Analysis of the Applicability of Accelerated Conditioning Protocols in Concrete Beams Reinforced with Steel and GFRP: Effects of Chloride Exposure

Abstract

1. Introduction

2. Experimental

2.1. Material Properties

2.2. Reinforced Concrete Beams

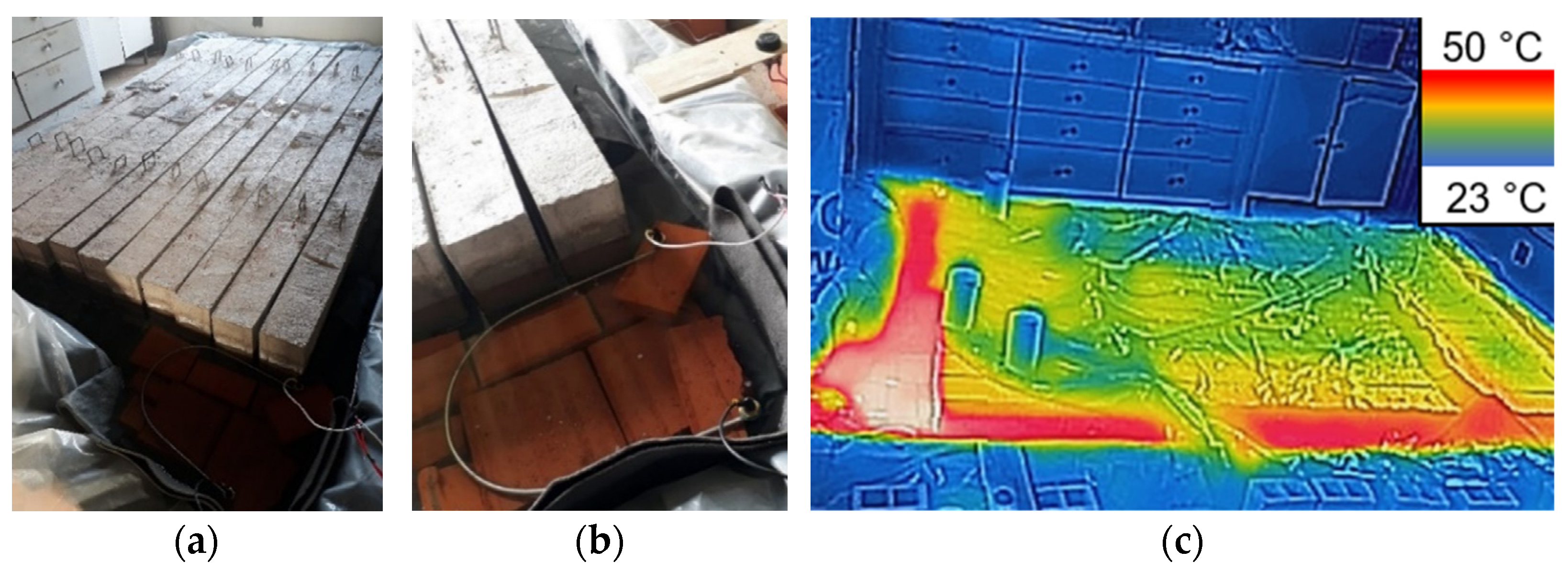

2.3. Exposure Environments

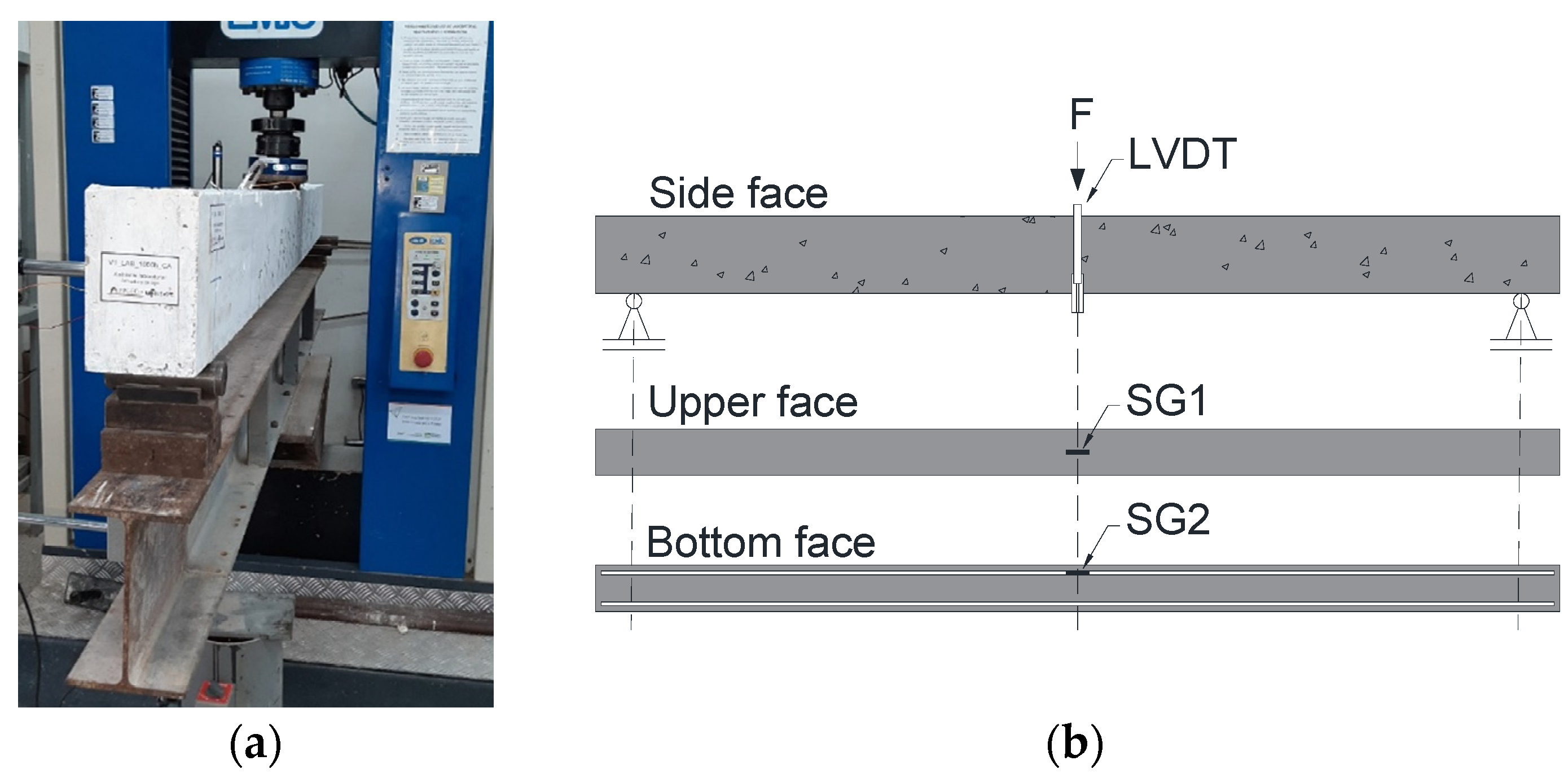

2.4. Instrumentation and Test Setup

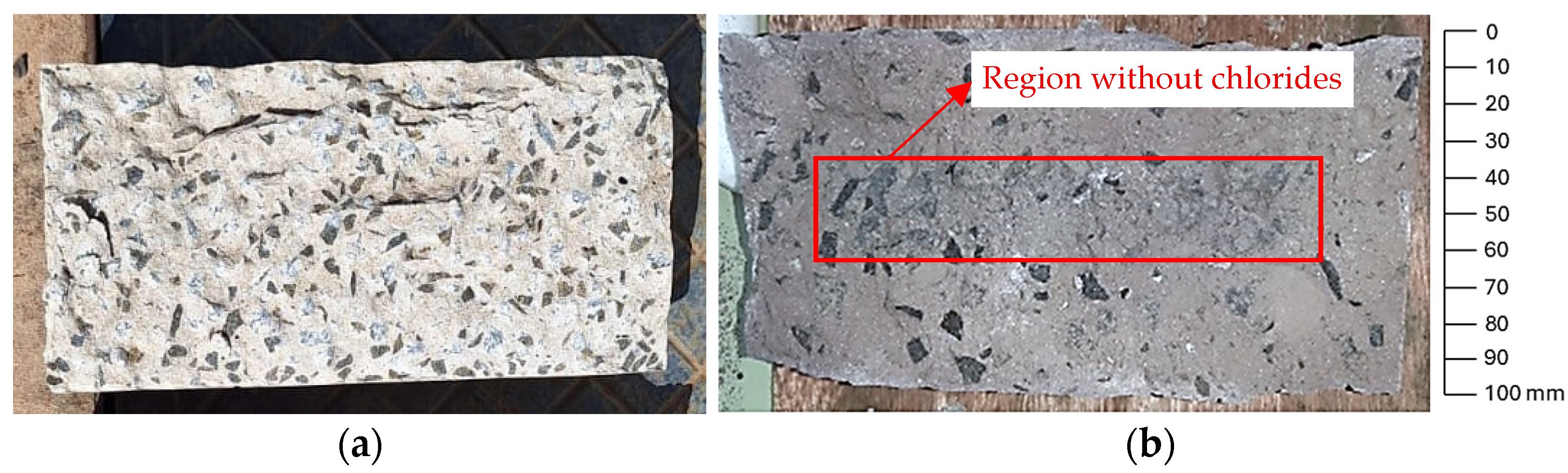

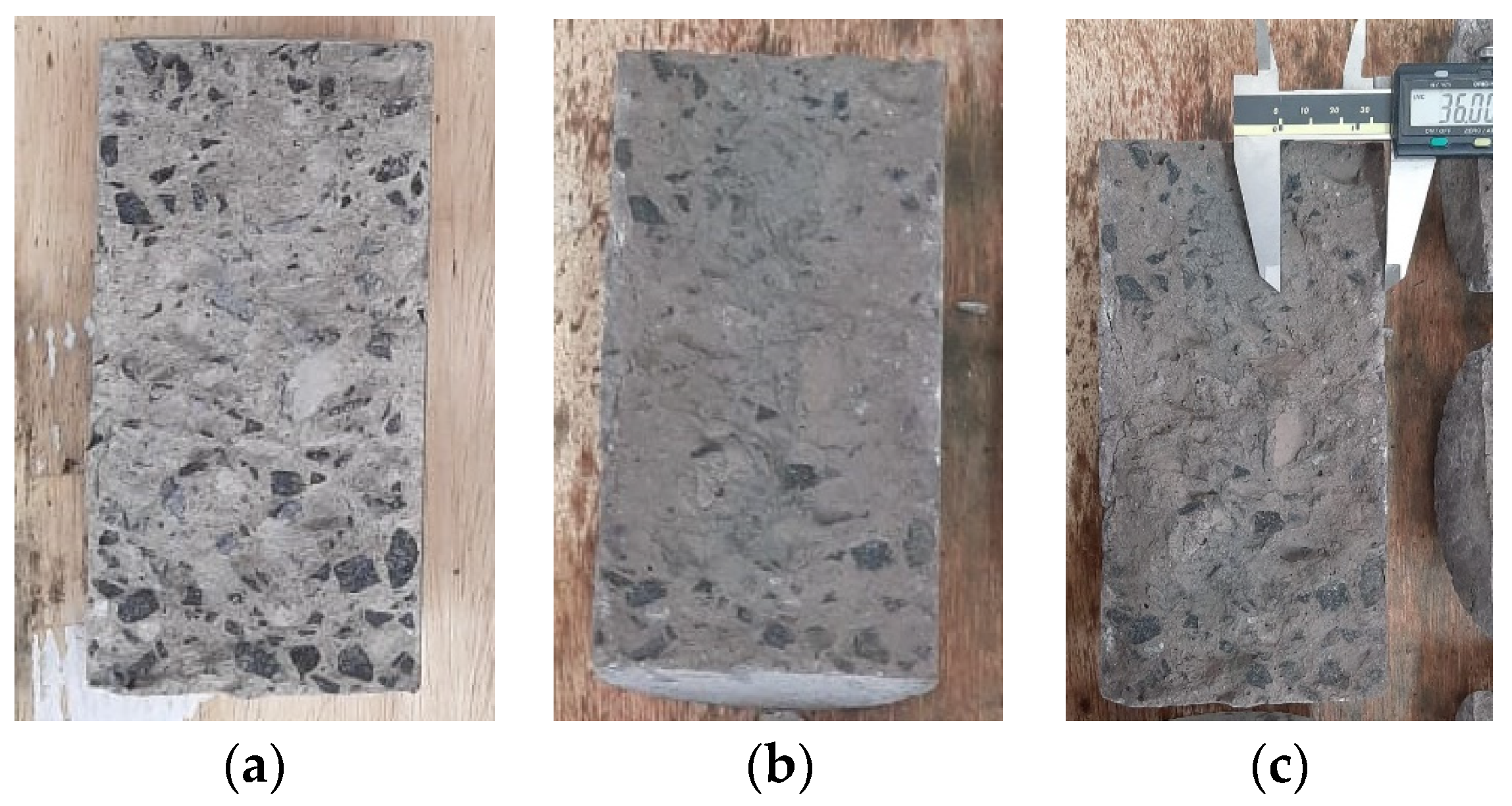

2.5. Chloride Penetration Depth

3. Results

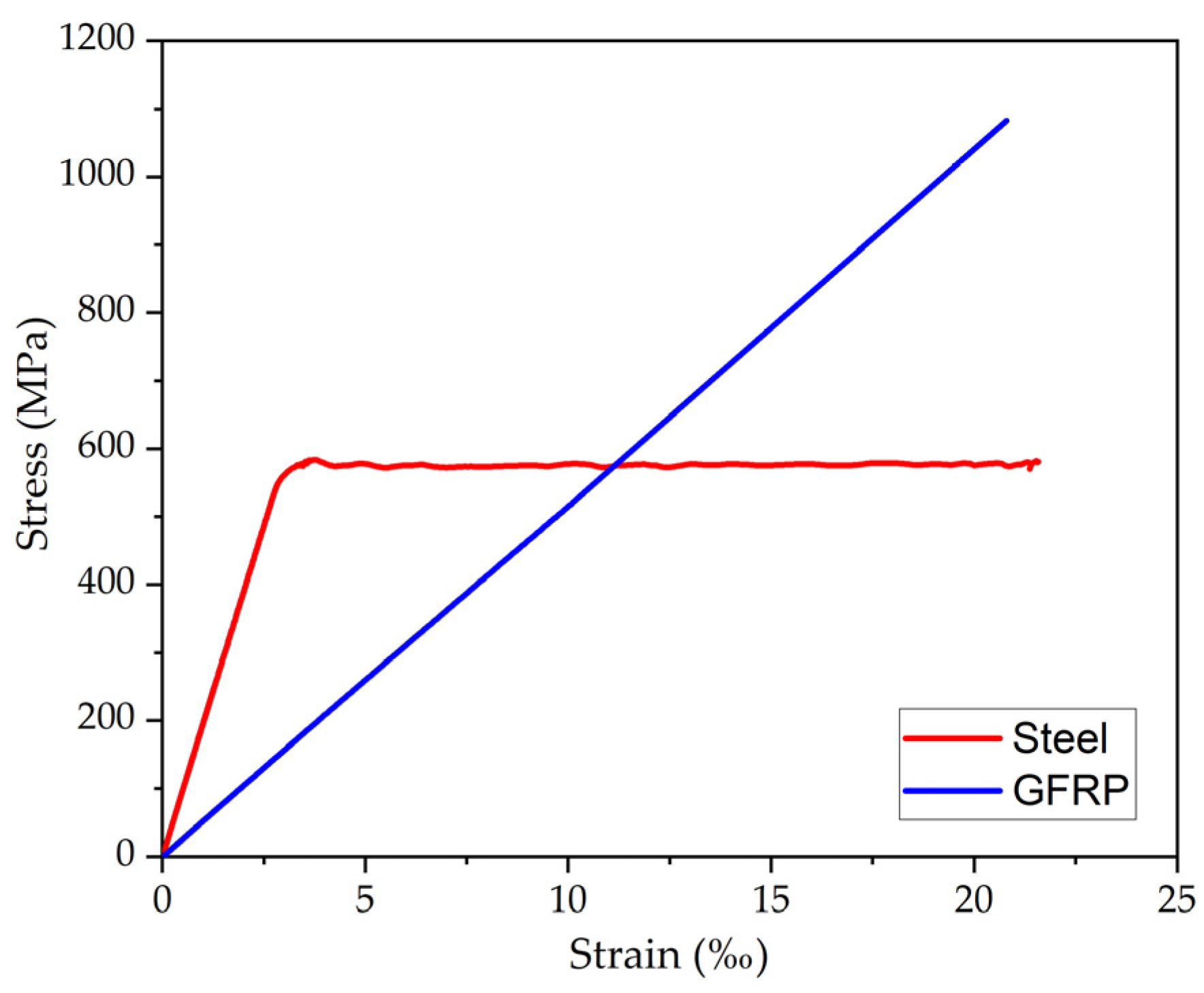

