Enhancing the Energy Absorption Performance of 3D-Printed CF/TPU Composite Materials by Introducing a “Rigid–Elastic” Structure Through Multi-Scale Synergies

Abstract

1. Introduction

2. Experimental

2.1. Materials

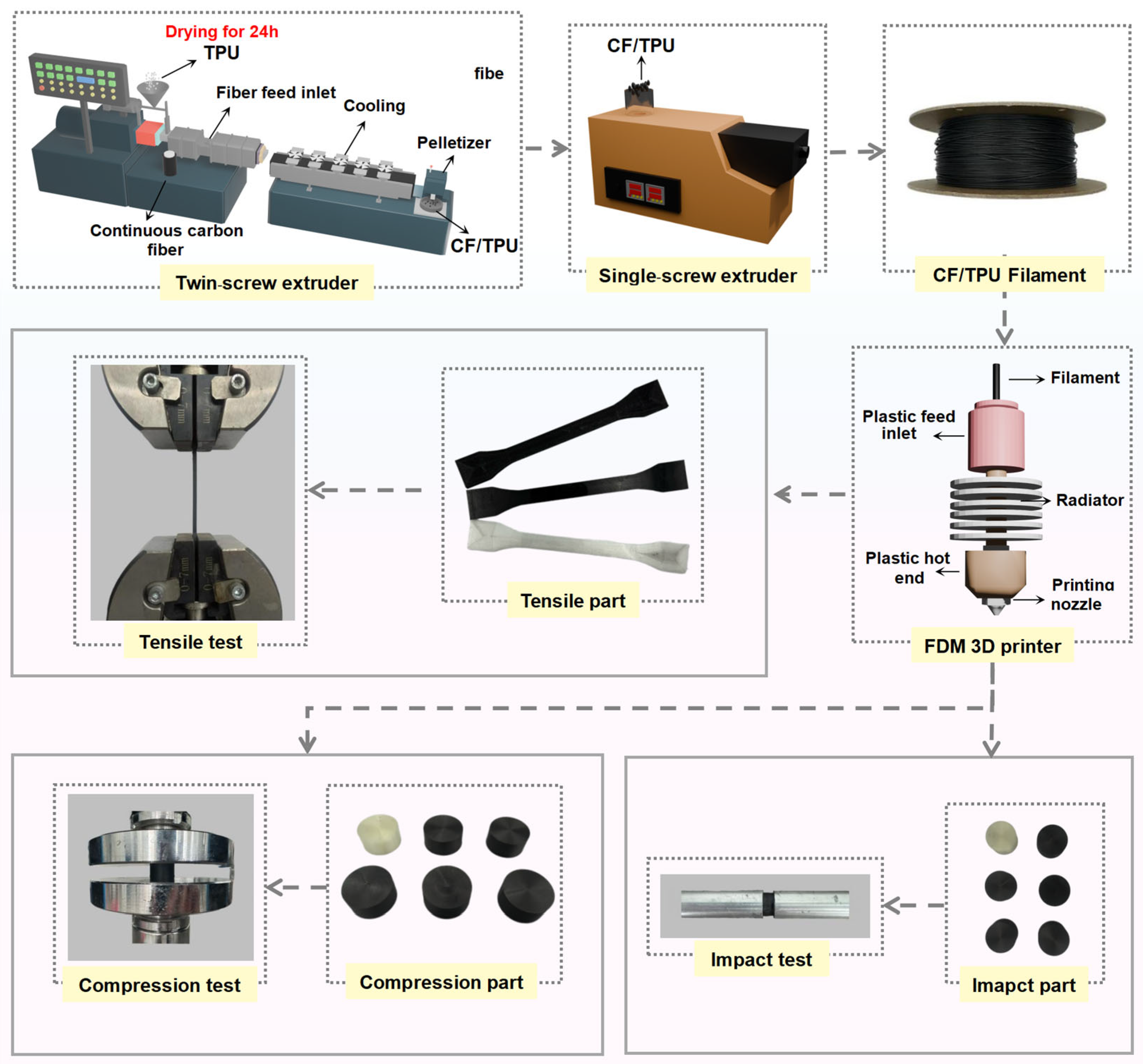

2.2. Preparation of CF/TPU Composite

2.3. 3D Printing of Composite Samples

