Comparison of Additive Manufacturing and Injection Molding of Biocomposites Reinforced with Alkali-Treated Wood Flour Derived from Recycled Wooden Pallets

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Particle Size Analysis of Wood Flour

2.2.2. Surface Modification of Wood Flour with Alkaline Treatment

2.2.3. Production of Filaments and Pellets

2.2.4. AM of Test Samples

2.2.5. IM of Test Samples

2.2.6. Determination of the Mechanical Properties

2.2.7. Determination of the Physical Properties

2.2.8. Morphological Characterization by Scanning Electron Microscopy (SEM)

2.2.9. Determination of the Thermal Properties

2.2.10. Chemical Characterization by Fourier Transform Infrared (FT-IR) Spectroscopy

2.2.11. Statistical Analysis of Mechanical Test Results

3. Results and Discussion

3.1. PSD of Wood Flour

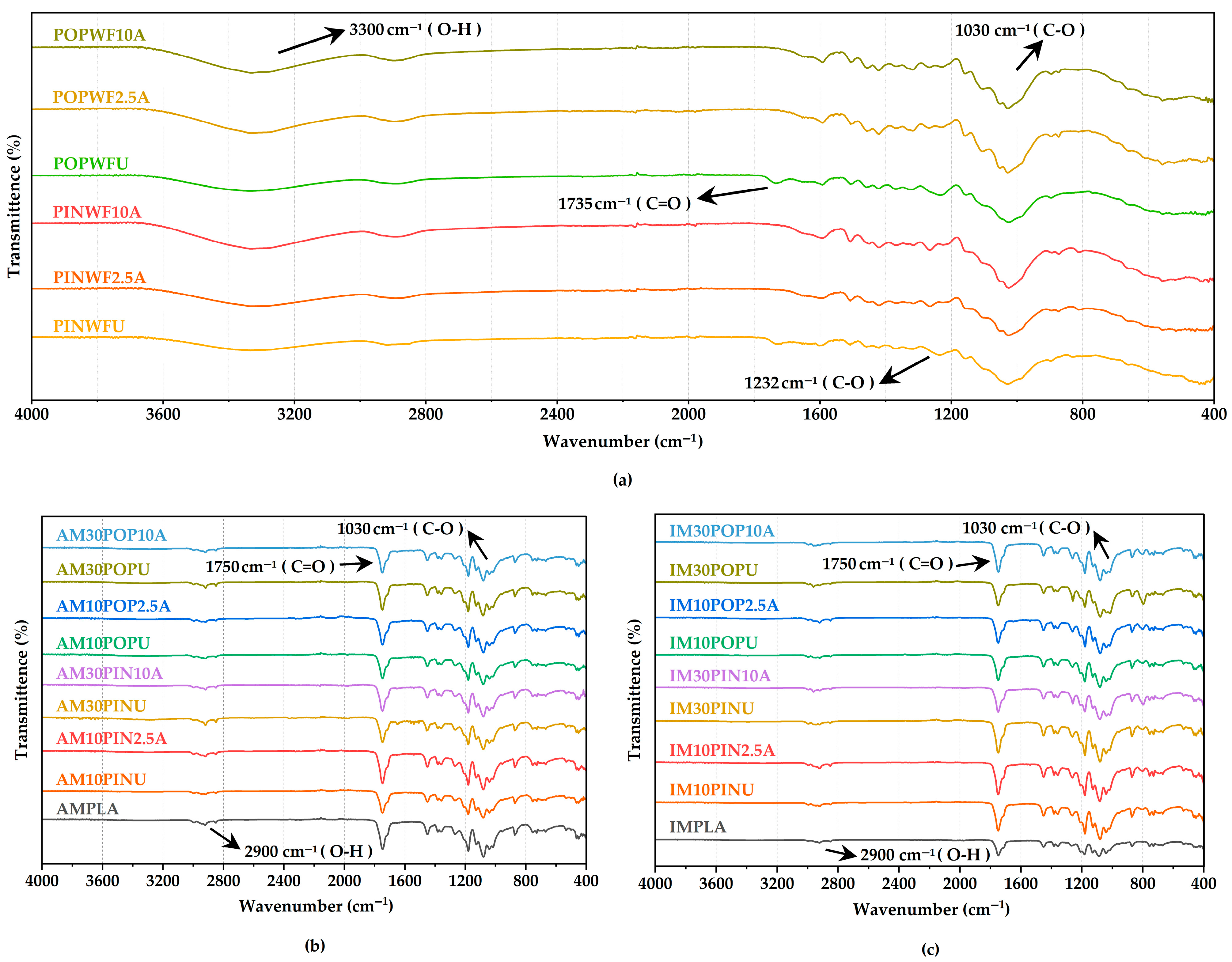

