Performance of Polystyrene-Impregnated and CCA-Preserved Tropical Woods Against Subterranean Termites in PNG Field and Treatment-Induced Color Change

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Wood Treatment Process

2.3. Discoloration

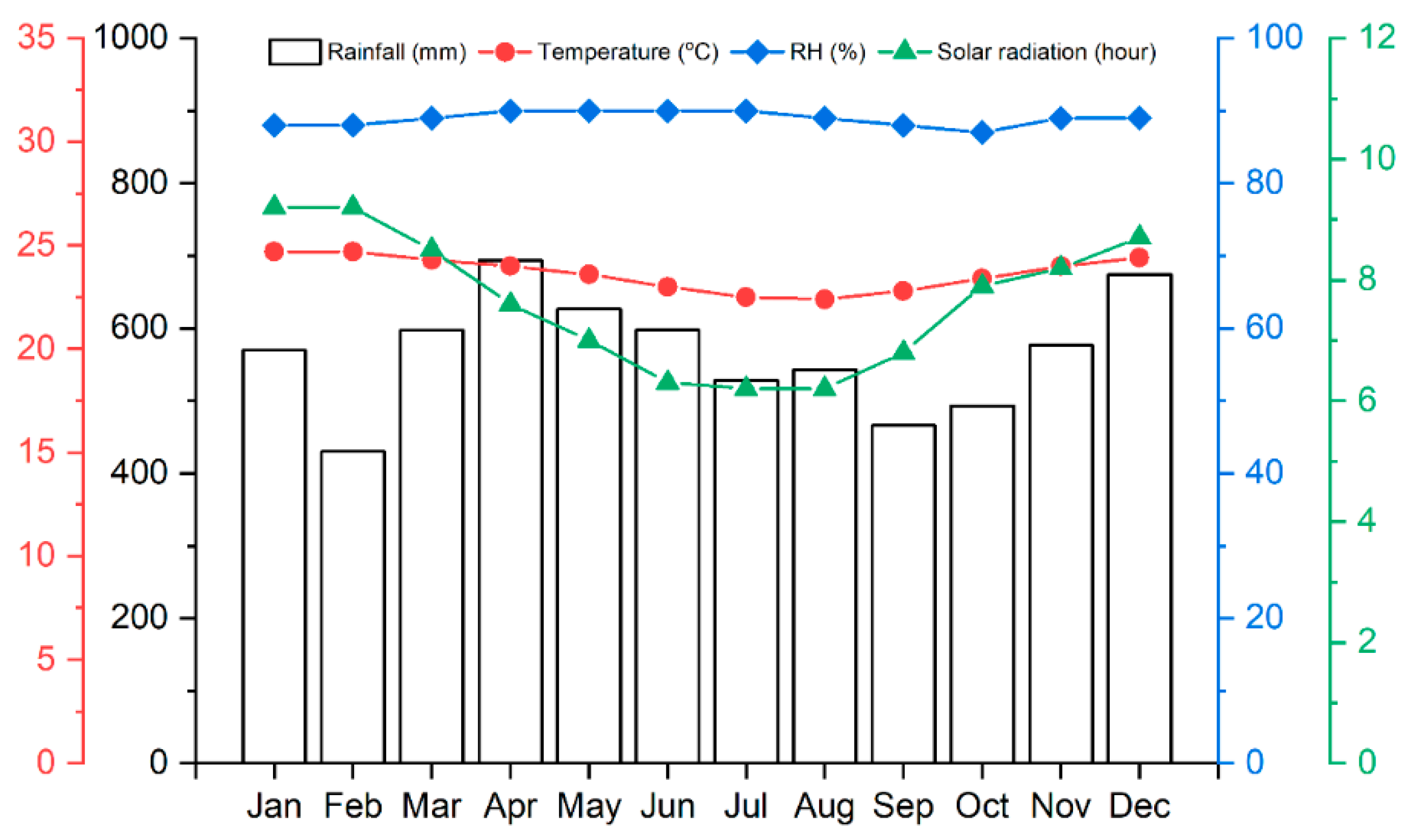

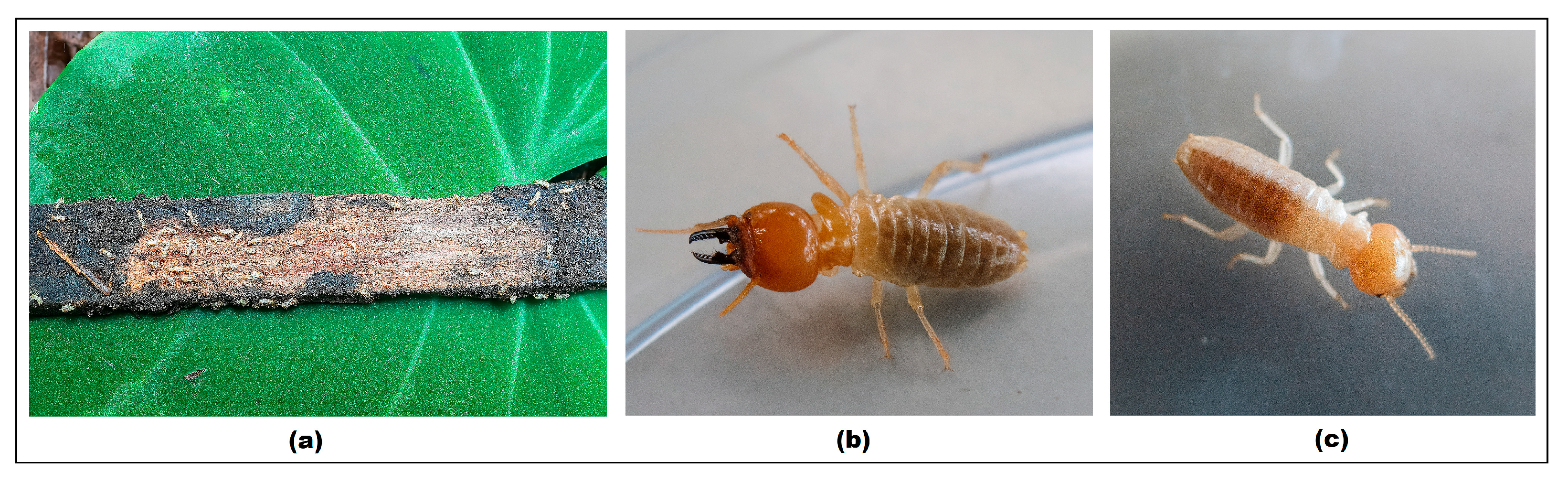

2.4. Termite Field Test

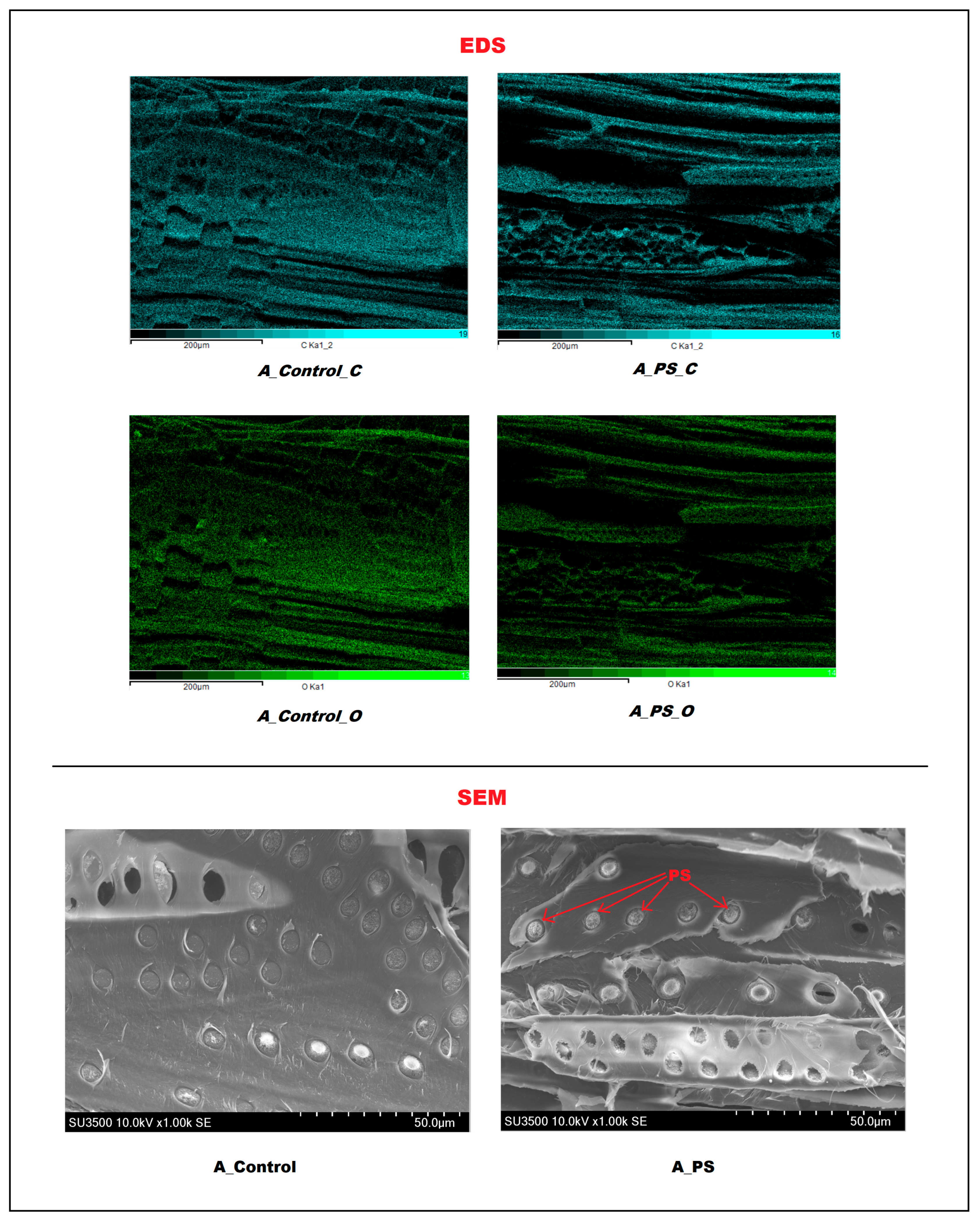

2.5. Scanning Electron Microscopy (SEM) Analysis

2.6. Energy Dispersive X-Ray Spectroscopy (EDS) Analysis

2.7. Data Analysis

3. Results and Discussion

3.1. Physical Properties

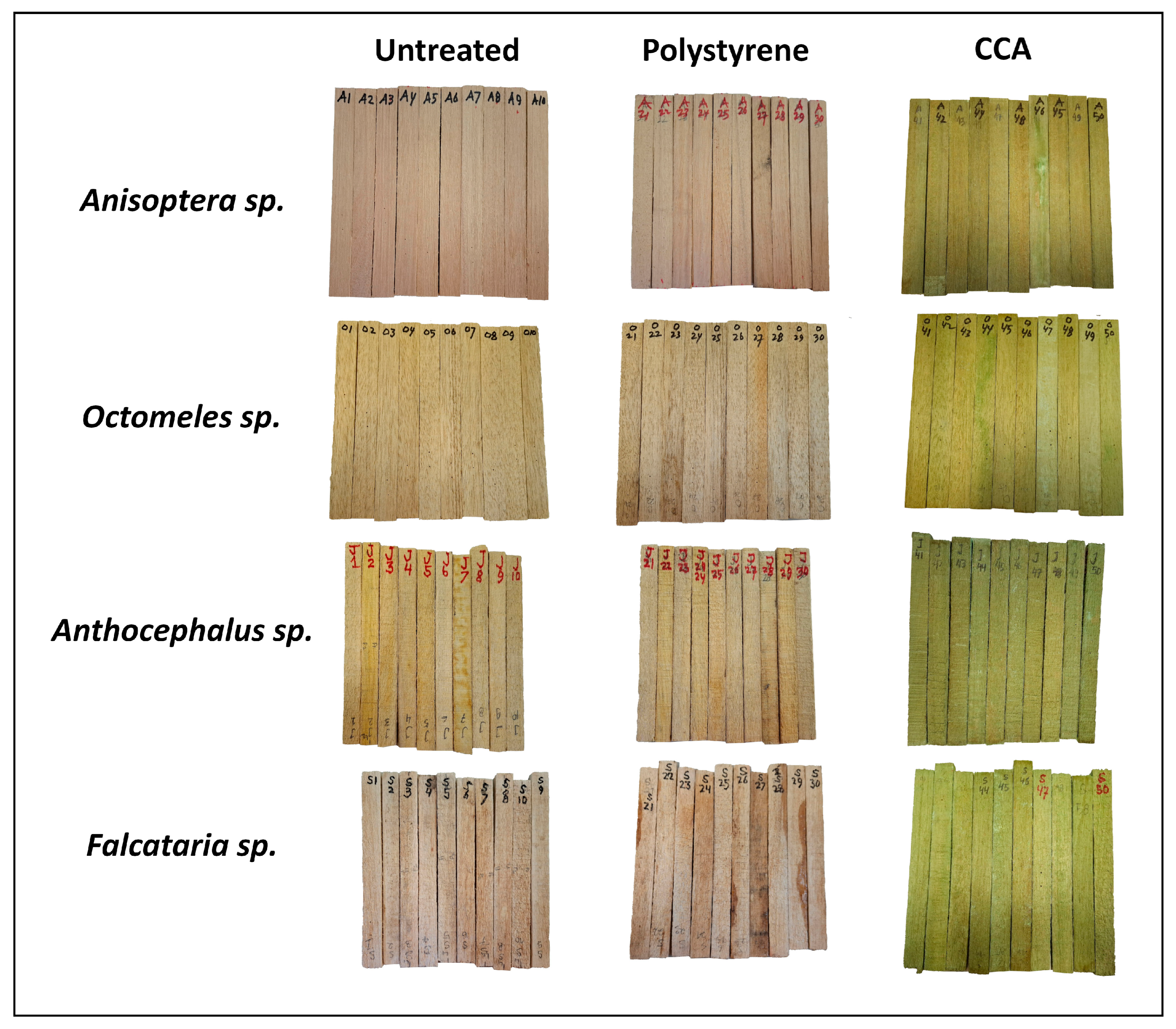

3.1.1. Wood Discoloration

