Influence of Nanosilica and PVA Fibers on the Mechanical and Deformation Behavior of Engineered Cementitious Composites

Abstract

1. Introduction

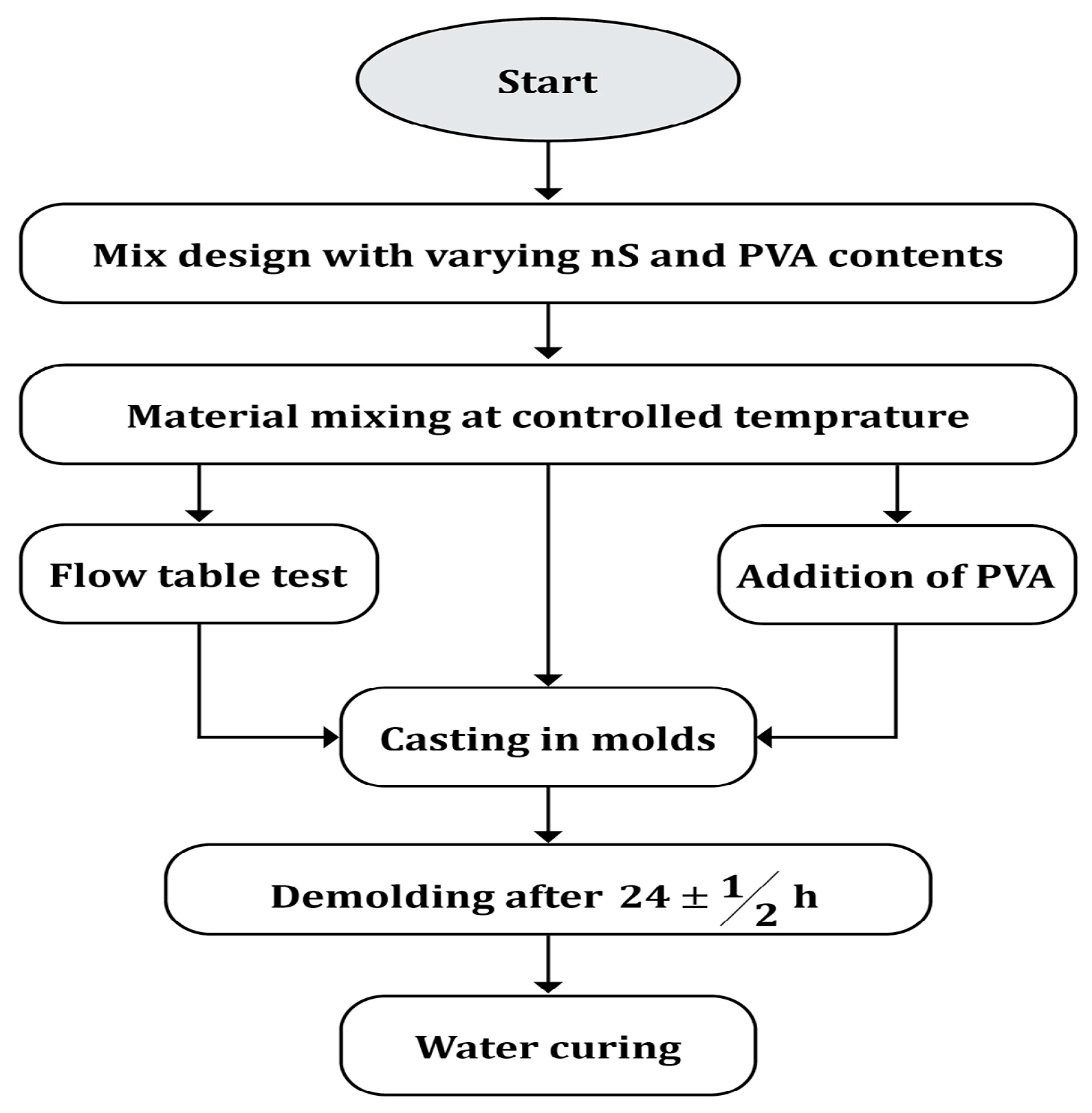

2. Materials and Methods

- Material preparation and mixture testing for the sample.

- Testing the samples.

- Examining the test results obtained.

