Effect of Surface-Modified Mica in Hybrid Filler Systems on the Curing and Mechanical Behavior of Ethylene–Propylene–Diene Monomer (EPDM)/Butadiene Rubber (BR) Blend

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Rubber Compounding

2.3. Modification of Mica

2.4. Specimen Preparation

2.5. Characterization

2.5.1. Curing and Rheological Properties

Rheometer

Mooney Viscosity

2.5.2. Crosslink Density

2.5.3. Mechanical Properties

Tensile Properties

Hardness

2.5.4. Elastic Properties

Rebound Resilience

Compression Set

Tan δ

2.5.5. Morphological Properties

3. Results and Discussions

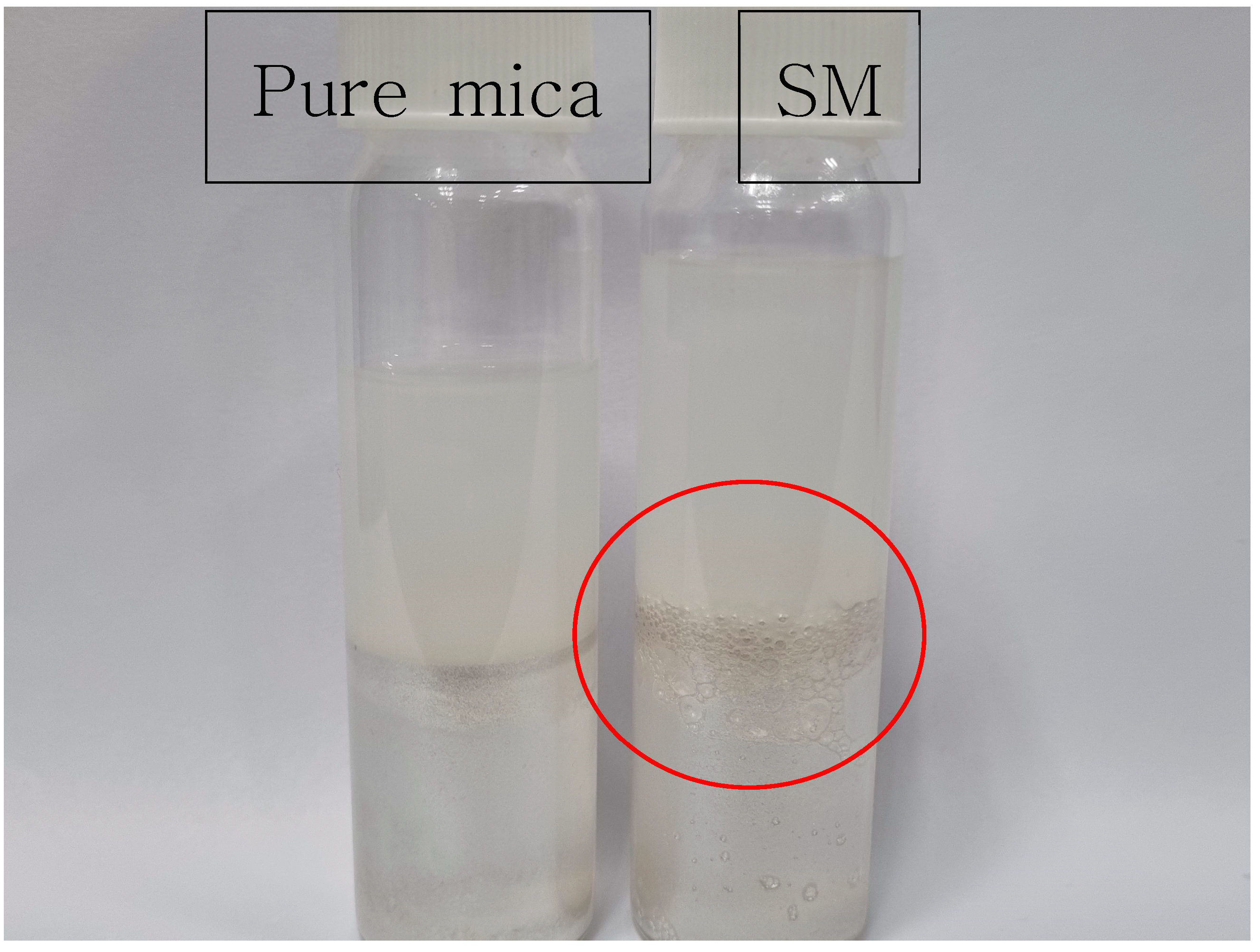