3.1. Concrete, Steel, and GFRP

3.2. Chloride Ions Penetration Depth

3.3. Reinforced Concrete Beams

4. Conclusions

- Until the occurrence of cracking, all beams displayed similar behavior, with the concrete effectively withstanding applied loads. Following the cracking initiation, the reinforcements came into play, leading to a noticeable loss of stiffness. The reductions in bending stiffness from pre- to post-cracking were approximately 49%, 59%, and 60% for beams V_LAB_S_45d, V_LAB_S_1000h, and V_ACP_S_1000h, respectively. Additionally, the reductions were about 91%, 86%, and 81% for beams V_LAB_GFRP_45d, V_LAB_GFRP_1000h, and V_ACP_GFRP_1000h, respectively. The more pronounced decreases in bending stiffness observed in GFRP-reinforced concrete beams from pre- to post-cracking can be attributed to the lower elasticity modulus of GFRP, approximately 76% lower than the elasticity modulus of steel bars. Consequently, the bending stiffness from pre- to post-cracking for beams V_LAB_GFRP_45d, V_LAB_GFRP_1000h, and V_ACP_GFRP_1000h were 66%, 72%, and 70% lower than those for V_LAB_S_45d, V_LAB_S_1000h, and V_ACP_S_1000h, respectively.

