Abstract

The accelerating global demand for sustainable materials has brought biodegradable polymers to the forefront of scientific and industrial innovation. These polymers, capable of decomposing through biological processes into environmentally benign byproducts, are increasingly seen as viable alternatives to conventional plastics in sectors such as packaging, agriculture, and biomedicine. However, despite significant advancements, the field remains fragmented due to the diversity of raw materials, synthesis methods, degradation mechanisms, and application requirements. This review aims to provide a comprehensive synthesis of the current state of biodegradable polymer development, including their classifications, sources (natural, synthetic, and microbially derived), degradation pathways, material properties, and commercial applications. It highlights critical scientific and technological challenges—such as optimizing degradation rates, ensuring mechanical performance, and scaling up production from renewable feedstocks. By consolidating recent research findings and regulatory considerations, this review serves as a crucial reference point for researchers, material scientists, and policymakers. It strives to bridge knowledge gaps in order to accelerate the deployment of biodegradable polymers as integral components of a circular and low-impact material economy.

1. Introduction

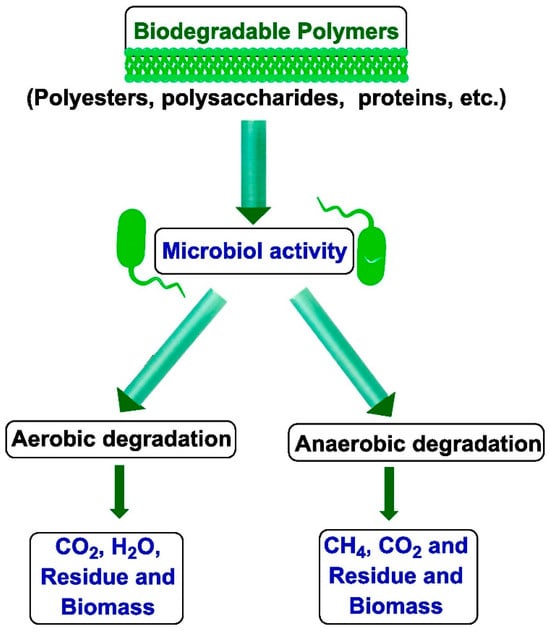

Biodegradable polymers are defined as materials capable of breaking down and being metabolized by natural microorganisms—such as bacteria, fungi, and algae—ultimately into carbon dioxide and water. The main advantage of these materials is their decomposition under the influence of the environment (biodegradability), and their final products are safe and environmentally friendly. The biodegradability of a polymer material (PM) is influenced more by its molecular structure, chemical bonds, and the presence of substituents than by the source of its raw material. Key factors include molecular weight, chain length, and micro-/macrostructure [1,2,3,4,5,6].

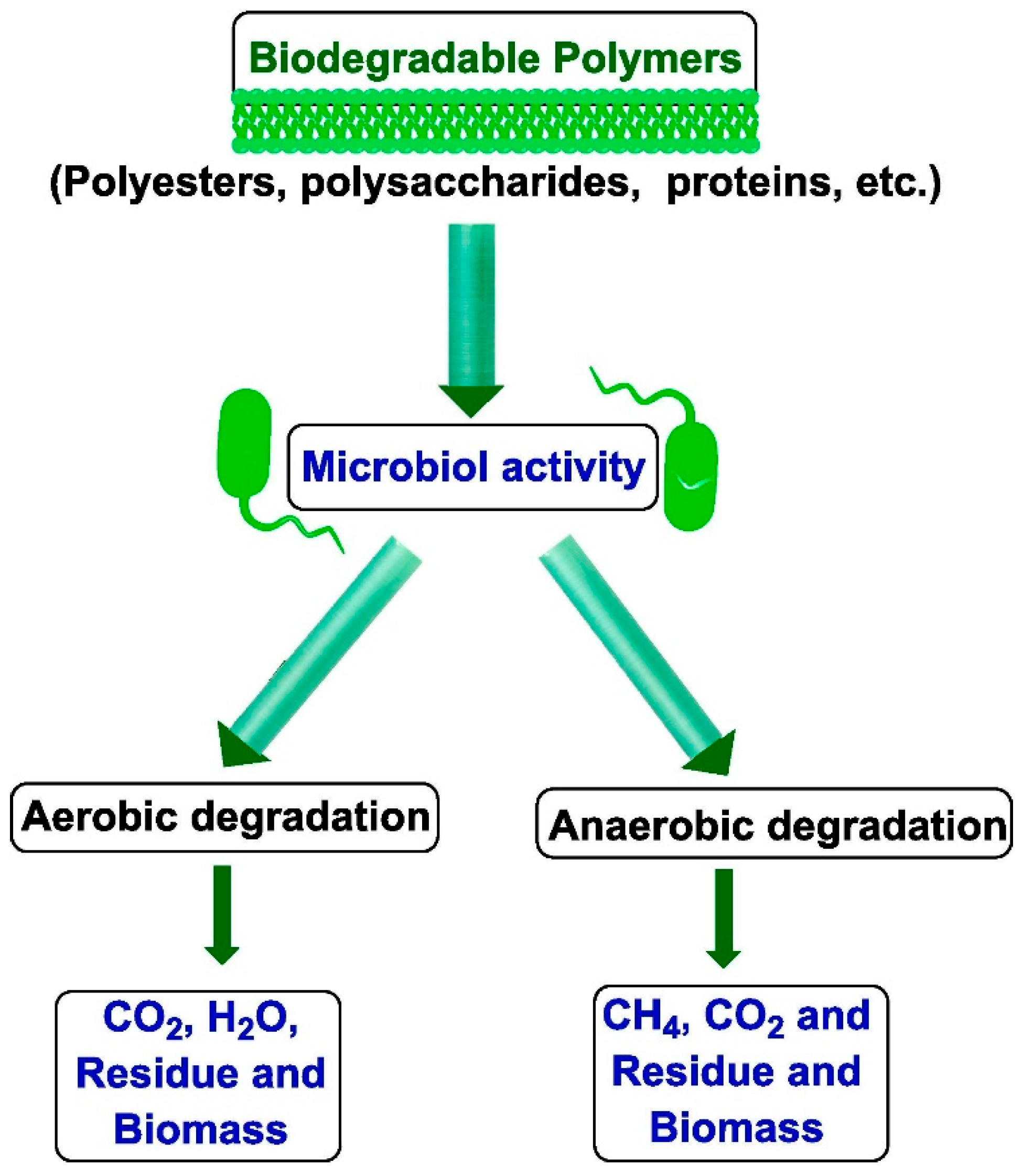

It is important that during degradation, these polymers do not generate any substances harmful to the natural environment. This process differs from composting, which involves creating optimal environmental conditions to accelerate microbial degradation, as illustrated in Figure 1. It is critical to harness nature’s vast bioresources through extensive fundamental research to develop effective, environmentally safe, and economically viable technological methodologies for converting biomass—carbohydrates, proteins, lipids, and terpenoids—into industrially feasible polymeric materials. This opens the door to new material production paths in light of increasing sustainability concerns. Many polymers derived from renewable resources can also be made biodegradable under appropriate conditions [7].

Figure 1.

Schematic representation of polymer degradation via biological processes [8]. (Permission to use was granted by Elsevier).

While a wide range of materials are technically biodegradable, substances like plastics and glass may require centuries to fully decompose [9]. Typically, the biodegradation of polymers begins with biodeterioration, a phase in which the material’s physical, chemical, and mechanical integrity is compromised by non-biological (abiotic) environmental factors [8].

A degradable plastic is engineered to experience substantial changes in its chemical structure when exposed to certain environmental conditions, leading to a measurable decline in its physical properties. This transformation is assessed using standardized tests appropriate to the type of plastic and its intended use within a specified timeframe [10]. Several standardization bodies have worked to develop definitions for (bio)degradable plastics. Generally, degradation is understood as a detrimental alteration in a plastic’s chemical structure, physical properties, or appearance.

Biodegradable plastics are used extensively in single-use applications where their environmental decomposition is a benefit, such as in food service, agriculture, and the packaging of perishable goods. A special category comprises biomedical resorbable polymers, used in sutures, wound dressings, screws, plates, and drug delivery agents [11]. The plasticity and elasticity of biodegradable polymers are achieved by incorporating plasticizers such as glycerol [12]. For large-scale manufacturing, polymers must exhibit sufficient thermal stability to avoid degradation during processing while maintaining their molecular weight and properties. Degradation is affected by time, temperature, impurities, and catalyst concentration [13].

While the importance of recycling bio-based, biodegradable plastics—such as bio-polyethylene terephthalate (bioPET), bio-polyethylene (bioPE), and bio-polypropylene (bioPP)—is evident, their end-of-life scenarios are more complex. Biodegradability is often seen as the only acceptable disposal route, yet it does not allow for material or monomer recovery, unlike mechanical or chemical recycling, which preserves resources. As bioplastic production increases, it is critical to determine optimal end-of-life strategies for each major bioplastic [14].

As outlined in the now-withdrawn ASTM D5488 94de1 standard, biodegradable polymers are described as substances that break down into carbon dioxide, methane, water, inorganic elements, or biomass primarily through microbial enzymatic activity, all occurring within a specified period and in controlled disposal environments [15]. The Japan Bioplastics Association (JBPA) defines biodegradability as the capacity of a material to be microbiologically decomposed into carbon dioxide and water, which are reintegrated into natural cycles. This must not be confused with disintegration, which refers merely to the material fragmenting into smaller pieces. Plastics can be certified as “green” only if they meet strict standards, including criteria on heavy metals and safe intermediates.

Certified standards for biodegradable polymers include the following [16]:

- ISO 17088:2021 [ISO 17088:2021; Plastics—Organic recycling—Specifications for compostable plastics. International Organization for Standardization: Geneva, Switzerland, 2021.];

- EN 13432:2000 [EN 13432:2000; Packaging—Requirements for packaging recoverable through composting and biodegradation—Test scheme and evaluation criteria for the final acceptance of packaging. European Committee for Standardization: Brussels, Belgium, 2000.], EN 14995:2006 [EN 14995:2006; Plastics—Evaluation of compostability—Test scheme and specifications. European Committee for Standardization: Brussels, Belgium, 2006.];

- ASTM D6400-12 [ASTM D6400 12; Standard Specification for Labeling of Plastics Designed to be Aerobically Composted in Municipal or Industrial Facilities. ASTM International: West Conshohocken, PA, USA, 2012.].

Biomaterials, per the ASTM, are defined as organic materials with carbon derived from renewable resources via biological processes. ASTM standards for assessing bio-based content via carbon isotope analysis include the following [15]:

- ASTM D6866-12 [ASTM D6866 12; Standard Test Methods for Determining the Biobased Content of Solid, Liquid, and Gaseous Samples Using Radiocarbon Analysis. ASTM International: West Conshohocken, PA, USA, 2012.];

- ASTM D7026-04 [ASTM D7026 04; Standard Guide for Sampling and Reporting of Results for Determination of Biobased Content of Materials via Carbon Isotope Analysis. ASTM International: West Conshohocken, PA, USA, 2004.].