3.1.2. Wood Density

3.1.3. Wood Moisture Content

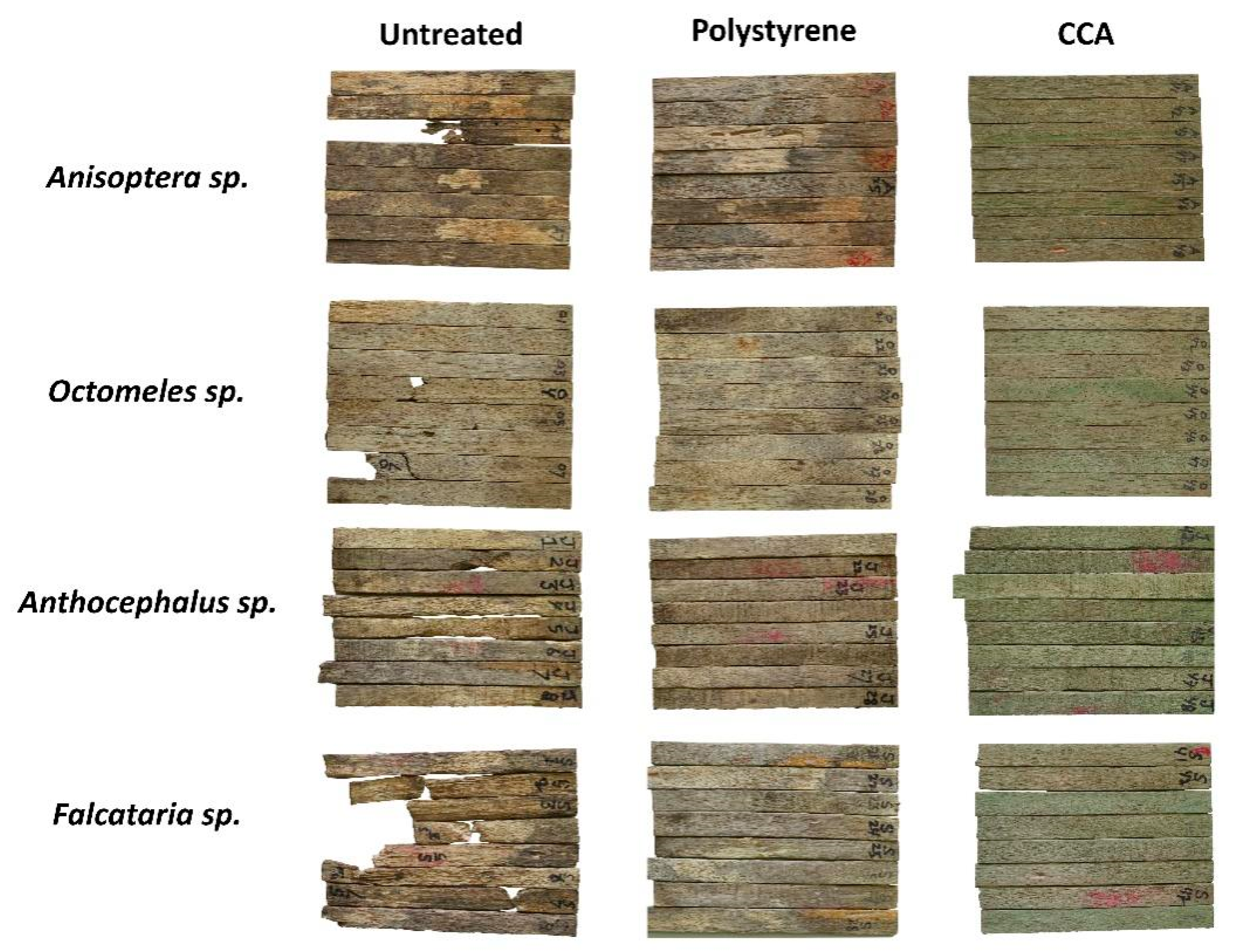

3.1.4. Wood Weight Loss

3.2. Wood Protection Level

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Balasbaneh, A.T.; Sher, W.; Yeoh, D. Recommending a new building structure to alleviate environmental impact in tropical climates: Increasing the use of wood in construction. Int. J. Life Cycle Assess. 2022, 27, 885–901. [Google Scholar] [CrossRef]

- Marais, B.N.; Brischke, C.; Militz, H. Wood durability in terrestrial and aquatic environments—A review of biotic and abiotic influence factors. Wood Mater. Sci. Eng. 2022, 17, 82–105. [Google Scholar] [CrossRef]

