A New Recycling Technology to Produce Premixed Thermal Insulating Mortars from Polyurethane Waste Foams

Abstract

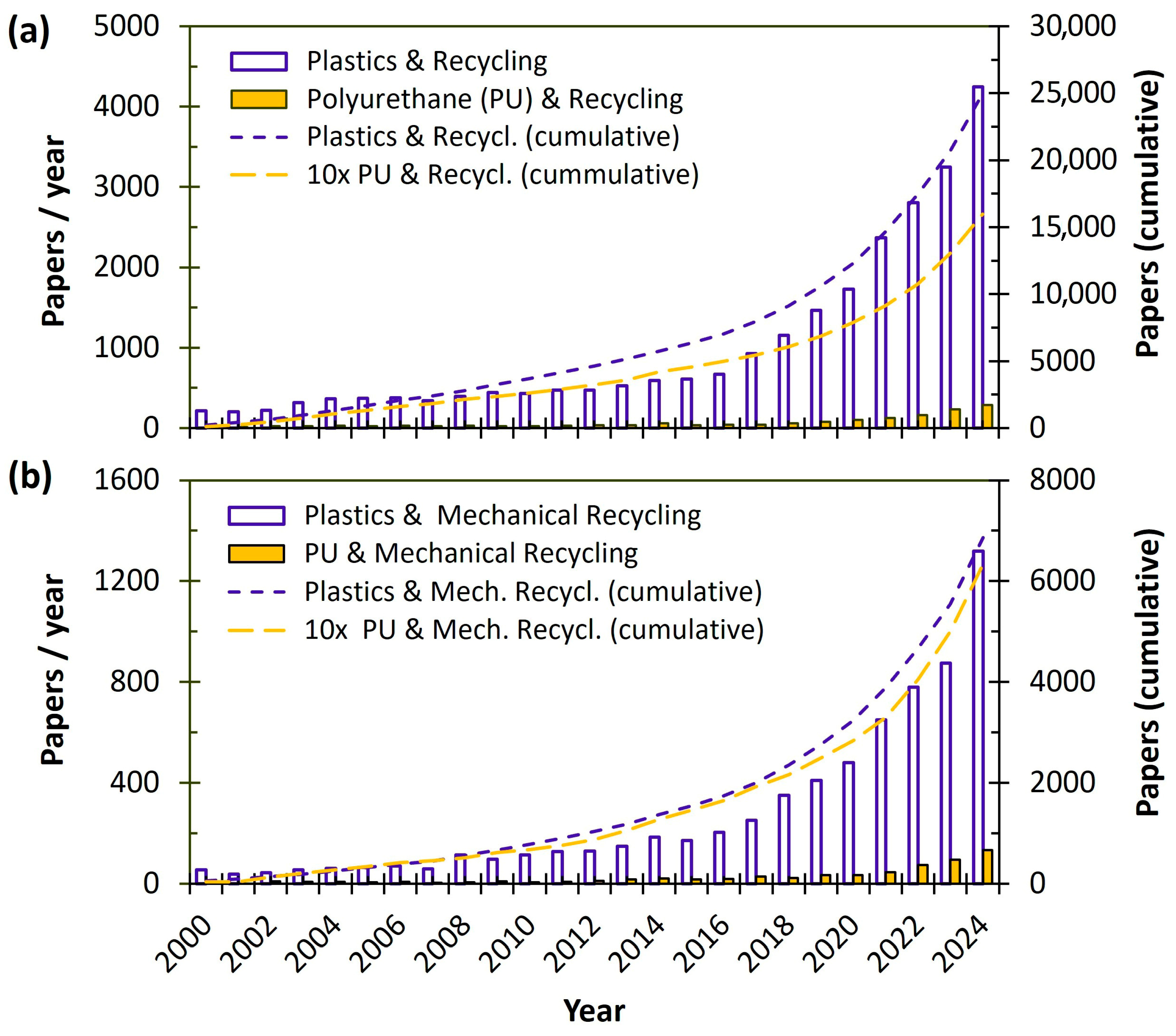