2.4. Thermal Characterization of CF/TPU Composite Filaments

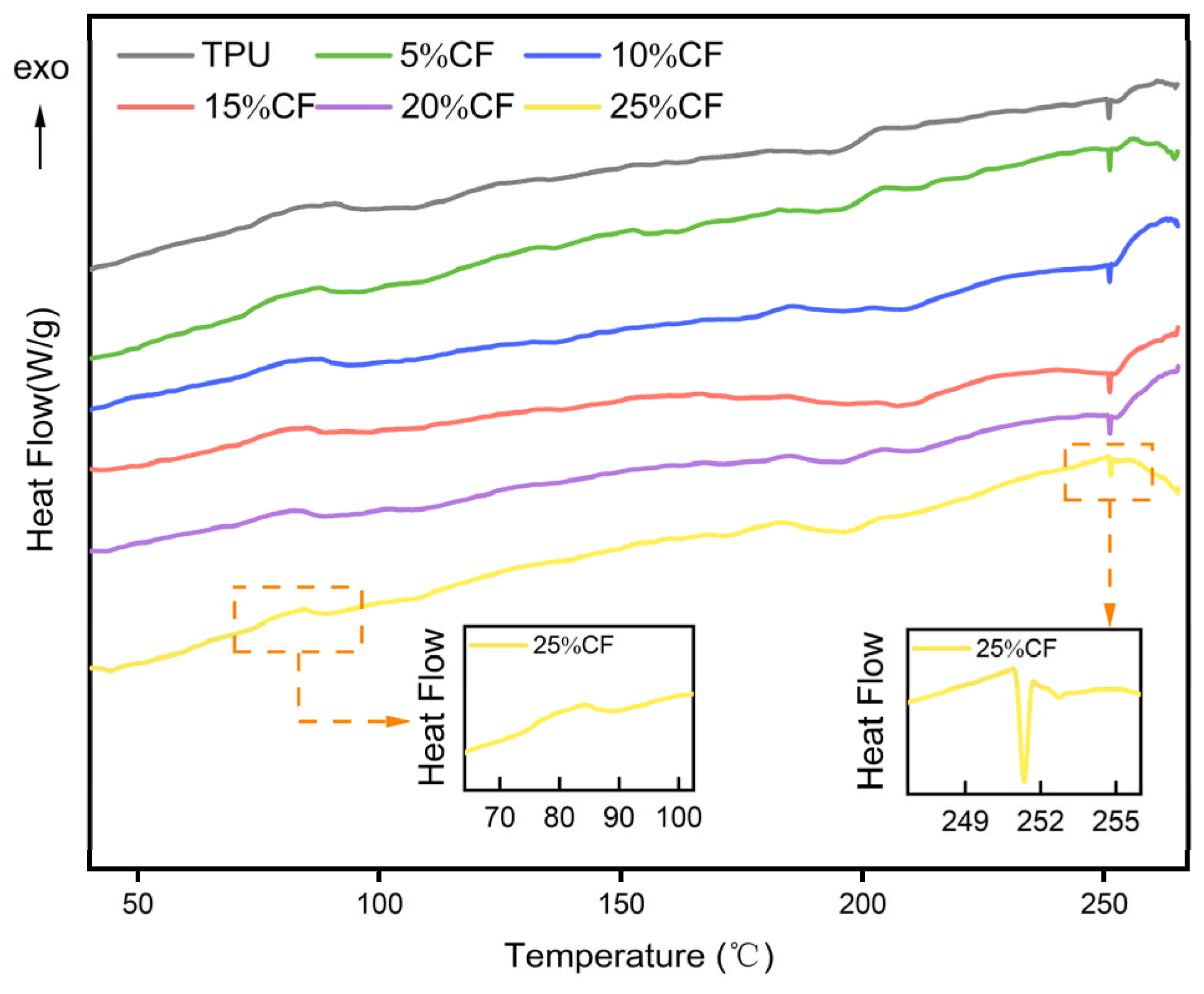

2.4.1. Analysis Using a Differential Scanning Calorimetry (DSC)

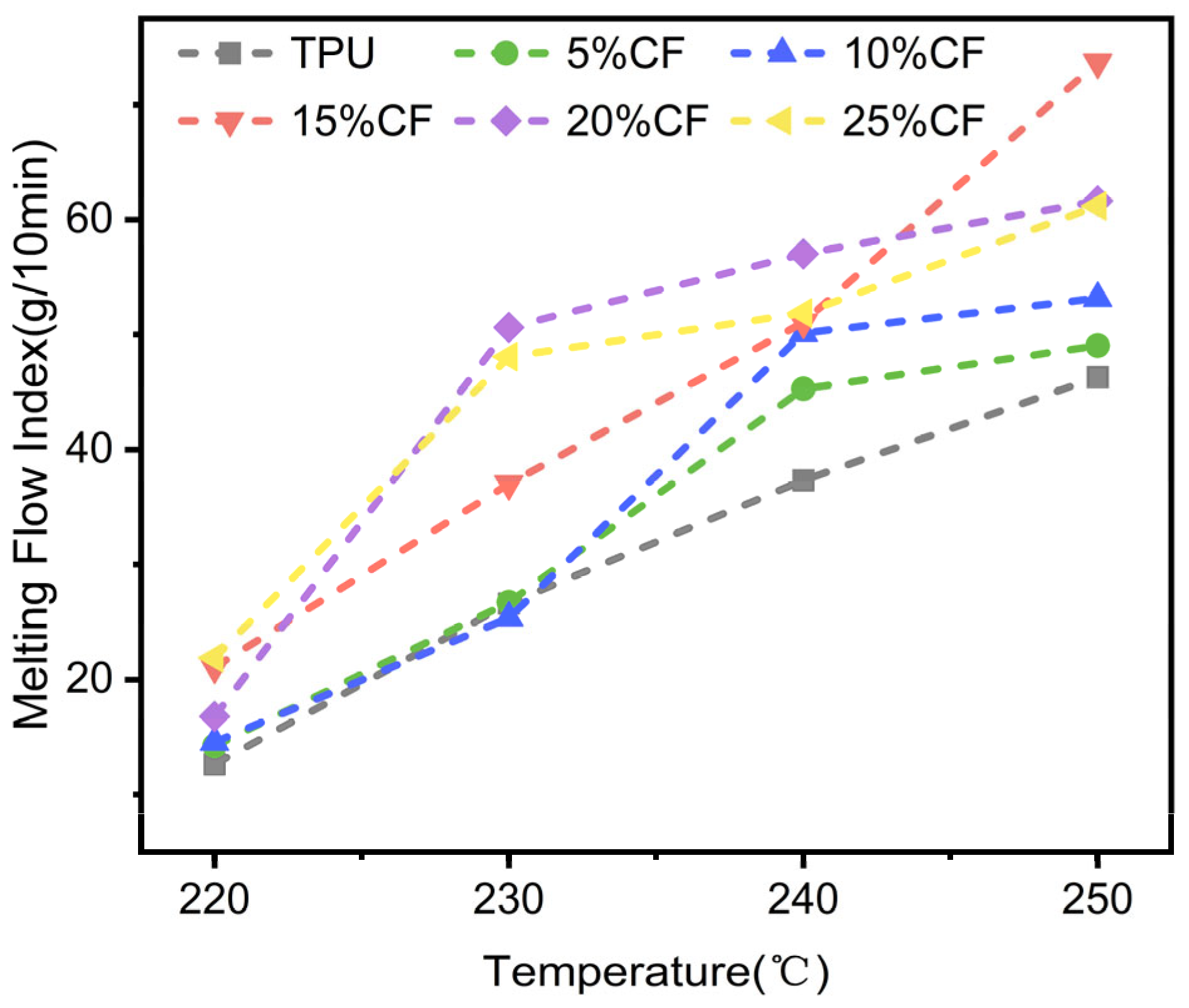

2.4.2. Determination of Melt Flow Rate

2.5. Tests for Mechanical Properties

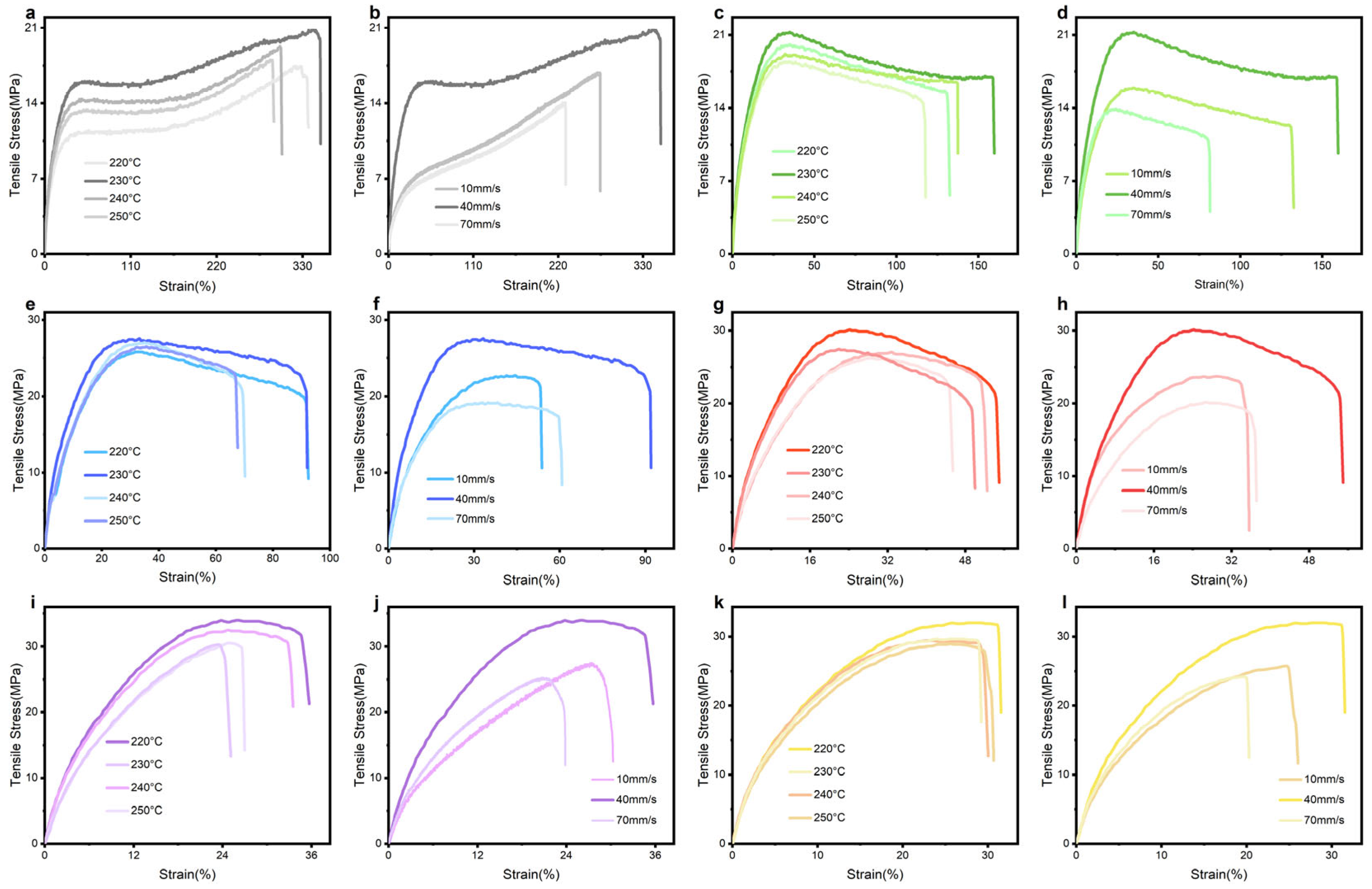

