Ultralow-Resistance High-Voltage Loaded Woven Air Filter for Fine Particle/Bacteria Removal

Abstract

1. Introduction

2. Materials and Methods

2.1. Filter Preparation

2.2. Filter Characterization and Simulation

3. Results and Discussion

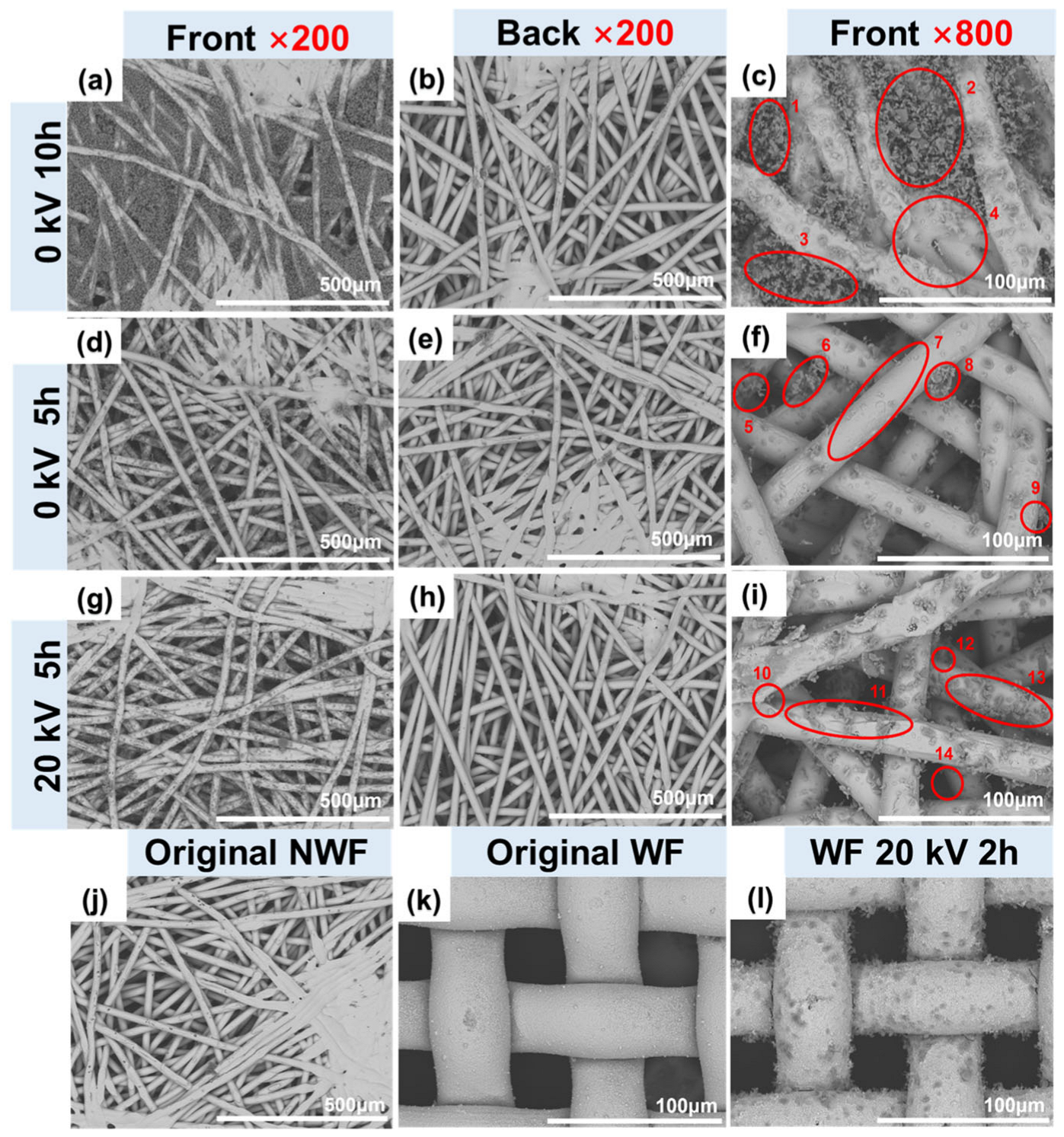

3.1. Effects of DOPA Modification Duration on the Surface Morphological, Chemical, and Electrical Properties

3.2. Effects of Base Fabric Structure on the Permeability, Mechanical, and Electrical Properties of Filters

