Adhesion of 3D-Printed Versus Milled Resin Posts to Composite Resin Core Build-Up Material: Influence of Surface Treatments

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Study Design

2.2. Specimens’ Preparation

2.3. Grouping of Specimens

2.4. Core Build-Up Procedure

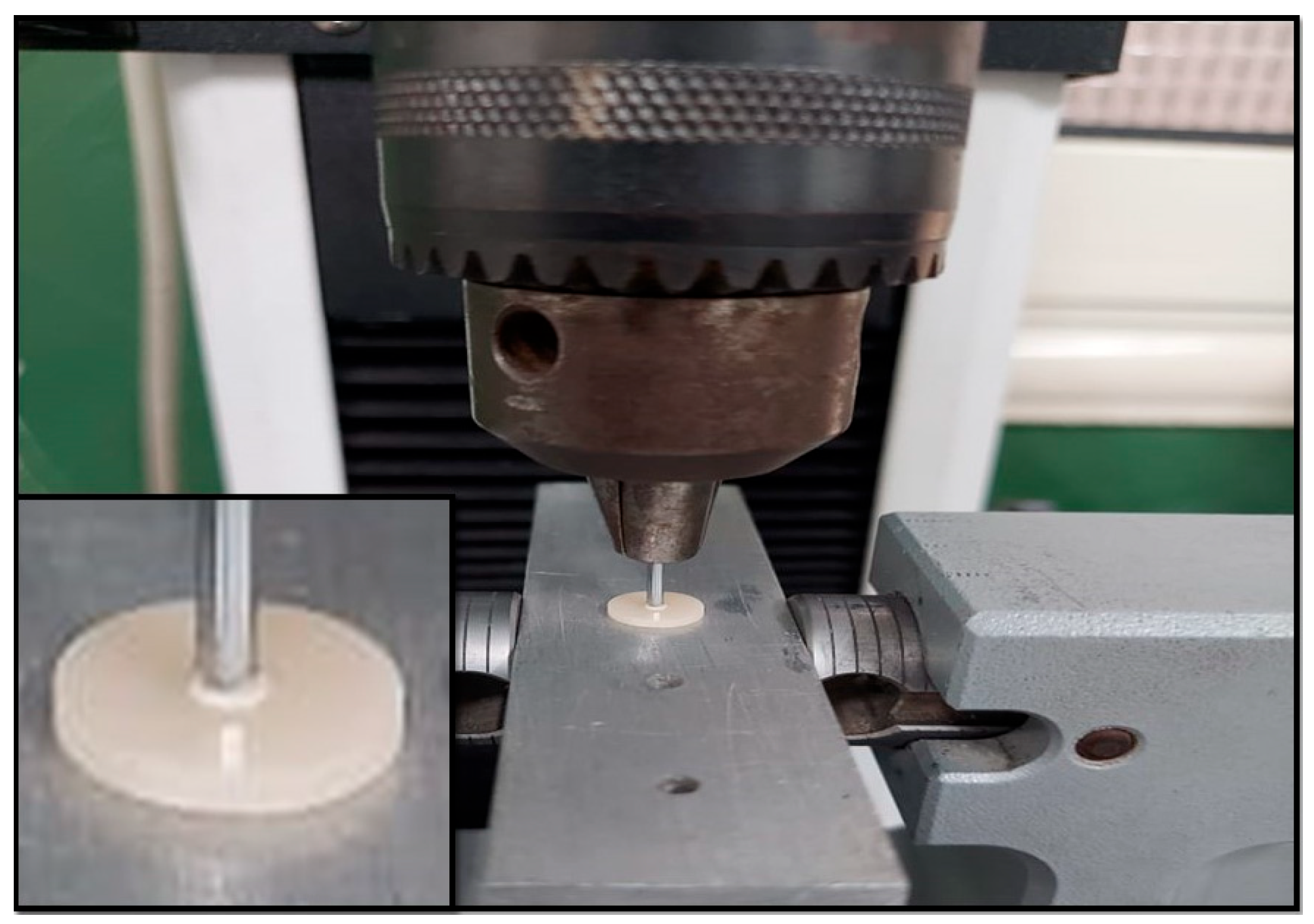

2.5. Push-Out Bond Strength Test

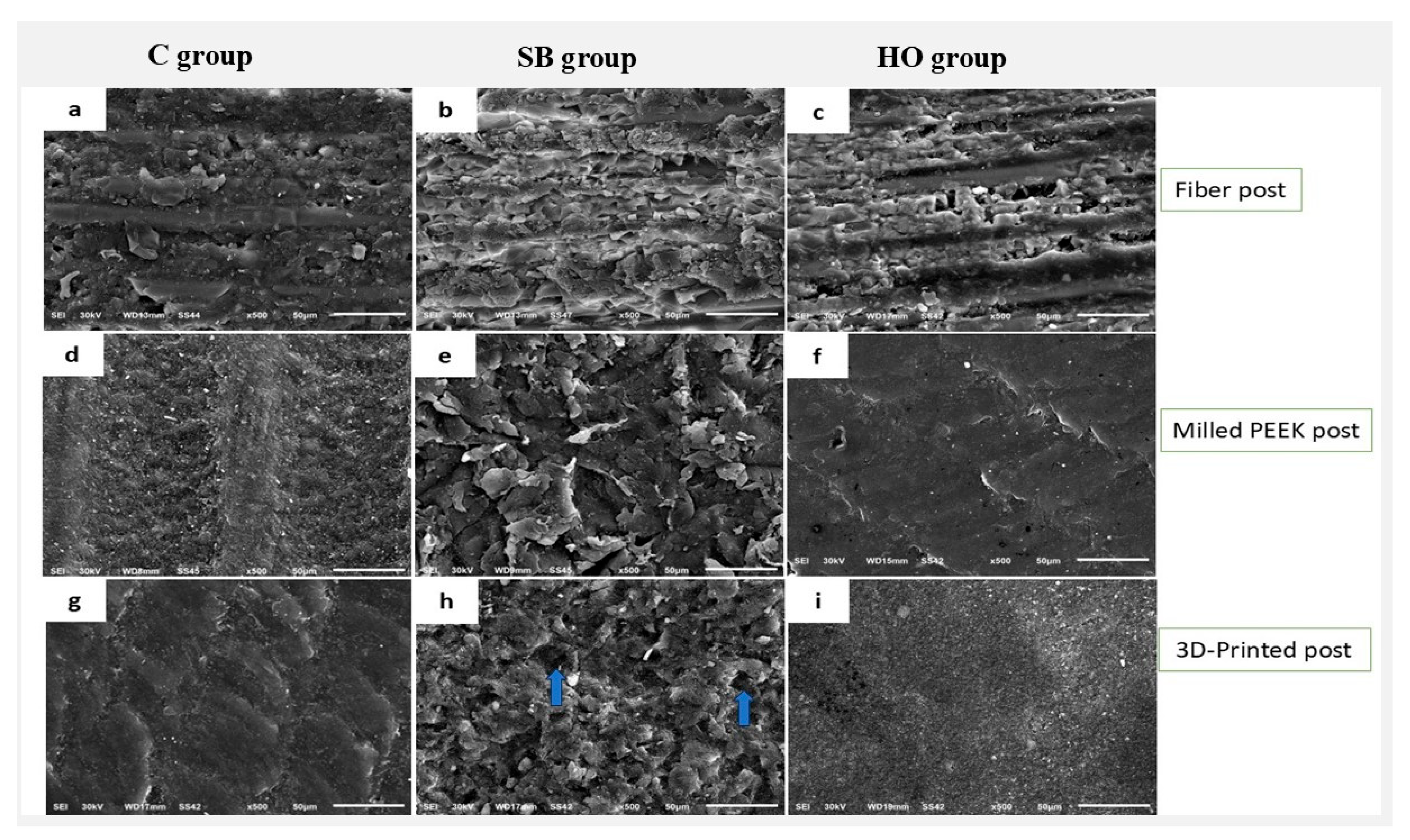

2.6. Scanning Electron Microscopy

2.7. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

- Air particle abrasion significantly improved the push-out bond strength of milled PEEK posts, while it did not have a similar effect on the 3D-printed resin posts.

- Application of 30% H2O2 for 5 min to 3D-printed resin post enhanced the adhesion to core build-up material, while it did not have a similar effect on milled PEEK post.

- The manufacturing method of posts, the surface treatments utilized, and their interactions affect the bond strength between posts and the composite resin core build-up material.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alshahrani, A.; Albaqami, M.; Naji, Z.; Al-Khunein, Y.; Alsubaie, K.; Alqahtani, A.; Al-Thobity, A.M. Impact of different surface treatment methods on bond strength between fiber post and composite core material. Saudi Dent. J. 2021, 33, 334–341. [Google Scholar] [CrossRef] [PubMed]

- Daneshkazemi, A.; Davari, A.; Askari, N.; Kaveh, M. Effect of different fiber post surface treatments on micro tensile bond strength to composite resin. J. Prosthet. Dent. 2016, 116, 896–901. [Google Scholar] [CrossRef] [PubMed]

