 of the work by Gong et al. [84], LCPs encompass diverse architectures, wholly aromatic main-chain systems, aromatic/aliphatic multiblock copolymers, and thermotropic side-chain polymers, each exploiting mesogen self-assembly to generate ordered nanostructures with dynamic properties. These structural principles translate directly to LCBCPs designed for biomedical use, where careful placement of mesogenic units within main-chain, multiblock, or side-chain segments allows simultaneous control over mechanical performance, optical response, and surface interactions. For example, introducing aromatic mesogens into the block architecture can provide mechanical anisotropy for load-bearing tissue scaffolds, while sidechain mesogens in amphiphilic LCBCPs enable stimuli-responsive drug release. Similarly, multiblock LCBCPs combining rigid mesogenic domains with soft biodegradable segments can produce elastomeric, bioadaptable materials that guide cell alignment and dynamically adapt to their environment [84].

Figure 5.

Molecular design for liquid-crystalline (LC) poly(L,L-lactide) derivatives in comparison with those of the conventional and previous LC polymers (reproduced with permission from Ref. [84]).

In addition to structural scaffolds, LCBCPs have shown remarkable promise in biosensing technologies. In the realm of biosensing, Omer et al. [85] developed a liquid crystal-based biosensor incorporating a block copolymer. The system creates a monolayer at the interface between a nematic LC and water, transferred via a Langmuir–Blodgett process. When exposed to positively charged proteins below their isoelectric points, the electrostatic interaction at the interface induces a change in the LC orientation, from homeotropic (molecules perpendicular to the surface) to planar, visible under polarized optical microscopy. Detection sensitivities ranged from 0.02 to 0.08 wt% for biomarkers such as hemoglobin and chymotrypsinogen [85].

Similarly, the drug delivery field has benefited from the unique structural versatility of LCBCPs. As shown in Figure 5, Jia et al. [86] developed cholesterol-containing LCBCPs with reduction-cleavable disulfide linkages that co-assembled with croconaine into photothermal–chemo co-micelles. These nanocarriers achieved NIR-triggered heating, glutathione-responsive doxorubicin release, real-time fluorescence/photothermal imaging, and significant tumor suppression in mice, demonstrating how LC order combined with block architecture enhances loading density, stability, and stimulus-responsiveness.

Light-responsive LCBCPs have further expanded biomedical functionality by enabling non-invasive, reversible control over nanostructure and release function. This concept was extended by Wen et al. [87] that reported the synthesis of photo-responsive azobenzene-containing LCBCPs, PDMAEMA-b-PMAAz, via polymerization-induced hierarchical self-assembly (PIHSA) using RAFT dispersion polymerization. The process yielded nanoparticles with well-defined internal liquid crystalline ordering and diverse morphologies, including spheres, worms, and fibers, determined by block composition and assembly conditions. The azobenzene mesogens within the LC block enabled reversible, light-induced morphological transitions through trans–cis isomerization under alternating UV and visible light [87].

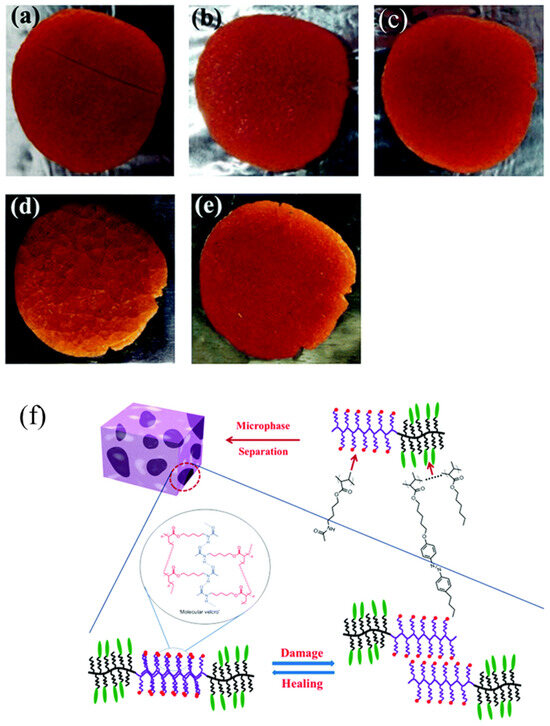

Complementing these functional nanocarriers, dynamic and adaptive LCBCP-based materials have been developed for tissue engineering. Yan et al. [88] developed supramolecular LC elastomers (LCEs) from block copolymers combining a side-chain LC polymer with hydrogen-bonding soft segments. The hydrogen bonds enable autonomous self-healing at room temperature (see Figure 6), while the LC phase enhances mechanical robustness and structural order, highlighting the potential for dynamic, self-repairing biomaterials in tissue engineering.

Figure 6.

Self-healing test of BCP-3: (a) cut at room temperature; (b) warming at 50 °C for 30 min; (c) warming at 50 °C for 60 min; (d) brittle fracture in liquid nitrogen; (e) warming at 50 °C for 3 h. (f) The aggregation morphology and the self-healing process of the BCPs. The figure was reproduced with permission from Ref. [88].

Together, these examples illustrate how mesophase ordering within microphase-separated domains can be strategically harnessed to guide cell alignment, regulate drug encapsulation and stimulus-triggered release, and integrate diagnostic and therapeutic capabilities within a single, multifunctional biomedical platform.

2.4. Energy Storage and Ion Transport

While initially studied in biomedical systems, attention has also turned to electronic systems, in which the ordered morphologies and dynamic responsiveness of LCBCPs can also be exploited in energy-related applications, with precise molecular organization playing a pivotal role in charge and ion transport. Recent advances in polymers have significantly enhanced molecular solar thermal fuels by improving energy storage capacity, half-life, and spectral absorption through strategies like molecular design and template self-assembly. These advances—spanning composites, linear, dendrimer, and hybrid polymer architectures—underscore LCBCPs as capable candidates for efficient, stimuli-responsive solar thermal energy materials. Their self-assembled nanostructure enhances charge transport, while their flexibility supports applications in wearable and foldable devices [89,90].

A key advantage of LCBCPs in this domain lies in their ability to combine anisotropic mesogen ordering with microphase-separated nanodomains to create efficient transport pathways. The anisotropic ordering of mesogenic units in LCBCPs, combined with their microphase-separated nanodomains, generates continuous, well-defined channels for directional ion transport. In smectic or columnar phases, aligned mesogenic segments form one-dimensional ion-conductive pathways, while flexible blocks provide mechanical stability and electrolyte compatibility. Such architectures have shown enhanced performance in lithium-ion batteries, solid-state electrolytes, and supercapacitors, where anisotropic ionic conductivities surpass those of amorphous polymers [90].

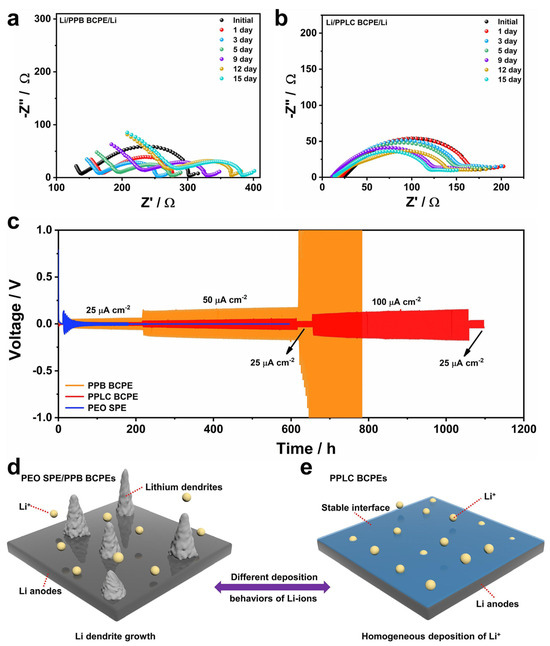

Recent material innovations demonstrate how targeted molecular design can further boost electrochemical performance. For instance, Zeng et al. [91] developed a boron-containing LC-multiblock copolymer electrolyte PPB-BCPE in which aligned LC domains form continuous Li+ channels, while electron-deficient boron atoms immobilize TFSI− anions to enhance ion transport. Figure 7 shows that Li/PPLC-BCPE/Li cells exhibit low, stable interfacial resistance during storage at 60 °C, unlike PPB BCPEs with irregular resistance due to poor electrode contact. In stripping/plating tests, PPLC-BCPE cells cycle for >1000 h at 25–100 µA·cm−2 with low overpotentials, whereas PEO and PPB BCPEs fail due to dendrite growth. SEM confirms smooth, dendrite-free Li surfaces for PPLC-BCPEs, highlighting how LC ordering and boron chemistry synergistically stabilize interfaces and suppress dendrites in solid-state batteries [91].

Figure 7.

