Development of a Mathematical Model for Predicting the Average Molten Zone Thickness of HDPE Pipes During Butt Fusion Welding

Abstract

1. Introduction

2. Materials and Methods

2.1. Nonlinear Material Properties of HDPE Pipe

2.2. Mathematical Model for AMZ Thickness of HDPE Pipe

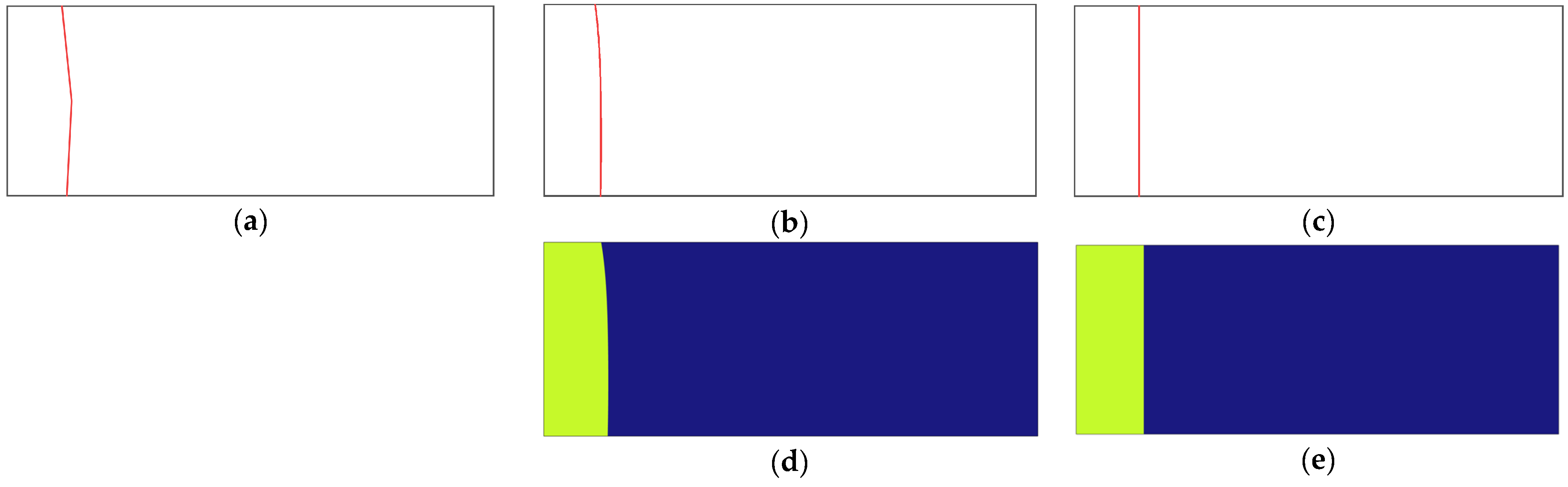

2.3. CFD Model for AMZ Thickness of HDPE Pipe

3. Results and Discussion

3.1. Parameter Solution of the Mathematical Model

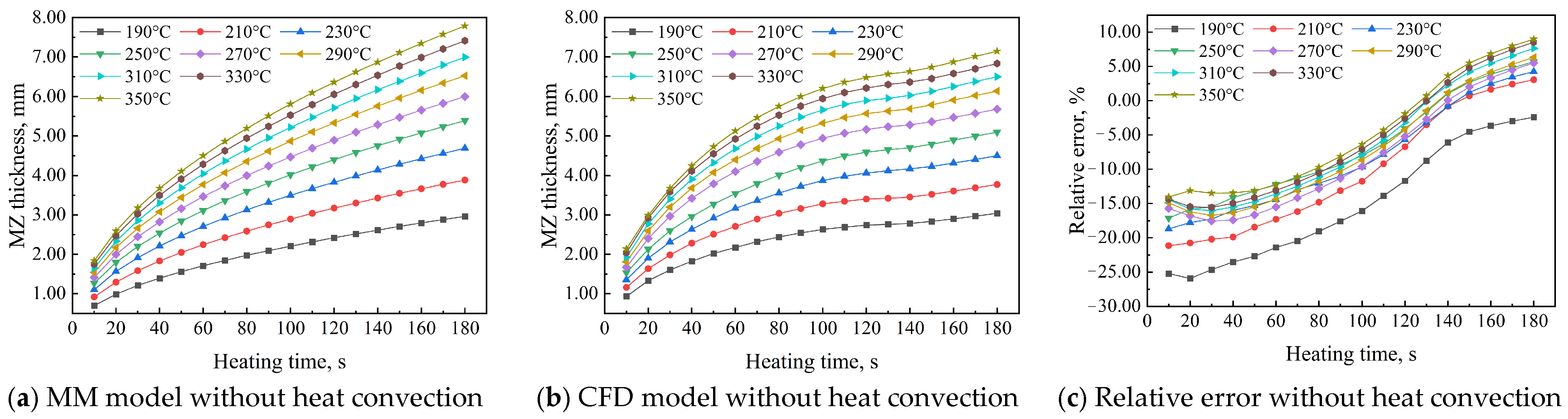

3.2. Effect of Heating Temperature on AMZ Thickness

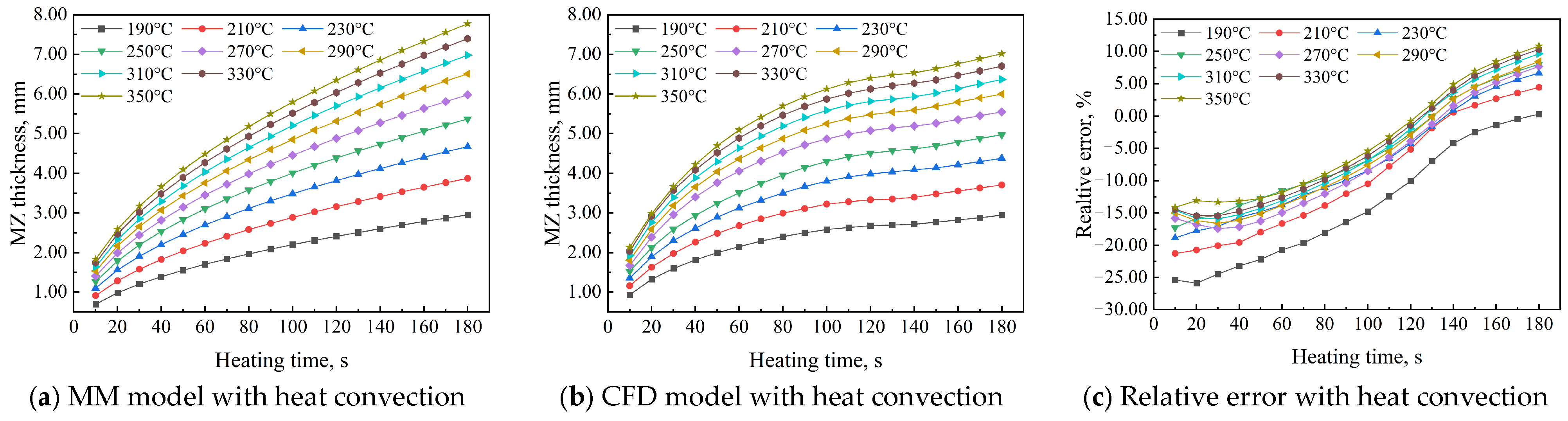

3.3. Effect of Heat Convection on AMZ Thickness

3.4. Comparison of the Effects on AMZ Thickness with and Without Heat Convection

3.5. Analysis of Potential Errors Affecting AMZ Thickness in MM and CFD Models

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Sadr-Al-Sadati, S.A.; Ghazizadeh, M.J. The experimental and numerical study of water leakage from High-Density Polyethylene pipes at elevated temperatures. Polym. Test. 2019, 74, 274–280. [Google Scholar] [CrossRef]

- Luo, X.; Ma, J.; Zheng, J.; Shi, J. Finite Element Analysis of Buried Polyethylene Pipe Subjected to Seismic Landslide. J. Press. Vessel. Technol. 2014, 136, 031801. [Google Scholar] [CrossRef]

- Lai, H.S.; Kim, J.Y.; Kil, S.H.; Yoon, K.B. Effects of Defects on Failure of Butt Fusion Welded Polyethylene Pipe. Procedia Eng. 2015, 130, 466–474. [Google Scholar] [CrossRef]

- Bae, H.; Lee, K.; Pyo, S.; Choi, S. Abnormality in using cyclic fatigue for ranking static fatigue induced slow crack growth behavior of polyethylene pipe grade resins. Polym. Test. 2016, 55, 101–108. [Google Scholar] [CrossRef]

- STP-Nu-057-2013; ASME Code Development Roadmap for HDPE Pipe in Nuclear Service. ASME: New York, NY, USA, 2013.

