The Design and Evaluation of Twisted HDPE Grass-Cutting Lines: A Performance Comparison with Commercial Nylon

Abstract

1. Introduction

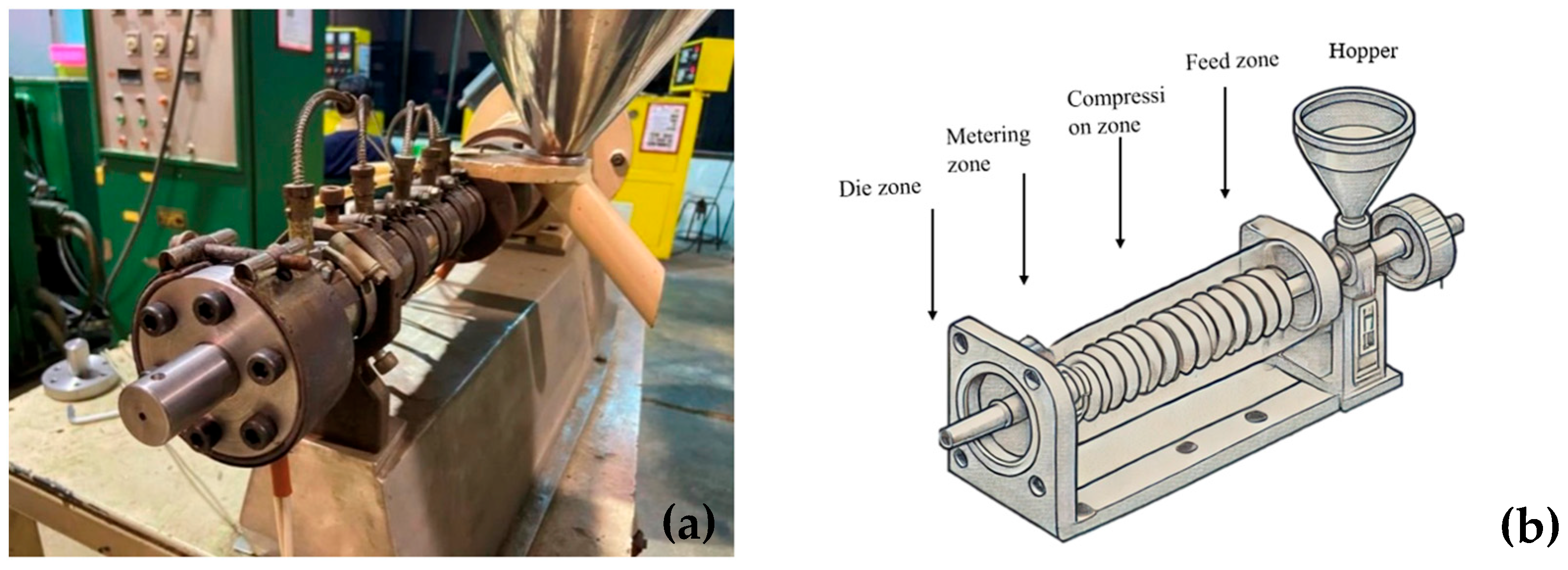

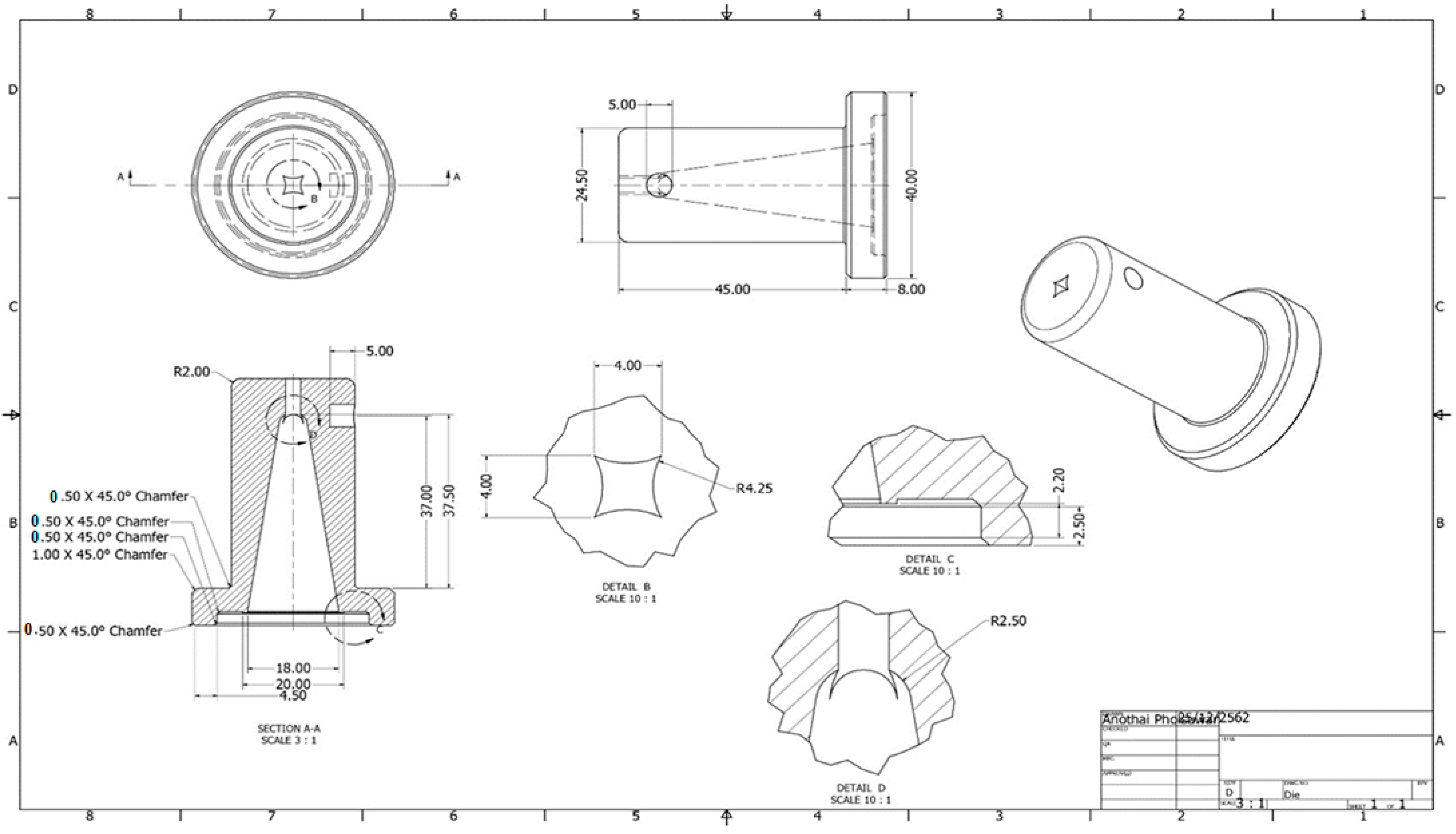

2. Materials and Methods

2.1. Materials and Preparation

2.2. Characterization

3. Results