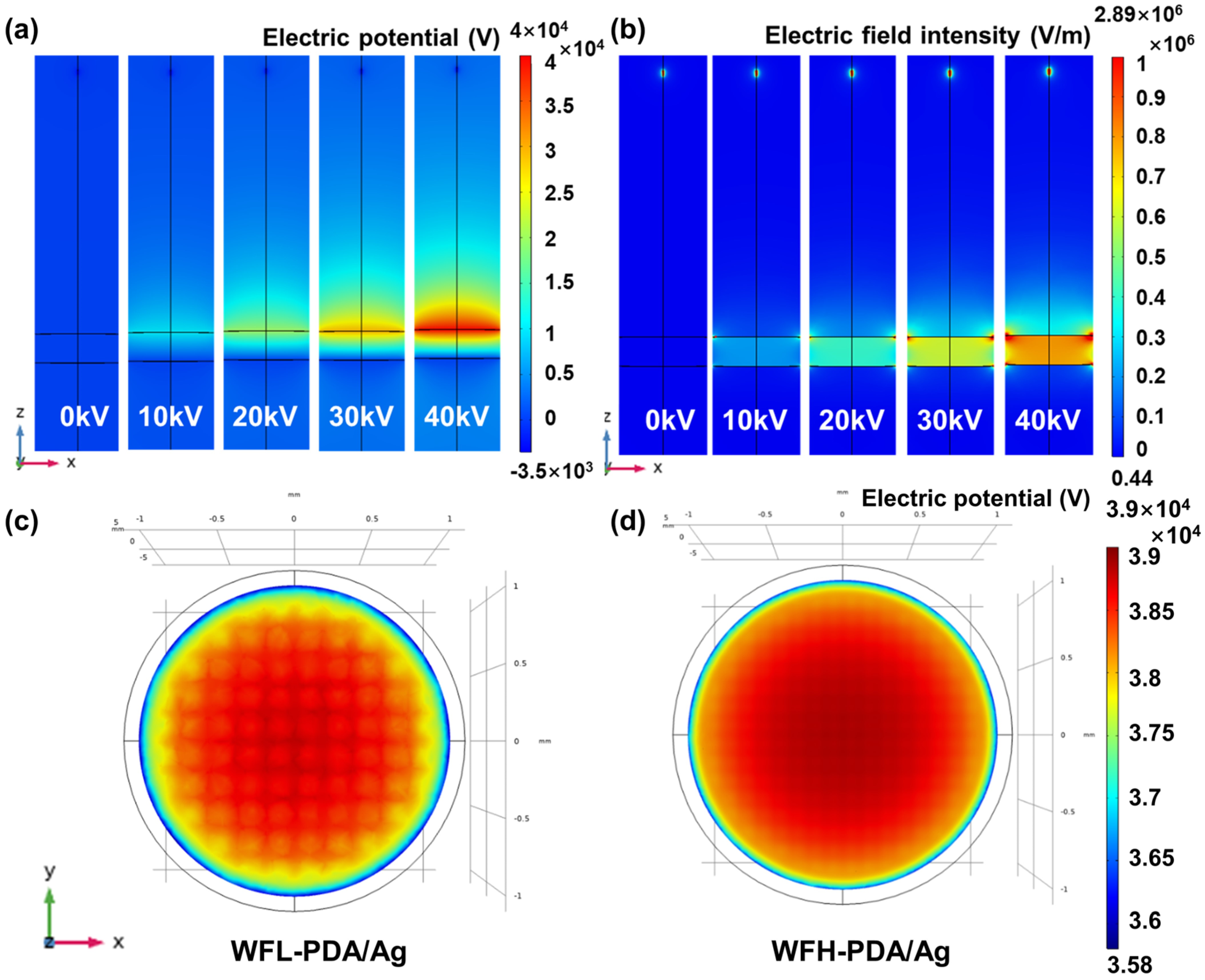

3.3. Effect of the Filter Structure on the Filtration Performance

3.4. Reusability of Voltage Loading Woven Air Filters

3.5. Dust Accumulation Behaviors on Filters