Most biodegradable polyesters are synthesized through the ring-opening polymerization of six- or seven-membered lactones. Among the various classes of biodegradable polymers, aliphatic polyesters are considered leading candidates due to their ability to hydrolyze or enzymatically break down into hydroxycarboxylic acids, which are typically metabolized further [17]. Aliphatic polyesters are among the few high-molecular-weight polymers that are truly biodegradable [18].

Critical properties of the polymer matrix, such as the glass transition temperature (Tg), indirectly affect degradation rates. Although biodegradability is independent of raw material origin, biomass represents a rich, renewable, and carbon-neutral source for biodegradable materials. Nature produces over 200 billion tons of biomass annually via photosynthesis, of which 75% falls into the carbohydrate class; yet, only 3.5% is utilized by humans [19,20,21,22]. Several parameters influence the degradation behavior of biodegradable polymers, with the most significant being chemical composition, molecular weight and its distribution, crystallinity, and (micro)structure. Recent research also indicates a strong impact of monomer sequence regularity on degradation properties [23]. The development of biodegradable fibers derived from aliphatic polyesters has been widely explored for their use in medical applications [24,25,26,27].

1.1. Current Trends and Challenges in the Field of Biodegradable Polymers

One of the major challenges faced by researchers all around the globe is the development of technological solutions aimed at creating synthetic polymers with accelerated biodegradability [28]. Bioplastics can be either bio-based (i.e., derived from renewable resources) or biodegradable (i.e., capable of decomposing into natural elements) [29]. One promising approach is the creation of synthetic additives or modifiers that can actively regulate the rate of biodegradation and significantly accelerate the degradation process of major industrial polymers such as polyolefins, polystyrene, and phthalates [30].

The lack of biodegradability in other polymers may impact their long-term environmental performance compared to biodegradable systems [31]. In nature, these polymers undergo significant transformations, including hydrolysis by water and oxidation by atmospheric oxygen, which alter their physical characteristics. Furthermore, such polymers can serve as substrates for the growth of specific microorganisms [32].

A biofilm is a community of microbial cells associated with a surface and embedded in a matrix of extracellular polymeric substances, consisting of 80–95% water and hydrated biopolymers (mainly polysaccharides) [33]. According to Donlan and others [33,34], biofilm formation causes the micro-swelling of polymer surfaces, making them more vulnerable to microbial attack.

Currently, researchers are focused on three major areas [35]:

- Introducing functional groups into biodegradable polymers to promote photodegradation;

- Creating composites of conventional polymers with natural biodegradable additives that initiate breakdown;

- Synthesizing new biodegradable plastics using existing synthetic industrial products.

Several technologies have been developed to impart biodegradability to traditional polymers [28,36]. These include the following:

- Introducing agro-industrial waste products (e.g., beet pulp, oat husks, buckwheat hulls, corn mash) as additives into synthetic polymers.

- Creating composite materials based on synthetic and natural biodegradable polymers (e.g., starch, cellulose, polylactic acid).

- Adding oxo-biodegradable additives to synthetic polymers, which contain transition metal salts that generate free radicals, leading to hydroperoxide and peroxide formation, which promotes biodegradation [37,38].

The use of hydrogen in the production of PGA is well established [39]. This process transforms organic substances, including waste, into bioplastics by initially gasifying them into carbon monoxide and hydrogen. These gases are then assimilated by photosynthetic bacteria into the cellular biomass under oxygen-free (anaerobic) conditions [40]. Acidogenic fermentation can also produce a sufficient hydrogen yield [41], which can be used for bioplastic production [42,43].

New biodegradable biopolymers are being developed using biotechnological processes. These are referred to as “green plastics” and are derived from plants. Green plastic is of significant interest to modern researchers as a sustainable alternative to traditional petroleum-based plastics. It must originate from renewable sources, be inherently biodegradable, and be environmentally friendly [44].

The production of low-cost raw bioplastics is feasible through the use of mixed microbial cultures under non-sterile cultivation conditions. The organic acids generated during the acidogenic fermentation of municipal solid waste (MSW) can serve as a predominant carbon source for the biosynthesis of raw bioplastics. The environmental benefits of producing and utilizing raw bioplastics derived from the organic fraction of MSW include the following:

- Reducing the volume of waste destined for incineration;

- Lowering the amount of ash requiring landfill disposal;

- Enabling the use of seawater for MSW separation, thereby conserving freshwater resources.

In 2019, bio-based polyamides accounted for approximately 12% of the global bioplastics market. Commercially available bio-based polyamides are typically derived from sebacic acid or undecanoic acid, both of which can be sourced from castor oil. Among these, polyamide 11 (PA11) is the most common and commercially available. However, other polyamides, such as PA610, PA1010, PA510, PA6, PA66, and PA12, can also be produced in fully or partially bio-based versions [45,46].

Products requiring rapid photodegradation primarily include packaging materials such as shopping bags, garbage bags, snack wrappers, and wrapping films for paper goods. Additionally, disposable tableware, drinking cups, egg cartons, dairy cartons, and personal hygiene products (e.g., diapers, tampon applicators, and bandages) are often cited as candidates for photodegradable materials. Notably, degradability in these cases is only relevant if such products are not properly disposed of; otherwise, photodegradability serves mainly to reduce littering impact [47]. The development of photo- and biodegradable plastics relies on the incorporation of photo- and bioactivating additives into the polymer chain, which should contain functional groups capable of degradation under ultraviolet radiation or anaerobic bacterial activity [35].

Raw bioplastics containing polyhydroxyalkanoates (PHAs) can be applied across multiple industries, particularly in construction and agriculture [48]. However, there are two potential challenges associated with the use of raw PHA-based nanocomposite bioplastics. The first is the high melting temperature of PHAs, typically in the range of 160–180 °C [49,50].

The melting temperature of PHB (polyhydroxybutyrate) is close to its thermal degradation point (Td) [51]. Similarly, the degradation temperatures of proteins, polysaccharides, and polynucleotides are also in this range, indicating that all biopolymers exhibit poor thermal stability near the melting point of PHAs. Natural antioxidants found in biomass can help reduce the rate of thermal degradation of biopolymers [52]. Protein itself can be regarded as a thermoplastic material when combined with plasticizers that suppress crosslinking reactions, which might otherwise result in the formation of thermosetting materials [53]. Therefore, the molding process for composite raw PHA-containing bioplastics should be kept as brief as possible to minimize the thermal degradation of PHAs and other bacterial biopolymers [54,55].

Currently, four main scientific approaches have been developed for the production of these environmentally friendly and sustainable bioplastics: (1) the partial modification of natural polymers (starch, cellulose, pullulan); (2) monomer production using de novo or fermentation processes followed by traditional chemical polymerization (e.g., PLA, polyethylene); (3) microbial cultivation and adaptation, including the use of genetically engineered colonies (e.g., PHA, PHB) [56]; and (4) the production of partially biodegradable polymers such as polybutylene terephthalate (PBT), poly(butylene adipate-co-terephthalate) (PBAT), polybutylene succinate (PBS), and polyurethane (PU) [57]. However, most commercially available biodegradable bioplastics degrade slowly under environmental conditions, even in the presence of microorganisms, as they are often designed to degrade in specific environments such as industrial composting facilities [58].

1.2. Relevance

The global urgency to reduce plastic pollution and reliance on fossil-based polymers has intensified the need for sustainable alternatives. Biodegradable polymers have emerged as promising materials capable of mitigating environmental degradation while supporting a circular economy. Their relevance spans across sectors such as packaging, agriculture, medicine, and consumer goods, where single-use plastics dominate. The increasing volume of plastic waste—projected to exceed 1.1 billion tons by 2050—has catalyzed a shift in policy, industry practices, and research priorities, all pointing towards biodegradable solutions. This review of biodegradable polymers is timely and essential, considering the current limitations of both industrial-scale adoption and the public understanding of these materials. This comprehensive synthesis of biodegradable polymer classifications, degradation pathways, and applications will enable stakeholders—from researchers to regulators—to make informed decisions that align with ecological and economic sustainability goals. Moreover, this review underscores the multidisciplinary nature of biodegradable polymer development, incorporating advances in microbiology, chemistry, materials science, and environmental engineering. As the push for zero-waste manufacturing intensifies, biodegradable polymers represent a pivotal innovation in reconciling industrial productivity with environmental stewardship.

1.3. Methodology

This review adopts a comprehensive literature-based methodology aimed at consolidating and synthesizing contemporary research on biodegradable polymers. Scientific publications, technical reports, and regulatory standards were systematically analyzed to map the current landscape of biodegradable materials. Sources include peer-reviewed journals in polymer science, materials engineering, biotechnology, and environmental science, with a particular focus on recent advances post-2010. The methodology encompasses three key analytical dimensions: (1) the classification and synthesis of biodegradable polymers, distinguishing natural, synthetic, and microbially derived materials; (2) an evaluation of degradation mechanisms—both abiotic and biotic—and their environmental dependencies; and (3) a critical assessment of application-specific challenges and commercial viability across industries. Special emphasis is placed on polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) given their dominance in current research and market penetration. Additionally, the review incorporates data from relevant standards organizations (e.g., ASTM, ISO, JBPA) to contextualize biodegradability within regulatory frameworks. This methodological approach ensures a balanced representation of scientific innovation, practical deployment, and policy implications, enabling a holistic view of the biodegradable polymer domain.

2. Classifications of Biopolymers and Biodegradation Mechanisms

2.1. Classifications of Biopolymers

Over the past two decades, there has been increased interest in polymers derived from renewable resources due to limited petroleum reserves and environmental concerns, such as waste accumulation and a resistance to degradation. The development of new biodegradable polymers based on plant-derived biopolymers and their derivatives, in combination with synthetic polymers, offers opportunities for innovative degradable systems [59,60,61]. The majority of researched biodegradable polymers are part of the polyester group, with a particular emphasis on poly(glycolic acid), poly(lactic acid), and their copolymers. These remain crucial in medical applications requiring resorbable materials [62]. To qualify as biodegradable, materials must pass a series of tests, including chemical composition (e.g., heavy metals), complete degradation under laboratory and real-world conditions, and the ecotoxicity of the resulting compost. Biodegradation should reduce plastic fragments to sizes below 2 mm in over 90% of the sample under real conditions [63].

Photodegradable polymers include ethylene–carbon monoxide copolymers. Vinyl ketone monomers serve as photo-initiators for the degradation of base polymers such as PE (polyethylene) and PS (polystyrene). When introduced in amounts of 2–5% as comonomers, these materials retain properties similar to PE or PS but become susceptible to photodegradation under UV light within the range of 290–320 nm [64]. Even a small number of keto groups in the polymer backbone renders polyethylene (PE) photodegradable, a desirable characteristic given current environmental pollution issues [65].

For many plastic types, hydrolytic degradation is the most common environmental decomposition route [66]. A powerful alternative is photodegradation. Intrachain keto groups are particularly effective for promoting photodegradation as they enable chain scission via Norrish Type I and Type II reactions [67].

Based on their raw material, biodegradable polymers can be divided into three categories [68]:

- Edible or cellulose-based packaging from biomass of terrestrial or marine origin (proteins, fats, polysaccharides);

- Polyesters synthesized from renewable and petroleum-based sources with properties similar to conventional plastics;

- Polyhydroxyalkanoates (PHAs) and similar biopolymers obtained from microbial fermentation.

