Use of Artificial Neural Networks for Recycled Pellets Identification: Polypropylene-Based Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Analytical Equipment and Measurements

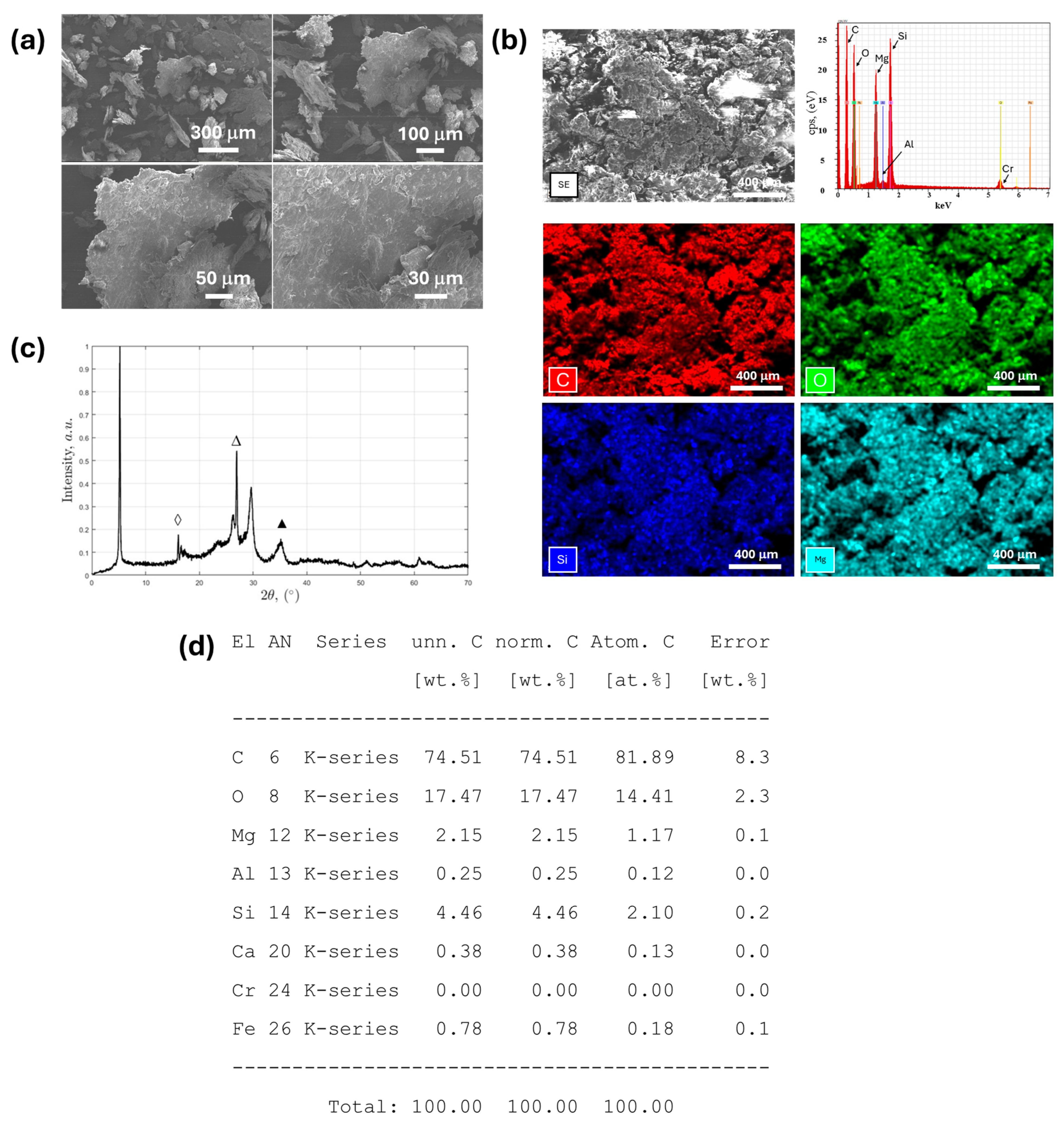

2.3. Physicochemical Characterization of Commercial Samples

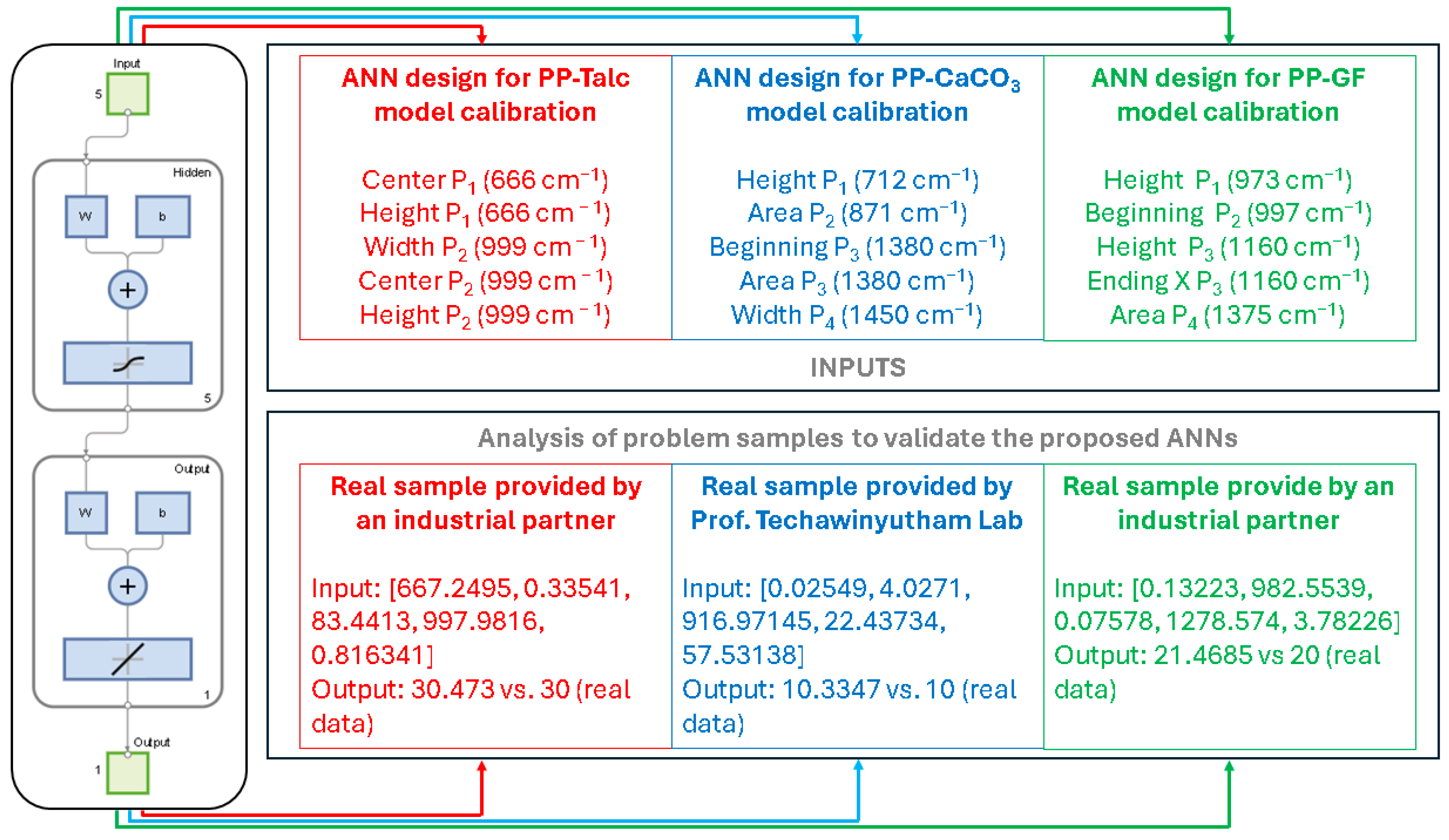

2.4. Artificial Neural Network Approach