- The reduced elasticity modulus of GFRP bars also influences the displacements of GFRP-reinforced concrete beams, resulting in vertical displacements at mid-span approximately 78% greater than those observed in steel-reinforced concrete beams. Conversely, GFRP-reinforced concrete beams exhibit an increased load capacity, with the maximum resisted force of beams V_LAB_GFRP_45d, V_LAB_GFRP_1000h, and V_ACP_GFRP_1000h exceeding that of beams V_LAB_S_45d, V_LAB_S_1000h, and V_ACP_S_1000h by 37%, 27%, and 28%, respectively.

- The exposure of steel-reinforced concrete beams to a chloride solution for 1000 h resulted in a maximum resisted load 12% lower than that observed in steel-reinforced concrete beams subjected to a laboratory environment for the same duration, indicating steel degradation. Concerning GFRP reinforcement, the GFRP-reinforced concrete beams exposed to a chloride solution for 1000 h exhibited a failure force and displacement approximately 10% and 8% lower, respectively, than that GFRP-reinforced concrete beams maintained in a laboratory environment for the same duration, indicating degradation of the GFRP.

- The steel-reinforced concrete beams exhibited a ductile failure mode, characterized by steel yielding followed by concrete crushing, while the GFRP-reinforced concrete beams displayed a brittle failure mode, marked by concrete crushing followed by GFRP rupture.

- The diminished elasticity modulus of GFRP influences the crack pattern of GFRP-reinforced concrete beams, as these beams exhibit cracks with greater height and length than steel-reinforced concrete beams.

- The guidelines of ACI design codes correctly predicted the failure modes of steel and GFRP-reinforced concrete beams and contributed to safety, given that the design results were conservative compared to the experimental results.

- Concerning the engineering interpretation, the findings of this study indicate that GFRP-RC beams exposed to chloride environments under ACP conditions retain sufficient flexural strength to meet the conservative predictions of ACI 440.1R for ultimate limit states.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Sheikh, M.N.; Légeron, F. Performance based seismic assessment of bridges designed according to Canadian Highway Bridge Design Code. Can. J. Civ. Eng. 2014, 41, 777–787. [Google Scholar] [CrossRef]

- Fergani, H.; Di Benedetti, M.; Oller, C.M.; Lynsdale, C.; Guadagnini, M. Durability and degradation mechanisms of GFRP reinforcement subjected to severe environments and sustained stress. Constr. Build. Mater. 2018, 170, 637–648. [Google Scholar] [CrossRef]

- El-Hassan, H.; El-Maaddawy, T. Microstructure characteristics of GFRP reinforcing bars in harsh environment. Adv. Mater. Sci. Eng. 2019, 2019, 8053843. [Google Scholar] [CrossRef]

- Jia, D.; Guo, Q.; Mao, J.; Lv, J.; Yang, Z. Durability of glass fibre-reinforced polymer (GFRP) bars embedded in concrete under various environments. I: Experiments and analysis. Compos. Struct. 2020, 234, 111687. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Alshahrani, H.; Kafi, A. Durability of pultruded GFRP rebar subjected to natural weathering in alkaline solution for 10 years. J. Polym. Environ. 2023, 31, 1090–1101. [Google Scholar] [CrossRef]

- Thongchom, C.; Bui, L.V.H.; Poonpan, N.; Phudtisarigorn, N.; Nguyen, P.T.; Keawsawasvong, S.; Mousa, S. Experimental and numerical investigation of steel- and GFRP-reinforced concrete beams subject to fire exposure. Buildings 2023, 13, 609. [Google Scholar] [CrossRef]

- Devaraj, R.; Olofinjana, A.; Gerber, C. Making a Case for hybrid GFRP-Steel reinforcement system in concrete beams: An Overview. Appl. Sci. 2023, 13, 1463. [Google Scholar] [CrossRef]

- Belay, A.A.; Krassowska, J.; Kosior-Kazberuk, M. Comparative performance analysis of small concrete beams reinforced with steel bars and non-metallic reinforcements. Appl. Sci. 2024, 14, 3957. [Google Scholar] [CrossRef]

- Wu, W.; He, X.; Yang, W.; Alam, M.S.; Wei, B.; He, J. Degradation factors and microstructure degradation characteristics of B/GFRP bars in harsh environment: A review. Constr. Build. Mater. 2023, 366, 130246. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, X.L.; Xian, G.; Wu, G.; Singh Raman, R.K.; Al-Saadi, S.; Haque, A. Long-term durability of basalt- and glass-fibre reinforced polymer (BFRP/GFRP) bars in seawater and sea sand concrete environment. Constr. Build. Mater. 2017, 139, 467–489. [Google Scholar] [CrossRef]

- Esmaeili, Y.; Eslami, A.; Newhook, J.; Benmokrane, B. Performance of GFRP-Reinforced Concrete Beams Subjected to High-Sustained Load and Natural Aging for 10 Years. J. Compos. Constr. 2020, 24, 04020054. [Google Scholar] [CrossRef]

- Moura, R.C.A.; Ribeiro, D.V.; Lima, P.R.L. Mechanical Damage Assessment of GFRP Rebars with Different Resins due to Hydrothermal Aging. Mater. Res. 2021, 24, e20210172. [Google Scholar] [CrossRef]

- Chen, Z.; Li, S.; Zhou, J.; Xu, R.; Dai, S. Flexural behavior of GFRP bars reinforced seawater sea sand concrete beams exposed to marine environment: Experimental and numerical study. Constr. Build. Mater. 2022, 349, 128784. [Google Scholar] [CrossRef]

- Mahato, K.K.; Dutta, K.; Ray, B.C. Static and dynamic behavior of fibrous polymeric composite materials at different environmental conditions. J. Polym. Environ. 2018, 26, 1024–1050. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, X.L.; Xian, G.; Wu, G.; Singh Raman, R.K.; Al-Saaadi, S. Durability study on interlaminar shear behaviour of basalt-, glass- and carbon-fibre reinforced polymer (B/G/CFRP) bars in seawater sea sand concrete environment. Constr. Build. Mater. 2017, 156, 985–1004. [Google Scholar] [CrossRef]