(a) The changes of interface impedance of the Li/PPB BCPEs/Li symmetrical batteries for different aging times at 60 °C. (b) The interface impedance of the Li/PPLC BCPEs/Li symmetrical batteries with the change of storage time at 60 °C. (c) Voltage profiles of Li/PPB BCPEs/Li, Li/PPLC BCPEs/Li, and Li/PEO SPE/Li symmetrical batteries during galvanostatic lithium stripping/plating experiments at different current densities of 25, 50, and 100 µA·cm−2. (d,e) Schematic illustration of the contrasting Li+ deposition behaviors in Li/PEO SPE/Li, Li/PPB BCPEs/Li (d), and Li/PPLC BCPEs/Li (e) batteries. The figure was reproduced with permission from Ref. [91].

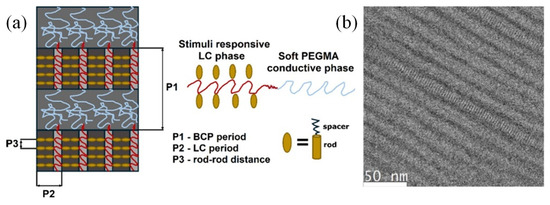

Processing strategies have also proven critical for optimizing ionic conductivity in LCBCP electrolytes. Gohy et al. [92] demonstrated that the synthesis of MALC-b-(EGMA-co-GM) enabled the formation of a smectic mesophase over a wide temperature range, both with and without lithium salt (see Figure 8). Their work highlighted that applying electric fields during solvent casting significantly improved the ionic conductivity of the resulting polymer electrolytes, achieving conductivities nearly an order of magnitude higher than films cast without an electric field, due to enhanced phase separation and longer-range ordering. Furthermore, they observed that DC electric fields promoted larger grain sizes and more extensive ordering compared to AC fields and that the smectic layers oriented perpendicularly to the applied field, a phenomenon attributed to dielectric contrast effects between the block copolymer components rather than the liquid crystalline mesogens themselves. These findings provide valuable insights into the design of block copolymer electrolytes with tailored morphologies for efficient lithium-ion transport [92].

Figure 8.

Hierarchical morphology of LC-containing BCPs and BCPEs: (a) scheme depicting the proposed structure, where LCs anchor homogeneously with respect to the BCP inter-material dividing surface, resulting in the perpendicular orientation of the smectic layer; (b) TEM micrograph depicting the lam-in-LAM microstructure of S1-Salt/DC with an LC layer spacing P2 of 3 nm. The figure was reproduced with permission from Ref. [92].

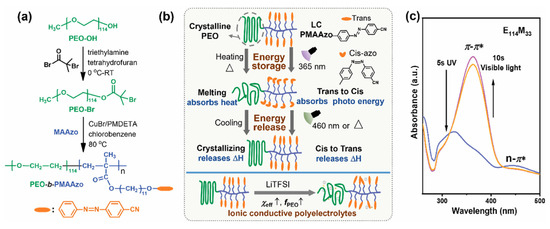

Beyond purely ionic systems, LCBCPs can integrate multiple energy storage mechanisms within a single material platform. Figure 9 shows that Sun et al. [93] synthesized a series of biphasic, phase-change azobenzene LCBCPs (PEO-b-PMAAzo) with remarkable energy storage capabilities. In this system, the PEO block stores energy via crystallization–melting transitions, while the azobenzene-containing PMAAzo block enables solar–chemical–thermal energy conversion through reversible conformational changes. Coordination of Li+ ions with both the PEO backbone and azobenzene units further facilitates biphasic ion conduction. By tuning block composition, applying UV irradiation, and varying lithium salt concentration, they achieved precise control over thermal behavior and self-assembly, generating thermally stable nanostructures (LAM, GYR, Fddd, HEX, and HPL) that are particularly advantageous for ion transport in electrochemical devices [93].

Figure 9.

(a) Synthesis route of PEO-b-PMAAzo block copolymers. (b) Schematic illustration of the energy and release process during the melting-crystallization of PEO and the photoisomerization of the Azo group under 365 nm UV light and 460 nm visible light irradiation, as well as the lithium salt solvation in the BCPs, which induce increases in χ and fPEO values and enable ionic conductivity. (c) UV–Vis spectra of E114M33 in solutions measured before and after 365 nm UV light irradiation for 5 s and then after 460 nm visible light irradiation for 10s. The figure was reproduced with permission from Ref. [93].

2.5. Stimuli-Responsive LCBCPs

LCBCPs can be designed to undergo stimuli-responsive changes, such as altering wettability, adhesion, or optical properties, triggered by external cues like light, temperature, electric or magnetic fields, and solvent exposure. This responsiveness enables applications across anti-fouling surfaces, self-cleaning coatings, and adaptive optical films for microfluidic or smart window technologies. For example, azobenzene-containing LCBCPs have been shown to undergo photo-induced reconfiguration of nanoscale morphology, such as from hemimicelles to chain-like structures upon UV exposure, demonstrating how light can precisely tune surface or film properties [94].

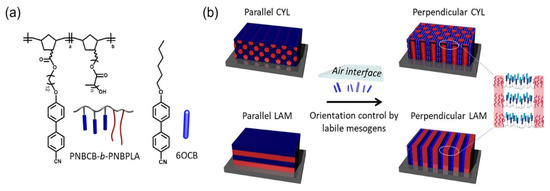

In addition to light-driven surface modulation, mesogen anchoring effects can be exploited to control microdomain orientation in thin films. Osuji et al. [95] investigated how the morphology of LCBCP thin films was controlled by the anchoring behavior of free, non-bonded (labile) mesogens at the film’s surface (see Figure 10). They found that adding mesogens induced a change in the orientation of LCBCP domains (cylinders or lamellae) from parallel to perpendicular relative to the film surface. This occurred because the labile mesogens adopted homeotropic (perpendicular) anchoring at the air interface, which, combined with homogeneous anchoring at the internal BCP interfaces, led to the perpendicular alignment of the BCP superstructure. Moreover, by systematically varying mesogen concentration, film thickness, and annealing conditions, they showed that the labile mesogens co-assembled with backbone-bound mesogens and influenced film morphology. They also demonstrated the formation of perpendicular BCP structures on topographically patterned substrates. Their work highlighted the importance of mesogen anchoring and steric constraints in controlling LCBCP film morphology and proposed design principles for mesogenic additives to engineer such morphologies [95].

Figure 10.

(a) Chemical structures of PNBCB-b-PNBPLA and 6OCB. (b) Schematic illustration for orientation control of CYL and LAM structures by labile mesogen addition. The labile mesogens adopt planar or homogeneous anchoring at the IMDS. The figure was reproduced with permission from Ref. [95].

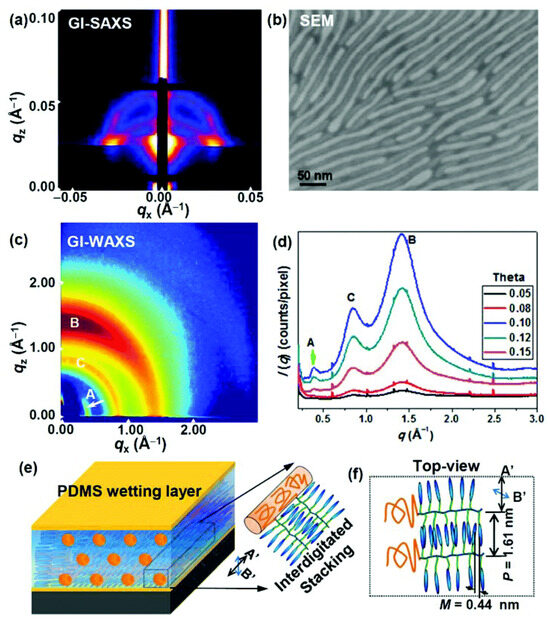

Temperature-dependent order–order transitions present another powerful mechanism for dynamic structure control. Liao et al. [96] investigated a high-interaction-parameter, silicon-containing side-chain LCBCP, PDMS-b-P(4CNB11C)MA (poly(dimethylsiloxane)-block-poly(4-cyanobiphenyl-based LC methacrylate)), with a PDMS volume fraction of ~27%. In bulk, the BCP self-assembled into sub-20 nm hexagonally packed (HEX) PDMS cylinders within a smectic LC matrix (smectic layer period: ~1.61 nm). Notably, the HEX structure persisted even after the LC block transitioned to isotropic (~120 °C). As Figure 11, in 140 nm thin films, PDMS cylinders lay parallel to the substrate; upon heating to ~160 °C, an order-to-order transition occurred, transforming the morphology from HEX cylinders to body-centered cubic (BCC) spheres. This dynamic behavior was captured in real time using in situ GISAXS (Grazing-Incidence Small-Angle X-ray Scattering) and GIWAXS (Grazing-Incidence Wide-Angle X-ray Scattering), both performed at National Synchrotron Light Source II at Brookhaven National Laboratory, and ex situ SEM and AFM elucidated the transient pathway between structures. GI-WAXS analysis revealed a sharp reflection from the smectic layer spacing and a broad arc from π–π mesogen stacking. These features persisted up to ~120 °C, indicating stable LC order even into the isotropic phase, but weakened near 160 °C, coinciding with the HEX → BCC morphology transition [96].

Figure 11.

