Research on High-Performance Underwater-Curing Polymer Composites for Offshore Oil Riser Pipes

Abstract

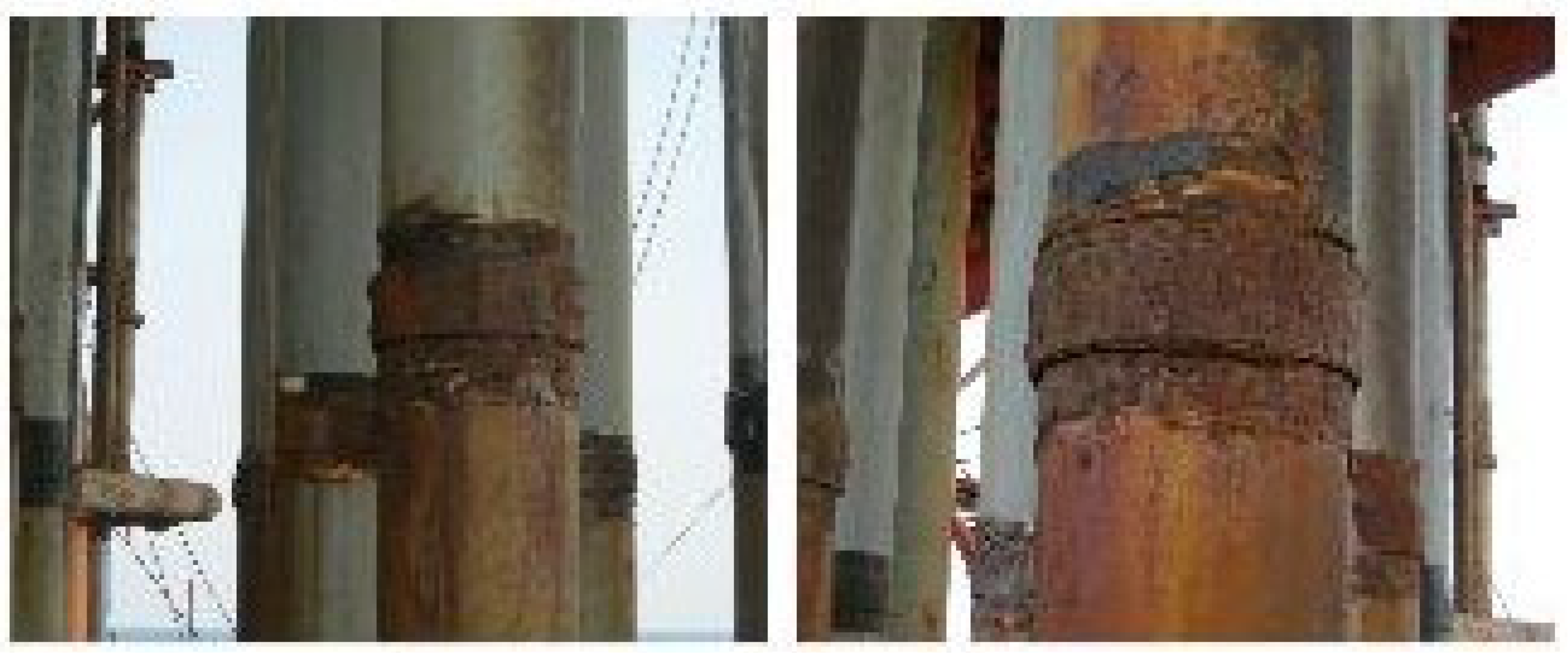

1. Introduction

2. Materials and Methods

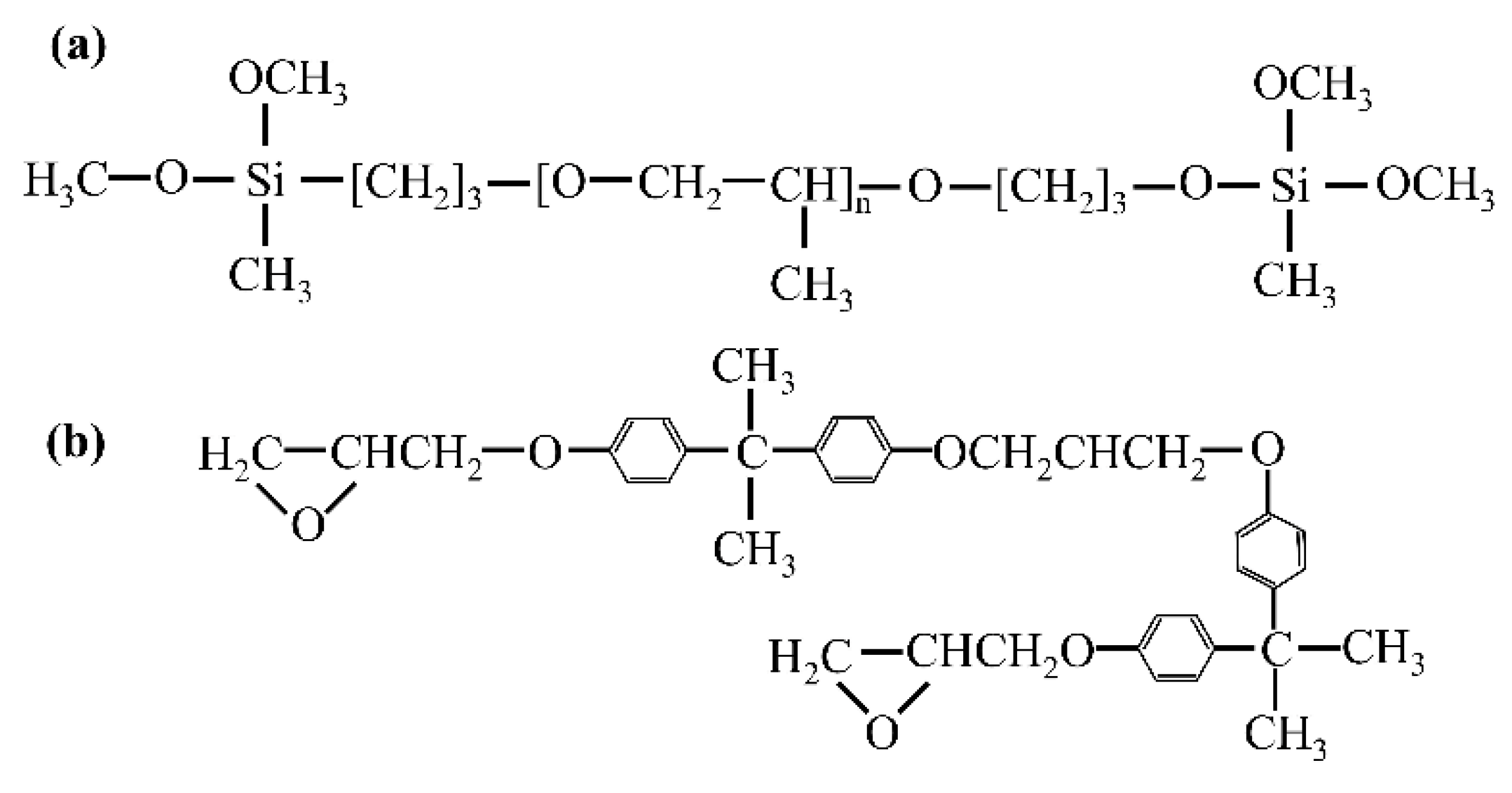

2.1. Polymeric Internal Protection Materials

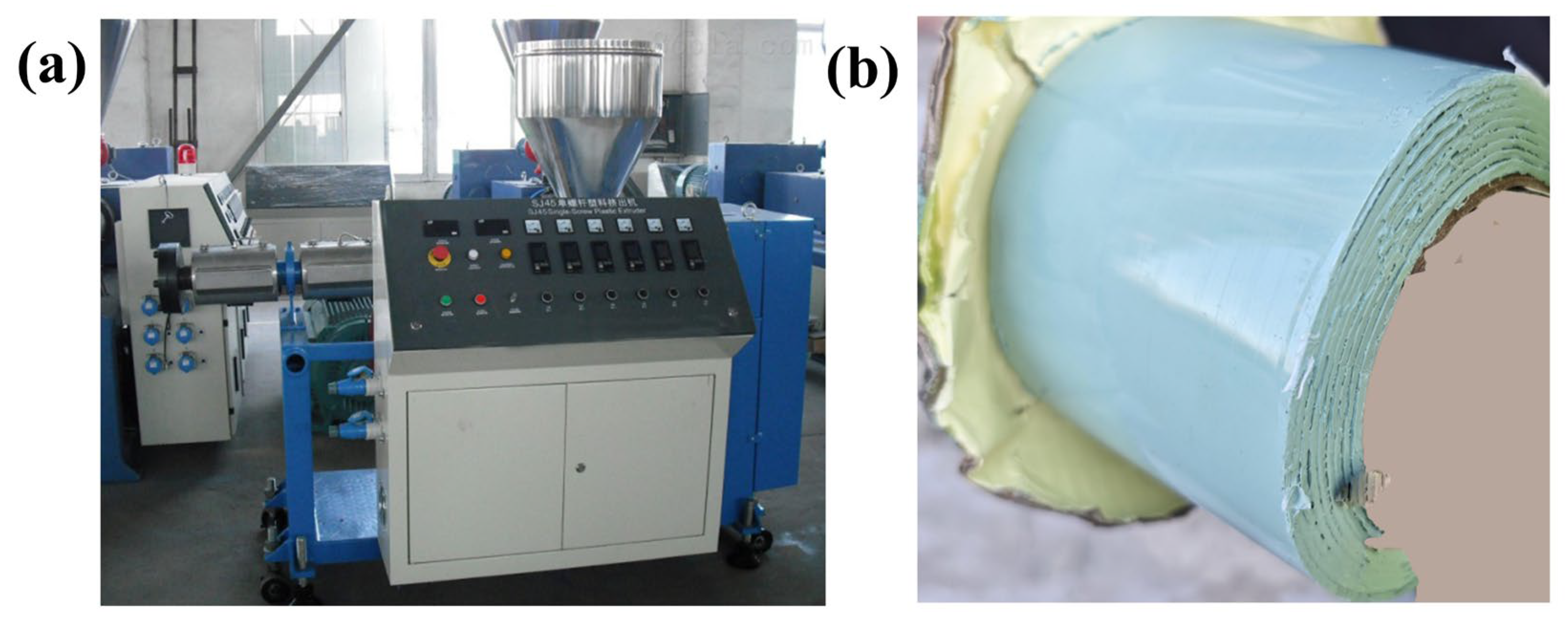

2.2. Preparation Process of Polymeric Internal Protection Materials