1. Introduction

2. Materials and Methods

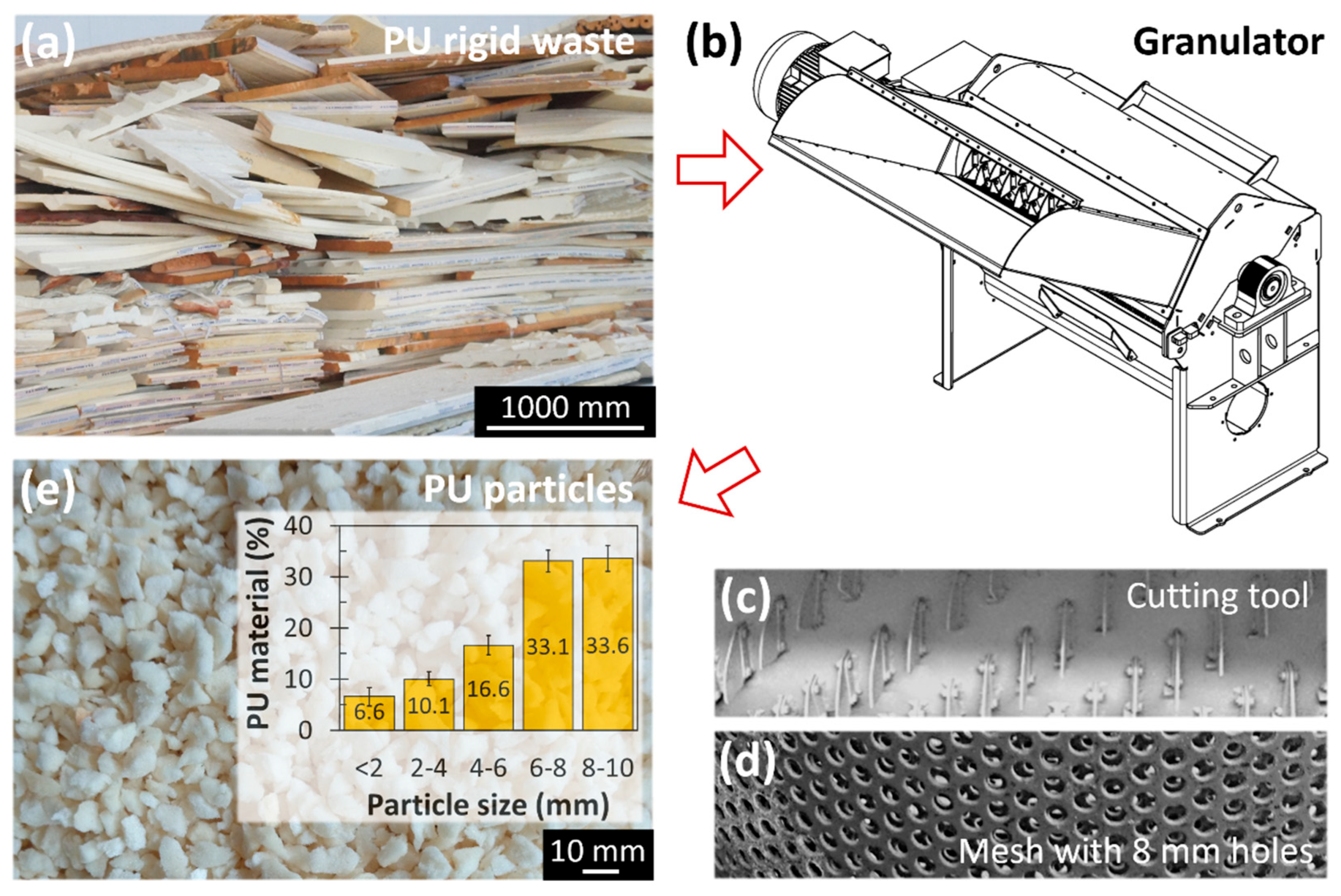

2.1. PU Waste Materials