- Lai, H.; Fan, D.; Liu, K. The Effect of Welding Defects on the Long-Term Performance of HDPE Pipes. Polymers 2022, 14, 3936. [Google Scholar] [CrossRef]

- Pathak, S.; Pradhan, S.K. Experimentation and Optimization of HDPE Pipe Electro Fusion and Butt Fusion Welding Processes. Mater. Today Proc. 2020, 27, 2925–2929. [Google Scholar] [CrossRef]

- Ševčík, M.; Knésl, Z.; Hutař, P.; Náhlík, L. The Effect of Polymer Pipe Weld Geometry on Creep Lifetime. Key Eng. Mater. 2011, 465, 175–178. [Google Scholar] [CrossRef]

- Mehdikhani, H.; Mostafapour, A.; Laieghi, H.; Najjar, R.; Lionetto, F. Mechanical and Microstructural Properties of HDPE Pipes Manufactured via Orbital Friction Stir Welding. Materials 2022, 15, 3810. [Google Scholar] [CrossRef]

- Pokharel, P.; Kim, Y.; Choi, S. Microstructure and Mechanical Properties of the Butt Joint in High Density Polyethylene Pipe. Int. J. Polym. Sci. 2016, 2016, 6483295. [Google Scholar] [CrossRef]

- Guo, W.; Xu, H.; Liu, Z.; Shi, J. Ultrasonic Technique for Testing Cold Welding of Butt fusion Joints in Polyethylene Pipe. In Volume 1A: Codes and Standards; American Society of Mechanical Engineers: Paris, France, 2013; p. V01AT01A011. [Google Scholar] [CrossRef]

- Riahi, M.; Kooshayan, K.; Ghanati, M.F. Analysis of Effect of Pressure and Heat on Mechanical Characteristics of Butt Fusion Welding of Polyethylene Pipes. Polym.-Plast. Technol. Eng. 2011, 50, 907–915. [Google Scholar] [CrossRef]

- Kolisnyk, R.; Korab, M.; Iurzhenko, M.; Masiuchok, O.; Mamunya, Y. Development of Heating Elements Based on Conductive Polymer Composites for Electrofusion Welding of Plastics. J. Appl. Polym. Sci. 2021, 138, 50418. [Google Scholar] [CrossRef]

- Tao, Y.; Guo, W.; Shi, Y.; Miao, C.; Tang, P. Study on Molten Zone of Butt Fusion Welding Process With Phased Array Ultrasonic Technology for Polyethylene Pipe. In Proceedings of the Pressure Vessels and Piping Conference, Atlanta, GA, USA, 16–21 July 2023; ASME: New York, NY, USA, 2023; p. V001T01A011. [Google Scholar] [CrossRef]

- Niou, S.; Chaoui, K.; Azzouz, S.; Hamlaoui, N.; Alimi, L. A Method for Mechanical Property Assessment across Butt Fusion Welded Polyethylene Pipes. Int. J. Adv. Manuf. Technol. 2018, 97, 543–561. [Google Scholar] [CrossRef]

- Walid, A.; Mondher, Z.; Maher, B.C. An Experimental-Based Thermal Prediction Model for Butt Fusion Welding of Polymer Pipes. Polym. Eng. Sci. 2024, 64, 3560–3574. [Google Scholar] [CrossRef]

- Belaziz, A.; Mohamed, M. Experimental Study of the Weld Bead Zones of a High-Density Polyethylene Pipe (HDPE). J. Fail. Anal. Prev. 2018, 18, 667–676. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, B.; Xiang, A.; Jiao, D.; Yu, F.; Zhang, Q.; Zhao, X. Comparative Study on the Performance of Butt Fusion-Welding Processes for Nuclear Safety Class Large-diameter, thick-walled PE Pipes. Nucl. Eng. Technol. 2024, 56, 4184–4194. [Google Scholar] [CrossRef]

- Walid, A.; Mondher, Z. Thermal Study for Optimization of the Thermomechanical Welding Butt Fusion Process of the PEHD Tubes (PE100). In Proceedings of the Advances in Additive Manufacturing Conference, Hammamet, Tunisia, 18–20 May 2023; pp. 114–124. [Google Scholar] [CrossRef]

- Shaheer, M.; Troughton, M.; Khamsehnezhad, A.; Song, J. A Study of the Micro-Mechanical Properties of Butt Fusion-Welded Joints in HDPE Pipes Using the Nanoindentation Technique. Weld World 2017, 61, 819–831. [Google Scholar] [CrossRef]

- Yoo, J.H.; Choi, S.; Nam, J.; Ahn, K.H.; Oh, J.S. Numerical Analysis of the Heat Transfer and Fluid Flow in the Butt fusion Welding Process. Korea-Aust. Rheol. J. 2017, 29, 37–49. [Google Scholar] [CrossRef]

- Amjadi, M.; Fatemi, A. Tensile Behavior of High-Density Polyethylene Including the Effects of Processing Technique, Thickness, Temperature, and Strain Rate. Polymers 2020, 12, 1857. [Google Scholar] [CrossRef]