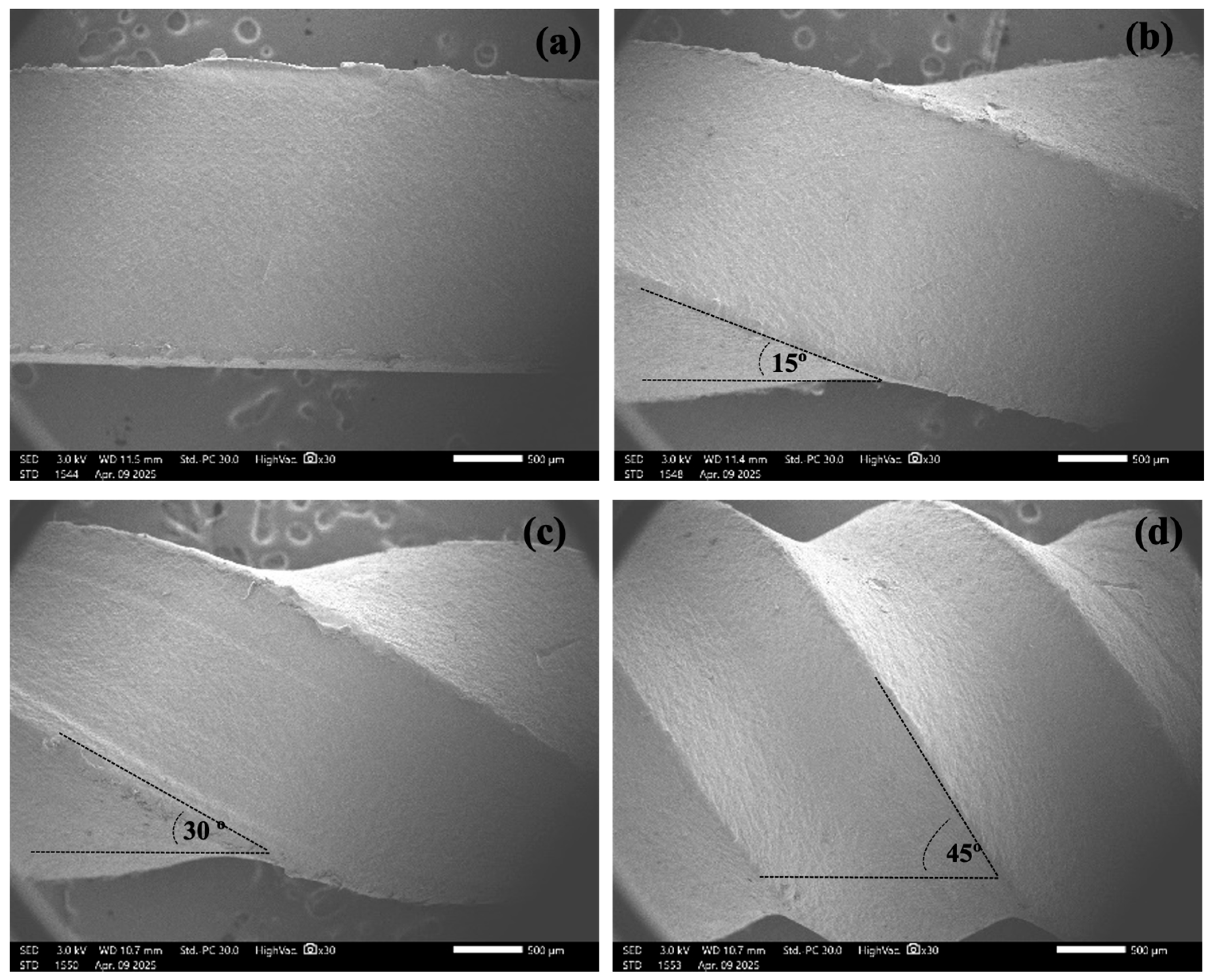

3.1. Macroscopic Structure of HDPE Twisted Grass-Cutting Lines

3.2. Mechanical Property Comparison Between Commercially Available and Twisted HDPE Grass-Cutting Lines

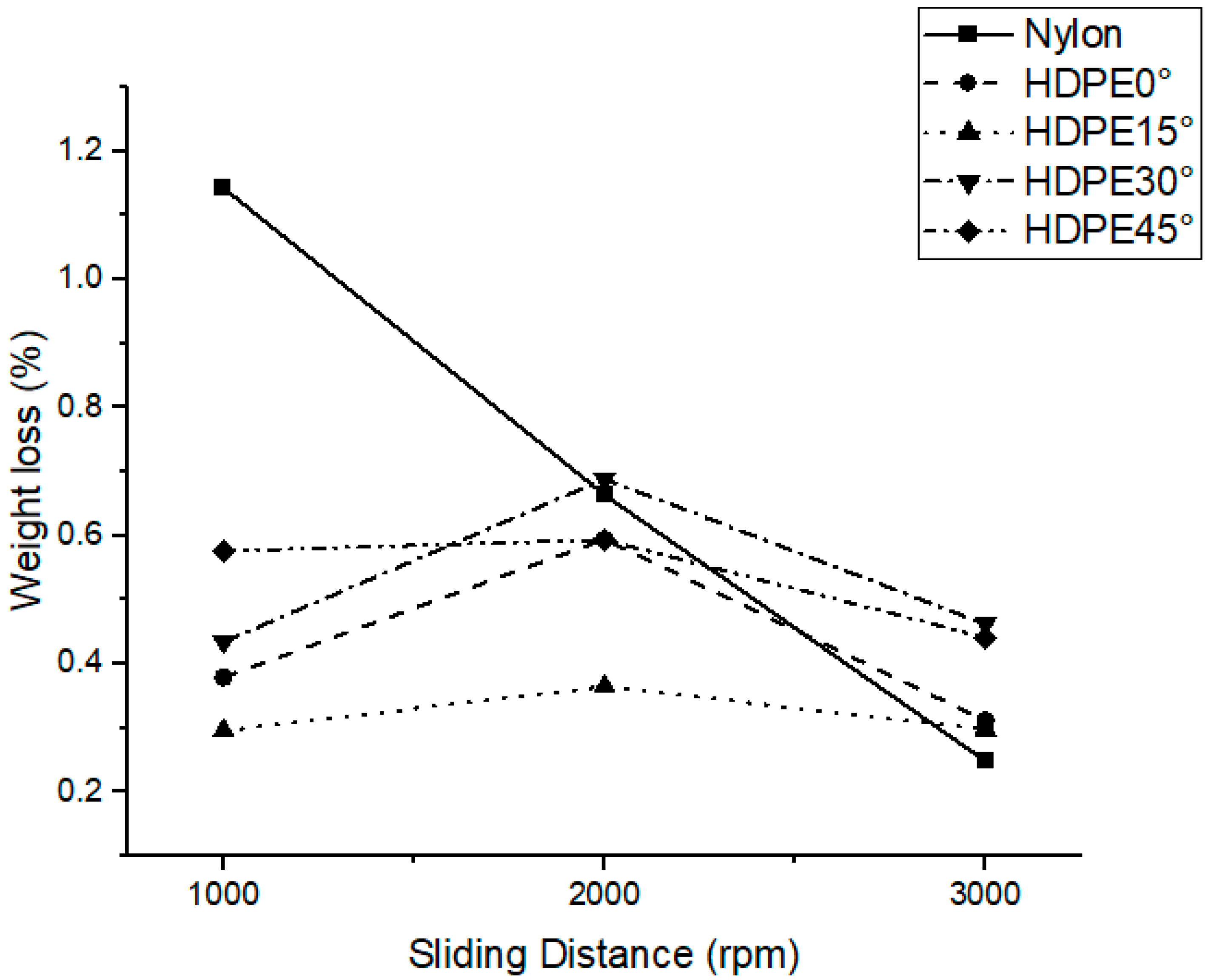

3.3. Wear Resistance of Grass-Cutting Lines

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alexander, B.M.; Graydon, P.S.; Pena, M.; Feng, H.A.; Beamer, B.R. Hazardous exposures and engineering controls in the landscaping services industry. J. Occup. Environ. Hyg. 2025, 22, 189–202. [Google Scholar] [CrossRef]

- Kotus, M.; Drlička, R.; Mikuš, R.; Žarnovský, J. Hazard analysis and risk assessment in metal cutting process. Multidiscip. Asp. Prod. Eng. 2019, 2, 382–391. [Google Scholar] [CrossRef]

- Chinniah, Y. Analysis and prevention of serious and fatal accidents related to moving parts of machinery. Saf. Sci. 2015, 75, 163–173. [Google Scholar] [CrossRef]