- Duarte, I.O.; Forti, N.C.S.; Pimentel, L.L.; Jacintho, A.E.P.G.A. A study of the shear behavior of concrete beams with synthetic fibers reinforced with Glass and Basalt Fiber-Reinforced polymer bars. Buildings 2024, 14, 2123. [Google Scholar] [CrossRef]

- Yan, F.; Lin, Z.; Yang, M. Bond mechanism and bond strength of GFRP bars to concrete: A review. Compos. B Eng. 2016, 98, 56–69. [Google Scholar] [CrossRef]

- Gooranorimi, O.; Nanni, A. GFRP reinforcement in concrete after 15 years of service. J. Compos. Constr. 2017, 21, 04017024. [Google Scholar] [CrossRef]

- Tu, J.; Xie, H.; Gao, K. Prediction of the Long-Term Performance and Durability of GFRP Bars Under the Combined Effect of a Sustained Load and Severe Environments. Materials 2020, 13, 2341. [Google Scholar] [CrossRef]

- Al-Khafaji, A.F.; Haluza, R.T.; Benzecry, V.; Myers, J.J.; Bakis, C.E.; Nanni, A. Durability assessment of 15- to 20-year-old GFRP bars extracted from bridges in the US. II: GFRP bar assessment. J. Compos. Constr. 2021, 25, 04021008. [Google Scholar] [CrossRef]

- Benzecry, V.; Al-Khafaji, A.F.; Haluza, R.T.; Bakis, C.E.; Myers, J.J.; Nanni, A. Durability Assessment of 15- to 20-Year-Old GFRP Bars Extracted from Bridges in the US. I: Selected Bridges, Bar Extraction, and Concrete Assessment. J. Compos. Constr. 2021, 25, 04021008. [Google Scholar] [CrossRef]

- Benmokrane, B.; Ali, A.H.; Mohamed, H.M.; ElSafty, A.; Manalo, A. Laboratory assessment and durability performance of vinyl-ester, polyester, and epoxy glass-FRP bars for concrete structures. Compos. B Eng. 2017, 114, 163–174. [Google Scholar] [CrossRef]

- Yan, F.; Lin, Z. New strategy for anchorage reliability assessment of GFRP bars to concrete using hybrid artificial neural network with genetic algorithm. Compos. B Eng. 2016, 92, 420–433. [Google Scholar] [CrossRef]

- Yan, F.; Lin, Z.; Zhang, D.; Gao, Z.; Li, M. Experimental study on bond durability of glass fiber reinforced polymer bars in concrete exposed to harsh environmental agents: Freeze-thaw cycles and alkaline-saline solution. Compos. B Eng. 2017, 116, 406–421. [Google Scholar] [CrossRef]

- Emparanza, A.R.; De Caso YBasalo, F.; Kampmann, R.; Usabiaga, I.A. Evaluation of the bond-to-concrete properties of GFRP rebars in marine environments. Infrastructures 2018, 3, 44. [Google Scholar] [CrossRef]

- Morales, C.N.; Claure, G.; Emparanza, A.R.; Nanni, A. Durability of GFRP reinforcing bars in seawater concrete. Constr. Build. Mater. 2021, 270, 121492. [Google Scholar] [CrossRef]

- Sawpan, M.A. Experimental investigation of long term seawater durability and shear properties of pultruded GFRP composite. J. Polym. Environ. 2021, 29, 3574–3586. [Google Scholar] [CrossRef]

- Pan, Y.; Yu, Y.; Yu, J.; Lu, Z.; Chen, Y. Effects of simulated seawater on static and fatigue performance of GFRP bar-concrete bond. J. Build. Eng. 2023, 68, 105985. [Google Scholar] [CrossRef]

- fib. Bulletin 40, FRP Reinforcement in RC Structures; FIB: Lausanne, Switzerland, 2007. [Google Scholar]

- ACI 440.1R-15; Guide for the Design and Construction of Structural Concrete Reinforced with Fiber-Reinforced Polymer (FRP) Bars. ACI: Farmington Hills, MI, USA, 2015.

- Guide to Accelerated Conditioning Protocols for Durability Assessment of Internal and External Fiber-Reinforced Polymer (FRP) Reinforcement. ACI: Farmington Hills, MI, USA, 2015.

- Chen, Y.; Davalos, J.F.; Ray, I.; Kim, H. Accelerated aging tests for evaluations of durability performance of FRP reinforcing bars for concrete structures. Compos. Struct. 2007, 78, 101–111. [Google Scholar] [CrossRef]

- Abeysinghe, H.P.; Edwards, W.; Pritchard, G.; Swampillai, G.J. Degradation of crosslinked resins in water and electrolyte solutions. Polymer 1982, 23, 1785–1790. [Google Scholar] [CrossRef]

- D’Antino, T.; Pisani, M.A.; Poggi, C. Effect of the environment on the performance of GFRP reinforcing bars. Compos. B Eng. 2018, 141, 123–136. [Google Scholar] [CrossRef]

- Zhu, H.G.; Leung, C.K.Y.; Kim, J.K.; Liu, M.Y. Degradation of glass fiber-reinforced plastic composites containing nanoclay in alkaline environment. J. Compos. Mater. 2011, 45, 2147–2156. [Google Scholar] [CrossRef]

- Arabi, N.; Molez, L.; Rangeard, D. Durability of alkali-resistant glass fibers reinforced cement composite: Microstructural observations of degradation. Period. Polytech. Civ. Eng. 2018, 62, 653–659. [Google Scholar] [CrossRef]

- Yan, F.; Lin, Z. Bond durability assessment and long-term degradation prediction for GFRP bars to fiber-reinforced concrete under saline solutions. Compos. Struct. 2017, 161, 393–406. [Google Scholar] [CrossRef]