(a) GISAXS pattern with an incident angle of 0.15° of the 140 nm thick BCP film after annealing at 120 °C; (b) a representative SEM image of oxidized PDMS cylindrical nanopatterns formed in the thin film; (c) 2D GIWAXS pattern with an incident angle of 0.15°; (d) the 1D GIWAXS profiles with an incident angle from 0.05° to 0.15°; (e,f) schematic illustrations of the in-plane cylinder with LC mesogens in a smectic LC phase, where the mesogen π–π interaction direction is perpendicular to the smectic layer direction. The figure was reproduced with permission from Ref. [96].

Coupling phase transitions with external fields can further amplify microdomain alignment. Gopinadhan et al. [97] demonstrated that LCBCPs undergoing a nematic-to-smectic-A (N→SmA) transition exhibit a dramatic increase in microdomain alignment when cooled under an applied magnetic field. While the nematic phase yielded weak alignment, entering the smectic-A phase triggered a strong orientational coupling between LC layering and block copolymer microdomains, yielding tightly aligned nanostructured arrays. In situ SAXS/WAXS during magnetic-field-assisted cooling of LCBCPs showed weak microdomain alignment in the nematic phase, but a sharp increase at the N–SmA transition. WAXS detected the onset of smectic layering, revealing strong coupling between LC translational order and block copolymer microdomain orientation. This finding underscores the potential of harnessing LC phase transitions for field-directed thermal-induced LCBCPs [97].

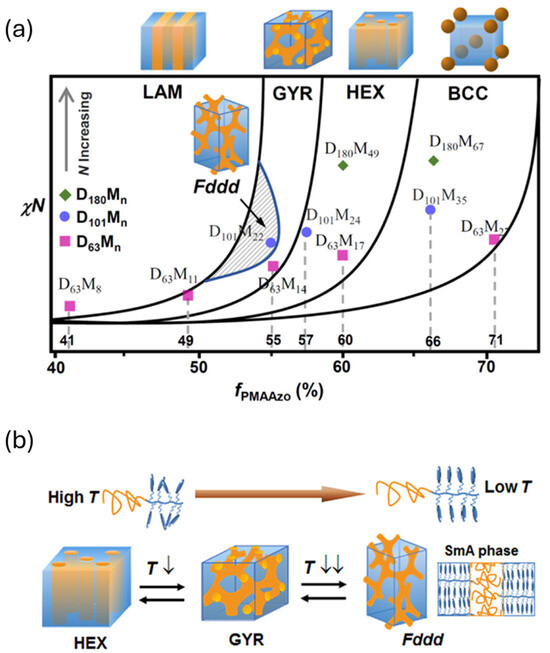

Stimuli-responsiveness can also be combined with complex network morphologies to achieve multifunctional materials. Weng et al. [52] synthesized silicon-containing PDMS-b-PMAAzo LCBCPs and examined their thermally induced structure-in-structure phase transitions and thin-film assembly. Varying the PMAAzo content yielded bulk morphologies including LAM, GYR, Fddd, HEX, and BCC (referred to as lamellar, gyroid, orthorhombic, hexagonal-cylinder, and body-centered cubic phases, respectively) after annealing at 150 °C, with LC phase behavior favoring the Fddd orthorhombic network. These LCBCPs combine morphology tunability, network structure formation, and thermos/photo-induced orientation switching (see Figure 12).

Figure 12.

(a) Schematic illustration of the phase diagram, χN vs. fPMAAzo, of the PDMS-b-PMAAzo BCPs with different total molecular weights. (b) Schematic illustration of the HEX-to-GYR-to-Fddd transition as well as the LC phase transition of the PMAAzo blocks. The figure was reproduced with permission from Ref. [52].

Surface-engineered LCBCPs represent an additional frontier for adaptive materials. In 2025, Feng et al. [98] reported a hierarchically structured, photo-responsive azo-copolymer coating inspired by natural superwetting surfaces. The terpolymer integrates azobenzene mesogens for light-triggered molecular reorientation, catechol groups for strong substrate adhesion, and fluorinated segments for low surface energy. Dip-coating onto a micro/nanostructured copper mesh produced a surface capable of reversible wettability switching between superhydrophobic and super-hydrophilic states under UV/visible light, driven by azobenzene trans–cis isomerization within the LC domains. The hierarchical surface structure amplified this effect, enabling robust, repeatable transitions even under abrasive and chemically harsh conditions. This study exemplifies how LC polymer architectures with multifunctional components can be engineered for adaptive, durable interfaces, offering clear design parallels for future LCBCP-based smart coatings and microfluidic devices.

2.6. Soft Robotic Systems

Soft robotic systems represent an emerging application area where LCBCPs hold unique promise. Soft robots offer promising potential for minimally invasive medical procedures but face significant challenges in fabrication, power, and navigation [99,100,101,102,103,104,105,106,107,108,109]. Despite their similarities to biological materials, LCBCPs remain an underexplored resource for designing these types of soft robots [50,110]. Moreover, soft robotics could be considered a subset of stimuli-responsive materials, since actuation and motion rely on controlled structural changes triggered by external cues such as heat, light, or electric/magnetic fields. However, this review discusses soft robotics in a dedicated section to emphasize the unique potential of LCBCPs in creating programmable, adaptive actuators that combine nanoscale ordering with macroscopic deformation. LCBCPs offer hierarchical control that enables fine-tuning of mechanical anisotropy, responsiveness speed, and actuation amplitude.

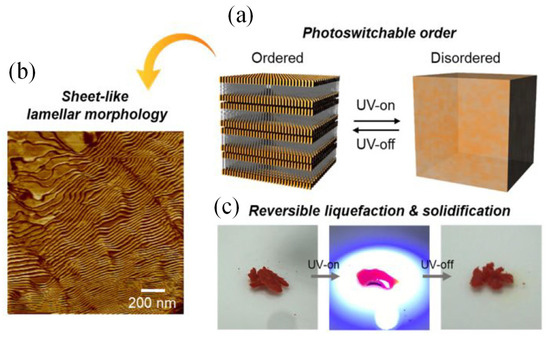

Recent work has shown how molecular design parameters can directly influence actuation kinetics and structural transitions. Lee et al. [57], in their recent study, developed Azo-based LCBCPs with rapid photo-switchable ordering transitions, revealing how end groups and carbon spacers influence self-assembly and switching kinetics. End groups and spacers modulate liquid-crystalline interactions, with a 12-carbon spacer enabling structure-in-structure organization (see Figure 13). All LCBCPs showed ordering and disordering within seconds, reordering at room temperature without heating or visible light, driven by strong electron-withdrawing groups (NO2, CN) and LC mesophase cooperativity. Rich polymorphism emerged, depending on illumination and thermal history, reflecting mesogen packing flexibility and triblock loop/bridge conformations [57].

Figure 13.

(a) AFM phase images of NO2-Azo12-ODMS. (b) Schematic illustration on the photo-switchable order. (c) Photographs showing switchable liquefaction and solidification. The figure was reproduced with permission from Ref. [57].

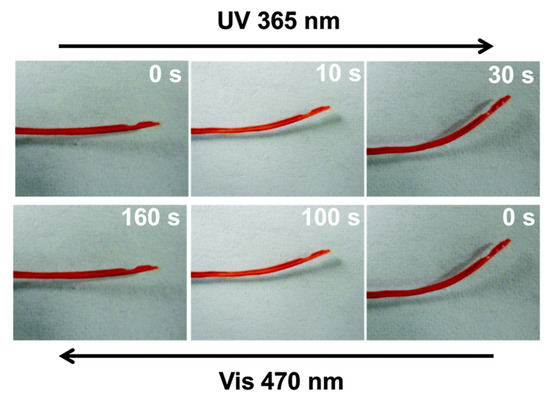

Building on such photomechanical responses, LCBCPs have been integrated into mechanically robust, yet highly responsive actuator films. A representative example of LCBCPs applied in soft actuation was reported by Lv et al. [111], see Figure 14, who synthesized a reactive liquid crystalline block copolymer composed of polyethylene oxide (PEO) and an azobenzene-containing polymethacrylate block (PEO-b-PAZO). The material exhibited well-defined microphase separation with a lamellar morphology, combining the ion-conducting properties of PEO with the photo-responsive anisotropic ordering of the azobenzene mesogens. Light crosslinking preserved both LC alignment and block copolymer nanostructure, enabling mechanically robust, yet responsive films. Upon UV irradiation, trans–cis photoisomerization of azobenzene disrupted mesogen packing, inducing rapid and reversible bending, while visible light restored the original shape [111].

Figure 14.

Images of photoinduced bending and unbending of the CLCP fiber upon irradiation with UV light and visible light (reproduced with permission from Ref. [111]).