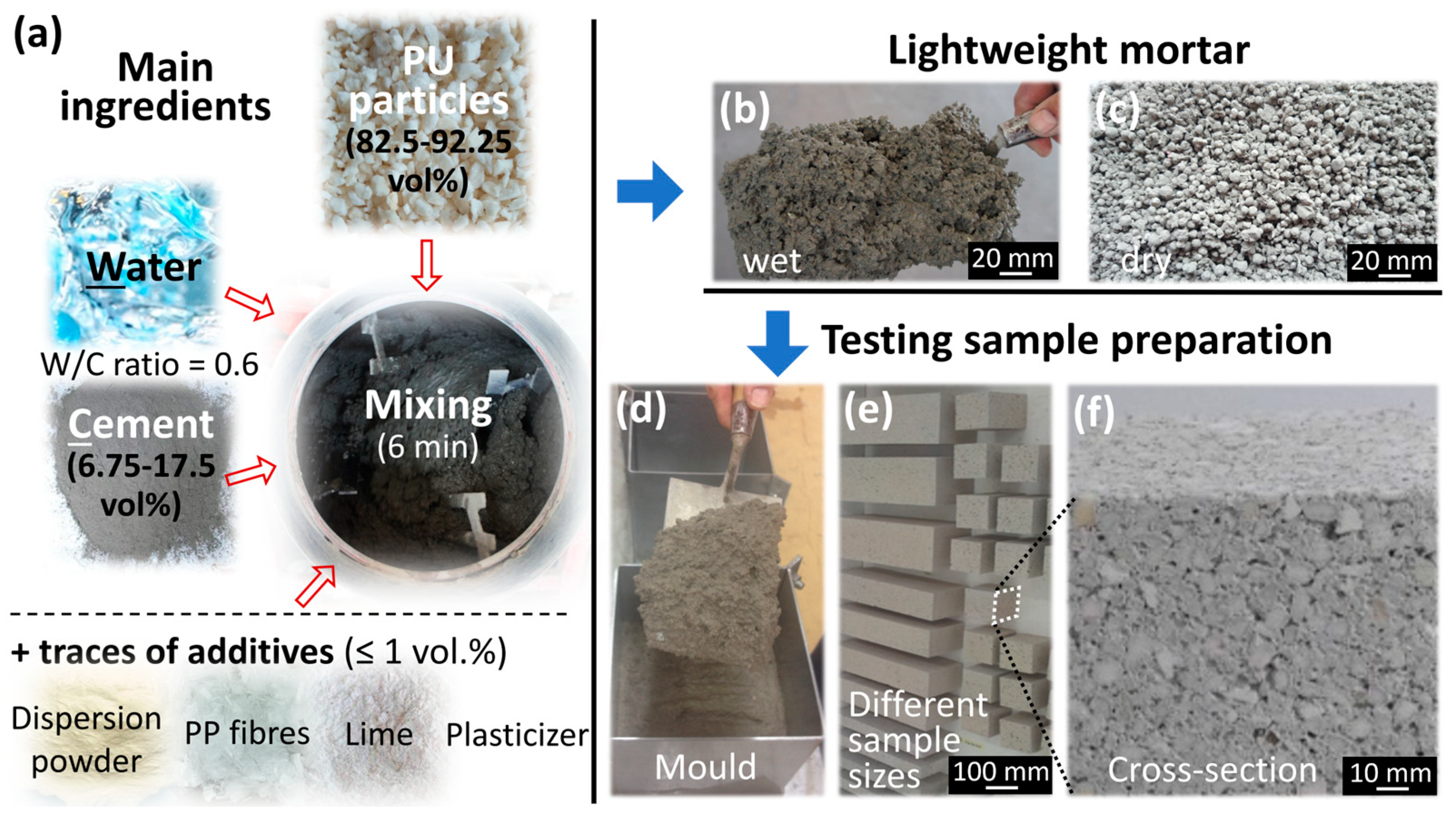

2.2. Preparation of Mortar Mixtures

2.3. Characterization Methods

3. Results and Discussion

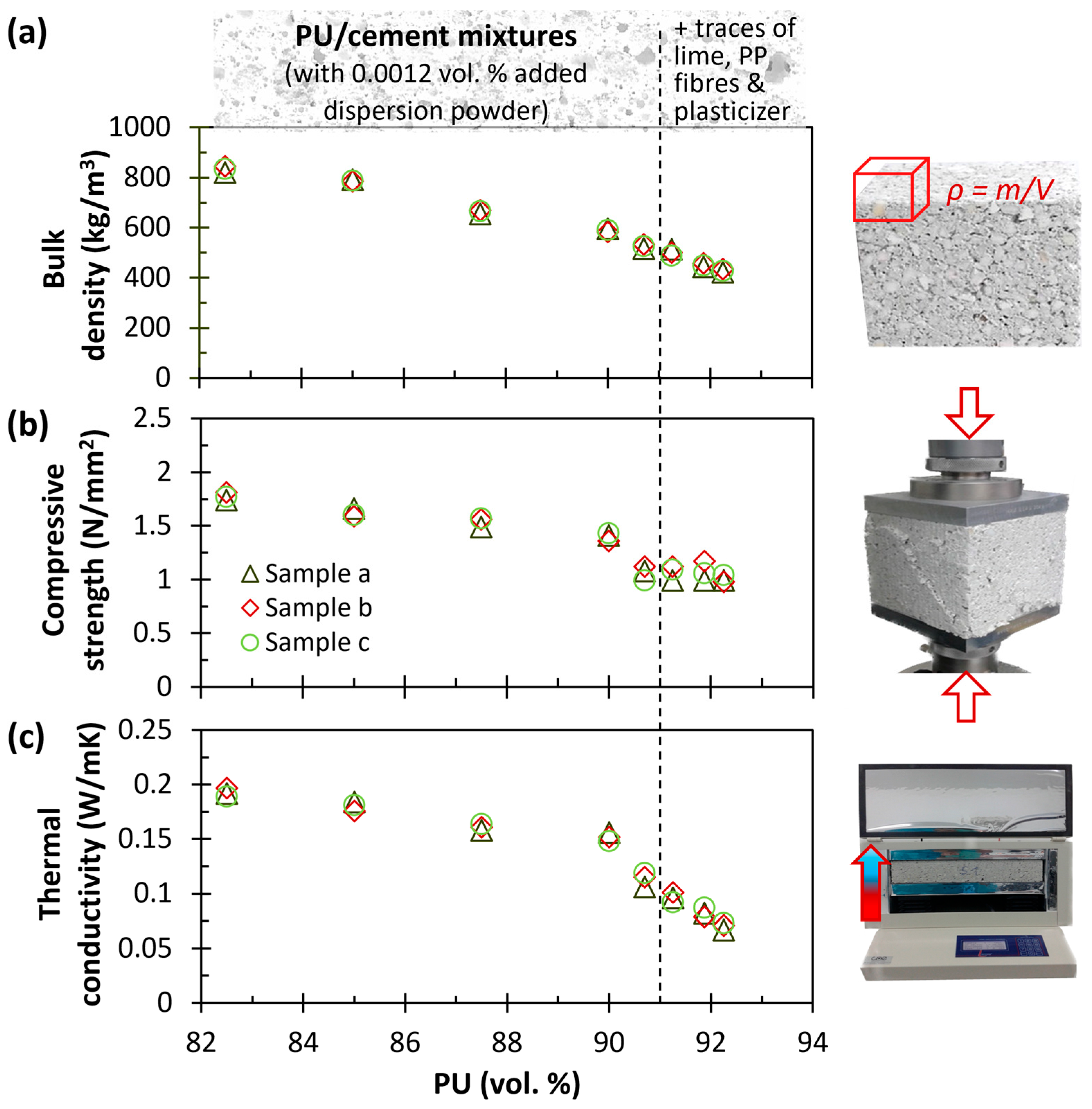

3.1. Development of Lightweight, Thermally Insulating Mortars Incorporating High Volumes of Recycled Rigid Polyurethane Foam