3. Results and Discussion

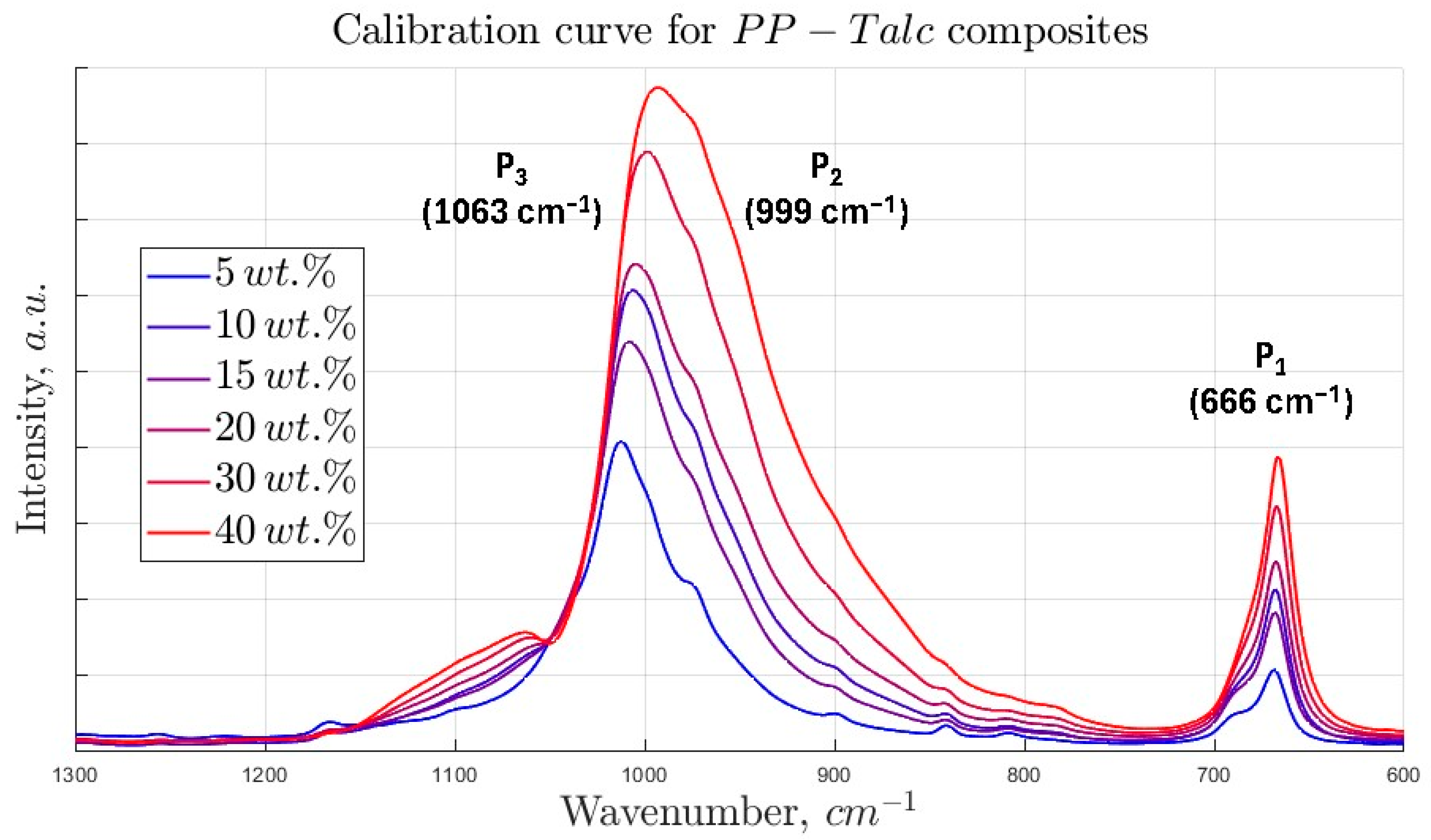

3.1. Spectral Fingerprint of Neat Polypropylene and Its Implications for Filler Quantification

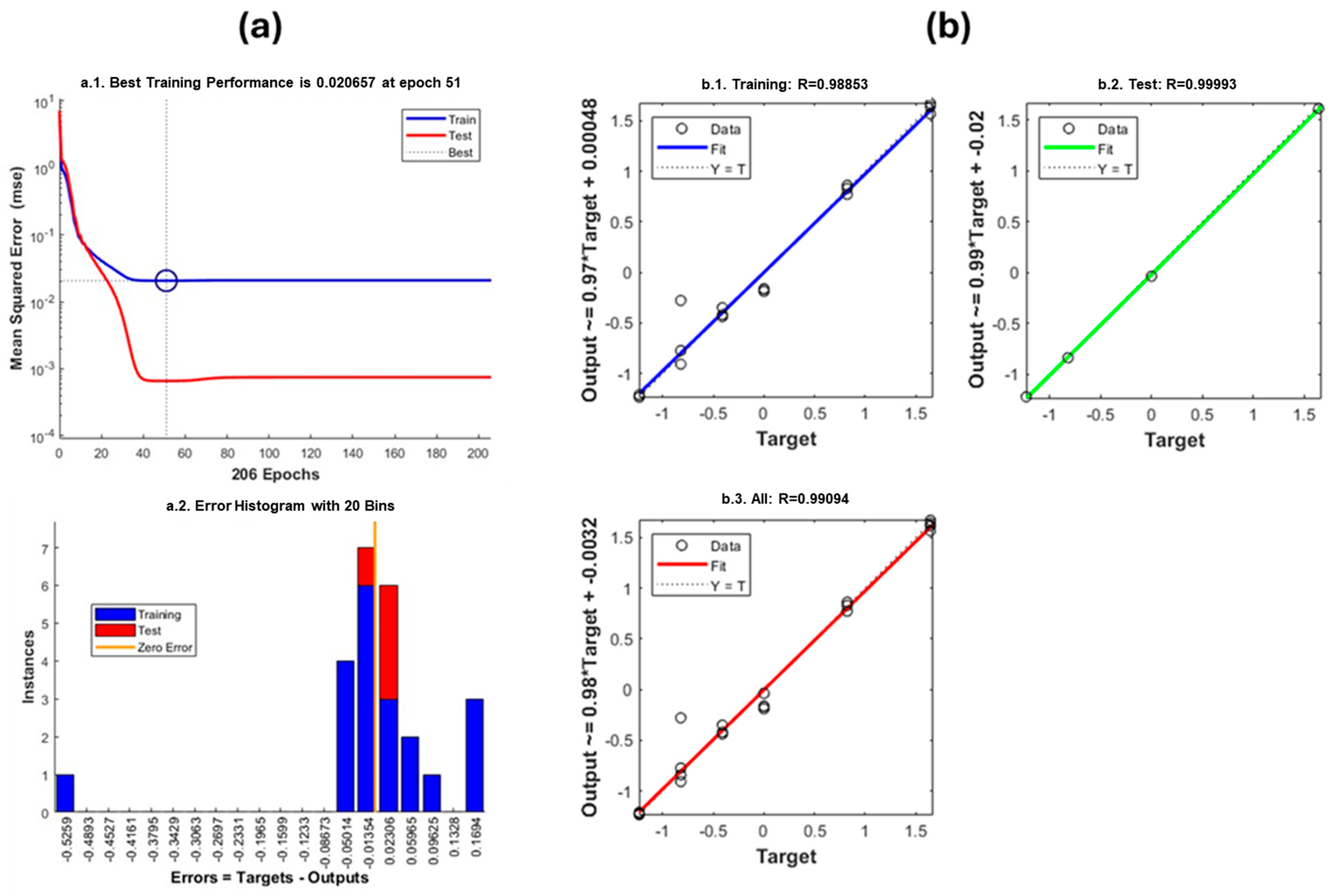

3.2. Construction of ANNs for the Prediction of Talc, CaCO3, and Fiberglass Content in Polypropylene-Based Composites

3.3. Use of the Proposed ANNs for the Study of Commercial Samples

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Carrera, B.; Mata, J.B.; Piñol, V.L.; Kim, K. Environmental Sustainability: A Machine Learning Approach for Cost Analysis in Plastic Recycling Classification. Resour. Conserv. Recycl. 2023, 197, 107095. [Google Scholar] [CrossRef]

- Stegmann, P.; Daioglou, V.; Londo, M.; Van Vuuren, D.P.; Junginger, M. Plastic Futures and Their CO2 Emissions. Nature 2022, 612, 272–276. [Google Scholar] [CrossRef]

- Neo, E.R.K.; Yeo, Z.; Low, J.S.C.; Goodship, V.; Debattista, K. A Review on Chemometric Techniques with Infrared, Raman and Laser-Induced Breakdown Spectroscopy for Sorting Plastic Waste in the Recycling Industry. Resour. Conserv. Recycl. 2022, 180, 106217. [Google Scholar] [CrossRef]