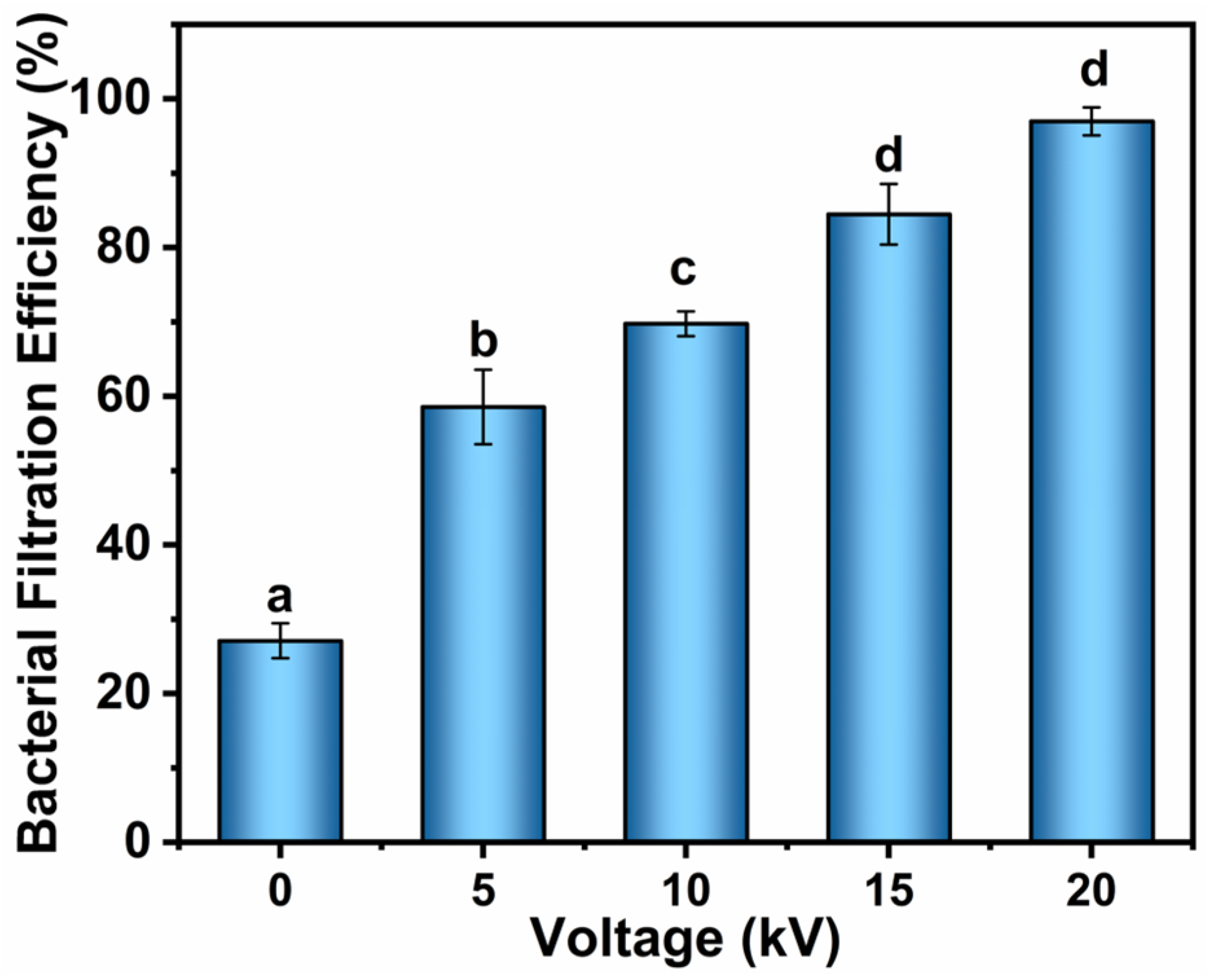

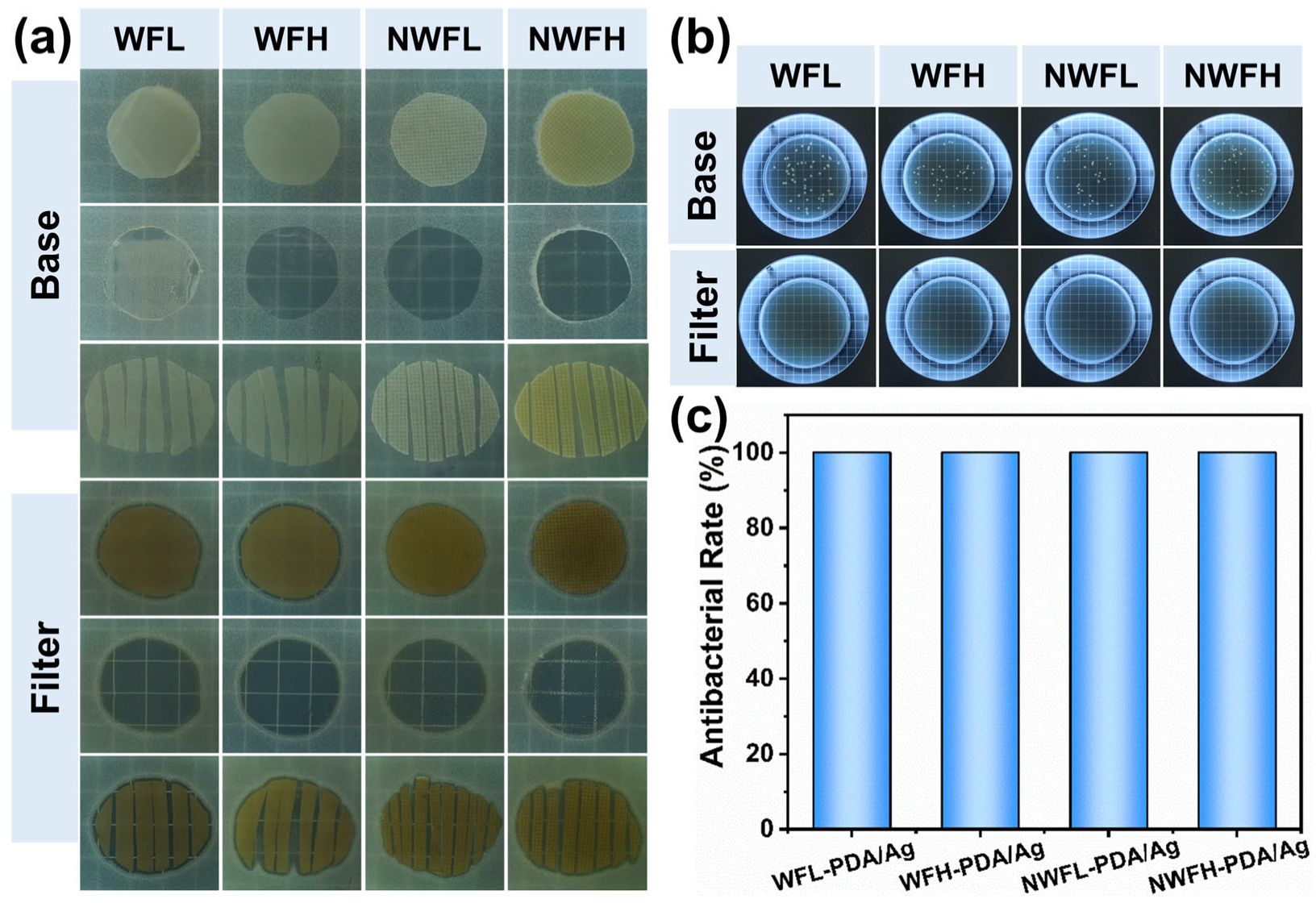

3.6. Performance of Bacterial Removal

4. Conclusions

5. Patents

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PET | Polyethylene terephthalate |