3.2. Chemical Properties of Fillers

3.3. Mechanical Properties of Biocomposites

3.3.1. Tensile Test Results

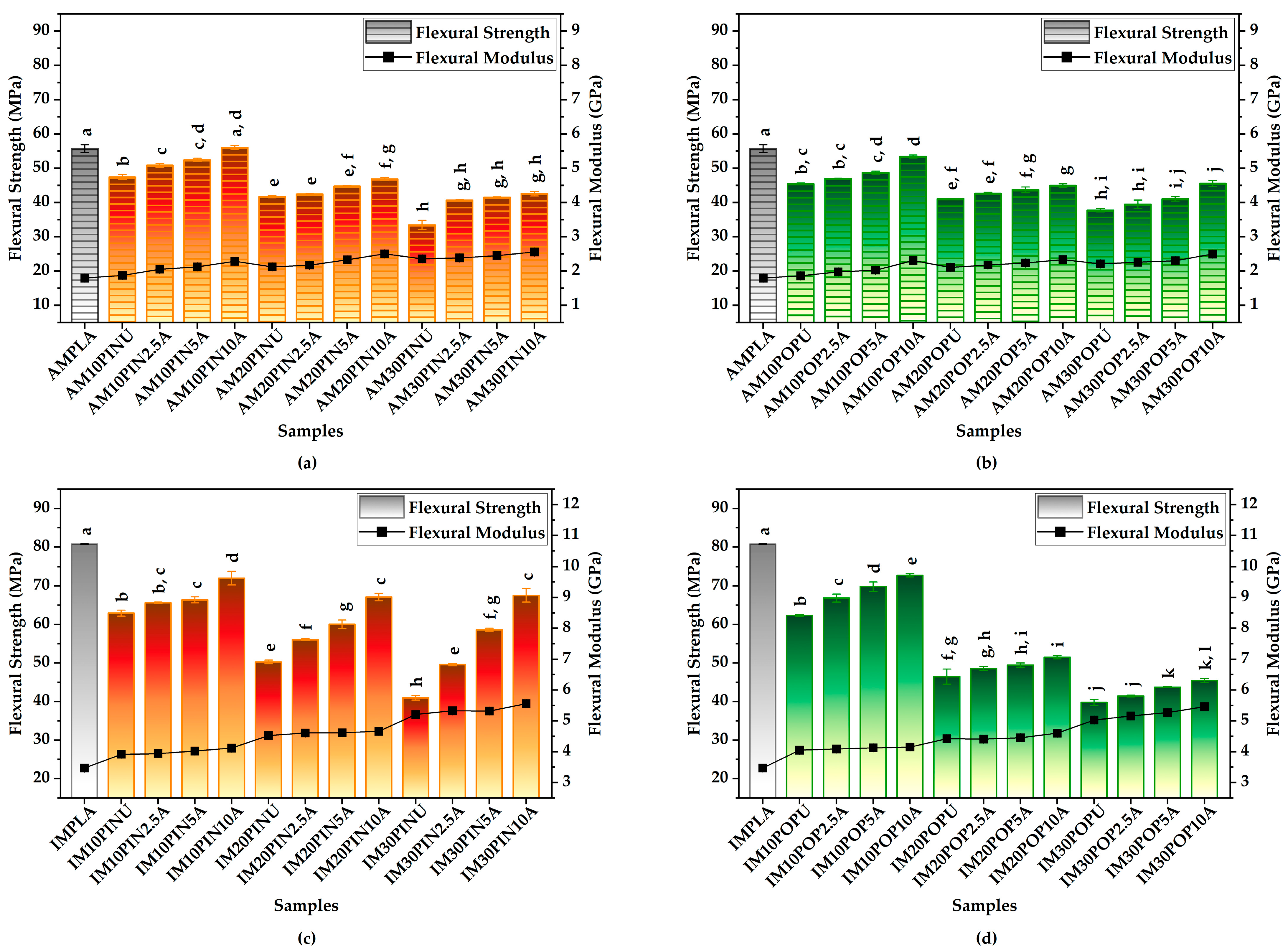

3.3.2. Flexural Test Results

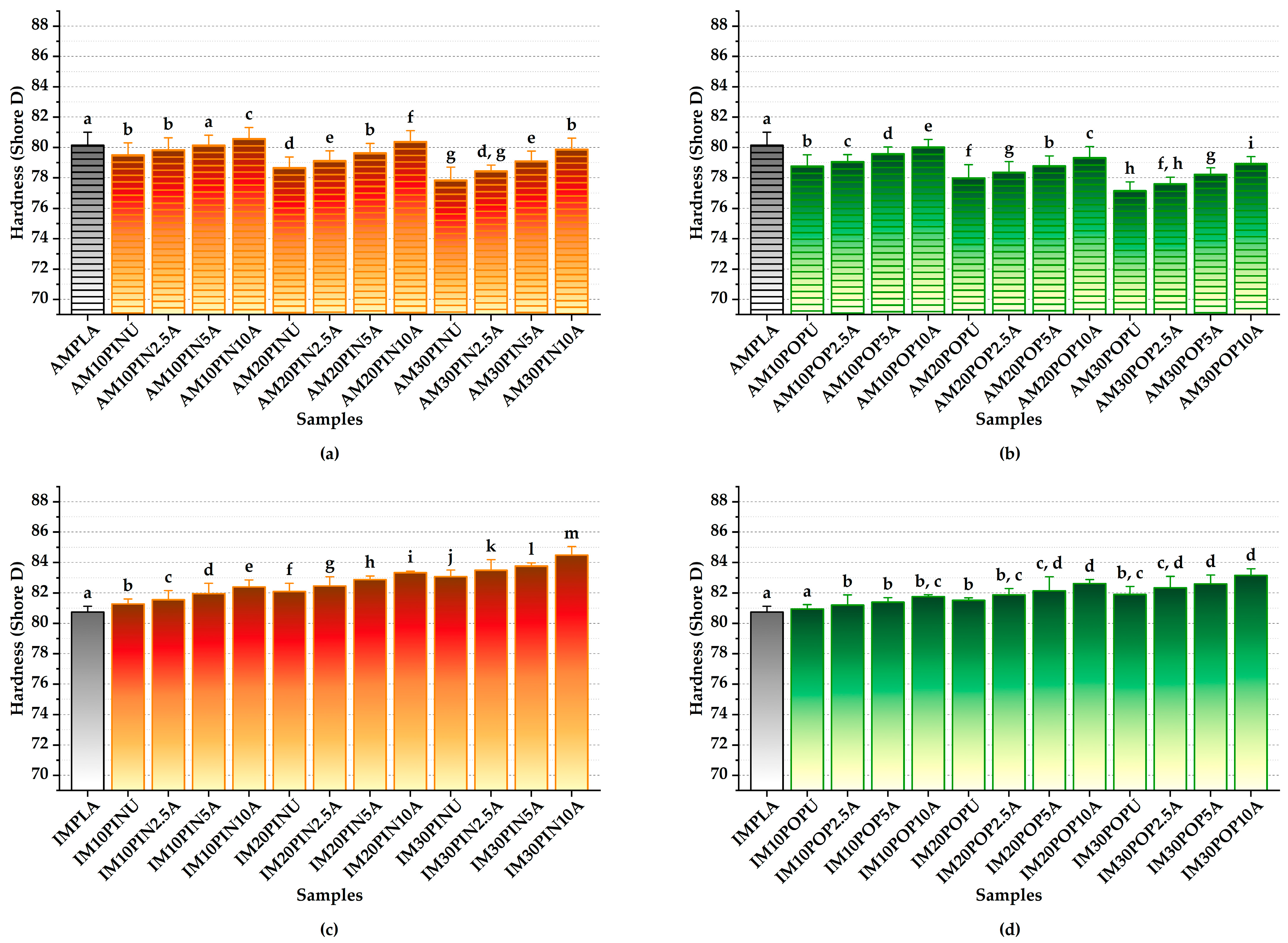

3.3.3. Hardness Test Results

3.4. Physical Properties of Biocomposites

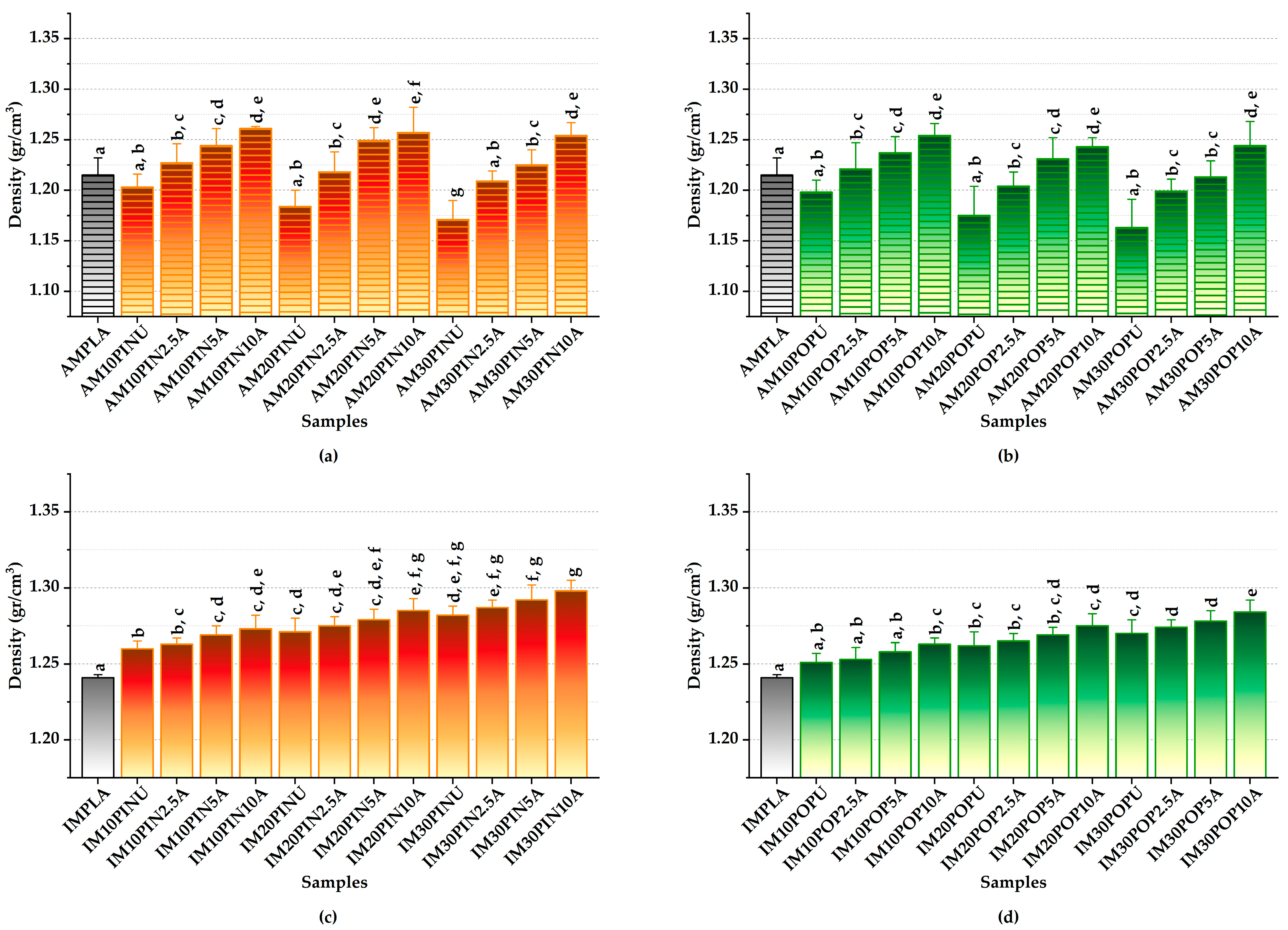

3.4.1. Density Test Results

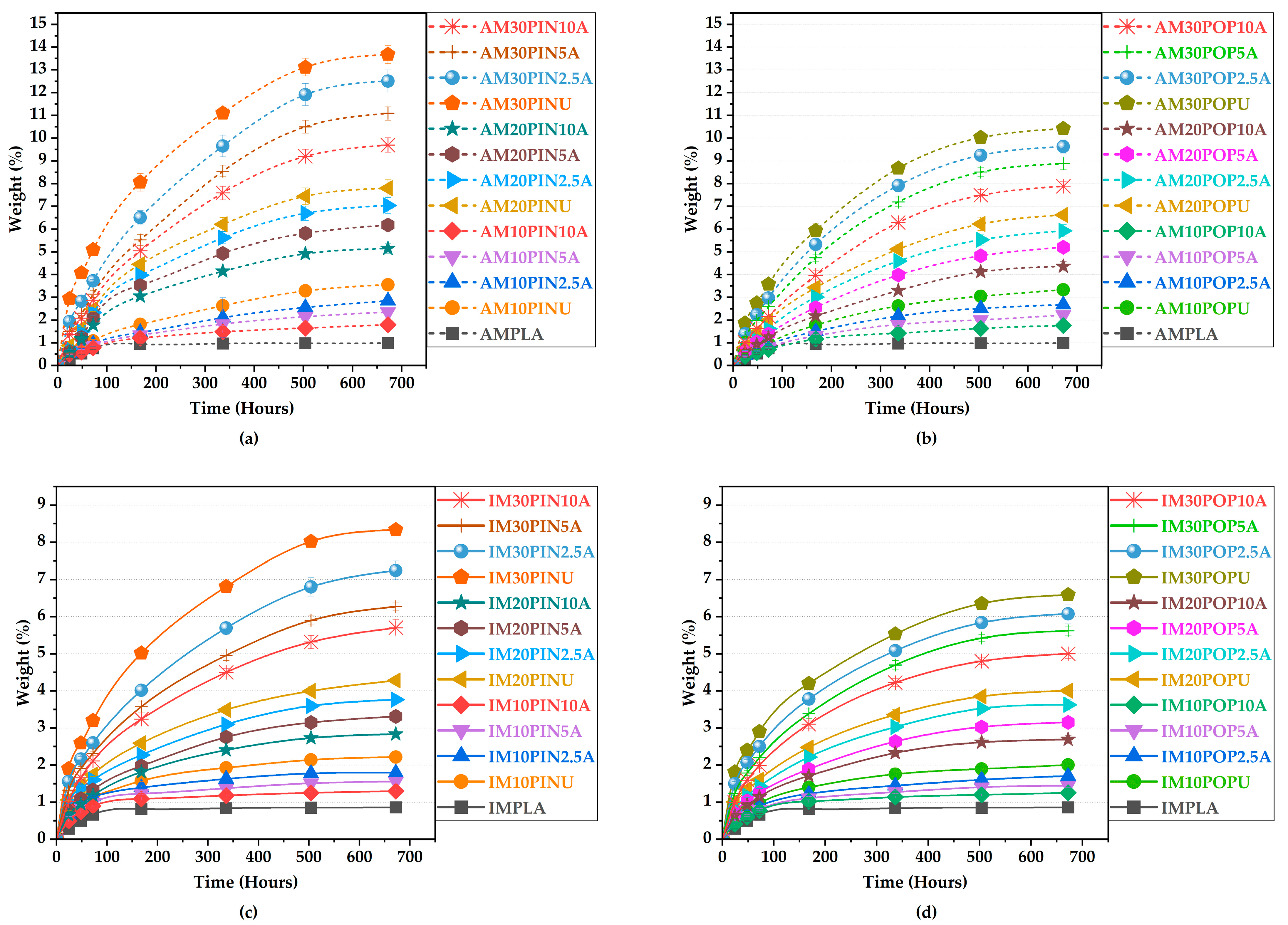

3.4.2. Water Absorption Test Results

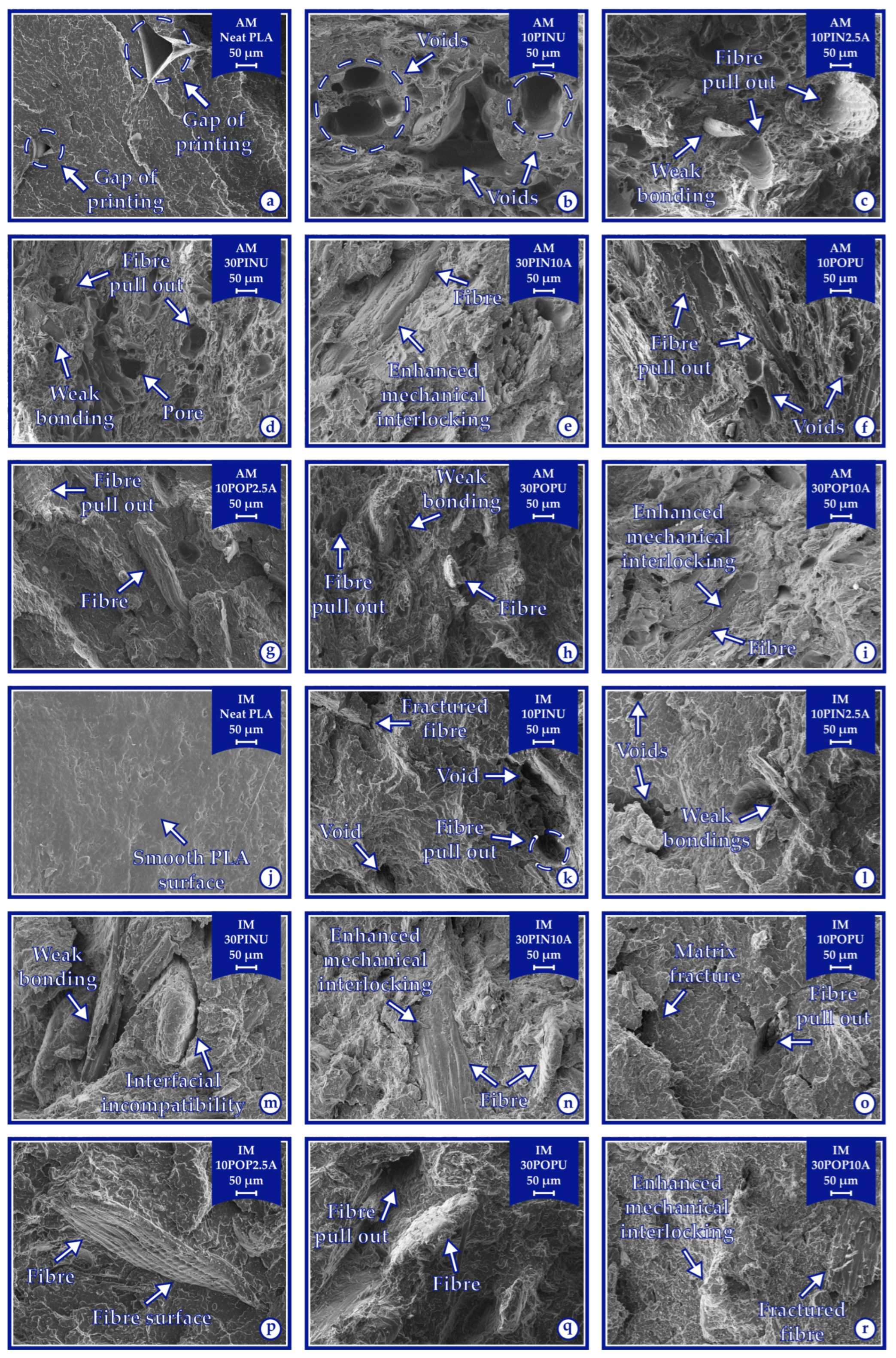

3.5. Morphological Properties of Biocomposites

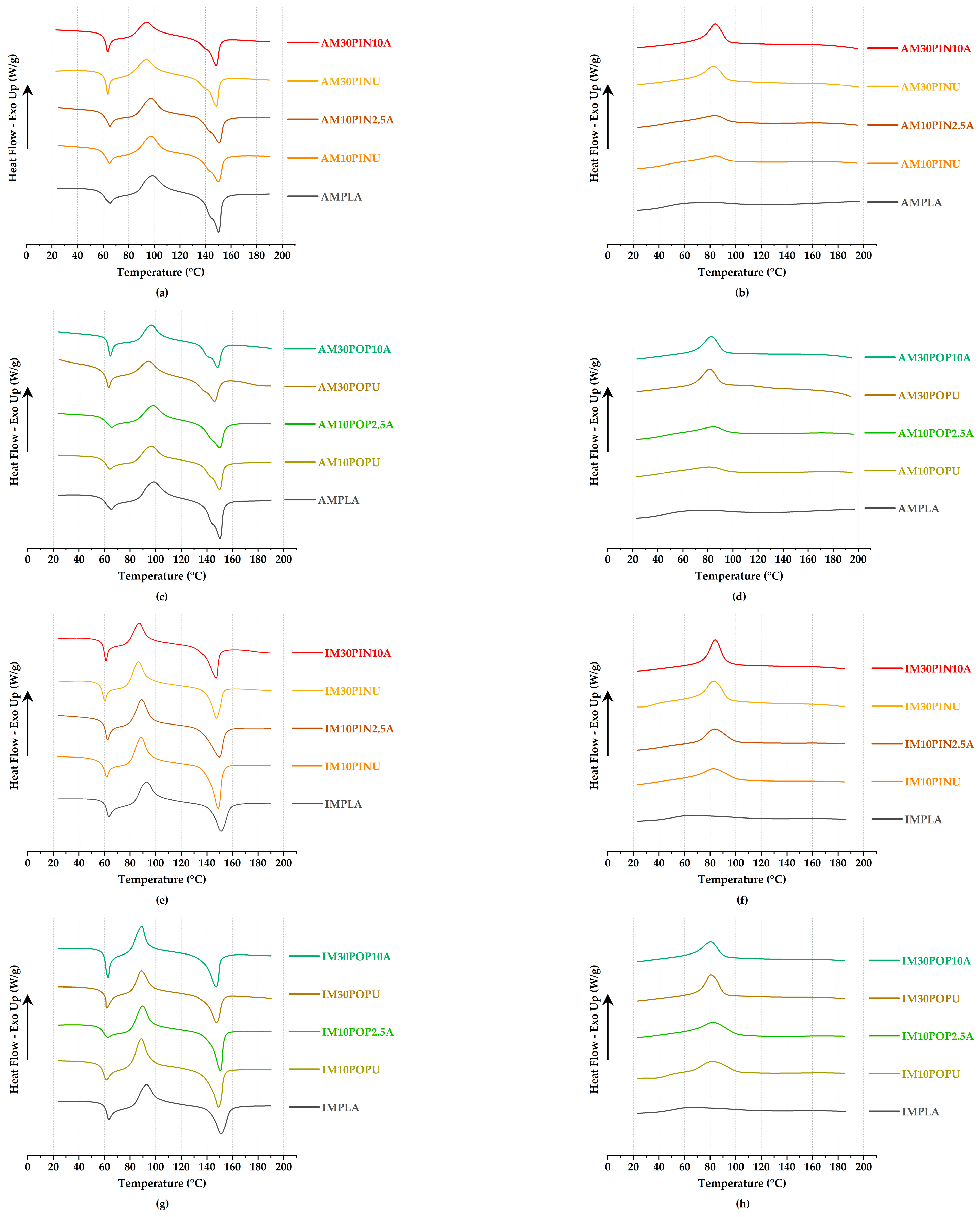

3.6. Thermal Properties of Biocomposites

3.6.1. DSC Results

3.6.2. TGA Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Forest Declaration Assessment. 2024 Forest Declaration Assessment: Forests Under Fire. 2024. Available online: https://forestdeclaration.org/wp-content/uploads/2024/10/2024ForestDeclarationAssessment.pdf (accessed on 30 May 2025).