3.1. Surface Modification of Mica

3.2. Morphological Properties

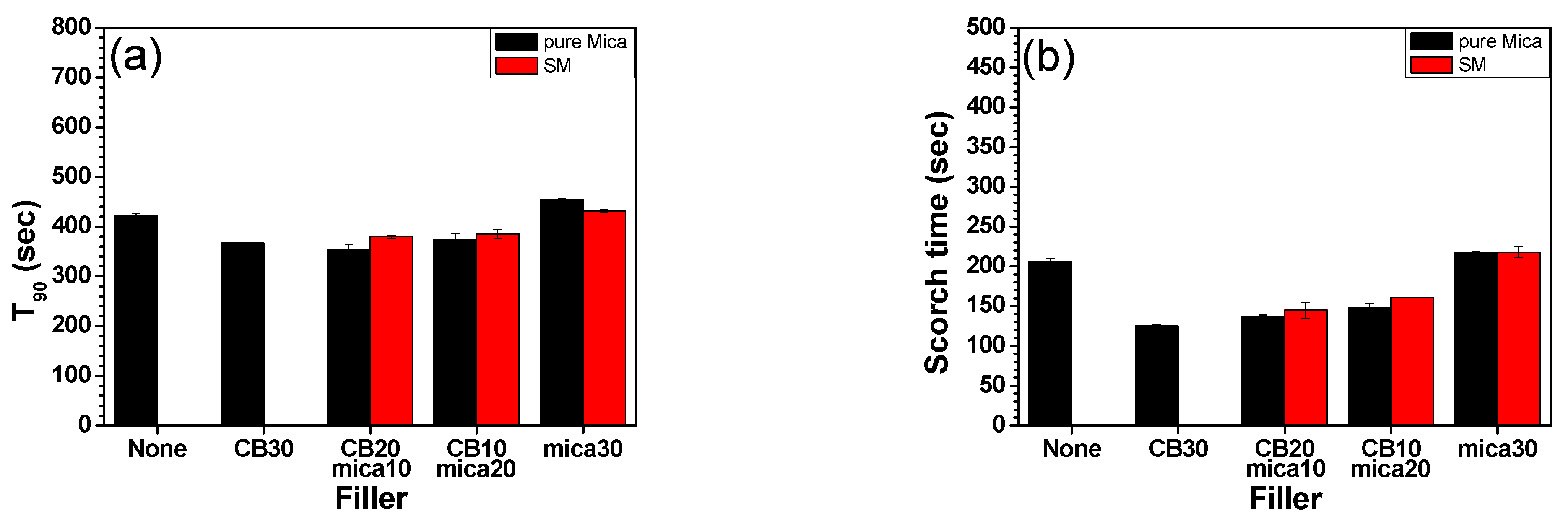

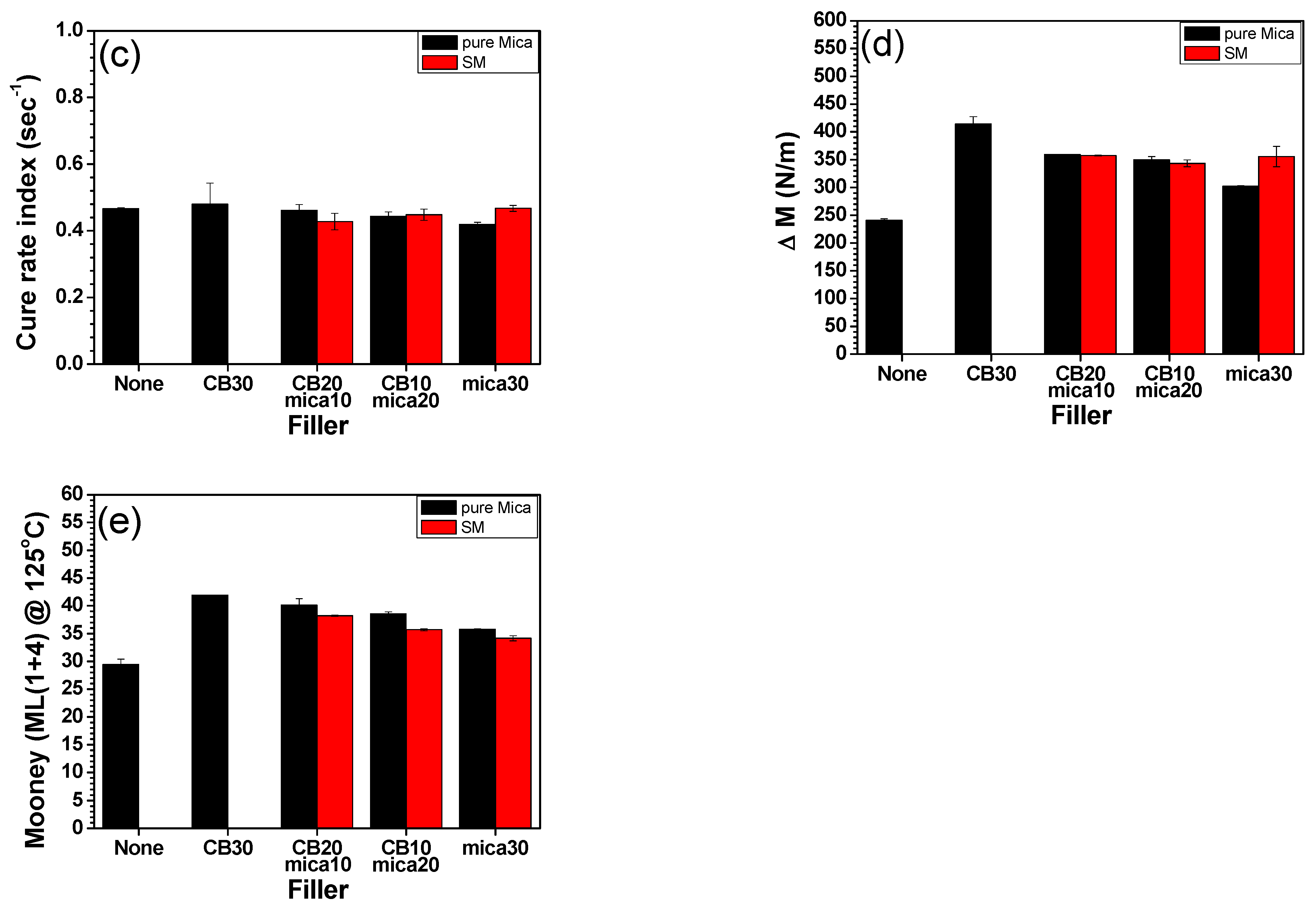

3.3. Curing and Rheological Properties

3.4. Crosslink Density

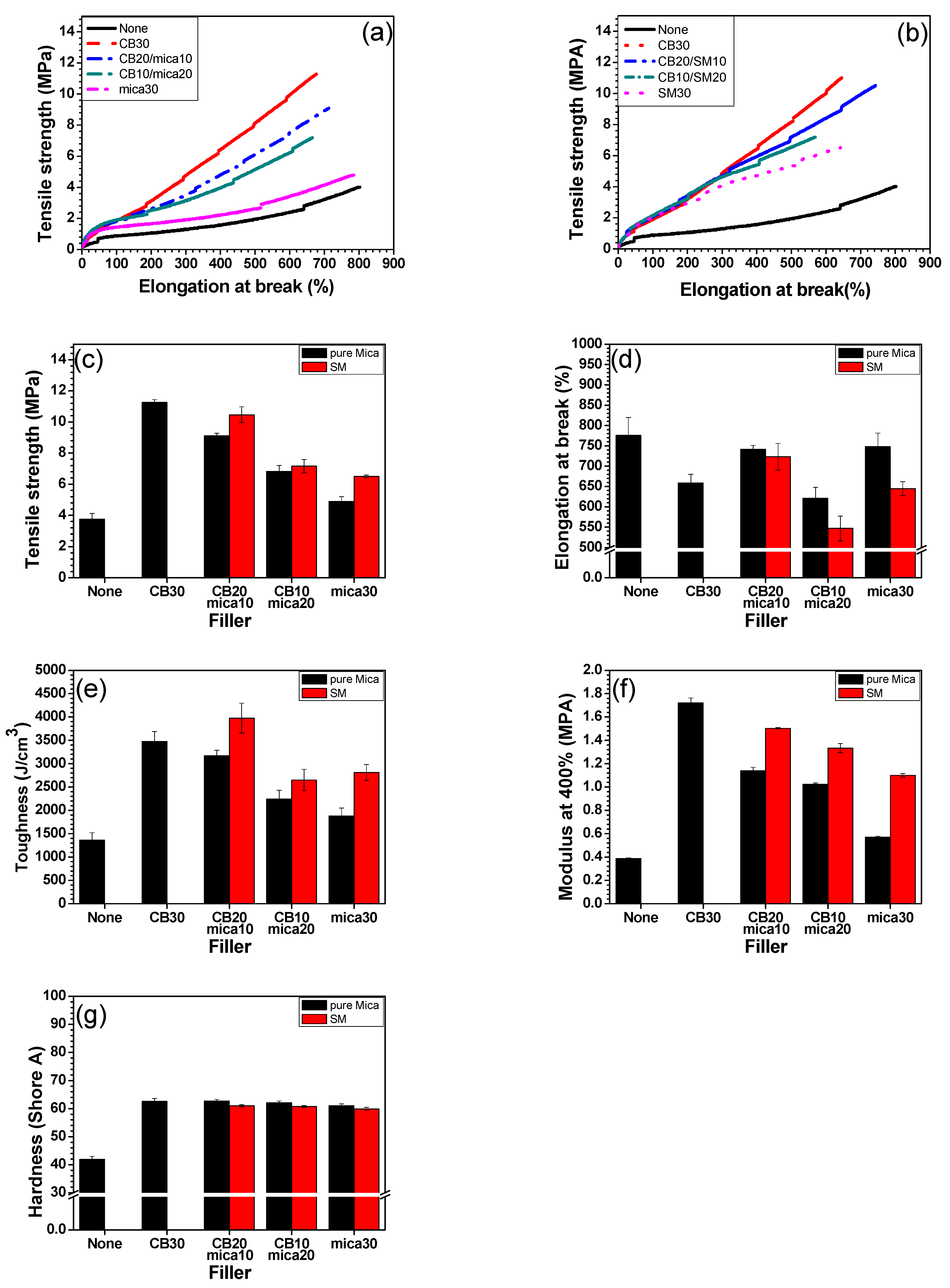

3.5. Mechanical Properties

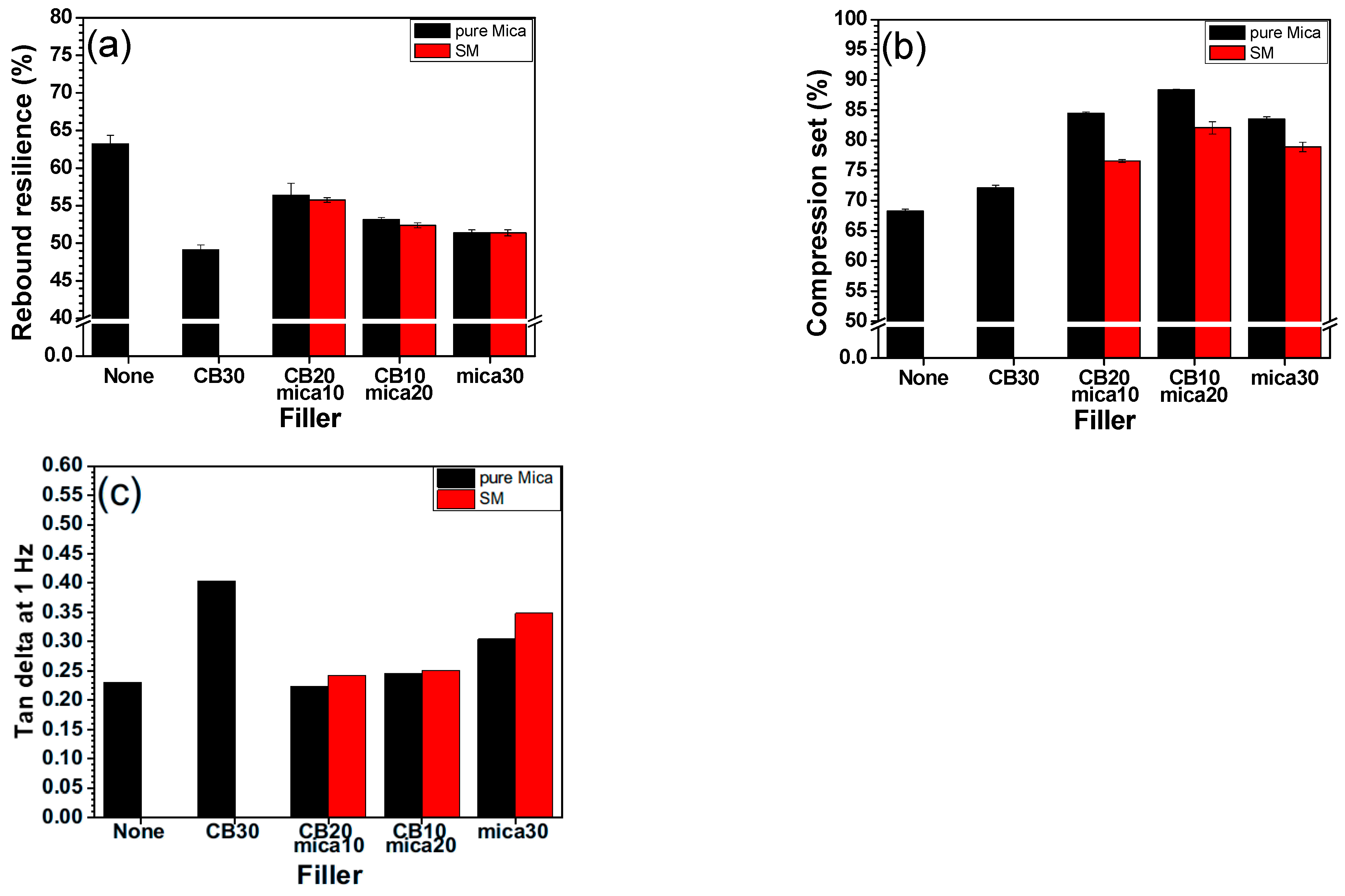

3.6. Elastic Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Leblanc, J.L. Rubber–Filler Interactions and Rheological Properties in Filled Compounds. Prog. Polym. Sci. 2002, 27, 627–687. [Google Scholar] [CrossRef]