- Rajendran, S.; Scelsi, L.; Hodzic, A.; Soutis, C.; Al-Maadeed, M.A. Environmental Impact Assessment of Composites Containing Recycled Plastics. Resour. Conserv. Recycl. 2012, 60, 131–139. [Google Scholar] [CrossRef]

- Colucci, G.; Simon, H.; Roncato, D.; Martorana, B.; Badini, C. Effect of Recycling on Polypropylene Composites Reinforced with Glass Fibres. J. Thermoplast. Compos. Mater. 2017, 30, 707–723. [Google Scholar] [CrossRef]

- Elen, M.; Kumar, V.; Fifield, L.S. Feasibility of Recovering and Recycling Polymer Composites from End-of-Life Marine Renewable Energy Structures: A Review. Sustainability 2024, 16, 10515. [Google Scholar] [CrossRef]

- Lahl, U.; Zeschmar-Lahl, B. Material Recycling of Plastics—A Challenge for Sustainability. Sustainability 2024, 16, 6630. [Google Scholar] [CrossRef]

- Torkelis, A.; Dvarionienė, J.; Denafas, G. The Factors Influencing the Recycling of Plastic and Composite Packaging Waste. Sustainability 2024, 16, 9515. [Google Scholar] [CrossRef]

- van den Tempel, P.; Picchioni, F. Polymer Recycling: A Comprehensive Overview and Future Outlook. Recycling 2025, 10, 1. [Google Scholar] [CrossRef]

- Ochigue, P.C.D.; Aguilos, M.A.; Lubguban, A.A.; Bacosa, H.P. Circular Economy Solutions: The Role of Thermoplastic Waste in Material Innovation. Sustainability 2025, 17, 764. [Google Scholar] [CrossRef]

- Stavinski, N.; Maheshkar, V.; Thomas, S.; Dantu, K.; Velarde, L. Mid-Infrared Spectroscopy and Machine Learning for Postconsumer Plastics Recycling. Environ. Sci. Adv. 2023, 2, 1099–1109. [Google Scholar] [CrossRef]

- Seifert, L.; Leuchtenberger-Engel, L.; Hopmann, C. Development of an Analytical Model for Predicting the Tensile Modulus of Complex Polypropylene Compounds. Polymers 2024, 16, 3403. [Google Scholar] [CrossRef]

- Fatriansyah, J.F.; Linuwih, B.D.P.; Andreano, Y.; Sari, I.S.; Federico, A.; Anis, M.; Surip, S.N.; Jaafar, M. Prediction of Glass Transition Temperature of Polymers Using Simple Machine Learning. Polymers 2024, 16, 2464. [Google Scholar] [CrossRef]

- Spanu, P.; Abaza, B.F.; Constantinescu, T.C. Analysis and Prediction of Temperature Using an Artificial Neural Network Model for Milling Glass Fiber Reinforced Polymer Composites. Polymers 2024, 16, 3283. [Google Scholar] [CrossRef]

- Gravgaard, D.P.; Henriksen, M.L.; Hinge, M. Dissolution Recycling for Recovery of Polypropylene and Glass Fibres. J. Mater. Cycles Waste Manag. 2024, 26, 961–969. [Google Scholar] [CrossRef]

- Monti, M.; Scrivani, M.T.; Gianotti, V. Effect of SEBS and OBC on the Impact Strength of Recycled Polypropylene/Talc Composites. Recycling 2020, 5, 9. [Google Scholar] [CrossRef]

- Vyncke, G.; Fiorio, R.; Cardon, L.; Ragaert, K. The Effect of Polyethylene on the Properties of Talc-Filled Recycled Polypropylene. Plast. Rubber Compos. 2022, 51, 118–125. [Google Scholar] [CrossRef]

- Gall, M.; Freudenthaler, P.J.; Fischer, J.; Lang, R.W. Characterization of Composition and Structure–Property Relationships of Commercial Post-Consumer Polyethylene and Polypropylene Recyclates. Polymers 2021, 13, 1574. [Google Scholar] [CrossRef] [PubMed]

- Techawinyutham, L.; Sumrith, N.; Srisuk, R.; Techawinyutham, W.; Siengchin, S.; Mavinkere Rangappa, S. Thermo-Mechanical, Rheological and Morphology Properties of Polypropylene Composites: Residual CaCO3 as a Sustainable by-Product. Polym. Compos. 2021, 42, 4643–4659. [Google Scholar] [CrossRef]