- Govorushko, S. Economic and ecological importance of termites: A global review. Entomol. Sci. 2019, 22, 21–35. [Google Scholar] [CrossRef]

- Verma, M.; Sharma, S.; Prasad, R. Biological alternatives for termite control: A review. Int. Biodeterior Biodegrad. 2009, 63, 959–972. [Google Scholar] [CrossRef]

- Schultz, T.P.; Nicholas, D.D.; McIntyre, C.R. Recent patents and developments in biocidal wood protection systems for exterior applications. Recent Pat. Mater. Sci. 2008, 1, 128–134. [Google Scholar] [CrossRef]

- Khademibami, L.; Bobadilha, G.S. Recent developments studies on wood protection research in academia: A review. Front. For. Glob. Chang. 2022, 5, 793177. [Google Scholar] [CrossRef]

- Miranji, E.K.; Kipkemboi, P.K.; Kibet, J.K. Hazardous organics in wood treatment sites and their etiological implications. J. Chem. Rev. 2022, 4, 40–66. [Google Scholar]

- Gérardin, P. New alternatives for wood preservation based on thermal and chemical modification of wood—A review. Ann. For. Sci. 2016, 73, 559–570. [Google Scholar] [CrossRef]

- Vilaplana, F.; Strömberg, E.; Karlsson, S. Environmental and resource aspects of sustainable biocomposites. Polym. Degrad. Stab. 2010, 95, 2147–2161. [Google Scholar] [CrossRef]