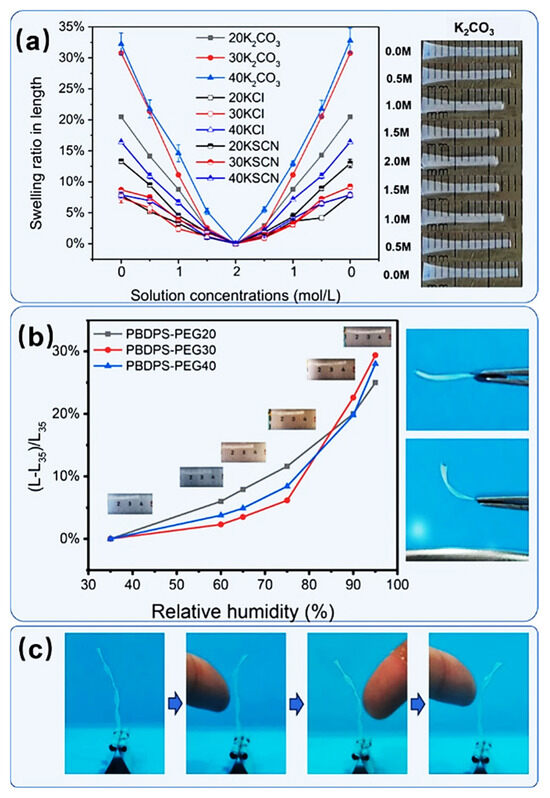

Another exciting advancement in LCBCP-based soft actuators comes from Wang et al. [48] in 2025, where they developed stress-free, two-way shape memory copolymer actuators that leverage the synergistic properties of liquid crystalline and semicrystalline domains. Their system, designed as a block copolymer with an LC domain fused to a semicrystalline segment, demonstrates reversible, bidirectional actuation across multiple stimuli (e.g., heat, light, or chemical triggers), without requiring external mechanical bias (see Figure 15). By harnessing distinct thermal transitions in both domains, the material achieves robust shape programming and autonomous movement, effectively advancing LCBCP design toward multi-stimuli-responsive soft robotics that combine precision, resilience, and adaptability [48].

Figure 15.

(a) Anisotropic swelling and deswelling of the PBDPS–PEG hydrogel actuators in salt solutions of varying concentrations; and photographs showing reversible shape changes triggered by different concentrations of K2CO3 solution. (b) Shape change ratio along the length of the PBDPS–PEG30 actuator at different relative humidity levels; (right) PBDPS–PEG30 actuator demonstrating a bending shape change when exposed to a bottle of water. (c) PBDPS–PEG30 actuator demonstrating a bending shape change triggered by proximity to a wet finger. The figure was reproduced with permission from Ref. [48].

2.7. Additive Manufacturing Technologies

Additive manufacturing (AM) technologies represent another rapidly growing application area where liquid crystalline block copolymers (LCBCPs) can play a transformative role. AM has revolutionized modern industries by enabling the creation of complex computer-designed geometries. However, 3D-printed polymer parts often suffer from poor mechanical properties, limiting their applications. Some studies have tackled this issue by incorporating LCBCP into 3D printing.

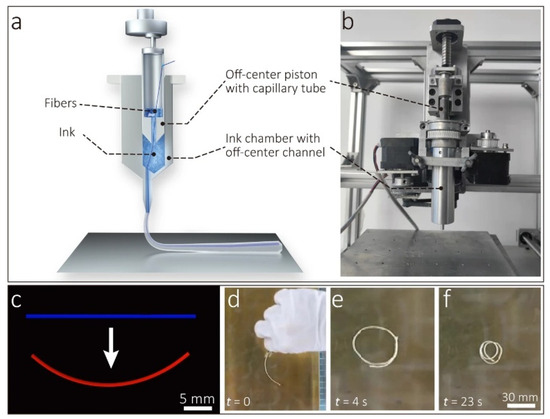

At the intersection of AM and soft robotics, recent work has demonstrated how LC-based structural design can be printed with programmable anisotropy and high strength. As shown in Figure 16, Wang et al. [112] developed a direct ink-writing 4D printing strategy for fabricating freestanding composites composed of continuous fiber-reinforced LC elastomers. By precisely controlling the off-center alignment of reinforcing fibers within the LC elastomer matrix, they achieved programmable, anisotropic deformation coupled with exceptional mechanical robustness. The printed actuators exhibited load-bearing capacities up to 2805 times their own weight and high-curvature bending when heated to 150 °C. This integration of microscale LC domain orientation with macroscale structural design offers a scalable pathway toward durable, reconfigurable, and high-performance soft robotic components for applications requiring both adaptability and mechanical strength [112].

Figure 16.

(a,b) Schematic of the equipment and simulation analysis of the thermal deformation effect of the LCE composite. (c) Simulation analysis of the thermal deformation effect of the LCE composite. (d–f) The deformation states of a filament at an ambient temperature of 150 °C and t = 0 s, 4 s, and 23 s. The figure was reproduced with permission from Ref. [112].

3. Challenges, Limitations and Future Directions

Despite their versatility, LCBCPs face persistent challenges in scalability, cost, and precise phase control. Synthesizing high-molecular-weight LCBCPs with consistent mesogenic alignment is inherently complex, and large-scale production remains expensive. Stability under varying environmental conditions, such as temperature, humidity, and mechanical stress, must be ensured for reliable real-world performance. Device integration poses another hurdle, as LCBCPs must be compatible with existing manufacturing workflows without losing their hierarchical ordering or stimuli-responsiveness [113,114,115,116].

Addressing these limitations will require coordinated advances in synthesis, processing, and material design. Future research should prioritize scalable synthesis strategies, such as cost-effective controlled polymerizations, improved mesogen alignment methods, and post-processing protocols that preserve phase order. Computational modeling offers a powerful tool to predict LCBCP phase behavior and optimize molecular designs before synthesis. Hybrid composites, combining LCBCPs with nanoparticles, conductive fillers, or bio-derived components, could further expand their utility in electronics, energy storage, and biomedical systems.

One particularly underexplored area is the integration of LCBCPs into advanced additive manufacturing workflows. Despite the extensive exploration of AM with liquid crystalline polymers and elastomers [117,118,119,120,121,122,123], the direct integration of LCBCPs into 3D printing platforms remains virtually unexplored. Given their intrinsic hierarchical self-assembly, anisotropic ordering, and stimuli-responsive properties, LCBCPs hold exceptional promise for fabricating complex architectures with programmable mechanical, optical, and actuation functions. Incorporating LCBCPs into advanced AM techniques represents a fertile and largely untapped research area where material design, processing optimization, and structural programming could converge to unlock new capabilities in printed functional materials.

Designing covalent LC architectures could further enhance structural stability during printing and end-use performance. Building on this approach, future research in 3D printing could replace the physically blended small-molecule LC (5CB) in PR-5CB systems [119] with covalently bound LC segments, such as in LC-containing block copolymers or LC side-chain polymers. In particular, LC semicrystalline block copolymers could offer a synergistic combination of properties: the semicrystalline block providing stiffness, thermal stability, and shape retention, while the LC block imparts anisotropic ordering and stimuli-responsiveness. This covalent architecture would prevent phase separation, ensure stable LC alignment during printing, and enable the design of printed parts with long-term structural integrity, tunable mechanical anisotropy, and programmable functional responses.

Inspiration from bio-inspired design strategies offers another promising pathway. Incorporating bioinspired hierarchical design and 3D printing strategies, as demonstrated in recent composite organo-hydrogels [124], could enable LCBCPs with enhanced mechanical robustness and customizable architectures for advanced photonic, biomedical, and soft robotic applications.

Concepts from supramolecular actuator design may also be translated into LCBCP platforms. Yu et al. [125] fabricated a photo-responsive mechanical actuator through intermolecular hydrogen−bond interactions. In this supramolecular network, UV light triggers trans–cis photoisomerization of the azobenzene moieties, generating rapid and reversible bending motions. The actuator demonstrated impressive mechanical performance, capable of lifting loads up to 200 times its own mass, highlighting the efficiency of light-to-mechanical energy conversion in H-bonded architectures. Although this system is not a block copolymer, the design concept readily translates to LCBCPs: embedding azobenzene mesogens in one block and engineering complementary H-bond donor/acceptor groups in the other could yield fully BCP-based, light-driven actuators with tunable mechanical anisotropy, rapid response, and high actuation force, traits ideal for untethered soft robotic devices.

Overcoming characterization barriers is equally critical for advancing LCBCP research and other complex materials [126,127,128,129]. Characterizing the internal structure and chain behavior of LCBCP cylindrical micelles is notoriously difficult. Traditional techniques such as TEM, SAXS, and DSC can reveal morphology, phase transitions, and thermal behavior, but they often require complex sample preparation, provide indirect information about molecular packing and may not capture subtle chain conformational changes within the micelle core and corona. Furthermore, detecting structural parameters like the critical micellization concentration (CMC) and LC phase transitions inside micellar cores with high accuracy remains a significant barrier, especially for systems where the LC domain’s ordering strongly influences functionality [42].

Innovative in situ and non-invasive techniques can help overcome these obstacles. In 2025, He et al. [130] addressed these limitations by incorporating aggregation-induced emission (AIE) moieties into carefully designed LCBCPs. The AIE effect, where fluorescence intensifies upon aggregation, enabled direct, sensitive, and non-invasive monitoring of micelle formation and internal ordering. By positioning the AIE unit in either the LC core-forming block or the corona-forming block, they could selectively probe different micellar regions. This approach allowed accurate determination of CMC and core LC phase transition temperatures and real-time monitoring of self-assembly without disruptive sample handling.