- Liang, X.; Ito, M.; Nakajima, K. Reinforcement Mechanism of Carbon Black-Filled Rubber Nanocomposite as Revealed by Atomic Force Microscopy Nanomechanics. Polymers 2021, 13, 3922. [Google Scholar] [CrossRef]

- Kang, M.-J.; Heo, Y.-J.; Jin, F.-L.; Park, S.-J. A review: Role of interfacial adhesion between carbon blacks and elastomeric materials. Carbon Lett. 2016, 18, 1–10. [Google Scholar] [CrossRef]

- Wang, M.-J.; Gray, C.A.; Reznek, S.A.; Mahmud, K.; Kutsovsky, Y. Carbon Black. In Kirk-Othmer Encyclopedia of Chemical Technology; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2003; ISBN 978-0-471-23896-6. [Google Scholar]

- Fan, Y.; Fowler, G.D.; Zhao, M. The Past, Present and Future of Carbon Black as a Rubber Reinforcing Filler—A Review. J. Clean. Prod. 2020, 247, 119115. [Google Scholar] [CrossRef]

- Khodabakhshi, S.; Fulvio, P.F.; Andreoli, E. Carbon Black Reborn: Structure and Chemistry for Renewable Energy Harnessing. Carbon 2020, 162, 604–649. [Google Scholar] [CrossRef]

- Fořt, J.; Kobetičová, K.; Böhm, M.; Podlesný, J.; Jelínková, V.; Vachtlová, M.; Bureš, F.; Černý, R. Environmental Consequences of Rubber Crumb Application: Soil and Water Pollution. Polymers 2022, 14, 1416. [Google Scholar] [CrossRef]

- Colom, X.; Carrillo-Navarrete, F.; Saeb, M.R.; Marin, M.; Formela, K.; Cañavate, J. Evaluation and Rationale of the Performance of Several Elastomeric Composites Incorporating Devulcanized EPDM. Polym. Test. 2023, 121, 107976. [Google Scholar] [CrossRef]

- Hu, Q.; Chen, Q.; Song, P.; Gong, X.; Chen, J.; Zhao, Y. Performance of Thermal-Oxidative Aging on the Structure and Properties of Ethylene Propylene Diene Monomer (EPDM) Vulcanizates. Polymers 2023, 15, 2329. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Q.; Li, X.; Hu, J.; Ye, Z. Degradation Characterization of Ethylene-Propylene-Diene Monomer (EPDM) Rubber in Artificial Weathering Environment. J. Fail. Anal. Preven. 2010, 10, 240–244. [Google Scholar] [CrossRef]