- Liao, J.; Mubarok, M. Revolutionizing Wood: Cutting-Edge Modifications, Functional Wood-Based Composites, and Innovative Applications. In Wood Industry—Impacts and Benefits [Working Title]; IntechOpen: London, UK, 2024. [Google Scholar] [CrossRef]

- Hadi, Y.S.; Herliyana, E.N.; Mulyosari, D.; Abdillah, I.B.; Pari, R.; Hiziroglu, S. Termite resistance of furfuryl alcohol and imidacloprid treated fast-growing tropical wood species as function of field test. Appl. Sci. 2020, 10, 6101. [Google Scholar] [CrossRef]

- Hadi, Y.S.; Mulyosari, D.; Herliyana, E.N.; Pari, G.; Arsyad, W.O.M.; Abdillah, I.B.; Gérardin, P. Furfurylation of wood from fast-growing tropical species to enhance their resistance to subterranean termite. Eur. J. Wood Wood Prod. 2021, 79, 1007–1015. [Google Scholar] [CrossRef]

- Hadi, Y.S.; Nawawi, D.S.; Abdillah, I.B.; Pari, G.; Pari, R. Evaluation of discoloration and subterranean termite resistance of four furfurylated tropical wood species after one-year outdoor exposure. Forests 2021, 12, 900. [Google Scholar] [CrossRef]

- Mubarok, M.; Militz, H.; Dumarçay, S.; Gérardin, P. Beech wood modification based on in situ esterification with sorbitol and citric acid. Wood Sci. Technol. 2020, 54, 479–502. [Google Scholar] [CrossRef]

- Martha, R.; Mubarok, M.; Batubara, I.; Rahayu, I.S.; Setiono, L.; Darmawan, W.; Akong, F.O.; George, B.; Gérardin, C.; Gérardin, P. Effect of furfurylation treatment on technological properties of short rotation teak wood. J. Mater. Res. Technol. 2021, 12, 1689–1699. [Google Scholar] [CrossRef]

- Mubarok, M.; Gérardin-Charbonnier, C.; Azadeh, E.; Akong, F.O.; Dumarçay, S.; Pizzi, A.; Gérardin, P. Modification of wood by tannin-furfuryl alcohol resins—Effect on dimensional stability, mechanical properties and decay durability. J. Renew. Mater. 2023, 11, 505–521. [Google Scholar] [CrossRef]

- Hadi, Y.S.; Massijaya, M.Y.; Arinana, A. Subterranean termite resistance of polystyrene-treated wood from three tropical wood species. Insects 2016, 7, 37. [Google Scholar] [CrossRef] [PubMed]

- Hadi, Y.S.; Hermawan, D.; Sulastiningsih, I.M.; Basri, E.; Pari, G.; Pari, R.; Abdillah, I.B. Color change and physical-mechanical properties of polystyrene-impregnated glulam from three tropical fast-growing wood species. Forests 2021, 12, 1420. [Google Scholar] [CrossRef]

- Hermawan, D.; Mubarok, M.; Abdillah, I.B.; Hadi, Y.S.; Yosi, C.K.; Chotikun, A.; Pari, R.; Pari, G. Resistance of polystyrene-impregnated glued laminated lumbers after exposure to subterranean termites in a field. J. Korean Wood Sci. Technol. 2024, 52, 70–86. [Google Scholar] [CrossRef]

- Hadi, Y.S.; Hermawan, D.; Abdillah, I.B.; Mubarok, M.; Arsyad, W.O.M.; Pari, R. Polystyrene-impregnated glulam resistance to subterranean termite attacks in a laboratory test. Polymers 2022, 14, 4003. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Fang, J.; Chen, S.; Zhu, L.; Xie, X.; Xing, H.; Liu, M.; Ding, Y.; Qiao, Y. Preservation of wood-based products against biotic and chemical degradation: Past, present and future. Wood Mater. Sci. Eng. 2025, 2, 1–22. [Google Scholar] [CrossRef]

- Richter, H.G.; Dallwitz, M.J. Commercial timbers: Anisoptera spp. (Mersawa). In Commercial Timbers: Descriptions, Illustrations, Identification, and Information Retrieval (English Version); University of Hamburg: Hamburg, Germany, 2000; Available online: https://www-archiv.fdm.uni-hamburg.de/b-online/wood/english/dipan-me.htm (accessed on 5 July 2025).

- Richter, H.G.; Dallwitz, M.J. Commercial timbers: Octomeles sumatrana Miq. (Binuang). In Commercial Timbers: Descriptions, Illustrations, Identification, and Information Retrieval (English Version); University of Hamburg: Hamburg, Germany, 2000; Available online: https://www-archiv.fdm.uni-hamburg.de/b-online/wood/english/datocsum.htm (accessed on 5 July 2025).

- Orwa, C.; Mutua, A.; Kindt, R.; Jamnadass, R.; Simons, A. Agroforestree Database: A Tree Reference and Selection Guide (Version 4.0); World Agroforestry Centre: Nairobi, Kenya, 2009; Available online: https://www.worldagroforestry.org/output/agroforestree-database (accessed on 5 July 2025).