Although LCBCPs are still at an early research stage, their unique properties suggest strong potential for future industrial translation. Unlike conventional LCPs, which are already commercialized in fiber and engineering plastics (such as Vectra), LCBCPs have not yet reached the market. Bridging this gap will require advances in scalable synthesis, processing, and application-driven design. We anticipate that the coming decade will see LCBCPs moving closer to practical use, with opportunities in many diverse applications.

4. Conclusions

Liquid crystalline block copolymers (LCBCPs) uniquely integrate microphase separation with mesogen-directed anisotropy, enabling hierarchical ordering across multiple length scales. This structural duality underpins their demonstrated utility in nanofabrication, photonics, biomedicine, energy storage, adaptive interfaces, soft robotics, and additive manufacturing. Recent advances highlight the power of molecular precision via tailored mesogen chemistry, blocks architecture, and processing pathways, to program coupled optical, mechanical, and stimuli-responsive functions. However, translating these laboratory successes into scalable, device-ready technologies remains constrained by challenges in high-molecular weight synthesis, mesogen alignment control, environmental stability, and manufacturing integration. Addressing these bottlenecks through synergistic advances in covalent LC architectures, bio-inspired structural motifs, computationally guided design, and high-resolution AM could unlock LCBCPs as a foundational materials platform for multifunctional, reconfigurable systems that bridge molecular order with macroscopic function.

Author Contributions

M.S. conceptualized the review outline and coordinated the writing process. M.S. conducted the literature search and organized the structure. J.A.W.H. reviewed and edited the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external fundings.

Data Availability Statement

No new data were created or analyzed in this study. The GA and Scheme 1 are plotted by Authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Goodby, J.W.; Collings, P.J.; Kato, T.; Tschierske, C.; Gleeson, H.; Raynes, P.; Vill, V. Handbook of Liquid Crystals, 8 Volume Set; John Wiley & Sons: New York, NY, USA, 2014; Volume 1, ISBN 3527327738. [Google Scholar]

- Khoo, I.-C. Liquid Crystals; John Wiley & Sons: New York, NY, USA, 2022; ISBN 1119705797. [Google Scholar]

- Pershan, P.S. Structure of Liquid Crystal Phases; World Scientific: Singapore, 1988; Volume 23, ISBN 9971507056. [Google Scholar]

- Priestly, E. Introduction to Liquid Crystals; Springer Science & Business Media: New York, NY, USA, 2012; ISBN 1468421751. [Google Scholar]

- Blinov, L.M. Structure and Properties of Liquid Crystals; Springer Science & Business Media: New York, NY, USA, 2010; Volume 123, ISBN 9789048188284. [Google Scholar]

- Shibaev, V. Liquid-crystalline polymer systems: From the past to the present. Polym. Sci. Ser. A 2014, 56, 727–762. [Google Scholar] [CrossRef]

- Bisoyi, H.K.; Li, Q. Liquid crystals: Versatile self-organized smart soft materials. Chem. Rev. 2021, 122, 4887–4926. [Google Scholar] [CrossRef] [PubMed]

- Collings, P.J.; Patel, J.S. Handbook of Liquid Crystal Research; Oxford University Press: New York, NY, USA, 1997; ISBN 019508442X. [Google Scholar]

- De Gennes, P.-G.; Prost, J. The Physics of Liquid Crystals; Oxford University Press: New York, NY, USA, 1993; ISBN 0198517858. [Google Scholar]

- Lagerwall, J.P.; Scalia, G. A new era for liquid crystal research: Applications of liquid crystals in soft matter nano-, bio-and microtechnology. Curr. Appl. Phys. 2012, 12, 1387–1412. [Google Scholar] [CrossRef]

- Yang, D.-K.; Wu, S.-T. Fundamentals of Liquid Crystal Devices; John Wiley & Sons: New York, NY, USA, 2014; ISBN 1118752007. [Google Scholar]

- Bahadur, B. Liquid Crystals: Applications and Uses; World Scientific: Singapore, 1990; Volume 1, ISBN 9810229755. [Google Scholar]

- Beeckman, J.; Neyts, K.; Vanbrabant, P.J. Liquid-crystal photonic applications. Opt. Eng. 2011, 50, 081202. [Google Scholar] [CrossRef]

- Donald, A.M.; Windle, A.H.; Hanna, S. Liquid Crystalline Polymers; Cambridge University Press: Cambridge, UK, 2006; ISBN 0521580013. [Google Scholar]

- Ciferri, A. Polymer Liquid Crystals; Elsevier: Amsterdam, The Netherlands, 2012; ISBN 0323152317. [Google Scholar]

- Mucha, M. Polymer as an important component of blends and composites with liquid crystals. Prog. Polym. Sci. 2003, 28, 837–873. [Google Scholar] [CrossRef]

- Noël, C.; Navard, P. Liquid crystal polymers. Prog. Polym. Sci. 1991, 16, 55–110. [Google Scholar] [CrossRef]

- Dobb, M.; McIntyre, J. Properties and Applications of Liquid-Crystalline Main-Chain Polymers; Springer: Berlin/Heidelberg, Germany, 2005; pp. 61–98. ISBN 978-3-540-38816-6. [Google Scholar]

- McArdle, C.B. Side Chain Liquid Crystal Polymers; Springer Science & Business Media: New York, NY, USA, 1990; ISBN 0216925037. [Google Scholar]

- Hsu, C.-S. The application of side-chain liquid-crystalline polymers. Prog. Polym. Sci. 1997, 22, 829–871. [Google Scholar] [CrossRef]

- Xiao, Y.-Y.; Jiang, Z.-C.; Zhao, Y. Liquid crystal polymer-based soft robots. Adv. Intell. Syst. 2020, 2, 2000148. [Google Scholar] [CrossRef]

- Ge, F.; Zhao, Y. Microstructured actuation of liquid crystal polymer networks. Adv. Funct. Mater. 2020, 30, 1901890. [Google Scholar] [CrossRef]

- Rajput, A.; Upma; Shukla, S.K.; Thakur, N.; Debnath, A.; Mangla, B. Advanced Polymeric Materials for Aerospace Applications; Wiley Online Library: Hoboken, NJ, USA, 2022; pp. 117–136. ISBN 9781119905264. [Google Scholar]

- Dyer, W.E.; Kumru, B. Polymers as aerospace structural components: How to reach sustainability? Macromol. Chem. Phys. 2023, 224, 2300186. [Google Scholar] [CrossRef]

- Xu, F.-F.; Qin, J.; Zhong, Y.-W.; Gao, D.; Dong, Y.; Feng, H. Recent Advances in Liquid Crystal Polymer-Based Circularly Polarized Luminescent Materials: A Review. Polymers 2025, 17, 1961. [Google Scholar] [CrossRef]

- Guardia, J.; Reina, J.A.; Giamberini, M.; Montane, X. An up-to-date overview of liquid crystals and liquid crystal polymers for different applications: A review. Polymers 2024, 16, 2293. [Google Scholar] [CrossRef]

- Lv, J.-a.; Liu, Y.; Wei, J.; Chen, E.; Qin, L.; Yu, Y. Photocontrol of fluid slugs in liquid crystal polymer microactuators. Nature 2016, 537, 179–184. [Google Scholar] [CrossRef]

- Hamley, I. Ordering in thin films of block copolymers: Fundamentals to potential applications. Prog. Polym. Sci. 2009, 34, 1161–1210. [Google Scholar] [CrossRef]

- Yang, G.G.; Choi, H.J.; Han, K.H.; Kim, J.H.; Lee, C.W.; Jung, E.I.; Jin, H.M.; Kim, S.O. Block copolymer nanopatterning for nonsemiconductor device applications. ACS Appl. Polym. Mater. 2022, 14, 12011–12037. [Google Scholar] [CrossRef] [PubMed]

- Lang, C.; Lloyd, E.C.; Matuszewski, K.E.; Xu, Y.; Ganesan, V.; Huang, R.; Kumar, M.; Hickey, R.J. Nanostructured block copolymer muscles. Nat. Nanotechnol. 2022, 17, 752–758. [Google Scholar] [CrossRef] [PubMed]

- Karayianni, M.; Pispas, S. Block copolymer solution self-assembly: Recent advances, emerging trends, and applications. J. Polym. Sci. 2021, 59, 1874–1898. [Google Scholar] [CrossRef]

- Cui, H.; Chen, Z.; Zhong, S.; Wooley, K.L.; Pochan, D.J. Block copolymer assembly via kinetic control. Science 2007, 317, 647–650. [Google Scholar] [CrossRef]

- Smart, T.; Lomas, H.; Massignani, M.; Flores-Merino, M.V.; Perez, L.R.; Battaglia, G. Block copolymer nanostructures. Nano Today 2008, 3, 38–46. [Google Scholar] [CrossRef]

- Liao, Y.; Sangroniz, L.; Safari, M.; Schmalz, H.; Müller, A.J. The Decisive Role of Confinement in Enhancing or Suppressing Self-Nucleation in Polyethylene-Containing Block Copolymers. Macromol. Chem. Phys. 2025, 226, e00056. [Google Scholar] [CrossRef]