2.1. Preparation for the Samples

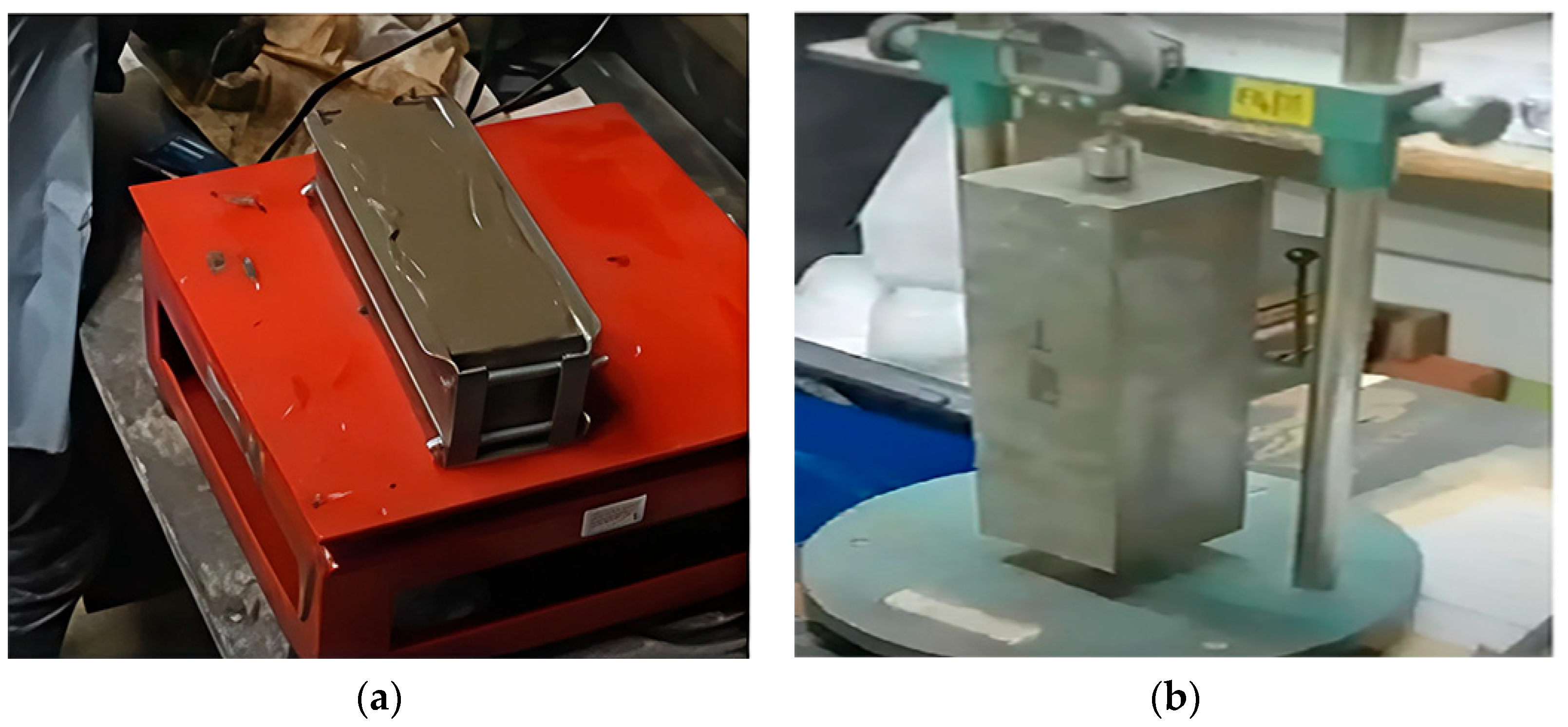

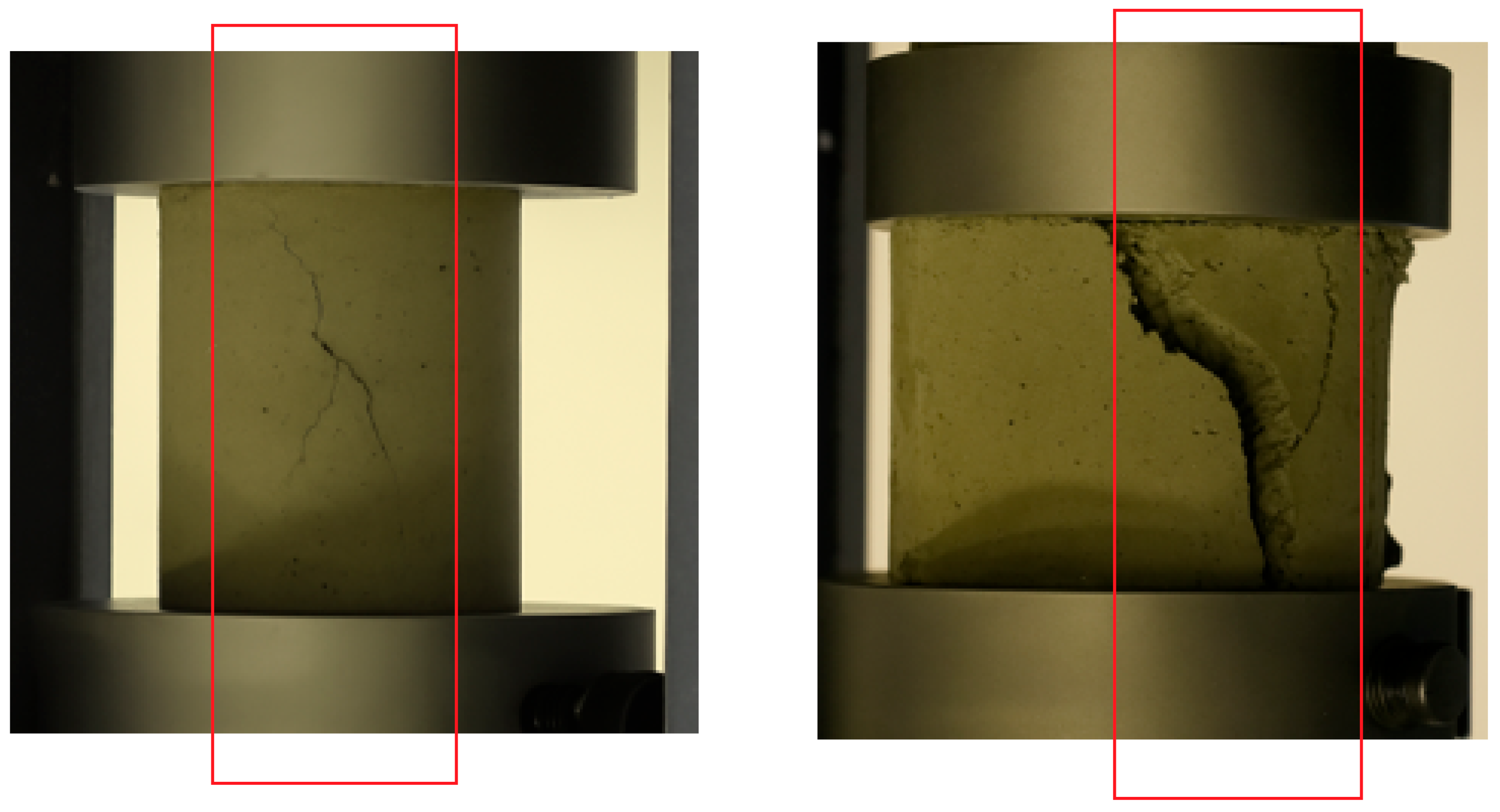

2.2. Testing Procedures

2.3. Abaqus Procedures

3. Results and Discussion

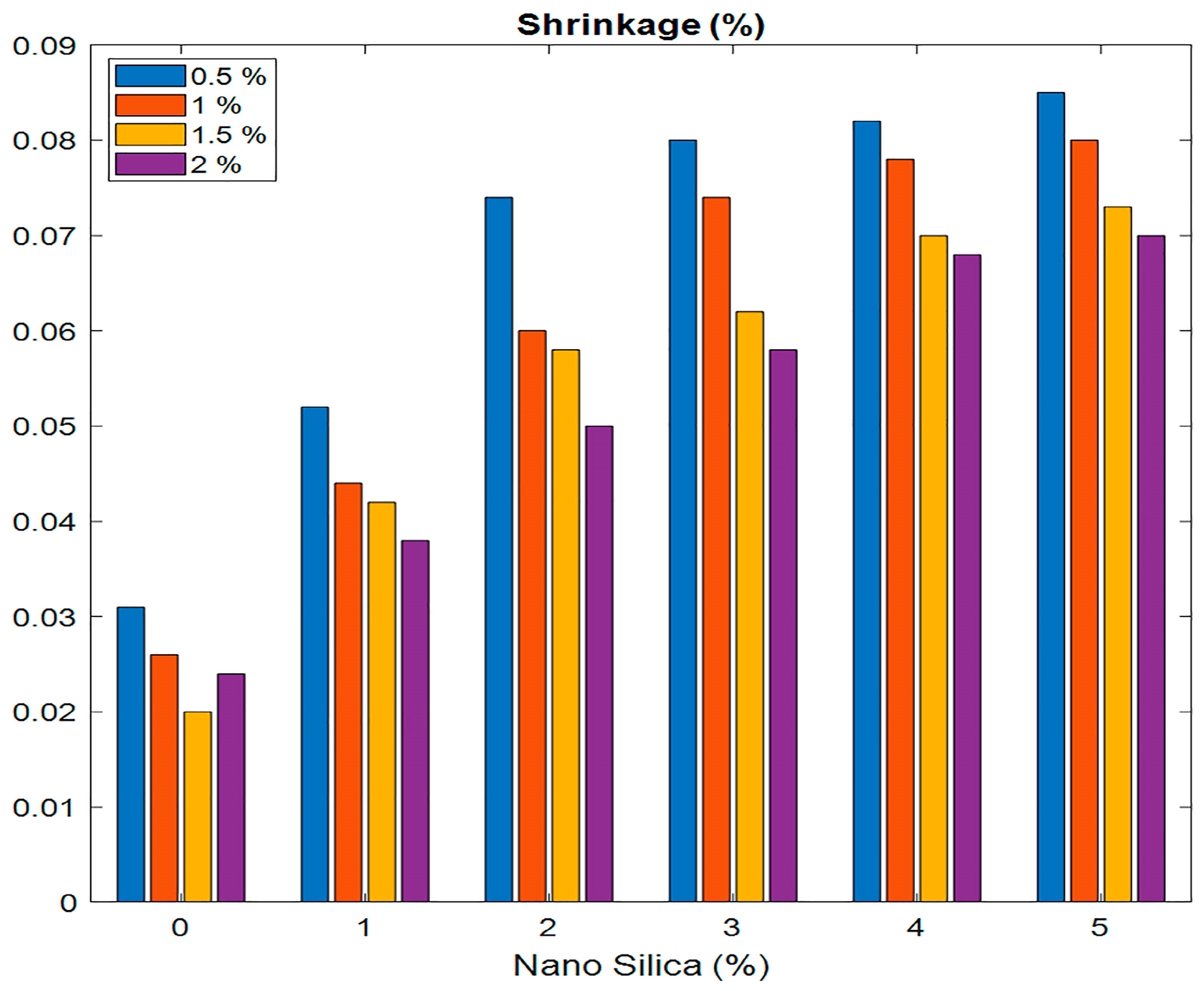

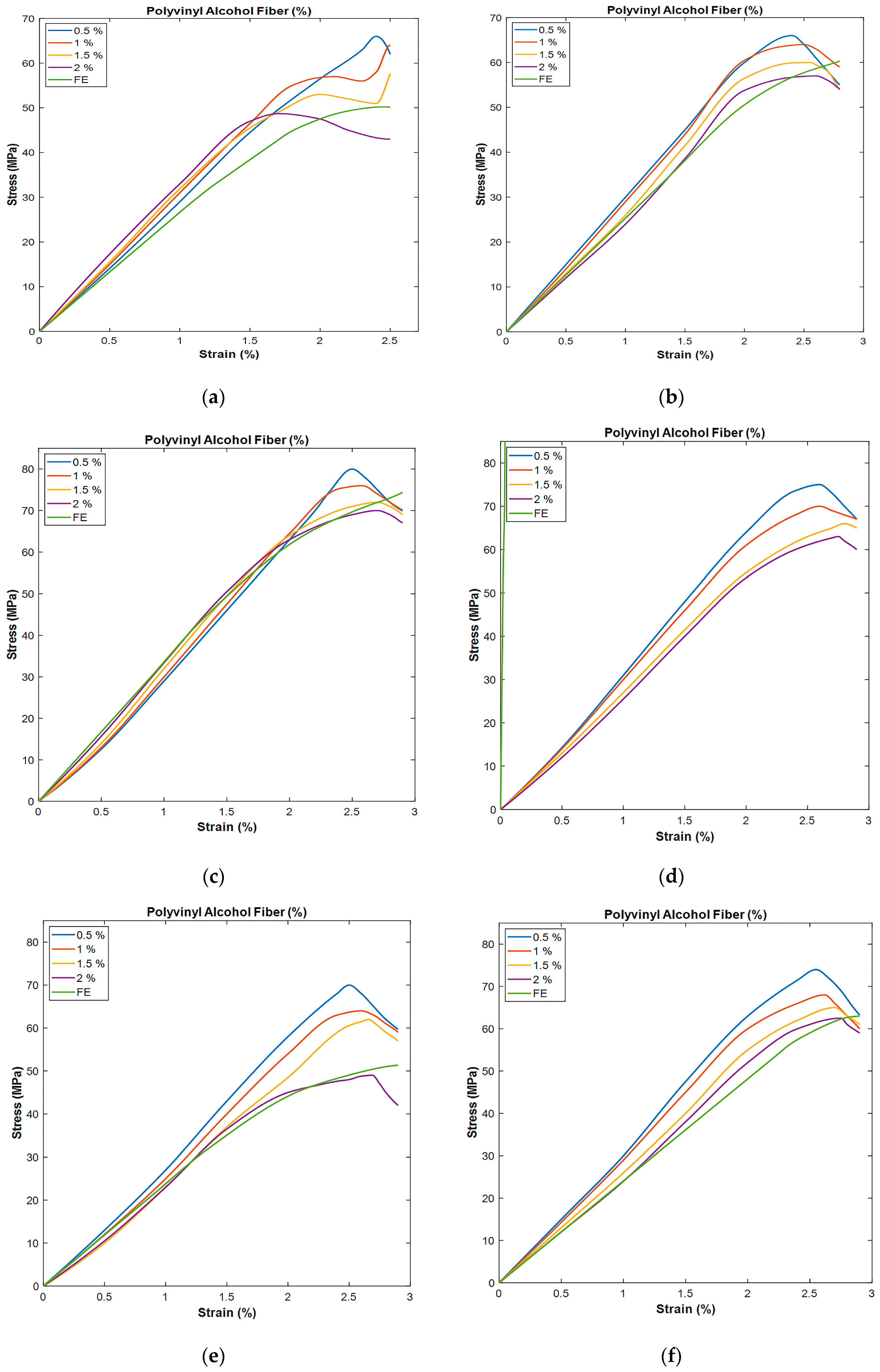

3.1. Influence of Nanosilica and PVA Fibers on the Mechanical and Deformation Behavior of ECC

3.2. Mechanism Analysis and Microstructural Interpretation

3.3. Environmental and Sustainability Performance of Modified ECC

4. Conclusions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Y.S.; Meng, L.Y.; Chen, L.; Wang, X.Y. An innovative strategy for CO2 conversion and utilization: Semi-wet carbonation pretreatment of wollastonite to prepare carbon-fixing products and produce LC3. Cem. Concr. Compos. 2025, 160, 106050. [Google Scholar] [CrossRef]