- Hanson, E.; Boland, M. Safety climate at agricultural cooperatives. J. Saf. Res. 2020, 75, 150–154. [Google Scholar] [CrossRef] [PubMed]

- Bull, M.J.; Agran, P.; Gardner, H.G.; Laraque, D.; Pollack, S.H.; Smith, G.A.; Spivak, H.R.; Tenebein, M.; Brenner, R.A.; Bryn, S.; et al. Lawn Mower-Related Injuries to Children. Pediatrics 2001, 107, 1480–1481. [Google Scholar] [CrossRef]

- Lau, S.T.; Lee, Y.-H.; Hess, D.J.; Brisseau, G.F.; Keleher, G.E.; Caty, M.G. Lawnmower injuries in children: A 10-year experience. Pediatr. Surg. Int. 2006, 22, 209–214. [Google Scholar] [CrossRef]

- Hottinger, D.G.; Nasr, I.; Canner, J.K.; Kattail, D.; Koka, R.; Schwengel, D. Incidence, Distribution, and Cost of Lawn-Mower Injuries in the United States, 2006–2013. Public Health Rep. 2018, 133, 570. [Google Scholar] [CrossRef]

- Khansa, I.; Pearson, G.D.; Bjorklund, K.; Fogolin, A.; Kirschner, R.E. Pediatric Lawnmower Injuries: A 25-year Review. JPRAS Open 2021, 29, 135–143. [Google Scholar] [CrossRef] [PubMed]

- Harris, C.; Madonick, J.; Hartka, T.R. Lawn mower injuries presenting to the emergency department: 2005 to 2015. Am. J. Emerg. Med. 2018, 36, 1565–1569. [Google Scholar] [CrossRef]

- Smith, G.A. Technical Report: Lawn Mower-Related Injuries to Children. Pediatrics 2001, 107, e106. [Google Scholar] [CrossRef]

- Pipatrattanathaworn, W.; Ausayakhun, S.; Tantraworasin, A. Clinical Features and Visual Outcomes of Eye and Orbital Injuries in Northern Thailand. J. Med. Assoc. Thail. 2019, 102, 564–569. [Google Scholar]

- Rodgers, B.; Waddell, W. Tire Engineering. In The Science and Technology of Rubber; Elsevier: Amsterdam, The Netherlands, 2013; pp. 653–695. [Google Scholar]

- Mukhopadhyay, S.K. Manufacturing, properties and tensile failure of nylon fibres. In Handbook of Tensile Properties of Textile and Technical Fibres; Elsevier: Amsterdam, The Netherlands, 2009; pp. 197–222. [Google Scholar]

- Crawford, R.J.; Throne, J.L. Rotational Molding Polymers. In Rotational Molding Technology; Elsevier: Amsterdam, The Netherlands, 2002; pp. 19–68. [Google Scholar]

- Rosato, D.V.; Rosato, D.V.; Rosato, M.V. Plastic Property. In Plastic Product Material and Process Selection Handbook; Elsevier: Amsterdam, The Netherlands, 2004; pp. 40–129. [Google Scholar]

- Seltzer, R.; Frontini, P.M.; Mai, Y.-W. Effect of hygrothermal ageing on morphology and indentation modulus of injection moulded nylon 6/organoclay nanocomposites. Compos. Sci. Technol. 2009, 69, 1093–1100. [Google Scholar] [CrossRef]

- Hybart, F.J.; Platt, J.D. The melting of 66 nylon: Observations by differential thermal analysis. J. Appl. Polym. Sci. 1967, 11, 1449–1460. [Google Scholar] [CrossRef]

- Fan, N.; Guo, P.Q.; Fu, X.L. Study on Nylon Cutting Properties Based on Cutting Temperature with Material Properties in Manufacturing System. Appl. Mech. Mater. 2012, 252, 319–322. [Google Scholar] [CrossRef]

- Grigore, M. Methods of Recycling, Properties and Applications of Recycled Thermoplastic Polymers. Recycling 2017, 2, 24. [Google Scholar] [CrossRef]