- Malakhov, S.N.; Dmitryakov, P.V.; Pichkur, E.B.; Chvalun, S.N. Nonwoven Materials Produced by Melt Electrospinning of Polypropylene Filled with Calcium Carbonate. Polymers 2020, 12, 2981. [Google Scholar] [CrossRef]

- Srebrenkoska, V.; Gaceva, G.B.; Avella, M.; Errico, M.E.; Gentile, G. Recycling of Polypropylene-Based Eco-Composites. Polym. Int. 2008, 57, 1252–1257. [Google Scholar] [CrossRef]

- Prambauer, M.; Paulik, C.; Burgstaller, C. The Influence of Paper Type on the Properties of Structural Paper—Polypropylene Composites. Compos. Part. A Appl. Sci. Manuf. 2015, 74, 107–113. [Google Scholar] [CrossRef]

- Vaidya, U.; Wasti, S.; Tekinalp, H.; Hassen, A.A.; Ozcan, S. Recycled Glass Polypropylene Composites from Transportation Manufacturing Waste. J. Compos. Sci. 2023, 7, 99. [Google Scholar] [CrossRef]

- Świetlicki, M.; Chocyk, D.; Klepka, T.; Prószyński, A.; Kwaśniewska, A.; Borc, J.; Gładyszewski, G. The Structure and Mechanical Properties of the Surface Layer of Polypropylene Polymers with Talc Additions. Materials 2020, 13, 698. [Google Scholar] [CrossRef] [PubMed]

- Blanco, A.; Juan, R.; Paredes, B.; Domínguez, C.; García-Muñoz, R.A. Advancing Polypropylene Quantification in Recycled HDPE: A Comparative Study of FTIR, DSC, TREF, and TGIC for Enhanced Plastic Circularity. Polym. Test. 2025, 149, 108855. [Google Scholar] [CrossRef]

- Ai, W.; Liu, S.; Liao, H.; Du, J.; Cai, Y.; Liao, C.; Shi, H.; Lin, Y.; Junaid, M.; Yue, X.; et al. Application of Hyperspectral Imaging Technology in the Rapid Identification of Microplastics in Farmland Soil. Sci. Total Environ. 2022, 807, 151030. [Google Scholar] [CrossRef]

- Carrasco-Fernández, M.; López-Martínez, E.I.; Flores-Gallardo, S.G.; Estrada-Moreno, I.A.; Mendoza-Duarte, M.E.; Vega-Rios, A. Innovative Poly(Lactic Acid) Blends: Exploring the Impact of the Diverse Chemical Architectures from Itaconic Acid. Polymers 2024, 16, 2780. [Google Scholar] [CrossRef] [PubMed]

- Leong, Y.W.; Abu Bakar, M.B.; Ishak, Z.A.M.; Ariffin, A.; Pukanszky, B. Comparison of the Mechanical Properties and Interfacial Interactions Between Talc, Kaolin, and Calcium Carbonate Filled Polypropylene Composites. J. Appl. Polym. Sci. 2004, 91, 3315–3326. [Google Scholar] [CrossRef]

- Wu, G.; Wen, B.; Hou, S. Preparation and Structural Study of Polypropylene-Talc Gradient Materials. Polym. Int. 2004, 53, 749–755. [Google Scholar] [CrossRef]

- Kassouf, A.; Maalouly, J.; Rutledge, D.N.; Chebib, H.; Ducruet, V. Rapid Discrimination of Plastic Packaging Materials Using MIR Spectroscopy Coupled with Independent Components Analysis (ICA). Waste Manag. 2014, 34, 2131–2138. [Google Scholar] [CrossRef]

- Sha, W.; Li, Y.; Tang, S.; Tian, J.; Zhao, Y.; Guo, Y.; Zhang, W.; Zhang, X.; Lu, S.; Cao, Y.C.; et al. Machine Learning in Polymer Informatics. InfoMat 2021, 3, 353–361. [Google Scholar] [CrossRef]

- Franca, T.; Goncalves, D.; Cena, C. ATR-FTIR Spectroscopy Combined with Machine Learning for Classification of PVA/PVP Blends in Low Concentration. Vib. Spectrosc. 2022, 120, 103378. [Google Scholar] [CrossRef]