- Qing, Y.; Zenan, Z.; Deyu, K.; Rongshen, C. Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar] [CrossRef]

- Gao, X.; Li, W.; Wang, P.; Lu, Y.; Zhou, J.; Wang, X.Q. Advancing Energy Solutions: Carbon-Based Cementitious Composites in Energy Storage and Harvesting. J. Build. Eng. 2024, 91, 109720. [Google Scholar] [CrossRef]

- Shahab, Z.; Anwar, W.; Alyami, M.; Hammad, A.W.; Alabduljabbar, H.; Nawaz, R.; Javed, M.F. Experimental investigation and predictive modeling of compressive strength and electrical resistivity of graphene nanoplatelets modified concrete. Mater. Today Commun. 2024, 38, 107639. [Google Scholar] [CrossRef]

- Han, J.; Pan, J.; Cai, J. Self-sensing properties and piezoresistive effect of high ductility cementitious composite. Constr. Build. Mater. 2022, 323, 126390. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Thomas, B.S.; Hawileh, R.A.; Yang, J.; Jindal, B.B.; Ariyachandra, E. Influence of nano-TiO2, nano-Fe2O3, nanoclay and nano-CaCO3 on the properties of cement/geopolymer concrete. Clean. Mater. 2022, 4, 100061. [Google Scholar] [CrossRef]

- Hisseine, O.A.; Tagnit-Hamou, A. Shear-bond behavior of nanocellulose-modified SHCC composite slabs: Translating material-level capacity into improved structural performance. Eng. Struct. 2023, 291, 116394. [Google Scholar] [CrossRef]

- Bahraq, A.A.; Al-Osta, M.A.; Al-Amoudi, O.S.B.; Saleh, T.A.; Obot, I.B. Atomistic simulation of polymer-cement interactions: Progress and research challenges. Constr. Build. Mater. 2022, 327, 126881. [Google Scholar] [CrossRef]

- Muzenski, S.; Flores-Vivian, I.; Farahi, B.; Sobolev, K. Towards ultrahigh performance concrete produced with aluminum oxide nanofibers and reduced quantities of silica fume. Nanomaterials 2020, 10, 2291. [Google Scholar] [CrossRef]

- Albaijan, I.; Mahmoodzadeh, A.; Mohammed, A.H.; Fakhri, D.; Ibrahim, H.H.; Elhadi, K.M. Optimal machine learning-based method for gauging compressive strength of nanosilica-reinforced concrete. Eng. Fract. Mech. 2023, 291, 109560. [Google Scholar] [CrossRef]

- Haruna, S.; Adamu, M.; Ibrahim, Y.E.; Haruna, S.I.; Seif ElDin, H.M.; Hamza, M.F.; Azab, M. Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview. Rev. Adv. Mater. Sci. 2023, 62, 20220309. [Google Scholar] [CrossRef]

- Ziada, M.; Erdem, S. Strain hardening green cementitious composites reinforced with nanoparticles: Mechanical and microstructural properties and high temperature effect. Case Stud. Constr. Mater. 2023, 18, e02033. [Google Scholar] [CrossRef]

- Öztürk, O.; Yıldırım, G.; Keskin, Ü.S.; Siad, H.; Şahmaran, M. Nano-tailored multi-functional cementitious composites. Compos. Part B Eng. 2020, 182, 107670. [Google Scholar] [CrossRef]

- Tanimola, J.O.; Efe, S. Recent Advances in Nano-Modified Concrete: Enhancing Durability, Strength, and Sustainability Through Nano Silica (nS) and Nano Titanium (nT) Incorporation. Appl. Eng. Sci. 2024, 19, 100189. [Google Scholar] [CrossRef]

- Bheel, N.; Mohammed, B.S.; Liew, M.S.; Zawawi, N.A.W.A. Effect of graphene oxide as a nanomaterial on the durability behaviors of engineered cementitious composites by applying RSM modelling and optimization. Buildings 2023, 13, 2026. [Google Scholar] [CrossRef]

- Tanyildizi, H.; Bulut, M.; Ziada, M. Bacteria-Based Crack Healing of Nanosilica and Carbon Nanotube Modified Engineered Cementitious Composites. J. Mater. Civ. Eng. 2024, 36, 04023515. [Google Scholar] [CrossRef]

- Tanyıldızı, H.; Bulut, M. The effect of carbon nanotube on self-healing properties of engineered cementitious composites subjected to high temperatures. Struct. Concr. 2024, 26, 1245–1260. [Google Scholar] [CrossRef]