- Coherent Market Insights. Wood Recycling Market Size and Share Analysis—Growth Trends and Forecasts (2025–2032). 2025. Available online: https://www.coherentmarketinsights.com/industry-reports/wood-recycling-market (accessed on 30 May 2025).

- Braghiroli, F.L.; Passarini, L. Valorization of biomass residues from forest operations and wood manufacturing presents a wide range of sustainable and innovative possibilities. Curr. For. Rep. 2020, 6, 172–183. [Google Scholar] [CrossRef]

- Rosenboom, J.G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef] [PubMed]

- Jyske, T.; Frantsi, J.; Georgs, V.; Hurmekoski, E.; Kettunen, E.; Kilpeläinen, P.; Kinnunen-Raudaskoski, K.; Kohl, O.; Lankinen, P.; Liimatainen, H.; et al. Novel wood-based biomaterials. In Forest Microbiology; Academic Press: Cambridge, MA, USA, 2025; pp. 277–305. [Google Scholar] [CrossRef]

- Bhattacharjya, J.; Kleine-Moellhoff, P. Environmental concerns in the design and management of pallets. In Collaborative Systems for Reindustrialization, Proceedings of the 14th IFIP WG 5.5 Working Conference on Virtual Enterprises, PRO-VE 2013, Dresden, Germany, 30 September–2 October 2013; Proceedings 14; Springer: Berlin/Heidelberg, Germany, 2013; pp. 569–576. [Google Scholar] [CrossRef]

- Shiner, Z.; Horvath, L.; Araman, P.; Gething, B. An investigation of wood pallets landfilled and recovered at US municipal solid waste facilities. BioResources 2021, 16, 1496–1522. [Google Scholar] [CrossRef]

- Freedonia Group. Global Pallets Report. 2024. Available online: https://www.freedoniagroup.com/industry-study/global-pallets (accessed on 30 May 2025).

