Controllable Preparation of Oriented Boron Nitride Nanosheets/Polyacrylate Pressure-Sensitive Adhesive Composites with Enhanced Thermal Conductivity

Abstract

1. Introduction

2. Experimental Sections

2.1. Materials

2.2. Preparation of m-BNNSs

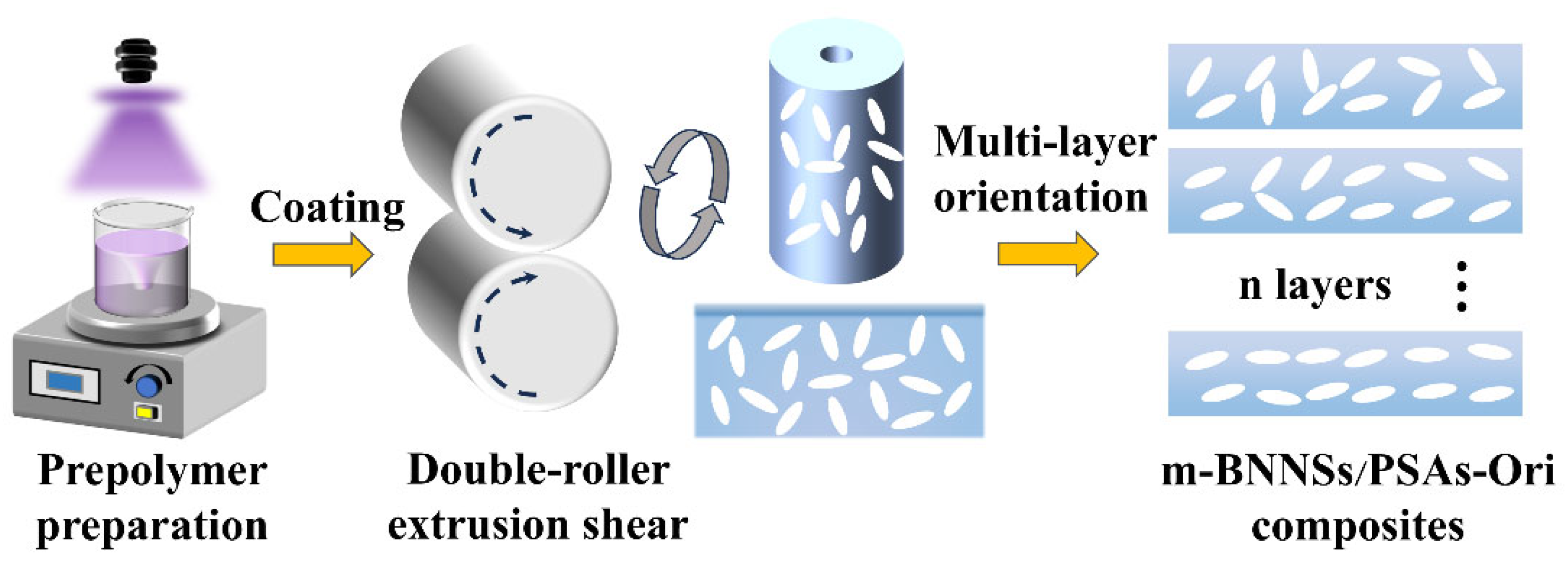

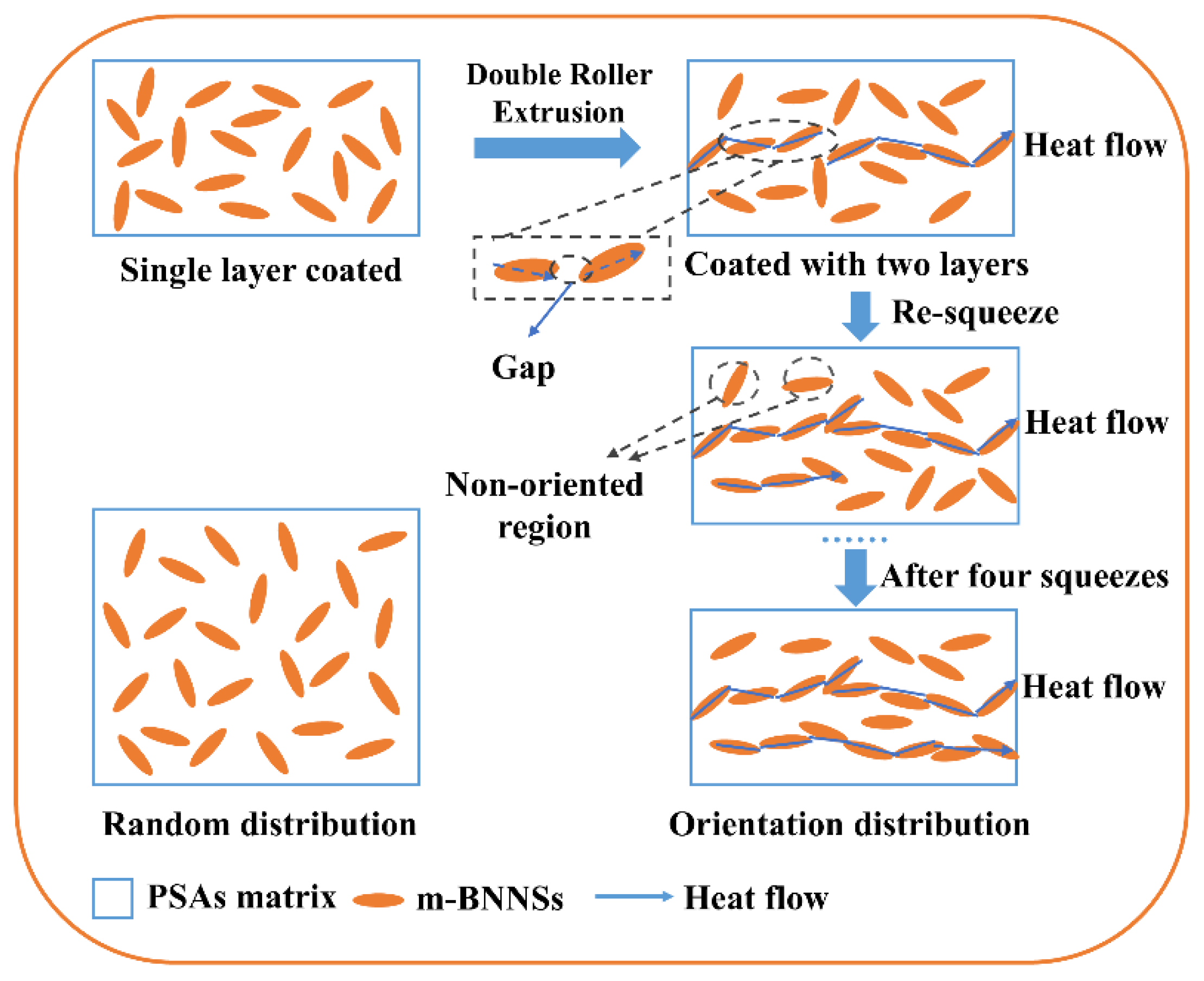

2.3. Preparation of m-BNNSs/PSAs-Ori Thermally Conductive Composites

Experimental Principle

- (1)

- TPO photoinitiated decomposition:

2.4. Characterization

3. Results and Discussion

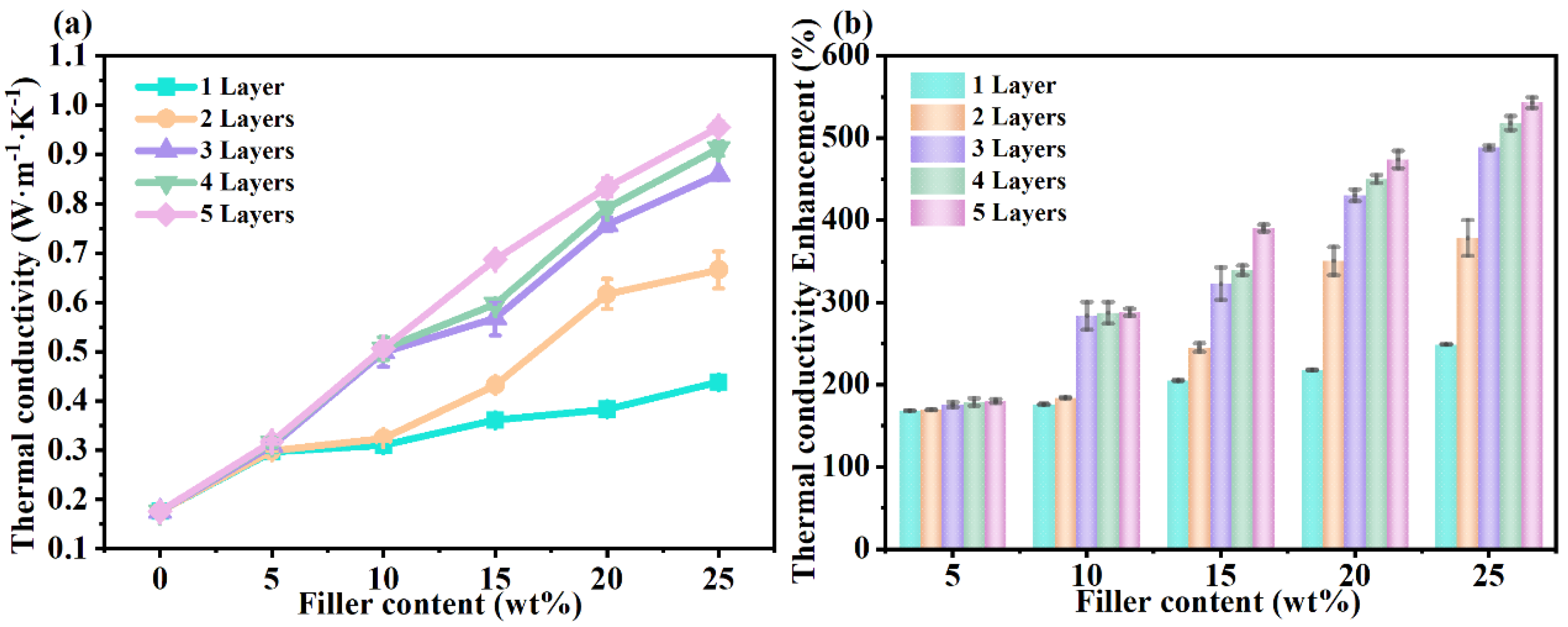

3.1. Thermal Conductivity of m-BNNSs/PSAs-Ori Composites

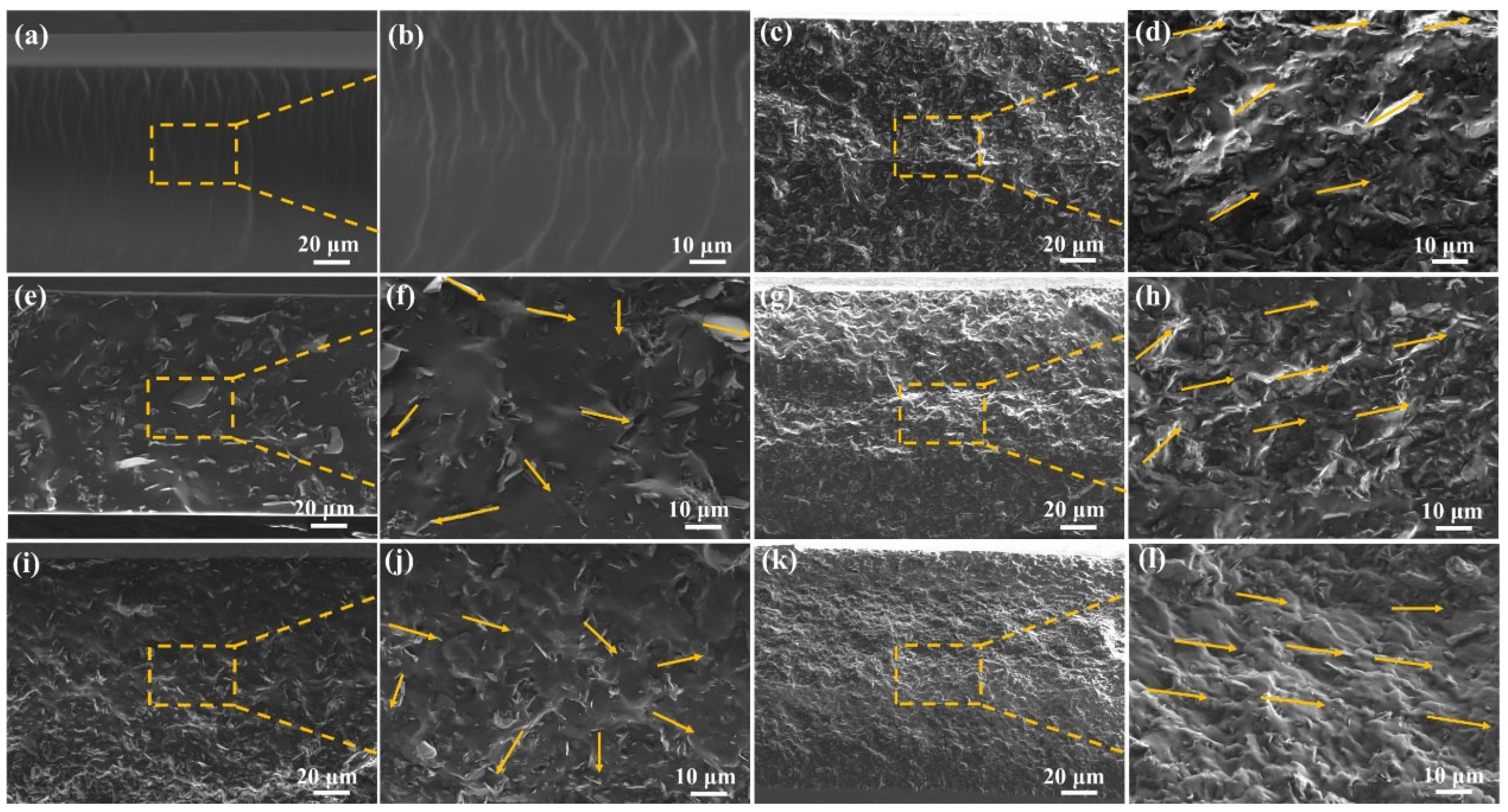