- Chadha, V.; Singla, S. A Review on Classification and Effect of Nanoparticles on Workability, Mechanical Properties, Durability, and Microstructure of Cement Composites. Iran. J. Sci. Technol. Trans. Civ. Eng. 2024, 49, 3365–3388. [Google Scholar] [CrossRef]

- Jakhar, S.K.; Kumar, R.; Nagappan, B.; Singh, A. Nanotechnology and high-performance concrete: Evaluating mechanical transformations, Multidisciplinary Reviews 2023. In Proceedings of the International Conference on Contemporary, Engineering, Technology and Management (ICCETM), Dubai, United Arab Emirates, 4–5 December 2023; p. 6. [Google Scholar]

- Rawat, S.; Zhang, Y.X.; Lee, C.K. Effect of specimen size and shape on the compressive performance of high strength engineered cementitious composites at elevated temperatures. Innov. Infrastruct. Solut. 2024, 9, 317. [Google Scholar] [CrossRef]

- Celik, D.N.; Yıldırım, G.; Al-Dahawi, A.; Ulugöl, H.; Han, B.; Şahmaran, M. Self-monitoring of flexural fatigue damage in large-scale steel-reinforced cementitious composite beams. Cem. Concr. Compos. 2021, 123, 104183. [Google Scholar] [CrossRef]

- Huang, B.T.; Dai, J.G.; Weng, K.F.; Zhu, J.X.; Shah, S.P. Flexural performance of UHPC–concrete–ECC composite member reinforced with perforated steel plates. J. Struct. Eng. 2021, 147, 04021065. [Google Scholar] [CrossRef]

- Shafiq, N.; Ayub, T.; Khan, S.U. Investigating the performance of PVA and basalt fibre reinforced beams subjected to flexural action. Compos. Struct. 2016, 153, 30–41. [Google Scholar] [CrossRef]

- ASTMC39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- Lee, J.; Fenves, G.L. Plastic-Damage Model for Cyclic Loading of Concrete Structures. J. Eng. Mech. 1998, 124, 892–900. [Google Scholar] [CrossRef]

- García, J.M.; Reyes, E. Evaluation of mesh sensitivity in CDP model using C3D8R and C3D8I elements. Eng. Struct. 2019, 180, 232–242. [Google Scholar]

- Liu, Y.; Tafsirojjaman, T.; Dogar, A.U.R.; Hückler, A. Bond behaviour improvement between infra-lightweight and high strength concretes using FRP grid reinforcements and development of bond strength prediction models. Constr. Build. Mater. 2021, 270, 121426. [Google Scholar] [CrossRef]

- Achara, B.E.; Malkawi, A.B.; Adamu, M.; Abbah, J.C.; Adeosun, K.D. Fresh and mechanical characteristics of engineered cementitious composites (ECC) modified with nano-silica. J. Mater. Eng. Struct. Comput. 2025, 4, 61–71. [Google Scholar]

- Wang, Y.; Chen, M.; Zhang, T.; Zhang, M. Rheology and mechanical properties of limestone calcined clay based engineered cementitious composites with nano CaCO3. Cem. Concr. Compos. 2025, 157, 105923. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R.; Jain, M. Novel approach in sustainable ECC using nano-silica and hybrid fibers. Constr. Build. Mater. 2022, 346, 127093. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, X.; Lyu, X. Comparative analysis of the effects of nano-SiO2 and carbon nanotubes on mechanical properties of polyethylene fibre reinforced cementitious composites. Sci. Rep. 2025, 15, 5727. [Google Scholar] [CrossRef]

- Gurbuz, E.; Erdem, S.; Zhang, M. Static and impact performance of engineered cementitious composites with hybrid graphite nano platelets modified PVA and shape memory alloy fibres. J. Build. Eng. 2024, 92, 109776. [Google Scholar] [CrossRef]

- Karthikeyan, N.K.; Elavenil, S. Dispersion effect of nano-structure pyrolytic carbon on mechanical, electrical, and microstructural characteristics of cement mortar composite. Int. J. Smart Nano Mater. 2024, 15, 534–578. [Google Scholar] [CrossRef]

- Karamzadeh, N.S.; Karimi, H.R.; Khedri, E. An investigation on the application of acrylic resin agent for fiber/matrix bond strengthening in green engineered cementitious composites (ECC). Case Stud. Constr. Mater. 2024, 20, e03355. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Y.; Wang, J.; Chen, X. Sustainability evaluation of nano-engineered cementitious composites using life cycle assessment. Eng. Geol. 2024, 324, 107747. [Google Scholar] [CrossRef]

| Material | Description | Key Properties |

|---|---|---|

| Cement (OPC) | Ordinary Portland Cement (43 grade) Specific surface = ~413 m2/kg | Specific surface: 413 m2/kg chemical composition: Ca–Si–O, Al, Mg, Fe present at clinker phases |

| Fly ash | Coarse silt to fine sand grain size (0.001 mm–0.6 mm); composed of heterogeneous minerals, predominantly SiO2, Al2O3, Fe2O3, and, sometimes, CaO | Specific gravity: 2.32, 1.98 Density: <1 Mg/m3 |