- Stark, N.M. Wood fiber derived from scrap pallets used in polypropylene composites. For. Prod. J. 1999, 49, 39–46. [Google Scholar]

- Asim, M.; Paridah, M.T.; Chandrasekar, M.; Shahroze, R.M.; Jawaid, M.; Nasir, M.; Siakeng, R. Thermal stability of natural fibers and their polymer composites. Iran. Polym. J. 2020, 29, 625–648. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Zuhri, M.Y.M.; Aisyah, H.A.; Asyraf, M.R.M.; Hassan, S.A.; Zainudin, E.S.; Sari, N.H. Natural fiber-reinforced polylactic acid, polylactic acid blends and their composites for advanced applications. Polymers 2022, 14, 202. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.H.; Khalina, A.; Lee, S.H. Importance of interfacial adhesion condition on characterization of plant-fiber-reinforced polymer composites: A review. Polymers 2021, 13, 438. [Google Scholar] [CrossRef] [PubMed]

- Sahu, P.; Gupta, M.K. A review on the properties of natural fibres and its bio-composites: Effect of alkali treatment. Proc. Inst. Mech. Eng. Part L 2020, 234, 198–217. [Google Scholar] [CrossRef]

- Zandi, M.D.; Jerez-Mesa, R.; Lluma-Fuentes, J.; Jorba-Peiro, J.; Travieso-Rodriguez, J.A. Study of the manufacturing process effects of fused filament fabrication and injection molding on tensile properties of composite PLA-wood parts. Int. J. Adv. Manuf. Technol. 2020, 108, 1725–1735. [Google Scholar] [CrossRef]

- Pereira, T.; Kennedy, J.V.; Potgieter, J. A comparison of traditional manufacturing vs additive manufacturing, the best method for the job. Procedia Manuf. 2019, 30, 11–18. [Google Scholar] [CrossRef]

- Mohanavel, V.; Ali, K.A.; Ranganathan, K.; Jeffrey, J.A.; Ravikumar, M.M.; Rajkumar, S. The roles and applications of additive manufacturing in the aerospace and automobile sector. Mater. Today Proc. 2021, 47, 405–409. [Google Scholar] [CrossRef]

- Praveena, B.A.; Lokesh, N.; Santhosh, N.; Praveena, B.L.; Vignesh, R. A comprehensive review of emerging additive manufacturing (3D printing technology): Methods, materials, applications, challenges, trends and future potential. Mater. Today Proc. 2022, 52, 1309–1313. [Google Scholar] [CrossRef]

- Prashar, G.; Vasudev, H.; Bhuddhi, D. Additive manufacturing: Expanding 3D printing horizon in industry 4.0. Int. J. Interact. Des. Manuf. 2023, 17, 2221–2235. [Google Scholar] [CrossRef] [PubMed]

- Donate, R.; Monzón, M.; Alemán-Domínguez, M.E. Additive manufacturing of PLA-based scaffolds intended for bone regeneration and strategies to improve their biological properties. e-Polymers 2020, 20, 571–599. [Google Scholar] [CrossRef]

- Lee, C.H.; Padzil, F.N.B.M.; Lee, S.H.; Ainun, Z.M.A.A.; Abdullah, L.C. Potential for natural fiber reinforcement in PLA polymer filaments for fused deposition modeling (FDM) additive manufacturing: A review. Polymers 2021, 13, 1407. [Google Scholar] [CrossRef] [PubMed]

- Cisneros-López, E.O.; Pal, A.K.; Rodriguez, A.U.; Wu, F.; Misra, M.; Mielewski, D.F.; Mohanty, A.K. Recycled poly(lactic acid)—Based 3D printed sustainable biocomposites: A comparative study with injection molding. Mater. Today Sustain. 2020, 7, 100027. [Google Scholar] [CrossRef]

- Pilipović, A.; Ilinčić, P.; Petruša, J.; Domitran, Z. Influence of polymer composites and memory foam on energy absorption in vehicle application. Polymers 2020, 12, 1222. [Google Scholar] [CrossRef] [PubMed]

- Stark, N.M.; Rowlands, R.E. Effects of wood fiber characteristics on mechanical properties of wood/polypropylene composites. Wood Fiber Sci. 2003, 35, 167–174. [Google Scholar]

- Sommerhuber, P.F.; Welling, J.; Krause, A. Substitution potentials of recycled HDPE and wood particles from post-consumer packaging waste in wood–plastic composites. Waste Manag. 2015, 46, 76–85. [Google Scholar] [CrossRef] [PubMed]

- Basalp, D.; Tihminlioglu, F.; Sofuoglu, S.C.; Inal, F.; Sofuoglu, A. Utilization of municipal plastic and wood waste in industrial manufacturing of wood–plastic composites. Waste Biomass Valorization 2020, 11, 5419–5430. [Google Scholar] [CrossRef]

- Iždinský, J.; Reinprecht, L.; Vidholdová, Z. Particleboards from recycled pallets. Forests 2021, 12, 1597. [Google Scholar] [CrossRef]

- Demir, M.; Çetin, N.; Narlıoğlu, N. Analysis of Chemical Compositions of Lignocellulosic Fibres Derived from Waste Wooden Pallets. In Proceedings of the 11th International Aegean Congress on Innovation Technologies & Engineering, İzmir, Türkiye, 4–6 April 2025; pp. 42–51, ISBN 979-8-89695-060-8. [Google Scholar]

- Özmen, N. A study of the effect of acetylation on hemp fibres with vinyl acetate. BioResources 2012, 7, 3800–3809. [Google Scholar] [CrossRef]

- Zimmermann, M.V.G.; Zattera, A.J. Recycling and reuse of waste from electricity distribution networks as reinforcement agents in polymeric composites. Waste Manag. 2013, 33, 1667–1674. [Google Scholar] [CrossRef] [PubMed]

- Migneault, S.; Koubaa, A.; Perré, P. Effect of fiber origin, proportion, and chemical composition on the mechanical and physical properties of wood–plastic composites. J. Wood Chem. Technol. 2014, 34, 241–261. [Google Scholar] [CrossRef]

- Narlıoğlu, N. Comparison of mechanical properties of 3D-printed and compression-molded wood–polylactic acid (PLA) composites. BioResources 2022, 17, 3291. [Google Scholar] [CrossRef]

- Narlıoğlu, N. Effect of 3D printing speed on mechanical and thermal properties of wood–PLA composite filament. Furn. Wood Mater. Res. J. 2024, 7, 97–106. [Google Scholar] [CrossRef]

- Savran, M.; Aydın, L.; Ayaz, A.; Uslu, T. A new strategy for manufacturing, modeling, and optimization of 3D printed polylactide based on multiple nonlinear neuro regression analysis and stochastic optimization methods. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2024, 09544089241272909. [Google Scholar] [CrossRef]

- Öncül, M.; Sever, K. Effect of particle size and loading of cherry tree branch fillers on the mechanical and viscoelastic properties of polypropylene composites. BioResources 2025, 20, 1703–1712. [Google Scholar] [CrossRef]

- Kovačević, Z.; Pilipović, A.; Meheš, M.; Bischof, S. Zero waste concept in production of PLA biocomposites reinforced with fibers derived from wild plant (Spartium junceum L.) and energy crop (Sida hermaphrodita (L.) Rusby). Polymers 2025, 17, 235. [Google Scholar] [CrossRef] [PubMed]

- Borah, J.S.; Kim, D.S. Recent development in thermoplastic/wood composites and nanocomposites: A review. Korean J. Chem. Eng. 2016, 33, 3035–3049. [Google Scholar] [CrossRef]

- Kuram, E. Advances in development of green composites based on natural fibers: A review. Emerg. Mater. 2022, 5, 811–831. [Google Scholar] [CrossRef]

- Kaya, N.; Atan, E.; Sütçü, M. Investigation of thermal properties of waste tungsten carbide (WC) loaded HDPE matrix. Mater. Today Commun. 2020, 25, 101547. [Google Scholar] [CrossRef]

- Sarkar, P.B.; Chatterjee, H.; Mazumdar, A.K. 28—THE ACID NATURE OF JUTE FIBRE. J. Text. Inst. Trans. 1947, 38, T318–T332. [Google Scholar] [CrossRef]

- ASTM D3641-21; Standard Practice for Injection Molding Test Specimens of Thermoplastic Molding and Extrusion Materials. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM D790-17; Standard Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D2240-15; Standard Test Method for Rubber Property—Durometer Hardness. ASTM: West Conshohocken, PA, USA, 2015.