- Richter, H.G.; Dallwitz, M.J. Falcataria moluccana. In Commercial Timbers: Descriptions, Illustrations, Identification, and Information Retrieval (Version: 4 May 2000); University of Hamburg: Hamburg, Germany, 2000; Available online: https://www.delta-intkey.com/wood/en/www/mimpafal.htm (accessed on 5 July 2025).

- BS 373:1957; British Standard. Methods of Testing Small Clear Specimens of Timber. British Standards Institution: London, UK, 1957.

- Christie, R.M. Colour Chemistry; The Royal Society of Chemistry Science Park: Cambride, UK, 2007. [Google Scholar]

- Hunter Lab. CIE L*a*b* color scale. Appl. Note 1996, 8, 1–4. [Google Scholar]

- Hrčková, M.; Koleda, P.; Koleda, P.; Barcík, Š.; Štefková, J. Color change of selected wood species affected by thermal treatment and sanding. BioResources 2018, 13, 8956–8975. [Google Scholar] [CrossRef]

- Climate-Data. Lae Climate (Papua New Guinea). 2021. Available online: https://en.climate-data.org/oceania/papua-new-guinea/morobe/lae-1272/ (accessed on 10 March 2025).

- ASTM D 1758-06; Standard Test Method of Evaluating Wood Preservatives by Field Tests with Stakes. American Society for Testing Materials: West Conshohocken, PA, USA, 2014.

- Acosta, A.P.; Labidi, J.; Barbosa, K.T.; Cruz, N.; Delucis, R.D.A.; Gatto, D.A. Termite resistance of a fast-growing pine wood treated by in situ polymerization of three different precursors. Forests 2020, 11, 865. [Google Scholar] [CrossRef]

- Hadi, Y.S.; Nawawi, D.S.; Herliyana, E.N.; Lawniczak, M. Termite attack resistance of four polystyrene impregnated woods from Poland. For. Prod. J. 1998, 48, 60–62. [Google Scholar]

- Bardet, S.; Beauchêne, J.; Thibaut, B. Influence of basic density and temperature on mechanical properties perpendicular to grain of ten wood tropical species. Ann. For. Sci. 2003, 60, 49–59. [Google Scholar] [CrossRef]

- Arango, R.A.; Green, F.; Hintz, K.; Lebow, P.K.; Miller, R.B. Natural durability of tropical and native woods against termite damage by Reticulitermes flavipes (Kollar). Int. Biodeterior. Biodegrad. 2006, 57, 146–150. [Google Scholar] [CrossRef]

- Mohammad, J.I.; Johari, N.; Fouladi, M.H. Numerical investigation on the sound absorption coefficients of Malaysian wood. In Proceedings of the 20th International Congress on Acoustics, ICA, Sydney, Australia, 23–27 August 2020; pp. 23–27. [Google Scholar]

- Orwa, C.; Mutua, A.; Kindt, R.; Jamnadass, R.; Simons, A. Agroforestree Database: A Tree Reference and Selection Guide, Version 4.0. 2009. Available online: https://www.cifor-icraf.org/knowledge/publication/25648/?utm_source=cifor-icraf.org&utm_medium=site-search&utm_campaign=traffic-source (accessed on 3 April 2025).

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Gindl, W.; Gupta, H.S. Cell-wall hardness and Young’s modulus of melamine-modified spruce wood by nano-indentation. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1141–1145. [Google Scholar] [CrossRef]

- Mai, C.; Militz, H. Modification of wood with thermoplastic polymers. Wood Sci. Technol. 2004, 37, 339–348. [Google Scholar] [CrossRef]

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons: Chichester, UK, 2006. [Google Scholar]

- Acosta, A.P.; Gallio, E.; Schulz, H.R.; Zanatta, P.; Barbosa, K.T.; De Avila Delucis, R.; Gatto, D.A. Wood-polymer composites produced by in situ polymerization of styrene into juvenile and mature pine woods. Int. Wood Prod. J. 2020, 11, 204–210. [Google Scholar] [CrossRef]

- Acosta, A.P.; de Avila Delucis, R.; Amico, S.C.; Gatto, D.A. Fast-growing pine wood modified by a two-step treatment based on heating and in situ polymerization of polystyrene. Constr. Build. Mater. 2021, 302, 124422. [Google Scholar] [CrossRef]

- Araujo, P.H.H.D.; Sayer, C.; Giudici, R.; Poco, J.G. Techniques for reducing residual monomer content in polymers: A review. Polym. Eng. Sci. 2002, 42, 1442–1468. [Google Scholar] [CrossRef]

- Kadir, K. Kadar Air Kering Udara di Bogor [Air Dry Moisture Content in Bogor]; Report No. 12; Forest Products Research Institute: Bogor, Indonesia, 1973. [Google Scholar]

- Usta, I. The effect of moisture content and wood density on the preservative uptake of Caucasian fir (Abies nordmanniana (Link.) Spach.) treated with CCA. Turk. J. Agric. For. 2004, 28, 1–7. [Google Scholar]

- Lee, A.W. Effect of CCA-treating and air-drying on the properties of southern pine lumber and plywood. Wood Fiber Sci. 1985, 17, 209–213. [Google Scholar]

- Boone, R.S.; Winandy, J.E.; Fuller, J.J. Effects of redrying schedule on preservative fixation and strength of CCA-treated lumber. For. Prod. J. 1995, 45, 65. [Google Scholar]