2.5.1. 3D Printing Parameters and Tensle Tests

2.5.2. Compression Tests

2.5.3. Dynamic Impact Tests

3. Results and Discussion

3.1. Thermal Characteristics

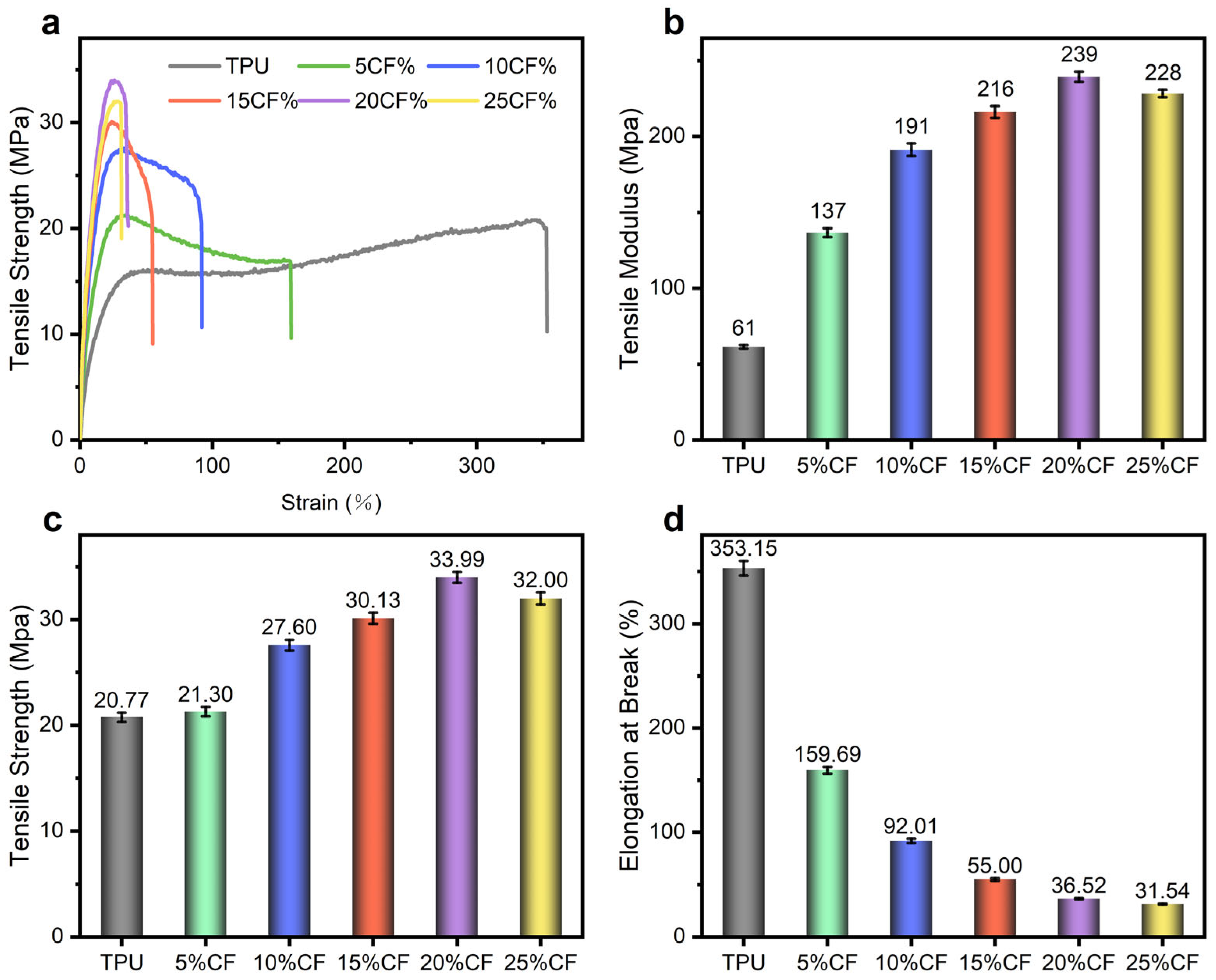

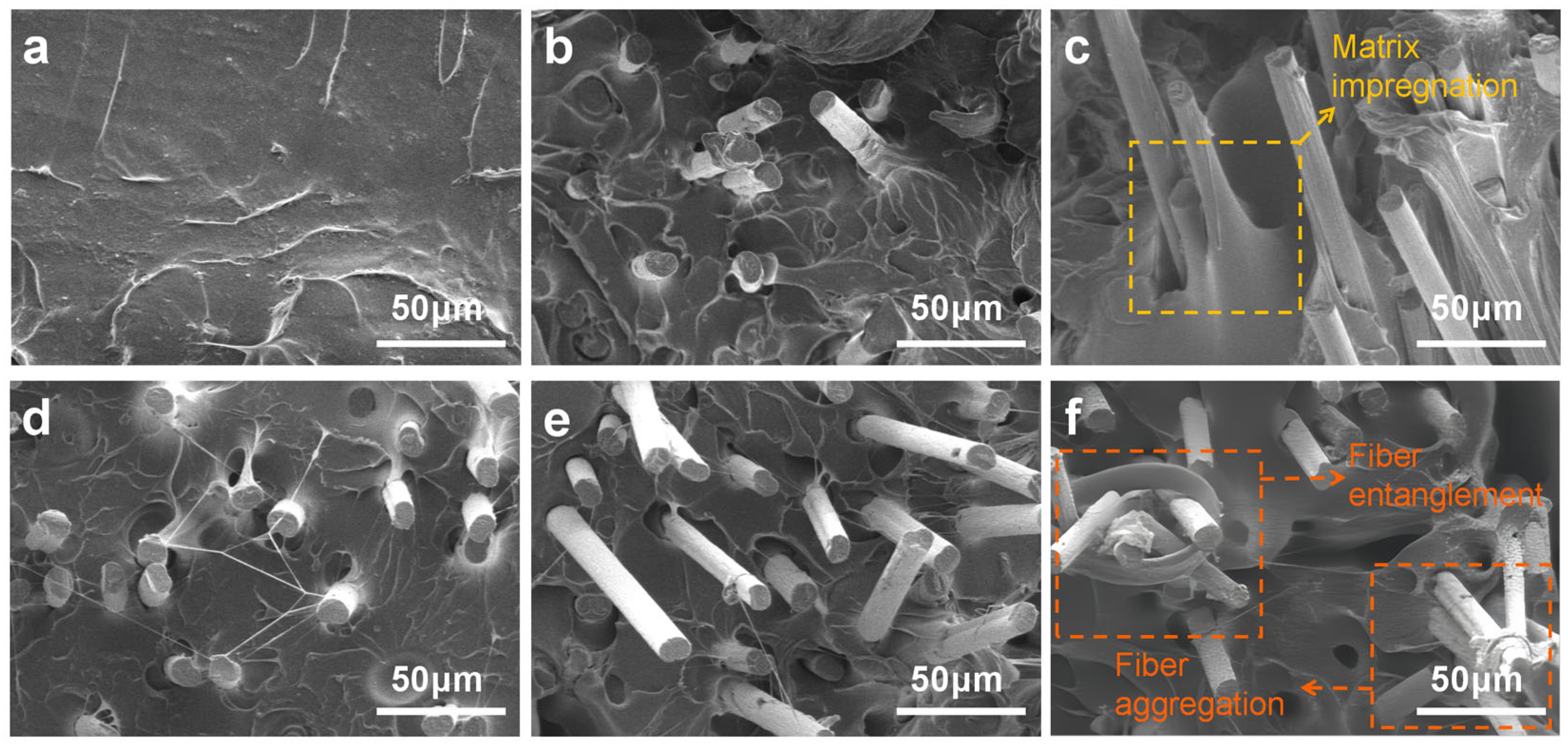

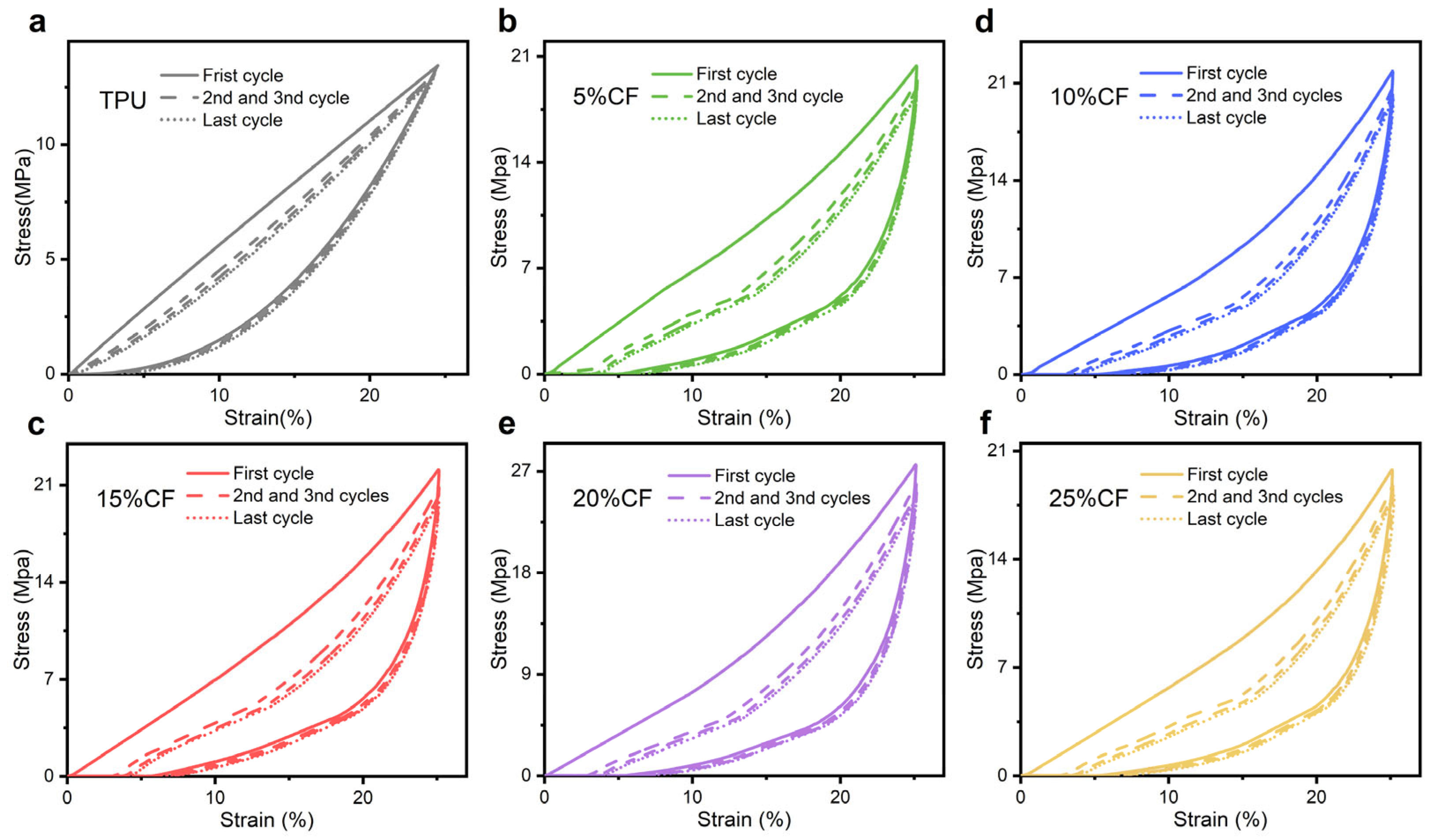

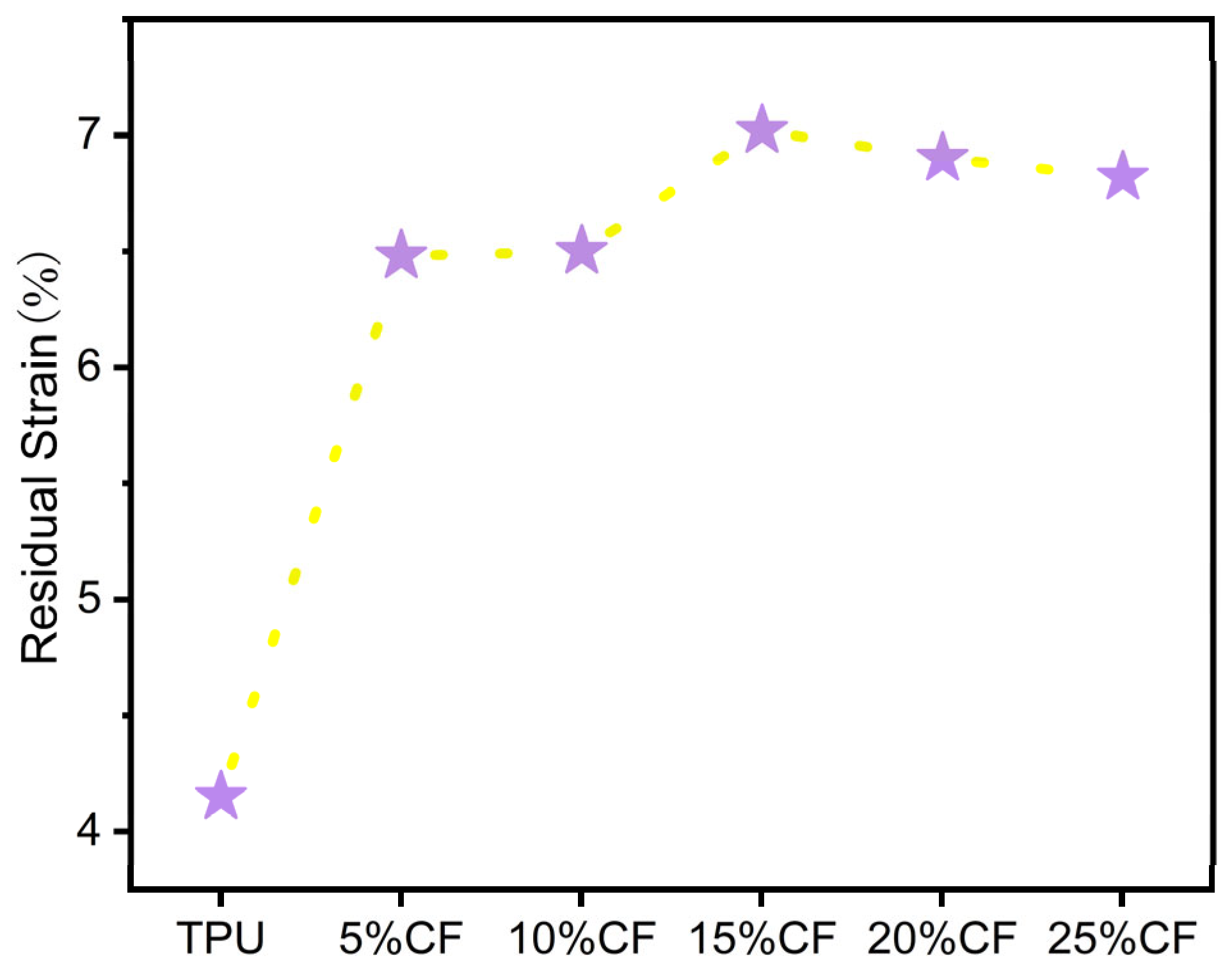