- Abduljawad, M.; Samran, A.; Kadour, J.; Al-Afandi, M.; Ghazal, M.; Kern, M. Effect of fiber posts on the fracture resistance of endodontically treated anterior teeth with cervical cavities: An in vitro study. J. Prosthet. Dent. 2016, 116, 80–84. [Google Scholar] [CrossRef]

- Mumcu, E.; Erdemir, U.; Topcu, F.T. Comparison of micro push-out bond strengths of two fiber posts luted using simplified adhesive approaches. Dent. Mater. J. 2010, 29, 286–296. [Google Scholar] [CrossRef] [PubMed]

- Soliman, T.A.; Robaian, A.; Al-Gerny, Y.; Hussein, E.M.R. Influence of surface treatment on repair bond strength of CAD/CAM long-term provisional restorative materials: An in vitro study. BMC Oral Health 2023, 23, 342. [Google Scholar] [CrossRef]

- Attia, M.A.; Shokry, T.E.; Abdel-Aziz, M. Effect of different surface treatments on the bond strength of milled polyetheretherketone posts. J. Prosthet. Dent. 2022, 127, 866–874. [Google Scholar] [CrossRef]

- Pyun, J.H.; Shin, T.B.; Lee, J.H.; Ahn, K.M.; Kim, T.H.; Cha, H.S. Effects of hydrogen peroxide pretreatment and heat activation of silane on the shear bond strength of fiber-reinforced composite posts to resin cement. J. Adv. Prosthodont. 2016, 8, 94–100. [Google Scholar] [CrossRef]

- de Sousa Menezes, M.; Queiroz, E.C.; Soares, P.V.; Faria-e-Silva, A.L.; Soares, C.J.; Martins, L.R. Fiber post etching with hydrogen peroxide: Effect of concentration and application time. J. Endod. 2011, 37, 398–402. [Google Scholar] [CrossRef]

- Song, C.H.; Choi, J.W.; Jeon, Y.C.; Jeong, C.M.; Lee, S.H.; Kang, E.S.; Yun, M.J.; Huh, J.B. Comparison of the micro tensile bond strength of a polyetherketoneketone (PEKK) tooth post cemented with various surface treatments and various resin cements. Materials 2018, 11, 916. [Google Scholar] [CrossRef]

- Yamada, Y.; Tsubota, Y.; Fukushima, S. Effect of restoration method on fracture resistance of endodontically treated maxillary premolars. Int. J. Prosthodont. 2004, 17, 94–98. [Google Scholar]

- Lee, M.; Kang, Y.J.; Park, Y.; Jeon, H.J.; Kim, J.H. Effect of vacuum plasma treatment on the shear bond strength of 3D-printed resin and self-adhesive resin cement. Dent. Mater. J. 2025, 44, 211–219. [Google Scholar] [CrossRef] [PubMed]

- Çelik Öge, S.; Küden, C.; Ekren, O. Evaluation of the Mechanical Properties of 3D-Printed Post and Core Systems. Int. J. Prosthodont. 2024, 37, 127–131. [Google Scholar] [CrossRef] [PubMed]

- Della Bona, A.; Cantelli, V.; Britto, V.T.; Collares, K.F.; Stansbury, J.W. 3D printing restorative materials using a stereolithographic technique: A systematic review. Dent. Mater. 2021, 37, 336–350. [Google Scholar] [CrossRef] [PubMed]

- Kessler, A.; Hickel, R.; Reymus, M. 3D printing in dentistry-state of the art. Oper. Dent. 2020, 45, 30–40. [Google Scholar] [CrossRef]

- Silthampitag, P.; Chaijareenont, P.; Tattakorn, K.; Banjongprasert, C.; Takahashi, H.; Arksornnukit, M. Effect of surface pretreatments on resin composite bonding to PEEK. Dent. Mater. J. 2016, 35, 668–674. [Google Scholar] [CrossRef]

- Soliman, T.A.; Raffat-Hussein, E.M.; Ellayeh, M.; Farahat, D.S. Effect of Surface Treatments on Adhesion of Milled Polyetheretherketone Post to Different Composite Resin Core Build-Up Materials. J. Clin. Exp. Dent. 2023, 15, e742–e748. [Google Scholar] [CrossRef]

- Çulhaoğlu, A.K.; Özkır, S.E.; Şahin, V.; Yılmaz, B.; Kılıçarslan, M.A. Effect of Various Treatment Modalities on Surface Characteristics and Shear Bond Strengths of Polyetherether ketone-Based Core Materials. J. Prosthodont. 2020, 29, 136–141. [Google Scholar] [CrossRef]