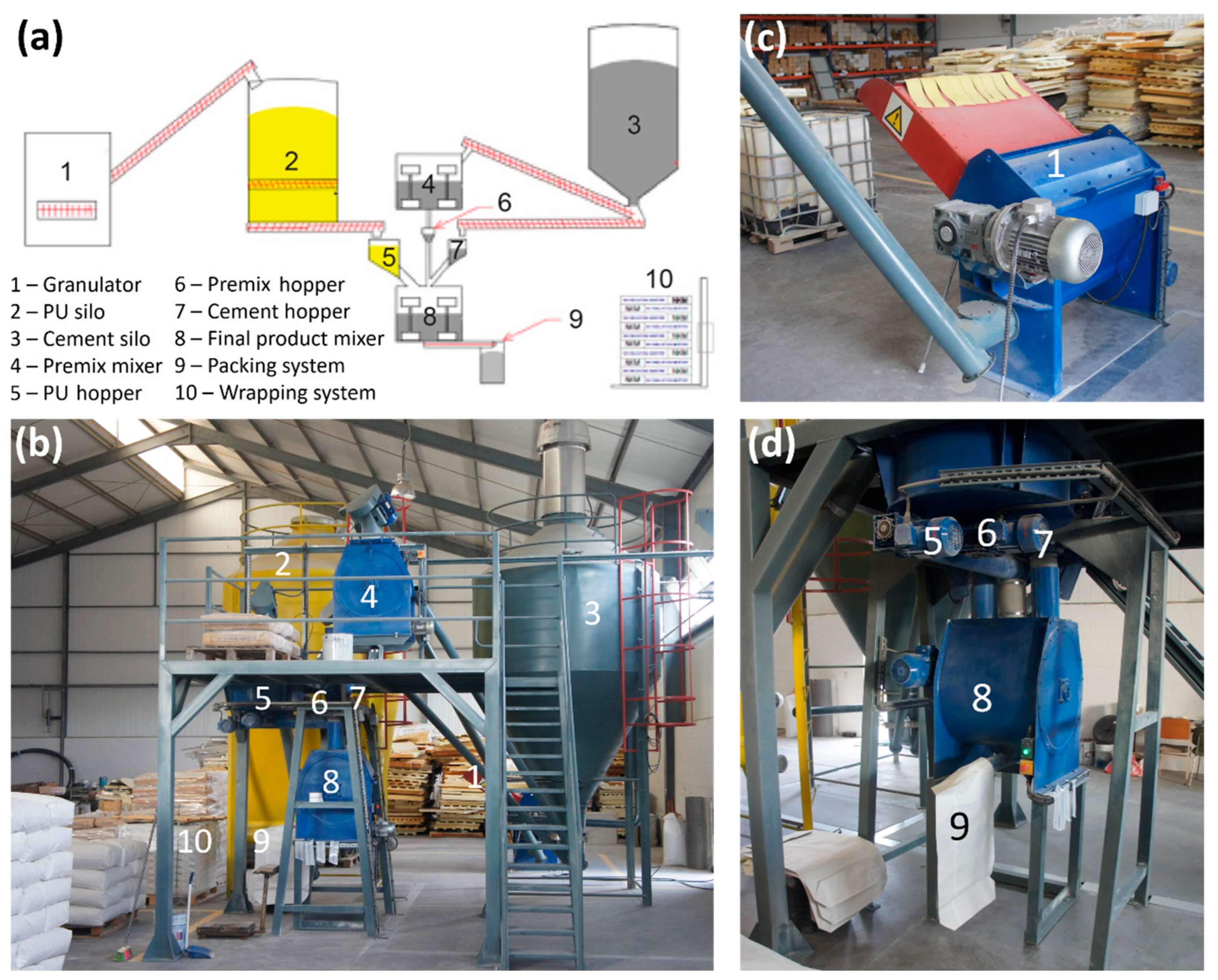

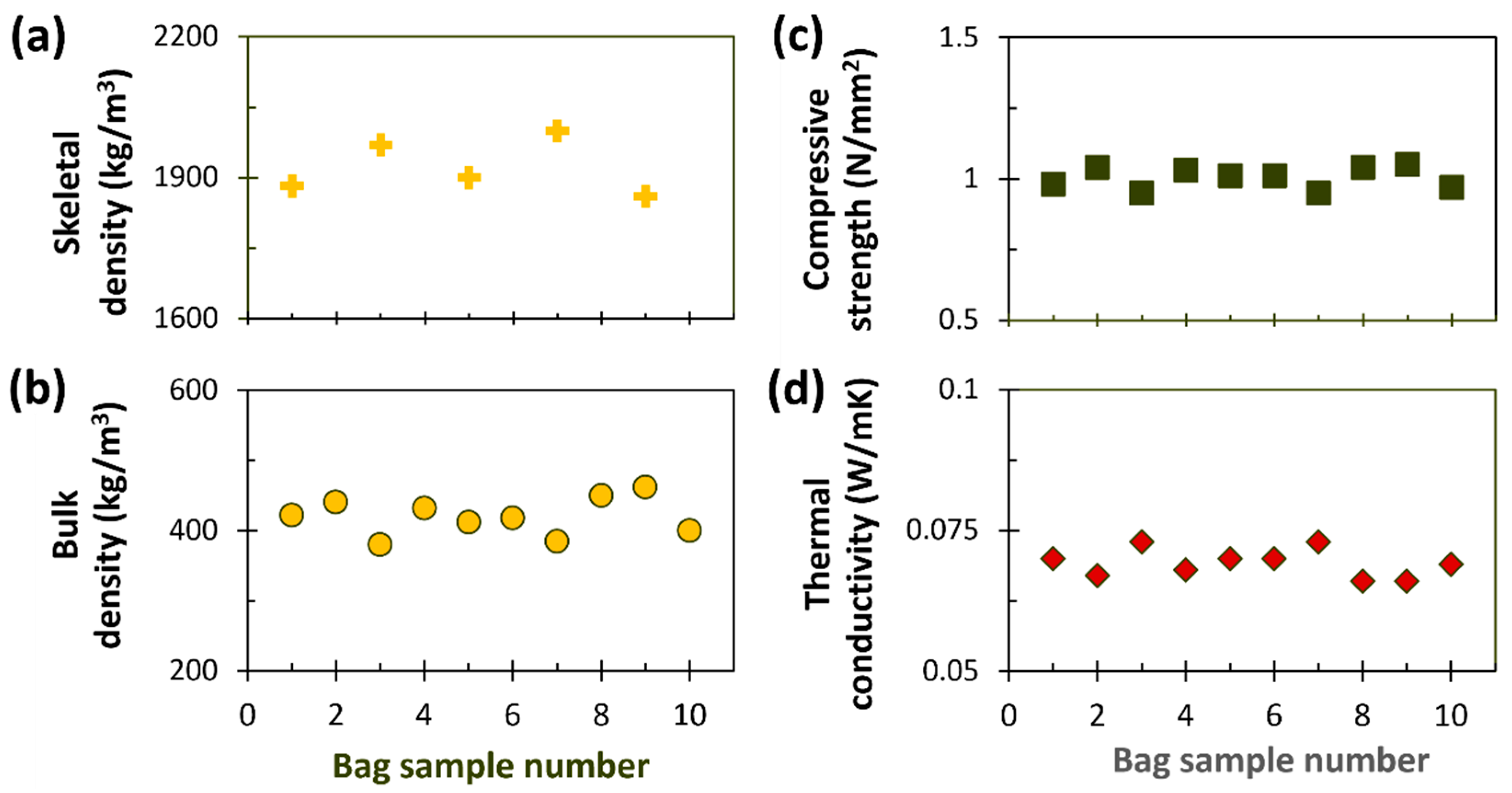

3.2. Design and Evaluation of Prototype Pilot-Scale Production System

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nayanathara Thathsarani Pilapitiya, P.G.C.; Ratnayake, A.S. The world of plastic waste: A review. Clean. Mater. 2024, 11, 100220. [Google Scholar] [CrossRef]

- Plastics Europe. Plastics—The Fast Facts 2023; Plastics Europe: Brussels, Belgium, 2023. [Google Scholar]

- Banik, J.; Chakraborty, D.; Rizwan, M.; Shaik, A.H.; Chandan, M.R. Review on disposal, recycling and management of waste polyurethane foams: A way ahead. Waste Manag. Res. 2023, 41, 1063–1080. [Google Scholar] [CrossRef]

- Rossignolo, G.; Malucelli, G.; Lorenzetti, A. Recycling of polyurethanes: Where we are and where we are going. Green Chem. 2023, 26, 1132–1152. [Google Scholar] [CrossRef]

- Dokl, M.; Copot, A.; Krajnc, D.; Fan, Y.V.; Vujanović, A.; Aviso, K.B.; Tan, R.R.; Kravanja, Z.; Čuček, L. Global projections of plastic use, end-of-life fate and potential changes in consumption, reduction, recycling and replacement with bioplastics to 2050. Sustain. Prod. Consum. 2024, 51, 498–518. [Google Scholar] [CrossRef]

- Janssens, V. Plastics—The Facts 2022; Plastics Europe: Brussels, Belgium, 2022. [Google Scholar]

- Kemona, A.; Piotrowska, M. Polyurethane recycling and disposal: Methods and prospects. Polymers 2020, 12, 1752. [Google Scholar] [CrossRef] [PubMed]

- Gadhave, R.V.; Srivastava, S.; Mahanwar, P.A.; Gadekar, P.T. Recycling and Disposal Methods for Polyurethane Wastes: A Review. Open J. Polym. Chem. 2019, 9, 39–51. [Google Scholar] [CrossRef]