Bioplastics are generally classified into three main categories [69]:

- Conventional plastics derived from fossil resources but modified to be biodegradable, such as PBAT;

- Non-biodegradable or partially biodegradable plastics, including bio-based polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and technically advanced biodegradable plastics such as polytrimethylene terephthalate (PTT) and thermoplastic polyester elastomers;

- Plastics that are both bio-based and biodegradable, for example, PLA (polylactic acid) and PHAs (polyhydroxyalkanoates).

2.2. Degradation Types and Mechanisms

The factors that influence the mechanical properties of biodegradable polymers are well known to polymer scientists. Key variables influencing polymer properties include the selection of monomers, the type of initiator employed, processing parameters, and the incorporation of additives. These factors collectively determine characteristics such as hydrophilicity, the degree of crystallinity, melting point, glass transition temperature, molecular weight and its distribution, the nature of end groups, the arrangement of monomer sequences (whether random or block), and the residual presence of unreacted monomers or added substances. The biodegradation of polymer composites is a two-stage process, consisting of abiotic and biotic oxidation. During the mineralization of plastics, low-molecular-weight polymer residues undergo enzymatic dissimilation—breaking down with the release of energy. This dissimilation process is intrinsically linked with assimilation. The assimilation of plastics refers to the metabolic processes by which microorganisms incorporate plastic components into their cellular metabolism, resulting not only in energy release but also in biomass growth and the formation of secondary metabolites. These assimilation features provide irrefutable evidence of the ongoing biodegradation of the polymer [70,71]. A novel biodegradable polyester was synthesized via the chain-extension of poly(p-dioxanone) (PPDO) with poly(butylene succinate) (PBS) [72].

Numerous studies and patents have explored the enzymatic breakdown of biodegradable aliphatic polyesters—such as PLA, PBS, PCL, PTT, and poly(butylene adipate) (PBA)—typically utilizing enzymes like lipases or proteinase K. These processes often continue with the further degradation of the produced oligomers. Despite this progress, enzymatic depolymerization remains a developing technology. Its current limitations include a relatively slow reaction rate, especially for polymers with a high crystallinity and strong intermolecular interactions. Moreover, enhancing the reaction speed by raising the temperature is not feasible, as it risks deactivating the enzymes involved [73]. The field of biodegradable polymeric materials has made significant progress in recent years.

There are five main types of synthetic polymer degradation, classified by external factors [74]:

- Bacterial degradation;

- Chemical degradation;

- Photodegradation due to sunlight;

- Thermal degradation;

- Mechanical degradation.

Polymer biodegradation occurs via two primary mechanisms: biological hydrolysis and biological oxidation [75,76]. Hydrolysis is mediated by specific depolymerase enzymes, while oxidation can occur non-enzymatically. Both these destructive processes act synergistically [77].

To initiate biodegradation, a composite should contain the following [78]:

- Heteroatoms;

- Biodegradable bonds (R = CH2; R = CH–R1; R–CH2–OH; R–CH(OH)–R; R–CO–H; R–CO–R1, etc.);

- Carbon chain fragments with fewer than five CH2 groups;

- Bulky substituents;

- Natural fillers that support microbial metabolism: starch, cellulose, lactose, magnesium, and urea.

Depending on the degradation mechanism, biodegradable polymers can be categorized into three main groups [79,80]:

- Biodegradable polymers—natural polymers such as cellulose, starch, agro-industrial waste, beet pulp, natural rubber, polyhydroxybutyrate (PHB), polybutyrolactone, polylactic acid (PLA), etc.;

- Polymers subject to biodeterioration—such as aliphatic polyesters and polyamides;

- Materials susceptible to bioerosion—typically blends or copolymers of synthetic polymers with natural polymers from Group 1 (e.g., polyethylene with starch).

2.3. Types of Biomaterials for Creating Biodegradable Coatings

Biodegradable polymers often used for coatings can be broadly categorized into natural, semi-synthetic, and synthetic types based on their origin and method of production. Each category encompasses materials with unique physicochemical properties and specific applications, particularly in agriculture, biomedicine, and environmental sustainability. The following classification highlights representative examples of biodegradable polymers along with their defining characteristics and practical uses.

- 1.

- Natural Polymers:Several notable examples of natural polymers include the following:

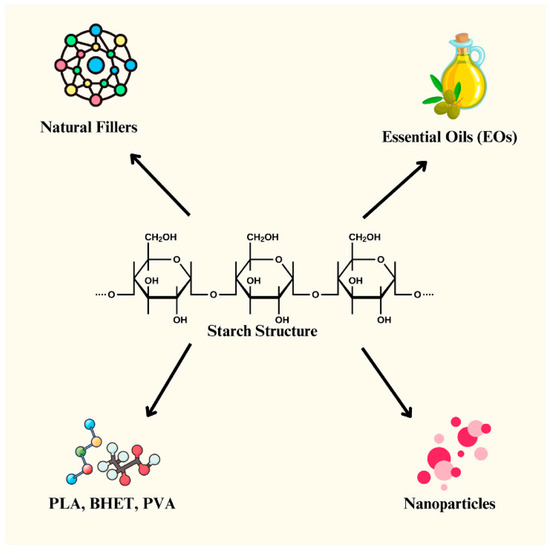

- Starch is biodegradable, thus reducing environmental pollution. Starch-based coatings can slow the release of fertilizers, allowing plants to absorb nutrients gradually, minimizing leaching into groundwater and reducing application frequency. Starch films also exhibit good mechanical strength and flexibility, making them suitable for encapsulation purposes [81].

- Gelatin is biocompatible and biodegradable. Due to its high water content, gelatin has low mechanical strength. To enhance its elasticity, additives such as other polymers or organic/inorganic compounds are commonly used [82].

- Wheat gluten can be processed to produce bioplastics [83,84].

- Collagen supports structural processes, cell growth, proliferation, and migration. It is biocompatible, biodegradable in tissue environments, and non-cytotoxic, making it an ideal material for rapid tissue scaffold formation [85].

- 2.

- Chitosan: Chitosan protects plants from pathogens due to its antibacterial properties, improving plant health. Chitosan is considered semi-synthetic; it is a naturally occurring biopolymer obtained by chemically modifying chitin, a structural polysaccharide present in the exoskeletons of marine crustaceans, certain insects, and the cell walls of fungi. This transformation is typically achieved through a deacetylation process, wherein acetyl groups are removed from chitin to yield chitosan, which imparts distinct physicochemical and biological properties [86,87,88]. It is highly biocompatible and safe for agricultural use, and it enables the controlled release of fertilizers [89]. Chitosan is biodegradable, non-toxic, and exhibits antimicrobial properties [90,91,92].

- 3.

- Synthetic Polymers:Below are a couple of notable examples of synthetic polymers:

- Polyethylene glycol (PEG) has tunable permeability based on temperature and humidity, enabling controlled nutrient release. Due to its hydrophilicity, PEG coatings help retain soil moisture and enhance plant nutrient uptake [93].

- Lactate-based polymers, derived from lactic acid, degrade rapidly in nature and break down into harmless byproducts like CO2 and water. These coatings can shield fertilizers from harsh environmental conditions until they are needed by plants [94].

Composite films made from a combination of chitosan, microcrystalline cellulose fibers, and gelatin have enhanced strength and biodegradability when buried in soil, making them suitable for packaging and tray manufacturing [95]. A growing method for imparting biodegradability to synthetic polymers involves blending them with natural biodegradable polymers like cellulose, starch, chitin, and chitosan. This approach began with materials filled with carbohydrate-based polymers, particularly starches [96,97].

3. Prominent Biodegradable Polymers

3.1. Polylactic Acid or Polylactide (PLA)

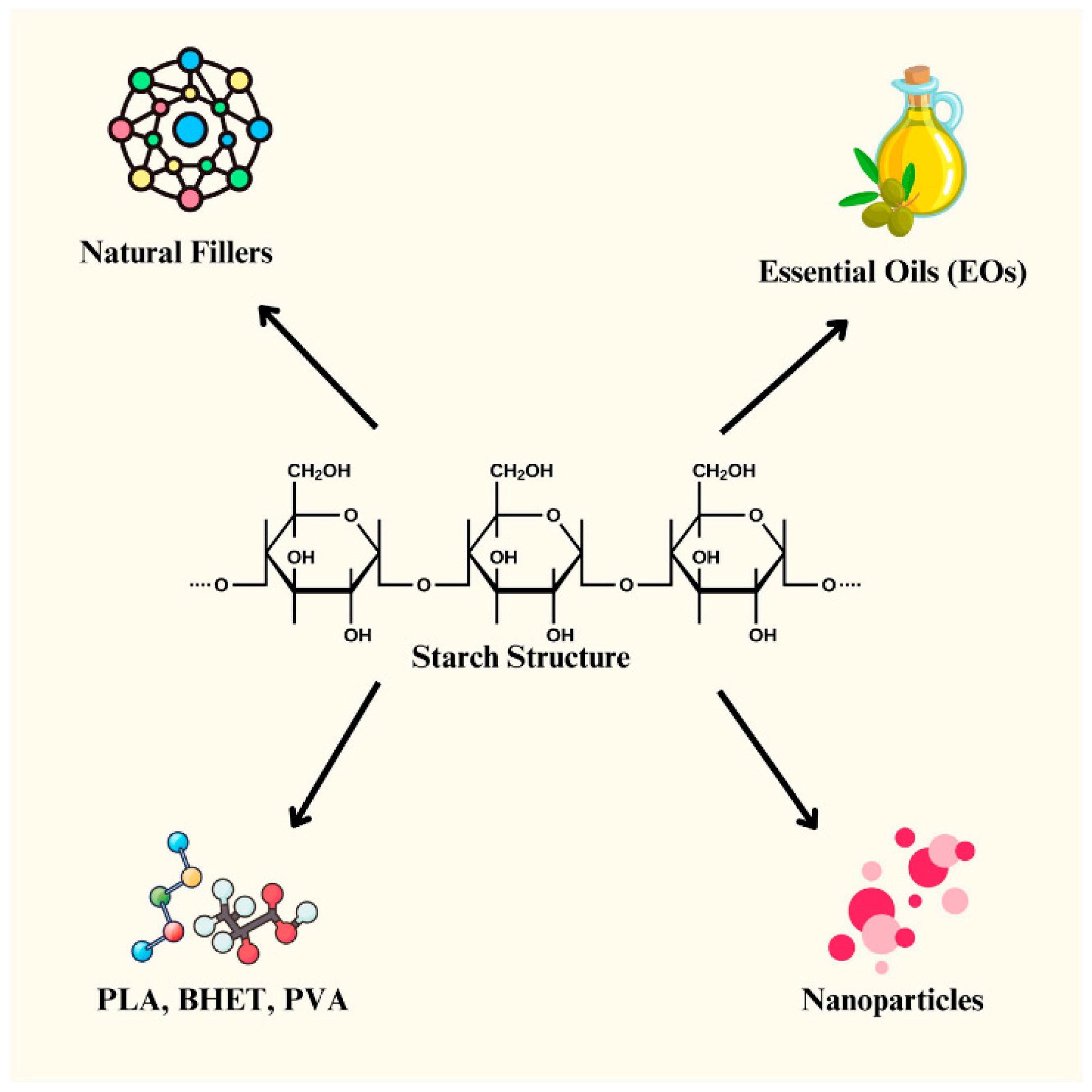

Among the most promising biodegradable plastics for packaging is polylactic acid (PLA)—a condensation product of lactic acid. The industrial synthesis of PLA occurs via the ring-opening polymerization of lactide [98,99,100] or via the azeotropic polycondensation of lactic acid [99]. Despite its advantages, PLA has a relatively slow degradation rate (half-life of approximately 168 days). Therefore, copolymerization with monomers like glycolide—derived from glycolic or monochloroacetic acid—is being explored to tailor its biodegradation profile [101]. PLA is a biodegradable thermoplastic widely recognized for its favorable mechanical strength, biocompatibility, and non-toxic degradation products, making it suitable for diverse applications ranging from packaging to biomedical devices [102]. Its potential in drug delivery has been demonstrated through numerous studies involving PLA and its copolymers [103,104,105,106,107]. Over the past decade, substantial advances have been made in the controlled polymerization of synthetic PLA. Among the various synthesis techniques explored [108,109], the ring-opening polymerization (ROP) of lactide has emerged as the most effective method [110].