- Alanazi, K.K.; Alzaid, A.A.; Elkaffas, A.A.; Bukhari, S.A.; Althubaity, R.O.; Alfaifi, K.A.; Alfahdi, I.M.; Alqahtani, A. Mechanical Assessment of CAD/CAM Fabricated Hybrid Ceramics: An In Vitro Study. Appl. Sci. 2024, 14, 7939. [Google Scholar] [CrossRef]

- Keßler, A.; Hickel, R.; Ilie, N. In vitro investigation of the influence of printing direction on the flexural strength, flexural modulus and fractographic analysis of 3D-printed temporary materials. Dent. Mater. J. 2021, 40, 641–649. [Google Scholar] [CrossRef]

- Kim, D.; Shim, J.S.; Lee, D.; Shin, S.H.; Nam, N.E.; Park, K.H.; Shim, J.S.; Kim, J.E. Effects of post-curing time on the mechanical and color properties of three-dimensional printed crown and bridge materials. Polymers 2020, 12, 2762. [Google Scholar] [CrossRef]

- Park, S.M.; Park, J.M.; Kim, S.K.; Heo, S.J.; Koak, J.Y. Flexural strength of 3D-printing resin materials for provisional fixed dental prostheses. Materials 2020, 13, 3970. [Google Scholar] [CrossRef]

- Goracci, C.; Raffaelli, O.; Monticelli, F.; Balleri, B.; Bertelli, E.; Ferrari, M. The adhesion between prefabricated FRC posts and composite resin cores: Micro tensile bond strength with and without post-silanization. Dent. Mater. 2005, 21, 437–444. [Google Scholar] [CrossRef] [PubMed]

- Balbosh, A.; Kern, M. Effect of surface treatment on retention of glass-fiber endodontic posts. J. Prosthet. Dent. 2006, 95, 218–223. [Google Scholar] [CrossRef]

- Arslan, E.; Caglar, I. Enhancing PEEK bond strength: The impact of chemical and mechanical surface modifications on surface characteristics and phase transformation. BMC Oral Health 2025, 25, 511. [Google Scholar] [CrossRef] [PubMed]

- Cekic-Nagas, I.; Ergun, G.; Nagas, E.; Tezvergil, A.; Vallittu, P.K.; Lassila, L.V. Comparison between regional micropush-out and microtensile bond strength of resin composite to dentin. Acta Odontol. Scand. 2008, 66, 73–81. [Google Scholar] [CrossRef] [PubMed]

- Sadek, F.T.; Monticelli, F.; Goracci, C.; Tay, F.R.; Cardoso, P.E.; Ferrari, M. Bond strength performance of different resin composites used as core materials around fiber posts. Dent. Mater. 2007, 23, 95–99. [Google Scholar] [CrossRef]

- Robaian, A.; Alshehri, A.M.; Alqhtani, N.R.; Almudahi, A.; Alanazi, K.K.; Abuelqomsan, M.A.S.; Raffat, E.M.; Elkaffas, A.; Hashem, Q.; Soliman, T.A. Effect of Surface Treatments and Thermal Aging on Bond Strength Between Veneering Resin and CAD/CAM Provisional Materials. Polymers 2025, 17, 563. [Google Scholar] [CrossRef]

- Valandro, L.F.; Yoshiga, S.; De Melo, R.M.; Galhano, G.A.P.; Mallmann, A.; Marinho, C.P.; Bottino, M.A. Microtensile bond strength between a quartz fiber post and a resin cement: Effect of post surface conditioning. J. Adhes. Dent. 2006, 8, 105. [Google Scholar]

- Monticelli, F.; Toledano, M.; Tay, F.R.; Sadek, F.T.; Goracci, C.; Ferrari, M. A simple etching technique for improving the retention of fiber posts to resin composites. J. Endod. 2006, 32, 44–47. [Google Scholar] [CrossRef]

- 3M™ Single Bond Universal Adhesive. Technical Product Profile. Available online: https://multimedia.3m.com/mws/media/1279637O/3m-single-bond-universal-adhesive-technical-product-profile.pdf?utm_source=chatgpt.com (accessed on 9 June 2025).