- Nakayama, M.; Wada, S.; Kuroki, S.; Nogami, M. Factors affecting cyclic durability of all-solid-state lithium polymer batteries using poly(ethylene oxide)-based solid polymer electrolytes. Energy Environ. Sci. 2010, 3, 1995–2002. [Google Scholar] [CrossRef]

- Chen, Y.; Davalos, J.F.; Ray, I. Durability prediction for GFRP reinforcing bars using short-term data of accelerated aging tests. J. Compos. Constr. 2006, 10, 279–286. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A.; El-Gamal, S.; Almusallam, T.H.; Alsayed, S.H.; Aqel, M. Effect of harsh environmental conditions on the tensile properties of GFRP bars. Compos. B Eng. 2013, 45, 835–844. [Google Scholar] [CrossRef]

- Debaiky, A.S.; Nkurunziza, G.; Benmokrane, B.; Cousin, P. Residual Tensile Properties of GFRP reinforcing bars after loading in severe environments. J. Compos. Constr. 2006, 10, 370–380. [Google Scholar] [CrossRef]

- Robert, M.; Cousin, P.; Benmokrane, B. Durability of GFRP reinforcing bars embedded in moist concrete. J. Compos. Constr. 2009, 13, 66–73. [Google Scholar] [CrossRef]

- Robert, M.; Benmokrane, B. Combined effects of saline solution and moist concrete on long-term durability of GFRP reinforcing bars. Constr. Build. Mater. 2013, 38, 274–284. [Google Scholar] [CrossRef]

- Almusallam, T.; Al-Salloum, Y.; Alsayed, S.; El-Gamal, S.E.; Aqel, M. Tensile properties degradation of glass fiber-reinforced polymer bars embedded in concrete under severe laboratory and field environmental conditions. J. Compos. Mater. 2013, 47, 393–407. [Google Scholar] [CrossRef]

- Li, W.; Wen, F.; Zhou, M.; Liu, F.; Jiao, Y.; Wu, Q.; Liu, H. Assessment and Prediction Model of GFRP Bars’ Durability Performance in Seawater Environment. Buildings 2022, 12, 127. [Google Scholar] [CrossRef]

- Wang, Z.; Xie, J.; Mai, Z.; Liu, P.; Lu, Z.; Li, L. Durability of GFRP bar-reinforced seawater-sea sand concrete beams: Coupled effects of sustained loading and exposure to a chloride environment. Eng. Struct. 2023, 283, 115814. [Google Scholar] [CrossRef]

- ACI 318; Building Code Requirements for Reinforced Concrete. ACI: Farmington Hills, MI, USA, 2019.

- ABNT NBR 5739; Concreto—Ensaio de Compressão de Corpos-de-Prova Cilíndricos ou Prismáticos de Concreto—Procedimento. ABNT: Rio de Janeiro, RJ, Brazil, 2018.

- ABNT NBR 8522; Concreto Endurecido—Determinação dos Módulos de Elasticidade e de Deformação—Parte 1: Módulos Estáticos à Compressão. ABNT: Rio de Janeiro, RJ, Brazil, 2021.

- ABNT NBR ISO 6892-1; Materiais Metálicos—Ensaio de tração, Parte 1: Método de Ensaio à Temperatura Ambiente. ABNT: Rio de Janeiro, RJ, Brazil, 2018.

- ABNT NBR 17201-1; Barras de Polímero Reforçado com Fibras (FRP) Destinadas a Armaduras para Estruturas de Concreto Armado. Parte 1: Requisitos. ABNT: Rio de Janeiro, RJ, Brazil, 2025.

- ABNT NBR 17201-2; Barras de Polímero Reforçado com Fibras (FRP) Destinadas a Armaduras para Estruturas de Concreto Armado. Parte 2: Determinação do Diâmetro Efetivo. ABNT: Rio de Janeiro, RJ, Brazil, 2025.

- ABNT NBR 17201-3; Barras de Polímero Reforçado com Fibras (FRP) Destinadas a Armaduras para Estruturas de Concreto Armado—Parte 3: Determinação da Resistência à Tração e do Módulo de Elasticidade. ABNT: Rio de Janeiro, RJ, Brazil, 2025.

- ABNT NBR 17201-10; Barras de Polímero Reforçado com Fibras (FRP) Destinadas a Armaduras para Estruturas de Concreto Armado—Parte 10: Determinação do teor de Fibra pelo Método de Combustão e do teor de Aditivo Mineral pelo Método de Ataque por Ácido. ABNT: Rio de Janeiro, RJ, Brazil, 2025.

- Goldston, M.; Remennikov, A.; Sheikh, M.N. Experimental investigation of the behaviour of concrete beams reinforced with GFRP bars under static and impact loading. Eng. Struct. 2016, 113, 220–232. [Google Scholar] [CrossRef]

- Toutanji, H.; Saafi, M. Flexural behavior of concrete beams reinforced with glass fiber-reinforced polymer (GFRP) bars. ACI Struct. J. 2000, 97, 712–719. [Google Scholar] [CrossRef] [PubMed]

| Reference | Fiber | Resin | Surface | Environmental Exposure | Temperature (°C) | Time (Days) | Tensile Strength (MPa) | Retention (%) |

|---|---|---|---|---|---|---|---|---|

| Chen et al. [32] | E-glass | Vinyl ester | Helically wrapped and slightly sand coated | Unconditioned | - | - | 771 | 100 |

| Tap water immersion | 60 | 70 | 544 | 71 | ||||

| Alkaline solution immersion | 60 | 70 | 564 | 73 | ||||

| Saline solution immersion | 60 | 70 | 572 | 74 | ||||

| E-glass | Vinyl ester | Helically wrapped and slightly sand coated | Unconditioned | - | - | 925 | 100 | |

| Alkaline solution immersion | 60 | 60 | 482 | 52 | ||||

| Embedded in concrete and immersed in tap water | Room | 90 | 836 | 90 | ||||

| Embedded in concrete and immersed in alkaline solution | 60 | 90 | 566 | 61 | ||||

| Robert, Cousin and Benmokrane [42] | E-glass | Vinyl ester | Sand coated | Unconditioned | - | - | 786 | 100 |