- Woo, M.W.; Wong, P.; Tang, Y.; Triacca, V.; Gloor, P.E.; Hrymak, A.N.; Hamielec, A.E. Melting Behavior and Thermal Properties of High-Density Polyethylene. Polym. Eng. Sci. 1995, 35, 151–156. [Google Scholar] [CrossRef]

- Cai, Z.; Dai, H.; Fu, X. Investigation on the Hot Melting Temperature Field Simulation of HDPE Water Supply Pipeline in Gymnasium Pool. Results Phys. 2018, 9, 1050–1056. [Google Scholar] [CrossRef]

- Lv, Y. Numerical Simulation of Hot Melt Welding of HDPE Pipe. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2017. (In Chinese). [Google Scholar]

- Zhao, L.; Song, P.; Cao, Z.; Fang, Z.; Guo, Z. Thermal Stability and Rheological Behaviors of High-Density Polyethylene/Fullerene Nanocomposites. J. Nanomater. 2012, 2012, 340962. [Google Scholar] [CrossRef]

- l-Bayaty, S.A.; Al-Uqaily, R.A.H.; Hameed, S. Study of Thermal Degradation Kinetics of High-Density Polyethylene (HDPE) by Using TGA Technique. AIP Conf. Proc. 2020, 2290, 020001. [Google Scholar] [CrossRef]

| Temperature °C | Thermal Conductivity | Enthalpy | |

|---|---|---|---|

| 0 | 0.445 | 1.83 | 0 |

| 50 | 0.405 | 2.05 | 95 |

| 100 | 0.340 | 2.87 | 200 |

| 125 | 0.300 | 5.56 | 318 |

| 132 | 0.268 | 15.51 | 485 |

| 150 | 0.265 | 2.65 | 535 |

| 200 | 0.264 | 2.67 | 700 |

| 250 | 0.263 | 3.03 | 900 |

| Density | Isobaric Heat Capacity | Thermal Conductivity | Thermal Diffusivity | |

|---|---|---|---|---|

| Solid phase | 980 | 2.31 | 0.49 | 2.16 × 10−7 |

| Melting phase | 780 | 2.51 | 0.26 | 1.18 × 10−7 |

| Melting temperature, °C | 135 | Latent heat, | 218 | |

| 190 °C | 210 °C | 230 °C | 250 °C | 270 °C | 290 °C | 310 °C | 330 °C | 350 °C | |

|---|---|---|---|---|---|---|---|---|---|

| 0.318 | 0.418 | 0.505 | 0.580 | 0.646 | 0.704 | 0.755 | 0.800 | 0.841 | |

| 0.322 | 0.422 | 0.509 | 0.585 | 0.651 | 0.709 | 0.760 | 0.805 | 0.846 | |

| 0.322 | 0.422 | 0.510 | 0.585 | 0.651 | 0.709 | 0.760 | 0.806 | 0.846 |

| 190 °C | 210 °C | 230 °C | 250 °C | 270 °C | 290 °C | 310 °C | 330 °C | 350 °C | |

|---|---|---|---|---|---|---|---|---|---|

| m | 2.185 | 2.866 | 3.463 | 3.981 | 4.433 | 4.829 | 5.179 | 5.491 | 5.771 |

| n | 2.207 | 2.893 | 3.493 | 4.013 | 4.466 | 4.862 | 5.212 | 5.524 | 5.804 |

| p | 2.210 | 2.897 | 3.497 | 4.018 | 4.470 | 4.867 | 5.217 | 5.529 | 5.809 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, D.; Iurzhenko, M.; Demchenko, V. Development of a Mathematical Model for Predicting the Average Molten Zone Thickness of HDPE Pipes During Butt Fusion Welding. Polymers 2025, 17, 1932. https://doi.org/10.3390/polym17141932

Zeng D, Iurzhenko M, Demchenko V. Development of a Mathematical Model for Predicting the Average Molten Zone Thickness of HDPE Pipes During Butt Fusion Welding. Polymers. 2025; 17(14):1932. https://doi.org/10.3390/polym17141932

Chicago/Turabian StyleZeng, Donghu, Maksym Iurzhenko, and Valeriy Demchenko. 2025. "Development of a Mathematical Model for Predicting the Average Molten Zone Thickness of HDPE Pipes During Butt Fusion Welding" Polymers 17, no. 14: 1932. https://doi.org/10.3390/polym17141932

APA StyleZeng, D., Iurzhenko, M., & Demchenko, V. (2025). Development of a Mathematical Model for Predicting the Average Molten Zone Thickness of HDPE Pipes During Butt Fusion Welding. Polymers, 17(14), 1932. https://doi.org/10.3390/polym17141932