| Polyvinyl alcohol (PVA) fiber | A strong fiber for use in strain-hardening purposes, produced through the polymerization of vinyl acetate | Nominal strength or Tensile strength: 1620 MP Young’s modulus: 42.82 GPa Diameter: 39 µm |

| Nanosilica particles | Length: 12 mm Specific gravity: 1.30 | |

| Fine aggregate (sand) | A critical material for the ridiculously low ECC deformation properties with a diameter of 20 nm | Crystalline height: 19 nm Density: 2.12 g/cm3 Specific surface: 160 m2/g |

| Water | River sand/river sand naturally collected from the river and graded between No. 4 and mostly retained on No. 200 sieve, naturally air-dried to eliminate moisture content | Specific gravity: 2 Fineness modulus: 3.42: conforms to BS 882: 1992 |

| Superplasticizer (Conplast SP430A1) | Normal and standard tap water, as required for concreting and curing purposes | - |

| Mix ID | PVA (kg) | Nanosilica (nS) (kg) | SP Total (kg) | SP Initial (kg) | SP Additional (kg) |

|---|---|---|---|---|---|

| 1 | 0.18 | 0.0 | 0.27 | 0.27 | 0.00 |

| 2 | 0.36 | 0.0 | 0.27 | 0.27 | 0.00 |

| 3 | 0.54 | 0.2 | 0.30 | 0.27 | 0.03 |

| 4 | 0.18 | 0.4 | 0.32 | 0.27 | 0.05 |

| 5 | 0.27 | 0.6 | 0.33 | 0.27 | 0.06 |

| 6 | 0.36 | 0.8 | 0.35 | 0.27 | 0.08 |

| 7 | 0.54 | 1.0 | 0.37 | 0.27 | 0.10 |

| 8 | 0.18 | 1.2 | 0.39 | 0.27 | 0.12 |

| 9 | 0.27 | 1.4 | 0.41 | 0.27 | 0.14 |

| 10 | 0.36 | 1.6 | 0.43 | 0.27 | 0.16 |

| 11 | 0.54 | 1.8 | 0.45 | 0.27 | 0.18 |

| 12 | 0.18 | 2.0 | 0.47 | 0.27 | 0.20 |

| 13 | 0.27 | 2.2 | 0.49 | 0.27 | 0.22 |

| 14 | 0.36 | 2.4 | 0.51 | 0.27 | 0.24 |

| 15 | 0.54 | 2.6 | 0.53 | 0.27 | 0.26 |

| 16 | 0.18 | 2.8 | 0.55 | 0.27 | 0.28 |

| 17 | 0.27 | 3.0 | 0.57 | 0.27 | 0.30 |

| 18 | 0.36 | 3.2 | 0.59 | 0.27 | 0.32 |

| 19 | 0.54 | 3.4 | 0.61 | 0.27 | 0.34 |

| 20 | 0.18 | 3.6 | 0.63 | 0.27 | 0.36 |

| 21 | 0.27 | 3.8 | 0.65 | 0.27 | 0.38 |

| 22 | 0.36 | 4.0 | 0.67 | 0.27 | 0.40 |

| 23 | 0.54 | 4.2 | 0.69 | 0.27 | 0.42 |

| 24 | 0.18 | 4.4 | 0.71 | 0.27 | 0.44 |

| 25 | 0.27 | 5.0 | 0.77 | 0.27 | 0.50 |

| Property | Value | Reference |

|---|---|---|

| Fiber Type | Polyvinyl Alcohol (PVA) | [12] |

| Average Length | 12 mm | [24] |

| Diameter | 40 µm | [12] |

| Tensile Strength | 1600 MPa | [24] |

| Modulus of Elasticity | 40 GPa | [12] |

| Elongation at Break | 6% | [24] |

| Density | 1.3 g/cm3 | [12] |

| Property | Value | Reference |

|---|---|---|

| Average Particle Size | 20 nm | [18] |

| Specific Surface Area | 200 m2/g | [18] |

| Purity | >99.8% SiO2 | [5] |

| pH Value (5% aqueous solution) | 3.5–4.0 | [18] |

| Bulk Density | 0.10–0.20 g/cm3 | [5] |

| Nanosilica (%) | PVA Fiber (%) | Ultimate Strength (MPa) | Strain (µm/m) | Mean Shrinkage (%) | Ultimate Strength SD (MPa) | Strain SD (µm/m) | Shrinkage SD (%) |