- Kaldas, M.; Cooper, P.A. Effect of wood moisture content on rate of fixation and leachability of CCA-treated red pine. For. Prod. J. 1996, 46, 67. [Google Scholar]

- Kim, G.H.; Ra, J.B. Effects of Temperatures and Conditioning Methods on Fixation of CCA-Type Band CCFZ Preservatives in Treated Wood. J. Korean Wood Sci. Technol. 1995, 23, 33–38. [Google Scholar]

- Nandika, D. Termite Attack in the Whole Country; Termite National Seminar: Jakarta, Indonesia, 2015. [Google Scholar]

- Martawijaya, A.; Kartasujana, I.; Kadir, K.; Prawira, S.A. Atlas Kayu Indonesia [Indonesian Wood Atlas]; Ministry of Forestry, Forestry Development and Research Agency: Bogor, Indonesia, 2014. [Google Scholar]

- Arinana; Tsunoda, K.; Herliyana, E.N.; Hadi, Y.S. Termite-susceptible species of wood for inclusion as a reference in Indonesian standardized laboratory testing. Insects 2012, 3, 396–401. [Google Scholar] [CrossRef] [PubMed]

- Thistleton, B.M.; Neal, M.; Peki, M.; Dobunaba, J. Mastotermes Darwiniensis in the Lae Area of PNG: An Assessment of Current and Potential Status of the Incursion, and Options for Management, Final Report; Australian Centre for International Agricultural Research: Canberra, Australia, 2007. [Google Scholar]

- SNI 7207:2014; National Standardization Agency of Indonesia. Preservative-Treated Wood: Performance Requirements. National Standardization Agency of Indonesia: Jakarta, Indonesia, 2014. (In Indonesian)

| Wood Species | Treatment | L* | a* | b* | ΔE |

|---|---|---|---|---|---|

| Anisoptera thurifera | Untreated | 63.8 (3.5) | 5.0 (1.2) | 15.8 (0.7) | |

| Polystyrene | 64.1 (4.4) | 4.7 (1.9) | 16.6 (1.5) | 2.7 (1.2) | |

| CCA wood | 57.8 (4.5) | −3.0 (0.9) | 37.4 (3.6) | 24.5 (2.7) | |

| Octomeles sumatrana | Untreated | 68.1 (1.7) | 1.8 (0.6) | 23.6 (2.8) | - |

| Polystyrene | 68.7 (2.0) | 1.9 (0.9) | 22.2 (3.0) | 2.0 (0.8) | |

| CCA wood | 63.9 (3.6) | −5.1 (1.0) | 41.5 (4.1) | 20.2 (4.0) | |

| Falcataria moluccana | Untreated | 67.2 (1.5) | 4.5 (1.2) | 17.2 (2.6) | - |

| Polystyrene | 67.9 (2.0) | 5.1 (0.9) | 17.4 (2.8) | 2.2 (1.4) | |

| CCA wood | 64.0 (2.9) | −8.3 (2.1) | 41.2 (2.9) | 27.7 (3.0) | |

| Anthocaphalus cadamba | Untreated | 67.1 (2.4) | 2.3 (1.5) | 26.6 (1.6) | - |

| Polystyrene | 66.9 (2.8) | 2.4 (1.2) | 26.1 (0.8) | 2.3 (1.0) | |

| CCA wood | 58.0 (4.4) | −7.1 (0.6) | 34.8 (2.3) | 16.4 (1.6) |

| Parameter | Wood Species | Treatment |

|---|---|---|

| L* (lightness) | ** | ** |

| a* (red-green) | ** | ** |

| b* (yellow-blue) | ** | ** |

| ∆E (discoloration) | ** | ** |

| Density | ** | ** |

| Moisture content | ** | ** |

| Weight loss | ** | ** |

| Protection level | ** | ** |

| Parameter | Wood Species | Treatment | |||||

|---|---|---|---|---|---|---|---|

| Anisoptera thurifera | Octomeles sumatrana | Falcataria moluccana | Anthocephalus cadamba | Untreated | Polystyrene | CCA Wood | |