| VLWF | High-voltage loaded woven filtration |

| WFL | Low density woven fabric |

| WFH | High density woven fabric |

| NWFL | Low density nonwoven fabric |

| NWFH | High density nonwoven fabric |

| DOPA | Dopamine hydrochloride |

| HVs | High voltages |

| PD | Pressure drop |

| QF | Quality factor |

| CQF | Comprehensive quality factor |

| TPA | Total power consumption per unit area |

| RPs | Removed particles |

References

- Tian, E.; Yu, Q.; Gao, Y.; Wang, H.; Wang, C.; Zhang, Y.; Li, B.; Zhu, M.; Mo, J.; Xu, G.; et al. Ultralow Resistance Two-Stage Electrostatically Assisted Air Filtration by Polydopamine Coated PET Coarse Filter. Small 2021, 17, 2102051. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.W.; An, S.; Seok, H.; Yarin, A.L.; Yoon, S.S. Transparent Metallized Microfibers as Recyclable Electrostatic Air Filters with Ionization. ACS Appl. Mater. Interfaces 2020, 12, 25266–25275. [Google Scholar] [CrossRef] [PubMed]

- Xiang, J.; Seto, E.; Mo, J.; Zhang, J.; Zhang, Y. Impacts of implementing Healthy Building guidelines for daily PM2.5 limit on premature deaths and economic losses in urban China: A population-based modeling study. Environ. Int. 2021, 147, 106342. [Google Scholar] [CrossRef] [PubMed]

- Wahid, A.; Zhang, H.; Qin, X. Electrospun nanofiber membranes with micro-gradient structure for highly efficient air filtration applications. Mater. Lett. 2025, 389, 138330. [Google Scholar] [CrossRef]

- Liu, F.; Wang, H.; Liu, M.; Lu, Z.; Lin, Z.; Chen, Y. Research on the process of preparing fiber filtration membrane by centrifugal blowing electrospinning technology. Appl. Polym. Sci. 2024, 141, e56172. [Google Scholar] [CrossRef]

- Martins, N.R.; Graca, G.C.D. Impact of PM2.5 in indoor urban environments: A review. Sustain. Cities Soc. 2018, 42, 259–275. [Google Scholar] [CrossRef]

- Soares, M.; Oliveira, H.; Alves, C. Airborne particulate matter inhalation bioaccessibility: A review of methodological aspects. Chem. Biol. Interact. 2025, 408, 111403. [Google Scholar] [CrossRef]

- Xue, T.; Kang, N.; Zhu, T. Health-Oriented Strategy for Clean Air and Climate Actions: Differential Health Effects of Atmospheric Components. Annu. Rev. Public Health 2025, 46, 275–294. [Google Scholar] [CrossRef]

- Dutta, S.; Bansal, P. Sustainability aspect of wearable clean room filters: A review. Polym. Bull. 2025, s00289. [Google Scholar] [CrossRef]

- Liu, H.; Cao, C.; Huang, J.; Chen, Z.; Chen, G.; Lai, Y. Progress on particulate matter filtration technology:Basic concepts, advanced materials, and performances. Nanoscale 2020, 12, 437–453. [Google Scholar] [CrossRef]

- Wang, F.; Meng, D.; Li, X.; Tan, J. Indoor-outdoor relationships of PM2.5 in four residential dwellings in winter in the Yangtze River Delta, China. Environ. Pollut. 2016, 215, 280–289. [Google Scholar] [CrossRef] [PubMed]

- Rosner, D.E.; Arias-Zugasti, M. Predicting the aerosol capture characteristics of fibrous filters. I. Exact- and tractable (3-moment) approximate-methods to incorporate aerosol polydispersity effects with a multi-mechanism, semi-analytic single-fiber particle capture fraction. Sep. Purif. Technol. 2021, 257, 117676. [Google Scholar] [CrossRef]

- Abdul-Wahab, S.; Fadlallah, S.; Al-Rashdi, M. Evaluation of the impact of ground-level concentrations of SO2, NOx, CO, and PM10 emitted from a steel melting plant on Muscat, Oman. Sustain. Cities Soc. 2018, 38, 675–683. [Google Scholar] [CrossRef]