- ASTM D570-22; Standard Test Method for Water Absorption of Plastics. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM D792-20; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM: West Conshohocken, PA, USA, 2020.

- Fischer, E.W.; Sterzel, H.J.; Wegner, G.K.Z. Investigation of the structure of solution-grown crystals of lactide co-polymers by means of chemical reactions. Kolloid Z. Z. Polym. 1973, 251, 980–990. [Google Scholar] [CrossRef]

- TAPPI T 257 cm-02; Sampling and Preparing Wood for Analysis. TAPPI: Peachtree Corners, GA, USA, 2012.

- TAPPI T 550 om-08; Determination of Equilibrium Moisture in Pulp, Paper and Paperboard for Chemical Analysis. TAPPI: Peachtree Corners, GA, USA, 2013.

- TAPPI T 211 om-02; Ash in Wood, Pulp, Paper and Paperboard: Combustion at 525 °C. TAPPI: Peachtree Corners, GA, USA, 2007.

- TAPPI T 204 cm-97; Solvent Extractives of Wood and Pulp. TAPPI: Peachtree Corners, GA, USA, 2007.

- TAPPI T 222 om-21; Acid-Insoluble Lignin in Wood and Pulp. TAPPI: Peachtree Corners, GA, USA, 2021.

- TAPPI T 203 cm-22; Alpha-, Beta- and Gamma-Cellulose in Pulp. TAPPI: Peachtree Corners, GA, USA, 2022.

- Bouza, R.; Marco, C.; Naffakh, M.; Barral, L.; Ellis, G. Effect of particle size and a processing aid on the crystallization and melting behavior of iPP/red pine wood flour composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 935–949. [Google Scholar] [CrossRef]

- Pokhrel, G.; Han, Y.; Gardner, D.J. Comparative study of the properties of wood flour and wood pellets manufactured from secondary processing mill residues. Polymers 2021, 13, 2487. [Google Scholar] [CrossRef] [PubMed]

- Setswalo, K.; Oladijo, O.P.; Namoshe, M.; Akinlabi, E.T.; Sanjay, M.R. The mechanical properties of alkali and laccase treated pterocarpus angolensis (mukwa)-polylactic acid (PLA) composites. Int. J. Biol. Macromol. 2022, 217, 398–406. [Google Scholar] [CrossRef] [PubMed]

- Brounstein, Z.; Yeager, C.M.; Labouriau, A. Development of antimicrobial PLA composites for fused filament fabrication. Polymers 2021, 13, 580. [Google Scholar] [CrossRef] [PubMed]

- Orue, A.; Eceiza, A.; Arbelaiz, A. The use of alkali treated walnut shells as filler in plasticized poly (lactic acid) matrix composites. Ind. Crops Prod. 2020, 145, 111993. [Google Scholar] [CrossRef]

- Alao, P.F.; Marrot, L.; Burnard, M.D.; Lavrič, G.; Saarna, M.; Kers, J. Impact of Alkali and silane treatment on hemp/PLA composites’ performance: From micro to macro scale. Polymers 2021, 13, 851. [Google Scholar] [CrossRef] [PubMed]

- Al Abdallah, H.; Abu-Jdayil, B.; Iqbal, M.Z. The effect of alkaline treatment on poly (lactic acid)/date palm wood green composites for thermal insulation. Polymers 2022, 14, 1143. [Google Scholar] [CrossRef] [PubMed]

- Samir, A.; Ashour, F.H.; Hakim, A.A.; Bassyouni, M. Recent advances in biodegradable polymers for sustainable applications. Npj Mater. Degrad. 2022, 6, 68. [Google Scholar] [CrossRef]

- Lekrine, A.; Belaadi, A.; Dembri, I.; Jawaid, M.; Ismail, A.S.; Abdullah, M.M.; Chai, B.X.; Al-Khawlani, A.; Ghernaout, D. Thermomechanical and structural analysis of green hybrid composites based on polylactic acid/biochar/treated W. filifera palm fibers. J. Mater. Res. Technol. 2024, 30, 9656–9667. [Google Scholar] [CrossRef]

- Madhu, P.; Sanjay, M.R.; Jawaid, M.; Siengchin, S.; Khan, A.; Pruncu, C.I. A new study on effect of various chemical treatments on Agave Americana fiber for composite reinforcement: Physico-chemical, thermal, mechanical and morphological properties. Polym. Test. 2020, 85, 106437. [Google Scholar] [CrossRef]

- Zarna, C.; Rodríguez-Fabià, S.; Echtermeyer, A.T.; Chinga-Carrasco, G. Preparation and characterisation of biocomposites containing thermomechanical pulp fibres, poly (lactic acid) and poly (butylene-adipate-terephthalate) or poly (hydroxyalkanoates) for 3D and 4D printing. Addit. Manuf. 2022, 59, 103166. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Asim, M.; Saba, N.; Sanjay, M.R.; Siengchin, S.; Fouad, H. Alkali treated coir/pineapple leaf fibres reinforced PLA hybrid composites: Evaluation of mechanical, morphological, thermal and physical properties. Express Polym. Lett. 2020, 14, 717–730. [Google Scholar] [CrossRef]

- Yu, W.; Dong, L.; Lei, W.; Zhou, Y.; Pu, Y.; Zhang, X. Effects of rice straw powder (RSP) size and pretreatment on properties of FDM 3D-printed RSP/poly (lactic acid) biocomposites. Molecules 2021, 26, 3234. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, A.; Jha, K.; Petru, M.; Kumar, R.; Sharma, S.; Saini, M.S.; Mohammed, K.A.; Kumar, A.; Abbas, M.; Tag-Eldin, E.M. Fabrication and characterization of weld attributes in hot gas welding of alkali treated hybrid flax fiber and pine cone fibers reinforced poly-lactic acid (PLA) based biodegradable polymer composites: Studies on mechanical and morphological properties. J. Mater. Res. Technol. 2023, 27, 272–297. [Google Scholar] [CrossRef]

- Beg, M.D.H.; Pickering, K.L.; Gauss, C. The effects of alkaline digestion, bleaching and ultrasonication treatment of fibre on 3D printed harakeke fibre reinforced polylactic acid composites. Compos. Part A Appl. Sci. Manuf. 2023, 166, 107384. [Google Scholar] [CrossRef]

- Surendran, A.N.; Malayil, S.; Satyavolu, J.; Kate, K. Influence of chemical pretreatment on the mechanical, chemical, and interfacial properties of 3D-printed, rice-husk-fiber-reinforced composites. J. Compos. Sci. 2023, 7, 357. [Google Scholar] [CrossRef]

- Kumar, S.; Dang, R.; Manna, A.; Sharma, S.; Dwivedi, S.P.; Kumar, A.; Li, C.; Abbas, M. Effect of chemically treated kenaf fiber on the mechanical, morphological, and microstructural characteristics of PLA-based sustainable bio-composites fabricated via direct injection molding route. Biomass Convers. Biorefinery 2024, 14, 31383–31399. [Google Scholar] [CrossRef]