2.3. Material Characterization and Verification Experiments

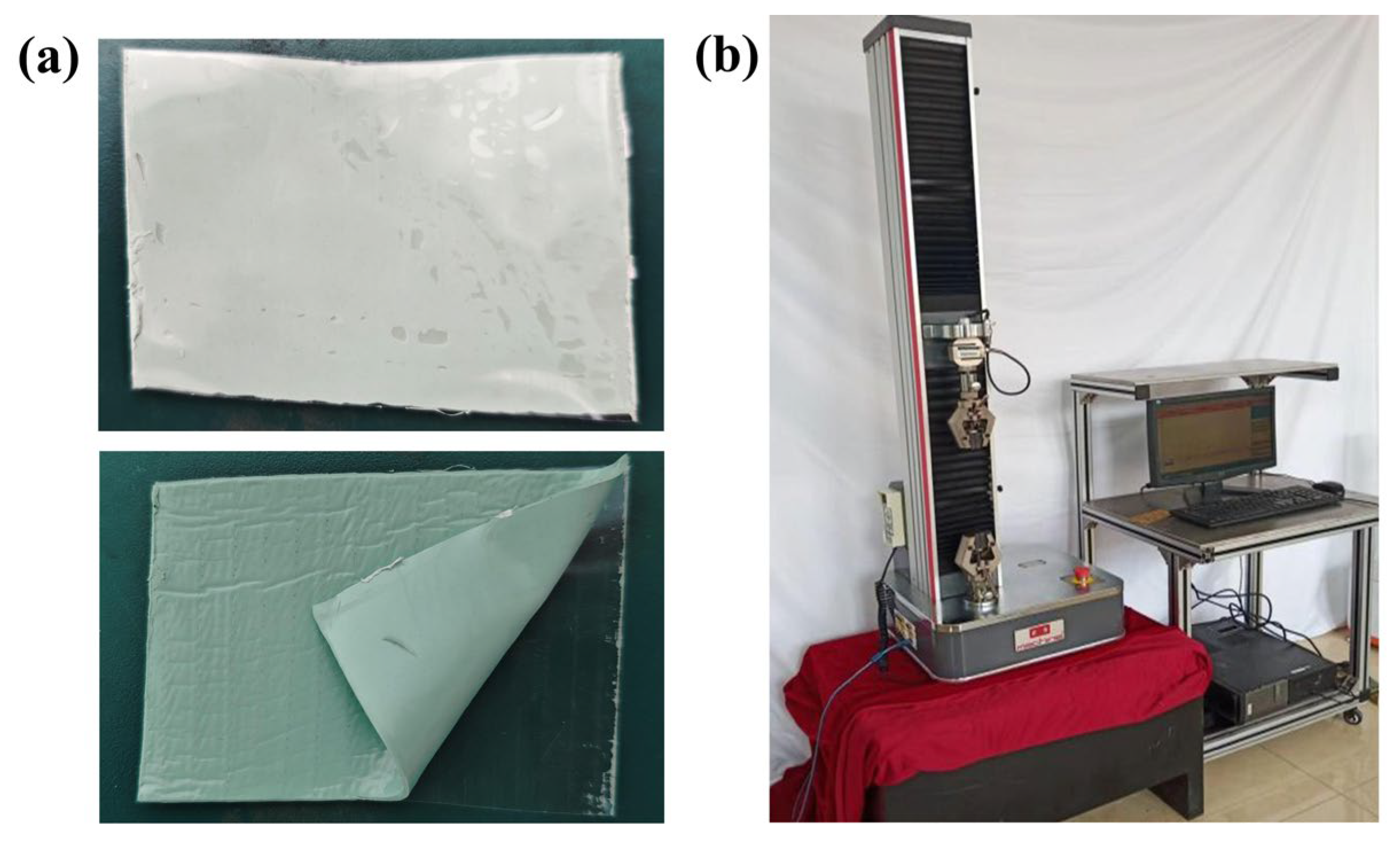

2.3.1. Basic Performance Experiments of Polymeric Internal Protection Materials

2.3.2. Repair Testing of Polymeric Internal Protection Materials

2.4. Reinforcement System Optimization

2.4.1. Reinforcement Materials

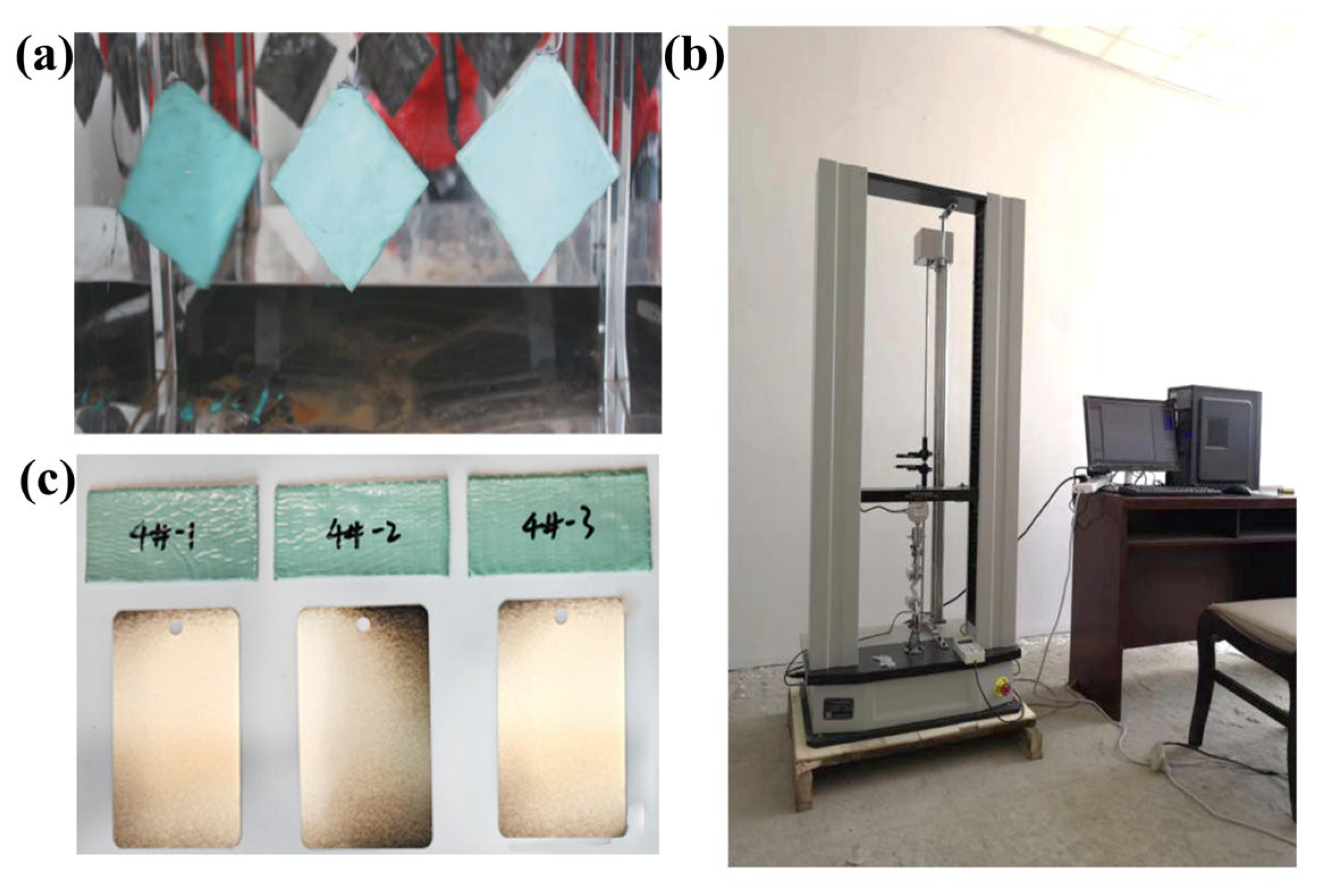