- Nofar, M.; Sacligil, D.; Carreau, P.J.; Kamal, M.R.; Heuzey, M.-C. Poly (lactic acid) blends: Processing, properties and applications. Int. J. Biol. Macromol. 2019, 125, 307–360. [Google Scholar] [CrossRef]

- Cao, M.; Cui, T.; Yue, Y.; Li, C.; Guo, X.; Jia, X.; Wang, B. Preparation and Characterization for the Thermal Stability and Mechanical Property of PLA and PLA/CF Samples Built by FFF Approach. Materials 2023, 16, 5023. [Google Scholar] [CrossRef]

- Abbas, A.T.; El Rayes, M.M.; Al-Abduljabbar, A.A.; Ragab, A.E.; Benyahia, F.; Elkaseer, A. Effects of Tool Edge Geometry and Cutting Conditions on the Performance Indicators in Dry Turning AISI 1045 Steel. Machines 2023, 11, 397. [Google Scholar] [CrossRef]

- Kuo, C.; Liu, J.; Chang, T.; Ko, S. The effects of cutting conditions and tool geometry on mechanics, tool wear and machined surface integrity when routing CFRP composites. J. Manuf. Process 2021, 64, 113–129. [Google Scholar] [CrossRef]

- Sedlak, J.; Zouhar, J.; Kolomy, S.; Slany, M.; Necesanek, E. Effect of high-speed steel screw drill geometry on cutting performance when machining austenitic stainless steel. Sci. Rep. 2023, 13, 9233. [Google Scholar] [CrossRef] [PubMed]

- Hardt, D.E.; Webb, R.D.; Suh, N.P. Sheet Metal Die Forming Using Closed-Loop Shape Control. CIRP Ann. 1982, 31, 165–169. [Google Scholar] [CrossRef]

- Shawn Cheng, H.; Cao, J.; Xia, Z.C. An accelerated springback compensation method. Int. J. Mech. Sci. 2007, 49, 267–279. [Google Scholar] [CrossRef]

- Zhao, X.; Hu, H.; Wang, X.; Yu, X.; Zhou, W.; Peng, S. Super tough poly(lactic acid) blends: A comprehensive review. RSC Adv. 2020, 10, 13316–13368. [Google Scholar] [CrossRef] [PubMed]

- Alves Fidelis, M.E.; Pereira, T.V.C.; Gomes, O.d.F.M.; de Andrade Silva, F.; Toledo Filho, R.D. The effect of fiber morphology on the tensile strength of natural fibers. J. Mater. Res. Technol. 2013, 2, 149–157. [Google Scholar] [CrossRef]

- Galea, T.; Mills, T.; Halliwell, R.; Jayaraman, K. Screwless Extrusion of Natural Fibre-Reinforced Thermoplastic Composites. In Composite Technologies for 2020; Elsevier: Amsterdam, The Netherlands, 2004; pp. 27–32. [Google Scholar]

- Rao, Y.; Farris, R.J. A modeling and experimental study of the influence of twist on the mechanical properties of high-performance fiber yarns. J. Appl. Polym. Sci. 2000, 77, 1938–1949. [Google Scholar] [CrossRef]

- Harker, K.R.; Velinsky, S.A. Analysis of a Rotary Head for Cutting Vegetation. Mech. Based Des. Struct. Mach. 2006, 34, 293–306. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Lambeth, R.H. Recycled polyethylene terephthalate as a new FFF feedstock material. Addit. Manuf. 2018, 21, 174–182. [Google Scholar] [CrossRef]

- Koller, M. Advances in Polyhydroxyalkanoate (PHA) Production. Bioengineering 2017, 4, 88. [Google Scholar] [CrossRef]

- Bijaisoradat, O.; Luttapreecha, M.; Manuspiya, H. Eco composites with synergistic combinations of natural rubber latex and wood flour toughened recycled HDPE. Mater. Today Commun. 2020, 25, 101483. [Google Scholar] [CrossRef]