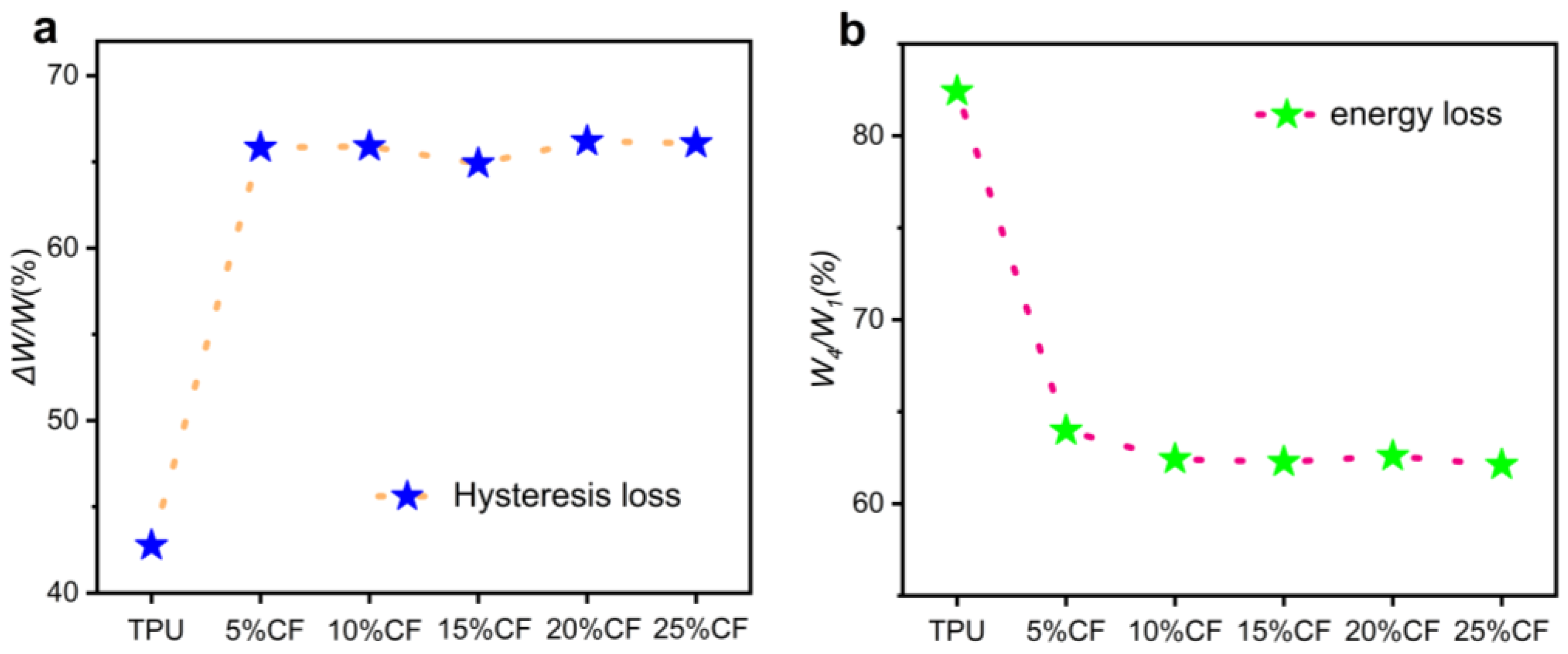

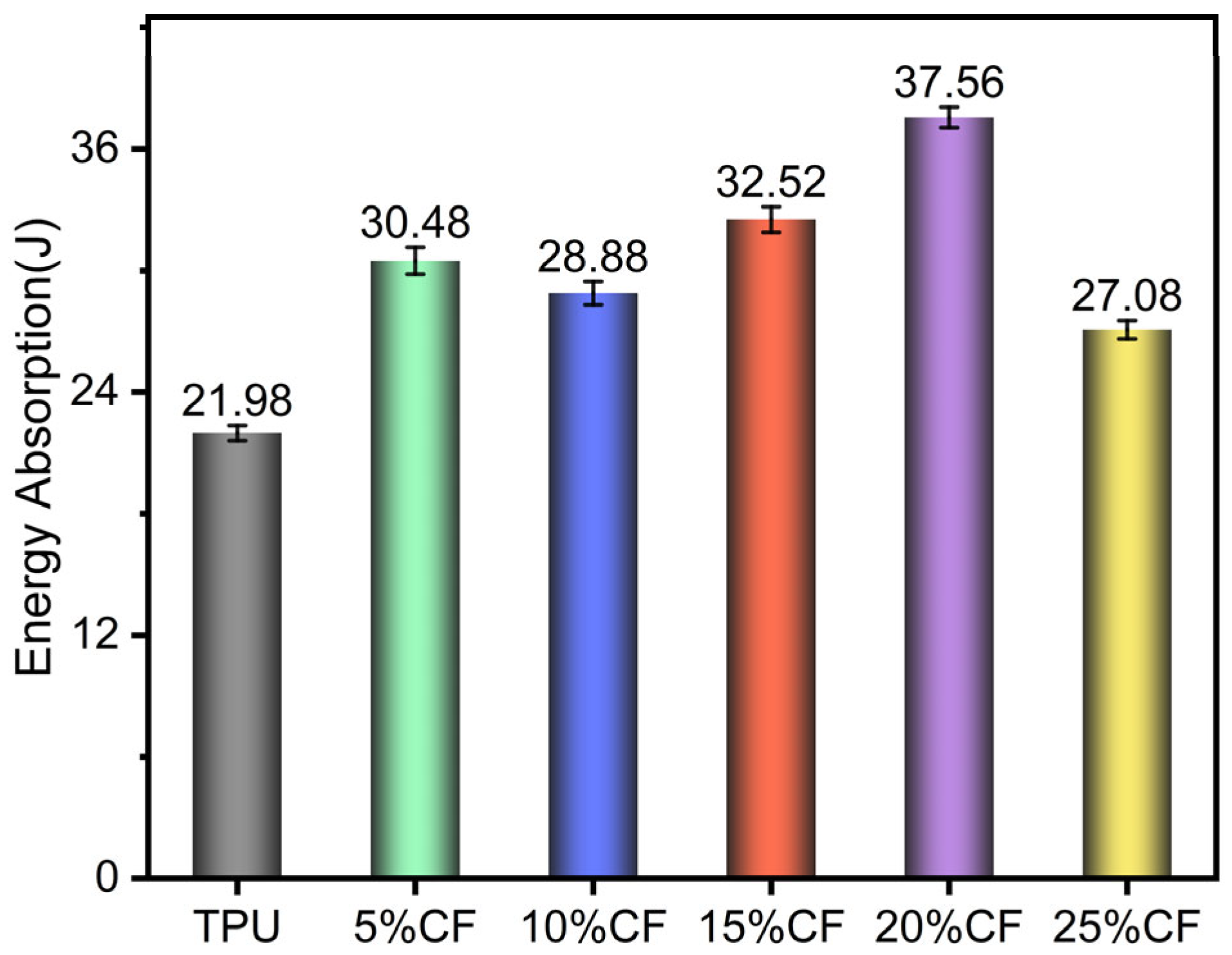

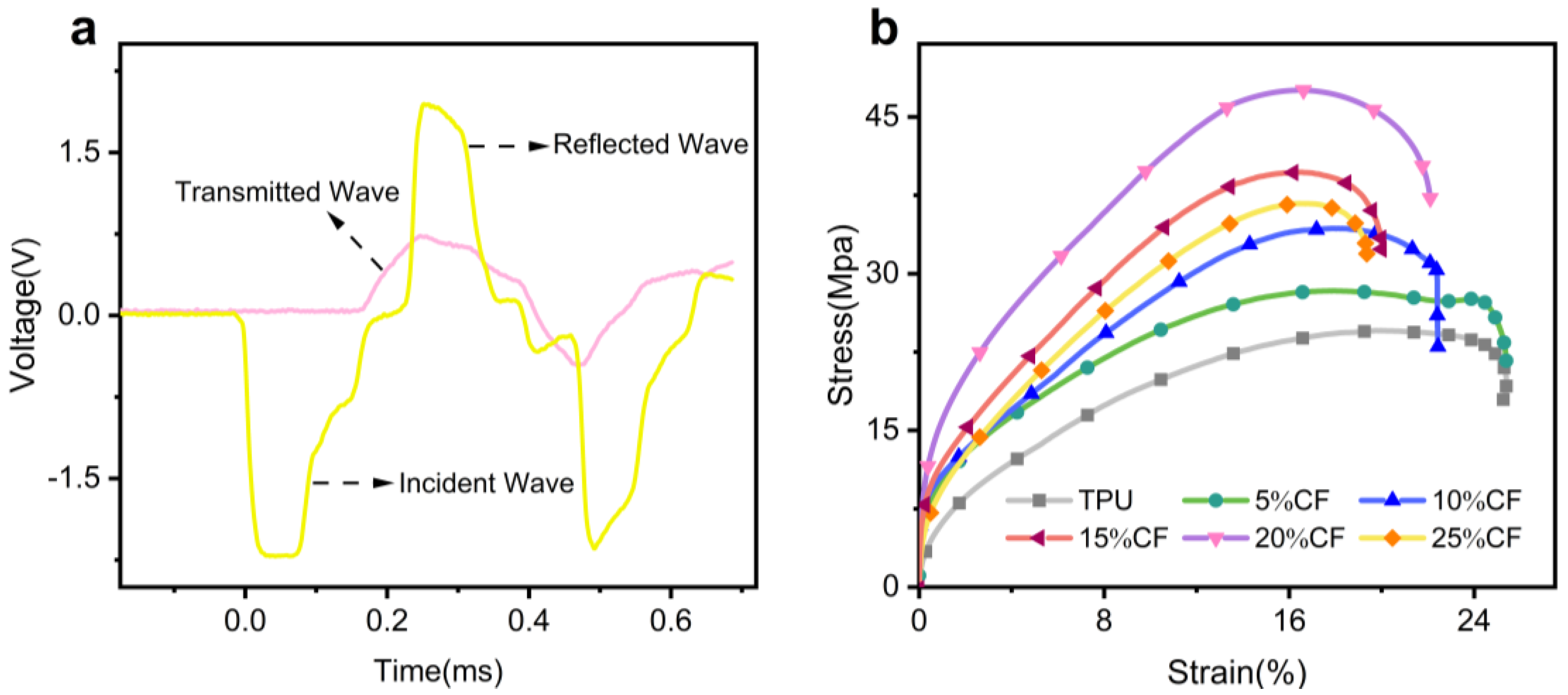

3.2. Mechanical Properties of 3D-Printed Parts

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, P.; Peng, H.; Huang, J.; Li, Y.; Dou, Q.; Suo, T. Effect of flight helmet mass characteristics and neck stress postures on pilot neck impact injury. Theor. Appl. Mech. Lett. 2024, 14, 409–418. [Google Scholar] [CrossRef]

- Tian, J.; Yang, Y.; Xue, T.; Chao, G.; Fan, W.; Liu, T. Highly flexible and compressible polyimide/silica aerogels with integrated double network for thermal insulation and fre-retardancy. J. Mater. Sci. Technol. 2022, 105, 194–202. [Google Scholar] [CrossRef]

- Shuguang, L.I.; Khan, M.I.; Ali, F.; Abdullaev, S.S.; Saadaoui, S.; Habibullah. Mathematical modeling of mixed convective mhd falkner-skan squeezed sutterby multiphase flow with non-fourier heat flux theory and porosity. Appl. Math. Mech. 2023, 44, 2005–2018. [Google Scholar]