2.4.2. Adhesion Testing of Reinforcement Materials

2.4.3. Performance Testing Experiments of the Reinforcement System

2.5. Application Experiment on Offshore Oil and Gas Well Conductor

3. Results and Discussion

3.1. Results and Discussion of Material Characterization Verification Experiments

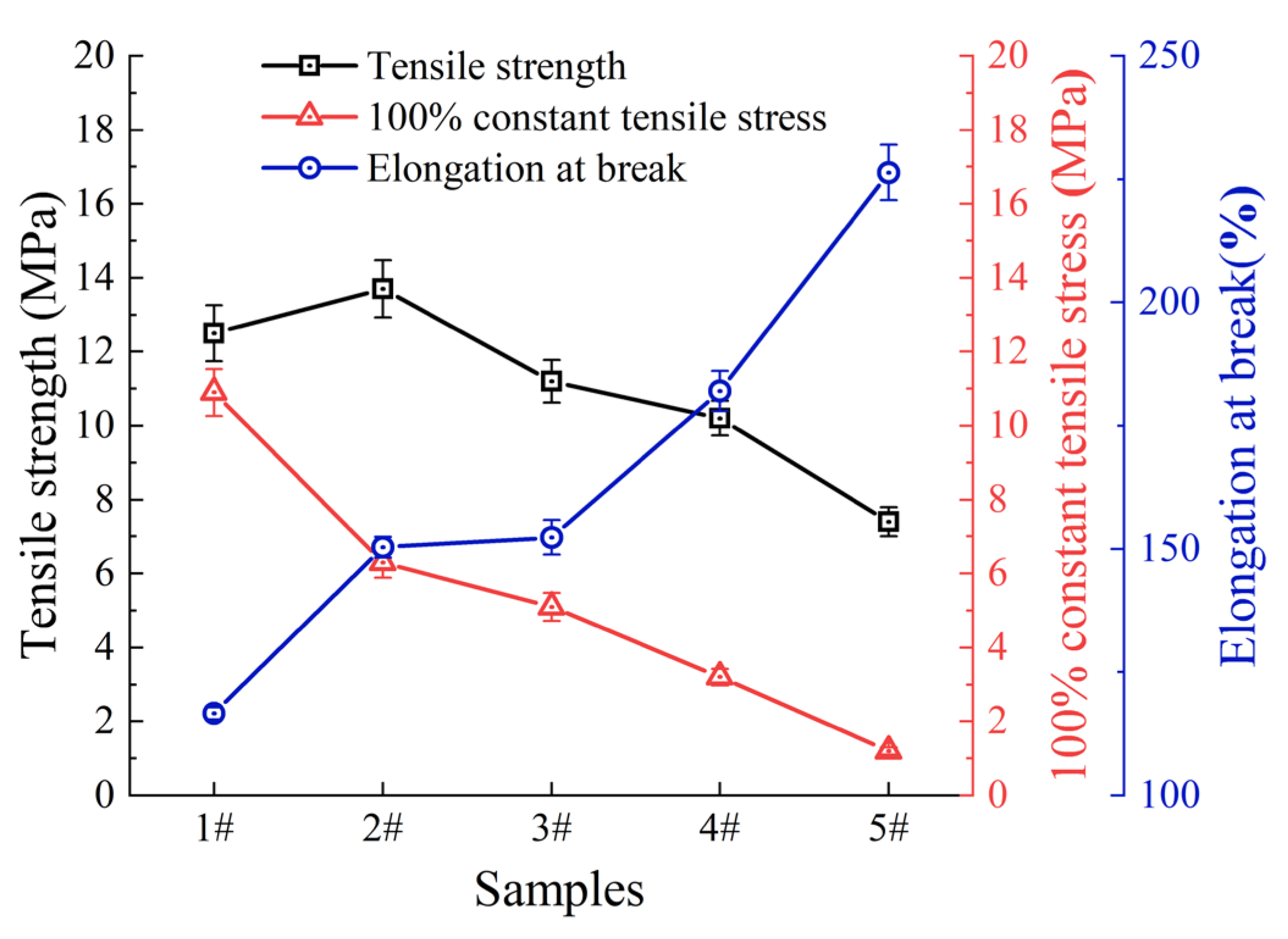

3.1.1. Basic Performance Experiments