- Safari, M.; Ocando, C.; Liao, Y.; Drechsler, M.; Volk, N.; Schaller, R.; Held, M.; Abetz, V.; Schmalz, H.; Müller, A.J. Morphology and confinement effects on crystallization kinetics in polyethylene containing block copolymers. Polymer 2024, 298, 126863. [Google Scholar] [CrossRef]

- Schmalz, H.; Abetz, V. Block Copolymers with Crystallizable Blocks: Synthesis, Self-Assembly and Applications. Polymers 2022, 14, 696. [Google Scholar] [CrossRef] [PubMed]

- Park, T.H.; Yu, S.; Park, J.; Park, C. Interactive structural color displays of nano-architectonic 1-dimensional block copolymer photonic crystals. Sci. Tech. Adv. Mater. 2023, 24, 2156256. [Google Scholar] [CrossRef] [PubMed]

- Cummins, C.; Lundy, R.; Walsh, J.J.; Ponsinet, V.; Fleury, G.; Morris, M.A. Enabling future nanomanufacturing through block copolymer self-assembly: A review. Nano Today 2020, 35, 100936. [Google Scholar] [CrossRef]

- Doerk, G.S.; Yager, K.G. Beyond native block copolymer morphologies. Mol. Syst. Des. Eng. 2017, 2, 518–538. [Google Scholar] [CrossRef]

- Xie, H.L.; Li, X.; Ren, J.; Bishop, C.; Arges, C.G.; Nealey, P.F. Controlling domain orientation of liquid crystalline block copolymer in thin films through tuning mesogenic chemical structures. J. Polym. Sci. Part B Polym. Phys. 2017, 55, 532–541. [Google Scholar] [CrossRef]

- Yu, H. Photoresponsive liquid crystalline block copolymers: From photonics to nanotechnology. Prog. Polym. Sci. 2014, 39, 781–815. [Google Scholar] [CrossRef]

- Omenat, A.; Hikmet, R.; Lub, J.; Van der Sluis, P. Synthesis, characterization, and physical properties of new ferroelectric liquid crystalline materials: Block copolymers. Macromolecules 1996, 29, 6730–6736. [Google Scholar] [CrossRef]

- Mahajan, L.H.; Ndaya, D.; Deshmukh, P.; Peng, X.; Gopinadhan, M.; Osuji, C.O.; Kasi, R.M. Optically active elastomers from liquid crystalline comb copolymers with dual physical and chemical cross-links. Macromolecules 2017, 50, 5929–5939. [Google Scholar] [CrossRef]

- Koyra, N.; Yu, H.; Drummond, C.J.; Zhai, J.; Dyett, B. Recent developments with pH-responsive lyotropic liquid crystalline lipid nanoparticles for targeted bioactive agent delivery. Expert Opin. Drug Deliv. 2025, 22, 1303–1324. [Google Scholar] [CrossRef]

- Collyer, A.A. Liquid Crystal Polymers: From Structures to Applications; Springer Science & Business Media: New York, NY, USA, 2012; Volume 1, ISBN 9401118701. [Google Scholar]

- Nickmans, K.; Schenning, A.P. Directed self-assembly of liquid-crystalline molecular building blocks for sub-5 nm nanopatterning. Adv. Mater. 2018, 30, 1703713. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Cheng, X.; Tang, Z.; Wang, Y.; He, Z.; Zhang, W. Construction of liquid-crystalline assemblies with tunable chiroptical properties through tailoring solvophilic chains in polymerization-induced chiral self-assembly. Chem. Commun. 2025, 61, 3880–3883. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ye, S.; Li, S.; Li, Y.; Yang, R. Stress-Free Two-Way Liquid Crystalline–Semicrystalline Shape Memory Copolymer Actuators with Multistimuli-Responsive Actuation Behaviors. Macromolecules 2025, 58, 3439–3449. [Google Scholar] [CrossRef]

- Hu, J.; Yu, M.; Wang, M.; Choy, K.-L.; Yu, H. Design, regulation, and applications of soft actuators based on liquid-crystalline polymers and their composites. ACS Appl. Mater. Interfaces 2022, 14, 12951–12963. [Google Scholar] [CrossRef]

- Schara, S.; Blau, R.; Church, D.C.; Pokorski, J.K.; Lipomi, D.J. Polymer chemistry for haptics, soft robotics, and human–machine interfaces. Adv. Funct. Mater. 2021, 31, 2008375. [Google Scholar] [CrossRef]

- Bagchi, K.; Emeršič, T.; Martínez-González, J.A.; de Pablo, J.J.; Nealey, P.F. Functional soft materials from blue phase liquid crystals. Sci. Adv. 2023, 9, eadh9393. [Google Scholar] [CrossRef]

- Weng, L.; Ma, M.; Yin, C.; Fei, Z.-X.; Yang, K.-K.; Ross, C.A.; Shi, L.-Y. Synthesis and self-assembly of silicon-containing azobenzene liquid crystalline block copolymers. Macromolecules 2023, 56, 470–479. [Google Scholar] [CrossRef]

- Gallot, B. Comb-like and block liquid crystalline polymers for biological applications. Prog. Polym. Sci. 1996, 21, 1035–1088. [Google Scholar] [CrossRef]

- Dong, L.; Chandra, A.; Wylie, K.; Nabae, Y.; Hayakawa, T. Tunable thin film periodicities by controlling the orientation of cylindrical domains in side chain liquid crystalline block copolymers. Int. J. Polym. Sci. 2022, 2022, 8286518. [Google Scholar] [CrossRef]

- Lee, W.; Kumar, S. Unconventional Liquid Crystals and Their Applications; Walter de Gruyter GmbH & Co KG: Berlin, Germany, 2021; ISBN 3110584379. [Google Scholar]

- Mukai, K.; Hara, M.; Nagano, S.; Seki, T. High-Density Liquid-Crystalline Polymer Brushes Formed by Surface Segregation and Self-Assembly. Angew. Chem. Int. Ed. 2016, 55, 14028–14032. [Google Scholar] [CrossRef]

- Lee, C.; Ndaya, D.; Bosire, R.; Kim, N.K.; Kasi, R.M.; Osuji, C.O. Fast photoswitchable order–disorder transitions in liquid-crystalline block co-oligomers. J. Am. Chem. Soc. 2021, 144, 390–399. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Kobayashi, T.; Yang, H. Liquid-crystalline ordering helps block copolymer self-assembly. Adv. Mater. 2011, 23, 3337–3344. [Google Scholar] [CrossRef] [PubMed]

- Cai, F.; Chen, Y.-X.; Wang, W.-Z.; Yu, H.-F. Macroscopic regulation of hierarchical nanostructures in liquid-crystalline block copolymers towards functional materials. Chin. J. Polym. Sci. 2021, 39, 397–416. [Google Scholar] [CrossRef]

- Zhong, H.-Y.; Chen, L.; Liu, X.-F.; Yang, R.; Wang, Y.-Z. Novel liquid crystalline copolyester containing amphi-mesogenic units toward multiple stimuli-response behaviors. J. Mater. Chem. C 2017, 5, 9702–9711. [Google Scholar] [CrossRef]

- Kato, T.; Uchida, J.; Ichikawa, T.; Soberats, B. Functional liquid-crystalline polymers and supramolecular liquid crystals. Polym. J. 2018, 50, 149–166. [Google Scholar] [CrossRef]

- Liu, C.-L.; Lin, C.-H.; Kuo, C.-C.; Lin, S.-T.; Chen, W.-C. Conjugated rod–coil block copolymers: Synthesis, morphology, photophysical properties, and stimuli-responsive applications. Prog. Polym. Sci. 2011, 36, 603–637. [Google Scholar] [CrossRef]

- Tao, L.; Li, M.-L.; Yang, K.-P.; Guan, Y.; Wang, P.; Shen, Z.; Xie, H.-L. Color-tunable and stimulus-responsive luminescent liquid crystalline polymers fabricated by hydrogen bonding. ACS Appl. Polym. Mater. 2019, 11, 15051–15059. [Google Scholar] [CrossRef]

- Vaidya, S.; Sharma, M.; Brückner, C.; Kasi, R.M. Hierarchically Structured Stimuli-Responsive Liquid Crystalline Terpolymer–Rhodamine Dye Conjugates. Molecules 2025, 30, 401. [Google Scholar] [CrossRef]

- Lugger, S.J.; Houben, S.J.; Foelen, Y.; Debije, M.G.; Schenning, A.P.; Mulder, D.J. Hydrogen-bonded supramolecular liquid crystal polymers: Smart materials with stimuli-responsive, self-healing, and recyclable properties. Chem. Rev. 2021, 122, 4946–4975. [Google Scholar] [CrossRef]

- Liu, F.; Urban, M.W. Recent advances and challenges in designing stimuli-responsive polymers. Prog. Polym. Sci. 2010, 35, 3–23. [Google Scholar] [CrossRef]

- Mahajan, L.; Ndaya, D.; Deshmukh, P.; Kasi, R. New Stimuli-Response Liquid Crystalline Polymer Architectures; Springer: Berlin/Heidelberg, Germany, 2020; pp. 479–492. ISBN 978-3-030-43350-5. [Google Scholar]