PLA was first synthesized in 1932 by DuPont scientist Wallace Carothers and became the first industrially produced bio-based and biodegradable polymer in the late 1990s [111]. It remains one of the most commercially viable biodegradable polyesters due to its biocompatibility and biodegradability. One of the reasons for this is that lactic acid is easily produced via a biotechnological process (usually based on a strain of lactobacilli) from inexpensive raw materials [112].

PLA is recognized for its dual functionality: it is biodegradable, making it suitable for short-term uses such as packaging, and biocompatible, allowing for its safe application in medical contexts like implants, sutures, and drug delivery systems. PLA undergoes abiotic degradation through the hydrolysis of its ester bonds, which does not require enzymatic assistance. In the subsequent phase of its breakdown, enzymes further degrade the resulting oligomers into simpler compounds, eventually leading to complete mineralization via biotic processes. As its primary building block—lactic acid—is derived from renewable carbohydrate sources through fermentation, PLA aligns well with global sustainability goals and is widely regarded as an eco-friendly material [113].

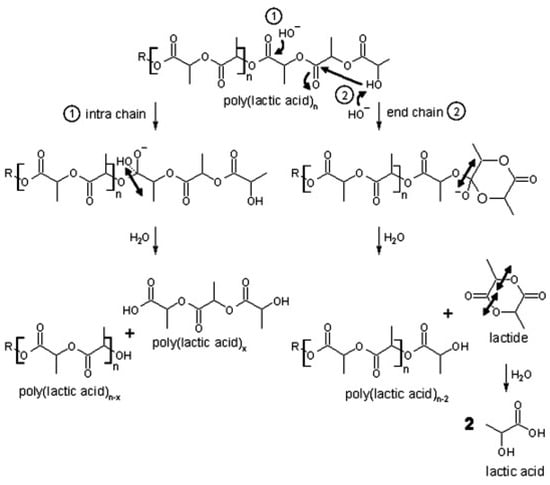

Polylactic acid (PLA) undergoes degradation in aqueous environments through the hydrolysis of its ester linkages. Similar to polycaprolactone (PCL) and poly(propylene carbonate) (PPC), PLA degrades slowly under neutral pH conditions but exhibits significantly accelerated degradation in alkaline environments compared to acidic ones [114].

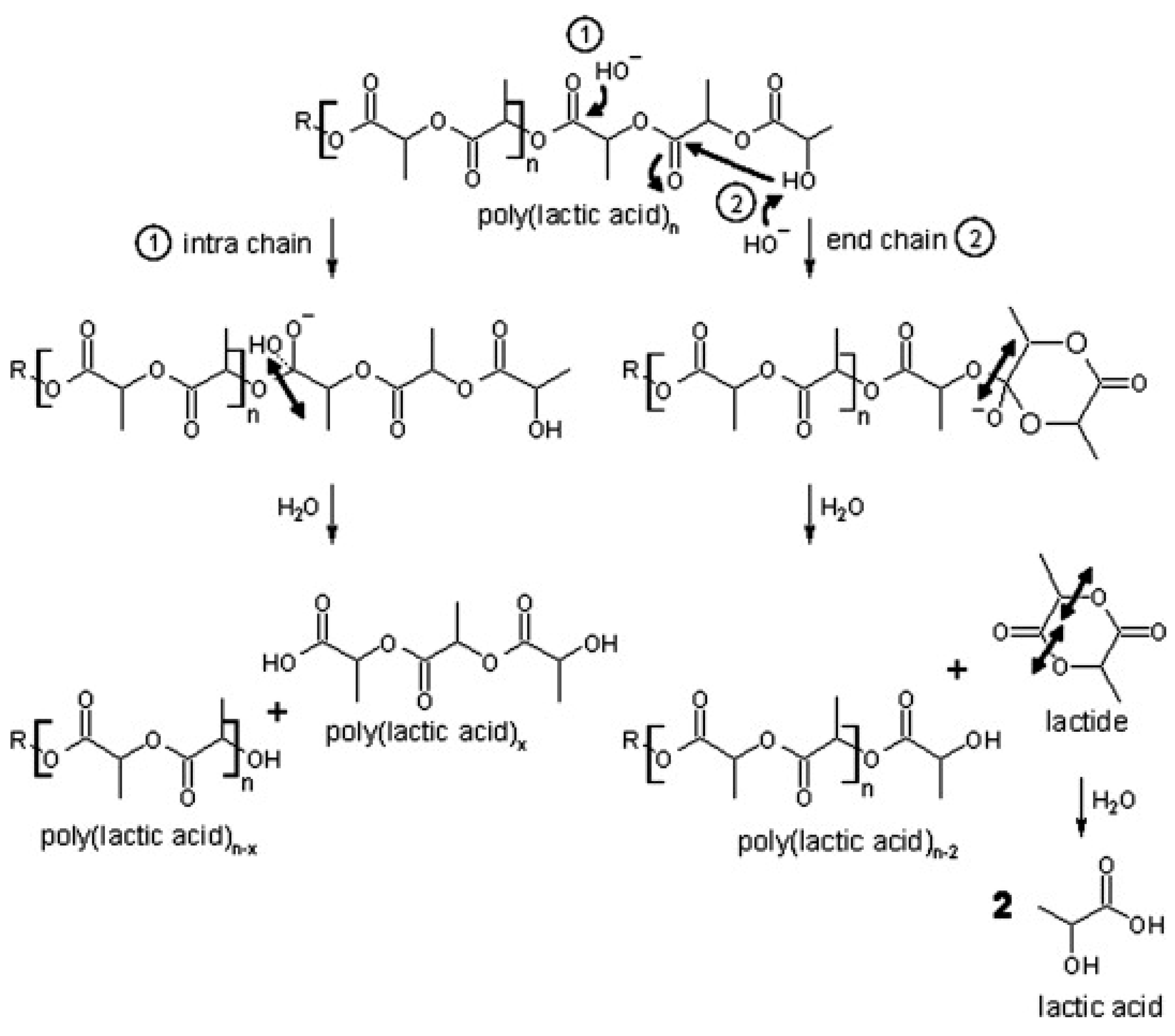

PLA depolymerization in basic conditions occurs via the gradual release of dimer units (see Figure 2). This process likely involves intramolecular transesterification at the polymer chain end. Under basic catalysis, the hydroxyl end-group performs an electrophilic attack on a neighboring carbonyl group, leading to ring formation. This step results in polymer chain shortening as the newly formed lactide is hydrolyzed. Subsequently, the lactide is further broken down into two lactic acid molecules. Additionally, random base-catalyzed attacks on the ester groups in the polymer backbone initiate intramolecular degradation, producing low-molecular-weight compounds through ester bond cleavage [115].

Figure 2.

Hydrolytic degradation of PLA under basic conditions [115]. (Permission to use was granted by Elsevier).

Lactic acid can be converted into its dehydrated dimer, lactide, which is then polymerized through ring-opening polymerization to produce high-molecular-weight polymers. These polymers can also be copolymerized with caprolactone to create valuable packaging films. Additionally, the bacterial fermentation of substrates such as glucose and acetic acid produces novel thermoplastic polyesters like poly(3-hydroxybutyrate) (PHB) [116]. Among biopolymers, those derived from crystalline nanocellulose sourced from agricultural materials exhibit the fastest biodegradation rates. The presence of E. faecium was found to cause the greatest decrease in degradation rate, while also slightly enhancing tensile strength when compared to strains of P. acidilactici [117].

One of the main limitations of polylactic acid (PLA) lies in its relatively low glass transition temperature (Tg) of 55–60 °C, above which the material becomes tacky. This characteristic, combined with its slow crystallization kinetics, complicates the drying and crystallization of amorphous PLA waste, such as films. Similarly, thermoplastic starch suffers from hydrolytic degradation during use, restricting the recyclability of such materials to lower-value applications. In addition, thermoplastic starch is immiscible with conventional packaging plastics and cannot be effectively co-processed into high-performance secondary products [118].

An increasing volume of research underscores PLA’s status as one of the most promising biodegradable polymers [119]. It is processable by standard industrial techniques—including injection molding, blow molding, thermoforming, and extrusion—and is commercially available in a variety of grades. Its biodegradability supports short-lived applications such as in packaging, while its compatibility with biological systems makes it ideal for medical uses, including sutures, implants, and drug encapsulation.

PLA is generally synthesized using homoleptic metal-based catalysts (e.g., tin, aluminum, and zinc). However, achieving high stereocontrol and catalyst activity has proven challenging due to complex equilibria and the formation of multinuclear species. Research into alternative catalysts, such as homoleptic yttrium alkoxides, continues to expand [120,121].

The degradation of PLA occurs abiotically via the hydrolysis of ester bonds, a process that does not require enzymatic catalysis. Biodegradation proceeds in two stages: initial abiotic hydrolysis, followed by microbial enzymatic activity that converts oligomers into mineralized end products. Given that PLA’s primary monomer—lactic acid—can be sourced from the fermentation of renewable carbohydrates, the polymer aligns with global sustainability initiatives and is regarded as an eco-friendly alternative to petroleum-based plastics [122]. In terms of processability, PLA is compatible with conventional plastic manufacturing methods and is increasingly being used in applications such as molded articles, fibers, textiles, and food packaging [123,124,125,126].

Despite its advantages, PLA remains more costly than traditional polymers like polyethylene and polystyrene. However, recent efforts aim to reduce its production costs through less energy-intensive manufacturing. To improve polymerization stereoselectivity, novel catalysts based on zirconium, hafnium, gold, and platinum are being explored [100]. Comprehensive overviews of PLA synthesis and industrial relevance are available in recent reviews [127,128].

PLA can be tailored to exhibit a wide range of chemical and mechanical properties depending on the synthesis method. This flexibility in synthesis allows PLA and its copolymers to be customized for high-performance applications, particularly in tissue engineering, where their biocompatibility and mechanical integrity support tissue regeneration [129].

The monomer lactic acid, a naturally occurring organic acid, is typically produced via the microbial fermentation of renewable feedstocks such as sugarcane. As a result, PLA is considered environmentally friendly and suitable for use in biomedical contexts due to its non-toxicity and renewable origin. The authors of [130] report on the fermentation-based production of lactic acid and subsequent polymerization routes for PLA, with an emphasis on its biomedical applications and relevance in sustainable material development.