- Kalkreuth, J.; Ullrich, A.; Garbev, K.; Merz, D.; Stemmermann, P.; Stapf, D. Accelerated Carbonation of Hardened Cement Paste: Quantification of Calcium Carbonate via ATR Infrared Spectroscopy. J. Am. Ceram. Soc. 2024, 107, 2627–2640. [Google Scholar] [CrossRef]

- López-Pérez, M.F.; Larrubia, M.Á.; Fernández, A.; Sempere, J. Overview of the Current Situation Relating to Chemical Engineering Degree Courses. Educ. Chem. Eng. 2023, 43, 73–82. [Google Scholar] [CrossRef]

- Alhusban, M.; Alhusban, M.; Alkhawaldeh, A.A. The Efficiency of Using Machine Learning Techniques in Fiber-Reinforced-Polymer Applications in Structural Engineering. Sustainability 2024, 16, 11. [Google Scholar] [CrossRef]

- Bae, J.S.; Oh, S.K.; Pedrycz, W.; Fu, Z. Design of Fuzzy Radial Basis Function Neural Network Classifier Based on Information Data Preprocessing for Recycling Black Plastic Wastes: Comparative Studies of ATR FT-IR and Raman Spectroscopy. Appl. Intell. 2019, 49, 929–949. [Google Scholar] [CrossRef]

- Feng, S.; Zhou, H.; Dong, H. Using Deep Neural Network with Small Dataset to Predict Material Defects. Mater. Des. 2019, 162, 300–310. [Google Scholar] [CrossRef]

- Izonin, I.; Tkachenko, R.; Berezsky, O.; Krak, I.; Kováč, M.; Fedorchuk, M. Improvement of the ANN-Based Prediction Technology for Extremely Small Biomedical Data Analysis. Technologies 2024, 12, 112. [Google Scholar] [CrossRef]

- Chylińska, M.; Kaczmarek, H.; Moszyński, D.; Królikowski, B.; Kowalonek, J. Surface Studies of UV Irradiated Polypropylene Films Modified with Mineral Fillers Designed as Piezoelectric Materials. Polymers 2020, 12, 562. [Google Scholar] [CrossRef]

- Madejová, J. FTIR Techniques in Clay Mineral Studies. Vib. Spectrosc. 2003, 31, 1–10. [Google Scholar] [CrossRef]

- Warren-Vega, W.M.; Zárate-Guzmán, A.I.; Carrasco-Marín, F.; Ramos-Sánchez, G.; Romero-Cano, L.A. Predicting Sodium-Ion Battery Performance through Surface Chemistry Analysis and Textural Properties of Functionalized Hard Carbons Using AI. Materials 2024, 17, 4193. [Google Scholar] [CrossRef]

- Chan, J.Y.-L.; Leow, S.M.H.; Bea, K.T.; Cheng, W.K.; Phoong, S.W.; Hong, Z.W.; Chen, Y.L. Mitigating the Multicollinearity Problem and Its Machine Learning Approach: A Review. Mathematics 2022, 10, 1283. [Google Scholar] [CrossRef]

- Kim, Y.; Caumon, M.C.; Barres, O.; Sall, A.; Cauzid, J. Identification and Composition of Carbonate Minerals of the Calcite Structure by Raman and Infrared Spectroscopies Using Portable Devices. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2021, 261, 119980. [Google Scholar] [CrossRef] [PubMed]

- Caban, R. FTIR-ATR Spectroscopic, Thermal and Microstructural Studies on Polypropylene-Glass Fiber Composites. J. Mol. Struct. 2022, 1264, 133181. [Google Scholar] [CrossRef]

- Zheng, Q.; Fang, W.; Fan, J. Determination of Antioxidant Irganox 1010 in Polypropylene by Infrared Spectrometry. IOP Conf. Ser. Earth Environ. Sci. 2020, 514, 052046. [Google Scholar] [CrossRef]

- Ambrogi, V.; Cerruti, P.; Carfagna, C.; Malinconico, M.; Marturano, V.; Perrotti, M.; Persico, P. Natural Antioxidants for Polypropylene Stabilization. Polym. Degrad. Stab. 2011, 96, 2152–2158. [Google Scholar] [CrossRef]

- Santos-Ventura, E.M.; Escalante-Álvarez, M.A.; González-Nuñez, R.; Esquivel-Alfaro, M.; Sulbarán-Rangel, B. Polypropylene Composites Reinforced with Lignocellulose Nanocrystals of Corncob: Thermal and Mechanical Properties. J. Compos. Sci. 2024, 8, 125. [Google Scholar] [CrossRef]