- Mohd Alauddin, S.; Fadhilah Kamalul Aripin, N.; Selvi Velayutham, T.; Martinez-Felipe, A. Liquid crystalline copolymers containing sulfonic and light-responsive groups: From molecular design to conductivity. Molecules 2020, 25, 2579. [Google Scholar] [CrossRef]

- Lv, Y.; Wang, L.; Wu, F.; Gong, S.; Wei, J.; Lin, S. Self-assembly and stimuli-responsive behaviours of side-chain liquid crystalline copolymers: A dissipative particle dynamics simulation approach. Phys. Chem. Chem. Phys. 2019, 21, 7645–7653. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; Chung, C.; Dunn, M.L.; Yu, K. 4D printing of liquid crystal elastomer composites with continuous fiber reinforcement. Nat. Commun. 2024, 15, 8491. [Google Scholar] [CrossRef] [PubMed]

- Shi, L.-Y.; Lan, J.; Lee, S.; Cheng, L.-C.; Yager, K.G.; Ross, C.A. Vertical lamellae formed by two-step annealing of a rod–coil liquid crystalline block copolymer thin film. ACS Nano 2020, 14, 4289–4297. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Kang, Y.; Kang, D.-G.; Park, H.; Kim, Y.; Osuji, C.O.; Ahn, H.; Lee, C.; Yoon, D.K. Nanoconfinement-induced orientation changes in liquid crystalline block co-oligomers. J. Mater. Chem. C 2025, 13, 17674–17681. [Google Scholar] [CrossRef]

- Zhang, Y.-D.; Ping, J.; Wu, Q.-W.; Pan, H.-B.; Fan, X.-H.; Shen, Z.; Zhou, Q.-F. Bulk self-assembly and ionic conductivity of a block copolymer containing an azobenzene-based liquid crystalline polymer and a poly (ionic liquid). Polym. Chem. 2017, 8, 1689–1698. [Google Scholar] [CrossRef]

- Takahashi, K.; Taguchi, D.; Kajitani, T.; Fukushima, T.; Kubo, S.; Shishido, A. Synthesis and Characterization of Side-Chain Liquid-Crystalline Block Copolymers Containing Cyano-Terminated Phenyl Benzoate Moieties. Molecules 2023, 28, 7849. [Google Scholar] [CrossRef]

- Luo, M.; Jin, B.; Luo, Y.; Li, X. Supramicellar nanofibrils with end-to-end coupled uniform cylindrical micelle subunits via one-step assembly from a liquid crystalline block copolymer. Macromolecules 2021, 54, 6845–6853. [Google Scholar] [CrossRef]

- Sun, Y.; Xu, B.; Li, J.; Wang, Y.; Li, X.; Lin, S. Formation of hierarchical platelets with morphological control by self-assembly of an azobenzene-containing liquid crystalline diblock copolymer. Mater. Chem. Front. 2022, 6, 1615–1622. [Google Scholar] [CrossRef]

- Hebner, T.S.; Bowman, C.N.; White, T.J. The contribution of intermolecular forces to phototropic actuation of liquid crystalline elastomers. Polym. Chem. 2021, 12, 1581–1587. [Google Scholar] [CrossRef]

- Yang, H.; Luo, Y.; Jin, B.; Chi, S.; Li, X. Convoluted micellar morphological transitions driven by tailorable mesogenic ordering effect from discotic mesogen-containing block copolymer. Nat. Commun. 2024, 15, 2968. [Google Scholar] [CrossRef]

- Ji, S.; Zhang, T.; Yuan, X.; Ren, L. Mesogen-jacketed liquid crystal like block copolymers: Synthesis and self-assembly to prepare 1D PC thin films. React. Funct. Polym. 2022, 181, 105452. [Google Scholar] [CrossRef]

- AboElsood, A.G.; Xiang, Y.; Lin, I.-M.; Chen, C.-R.; Chiang, Y.-W. Coincident augmentation and alignment of lamellar stacking structures for rapid fabrication of solid-state polymer photonic crystal films. J. Taiwan Inst. Chem. Eng. 2025, 172, 106107. [Google Scholar] [CrossRef]

- Czubak, B.; Warren, N.J.; Nagaraj, M. Steroid-based liquid crystalline polymers: Responsive and biocompatible materials of the future. Crystals 2022, 12, 1000. [Google Scholar] [CrossRef]

- Prévôt, M.; Andro, H.; Alexander, S.; Ustunel, S.; Zhu, C.; Nikolov, Z.; Rafferty, S.; Brannum, M.; Kinsel, B.; Korley, L. Liquid crystal elastomer foams with elastic properties specifically engineered as biodegradable brain tissue scaffolds. Soft Matter 2018, 14, 354–360. [Google Scholar] [CrossRef]

- Zheng, M.; Yuan, J. Polymeric nanostructures based on azobenzene and their biomedical applications: Synthesis, self-assembly and stimuli-responsiveness. Org. Biomol. Chem. 2022, 20, 749–767. [Google Scholar] [CrossRef]

- Gong, Y.; Tu, S.; Ueki, R.; Fujii, Y.; Yasuda, S.; Sando, S.; Uchida, J.; Fukushima, K.; Kato, T. Liquid-Crystalline Block Copolymers Comprising Cholesterol-Based Dendritic Moieties and Poly (L, L-lactide) Chains. ACS Appl. Polym. Mater. 2025, 7, 1875–1885. [Google Scholar] [CrossRef]

- Omer, M.; Islam, M.T.; Khan, M.; Kim, Y.K.; Lee, J.H.; Kang, I.-K.; Park, S.-Y. Liquid crystal-based biosensors using a strong polyelectrolyte-containing block copolymer, poly (4-cyanobiphenyl-4′-oxyundecylacrylate)-b-poly (sodium styrene sulfonate). Macromol. Res. 2014, 22, 888–894. [Google Scholar] [CrossRef]

- Lu, Y.; Cai, T.; Gao, J.; Ren, Y.; Ding, Y.; Liu, S.; Liu, L.; Huang, H.; Wang, H.; Wang, C. Nanoplatform for synergistic therapy constructed via the co-assembly of a reduction-responsive cholesterol-based block copolymer and a photothermal amphiphile. Mater. Today Bio 2024, 29, 101355. [Google Scholar] [CrossRef]

- Wen, W.; Ouyang, W.; Guan, S.; Chen, A. Synthesis of azobenzene-containing liquid crystalline block copolymer nanoparticles via polymerization induced hierarchical self-assembly. Polym. Chem. 2021, 12, 458–465. [Google Scholar] [CrossRef]

- Yan, M.; Tang, J.; Xie, H.-L.; Ni, B.; Zhang, H.-L.; Chen, E.-Q. Self-healing and phase behavior of liquid crystalline elastomer based on a block copolymer constituted of a side-chain liquid crystalline polymer and a hydrogen bonding block. J. Mater. Chem. C 2015, 3, 8526–8534. [Google Scholar] [CrossRef]

- Xu, X.; Feng, J.; Li, W.-Y.; Wang, G.; Feng, W.; Yu, H. Azobenzene-containing polymer for solar thermal energy storage and release: Advances, challenges, and opportunities. Prog. Polym. Sci. 2024, 149, 101782. [Google Scholar] [CrossRef]

- Liu, S.; Zhou, L.; Zheng, Y.; Neyts, K. Revolutionizing Lithium-Ion Batteries: Exploiting Liquid Crystal Electrolytes. EES Batter. 2025. [Google Scholar] [CrossRef]

- Zeng, Q.; Liu, Y.; Wujieti, B.; Li, Z.; Chen, A.; Guan, J.; Wang, H.; Jiang, Y.; Zhou, H.; Cui, W. Rapid ion conduction enabled by synergism of oriented liquid crystals and Electron-Deficient boron atoms in multiblock copolymer electrolyte for advanced Solid-State Lithium-Ion battery. Chem. Eng. J. 2024, 486, 150298. [Google Scholar] [CrossRef]

- Álvarez Moisés, I.; Król, M.; Keus, G.; He, Z.; Innocenti, A.; Passerini, S.; Ruokolainen, J.; Gohy, J.-F. Enhancement of Lithium-Ion Conductivity in Liquid Crystalline Block Copolymer Electrolyte by Electric Field Alignment. J. Am. Chem. Soc. 2025, 147, 20347–20358. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Z.; Cui, C.; Weng, L.; Yin, C.; Yang, D.; Shi, L.-Y. Self-assembly and energy storage potentials of biphasic phase change azobenzene liquid crystalline block copolymers. Polymer 2024, 312, 127641. [Google Scholar] [CrossRef]

- Wang, J.; Song, T.; Zhang, Y.; Liu, J.; Yu, M.; Yu, H. Light-driven autonomous self-oscillation of a liquid-crystalline polymer bimorph actuator. J. Mater. Chem. C. 2021, 9, 12573–12580. [Google Scholar] [CrossRef]