Poly(L-lactic acid) (PLLA), a semi-crystalline form of PLA derived from L-lactide, typically exhibits a tensile modulus of ~3 GPa and tensile strength around 60 MPa, along with high transparency and good processability [99]. Its crystallinity (~37%) contributes to its wide usage in packaging, including disposable cups, containers, films, and bottles. PLA fibers, produced via thermal spinning, exhibit properties comparable to those of PET and nylon [131,132,133]. These fibers can be fabricated by either solvent-based or melt-spinning techniques, with solvent-spun fibers often offering superior mechanical properties due to reduced thermal degradation during processing [134].

Beyond its packaging and biomedical uses, PLA is employed in the production of textiles, hygienic products, disposable tableware, agricultural mulch films, and even in a foamed form as a sustainable alternative to polystyrene for insulation and cushioning applications [135,136,137].

For convenience, the key points are summarized and provided in Table 1.

Table 1.

Key points on PLA.

3.2. Polyhydroxyalkanoates (PHAs)

PHAs are bio-derived and biodegradable aliphatic polyesters synthesized through the polymerization of β-, γ-, and δ-hydroxyalkanoic acids. These acids are primarily obtained via the fermentation of sugars and lipids (e.g., glucose, sucrose, and vegetable oils) derived from a broad range of raw materials [15,138]. This exciting class of polyesters offers biodegradability, thermoplasticity, and favorable mechanical properties. They can also be produced by various microbial strains using renewable resources under stress conditions—such as carbon excess and limitations in nitrogen, oxygen, or phosphorus [139].

Similar to PLA, PHAs are used in various disposable applications across the packaging and biomedical sectors. Owing to their excellent biocompatibility, specific types like PHB and PHBV are currently under investigation for biomedical uses such as bioresorbable surgical sutures, wound healing materials, tissue engineering scaffolds, bone fixation devices, and porous membranes that support soft tissue regeneration [16,140]. Biopolymers based on cellulose, starch, PHAs, bio-derived polyethylene, and PLA are also employed in agricultural applications, including the production of shading nets and biodegradable mulching films [141,142,143]. Additionally, PHAs have been utilized in the formulation of printing toners and as components in coating adhesives [144]. Their potential in agriculture further extends to applications such as seed coatings, encapsulated slow-release fertilizers, biodegradable films for crop protection, and compostable containers for greenhouse use [145].

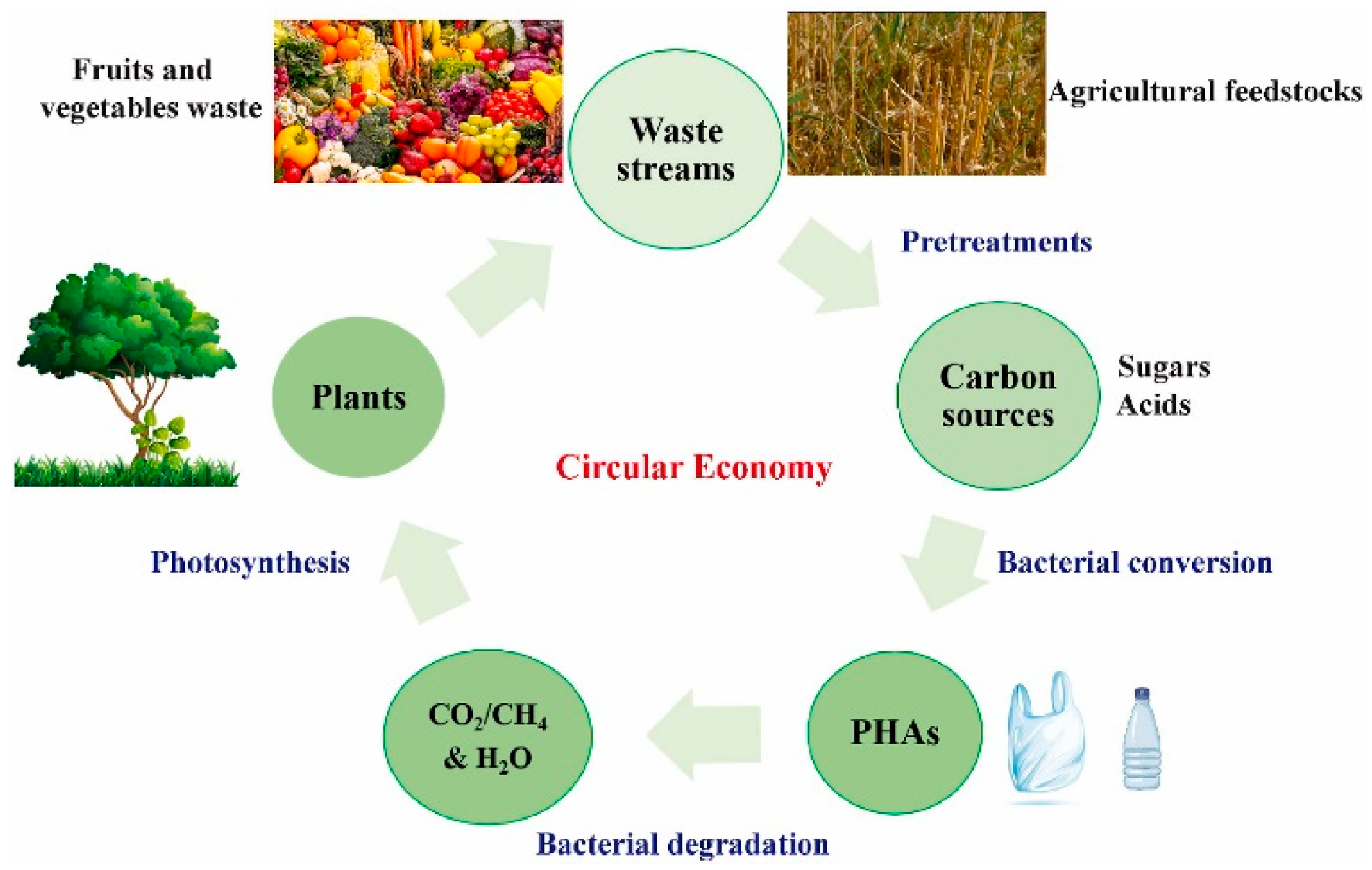

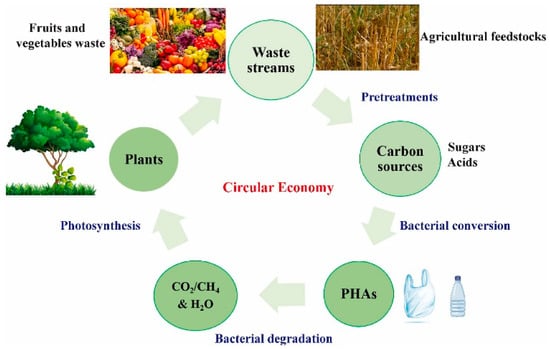

Figure 3 illustrates the overall closed-loop process of producing polyhydroxyalkanoates (PHAs) using waste-derived feedstocks. Typically, complex organic materials present in waste streams are first broken down into simpler sugars, and are then fermented—often under anaerobic conditions—into volatile fatty acids (VFAs). While pretreatment methods can aid this conversion, they often raise processing costs and may produce toxic byproducts such as furfural, which can hinder PHA biosynthesis. To ensure the reliable and sustainable generation of sugars and VFAs from waste, it is essential to fine-tune operational parameters. Moreover, controlling or preventing acidogenic inhibition during fermentation is crucial. Therefore, implementing environmentally friendly, efficient, and economically viable pretreatment strategies is key for large-scale applications [146].

Figure 3.

Schematic representation of a closed-loop system for producing PHAs from waste materials [146]. (This Figure is available as open access).

The properties of PHAs vary with the length and structure of the side chains in their repeating units, and the type of polyester formed depends on the microbial strain used. PHAs accumulate as intracellular granules (0.2–0.7 µm in diameter) in bacterial cytoplasm [147]. Their property profiles can be tuned through substrate selection, bacterial strain, and fermentation conditions.

Plant biomass can serve as a feedstock, contributing to a closed carbon cycle [148]. Sustainable carbon sources include biomass, municipal waste, and industrial waste streams, which reduce environmental waste and production costs since 30–50% of total PHA production costs arise from raw materials [149]. Other sustainable inputs include wood chips, cardboard scraps, and waste from plastic bottles and bags [150,151].

Naturally occurring biopolymers serve as biological storage systems or protective mechanisms. Microalgae play a crucial role in biological carbon fixation through photosynthesis, ultimately leading to the synthesis of branched polysaccharides. PHA is a leading microbial-derived biopolymer. For example, rice bran is a viable substrate for biopolymer synthesis catalyzed by a bacterium known as Sinorhizobium meliloti MTCC 100, this method is preferred over other synthetic methods due to its environmental safety and low agro-waste output [152].

Key attributes of PHAs include biodegradability, closed-loop carbon cycling, production from renewable sources, environmental friendliness, low energy requirements, a lack of toxic byproducts, and minimal greenhouse gas emissions. The global PHA market was projected to reach 23,734.65 metric tons by 2021, with a compound annual growth rate of 6.27% [153]. Potential markets for raw PHA-based bioplastics include packaging, food service products, consumer electronics, medical devices, agriculture (biodegradable mulch films), toys, and textiles [154].

The wide range of physical properties of PHA families, as well as the enhanced performance achievable through chemical modification [155] or blending [156,157,158,159], provide them with a broad spectrum of potential applications. These primarily focus on packaging, including containers and films, as well as biodegradable personal care items such as diapers and their packaging [160].

Sustainable PHA production must consider four “E” aspects: economic, ethical, environmental, and engineering [161]. PHA production can contribute to a reduction in greenhouse gas (GHG) emissions (by approximately 200%), decreasing fossil energy consumption (by around 95%), minimizing waste, and supporting bioeconomy concepts [162].

Commercial applications of PHAs include a wide range of packaging uses for everyday items such as razors, shampoo bottles (e.g., by Wella AG), feminine hygiene products, plastic bags, surgical garments, carpets, and upholstery (developed by Biomers, P&G, Metabolix, and other companies) [163].

For convenience, the key points are summarized and provided in Table 2.

Table 2.

Key points on PHAs.

3.3. Other Noteworthy Biodegradable Polymers

Poly(butylene succinate) (PBS) is used in various applications such as food packaging films, shopping bags, agricultural mulch films, plant pots, and hygiene products. However, its use in the biomedical field is limited due to its low biocompatibility and biological activity. PBS is also employed in blends and composites where fillers are added to enhance thermal conductivity, mechanical strength, gas barrier properties, and flame retardancy [164,165,166].

Polymers synthesized from poly(butylene adipate-co-terephthalate), poly(butylene succinate/adipate), and poly(ε-caprolactone) are considered biodegradable due to the vulnerability of their carbon backbones to breakdown by enzymatic activity [167].

Polycaprolactone (PCL) is notable for its biocompatibility and slow degradation rate in vivo (1–2 years), which makes it suitable for medical applications requiring gradual bioresorption, such as some suture materials, drug delivery systems, and tissue engineering scaffolds [168,169,170]. PCL is synthesized through the ring-opening polymerization of caprolactone monomers, a process closely linked to its degradation behavior [171].