- Liu, X.; Ding, S.; Wang, F.; Shi, Y.; Wang, X.; Wang, Z. Controlling energy dissipation during deformation by selection of the hard-segment component for thermoplastic polyure-thanes. Ind. Eng. Chem. Res. 2022, 25, 61. [Google Scholar]

- Wang, A.D.; Guo, J.H.; Shao, C.K.; Chen, C.F. Flexible Thermoplastic Polyurethane Composites with Ultraviolet Resistance for Fused Deposition Modeling 3D Printing. 3D Print. Addict. Manuf. 2024, 11, 1810–1818. [Google Scholar] [CrossRef] [PubMed]

- Oladipo, B.; Doner, S.; Lyngdoh, G.A.; Villada, J.T.; Wanchoo, P.; Matos, H.; Shukla, A.; Das, S. Shock response of sandwich panels with additively manufactured polymer gyroid lattice cores. Mater. Today Commun. 2024, 41, 110644. [Google Scholar] [CrossRef]

- Bakır, A.A.; Neshani, R.; Özerinç, S. Mechanical Properties of 3D-Printed Elastomers Produced by Fused Deposition Modeling. In Fused Deposition Modeling Based 3D Printing; Springer: Berlin/Heidelberg, Germany, 2021; pp. 107–130. [Google Scholar]

- Płatek, P.; Rajkowski, K.; Cieplak, K.; Sarzyński, M.; Małachowski, J.; Woźniak, R.; Janiszewski, J. Deformation Process of 3D Printed Structures Made from Flexible Material with Different Values of Relative Density. Polymers 2020, 12, 2120. [Google Scholar] [CrossRef]

- Singh, S.; Singh, R. Mechanical characterization and comparison of additive manufactured ABS, Polyflex™ and ABS/Polyflex™ blended functional prototypes. Rapid Prototyp. J. 2020, 26, 225–237. [Google Scholar] [CrossRef]

- Yarwindran, M.; Sa’aban, N.A.; Ibrahim, M.; Periyasamy, R. Thermoplastic elastomer infill pattern impact on mechanical properties 3D printed customized orthotic insole. ARPN J. Eng. Appl. Sci. 2016, 11, 6519–6524. [Google Scholar]

- Cakar, S.; Ehrmann, A. 3D Printing with Flexible Materials-kMechanical Properties and Material Fatigue. Macromol. Symp. 2021, 395, 2000203. [Google Scholar] [CrossRef]

- Bard, S.; Tran, T.; Schnl, F.; Rosenfeldt, S.; Demleitner, M.; Ruckdschel, H. Relationship between the tensile modulus and the thermal conductivity perpendicular and in the fiber direction of PAN-based carbon fibers. Carbon. Lett. 2024, 34, 361–369. [Google Scholar] [CrossRef]

- Gao, X.Z.; Han, T.C.; Tang, B.L.; Yi, J.; Cao, M. Reinforced Structure Effect on Thermo-Oxidative Stability of Polymer-Matrix Composites: 2-D Plain Woven Composites and 2.5-D Angle-Interlock Woven Composites. Polymers 2022, 14, 3454. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, Q.; Wang, J.; Kang, M.; Wang, X.; Zhang, T. Performance study of short fiber reinforced thermoplastic polyurethane elastomer composites. Fiber Compos. 2014, 31, 15–19. [Google Scholar]

- Georgopoulou, A.; Egloff, L.; Vanderborght, B.; Clemens, F. A Sensorized Soft Pneumatic Actuator Fabricated with Extrusion-Based Additive Manufacturing. Actuators 2021, 10, 102. [Google Scholar] [CrossRef]

- Wang, J.; Yang, B.; Lin, X.; Gao, L.; Liu, T.; Lu, Y.; Wang, R. Research of TPU Materials for 3D Printing Aiming at Non-Pneumatic Tires by FDM Method. Polymers 2020, 12, 2492. [Google Scholar] [CrossRef]

- Rodríguez-Parada, L.; de la Rosa, S.; Mayuet, P. Influence of 3D-Printed TPU Properties for the Design of Elastic Products. Polymers 2021, 13, 2519. [Google Scholar] [CrossRef]

- Iacob, M.C.; Popescu, D.; Stochioiu, C.; Baciu, F.; Hadar, A. Compressive behavior of thermoplastic polyurethane with an active agent foaming for 3D-printed customized comfort insoles. Polym. Testing 2024, 137, 18. [Google Scholar] [CrossRef]

- Shin, E.J.; Jung, Y.S.; Choi, H.Y.; Lee, S. Synthesis and fabrication of biobased thermoplastic polyurethane filament for FDM 3D printing. J. Appl. Polym. Sci. 2022, 139, 40. [Google Scholar] [CrossRef]

- Varsavas, S.D.; Kaynak, C. Effects of glass fiber reinforcement and thermoplastic elastomer blending onthe mechanical performance of polylactide. Compos. Commun. 2018, 8, 24–30. [Google Scholar] [CrossRef]

- Fu, Y.T.; Li, J.; Guo, F.L.; Li, Y.Q.; Fu, S.Y. Micro-structure and tensile property analyses of 3D printed short carbon fiber reinforced PEEK composites. Compos. Commun. 2023, 41, 101655. [Google Scholar] [CrossRef]

- Wang, G.S.; Wang, F.J.; Wang, H.Q.; Fu, R.; Zhou, J.M. Study on short fiber reinforcement mechanism for mechanical performance improvement of 3D-printed short-continuous carbon fiber reinforced thermoplastic composites. Polym. Compos. 2024, 45, 16244–16261. [Google Scholar] [CrossRef]

- Tanabi, H. Investigation of the shear properties of 3D printed short carbon fiber-reinforced thermoplastic composites. J. Thermoplast. Compos. Mater. 2022, 35, 2177–2193. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B. Improvement of Heat Treatment Process on Mechanical Properties of FDM 3D-Printed Short- and Continuous-Fiber-Reinforced PEEK Composites. Coatings 2022, 12, 827. [Google Scholar] [CrossRef]

- Wang, X.; Tang, W.; Wang, B.; Wang, L. Precise Control of Fiber Content in Fiber Reinforced thermoplastic. Aerosp. Mater. Technol. 2012, 43, 62–65. [Google Scholar]

- Zhai, H.; Li, X.; Yu, S.; Wang, J.; Zhou, L.; Xiong, X. 4D printing of Nd-Fe-B composites with both shape memory and permanent magnet excitation deformation. Compos. Part. Appl. Sci. Manuf. 2024, 187, 16. [Google Scholar] [CrossRef]

- Alzahrani, M.; Alhumade, H.; Simon, L.; Yetilmezsoy, K.; Madhuranthakam, C.M.R.; Elkamel, A. Additive Manufacture of Recycled Poly(Ethylene Terephthalate) Using Pyromellitic Dianhydride Targeted for FDM 3D-Printing Applications. Sustainability 2023, 15, 5004. [Google Scholar] [CrossRef]

- Frick, A.; Rochman, A. Characterization of tpu-elastomers by thermal analysis (DSC). Polym. Test. 2004, 23, 413–417. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, K.; Yan, D. Crystallization, morphology, and dynamic mechanical properties of poly(trimethylene terephthalate)/clay nanocomposites. Eur. Polym. J. 2003, 39, 2359–2366. [Google Scholar] [CrossRef]