- Lim, N.K.; Shin, S.Y. Bonding of conventional provisional resin to 3D printed resin: The role of surface treatments and type of repair resins. J. Adv. Prosthodont. 2020, 12, 322–328. [Google Scholar] [CrossRef]

- Elsaka, S.E. Influence of chemical surface treatments on adhesion of fiber posts to composite resin core materials. Dent. Mater. 2013, 29, 550–558. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.S.; Shin, M.S.; Lee, J.Y.; Ryu, J.J.; Shin, S.W. Shear bond strength of composite resin to high performance polymer PEKK according to surface treatments and bonding materials. J. Adv. Prosthodont. 2017, 9, 350–357. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Qien, Y.; Zhu, Y.; Liu, H.; Gan, K.; Guo, J. The effect of different surface treatments on the bond strength of PEEK composite materials. Dent. Mater. 2014, 30, 209–215. [Google Scholar] [CrossRef] [PubMed]

| Materials | Product (Composition) | Composition/Manufacturer | Lot. No. | Code |

|---|---|---|---|---|

| Post | Ready-made-fiber post (Rely X) (Size #3) | - Glass fiber-reinforced (composite, methacrylate resin) - 3M ESPE, St. Paul, MN, USA | 255531407 | RX |

| CAD/CAM milled post Bre CAM Bio HPP (PEEK) | - Poly ether ether ketone, 20wt% titanium dioxide ceramic filler and Aluminum oxide sand (50 µm mean particle size) - Bredent GmbH & Co., Senden, Germany. | 56654456 | PK | |

| 3D-printed resin post Saremco print CROWNTEC | Bisphenol A diglycidyl methacrylate ethoxylated, trimethyl benzoyl diphenyl phosphine oxide - Saremco Dental AG, Rebstein, Switzerland | E394 | CT | |

| Core build-up material | Grandio Core DC (dual-cured composite core material) | - Matrix: Bis-GMA, UDMA resins. Filler: silica/Ba-glass ceramics (77%, wt). Amines, benzoyl peroxide, BHT). - VOCO GmbH, Cuxhaven, Germany. | Z01X78 | GDC |

| Source of Variations | Sum of Squares | df | Mean Squares | F | p Value |

|---|---|---|---|---|---|

| Post type | 195.790 | 2 | 97.895 | 79.968 | p < 0.001 |

| Surface treatment | 1428.725 | 2 | 714.362 | 583.546 | p < 0.001 |

| Post type × Surface treatment | 1301.254 | 4 | 325.314 | 265.741 | p < 0.001 |

| Total | 22,324.641 | 108 | — | — | — |

| Post Type | Surface Treatments | ||

|---|---|---|---|

| C | SB | HO | |

| RX | 11.07 ± 0.99 Ac | 19.55 ± 0.83 Ba | 15.06 ± 1.33 Ab |

| PK | 10.52 ± 0.79 Ab | 23.88 ± 1.51 Aa | 8.82 ± 1.11 Bb |

| CT | 11.27 ± 0.73 Ab | 11.79 ± 0.81 Cb | 14.09 ± 1.48 Aa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alanazi, K.K.; Robaian Alqahtani, A.; Alshehri, A.M.; Alqahtani, A.A.; Almudahi, A.; Al-Mansour, O.A.; Al-Harbi, N.A.; Alqahtani, S.S.A.; Raffat Hussein, E.M.; Soliman, T.A. Adhesion of 3D-Printed Versus Milled Resin Posts to Composite Resin Core Build-Up Material: Influence of Surface Treatments. Polymers 2025, 17, 1711. https://doi.org/10.3390/polym17121711

Alanazi KK, Robaian Alqahtani A, Alshehri AM, Alqahtani AA, Almudahi A, Al-Mansour OA, Al-Harbi NA, Alqahtani SSA, Raffat Hussein EM, Soliman TA. Adhesion of 3D-Printed Versus Milled Resin Posts to Composite Resin Core Build-Up Material: Influence of Surface Treatments. Polymers. 2025; 17(12):1711. https://doi.org/10.3390/polym17121711

Chicago/Turabian StyleAlanazi, Khalid K., Ali Robaian Alqahtani, Abdullah Mohammed Alshehri, Abdullah Ali Alqahtani, Abdulellah Almudahi, Omar Abdulaziz Al-Mansour, Nawaf Abdullah Al-Harbi, Sultan Sahman Abdulrahman Alqahtani, Eman Mohamed Raffat Hussein, and Tarek Ahmed Soliman. 2025. "Adhesion of 3D-Printed Versus Milled Resin Posts to Composite Resin Core Build-Up Material: Influence of Surface Treatments" Polymers 17, no. 12: 1711. https://doi.org/10.3390/polym17121711

APA StyleAlanazi, K. K., Robaian Alqahtani, A., Alshehri, A. M., Alqahtani, A. A., Almudahi, A., Al-Mansour, O. A., Al-Harbi, N. A., Alqahtani, S. S. A., Raffat Hussein, E. M., & Soliman, T. A. (2025). Adhesion of 3D-Printed Versus Milled Resin Posts to Composite Resin Core Build-Up Material: Influence of Surface Treatments. Polymers, 17(12), 1711. https://doi.org/10.3390/polym17121711