- Tian, E.; Mo, J. Toward energy saving and high efficiency through an optimized use of a PET coarse filter: The development of a new electrostatically assisted air filter. Energy Build 2019, 186, 276–283. [Google Scholar] [CrossRef]

- Zhao, K.; Huang, J.; Mao, J.; Bao, Z.; Chen, Z.; Lai, Y. Charged graphene aerogel filter enabled superior particulate matter removal efficiency in harsh environment. Chem. Eng. 2020, 395, 125086. [Google Scholar] [CrossRef]

- Wang, Q.; Khan, F.; Wei, L.; Shen, H.; Zhang, C.; Jiang, Q.; Qiu, Y. Filtration properties of carbon woven fabric filters supplied with high voltage for removal of PM 1.0 particles. Sep. Purif. Technol. 2017, 177, 40–48. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Y.; Liu, W.; Jin, X. Needle-punched electret air filters (NEAFs) with high filtration efficiency, low filtration resistance, and superior dust holding capacity. Sep. Purif. Technol. 2022, 282, 120146. [Google Scholar] [CrossRef]

- Li, C.L.; Song, W.Z.; Sun, D.J.; Zhang, M.; Zhang, J.; Chen, Y.Q.; Ramakrishna, S.; Long, Y.Z. A self-priming air filtration system based on triboelectric nanogenerator for active air purification. Chem. Eng. 2023, 452, 139428. [Google Scholar] [CrossRef]

- Kim, M.W.; An, S.; Seok, H.; Yoon, S.S.; Yarin, A.L. Electrostatic Transparent Air Filter Membranes Composed of Metallized Microfibers for Particulate Removal. ACS Appl. Mater. Interfaces 2019, 11, 26323–26332. [Google Scholar] [CrossRef]

- Joubert, A.; Abd Ali, S.A.Z.; Frossard, M.; Andrès, Y. Dust and microbial filtration performance of regular and antimicrobial HVAC filters in realistic conditions. Environ. Sci. Pollut. Res. 2021, 28, 39907–39919. [Google Scholar] [CrossRef]

- Jafari, M.; Shim, E.; Joijode, A. Fabrication of Poly(lactic acid) filter media via the meltblowing process and their filtration performances: A comparative study with polypropylene meltblown. Sep. Purif. Technol. 2021, 260, 118185. [Google Scholar] [CrossRef]

- Guo, J.; Hanif, A.; Shang, J.; Deka, B.J.; Zhi, N.; An, A.K. PAA@ZIF-8 incorporated nanofibrous membrane for high-efficiency PM2.5 capture. Chem. Eng. 2021, 405, 126584. [Google Scholar] [CrossRef]

- Wang, G.; Sun, L.; Zhao, B.; Fang, Y.; Qi, Y.; Ning, G.; Ye, J. Reusable Electrospun Nanofibrous Membranes with Antibacterial Activity for Air Filtration. ACS Appl. Nano Mater. 2023, 6, 10872–10880. [Google Scholar] [CrossRef]

- Kim, S.; Sioutas, C.; Chang, M. Electrostatic Enhancement of the Collection Efficiency of Stainless Steel Fiber Filters. Aerosol Sci. Technol. 2000, 32, 197–213. [Google Scholar] [CrossRef]

- Choi, D.Y.; Jung, S.-H.; Song, D.K.; An, E.J.; Park, D.; Kim, T.-O.; Jung, J.H.; Lee, H.M. Al-Coated Conductive Fibrous Filter with Low Pressure Drop for Efficient Electrostatic Capture of Ultrafine Particulate Pollutants. ACS Appl. Mater. Interfaces 2017, 9, 16495–16504. [Google Scholar] [CrossRef]

- Zhao, P.; Riesch, J.; Höschen, T.; Almanstötter, J.; Balden, M.; Coenen, J.W.; Himml, R.; Pantleon, W.; Toussaint, U.V.; Neu, R. Microstructure, mechanical behaviour and fracture of pure tungsten wire after different heat treatments. Int. J. Refract. Met. Hard Mater. 2017, 68, 29–40. [Google Scholar] [CrossRef]