Like other petroleum-derived biodegradable plastics, PCL is also blended with bio-based biodegradable plastics such as starch-based polymers, PLA, PHA, and PBS [172].

Polyvinyl alcohol (PVA) is commonly used in multilayer assemblies for food packaging due to its excellent film-forming ability and oxygen barrier properties. PVA is a biodegradable synthetic polymer known for its excellent film formation, strong adhesion, and high thermal stability. It has become widely used in the materials industry [173,174,175]. Additional applications include water treatment chemicals, dyes, detergents, disinfectants, and agricultural products [176,177,178]. PVA is also widely used in fiber production using various spinning methods, including electrospinning. Its physical properties—such as electrical resistance, water solubility, thermal behavior, and gas permeability—are influenced by its degree of crystallinity, which is determined by the degree of hydrolysis and molecular weight. Crystallinity is also affected by plasticizer content, bound water molecules, and similar factors. Since PVA is a relatively expensive polymer, its blends with cheaper fillers such as starch and cellulose are extensively studied to reduce costs and potentially improve biodegradability [179]. PVA is widely utilized due to its water solubility and ease of biodegradation by microorganisms and enzymes. In biomedical applications, poly(alkyl cyanoacrylates) are commonly used due to their rapid degradation—ranging from hours to days [180,181]. PVA fibers are particularly employed in biomedical fields and to enhance the mechanical properties of binding materials [182,183].

Poly(butylene adipate terephthalate) (PBAT) is widely used in compostable bags for organic waste, agricultural mulch films, packaging wraps, and disposable tableware. It is a biodegradable aliphatic–aromatic random copolyester synthesized via the polycondensation of adipic acid, terephthalic acid, and 1,4-butanediol. PBAT offers excellent flexibility, high elongation at break (up to 700%), good resistance to oil and water, and moderate tensile strength (~30 MPa) [184,185].

Other emerging bio-based polymers include polyethylene furanoate (PEF) and other furan dicarboxylate-based polyesters [186].

Polyglycolide (PGA), also known as polyglycolic acid, is the simplest linear aliphatic polyester. It is a petroleum-derived biopolymer characterized by a straightforward polyester molecular structure [187,188]. Like PLA, it belongs to the group of poly(α-hydroxy acids) and undergoes degradation primarily through hydrolytic bulk erosion in aqueous conditions. This degradation process initiates with a reduction in molecular weight, followed by material mass loss. The rate at which these polymers degrade is largely influenced by their initial molecular weight and the specific ratio used in copolymer formation.

Poly(L-lactide) (PLLA), a semi-crystalline variant of PLA, degrades more slowly and possesses superior mechanical properties, making it particularly well suited for structural or load-bearing applications [189]. Some reports describe the synthesis of PLA with molecular weights reaching 102,000 and exceptionally high melting temperatures (ranging from 210 to 218 °C), attributed to the formation of a distinctive supramolecular structure [100,190,191]. PLLA is recognized for being both biodegradable and biocompatible, offering strong mechanical performance along with favorable chemical and physical stability and low biological toxicity [192,193]. Another important copolymer, poly(lactic-co-glycolic acid) (PLGA), is synthesized via the ring-opening polymerization of lactide and glycolide and is widely known for its biodegradability and compatibility with biological systems [194,195]. Meanwhile, poly(DL-lactide) (PDLLA) is an amorphous polymer, offering different properties from its semi-crystalline counterpart [196]. Poly(trimethylene carbonate) (PTMC), part of the polycarbonate family, is produced through the ring-opening polymerization of trimethylene carbonate using diethylzinc as a catalyst, and copolymers incorporating glycolide and dioxanone have also been developed to enhance its properties [197].

Polyurethanes (PUs) are unique polymeric materials that exhibit a wide range of physical and chemical properties. This versatility has enabled their widespread adoption in modern technologies for applications such as coatings, adhesives, fibers, foams, and thermoplastic elastomers [198]. The biodegradability of polyurethanes is largely dependent on the chemical nature of their segments. By selecting appropriate soft segments, the degradation behavior of the polymer can be tailored. Polyurethanes based on polyester polyols are generally more susceptible to biodegradation, whereas those based on polyether polyols tend to be more resistant [199,200]. Poly(ester urethanes) have been synthesized through the reaction of lysine diisocyanate with polyester diols derived from lactide or ε-caprolactone [201,202]. A novel waterborne polyurethane was synthesized using a rapeseed oil-based polyol as a soft segment. These water-dispersible polyurethanes were employed to modify plasticized starch, aiming to produce new biodegradable materials with enhanced performance [203,204].

Bio-polypropylene (Bio-PP) is derived from renewable resources. Propylene, the second most important monomer for polyolefins after ethylene, is used to produce polypropylene, which held a 20% market share in 2019 [205]. According to Bioplastics Europe, the PP production capacity is expected to increase almost sixfold by 2024 [206].

A critical issue is imparting biodegradability to established industrial polymers such as polyethylene (PE), polypropylene (PP), PVC, polystyrene (PS), and polyethylene terephthalate (PET), which can persist in landfills indefinitely [207].

Polypropylene carbonate (PPC) is synthesized via the copolymerization of propylene oxide and carbon dioxide. It has favorable properties such as compatibility and impact resistance, although its thermal resistance and biodegradability require improvement, typically achieved through blending with other polymers [208].

Polyethylene terephthalate (PET), a type of polyester, has recently been suggested as a biodegradable option for packaging applications [209]. While PET can be recycled, incinerated, or disposed of in landfills, its primary intended end-of-life process is composting, where it undergoes soil degradation to break down into carbon dioxide and water [210].

Polydioxanone (PDO) is fully biodegradable and is considered a promising material for future biomedical applications [211,212,213].

Unlike bio-derived, non-biodegradable plastics, aliphatic polyesters based on 2,5-furandicarboxylic acid have no commercially available petrochemical counterpart. Nevertheless, this class of polymers is emerging as a “sleeping giant” in the bioplastics market. These polyesters, known as poly(2,5-alkylenefuranoates), are synthesized via polycondensation between an alkylene glycol and 2,5-furandicarboxylic acid (FDCA) [214]. Environmental concerns have led to renewed interest in products derived from renewable resources. The main groups are the following: (i) agropolymers (e.g., polysaccharides, proteins) and (ii) biopolyesters (biodegradable polyesters) such as polylactic acid (PLA), polyhydroxyalkanoate (PHA), and both aromatic and aliphatic copolyesters [215].

Biodegradable nonwoven materials can be utilized in nearly all traditional nonwoven applications. In the sanitary and medical industries, a hair cap made of a nonwoven material based on thermoplastic poly(L-lactic acid) resin demonstrated good hair-retention properties, as described in Japanese Patent JP 2002345541 [216]. A breathable, biodegradable/compostable disposable personal hygiene product was produced from Bionolle 3001 nonwovens, as described in WO Patent 2002053376 and JP Patent 2002035037 [217,218].

Natural coconut fibers (coir) were used in biodegradable erosion control mats developed by Landlok for use in the geotextile industry. In the automotive industry, most European manufacturers already use natural fiber-based car interiors. In Germany alone, 3630 tons of flax, sisal, and jute were used in car interiors in 1996, rising to 11,800 tons by 1999. Although the absolute production volume remains modest, the average annual growth rate of approximately 50% is promising [219].

Nonwoven materials made from kenaf fibers offer good sound insulation properties for vehicle interiors [220]. Yachmenev and colleagues reported that various moldable nonwoven cellulose-based composites for automotive applications, with excellent thermal insulation properties, were manufactured using kenaf, jute, flax, and cotton waste in combination with recycled polyester and low-grade polypropylene [221]. In the filtration industry, biodegradable PLA-based nonwoven materials were used in products such as trash bags and sink drain filters [222]. Additionally, biodegradable pleated filter materials and filter blocks were developed for air purification and liquid filtration [223].

It is worth emphasizing that among all the biodegradable polymers synthesized from renewable resources, PLA is undoubtedly the most promising polymer to date [224]. Derived from 100% renewable sources such as corn and sugar beet, these polymers have recently become commercially viable alternatives to traditional polyolefin-based materials [225]. The biodegradation of polyolefins in the presence of starch is a complex process, heavily influenced by various factors, including the oxidation reactions of carbogenic macromolecules [226]. PLA is recyclable and compostable [227], and its physical and mechanical properties can be modified through polymer architecture [228,229,230].

Bio-based PDO (1,3-propanediol) is produced by the microbial fermentation of glucose using a process developed by DuPont and Genencor in 2003 [231]. This biotechnological route enables the production of high-purity and economically competitive PDO, facilitating its broader application in biopolymers and other chemical products [232].

Bio-based polyamides (BioPAs) are condensation polymers featuring repeating amide bonds in their molecular chains, which enable interchain hydrogen bonding, leading to an ordered microstructure and high crystallinity. This accounts for their strong mechanical properties, such as good impact resistance, high hardness, and excellent abrasion resistance. Polyamides may be synthesized via the condensation of diacids and diamines or from a single repeating unit containing both carboxylic and amine functionalities [233].

Though bio-based PET (Bio-PET) and polytrimethylene terephthalate (Bio-PTT) are only partially derived from biological sources due to their petrochemical-based terephthalic acid (TA), recent advances have made it possible to produce bio-based TA from various intermediates such as isobutanol, limonene, muconic acid, and furan derivatives like hydroxymethylfurfural [234].

Although PET is generally regarded as non-biodegradable and non-compostable, some natural biodegradation has been reported due to enzymatic activity. A newly identified bacterium has demonstrated the ability to utilize low-crystallinity PET as a carbon source through the action of PET-hydrolyzing enzymes such as PETase, which may pave the way for new biorecycling methods [235].

For convenience, the key points are summarized and provided in Table 3.

Table 3.

Key points on other biodegradable polymers.

4. Applications in Various Sectors

4.1. Medicine, Tissue Engineering, and Scaffolding

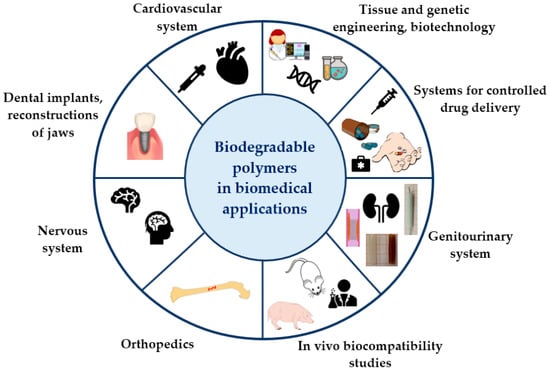

There is a growing interest in biodegradable materials for applications in medicine and other sectors of the national economy. Synthetic biodegradable polymers are widely used in medicine for developing controlled drug delivery systems, surgical sutures, and orthopedic devices (such as screws, pins, and rods), as well as for the fabrication of nonwoven materials and matrices for tissue engineering. The most in-demand polymers for biomedical applications include aliphatic polyesters of α-hydroxy acids, such as polylactide (PLA), polyglycolide (PGA), poly(ε-caprolactone) (PCL), polydioxanone (PDO), and their copolymers. Materials derived from chitin offer promising advantages due to their enhanced biodegradability, making them attractive for medical applications [200].