| L* value | 66.3 c | 66.9 c | 61.9 a | 64.1 b | 66.5 e | 66.9 e | 61.0 d |

| a* value | 0.5 b | −0.4 a | 2.2 c | −0.8 a | 3.5 e | 3.6 e | −5.9 d |

| b* value | 25.2 b | 29.1 c | 23.2 a | 29.2 c | 20.8 d | 20.6 d | 38.7 e |

| ∆E treatment | 13.6 b | 11.1 a | 14.8 b | 9.3 a | - | 2.3 c | 22.2 d |

| Wood Species | Treatment | Density (g/cm3) | Moisture Content (%) |

|---|---|---|---|

| Anisoptera thurifera | Untreated | 0.59 (0.01) | 14.29 (0.29) |

| Polystyrene | 0.62 (0.02) | 9.25 (0.48) | |

| CCA wood | 0.61 (0.01) | 12.33 (0.67) | |

| Octomeles sumatrana | Untreated | 0.27 (0.02) | 17.03 (0.59) |

| Polystyrene | 0.68 (0.02) | 9.94 (0.40) | |

| CCA wood | 0.32 (0.02) | 11.03 (0.42) | |

| Anthocephalus cadamba | Untreated | 0.48 (0.06) | 15.04 (0.18) |

| Polystyrene | 0.68 (0.02) | 9.25 (0.12) | |

| CCA wood | 0.51 (0.04) | 15.03 (0.89) | |

| Falcataria moluccana | Untreated | 0.24 (0.01) | 17.03 (0.59) |

| Polystyrene | 0.54 (0.07) | 9.23 (0.13) | |

| CCA wood | 0.27 (0/03) | 15.06 (0.62) |

| Treatment | Unit | Anisosptera sp. | Octomeles sp. | Anthocephalus sp. | Falcataria sp. |

|---|---|---|---|---|---|

| Polystyrene | Polymer loading, % | 12.3 (1.5) | 233.6 (25.5) | 132.5 (15.8) | 210.8 (43.0) |

| Preservation | Retention, kg/m3 | 7.4 (0.9) | 13.5 (0.8) | 7.1 (0.3) | 5.7 (0.7) |

| Response | Wood Species | Treatment | |||||

|---|---|---|---|---|---|---|---|

| Anisoptera sp. | Octomeles sp. | Anthocephalus sp. | Falcataria sp. | Untreated | Polystyrene | Preserved | |

| Density | 0.68 d | 0.42 b | 0.55 c | 0.35 a | 0.42 e | 0.64 g | 0.45 f |

| MC | 12.0 a | 12.7 b | 13.1 bc | 13.8 c | 15.8 c | 9.4 a | 13.4 b |

| Wood Species | Treatment | Weight Loss (%) | Protection Level |

|---|---|---|---|

| Anisoptera thurifera | Untreated | 14.73 (24.70) | 7.9 (3.2) |

| Polystyrene | 6.49 (2.47) | 9.8 (0.5) | |

| CCA wood | 0.56 (0.46) | 9.8 (0.5) | |

| Octomeles sumatrana | Untreated | 14.89 (9.82) | 7.3 (2.2) |

| Polystyrene | 2.20 (0.51) | 10.0 (0.0) | |

| CCA wood | 0.72 (0.41) | 10.0 (0.0) | |

| Anthocephalus cadamba | Untreated | 18.53 (11.99) | 5.6 (1.7) |

| Polystyrene | 7.36 (2.29) | 9.8 (0.5) | |

| CCA wood | 2.28 (2.23) | 9.8 (0.5) | |

| Falcataria moluccana | Untreated | 30.31 (13.28) | 7.5 (2.3) |

| Polystyrene | 9.04 (6.00) | 9.8 (0.5) | |

| CCA wood | 3.91 (2.74) | 9.8 (0.5) |

| Response | Wood Species | Treatment | |||||

|---|---|---|---|---|---|---|---|

| Anisoptera sp. | Octomeles sp. | Anthocephalus sp. | Falcataria sp. | Untreated | Polystyrene | CCA | |

| Weight loss | 6.34 a | 5.93 a | 9.39 a | 14.42 b | 18.92 c | 6.27 d | 1.87 e |

| Protection | 8.58 b | 8.45 b | 8.08 ab | 7.67 a | 7.06 c | 8.15 d | 9.37 e |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hadi, Y.S.; Yosi, C.; Marai, P.; Mubarok, M.; Abdillah, I.B.; Pari, R.; Pari, G.; Syukur, A.; Zaini, L.H.; Hermawan, D.; et al. Performance of Polystyrene-Impregnated and CCA-Preserved Tropical Woods Against Subterranean Termites in PNG Field and Treatment-Induced Color Change. Polymers 2025, 17, 1945. https://doi.org/10.3390/polym17141945

Hadi YS, Yosi C, Marai P, Mubarok M, Abdillah IB, Pari R, Pari G, Syukur A, Zaini LH, Hermawan D, et al. Performance of Polystyrene-Impregnated and CCA-Preserved Tropical Woods Against Subterranean Termites in PNG Field and Treatment-Induced Color Change. Polymers. 2025; 17(14):1945. https://doi.org/10.3390/polym17141945

Chicago/Turabian StyleHadi, Yusuf Sudo, Cossey Yosi, Paul Marai, Mahdi Mubarok, Imam Busyra Abdillah, Rohmah Pari, Gustan Pari, Abdus Syukur, Lukmanul Hakim Zaini, Dede Hermawan, and et al. 2025. "Performance of Polystyrene-Impregnated and CCA-Preserved Tropical Woods Against Subterranean Termites in PNG Field and Treatment-Induced Color Change" Polymers 17, no. 14: 1945. https://doi.org/10.3390/polym17141945

APA StyleHadi, Y. S., Yosi, C., Marai, P., Mubarok, M., Abdillah, I. B., Pari, R., Pari, G., Syukur, A., Zaini, L. H., Hermawan, D., & Liao, J. (2025). Performance of Polystyrene-Impregnated and CCA-Preserved Tropical Woods Against Subterranean Termites in PNG Field and Treatment-Induced Color Change. Polymers, 17(14), 1945. https://doi.org/10.3390/polym17141945