| Embedded in concrete and immersed in tap water | 23 | 240 | 714 | 91 | ||||

| 40 | 240 | 708 | 90 | |||||

| 50 | 240 | 665 | 85 | |||||

| Robert and Benmokrane [43] | E-glass | Vinyl ester | Sand coated | Unconditioned | - | - | 786 | 100 |

| Embedded in concrete and immersed in saline solution | 23 | 365 | 726 | 92 | ||||

| 40 | 365 | 712 | 91 | |||||

| 50 | 365 | 702 | 89 | |||||

| 70 | 120 | 744 | 95 | |||||

| Almusallam et al. [44] | E-glass | Vinyl ester | Regular ribs | Unconditioned | - | - | 1478 | 100 |

| Embedded in concrete and immersed in tap water | 50 | 180 | 1229 | 83 | ||||

| 50 | 360 | 1158 | 78 | |||||

| 50 | 540 | 1123 | 76 | |||||

| Embedded in concrete and immersed in seawater | 50 | 180 | 1269 | 86 | ||||

| 50 | 360 | 1300 | 88 | |||||

| 50 | 540 | 1238 | 84 | |||||

| Fergani et al. [2] | ECR glass | Vinyl ester | Ribs | Unconditioned | - | - | 1542 | 100 |

| Embedded in concrete and immersed in tap water | 60 | 42 | 1244 | 81 | ||||

| 60 | 83 | 1227 | 80 | |||||

| 60 | 270 | 917 | 59 | |||||

| Jia et al. [4] | E-glass | Vinyl ester | Helically wrapped and sand coated | Unconditioned | - | - | - | 100 |

| Embedded in concrete and immersed in tap water | 60 | 120 | - | 61.6 | ||||

| Embedded in concrete and immersed in salt water | 60 | 120 | - | 60.7 | ||||

| Morales et al. [26] | ECR glass | Vinyl ester | Double helically fiber-wrapped | Unconditioned | - | - | 822 | 100 |

| Embedded in seawater concrete and exposed to subtropical region | 25 | 30 | 821 | 100 | ||||

| 180 | 795 | 97 | ||||||

| 360 | 827 | 101 | ||||||

| 720 | 811 | 99 | ||||||

| Embedded in seawater concrete and immersed in seawater | 60 | 30 | 764 | 93 | ||||

| 180 | 679 | 83 | ||||||

| 360 | 616 | 75 | ||||||

| 720 | 607 | 74 | ||||||

| Wang et al. [46] | Glass | Vinyl ester | Ribs and sand coated | Unconditioned | - | - | 1102 | 100 |

| Embedded in seawater and sea sand concrete and subjected to seawater wet-dry cycles | 40 (cycles) | 90 | - | 81 | ||||

| 180 | - | 76 | ||||||

| 270 | - | 76 |

| Researchers | Environment | Exposure | Evaluation | Structural Beams Tested? |

|---|---|---|---|---|

| Robert, Cousin and Benmokrane [42] | Bars in moist concrete | Tap water/pore solution, 23–50 °C | Bar property retention | No |

| Robert and Benmokrane [43] | Concrete-wrapped bars | Saline + moist concrete | Residual bar properties | No |

| Benmokrane et al. [22] | Bars (different resins) | Alkaline solution, 60 °C | Durability by resin type | No |

| Fergani et al. [2] | Bars/coupons under stress | Severe environments + sustained load | Degradation mechanisms | No |

| This study | Full RC beams (steel & GFRP) | ACI 440.9R NaCl 3.5%, 50 °C, 1000 h | Flexural stiffness, cracking, failure, design conservatism | Yes |

| Exposure Environment | Age of Test | Specimens | ||||

|---|---|---|---|---|---|---|

| Beams | Concrete | Steel | GFRP | |||

| Steel | GFRP | |||||

| Laboratory | 45 days | 2 | 2 | 3 | 2 | 5 |

| Laboratory | 45 days + 1000 h (87 days) | 2 | 2 | 3 | 2 | |

| Chloride attack | 45 days + 1000 h (87 days) | 2 | 2 | 3 | 2 | 5 |

| Properties | Characteristic Values of Mechanical Properties for GFRP and BFRP Members |

|---|---|

| Fiber content (%) | ≥75 |

| Tensile strength (MPa) | ≥800 |

| Modulus of elasticity (GPa) | ≥45 |

| Ultimate tensile strain (%) | ≥1.1 |

| Effective cross-section | Table 5 |

| Nominal Diameter (mm) | Nominal Cross-Section Area (mm2) | Effective Area Limits of the Cross-Section (mm2) | |

|---|---|---|---|

| Minimum | Maximum | ||

| 4 | 12.6 | 11.8 | 17.7 |

| 5 | 19.6 | 18.5 | 25.4 |

| 6 | 28.3 | 26.6 | 45.2 |

| 8 | 50.3 | 47.2 | 70.7 |

| 10 | 78.5 | 73.8 | 101.8 |

| 12 | 113.1 | 106.3 | 138.5 |

| 14 | 153.9 | 144.7 | 181.0 |

| 16 | 201.1 | 189.0 | 229.0 |

| 18 | 254.5 | 239.2 | 282.7 |

| 20 | 314.2 | 295.3 | 342.1 |

| 22 | 380.1 | 357.3 | 441.8 |

| 25 | 490.9 | 461.4 | 554.2 |

| 28 | 615.7 | 578.8 | 723.8 |

| 32 | 804.2 | 756.0 | 910.0 |

| Beam | Design Code | Mn (kN·m) | Fmax (kN) | Failure Mode |

|---|---|---|---|---|

| V_LAB_S_45d | ACI 318 [47] | 14.36 | 24.98 | Steel yielding |

| V_LAB_S_1000h | 14.34 | 24.94 | Steel yielding | |

| V_ACP_S_1000h | 14.20 | 24.70 | Steel yielding | |

| V_LAB_GFRP_45d | ACI 440.1R [30] | 15.28 | 26.57 | Concrete crushing |

| V_LAB_ GFRP _1000h | 15.42 | 26.82 | Concrete crushing | |

| V_ACP_ GFRP _1000h | 15.40 | 26.79 | Balanced rupture |

| Exposure Condition | Age (Days) | Concrete | Steel | GFRP | |||||

|---|---|---|---|---|---|---|---|---|---|

| fcm (MPa) | Ecm (GPa) | fy (MPa) | εsy (‰) | Es (GPa) | ffu (MPa) | εfu (‰) | Ef (GPa) | ||