|---|---|---|---|---|---|---|---|

| 0% | 0.5 | 60.0 | 2300 | 0.03 | 1.50 | 35 | ±0.002 |

| 1.0 | 57.0 | 2400 | 0.026 | 1.43 | 36 | ±0.002 | |

| 1.5 | 53.0 | 2450 | 0.021 | 1.33 | 37 | ±0.001 | |

| 2.0 | 51.0 | 2500 | 0.023 | 1.28 | 38 | ±0.001 | |

| 1% | 0.5 | 61.0 | 2450 | 0.052 | 1.53 | 37 | ±0.003 |

| 1.0 | 58.0 | 2600 | 0.045 | 1.45 | 39 | ±0.002 | |

| 1.5 | 55.0 | 2650 | 0.043 | 1.38 | 40 | ±0.002 | |

| 2.0 | 52.0 | 2700 | 0.04 | 1.30 | 41 | ±0.002 | |

| 2% | 0.5 | 63.0 | 2600 | 0.075 | 1.58 | 39 | ±0.004 |

| 1.0 | 60.0 | 2750 | 0.06 | 1.50 | 41 | ±0.003 | |

| 1.5 | 57.0 | 2800 | 0.058 | 1.43 | 42 | ±0.002 | |

| 2.0 | 55.0 | 2850 | 0.05 | 1.38 | 43 | ±0.002 | |

| 3% | 0.5 | 65.0 | 2750 | 0.08 | 1.63 | 41 | ±0.004 |

| 1.0 | 62.0 | 2850 | 0.074 | 1.55 | 43 | ±0.004 | |

| 1.5 | 60.0 | 2900 | 0.062 | 1.50 | 44 | ±0.003 | |

| 2.0 | 58.0 | 2950 | 0.058 | 1.45 | 44 | ±0.003 | |

| 0.5 | 66.0 | 2850 | 0.083 | 1.65 | 43 | ±0.004 | |

| 1.0 | 63.0 | 2950 | 0.078 | 1.58 | 44 | ±0.004 | |

| 4% | 1.5 | 61.0 | 3000 | 0.07 | 1.53 | 45 | ±0.003 |

| 2.0 | 59.0 | 3050 | 0.068 | 1.48 | 46 | ±0.003 | |

| 0.5 | 65.0 | 2750 | 0.087 | 1.63 | 41 | ±0.005 | |

| 5% | 1.0 | 62.0 | 2850 | 0.082 | 1.55 | 43 | ±0.004 |

| 1.5 | 60.0 | 2900 | 0.074 | 1.50 | 44 | ±0.003 | |

| 2.0 | 57.0 | 2950 | 0.072 | 1.43 | 44 | ±0.003 |

| Characteristic | Fiber Rupture | Fiber Pull-Out |

|---|---|---|

| Crack pattern | Few macro-cracks | Multiple micro-cracks |

| Energy absorption before failure | Low | High |

| Post-cracking behavior | Brittle | Ductile (strain-hardening) |

| Final failure mode | Sudden and brittle | Gradual with distributed cracking |

| Ref. | Nano Material | Max Strength (MPa) | Max Strain (µm/m) | Main Results |

|---|---|---|---|---|

| [25] | Nano-SiO2 | ~70 | ~2500 | Confirms 2% nS as optimal for strength and workability |

| [26] | Nano-CaCO3 | ~68 | ~2400 | Beyond 2% leads to reduced performance due to particle clustering |

| [27] | Nano-SiO2 + CNTs | 72 | ~2550 | Slightly lower strength than current; strain similar |

| [28] | Graphite + SMA + PVA | ~66 | ~2200–2500 | High ductility from hybrid fibers; lower strength compared to current |

| [29] | Nano-structured carbon | <65 | ~2300 | Poor dispersion at high nS concentrations resulted in degraded properties |

| Current study | Nano-SiO2 + PVA | 80 | 2750 | Peak strength and high ductility; performance drops at >3% nS |

| Parameter. | Effect of nS | Effect of PVA | Combined Effect |

|---|---|---|---|

| Compressive Strength | Matrix densification | Negligible direct effect | Optimal at 2–3% nS with 0.5% PVA |

| Strain Capacity | Slight due to improved matrix | Crack bridging | Maximum at 1.5% PVA with 3% nS |

| Crack Pattern | Fine microcracks | Distributed multiple microcracks | Enhanced energy dissipation |

| Durability Potential | Reduced porosity | Restrained crack width | Superior resistance to degradation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albadrani, M.A. Influence of Nanosilica and PVA Fibers on the Mechanical and Deformation Behavior of Engineered Cementitious Composites. Polymers 2025, 17, 2067. https://doi.org/10.3390/polym17152067

Albadrani MA. Influence of Nanosilica and PVA Fibers on the Mechanical and Deformation Behavior of Engineered Cementitious Composites. Polymers. 2025; 17(15):2067. https://doi.org/10.3390/polym17152067

Chicago/Turabian StyleAlbadrani, Mohammed A. 2025. "Influence of Nanosilica and PVA Fibers on the Mechanical and Deformation Behavior of Engineered Cementitious Composites" Polymers 17, no. 15: 2067. https://doi.org/10.3390/polym17152067

APA StyleAlbadrani, M. A. (2025). Influence of Nanosilica and PVA Fibers on the Mechanical and Deformation Behavior of Engineered Cementitious Composites. Polymers, 17(15), 2067. https://doi.org/10.3390/polym17152067