Polyglycolic acid (PGA), due to its strong mechanical properties and high biodegradability, is especially suitable for use as absorbable surgical sutures. In 2010, the market for biomaterials for sutures was valued at GBP 1.1 billion [236]. PGA and its copolymers represent the largest segment by volume in the medical suture industry among commercial biopolymers [237]. Glycolide is often copolymerized with L-lactide to produce a polyglycolide-co-lactide (90:10) copolymer (PGLA). PGA-based materials are widely used in medical procedures including screws, nails, bone fracture treatments, and internal organ repairs [238]. PGA accounts for less than 1% of the biopolymer market. Since it is used solely in medical applications, where it biodegrades in the body, it does not require collection or recycling [118]. PLA and PGA are among the few synthetic polymers approved for clinical human use [239]. Currently, they are used as surgical sutures [240] and in controlled-release drug delivery systems [241], among other medical and pharmaceutical applications [242].

Adjusting the molecular and supramolecular architecture of biodegradable polymers enables the customization of their physical, chemical, and mechanical characteristics, along with the regulation of their degradation rate over time. This allows for the selection of optimal compositions and structures for the development of a wide range of biomedical devices. Incorporating various functional fillers, such as calcium phosphates, into the material structure enables the creation of bioactive composite materials with enhanced mechanical properties [243,244].

Techniques like electrospinning and lyophilization are utilized to fabricate finely dispersed biomedical materials, particularly for applications in regenerative medicine. Biocompatible materials are currently in high demand for general and cardiovascular surgery and the fabrication of pins and stents, vascular prostheses, artificial heart valves, and extracorporeal circulation systems, as well as for orthopedics, traumatology, and dentistry. They are also essential in cellular and tissue engineering, including reconstructive surgery, the development of artificial organs and tissues, and/or the restoration of the functions of damaged organs [245,246].

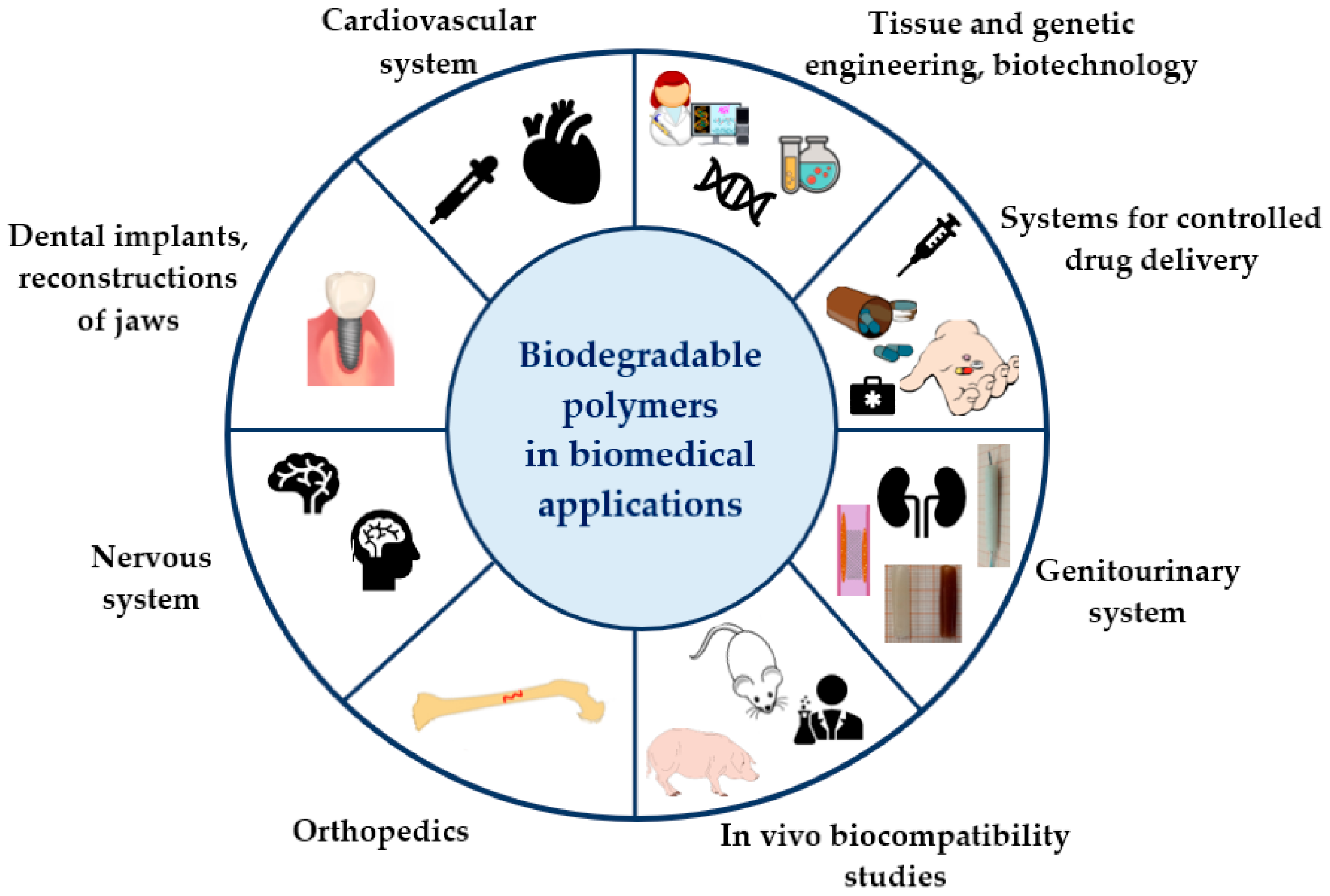

Figure 4 displays a schematic comparison highlighting the benefits of biodegradable polymers in contrast to non-biodegradable materials, particularly emphasizing their fundamental advantages.

Figure 4.

Schematic comparison highlighting the benefits of biodegradable polymers [247]. (This Figure is available as open access).

Furthermore, nanostructured, biodegradable, and biocompatible polymers are increasingly being used in the development of next-generation drug delivery systems. Manipulating the molecular structure and supramolecular organization of polymers makes it possible to regulate not only the physicochemical properties and resorption time of materials and products but also their interaction with the living tissues of the patient [248].

Materials based on lactic and glycolic acids, as well as others such as poly(dioxanone), copolymers of poly(trimethylene carbonate), and homopolymers and copolymers of poly(ε-caprolactone), have been approved for use in medical devices [249]. In addition, poly(lactic-co-glycolic acid) copolymers offer a wide range of degradation rates—from days to years—achieved by varying the monomer ratio [250]. Numerous biodegradable polymers have been explored as scaffolds for tissue engineering. Porous polymer scaffolds promote tissue regeneration by providing a temporary framework for cell attachment and matrix synthesis [251].

Microbial synthesis has also proven effective in producing poly(β-hydroxybutyrate) (PHB), a strong and biodegradable PHA biopolymer. The bacterial synthesis of PHB depends on the availability of carbon-rich precursors used as a food and energy source. Unlike other microbially synthesized biopolymers, PHB is suitable for high-strength applications due to its mechanical properties, which closely resemble those of petroleum-based polymers like polypropylene. Its main limitation is its cost—approximately nine times higher than other biopolymers—driven by the market price of carbon-rich feedstocks. This cost challenge has been addressed through the use of agricultural waste, such as rice and sorghum processing residues [252].

PLA/layered silicate nanocomposites have been extensively studied by Sinha Ray and colleagues [253,254] and other researchers [255,256]. They successfully developed a series of biodegradable PLA nanobiocomposites mainly through PLA melt extrusion, often with organically modified montmorillonite (O-MMT), aiming to exfoliate nanofillers within the matrix. The production of biodegradable nanoporous polymer foams using PLA/layered silicate nanocomposite technology has also been described [254,257], using supercritical carbon dioxide as the foaming agent, with silicate acting as a nucleating site. Porous PLA structures can also be fabricated via co-continuous phase structures and the selective extraction of one component [258].

Extensive research has been carried out on PLA and its copolymers for biomedical applications in absorbable medical implants [259,260,261,262] in the form of rods, plates, screws, fibers, sheets, sponges, and microspheres for drug delivery systems [263], or as films and foils for wound treatment and agricultural use (e.g., mulching, slow-release fertilizers, and pesticides) [264].

Biodegradable polymers are widely used for the production of resorbable medical devices and organ/tissue prototypes. A key challenge is the modification of biodegradable polymers to introduce new functional properties. The clinical “gold standard” in regenerative therapy for wounds and burns is autologous skin grafts. These do not trigger immune responses and inherently possess the necessary biological and physicochemical characteristics. Both natural and synthetic polymers can serve as scaffolds for skin equivalents, but biodegradability is essential to enable scar-free tissue replacement. The biomechanical properties of the scaffold significantly influence fibroblast proliferation: more robust matrices tend to resist contraction, which enhances cell viability [265,266].

Nano- and microfibrous structures made from biodegradable polymers offer numerous advantages for biomedical applications, including tissue engineering systems. In one study, a mixture of poly(lactic acid) (PLA) and gelatin (GEL) conjugated with epidermal growth factors (EGFs) was used to electrospin nanofibrous scaffolds for their potential application in diabetic wound care [267].

Porous biodegradable polymer scaffolds are promising matrices for the reconstruction of damaged tissues and organs. Several methods have been described for the fabrication of such materials. Many of these methods involve polymer dissolution and salt leaching [268,269]. However, the porosity of PLA-based polymers has also been achieved through methods such as freeze-drying emulsions [270], gas-foaming agents [271], high-pressure gas saturation [272], phase inversion via immersion precipitation [273,274,275], thermally induced phase separation (TIPS) [276], and polymer blending followed by extraction [277,278].

Microfibrous structures of nonwoven, biocompatible, biodegradable polymers that release medical agents upon contact with the wound surface satisfy most requirements for wound and burn dressings. Electrospinning from polymer solutions is currently the most effective method for producing nonwoven materials made of micro- and nanofibers. This method allows for the fabrication of highly porous materials with unique filtration properties. Moreover, depending on the application, materials can be produced with uniformly or superficially distributed fillers within the fibers [279,280].

Designing or selecting porous scaffolds for tissue engineering involves a thorough understanding of how the scaffold’s three-dimensional microarchitecture influences both its biological integration and mechanical performance. The body’s response to an implanted scaffold is shaped by numerous parameters, including the choice of biomaterial, its degradation characteristics, and its structural design at the microscale level [281,282,283]. Biodegradable polymers offer several key advantages over permanent solid implants, particularly in medical and clinical settings. These benefits extend beyond functionality, including cost-effectiveness and improved patient experience. For instance, unlike metallic implants, biodegradable alternatives eliminate the need for secondary surgical procedures to remove the device after healing is complete [284,285,286].

An implantable device that does not require surgical removal offers additional benefits. For instance, a broken bone fixed with a rigid, non-biodegradable stainless-steel implant tends to refracture upon implant removal due to load shielding. However, a biodegradable polymer implant can be designed to degrade gradually, transferring the load to the healing bone over time [287]. Another exciting application of biodegradable polymers is in drug delivery—either as standalone delivery systems or integrated into medical devices. In orthopedic applications, for example, the delivery of bone morphogenetic protein can accelerate fracture healing [288], and antibiotic delivery may help prevent postoperative osteomyelitis [289].