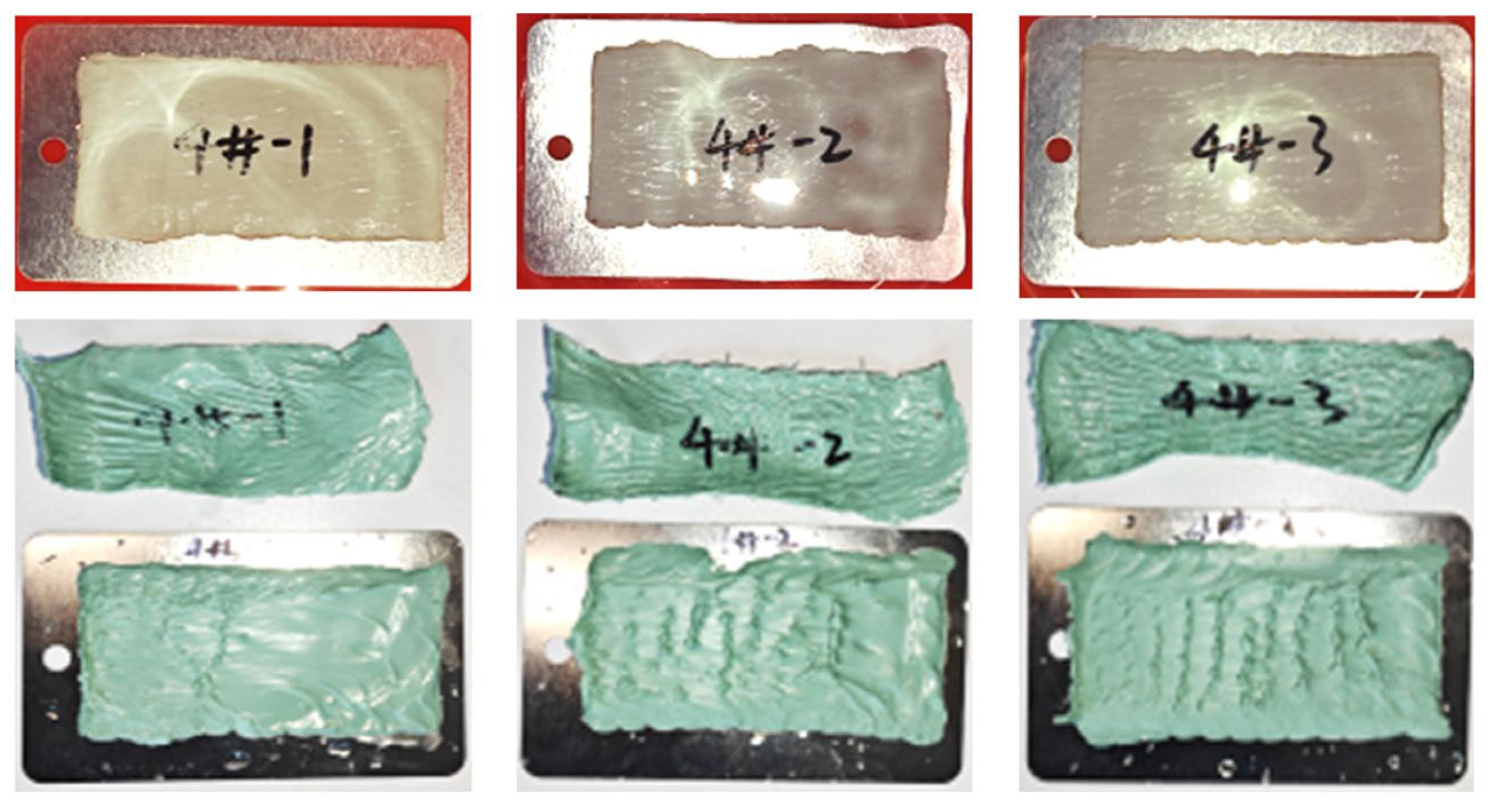

3.1.2. Repair Test Results

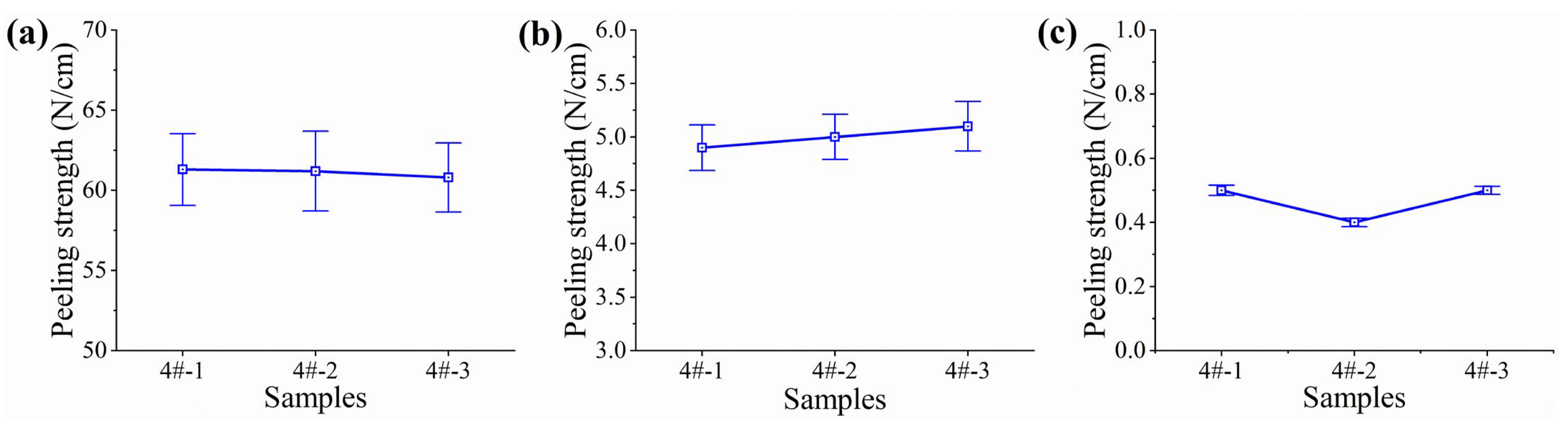

3.2. Results and Discussion of Reinforcement System Performance Testing Experiments

3.3. Results and Discussion of Application Experiments on Offshore Oil and Gas Well Conductors

4. Conclusions

- (1)

- The internal plasticizing effect of medium molecular weight PIB synergizes with the IIR crosslinking network, breaking the contradiction between material elasticity and strength; utilizing the hypothesized interfacial effect of nano-fillers, a stable peel strength of ≥0.3 N/cm is achieved across a wide temperature range from −45 °C to 80 °C. This mechanism warrants further microstructural investigation in future work.