- Bahadur, S. The development of transfer layers and their role in polymer tribology. Wear 2000, 245, 92–99. [Google Scholar] [CrossRef]

- Jain, V.K.; Bahadur, S. Material transfer in polymer-polymer sliding. Wear 1978, 46, 177–188. [Google Scholar] [CrossRef]

| Properties | ||

|---|---|---|

| Functional Groups | (–CH2–CH2–) | (–CONH–) |

| Mechanical Properties | ||

| Tensile Strength (MPa) | 20–37 | 60–100 |

| Hardness (Shore D) | 55–70 | 75–85 |

| Coefficient of Friction (COF) | ||

| - Static COF | 0.20–0.30 | 0.25–0.35 |

| - Dynamic (Kinetic) COF | 0.10–0.22 | 0.25–0.40 |

| Thermal Properties | ||

| Melting Point (°C) | 180 | 240 |

| Specific Heat (J/kg·K) | 2300 | 1700 |

| Latent Heat of Melting (J/kg) | 240 | 160 |

| Price (USD per kg) | 1.11 | 2.04 |

| Zone | Temperature (°C) |

|---|---|

| Feed Zone | 140 |

| Compression Zone | 150 |

| Metering Zone | 160 |

| Die Zone | 180 |

| Angle (°) | Tension Speed (rpm) | Rotation Speed (rpm) |

|---|---|---|

| 0 | 35 | 0 |

| 15 | 35 | 10 |

| 30 | 35 | 20 |

| 45 | 35 | 35 |

| Type of Grass-Cutting Line | Tensile Strength (MPa) | Elongation (%) | Elastic Modulus (MPa) |

|---|---|---|---|

| Square (Commercially Available) | 350.39 ± 2.50 | 346 ± 3 | 768.34 ± 1.80 |

| Twisted HDPE (0°) | 36.60 ± 1.40 | 619.47 ± 0.84 | 36.50 ± 2.26 |

| Twisted HDPE (15°) | 30.84 ± 1.30 | 476.9 ± 1.09 | 19.31 ± 1.54 |

| Twisted HDPE (30°) | 35.70 ± 0.93 | 604.36 ± 4.71 | 34.63 ± 1.04 |

| Twisted HDPE (45°) | 39.24 ± 1.27 | 605.43 ± 2.31 | 40.50 ± 1.53 |

| Grass-Cutting Line Type | Weight of Cut Grass (g) |

|---|---|

| Commercially available grass-cutting lines | |

| Square | 203 |

| Twisted grass-cutting lines | |

| Twisted HDPE (0°) | 105 |

| Twisted HDPE (15°) | 164 |

| Twisted HDPE (30°) | 133 |

| Twisted HDPE (45°) | 210 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pholsuwan, A.; Chailad, W.; Simpraditpan, A.; Martwong, E.; Chattrakul, K. The Design and Evaluation of Twisted HDPE Grass-Cutting Lines: A Performance Comparison with Commercial Nylon. Polymers 2025, 17, 1804. https://doi.org/10.3390/polym17131804

Pholsuwan A, Chailad W, Simpraditpan A, Martwong E, Chattrakul K. The Design and Evaluation of Twisted HDPE Grass-Cutting Lines: A Performance Comparison with Commercial Nylon. Polymers. 2025; 17(13):1804. https://doi.org/10.3390/polym17131804

Chicago/Turabian StylePholsuwan, Anothai, Wichain Chailad, Athapon Simpraditpan, Ekkachai Martwong, and Kawita Chattrakul. 2025. "The Design and Evaluation of Twisted HDPE Grass-Cutting Lines: A Performance Comparison with Commercial Nylon" Polymers 17, no. 13: 1804. https://doi.org/10.3390/polym17131804

APA StylePholsuwan, A., Chailad, W., Simpraditpan, A., Martwong, E., & Chattrakul, K. (2025). The Design and Evaluation of Twisted HDPE Grass-Cutting Lines: A Performance Comparison with Commercial Nylon. Polymers, 17(13), 1804. https://doi.org/10.3390/polym17131804