- Wang, C.; Jiang, J.; Wang, P.; Kong, L.; Liu, J. Exploring the potential of a novel electrostatic precipitator as an alternative to air filters in air purifiers. Build Environ. 2025, 270, 112535. [Google Scholar] [CrossRef]

- Güler, O.; Varol, T.; Alver, Ü.; Çanakçı, A. The effect of flake-like morphology on the coating properties of silver coated copper particles fabricated by electroless plating. J. Alloys Compd. 2019, 782, 679–688. [Google Scholar] [CrossRef]

- Kim, Y.I.; Kim, M.W.; An, S.; Yarin, A.L.; Yoon, S.S. Reusable Filters Augmented with Heating Microfibers for Antibacterial and Antiviral Sterilization. ACS Appl. Mater. Interfaces 2020, 13, 857–867. [Google Scholar] [CrossRef]

- Liu, G.; Zhou, N.; Xiong, Q. Preparation of highly conductive and flexible Ag-coated single fiberglass via dopamine functionalization and electroless depositing. Mater. Sci. Mater. Electron 2021, 32, 3661–3672. [Google Scholar] [CrossRef]

- Cui, A.; Yao, J.; Xu, J.; Wang, R.; Hao, L. Fabricating durable conductive coatings from PEDOT: PSS/Ag composite and PDA by sustainable ink-jet printing on cotton fabric. Prog. Org. Coat. 2024, 192, 108497. [Google Scholar] [CrossRef]

- Sun, J.; Hu, J.; Liang, M.; Gao, L.; Cao, H.; Liu, T.; Zhao, Y.; Wei, J.; Zhang, H.; Wang, H.; et al. Rapid preparation of mussel-inspired coatings with adjustable properties under electrochemical drive. Surf. Interfaces 2025, 61, 106121. [Google Scholar] [CrossRef]

- Tan, S.; Song, S.; Pang, L.; Zhang, X.; Xu, R.; Zheng, J.; Zhao, S.; Li, L. Construction of effective conductive network of the core-shell SiO2 microspheres hybrid MWCNTs in NR matrix. Compos. Commun. 2025, 56, 102382. [Google Scholar] [CrossRef]

- Ren, X.; Hao, R.; Yang, Y.; Zhao, G.; Liu, Y.; Duan, H. A facile and green strategy to achieve metallized woven carbon fiber through the triple roles of dopamine in in-situ thermal reduction of Ag. Compos. Commun. 2023, 40, 101585. [Google Scholar] [CrossRef]

- Duygulu, N.E.; Altinbay, A.; Ciftci, F. Antibacterial, Mechanical, and Thermal Properties of Ag, ZnO, TiO2 Reinforced PVA Nanocomposite Fibers. ChemistrySelect 2024, 9, e202402311. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, H.; Liu, S.; Shao, H.; Fu, S.; Rutledge, G.C.; Lin, T. Durable, self-healing, superhydrophobic fabrics from fluorine-free, waterborne, polydopamine/alkyl silane coatings. RSC Adv. 2017, 7, 33986–33993. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, X.; Wei, J.; Wu, H. Characterization and Application to Fiber Reinforced Composite of Catechol/polyethyleneimine Modified Polyester Fabrics by Mussel-inspiration. Fibers Polym. 2020, 21, 2625–2634. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, S.; Mahmood, K.; Jin, Y.; Huang, C.; Huang, Z.; Zhang, S.; Ming, W. Fabrication of multifunctional PET fabrics with flame retardant, antibacterial and superhydrophobic properties. Prog. Org. Coat. 2021, 157, 106296. [Google Scholar] [CrossRef]

- Du, J.; Jing, C. One-step fabrication of dopamine-inspired Au for SERS sensing of Cd2+ and polycyclic aromatic hydrocarbons. Anal. Chim. Acta 2019, 1062, 131–139. [Google Scholar] [CrossRef]

- Zhu, S.; Gu, Z.; Xiong, S.; An, Y.; Liu, Y.; Yin, T.; You, J.; Hu, Y. Fabrication of a novel bio-inspired collagen–polydopamine hydrogel and insights into the formation mechanism for biomedical applications. RSC Adv. 2016, 6, 66180–66190. [Google Scholar] [CrossRef]