- (2)

- Innovative two-component solvent-free epoxy system, combining medium molecular weight PIB internal plasticization, nano-silica hydrogen bond enhancement, and latent curing agent regulation, achieving rapid surface drying in 30 min underwater and pull-off strength > 3.5 MPa.

- (3)

- Formula 4# has the best comprehensive performance, with peel strength against steel > 0.3 N/cm at different temperature ranges, and underwater adhesive layer retention rate > 95%. The two-component solvent-free epoxy reinforcement material has high strength after curing, can effectively reinforce polymer materials, and meets engineering requirements.

- (4)

- The combined action of internal protection polymer material and two-component solvent-free epoxy can seal pipes after 24 h of curing. Under internal high-pressure tests, there are no abnormalities with 25 MPa pressure maintained for 15 min, and the material has high peel strength at low temperatures, is impact-resistant, and can protect damaged areas of pipes.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| IIR | Butyl rubber |

| DOP | Dioctyl phthalate |

| m-PIB | Medium molecular weight polyisobutylene |

| PIB | Polyisobutylene |

References

- Li, J.; Ning, B.; Qiu, D.Z.; Ou, F.; Geng, L.; Xu, P.; Kou, B. Sealing Characteristics Analysis of New Subsea Wellhead Sealing Device. Processes 2024, 12, 2124. [Google Scholar] [CrossRef]

- Li, Y.H.; Hu, Z.Q. Comparative study of two cost assessment approaches to models for offshore oil and gas platform decommissioning. J. Ocean. Eng. Sci. 2025, 10, 136–149. [Google Scholar] [CrossRef]

- Wen, Z.X.; Wang, J.J.; Wang, Z.; He, Z.; Song, C.; Chen, R.; Liu, X.; Ji, T.; Li, Z. Analysis of the current status of global oil, gas, and associated resources exploration in 2023. Pet. Explor. Dev. 2024, 51, 1465–1479. [Google Scholar] [CrossRef]

- Yin, Z.M.; Ren, M.P.; Ma, Y.W.; Yang, X.; Tian, D.; Wang, H.; Xiao, C.; Qu, J. Research on the Risk of Drilling Phases Based on the Development Model of Shallow-Water Subsea Trees. J. Mar. Sci. Eng. 2024, 12, 1909. [Google Scholar] [CrossRef]

- Bolobov, V.I.; Latipov, I.U.; Zhukov, V.S.; Popov, G.G. Using the Magnetic Anisotropy Method to Determine Hydrogenated Sections of a Steel Pipeline. Energies 2023, 16, 5585. [Google Scholar] [CrossRef]

- Pang, M.; Zhang, Y.C.; Li, Q.; Zhang, Z. Study on the Causes of Wellbore Leakage in Carbon Capture, Utilization, and Storage-Enhanced Oil Recovery. Sustainability 2025, 17, 1206. [Google Scholar] [CrossRef]

- Wang, J.T.; He, Z.J.; Yan, Y.C.; Liu, L.; Yan, J.; Liao, B.; Zhao, K.; Li, Y.; Chen, L. Development of a dual-functional inhibitor for natural gas hydrates and construction of drilling fluid system. Gas Sci. Eng. 2024, 122, 205218. [Google Scholar] [CrossRef]

- Dong, Z.Q.; Xu, Z.Z.; Wang, W.K.; Bi, Z.; Zhang, J. Numerical Simulation and Experimental Confirmation of a Bimetallic Pipe Forming Process. Materials 2020, 13, 3561. [Google Scholar] [CrossRef]

- Ebrahiem, E.E.; Noaman, A.A.; Aly, I.H.M.; Abdel-Rahman, M.A. The Effect of Fiber-Adhesive Composite on Bond Strength of Plastic Plates- Part I: Adhesion Type & Thickness. Egypt. J. Chem. 2020, 63, 5145–5159. [Google Scholar] [CrossRef]

- Liu, H.S.; Xue, R.L.; Zhou, J.P.; Bao, Y.; Xu, Y. Effects of Oscillation Width on Arc Characteristics and Droplet Transfer in Vertical Oscillation Arc Narrow-Gap P-GMAW of X80 Steel. Metals 2023, 13, 1057. [Google Scholar] [CrossRef]

- Ahmed, J.; Mushtaq, S. Effects of silane-modified AlO and its hybrid filler on thermal stability and mechanical properties of ethylene-vinyl acetate copolymer/polyamide composites. Iran. Polym. J. 2022, 31, 1571–1581. [Google Scholar] [CrossRef]

- Mohamed, M.G.; Ahmed, N.M.; Mohamed, W.S.; Mabrouk, M.R. Influence of Anticorrosive Coatings Integrated with Novel Core-Shell Pigment on the Corrosion Protection of Pipelines in CO Environment. J. Mater. Eng. Perform. 2020, 29, 5728–5737. [Google Scholar] [CrossRef]

- Jin, H.; Ji, R.J.; Sun, H.; Liu, S.; Dong, T.; Wang, L.; Zhao, L.; Ma, C.; Liu, Y.; Cai, B.; et al. Efficient preparation of Ni-Fe-SiC pipeline internal surface coating by active/inert metal combined anode jet electrodeposition. J. Manuf. Process. 2023, 89, 284–297. [Google Scholar] [CrossRef]

- Akbari, M.; Naderi, R.; Ramezanzadeh, B. Novel manufacturing of intelligent hierarchical molybdenum-polydopamine hollow nanocarriers for smart coating. Appl. Mater. Today 2023, 33, 101880. [Google Scholar] [CrossRef]

- Condini, A.; Trentalange, C.; Giuliani, A.; Cristoforetti, A.; Rossi, S. Advancing corrosion protection in confined spaces: A solvent-free UV LED-curable coating for steel pipelines with enhanced barrier properties and harsh environment performance. J. Coat. Technol. Res. 2024, 21, 2009–2022. [Google Scholar] [CrossRef]