- Benoit, N.; González-Núñez, R.; Rodrigue, D. High Density Polyethylene Degradation Followed by Closedloop Recycling. Progress. Rubber Plast. Recycl. Technol. 2017, 33, 17–37. [Google Scholar] [CrossRef]

- Wolpert, D.H.; Macready, W.G. No Free Lunch Theorems for Optimization. IEEE Trans. Evol. Comput. 1997, 1, 67–82. [Google Scholar] [CrossRef]

- Parveen, N.; Zaidi, S.; Danish, M. Development of SVR-Based Model and Comparative Analysis with MLR and ANN Models for Predicting the Sorption Capacity of Cr(VI). Process Saf. Environ. Prot. 2017, 107, 428–437. [Google Scholar] [CrossRef]

- Zhou, Z.; Qiu, C.; Zhang, Y. A Comparative Analysis of Linear Regression, Neural Networks and Random Forest Regression for Predicting Air Ozone Employing Soft Sensor Models. Sci. Rep. 2023, 13, 22420. [Google Scholar] [CrossRef]

- Essabir, H.; Bensalah, M.O.; Rodrigue, D.; Bouhfid, R.; Qaiss, A.e.k. A Comparison between Bio- and Mineral Calcium Carbonate on the Properties of Polypropylene Composites. Constr. Build. Mater. 2017, 134, 549–555. [Google Scholar] [CrossRef]

- Hou, J.; Zhao, G.; Wang, G. Polypropylene/Talc Foams with High Weight-Reduction and Improved Surface Quality Fabricated by Mold-Opening Microcellular Injection Molding. J. Mater. Res. Technol. 2021, 12, 74–86. [Google Scholar] [CrossRef]

- Pi-Puig, T.; Animas-Torices, D.Y.; Solé, J. Mineralogical and Geochemical Characterization of Talc from Two Mexican Ore Deposits (Oaxaca and Puebla) and Nine Talcs Marketed in Mexico: Evaluation of Its Cosmetic Uses. Minerals 2020, 10, 388. [Google Scholar] [CrossRef]

- Huang, X.; Li, J.; Su, X.; Fang, K.; Wang, Z.; Liu, L.; Wang, H.; Yang, C.; Wang, X. Remarkable Damage in Talc Caused by Electron Beam Irradiation with a Dose of up to 1000 KGy: Lattice Shrinkage in the Z- and Y-Axis and Corresponding Intrinsic Microstructural Transformation Process Speculation. RSC Adv. 2021, 11, 21870–21884. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gómez-Bacab, M.T.; Quezada-Campos, A.L.; Patiño-Arévalo, C.D.; Zepeda-Rodríguez, Z.; Romero-Cano, L.A.; Zárate-Navarro, M.A. Use of Artificial Neural Networks for Recycled Pellets Identification: Polypropylene-Based Composites. Polymers 2025, 17, 2349. https://doi.org/10.3390/polym17172349

Gómez-Bacab MT, Quezada-Campos AL, Patiño-Arévalo CD, Zepeda-Rodríguez Z, Romero-Cano LA, Zárate-Navarro MA. Use of Artificial Neural Networks for Recycled Pellets Identification: Polypropylene-Based Composites. Polymers. 2025; 17(17):2349. https://doi.org/10.3390/polym17172349

Chicago/Turabian StyleGómez-Bacab, Maya T., Aldo L. Quezada-Campos, Carlos D. Patiño-Arévalo, Zenen Zepeda-Rodríguez, Luis A. Romero-Cano, and Marco A. Zárate-Navarro. 2025. "Use of Artificial Neural Networks for Recycled Pellets Identification: Polypropylene-Based Composites" Polymers 17, no. 17: 2349. https://doi.org/10.3390/polym17172349

APA StyleGómez-Bacab, M. T., Quezada-Campos, A. L., Patiño-Arévalo, C. D., Zepeda-Rodríguez, Z., Romero-Cano, L. A., & Zárate-Navarro, M. A. (2025). Use of Artificial Neural Networks for Recycled Pellets Identification: Polypropylene-Based Composites. Polymers, 17(17), 2349. https://doi.org/10.3390/polym17172349