- Serra-Parareda, F.; Espinach, F.X.; Pelach, M.À.; Méndez, J.A.; Vilaseca, F.; Tarrés, Q. Effect of NaOH treatment on the flexural modulus of hemp core reinforced composites and on the intrinsic flexural moduli of the fibers. Polymers 2020, 12, 1428. [Google Scholar] [CrossRef] [PubMed]

- Pokhriyal, M.; Rakesh, P.K. Processing and characterization of novel Himalayacalamus falconeri fiber reinforced biodegradable composites. Biomass Convers. Biorefinery 2024, 14, 21245–21260. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R.; Singh, T.P.; Batish, A. Investigations of polylactic acid reinforced composite feedstock filaments for multimaterial three-dimensional printing applications. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 5953–5965. [Google Scholar] [CrossRef]

- Jiang, J.; Gu, H.; Li, B.; Zhang, J. Preparation and properties of straw/PLA wood plastic composites for 3D printing. IOP Conf. Ser. Earth Environ. Sci. 2021, 692, 032004. [Google Scholar] [CrossRef]

- Mazáň, A.; Vančo, M.; Barcík, Š. Influence of technological parameters on tool durability during machining of juvenile wood. BioResources 2017, 12, 2367–2378. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Abdullah, L.C.; Ratnam, C.T. Mechanical and Physical Properties of Kenaf-reinforced Poly (lactic acid) Plasticized with Epoxidized Jatropha Oil. BioResources 2019, 14, 9001–9020. [Google Scholar] [CrossRef]

- Estakhrianhaghighi, E.; Mirabolghasemi, A.; Zhang, Y.; Lessard, L.; Akbarzadeh, A. 3D-printed wood-fiber reinforced architected cellular composites. Adv. Eng. Mater. 2020, 22, 2000565. [Google Scholar] [CrossRef]

- Brahmia, F.Z.; Alpar, T.; Horváth, P.G.; Csiha, C. Comparative analysis of wettability with fire retardants of Poplar (Populus cv. euramericana I214) and Scots pine (Pinus sylvestris). Surf. Interfaces 2020, 18, 100405. [Google Scholar] [CrossRef]

- Ramesh, P.; Prasad, B.D.; Narayana, K.L. Influence of montmorillonite clay content on thermal, mechanical, water absorption and biodegradability properties of treated kenaf fiber/PLA-hybrid biocomposites. Silicon 2021, 13, 109–118. [Google Scholar] [CrossRef]

- Pérez-Fonseca, A.A.; Martín Del Campo, A.S.; Robledo-Ortíz, J.R.; González-López, M.E. Compatibilization strategies for PLA biocomposites: A comparative study between extrusion-injection and dry blending-compression molding. Compos. Interfaces 2022, 29, 274–292. [Google Scholar] [CrossRef]

- Awad, S.; Hamouda, T.; Midani, M.; Katsou, E.; Fan, M. Polylactic acid (PLA) reinforced with date palm sheath fiber bio-composites: Evaluation of fiber density, geometry, and content on the physical and mechanical properties. J. Nat. Fibers 2023, 20, 2143979. [Google Scholar] [CrossRef]

- Setswalo, K.; Oladijo, O.P.; Namoshe, M.; Akinlabi, E.T.; Sanjay, R.M.; Siengchin, S.; Srisuk, R. The water absorption and thermal properties of green Pterocarpus angolensis (Mukwa)-polylactide composites. J. Nat. Fibers 2023, 20, 2124217. [Google Scholar] [CrossRef]

- Komal, U.K.; Kasaudhan, B.K.; Singh, I. Comparative performance analysis of polylactic acid parts fabricated by 3D printing and injection molding. J. Mater. Eng. Perform. 2021, 30, 6522–6528. [Google Scholar] [CrossRef]

- Song, X.; He, W.; Han, X.; Qin, H. Fused deposition modeling of poly (lactic acid)/nutshells composite filaments: Effect of alkali treatment. J. Polym. Environ. 2020, 28, 3139–3152. [Google Scholar] [CrossRef]

- Aliotta, L.; Sciara, L.M.; Cinelli, P.; Canesi, I.; Lazzeri, A. Improvement of the PLA crystallinity and heat distortion temperature optimizing the content of nucleating agents and the injection molding cycle time. Polymers 2022, 14, 977. [Google Scholar] [CrossRef] [PubMed]

- Wasti, S.; Triggs, E.; Farag, R.; Auad, M.; Adhikari, S.; Bajwa, D.; Li, M.; Ragauskas, A.J. Influence of plasticizers on thermal and mechanical properties of biocomposite filaments made from lignin and polylactic acid for 3D printing. Compos. Part B Eng. 2021, 205, 108483. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Abdullah, L.C.; Aung, M.M.; Ratnam, C.T. Thermal and structural analysis of epoxidized jatropha oil and alkaline treated kenaf fiber reinforced poly (Lactic acid) biocomposites. Polymers 2020, 12, 2604. [Google Scholar] [CrossRef] [PubMed]

- Verdejo de Toro, E.; Coello Sobrino, J.; Martínez Martínez, A.; Miguel Eguía, V.; Ayllón Pérez, J. Investigation of a short carbon fibre-reinforced polyamide and comparison of two manufacturing processes: Fused Deposition Modelling (FDM) and polymer injection moulding (PIM). Materials 2020, 13, 672. [Google Scholar] [CrossRef] [PubMed]

- Jamadi, A.H.; Razali, N.; Petrů, M.; Taha, M.M.; Muhammad, N.; Ilyas, R.A. Effect of chemically treated kenaf fibre on mechanical and thermal properties of PLA composites prepared through fused deposition modeling (FDM). Polymers 2021, 13, 3299. [Google Scholar] [CrossRef] [PubMed]

- Ismail, N.F.; Mohd Radzuan, N.A.; Sulong, A.B.; Muhamad, N.; Che Haron, C.H. The effect of alkali treatment on physical, mechanical and thermal properties of kenaf fiber and polymer epoxy composites. Polymers 2021, 13, 2005. [Google Scholar] [CrossRef] [PubMed]

| Sample Group | Production Methods | PLA (wt%) | Wood Flour (wt%) | NaOH (%) | |

|---|---|---|---|---|---|

| AM | IM | ||||

| Sample ID | |||||

| Control | AMPLA | IMPLA | 100 | - | - |

| Pine | AM10PINU | IM10PINU | 90 | 10 | - |

| AM10PIN2.5A | IM10PIN2.5A | 90 | 10 | 2.5 | |

| AM10PIN5A | IM10PIN5A | 90 | 10 | 5 | |

| AM10PIN10A | IM10PIN10A | 90 | 10 | 10 | |

| AM20PINU | IM20PINU | 80 | 20 | - | |

| AM20PIN2.5A | IM20PIN2.5A | 80 | 20 | 2.5 | |

| AM20PIN5A | IM20PIN5A | 80 | 20 | 5 | |

| AM20PIN10A | IM20PIN10A | 80 | 20 | 10 | |

| AM30PINU | IM30PINU | 70 | 30 | - | |

| AM30PIN2.5A | IM30PIN2.5A | 70 | 30 | 2.5 | |

| AM30PIN5A | IM30PIN5A | 70 | 30 | 5 | |

| AM30PIN10A | IM30PIN10A | 70 | 30 | 10 | |

| Poplar | AM10POPU | IM10POPU | 90 | 10 | - |

| AM10POP2.5A | IM10POP2.5A | 90 | 10 | 2.5 | |

| AM10POP5A | IM10POP5A | 90 | 10 | 5 | |

| AM10POP10A | IM10POP10A | 90 | 10 | 10 | |

| AM20POPU | IM20POPU | 80 | 20 | - | |

| AM20POP2.5A | IM20POP2.5A | 80 | 20 | 2.5 | |

| AM20POP5A | IM20POP5A | 80 | 20 | 5 | |

| AM20POP10A | IM20POP10A | 80 | 20 | 10 | |

| AM30POPU | IM30POPU | 70 | 30 | - | |

| AM30POP2.5A | IM30POP2.5A | 70 | 30 | 2.5 | |

| AM30POP5A | IM30POP5A | 70 | 30 | 5 | |

| AM30POP10A | IM30POP10A | 70 | 30 | 10 | |

| Wood Flour | D10 | D50 | D90 |

|---|---|---|---|

| μm | |||

| Pine | 155 | 346 | 737 |

| Poplar | 151 | 341 | 722 |

| Waste Wood Flour | Holocellulose | Lignin | Extractive Substance | Ash | Moisture Content | |||