- Fan, K.F.; Zhu, X.Y.; Yu, C.H.; Huang, J.; Zhou, S.; Lei, Y.; Li, W.; Li, R.; Wan, Y.; Li, S. Advances in pipeline wax inhibition technology based on material properties and surface modifications. Chin. Sci. Bull. Chin. 2024, 69, 5259–5270. [Google Scholar] [CrossRef]

- Devi, M.G.; Al Ghanbusi, B. Synthesis of aluminium oxide nanoparticles from waste aluminium foils for corrosion inhibition of mild steel pipe. Indian J. Chem. Technol. 2024, 31, 233–239. [Google Scholar] [CrossRef]

- Zavareh, M.A.; Sarhan, A.A.D.M.; Karimzadeh, R.; Singh, R.S.A. Analysis of corrosion protection behavior of Al2O3-TiO2 oxide ceramic coating on carbon steel pipes for petroleum industry. Ceram. Int. 2018, 44, 5967–5975. [Google Scholar] [CrossRef]

- Abd El-Mageed, A.I.A.; Desouky, M.M.; El-Sayed, M.; Salem, T.; Radwan, A.B.; Hassan, M.K.; Al-Oufy, A.K.; El-Dessouky, H.M. Carbon Fiber-Reinforced Thermoplastic Composite Coatings for Steel Pipelines. Polymers 2024, 16, 3417. [Google Scholar] [CrossRef]

- Altabey, W.A.; Wu, Z.S.; Noori, M.; Fathnejat, H. Structural Health Monitoring of Composite Pipelines Utilizing Fiber Optic Sensors and an AI-Based Algorithm-A Comprehensive Numerical Study. Sensors 2023, 23, 3887. [Google Scholar] [CrossRef]

- Chandra, K.V.; Sharma, B.S.V.; Kumar, P.N.; Mahajan, P. Development of nano filler reinforced semi-solid rapid curing sealant paste for through-thickness leaking defect repair in pipelines. J. Adhes. Sci. Technol. 2024, 38, 770–794. [Google Scholar] [CrossRef]

- Yudaev, P.; Tamboura, B.; Konstantinova, A.; Babu, H.V.; Muralidharan, K. Epoxy Resins and Their Hardeners Based on Phosphorus–Nitrogen Compounds. J. Compos. Sci. 2025, 9, 277. [Google Scholar] [CrossRef]

- Ma, L.; Gao, J.J.; Wang, Y.D.; Ge, H.; Lin, X.B.; Zhu, Z.M. Preparation of phosphorus/nitrogen-containing MXene nanohybrids via in situ polymerization and their application in epoxy resins. Prog. Org. Coat. 2025, 203, 109163. [Google Scholar] [CrossRef]

- Li, Y.; Wang, G.Q.; Guo, Y.L.; Fang, N.; Li, J.; Li, Z.; Li, J. Preparation of cardanol-based curing agent for underwater drainage pipeline repairs. E-Polymers 2024, 24, 20230190. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Ma, P.; Bi, J.J.; Ma, B.; Zhou, H.; Liu, K.; Geisbush, J.; Wu, H. Mitigating aging infrastructure risks: An optimized epoxy resin system for water supply pipeline rehabilitation. Polymer 2024, 315, 127791. [Google Scholar] [CrossRef]

- Karim, M.A.; Abdullah, M.Z.; Deifalla, A.F.; Azab, M.; Waqar, A. An assessment of the processing parameters and application of fibre-reinforced polymers (FRPs) in the petroleum and natural gas industries: A review. Results Eng. 2023, 18, 101091. [Google Scholar] [CrossRef]

- Quintella, C.M.; Rodrigues, P.D.; Hanna, S.A.; Nicoleti, J.L.; Carvalho, E.B.; de Medeiros, A.C.G.; Ramos-De-Souza, E.; dos Santos, E.S.; Vasconcelos, A.C.; de Moura, J.D.; et al. Sustainable Enhanced Oil Recovery Fluid Based on Synergic Effects of Cationic, Anionic, and Nonionic Surfactants in Low Salinity: SLS; QA; and SDBS. ACS Omega 2025, 10, 8408–8419. [Google Scholar] [CrossRef]

- Feng, Y.F.; Li, Y.D.; Deng, Q.H.; Wu, Q.; Peng, C.; Hu, J.B.; Xu, Z.C. Fast curing velocity, low volume shrinkage and high heat resistance achieved in novel ultraviolet curing adhesives. Mater. Res. Express 2018, 5, 076402. [Google Scholar] [CrossRef]

- Manjunath, R.N.; Khatkar, V.; Behera, B.K. Investigation on Seawater Ageing of PET-Epoxy Composites: An Ecological and Sustainable Approach for Marine Applications. J. Polym. Environ. 2020, 28, 2289–2300. [Google Scholar] [CrossRef]

- Merah, N.; Ashraf, F.; Shaukat, M.M. Mechanical and Moisture Barrier Properties of Epoxy-Nanoclay and Hybrid Epoxy-Nanoclay Glass Fibre Composites: A Review. Polymers 2022, 14, 1620. [Google Scholar] [CrossRef]

- Moreira, V.B.; Rintjema, J.; Bravo, F.; Kleij, A.W.; Franco, L.; Puiggalí, J.; Armelin, E. Novel Biobased Epoxy Thermosets and Coatings from Poly(limonene carbonate) Oxide and Synthetic Hardeners. ACS Sustain. Chem. Eng. 2022, 10, 2708–2719. [Google Scholar] [CrossRef] [PubMed]

- Rashed, M.K.; Salleh, M.A.M.; Abdulbari, H.A.; Ismail, M.H.S. Enhancing the Drag Reduction Phenomenon within a Rotating Disk Apparatus Using Polymer-Surfactant Additives. Appl. Sci. 2016, 6, 355. [Google Scholar] [CrossRef]