| Laboratory | 45 | 32.79 (10.21) | - 1 | 565.35 (0.08) | 3.07 (4.69) | 194.33 (1.16) | 1048.98 (4.90) | 20.83 (3.96) | 50.36 (2.00) |

| Laboratory | 87 | 33.49 (2.00) | 34.50 (1.17) | 563.36 (0.06) | 3.02 (7.65) | 197.47 (0.67) | |||

| Chloride attack | 87 | 34.60 (1.08) | 37.84 (10.63) | 559.85 (0.06) | 2.99 (2.97) | 195.80 (1.35) | 911.86 (4.73) | 17.89 (3.13) | 50.96 (2.10) |

| Beams | First Crack | Reinforcement Yielding | Concrete Crushing | Maximum Load | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F | δ | εs/f | εc | F | δ | εs/f | εc | F | δ | εs/f | εc | F | δ | εs/f | εc | |

| kN | mm | ‰ | ‰ | kN | mm | ‰ | ‰ | kN | mm | ‰ | ‰ | kN | mm | ‰ | ‰ | |

| V1_LAB_S_45d | 7.1 | 1.9 | 0.2 | −0.2 | 23.0 | 10.9 | 2.1 | −0.9 | 24.0 | 19.6 | 13.9 | −2.6 | 25.4 | 49.2 | x | x |

| V2_LAB_S_45d | 6.9 | 2.6 | x | x | 24.7 | 13.3 | x | x | 26.0 | 21.2 | x | x | 26.7 | 32.9 | x | x |

| V1_LAB_GFRP_45d | 4.8 | 1.1 | 0.1 | −0.1 | - | - | - | - | 27.3 | 40.2 | x | −3.2 | 38.1 | 70.1 | x | −4.6 |

| V2_LAB_GFRP_45d | 3.8 | 0.3 | 0.1 | −0.1 | - | - | - | - | 25.6 | 41.5 | x | −3.1 | 33.1 | 61.5 | x | x |

| V1_LAB_S_1000h | 6.3 | 1.2 | 0.3 | −0.1 | 25.7 | 12.1 | 2.4 | −1.3 | 26.9 | 20.7 | 8.4 | −3.2 | 28.6 | 61.7 | x | x |

| V2_LAB_S_1000h | 6.4 | 1.4 | x | −0.2 | 26.0 | 11.3 | x | −1.2 | 27.7 | 18.3 | x | −3.1 | 29.6 | 74.6 | x | x |

| V1_LAB_GFRP_1000h | 4.1 | 0.7 | 0.1 | −0.1 | - | - | - | - | 28.5 | 44.7 | x | −3.5 | 37.2 | 67.8 | x | −6.4 |

| V2_LAB_GFRP_1000h | 1.1 | 0.6 | 0.3 | −0.1 | - | - | - | - | 30.2 | 46.9 | x | x | 36.8 | 67.7 | x | x |

| V1_ACP_S_1000h | 5.1 | 1.2 | 0.1 | −0.1 | 22.7 | 10.6 | 2.3 | x | 23.2 | 20.8 | x | x | 25.1 | 73.1 | x | x |

| V2_ACP_S_1000h | 5.9 | 1.2 | 0.4 | −0.1 | 24.2 | 11.3 | 2.3 | −0.9 | 24.5 | 20.4 | x | −3.2 | 26.8 | 74.8 | x | x |

| V1_ACP_GFRP_1000h | 3.4 | 1.0 | x | −0.1 | - | - | - | - | 29.1 | 49.7 | x | x | 31.7 | 59.3 | x | x |

| V2_ACP_GFRP_1000h | 4.0 | 1.3 | x | −0.1 | - | - | - | - | 32.0 | 54.0 | x | x | 34.5 | 65.2 | x | x |

| Beam | Design | Experimental | Fmax,d/Fmax,e | ||

|---|---|---|---|---|---|

| Fmax,d (kN) | Failure Mode | Fmax,e (kN) | Failure Mode | ||

| V_LAB_S_45d | 24.98 | Steel yielding | 26.05 | Steel yielding | 0.96 |

| V_LAB_S_1000h | 24.94 | Steel yielding | 29.10 | Steel yielding | 0.86 |

| V_ACP_S_1000h | 24.70 | Steel yielding | 25.95 | Steel yielding | 0.95 |

| V_LAB_GFRP_45d | 26.57 | Concrete crushing | 35.60 | Concrete crushing | 0.75 |

| V_LAB_GFRP_1000h | 26.82 | Concrete crushing | 37.00 | Concrete crushing | 0.72 |

| V_ACP_GFRP_1000h | 26.79 | Balanced rupture | 33.10 | Concrete crushing | 0.81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mazzú, A.D.E.; Dalfré, G.M. Analysis of the Applicability of Accelerated Conditioning Protocols in Concrete Beams Reinforced with Steel and GFRP: Effects of Chloride Exposure. Polymers 2025, 17, 2423. https://doi.org/10.3390/polym17172423

Mazzú ADE, Dalfré GM. Analysis of the Applicability of Accelerated Conditioning Protocols in Concrete Beams Reinforced with Steel and GFRP: Effects of Chloride Exposure. Polymers. 2025; 17(17):2423. https://doi.org/10.3390/polym17172423

Chicago/Turabian StyleMazzú, Amanda Duarte Escobal, and Gláucia Maria Dalfré. 2025. "Analysis of the Applicability of Accelerated Conditioning Protocols in Concrete Beams Reinforced with Steel and GFRP: Effects of Chloride Exposure" Polymers 17, no. 17: 2423. https://doi.org/10.3390/polym17172423

APA StyleMazzú, A. D. E., & Dalfré, G. M. (2025). Analysis of the Applicability of Accelerated Conditioning Protocols in Concrete Beams Reinforced with Steel and GFRP: Effects of Chloride Exposure. Polymers, 17(17), 2423. https://doi.org/10.3390/polym17172423