- Jethy, B.; Paul, S.; Das, S.K.; Adesina, A.; Mustakim, S.M. Critical review on the evolution, properties, and utilization of plasticwastes for construction applications. J. Mater. Cycles Waste Manag. 2022, 24, 435–451. [Google Scholar] [CrossRef]

- Alqahtani, F.K.; Zafar, I. Plastic-based sustainable synthetic aggregate in Green Lightweight concrete—A review. Constr. Build. Mater. 2021, 292, 123321. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Faraj, R.H.; Hilal, N.; Mohammed, A.A.; Sherwani, A.F.H. Use of recycled fibers in concrete composites: A systematic comprehensive review. Compos. Part B Eng. 2021, 215, 108769. [Google Scholar] [CrossRef]

- Adesina, A. Overview of the influence of waste materials on the thermal conductivity of cementitious composites. Clean. Eng. Technol. 2021, 2, 100046. [Google Scholar] [CrossRef]

- Roobankumar, R.; SenthilPandian, M. A review of utilization of waste polyurethane foam as lightweight aggregate in concrete. Heliyon 2024, 10, e40479. [Google Scholar] [CrossRef]

- Mistry, M.; Prajapati, V.; Dholakiya, B.Z. Redefining Construction: An In-Depth Review of Sustainable Polyurethane Applications; Springer: New York, NY, USA, 2024; Volume 32, ISBN 1092402303161. [Google Scholar]

- Somarathna, H.M.C.C.; Raman, S.N.; Mohotti, D.; Mutalib, A.A.; Badri, K.H. The use of polyurethane for structural and infrastructural engineering applications: A state-of-the-art review. Constr. Build. Mater. 2018, 190, 995–1014. [Google Scholar] [CrossRef]

- Gómez-Rojo, R.; Alameda, L.; Rodríguez, Á.; Calderón, V.; Gutiérrez-González, S. Characterization of polyurethane foam waste for reuse in eco-efficient building materials. Polymers 2019, 11, 359. [Google Scholar] [CrossRef]

- Nodehi, M. Epoxy, polyester and vinyl ester based polymer concrete: A review. Innov. Infrastruct. Solut. 2022, 7, 64. [Google Scholar] [CrossRef]

- Saikia, N.; De Brito, J. Use of plastic waste as aggregate in cement mortar and concrete preparation: A review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Mounanga, P.; Gbongbon, W.; Poullain, P.; Turcry, P. Proportioning and characterization of lightweight concrete mixtures made with rigid polyurethane foam wastes. Cem. Concr. Compos. 2008, 30, 806–814. [Google Scholar] [CrossRef]

- Ben Fraj, A.; Kismi, M.; Mounanga, P. Valorization of coarse rigid polyurethane foam waste in lightweight aggregate concrete. Constr. Build. Mater. 2010, 24, 1069–1077. [Google Scholar] [CrossRef]

- Rooban Kumar, R.; Senthil Pandian, M. Utilisation of solid waste polyurethane foam as coarse aggregate in concrete: An experimental study with ecological and cost assessment. J. Mater. Cycles Waste Manag. 2024, 27, 241–256. [Google Scholar] [CrossRef]

- Gadea, J.; Rodríguez, A.; Campos, P.L.; Garabito, J.; Calderón, V. Lightweight mortar made with recycled polyurethane foam. Cem. Concr. Compos. 2010, 32, 672–677. [Google Scholar] [CrossRef]

- Junco, C.; Gadea, J.; Rodríguez, A.; Gutiérrez-González, S.; Calderón, V. Durability of lightweight masonry mortars made with white recycled polyurethane foam. Cem. Concr. Compos. 2012, 34, 1174–1179. [Google Scholar] [CrossRef]

- Junco, C.; Rodríguez, A.; Calderón, V.; Muñoz-Rupérez, C.; Gutiérrez-González, S. Fatigue durability test of mortars incorporating polyurethane foam wastes. Constr. Build. Mater. 2018, 190, 373–381. [Google Scholar] [CrossRef]

- Gomes, M.G.; Flores-Colen, I.; da Silva, F.; Pedroso, M. Thermal conductivity measurement of thermal insulating mortars with EPS and silica aerogel by steady-state and transient methods. Constr. Build. Mater. 2018, 172, 696–705. [Google Scholar] [CrossRef]

- EN 1015-10; Methods of Test for Mortar for Masonry—Part 10. Determination of Dry Bulk Density of Hardened Mortar 1999. European Committee for Standardization: Brussels, Belgium, 1999.