- Lee, C.; Ndaya, D.; Bosire, R.; Gabinet, U.R.; Sun, J.; Gopalan, P.; Kasi, R.M.; Osuji, C.O. Effects of labile mesogens on the morphology of liquid crystalline block copolymers in thin films. Macromolecules 2021, 54, 3223–3231. [Google Scholar] [CrossRef]

- Liao, F.; Shi, L.-Y.; Cheng, L.-C.; Lee, S.; Ran, R.; Yager, K.G.; Ross, C.A. Self-assembly of a silicon-containing side-chain liquid crystalline block copolymer in bulk and in thin films: Kinetic pathway of a cylinder to sphere transition. Nanoscale 2019, 11, 285–293. [Google Scholar] [CrossRef]

- Gopinadhan, M.; Choo, Y.; Osuji, C.O. Strong orientational coupling of block copolymer microdomains to smectic layering revealed by magnetic field alignment. ACS Macro Lett. 2016, 5, 292–296. [Google Scholar] [CrossRef]

- Feng, B.-L.; Zhai, C.-C.; Zhang, D.-B.; Guo, H.-C.; Zhang, H.-L.; Zhang, L.; Li, H.; Wang, L.; Lei, L.; Zong, C.-Y. Robust photo-responsive superwetting surfaces on hierarchical-structured copper mesh via dip-coating with mussel-inspired azo-copolymer. Chin. J. Polym. Sci. 2025, 43, 1134–1145. [Google Scholar] [CrossRef]

- Wang, J.; Chortos, A. Control strategies for soft robot systems. Adv. Intell. Syst. 2022, 4, 2100165. [Google Scholar] [CrossRef]

- Hu, C.; Pané, S.; Nelson, B.J. Soft micro-and nanorobotics. Annu. Rev. Control Robot. Auton. 2018, 1, 53–75. [Google Scholar] [CrossRef]

- Lee, C.; Kim, M.; Kim, Y.J.; Hong, N.; Ryu, S.; Kim, H.J.; Kim, S. Soft robot review. Int. J. Control Autom. Syst. 2017, 15, 3–15. [Google Scholar] [CrossRef]

- Ng, C.S.X.; Tan, M.W.M.; Xu, C.; Yang, Z.; Lee, P.S.; Lum, G.Z. Locomotion of miniature soft robots. Adv. Mater. 2021, 33, 2003558. [Google Scholar] [CrossRef]

- St. Pierre, R.; Bergbreiter, S. Toward autonomy in sub-gram terrestrial robots. Annu. Rev. Control Robot. Auton. 2019, 2, 231–252. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft robotic grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef]

- Whitesides, G.M. Soft robotics. Angew. Chem. Int. Ed. 2018, 57, 4258–4273. [Google Scholar] [CrossRef]

- Naji, L.; Safari, M.; Moaven, S. Fabrication of SGO/Nafion-based IPMC soft actuators with sea anemone-like Pt electrodes and enhanced actuation performance. Carbon 2016, 100, 243–257. [Google Scholar] [CrossRef]

- Safari, M.; Naji, L.; Baker, R.T.; Afshar Taromi, F. Influence of electrolytes of L i salts, EMIMBF 4, and mixed phases on electrochemical and physical properties of N afion membrane. J. Appl. Polym. Sci. 2017, 134, 45239. [Google Scholar] [CrossRef]

- Safari, M.; Naji, L.; Baker, R.T.; Taromi, F.A. The enhancement effect of lithium ions on actuation performance of ionic liquid-based IPMC soft actuators. Polymer 2015, 76, 140–149. [Google Scholar] [CrossRef]

- Rajabi, N.; Scarfo, M.G.; Fredericks, C.M.; Herrera Restrepo, R.S.; Adibi, A.; Shahsavan, H. From Anisotropic Molecules and Particles to Small-Scale Actuators and Robots: An Account of Polymerized Liquid Crystals. Acc. Mater. Res. 2024, 5, 1520–1531. [Google Scholar] [CrossRef]

- Lv, J.-a.; Wang, W.; Wu, W.; Yu, Y. A reactive azobenzene liquid-crystalline block copolymer as a promising material for practical application of light-driven soft actuators. J. Mater. Chem. C 2015, 3, 6621–6626. [Google Scholar] [CrossRef]

- Wang, Q.; Tian, X.; Zhang, D.; Zhou, Y.; Yan, W.; Li, D. Programmable spatial deformation by controllable off-center freestanding 4D printing of continuous fiber reinforced liquid crystal elastomer composites. Nat. Commun. 2023, 14, 3869. [Google Scholar] [CrossRef] [PubMed]

- Epps, T.H., III; O’Reilly, R.K. Block copolymers: Controlling nanostructure to generate functional materials–synthesis, characterization, and engineering. Chem. Sci. 2016, 7, 1674–1689. [Google Scholar] [CrossRef]

- Lv, F.; An, Z.; Wu, P. Scalable preparation of alternating block copolymer particles with inverse bicontinuous mesophases. Nat. Commun. 2019, 10, 1397. [Google Scholar] [CrossRef]

- Gopinadhan, M.; Majewski, P.W.; Choo, Y.; Osuji, C.O. Order-Disorder Transition and Alignment Dynamics of a Block Copolymer Under High Magnetic Fields by In Situ X-Ray Scattering. Phys. Rev. Lett. 2013, 110, 078301. [Google Scholar] [CrossRef]

- Chang, C.-Y.; Chen, Y.-H.; Ho, R.-M. Metastable network phases from controlled self-assembly of high-χ block copolymers. Phys. Rev. Mater. 2024, 8, 030301. [Google Scholar] [CrossRef]

- Houriet, C.; Claassen, E.; Mascolo, C.; Jöhri, H.; Brieva, A.; Szmolka, S.; Vincent-Bonnieu, S.; Suliga, A.; Heeb, R.; Gantenbein, S. 3D Printing of Liquid Crystal Polymers for Space Applications. Adv. Mater. Technol. 2025, 10, 2400571. [Google Scholar] [CrossRef]

- Johann, K.S.; Wolf, A.; Bonten, C. Mechanical Properties of 3D-Printed Liquid Crystalline Polymers with Low and High Melting Temperatures. Materials 2023, 17, 152. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Chen, S.; Qu, B.; Wang, R.; Zheng, Y.; Liu, X.; Li, W.; Gao, J.; Chen, Q.; Zhuo, D. Light-oriented 3D printing of liquid crystal/photocurable resins and in-situ enhancement of mechanical performance. Nat. Commun. 2023, 14, 6586. [Google Scholar] [CrossRef] [PubMed]

- Chan, C.L.C.; Lei, I.M.; van de Kerkhof, G.T.; Parker, R.M.; Richards, K.D.; Evans, R.C.; Huang, Y.Y.S.; Vignolini, S. 3D printing of liquid crystalline hydroxypropyl cellulose—Toward tunable and sustainable volumetric photonic structures. Adv. Funct. Mater. 2022, 32, 2108566. [Google Scholar] [CrossRef]

- Wang, Z.; Guo, Y.; Cai, S.; Yang, J. Three-dimensional printing of liquid crystal elastomers and their applications. ACS Appl. Polym. Mater. 2022, 4, 3153–3168. [Google Scholar] [CrossRef]

- Choi, W.; Advincula, R.C.; Wu, H.F.; Jiang, Y. Artificial intelligence and machine learning in the design and additive manufacturing of responsive composites. MRS Commun. 2023, 13, 714–724. [Google Scholar] [CrossRef]

- Shimoga, G.; Choi, D.-S.; Kim, S.-Y. Bio-inspired soft robotics: Tunable photo-actuation behavior of azo chromophore containing liquid crystalline elastomers. Appl. Sci. 2021, 11, 1233. [Google Scholar] [CrossRef]

- Liu, Q.; Dong, X.; Qi, H.; Zhang, H.; Li, T.; Zhao, Y.; Li, G.; Zhai, W. 3D printable strong and tough composite organo-hydrogels inspired by natural hierarchical composite design principles. Nat. Commun. 2024, 15, 3237. [Google Scholar] [CrossRef]

- Yu, C.-Y.; Mu, J.-H.; Fu, Y.-L.; Zhang, Y.-C.; Han, J.-S.; Zhao, R.-Y.; Zhao, J.; Wang, Z.-H.; Zhao, Z.-C.; Li, W.-J. Azobenzene based photo-responsive mechanical actuator fabricated by intermolecular H-bond interaction. Chin. J. Polym. Sci. 2021, 39, 417–424. [Google Scholar] [CrossRef]

- Ilyin, S.O. Structural rheology in the development and study of complex polymer materials. Polymers 2024, 16, 2458. [Google Scholar] [CrossRef]

- Schröder, E.; Müller, G.; Arndt, K.-F. Polymer Characterization; Walter de Gruyter GmbH & Co KG: Berlin, Germany, 2022; ISBN 3112470923. [Google Scholar]

- Danielsen, S.P.; Beech, H.K.; Wang, S.; El-Zaatari, B.M.; Wang, X.; Sapir, L.; Ouchi, T.; Wang, Z.; Johnson, P.N.; Hu, Y. Molecular characterization of polymer networks. Chem. Rev. 2021, 121, 5042–5092. [Google Scholar] [CrossRef]