- Wang, W.; Cheng, W.; Tian, M.; Zou, H.; Li, L.; Zhang, L. Preparation of PET/Ag hybrid fibers via a biomimetic surface functionalization method. Electrochim. Acta 2012, 79, 37–45. [Google Scholar] [CrossRef]

- Wang, N.; Yang, Y.; Al-Deyab, S.S.; El-Newehy, M.; Yu, J.; Ding, B. Ultra-light 3D nanofibre-nets binary structured nylon 6–polyacrylonitrile membranes for efficient filtration of fine particulate matter. Mater. Chem. 2015, 3, 23946–23954. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, J.; Nie, X.; Fan, Y.; Wang, H.; Cui, Y. Establishment of air fiber filtration model based on fractal theory and analysis of filtration performances. Mater. Today Commun. 2023, 34, 105301. [Google Scholar] [CrossRef]

- Lee, K.S.; Hasolli, N.; Lee, J.R.; Kim, K.D.; Kim, S.D.; Park, Y.O.; Hwang, J. Dust loading performance of a non-electret HVAC filter module in the presence of an external electric field. Sep. Purif. Technol. 2020, 250, 117204. [Google Scholar] [CrossRef]

- Tian, E.; Mo, J.; Li, X. Electrostatically assisted metal foam coarse filter with small pressure drop for efficient removal of fine particles: Effect of filter medium. Build Environ. 2018, 144, 419–426. [Google Scholar] [CrossRef]

- Standard Test Method for Characterizing the Pressure Drop and Filtration Performance of Cleanable Filter Media. Available online: https://store.astm.org/d6830-02.html (accessed on 20 June 2025).

- Feng, Z.; Long, Z.; Mo, J. Experimental and theoretical study of a novel electrostatic enhanced air filter (EEAF) for fine particles. Aerosol Sci. 2016, 102, 41–54. [Google Scholar] [CrossRef]

- Tian, E.; Xia, F.; Wu, J.; Zhang, Y.; Li, J.; Wang, H.; Mo, J. Electrostatic Air Filtration by Multifunctional Dielectric Heterocaking Filters with Ultralow Pressure Drop. ACS Appl. Mater. Interfaces 2020, 12, 29383–29392. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, W.; Liu, G.; Liu, S.; Chen, H.; Lyu, G.; Yang, G.; Liu, Y.; Ni, Y. Preparation of ultrafine and highly loaded silver nanoparticle composites and their highly efficient applications as reductive catalysts and antibacterial agents. Colloid Interface Sci. 2023, 629, 766–777. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, W.; Wei, S.; Zhang, Z.; Shi, L.; Wang, J.; Hao, W.; Zhang, K.; Jiang, Q. Ultralow-Resistance High-Voltage Loaded Woven Air Filter for Fine Particle/Bacteria Removal. Polymers 2025, 17, 1765. https://doi.org/10.3390/polym17131765

Fan W, Wei S, Zhang Z, Shi L, Wang J, Hao W, Zhang K, Jiang Q. Ultralow-Resistance High-Voltage Loaded Woven Air Filter for Fine Particle/Bacteria Removal. Polymers. 2025; 17(13):1765. https://doi.org/10.3390/polym17131765

Chicago/Turabian StyleFan, Weisi, Sanqiang Wei, Ziyun Zhang, Lulu Shi, Jun Wang, Wenlan Hao, Kun Zhang, and Qiuran Jiang. 2025. "Ultralow-Resistance High-Voltage Loaded Woven Air Filter for Fine Particle/Bacteria Removal" Polymers 17, no. 13: 1765. https://doi.org/10.3390/polym17131765

APA StyleFan, W., Wei, S., Zhang, Z., Shi, L., Wang, J., Hao, W., Zhang, K., & Jiang, Q. (2025). Ultralow-Resistance High-Voltage Loaded Woven Air Filter for Fine Particle/Bacteria Removal. Polymers, 17(13), 1765. https://doi.org/10.3390/polym17131765