- EN 1015-11; Methods of Test for Mortar for Masonry—Part 11. Determination of Flexural and Compressive Strength of Hardened Mortar 2000. European Committee for Standardization: Brussels, Belgium, 2000.

- EN 12664; Thermal performance of building materials and products—Determination of thermal resistance by means of guarded hot plate and heat flow meter methods—Dry and moist products of medium and low thermal resistance 2001. European Committee for Standardization: Brussels, Belgium, 2001.

- ISO 11925-2; Reaction to Fire Tests—Ignitability of Products Subjected to Direct Impingement of Flame—Part 2: Single-Flame Source Test. ISO: Geneva, Switzerland, 2020.

- EN 13501-1+A1; Fire classification of Construction Products and Building Elements—Part 1: Classification Using Data from Reaction to Fire Tests. European Committee for Standardization: Brussels, Belgium, 2010.

- EN ISO 9239-1; Reaction to Fire Tests for Floorings—Part 1: Determination of Burning Behaviour Using a Radiant Heat Source. European Committee for Standardization: Brussels, Belgium, 2010.

- EN ISO 1716; Determination of the Gross Heat of Combustion. European Committee for Standardization: Brussels, Belgium, 2010.

- Li, H.; Gu, L.; Dong, B.; Chen, Q.; Xu, C.; Yang, X.; Wang, W. Improvements in setting behavior and strengths of cement paste/mortar with EVA redispersible powder using C-S-Hs-PCE. Constr. Build. Mater. 2020, 262, 120097. [Google Scholar] [CrossRef]

- Emmanuel, O.U.; Kuqo, A.; Mai, C. Non-conventional mineral binder-bonded lignocellulosic composite materials: A review. BioResources 2021, 16, 4606–4648. [Google Scholar] [CrossRef]

- Yang, S.; Yue, X.; Liu, X.; Tong, Y. Properties of self-compacting lightweight concrete containing recycled plastic particles. Constr. Build. Mater. 2015, 84, 444–453. [Google Scholar] [CrossRef]

- Park, S.; Kang, M.C.; Oinam, Y.; Amoozegar, A.; Pyo, S. Measurement of skeletal density and porosity of construction materials using a new proposed vacuum pycnometer. Meas. J. Int. Meas. Confed. 2022, 196, 111209. [Google Scholar] [CrossRef]

- He, R.; Ma, H.; Hafiz, R.B.; Fu, C.; Jin, X.; He, J. Determining porosity and pore network connectivity of cement-based materials by a modified non-contact electrical resistivity measurement: Experiment and theory. Mater. Des. 2018, 156, 82–92. [Google Scholar] [CrossRef]

- Mizera, K.; Sałasińska, K.; Borucka, M.; Przybysz, J.; Gajek, A. Analysis of the Thermal Decomposition and Flammability of Polyurethane Materials Used in Building Insulation and in the Automotive Industry. Fire Mater. 2025, 49, 359–370. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kountouris, A.; Efstathiou, K.; Kostoglou, N.; Manolakos, D.; Rebholz, C. A New Recycling Technology to Produce Premixed Thermal Insulating Mortars from Polyurethane Waste Foams. Polymers 2025, 17, 2233. https://doi.org/10.3390/polym17162233

Kountouris A, Efstathiou K, Kostoglou N, Manolakos D, Rebholz C. A New Recycling Technology to Produce Premixed Thermal Insulating Mortars from Polyurethane Waste Foams. Polymers. 2025; 17(16):2233. https://doi.org/10.3390/polym17162233

Chicago/Turabian StyleKountouris, Antonis, Kypros Efstathiou, Nikolaos Kostoglou, Dimitrios Manolakos, and Claus Rebholz. 2025. "A New Recycling Technology to Produce Premixed Thermal Insulating Mortars from Polyurethane Waste Foams" Polymers 17, no. 16: 2233. https://doi.org/10.3390/polym17162233

APA StyleKountouris, A., Efstathiou, K., Kostoglou, N., Manolakos, D., & Rebholz, C. (2025). A New Recycling Technology to Produce Premixed Thermal Insulating Mortars from Polyurethane Waste Foams. Polymers, 17(16), 2233. https://doi.org/10.3390/polym17162233