To improve the flexibility and processability of polyhydroxybutyrate (PHB), researchers have examined the incorporation of biodegradable, low-molecular-weight, and non-toxic plasticizers such as dibutyl sebacate (DBS), dioctyl sebacate (DOS), polyethylene glycol (PEG), Lapro1503 (L503), Lapro15003 (L5003), and polyisobutylene (PIB), a non-polar polymer. These additives have been studied in concentrations reaching up to 50 wt%. Within the range of 15–20 wt%, the plasticizers remained highly compatible with PHB, resulting in homogeneous, single-phase blends. However, exceeding this concentration threshold typically led to a decline in system integrity due to over-plasticization. Many of these plasticizers were found to effectively lower the crystallization temperature while enhancing the material’s mechanical performance. Additional plasticizers mentioned in the literature include dodecanol, lauric acid, tributyrin, and trilaurin [290].

Historically and currently, the industrial use of PHA-based bioplastics has concentrated heavily on biomedical applications due to the excellent biocompatibility and biodegradability of PHAs. Products such as artificial skin, heart valves, vascular grafts, bone graft substitutes, scaffolds, and drug delivery systems have all been developed using PHAs [291]. Their biodegradability, compatibility with biological systems, and production from renewable feedstocks make PHAs suitable for various medical purposes, including surgical sutures, implantable devices, artificial blood vessels, tissue scaffolding, and controlled-release drug carriers [292,293]. Recognizing their commercial promise, numerous companies have launched PHA production initiatives at both pilot and industrial levels. Currently, close to 20 companies across nations including the United States, Austria, the United Kingdom, Germany, Italy, Japan, Brazil, and China are actively engaged in PHA manufacturing and commercialization [294].

The use of bioplastics containing polyhydroxyalkanoates (PHAs) for the production of small-scale, high-value biomedical devices is becoming a reality. However, even for these applications, more efficient and cost-effective processes must be developed for the production, extraction, purification, and enhancement of PHA material properties [295].

Biomedical applications of polylactic acid (PLA) include the development of scaffolds [296], biodegradable/resorbable fibrous medical textiles [297,298], orthopedic screws [299], biocomposite materials [300,301], and sutures [302,303]. In addition, low-molecular-weight PLA is used for tissue engineering [304,305,306].

Photo-crosslinked synthetic biodegradable polymer networks are particularly promising for biomedical applications such as drug delivery, cell encapsulation, and tissue-engineering scaffolds. By modifying the architecture, chemistry, degree of functionalization, and molecular weight of macromer precursors, networks with a broad range of physicomechanical properties, crosslinking densities, and degradation characteristics can be developed for various applications. These networks are easily fabricated and can incorporate a wide range of biologically active substances and cells. Moreover, the spatial and temporal control of crosslinking during additive manufacturing enables the fabrication of complex, structured networks. Photo-crosslinked networks have been used in drug delivery systems to provide controlled, prolonged release. Additive manufacturing methods such as extrusion-based techniques and stereolithography have been employed to prepare photo-crosslinked tissue engineering matrices. These methods allow precise control over pore size, architecture, and mechanical properties. Specifically, a variety of resins based on biodegradable photo-crosslinkable macromers have been developed for stereolithography [307].

The key points of this chapter are summarized in Table 4.

Table 4.

Biodegradable polymers in biomedical applications.

4.2. Edible Packaging and Films

A wide range of biopolymer-based materials have demonstrated potential for use in food packaging applications. The list of these materials includes (but is not limited to) the following: polylactic acid (PLA), sugar palm nanofibrillated cellulose (SPNFC), composites made from coffee grounds, and PBAT, as well as materials derived from blueberry agro-waste and corn starch. Innovations such as photobleaching have been used to alter the microstructure of starch-based and blueberry-derived biopolymers, leading to the creation of intelligent packaging systems capable of monitoring food quality [308]. Since the 1970s, starch-based biodegradable plastics have been under active investigation worldwide. Advances in processing have enabled the commercial-scale production of extruded films and molded products containing over 50% starch. To address their inherent sensitivity to moisture, these materials are often laminated with polyvinyl chloride to enhance performance, which is not itself biodegradable [309]. Bioplastics are primarily produced from renewable organic feedstocks, including polysaccharides (like starch, cellulose, lignin, and chitin), proteins (such as casein, gelatin, and gluten), and lipids derived from both plant oils and animal fats [310].

Enhancing mechanical strength often compromises biodegradability, necessitating blending with other polymers [311]. Some biologically derived precursors, such as cellulose acetate, possess high tensile strength (~90 MPa) but are not biodegradable [312]. The polymer industry faces the critical task of developing packaging materials that preserve product integrity throughout its life cycle and are capable of biological or physicochemical degradation post-use under environmental exposure [313]. Such packaging should decompose into harmless substances such as water and CO2, minimizing environmental impact. These materials often incorporate plant-based components, such as polysaccharides, grain-processing waste, and various types of starch [314]. Recent environmental concerns have spurred interest in biodegradable packaging materials. Such materials are often derived from agricultural biopolymers capable of forming coherent, continuous matrices. Initially, most research focused on cellulose and starch due to their abundance and low cost. However, their poor elasticity limits their application [315,316].

Over the past twenty years, the production of plastic products for packaging goods and food—such as polyolefins—has grown, leading to a corresponding increase in plastic waste. This is due to the tendency of such materials to accumulate in nature as a result of their superior mechanical strength and resistance to chemical, atmospheric, and biological degradation [317,318]. In the last decade, there has been a heightened interest in using commercially available proteins to prepare biomaterials, especially films [319,320].

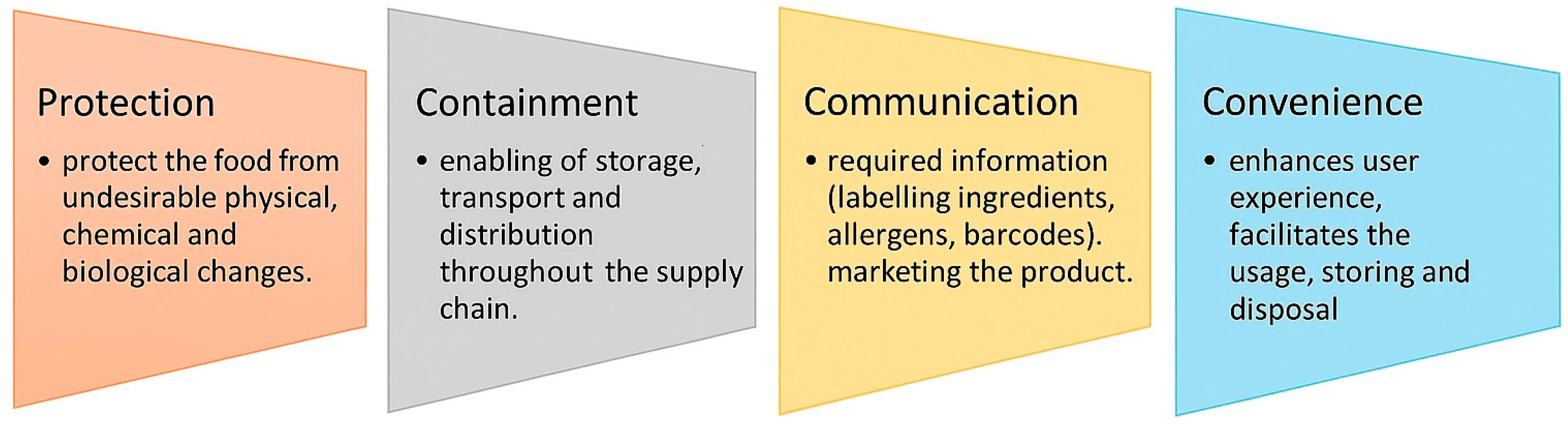

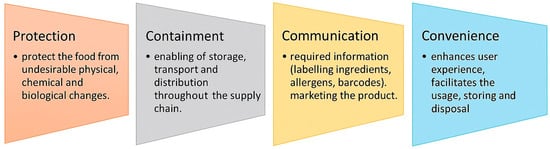

Biodegradable plastics are primarily used in the food packaging and agricultural industries. In the food sector, packaging serves multiple roles, as demonstrated in Figure 5.

Figure 5.

Roles and functions of packaging. Reproduced from [321]. (This Figure is available as open access).

Convenience in food packaging enhances the user experience, encourages repeated purchase, and can differentiate a product in a competitive market. Packaging should make the product easy to use, handle, open, reseal, store, and dispose of. Examples of such packaging features include the following: resealable zip-locks for freshness, microwavable containers for quick heating, portion-controlled packaging for on-the-go consumption, easy-tear seals or ergonomic designs for elderly or disabled users, etc. [322,323].

Certain plant proteins demonstrate useful properties for preparing packaging biomaterials, such as network-forming ability, plasticity, and elasticity. Research on the film-forming potential of various plant proteins has primarily focused on soy proteins. Edible films have been made from isolated soy protein (ISP). Alkaline treatment increased the elongation percentage. Water vapor permeability (WVP), oxygen permeability (O2P), and tensile strength (TS) were not significantly affected by the alkaline treatment. A minimum pH of 8 was required when using ammonium hydroxide as an alkaline source to produce a satisfactory film, and pH levels above 8 did not further enhance the film properties. The exceptionally low oxygen permeability values of ISP films make them promising for protecting food products from oxidative spoilage [324]. Synthetic polymers play a key role in many industrial sectors, especially in the packaging industry [325].

Chitin and chitosan blends are gaining increasing importance as bases for the production of biodegradable packaging films and textile fibers. Chitosan-based films are formed from acetic acid solutions, with their solubility and swelling behavior regulated by crosslinking the chitosan with glutaraldehyde or oligomeric diepoxides [326].

Crosslinking polymers and the graft copolymerization of natural polymers with synthetic monomers are additional valuable approaches in creating biodegradable packaging films. A further advantage of such materials is that upon biodegradation, decomposition, or composting, they can act as fertilizers and soil enhancers, thereby contributing to improved crop yields. Although biopackaging is relatively expensive, it represents the future of packaging—particularly for several types of value-added food products [327]. Composites are being developed for packaging applications using polyethylene and polypropylene waste mixed with residues from the flour milling, starch production, sugar processing, and confectionery industries [328]. Chitin and chitosan have also been utilized as fillers [329,330].

PLA is inherently a polar material due to its repeating lactic acid unit. This high polarity imparts several unique characteristics, such as high critical surface energy, which ensures excellent printability. PLA is also used in agricultural films, compostable garbage bags, thermoformed trays for fruits and vegetables, disposable plates and cups, toys, tableware, fiber composites [331], and layered silicate nanocomposites [332,333,334,335]. Commercially available PLA packaging can exhibit superior mechanical properties compared to polystyrene and possesses properties more or less comparable to PET. Market studies indicate that PLA is economically viable for packaging applications and currently represents the largest market segment by volume for biodegradable packaging [336]. Bioplastics are considered highly significant for promoting sustainability, which encompasses the balance between the economic, environmental, and social aspects of business and can be applied across numerous industries.