- Song, L.-F.; Bai, N.; Shi, Y.; Wang, Y.-X.; Song, L.-X.; Liu, L.-Z. Effects of Ethylene-Propylene-Diene Monomers (EPDMs) with Different Moony Viscosity on Crystallization Behavior, Structure, and Mechanical Properties of Thermoplastic Vulcanizates (TPVs). Polymers 2023, 15, 642. [Google Scholar] [CrossRef]

- Mansilla, M.A.; Rodríguez Garraza, A.L.; Silva, L.; Salgueiro, W.; Macchi, C.; Marzocca, A.J.; Somoza, A. Evolution of the Free Volume and Glass Transition Temperature with the Degree of Cure of Polybutadiene Rubbers. Polym. Test. 2013, 32, 686–690. [Google Scholar] [CrossRef]

- Hamed, G.R. Morphology-Property Relationships in EPDM-Polybutadiene Blends. Rubber Chem. Technol. 1982, 55, 151–160. [Google Scholar] [CrossRef]

- Yasin, S.; Hussain, M.; Zheng, Q.; Song, Y. Thermo-Soil Weathering and Life Cycle Assessment of Carbon Black, Silica and Cellulose Nanocrystal Filled Rubber Nanocomposites. Sci. Total Environ. 2022, 835, 155521. [Google Scholar] [CrossRef] [PubMed]

- Yong, M.; Anderle, L.; Levy, L.; McCunney, R.J. Carbon Black and Lung Cancer Mortality—A Meta-Regression Analysis Based on Three Occupational Cohort Studies. J. Occup. Environ. Med. 2019, 61, 949. [Google Scholar] [CrossRef]

- Niranjan, R.; Thakur, A.K. The Toxicological Mechanisms of Environmental Soot (Black Carbon) and Carbon Black: Focus on Oxidative Stress and Inflammatory Pathways. Front. Immunol. 2017, 8, 763. [Google Scholar] [CrossRef]

- Miedzianowska-Masłowska, J.; Masłowski, M.; Delekta, M.; Strzelec, K. Waste Management of Straw to Manufacture Biochar: An Alternative Reinforcing Filler for Natural Rubber Biocomposites. Ind. Crops Prod. 2024, 222, 119629. [Google Scholar] [CrossRef]

- Schouw, C.; Bernal-Ortega, P.; Anyszka, R.; Bijl, A.; Gucho, E.; Blume, A. Toward Eco-Friendly Rubber: Utilizing Paper Waste-Derived Calcium Carbonate to Replace Carbon Black in Natural Rubber Composites. J. Compos. Sci. 2025, 9, 115. [Google Scholar] [CrossRef]

- Eissa, M.M.; Botros, S.H.; Diab, M.; Shafik, E.S.; Rozik, N.N. Rice Husk Fibers and Their Extracted Silica as Promising Bio-Based Fillers for EPDM/NBR Rubber Blend Vulcanizates. Clean Technol. Environ. Policy 2023, 25, 3203–3218. [Google Scholar] [CrossRef]

- Furtado, C.R.G.; Leblanc, J.L.; Nunes, R.C.R. Mica as Additional Filler in SBR–Silica Compounds. Eur. Polym. J. 2000, 36, 1717–1723. [Google Scholar] [CrossRef]

- Somarathna, Y.R.; Rathnayake, G.L.H.; Rupasinghe, P.S.V.; Samarasinghe, I.H.K.; Sudusingha, Y.C.Y.; Siriwardena, S.; Epaarachchi, J.A. Development of Exfoliated Mica Waste/Natural Rubber Composites by Latex Stage Mixing. Polym. Plast. Technol. Mater. 2023, 62, 2143–2158. [Google Scholar] [CrossRef]

- Raaen, S. Adsorption of Carbon Dioxide on Mono-Layer Thick Oxidized Samarium Films on Ni(100). Nanomaterials 2021, 11, 2064. [Google Scholar] [CrossRef]

- Parvaiz, M.R.; Mahanwar, P.A.; Mohanty, S.; Nayak, S.K. Morphological, Mechanical, Thermal, Electrical and Rheological Properties of Polycarbonate Composites Reinforced with Surfaces Modified Mica. J. Miner. Mater. Charact. Eng. 2010, 9, 985. [Google Scholar] [CrossRef]

- Mica Market: Trends, Opportunities and Competitive Analysis. Available online: https://www.lucintel.com/mica-market.aspx?utm (accessed on 16 July 2025).