- Xu, J.; Hrnjak, P. Quantification of flow and retention of oil in compressor discharge pipe. Int. J. Refrig. Rev. Int. Du Froid 2017, 80, 252–263. [Google Scholar] [CrossRef]

- Ashikin, W.H.N.S.; Wong, T.W.; Law, C.L. Plasticity of hot air-dried mannuronate- and guluronate-rich alginate films. Carbohydr. Polym. 2010, 81, 104–113. [Google Scholar] [CrossRef]

- Foteinopoulou, K.; Karayiannis, N.C.; Mavrantzas, V.G.; Kröger, M. Primitive path identification and entanglement statistics in polymer melts: Results from direct topological analysis on atomistic polyethylene models. Macromolecules 2006, 39, 4207–4216. [Google Scholar] [CrossRef]

- Giller, C.B.; Roland, C.M. Strength Enhancement in Miscible Blends of Butyl Rubber and Polyisobutylene. Macromolecules 2013, 46, 2818–2822. [Google Scholar] [CrossRef]

- Wachowicz, M.; White, J.L. Miscible blend dynamics and thermodynamics: Quantitatively untangling slow conformational events in amorphous polymer mixtures. Macromolecules 2007, 40, 5433–5440. [Google Scholar] [CrossRef]

- GB/T4852-2002; Test Method for Tack of Pressure-Sensitive Adhesive Tapes by Rolling Ball. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2022.

- GB/T51241-2017; Technical Code for Field Joint Coatings of Pipeline. The Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2017.

- GB/T2792-2014; Measurement of Peel Adhesion Properties for Adhesive Tapes (ISO 29862:2007, Self Adhesive Tapes Determination of Pceladhesion Properties, MOD). General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China National Standardization Administration: Beijing, China, 2014.

- GB/T 5210-2006; Paints and Varnishes. Pull-Off Test for Adhesion. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China: Beijing, China, 2006.

- GB/T 6739-2022; Paints and Varnishes—Determination of Film Hardness by Pencil Test. State Administration for Market Regulation of China, Standardization Administration of China: Beijing, China, 2022.

- GB/T 1732-2020; Determination of Impact Resistance of Coating Films. State Administration for Market Regulation of China, Standardization Administration of China: Beijing, China, 2020.

- GB/T 9272-1988; Determination of Volume of Dry Coating (Non-Volatile Matter) in a Given Volume of Liquid Coating. Ministry of Chemical Industry of the People’s Republic of China: Beijing, China, 1988.

| Parts by Weight | 1# | 2# | 3# | 4# | 5# |

|---|---|---|---|---|---|

| Number of Copies | |||||

| IIR | 240 | 192 | 168 | 144 | 120 |

| PIB | 0 | 48 | 72 | 96 | 120 |

| Equipment | Contents of the Experiment (Brand and Model Name, Manufacturers and Locations, Test Details) |

|---|---|

| Single-screw extruder | JYM SJ 30, (qdjingke Plastic Machinery Co., Ltd., Qingdao, Shandong Province, China, prepared composite samples with fiber-reinforced mesh sandwiched between them) |

| Universal testing machine | WDW i5, (Shandong Shijin Instrument Equipment Co., Ltd., Jinan, Shandong Province, China; HST UTM5305, Jinan Hengsi Shengda Instrument Co., Ltd. Jinan, Shandong Province, China; initial adhesion test and underwater adhesion performance test) |

| Adhesion tester | KT-500Z, (Shenzhen KeTan Electronic Technology Co., Ltd., Shenzhen, Guangdong Province, China, adhesion test experiment (100 × 100 mm, apply thickness of 0.3–0.5 mm)) |

| Thermal oven | KV 101-2A, (Shandong Yisheng Heavy Industry Technology Co., Ltd., Taian, Shandong Province, China, drying test (100 × 100, apply thickness of 0.3–0.5 mm)) |

| Pencil hardness rating tester | OU4300-2H, (Cangzhou Oupu Testing Instrument Co., Ltd., Cangzhou, Hebei Province, China, determination of coating surface hardness (100 × 100, apply thickness of 0.3–0.5 mm)) |

| Impact tester | BF-F-315ST, (Guangdong Bell Experiment Equipment Co., Ltd., Dongguan, Guangdong Province, China, determination of the overall hardness of the sample via the free-fall experiment (100 × 100, apply thickness of 0.3–0.5 mm)) |

| Item | Technical Specifications |

|---|---|

| Color | Dark red |

| Solid content, % | 99.3 |

| Adhesion, MPa | 3 |

| Impact resistance, cm | 50 |

| Drying time, h | Surface dry ≤ 1.5 |

| Thoroughly dry ≤ 24 | |

| Pencil hardness | 6H |

| Temperature resistance | 120 °C |

| Salt spray resistance | No abnormality after 1000 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Wan, J.; Qv, X.; Yu, Y.; Zhao, H. Research on High-Performance Underwater-Curing Polymer Composites for Offshore Oil Riser Pipes. Polymers 2025, 17, 1827. https://doi.org/10.3390/polym17131827

Zhao X, Wan J, Qv X, Yu Y, Zhao H. Research on High-Performance Underwater-Curing Polymer Composites for Offshore Oil Riser Pipes. Polymers. 2025; 17(13):1827. https://doi.org/10.3390/polym17131827

Chicago/Turabian StyleZhao, Xuan, Jun Wan, Xuefeng Qv, Yajun Yu, and Huiyan Zhao. 2025. "Research on High-Performance Underwater-Curing Polymer Composites for Offshore Oil Riser Pipes" Polymers 17, no. 13: 1827. https://doi.org/10.3390/polym17131827

APA StyleZhao, X., Wan, J., Qv, X., Yu, Y., & Zhao, H. (2025). Research on High-Performance Underwater-Curing Polymer Composites for Offshore Oil Riser Pipes. Polymers, 17(13), 1827. https://doi.org/10.3390/polym17131827