- Kanbur, Y.; Tayfun, U. Development of multifunctional polyurethane elastomer composites containing fullerene: Mechanical, damping, thermal, and flammability behaviors. J. Elastomers Plast. 2019, 51, 262–279. [Google Scholar] [CrossRef]

- Tikhani, F.; Gurbin, A.; Hubert, P. Unveiling the impact of short fibre reinforcement and extrusion properties on microstructure of 3D printed polycarbonate composites. Addit. Manuf. 2024, 93, 104432. [Google Scholar] [CrossRef]

- Lei, J.; Shen, Q.; Liu, T.; Sun, H.; Yin, Z. Influence of fused deposition process parameters on static and dynamic mechanical properties of thermoplastic polyurethane elastomer. Cina. Plast. 2022, 36, 29–35. [Google Scholar]

- Brancewicz-Steinmetz, E.; Brancewicz-Steinmetz, E.; Sawicki, J.; Sawicki, J.; Byczkowska, P.; Byczkowska, P. The Influence of 3D Printing Parameters on Adhesion between Polylactic Acid (PLA) and Thermoplastic Polyurethane (TPU). Materials 2021, 14, 6464. [Google Scholar] [CrossRef]

- Gallup, L.; Trabia, M.; O′Toole, B.; Fahmy, Y. Influence of Fused Deposition Modeling Process Parameters on Constitutive Model of Hyperelastic Thermoplastic Polyurethane. Polymers 2025, 17, 26. [Google Scholar] [CrossRef]

- Desai, S.M.; Sonawane, R.Y.; More, A.P. Thermoplastic polyurethane for three-dimensional printing applications: A review. Polym. Adv. Technol. 2023, 34, 2061–2082. [Google Scholar] [CrossRef]

- Arifvianto, B.; Iman, T.N.; Prayoga, B.T.; Dharmastiti, R.; Suyitno, S. Tensile properties of the fff-processed thermoplastic polyurethane (tpu) elastomer. Int. J. Adv. Manuf. Technol. 2021, 117, 1709–1719. [Google Scholar] [CrossRef]

- Zheng, H.; Zhu, S.; Li, Z. Continuous Deformation Monitoring by Polymermatrix Carbon Fiber Sensitive Layer. J. Wuhan Univ. Technol. 2016, 31, 705–712. [Google Scholar] [CrossRef]

- León-Calero, M.; Vales, S.C.R.; Marcos-Fernandez, A.; Rodriguez-Hernandez, J. 3D Printing of Thermoplastic Elastomers: Role of the Chemical Composition and Printing Parameters in the Production of Parts with Controlled Energy Absorption and Damping Capacity. Polymers 2021, 13, 3551. [Google Scholar] [CrossRef]

- Ma, Y.; Li, Z.; Li, X.; Zhu, S.; Yan, S. Experimental study on the cyclic mechanical behavior of polyurethane at different compression strains. J. Exp. Mech. 2024, 39, 75–85. [Google Scholar]

- REY, T.; Chagnon, G.; Le Cam, J.B.; Favier, D. Influence of the temperature on the mechanical behaviour of filled and unfilled silicone rubbers. J. Polymer Testing 2013, 32, 492–501. [Google Scholar] [CrossRef]

- Bai, J.Q.; Qi, S.B.; Xie, Y.C.; Yuan, M.Q.; Li, M.L. Ballistic response of an airbag with parallel ribs under spherical projectile impact. Compos. Struct. 2025, 353, 118734. [Google Scholar] [CrossRef]

| Sample | Main Engine Speed /r∙min−1 | TPU Feeding Speed /r∙min−1 | TPU Feed Rate /g∙min−1 | Number of Fibers /n |

|---|---|---|---|---|

| TPU | 200 | 4.0 | 34.0 | 0 |

| 5%CF/TPU | 200 | 4.5 | 38.0 | 1 |

| 10%CF/TPU | 200 | 4.2 | 36.0 | 2 |

| 15%CF/TPU | 200 | 2.7 | 22.9 | 2 |

| 20%CF/TPU | 200 | 2.8 | 23.8 | 3 |

| 25%CF/TPU | 200 | 2.8 | 23.8 | 4 |

| Sample | Front Temperature/°C | Back Temperature/°C |

|---|---|---|

| TPU | 213 | 203 |

| 5%CF-TPU | 215 | 205 |

| 10%CF-TPU | 217 | 207 |

| 15%CF-TPU | 220 | 209 |

| 20%CF-TPU | 223 | 211 |

| 25%CF-TPU | 225 | 213 |

| Sample | Tc/°C | Tm/°C | ΔHm/J∙g−1 | Xc/% |

|---|---|---|---|---|

| TPU | 90.33 | 250.95 | 4.6 | 3.1 |

| 5%CF/TPU | 87.36 | 251.12 | 4.3 | 2.9 |

| 10%CF/TPU | 86.81 | 251.06 | 3.9 | 2.6 |

| 15%CF/TPU | 85.05 | 251.10 | 2.4 | 1.6 |

| 20%CF/TPU | 83.11 | 251.14 | 2.3 | 1.5 |

| 25%CF/TPU | 84.22 | 251.36 | 2.1 | 1.4 |

| Sample | Printing Temperatures/°C | Printing Speeds/mm∙s−1 |

|---|---|---|

| TPU | 230 | 40 |

| 5%CF/TPU | 230 | 40 |

| 10%CF/TPU | 230 | 40 |

| 15%CF/TPU | 220 | 40 |

| 20%CF/TPU | 220 | 40 |

| 25%CF/TPU | 220 | 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Ouyang, H.; Zhang, Y.; Zhu, Z.; Wang, Z.; Cheng, Z.; Hu, Y.; Zhang, Y. Enhancing the Energy Absorption Performance of 3D-Printed CF/TPU Composite Materials by Introducing a “Rigid–Elastic” Structure Through Multi-Scale Synergies. Polymers 2025, 17, 1880. https://doi.org/10.3390/polym17131880

Zhou X, Ouyang H, Zhang Y, Zhu Z, Wang Z, Cheng Z, Hu Y, Zhang Y. Enhancing the Energy Absorption Performance of 3D-Printed CF/TPU Composite Materials by Introducing a “Rigid–Elastic” Structure Through Multi-Scale Synergies. Polymers. 2025; 17(13):1880. https://doi.org/10.3390/polym17131880

Chicago/Turabian StyleZhou, Xuanyu, He Ouyang, Yuan Zhang, Ziqiang Zhu, Zhen Wang, Zirui Cheng, Yubing Hu, and Yanan Zhang. 2025. "Enhancing the Energy Absorption Performance of 3D-Printed CF/TPU Composite Materials by Introducing a “Rigid–Elastic” Structure Through Multi-Scale Synergies" Polymers 17, no. 13: 1880. https://doi.org/10.3390/polym17131880

APA StyleZhou, X., Ouyang, H., Zhang, Y., Zhu, Z., Wang, Z., Cheng, Z., Hu, Y., & Zhang, Y. (2025). Enhancing the Energy Absorption Performance of 3D-Printed CF/TPU Composite Materials by Introducing a “Rigid–Elastic” Structure Through Multi-Scale Synergies. Polymers, 17(13), 1880. https://doi.org/10.3390/polym17131880