- Carbon Black Price Trend, Chart, Index and Forecast. 2025. Available online: https://www.imarcgroup.com/carbon-black-pricing-report (accessed on 16 July 2025).

- Ismail, H.; Ishak, S.; Hamid, Z.A.A. Comparison Effect of Mica and Talc as Filler in EPDM Composites on Curing, Tensile and Thermal Properties. Prog. Rubber Plast. Recycl. Technol. 2013, 29, 109–122. [Google Scholar] [CrossRef]

- Lee, S.-H.; Park, G.-W.; Kim, H.-J.; Chung, K.; Jang, K.-S. Effects of Filler Functionalization on Filler-Embedded Natural Rubber/Ethylene-Propylene-Diene Monomer Composites. Polymers 2022, 14, 3502. [Google Scholar] [CrossRef] [PubMed]

- Lee, B.-Y.; Lee, D.-H.; Jang, K.-S. Impact Modifiers and Compatibilizers for Versatile Epoxy-Based Adhesive Films with Curing and Deoxidizing Capabilities. Polymers 2021, 13, 1129. [Google Scholar] [CrossRef]

- Liao, Y.; Weng, Y.; Wang, J.; Zhou, H.; Lin, J.; He, S. Silicone Rubber Composites with High Breakdown Strength and Low Dielectric Loss Based on Polydopamine Coated Mica. Polymers 2019, 11, 2030. [Google Scholar] [CrossRef]

- Ismail, H.; Ishak, S.; Hamid, Z.A.A. Effect of Silane Coupling Agent on the Curing, Tensile, Thermal, and Swelling Properties of Ethylene-Propylene-Diene Monomer Rubber (EPDM)/Mica Composites. J. Vinyl Addit. Technol. 2014, 20, 116–121. [Google Scholar] [CrossRef]

- Zhu, F.; Lu, Y.; Li, L. Synthesis, Adsorption Kinetics and Thermodynamics of Ureido-Functionalized Pb(II) Surface Imprinted Polymers for Selective Removal of Pb(II) in Wastewater. RSC Adv. 2016, 6, 111120–111128. [Google Scholar] [CrossRef]

- Silane Modified Fillers for Reinforcing Polymers—Ludwik Domka, Andrzej Krysztafkiewicz, Maciej Kozak. 2002. Available online: https://journals.sagepub.com/doi/abs/10.1177/096739110201000706 (accessed on 25 July 2025).

- ISO 37:2024; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. International Organization for Standardization: Geneva, Switzerland, 2024.

- ISO 48-2:2018; Rubber, Vulcanized or Thermoplastic—Determination of Hardness—Part 2: IRHD Pocket Meter Method. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 4662:2017; Rubber, Vulcanized or Thermoplastic—Determination of Rebound Resilience. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 815-1:2019; Rubber, Vulcanized or Thermoplastic—Determination of Compression Set—Part 1: At Ambient or Elevated Temperatures. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 6721-12:2019; Plastics—Determination of Dynamic Mechanical Properties—Part 12: Compressive Vibration–Non-Resonance Method. International Organization for Standardization: Geneva, Switzerland, 2019.

- Chung, J.-Y.; Lee, B.; Park, I.-K.; Park, H.H.; Jung, H.S.; Park, J.C.; Cho, H.C.; Nam, J.-D. High Thermal Conductive Natural Rubber Composites Using Aluminum Nitride and Boron Nitride Hybrid Fillers. Elastomers Compos. 2020, 55, 59–66. [Google Scholar] [CrossRef]

- Song, S.; Jeong, J.; Ha, J.U.; Park, D.; Ryu, G.; Kim, D.; Hwang, K.; Chung, S.; Kim, W. Influence of Blending Method on the Generation of Wear Particulate Matters and Physical Properties in TBR Tire Tread Compounds. Elastomers Compos. 2023, 58, 161–172. [Google Scholar] [CrossRef]

- Somarathna, Y.R.; Nuwan, L.M.A.; Sudusingha, Y.C.Y.; Mallikaarachchi, D.V.D.; Siriwardena, S. Waste Mica and Carbon Black Filled Natural Rubber Composites: A Comparative Study. Iran. Polym. J. 2022, 31, 1209–1223. [Google Scholar] [CrossRef]