|---|---|---|---|---|---|---|---|---|

| Alpha Cellulose | Hemicellulose | |||||||

| Raw | Pine | 47.45 | 23.83 | 27.36 | 0.61 | 0.75 | 11.25 | Ref. [27] |

| Poplar | 48.11 | 29.26 | 21.01 | 1.08 | 0.54 | 12.33 | ||

| 2.5% NaOH | Pine | 53.62 | 18.64 | 26.52 | 0.56 | 0.68 | 11.04 | Present study |

| Poplar | 56.49 | 22.37 | 19.76 | 0.93 | 0.45 | 11.97 | ||

| 10% NaOH | Pine | 64.94 | 12.75 | 21.33 | 0.41 | 0.57 | 10.53 | |

| Poplar | 65.87 | 17.89 | 15.01 | 0.87 | 0.36 | 11.28 | ||

| Sample ID | Tg (°C) | Tc (°C) | Tm (°C) | ΔHm (J.g−1) | Tcc (°C) | ΔHcc (J.g−1) | Xcr (%) |

|---|---|---|---|---|---|---|---|

| AMPLA | 65.71 | 99.14 | 151.51 | 21.59 | 82.61 | 8.20 | 14.40 |

| AM10PINU | 64.87 | 97.76 | 150.33 | 21.06 | 82.60 | 7.24 | 13.37 |

| AM10PIN2.5A | 65.25 | 97.93 | 151.02 | 21.49 | 82.66 | 7.50 | 13.54 |

| AM30PINU | 63.47 | 93.70 | 148.56 | 20.17 | 82.29 | 6.00 | 10.67 |

| AM30PIN10A | 63.48 | 94.02 | 148.70 | 20.28 | 83.79 | 6.02 | 10.73 |

| AM10POPU | 64.23 | 96.82 | 150.16 | 20.96 | 80.78 | 7.18 | 13.33 |

| AM10POP2.5A | 65.71 | 98.66 | 151.25 | 21.17 | 82.83 | 7.22 | 13.50 |

| AM30POPU | 63.20 | 94.39 | 146.30 | 19.92 | 80.69 | 5.95 | 10.51 |

| AM30POP10A | 64.55 | 96.72 | 148.81 | 20.22 | 82.31 | 6.23 | 10.53 |

| IMPLA | 63.12 | 93.23 | 151.08 | 22.08 | 82.17 | 8.36 | 14.75 |

| IM10PINU | 61.63 | 88.63 | 149.03 | 21.63 | 82.11 | 7.44 | 13.73 |

| IM10PIN2.5A | 62.27 | 89.06 | 150.22 | 21.80 | 82.58 | 7.49 | 13.85 |

| IM30PINU | 60.05 | 86.75 | 147.58 | 20.34 | 82.05 | 6.12 | 10.70 |

| IM30PIN10A | 61.08 | 87.11 | 147.63 | 20.76 | 83.74 | 6.39 | 10.82 |

| IM10POPU | 61.16 | 88.84 | 149.09 | 21.46 | 80.03 | 7.41 | 13.59 |

| IM10POP2.5A | 62.40 | 89.99 | 150.68 | 21.64 | 82.26 | 7.45 | 13.74 |

| IM30POPU | 61.09 | 88.52 | 147.42 | 20.26 | 80.01 | 6.11 | 10.65 |

| IM30POP10A | 62.98 | 89.21 | 147.61 | 20.53 | 80.79 | 6.24 | 10.76 |

| Sample ID | Tonset (°C) | Tmax (°C) | Toffset (°C) |

|---|---|---|---|

| UPINWF | 265.42 | 351.12 | 381.02 |

| UPIN2.5A | 266.25 | 365.94 | 382.27 |

| UPIN10A | 269.64 | 369.12 | 388.03 |

| UPOPWF | 263.92 | 350.34 | 380.15 |

| UPOP2.5A | 265.24 | 351.11 | 381.33 |

| UPOP10A | 266.00 | 356.04 | 383.39 |

| Sample ID | Tonset (°C) | Tmax (°C) | Toffset (°C) |

|---|---|---|---|

| AMPLA | 294.59 | 332.95 | 391.13 |

| AM10PINU | 290.11 | 327.29 | 389.35 |

| AM10PIN2.5A | 296.07 | 336.22 | 390.23 |

| AM30PINU | 285.47 | 324.33 | 385.74 |

| AM30PIN10A | 298.31 | 345.51 | 387.68 |

| AM10POPU | 288.08 | 324.36 | 388.49 |

| AM10POP2.5A | 296.00 | 334.17 | 389.91 |

| AM30POPU | 284.88 | 322.47 | 383.34 |

| AM30POP10A | 297.53 | 337.06 | 384.72 |

| IMPLA | 293.35 | 330.56 | 384.03 |

| IM10PINU | 282.24 | 321.68 | 382.08 |

| IM10PIN2.5A | 285.75 | 332.00 | 383.44 |

| IM30PINU | 280.72 | 319.32 | 380.18 |

| IM30PIN10A | 286.66 | 342.78 | 381.14 |

| IM10POPU | 281.12 | 320.70 | 380.93 |

| IM10POP2.5A | 282.35 | 321.83 | 382.22 |

| IM30POPU | 279.11 | 318.90 | 378.72 |

| IM30POP10A | 286.47 | 325.12 | 379.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Demir, M.; Çetin, N.; Narlıoğlu, N. Comparison of Additive Manufacturing and Injection Molding of Biocomposites Reinforced with Alkali-Treated Wood Flour Derived from Recycled Wooden Pallets. Polymers 2025, 17, 2004. https://doi.org/10.3390/polym17152004

Demir M, Çetin N, Narlıoğlu N. Comparison of Additive Manufacturing and Injection Molding of Biocomposites Reinforced with Alkali-Treated Wood Flour Derived from Recycled Wooden Pallets. Polymers. 2025; 17(15):2004. https://doi.org/10.3390/polym17152004

Chicago/Turabian StyleDemir, Mehmet, Nilgül Çetin, and Nasır Narlıoğlu. 2025. "Comparison of Additive Manufacturing and Injection Molding of Biocomposites Reinforced with Alkali-Treated Wood Flour Derived from Recycled Wooden Pallets" Polymers 17, no. 15: 2004. https://doi.org/10.3390/polym17152004

APA StyleDemir, M., Çetin, N., & Narlıoğlu, N. (2025). Comparison of Additive Manufacturing and Injection Molding of Biocomposites Reinforced with Alkali-Treated Wood Flour Derived from Recycled Wooden Pallets. Polymers, 17(15), 2004. https://doi.org/10.3390/polym17152004