- Ramier, J.; Chazeau, L.; Gauthier, C.; Guy, L.; Bouchereau, M.N. Influence of Silica and Its Different Surface Treatments on the Vulcanization Process of Silica Filled SBR. Rubber Chem. Technol. 2007, 80, 183–193. [Google Scholar] [CrossRef]

- Tabsan, N.; Wirasate, S.; Suchiva, K. Abrasion Behavior of Layered Silicate Reinforced Natural Rubber. Wear 2010, 269, 394–404. [Google Scholar] [CrossRef]

- Jia, S.; Wang, Z.; Zhu, Y.; Chen, L.; Fu, L. Composites of Poly(Lactic) Acid/Thermoplastic Polyurethane/Mica with Compatibilizer: Morphology, Miscibility and Interphase. RSC Adv. 2015, 5, 98915–98924. [Google Scholar] [CrossRef]

- Mostafa, A.; Abouel-Kasem, A.; Bayoumi, M.R.; El-Sebaie, M.G. Rubber-Filler Interactions and Its Effect in Rheological and Mechanical Properties of Filled Compounds. J. Test. Eval. 2010, 38, 347–359. [Google Scholar] [CrossRef]

- Park, S.-J.; Cho, K.-S. Filler–Elastomer Interactions: Influence of Silane Coupling Agent on Crosslink Density and Thermal Stability of Silica/Rubber Composites. J. Colloid. Interface Sci. 2003, 267, 86–91. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Chen, W.; Jiang, D. Review on Heat Generation of Rubber Composites. Polymers 2023, 15, 2. [Google Scholar] [CrossRef]

- Kyei-Manu, W.A.; Tunnicliffe, L.B.; Herd, C.R.; Akutagawa, K.; Kratina, O.; Stoček, R.; Busfield, J.J.C. Effect of Carbon Black on Heat Build-up and Energy Dissipation in Rubber Materials. In Advances in Understanding Thermal Effects in Rubber: Experiments, Modelling, and Practical Relevance; Heinrich, G., Kipscholl, R., Le Cam, J.-B., Stoček, R., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 125–143. ISBN 978-3-031-71056-8. [Google Scholar]

- Lee, H.G.; Park, C.Y. Dynamic Mechanical and Morphological Properties of Natural Rubber Vulcanizates Containing Fillers. Elastomers Compos. 2016, 51, 218–225. [Google Scholar] [CrossRef]

| Rubber Matrix (wt%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| PB | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| EPDM | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Additive (phr) | ||||||||

| Zinc oxide | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| stearic acid | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| CB | - | 30 | 20 | 10 | - | 20 | 10 | - |

| Mica (M) | - | - | 10 | 20 | 30 | |||

| URE-Mica (SM) | 10 | 20 | 30 | |||||

| TMTD | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| DM | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| Sulfur | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, W.-Y.; Cho, S.-W.; Jang, K.-S. Effect of Surface-Modified Mica in Hybrid Filler Systems on the Curing and Mechanical Behavior of Ethylene–Propylene–Diene Monomer (EPDM)/Butadiene Rubber (BR) Blend. Polymers 2025, 17, 2250. https://doi.org/10.3390/polym17162250

Jung W-Y, Cho S-W, Jang K-S. Effect of Surface-Modified Mica in Hybrid Filler Systems on the Curing and Mechanical Behavior of Ethylene–Propylene–Diene Monomer (EPDM)/Butadiene Rubber (BR) Blend. Polymers. 2025; 17(16):2250. https://doi.org/10.3390/polym17162250

Chicago/Turabian StyleJung, Won-Young, Seong-Woo Cho, and Keon-Soo Jang. 2025. "Effect of Surface-Modified Mica in Hybrid Filler Systems on the Curing and Mechanical Behavior of Ethylene–Propylene–Diene Monomer (EPDM)/Butadiene Rubber (BR) Blend" Polymers 17, no. 16: 2250. https://doi.org/10.3390/polym17162250

APA StyleJung, W.-Y., Cho, S.-W., & Jang, K.-S. (2025). Effect of Surface-Modified Mica in Hybrid Filler Systems on the Curing and Mechanical Behavior of Ethylene–Propylene–Diene Monomer (EPDM)/Butadiene Rubber (BR) Blend. Polymers, 17(16), 2250. https://doi.org/10.3390/polym17162250