3.2. The SEM Images of m-BNNSs/PSAs-Ori Composites

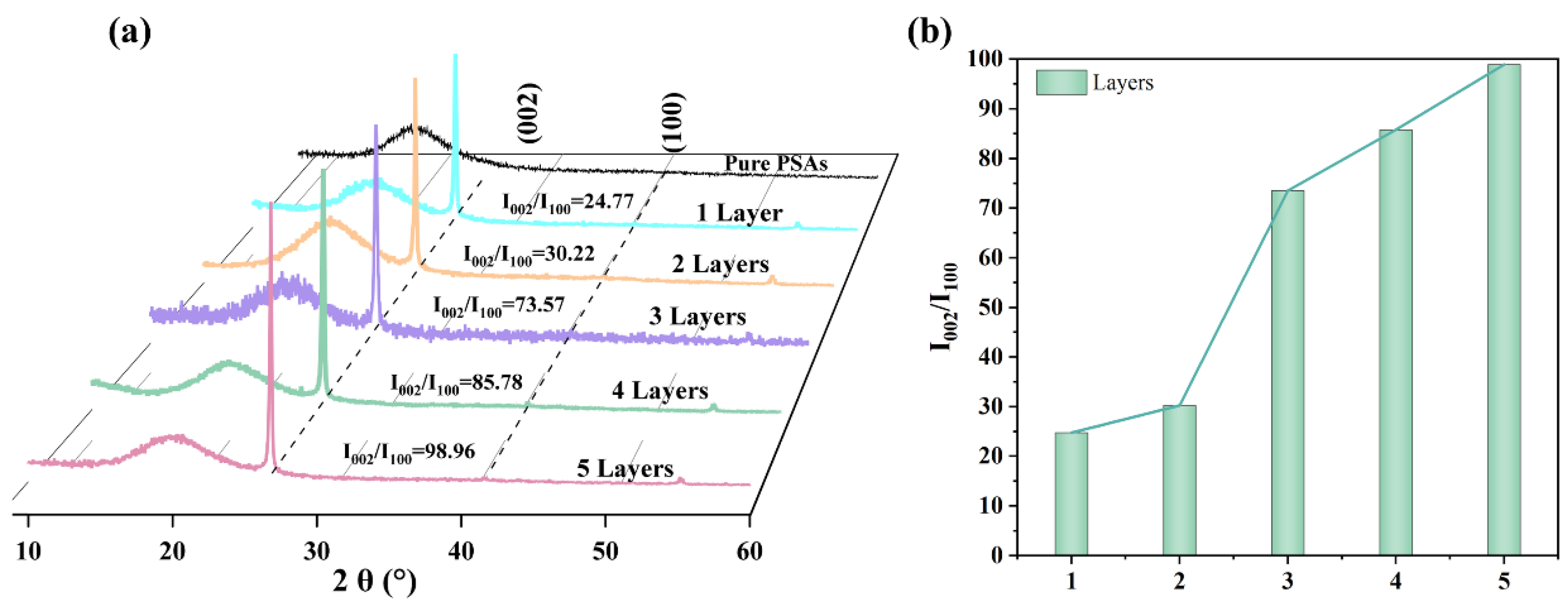

3.3. Orderliness of m-BNNSs/PSAs-Ori Composites

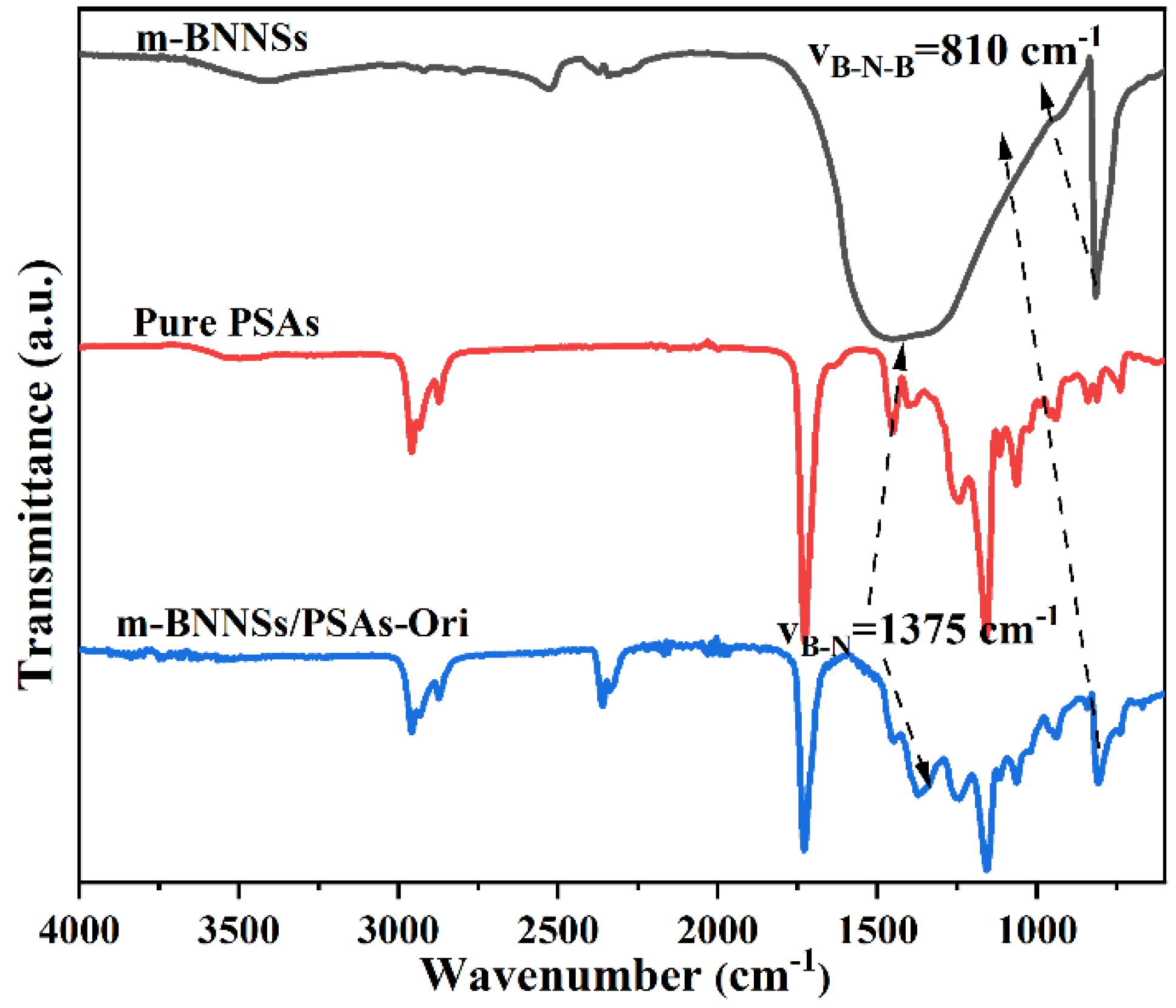

3.4. Infrared Spectra of m-BNNSs/PSAs-Ori Composites

3.5. Viscoelasticity of m-BNNSs/PSAs-Ori Composites

3.6. Thermal Stability Properties of m-BNNSs/PSAs-Ori Composites

3.7. Thermal Diffusion Ability

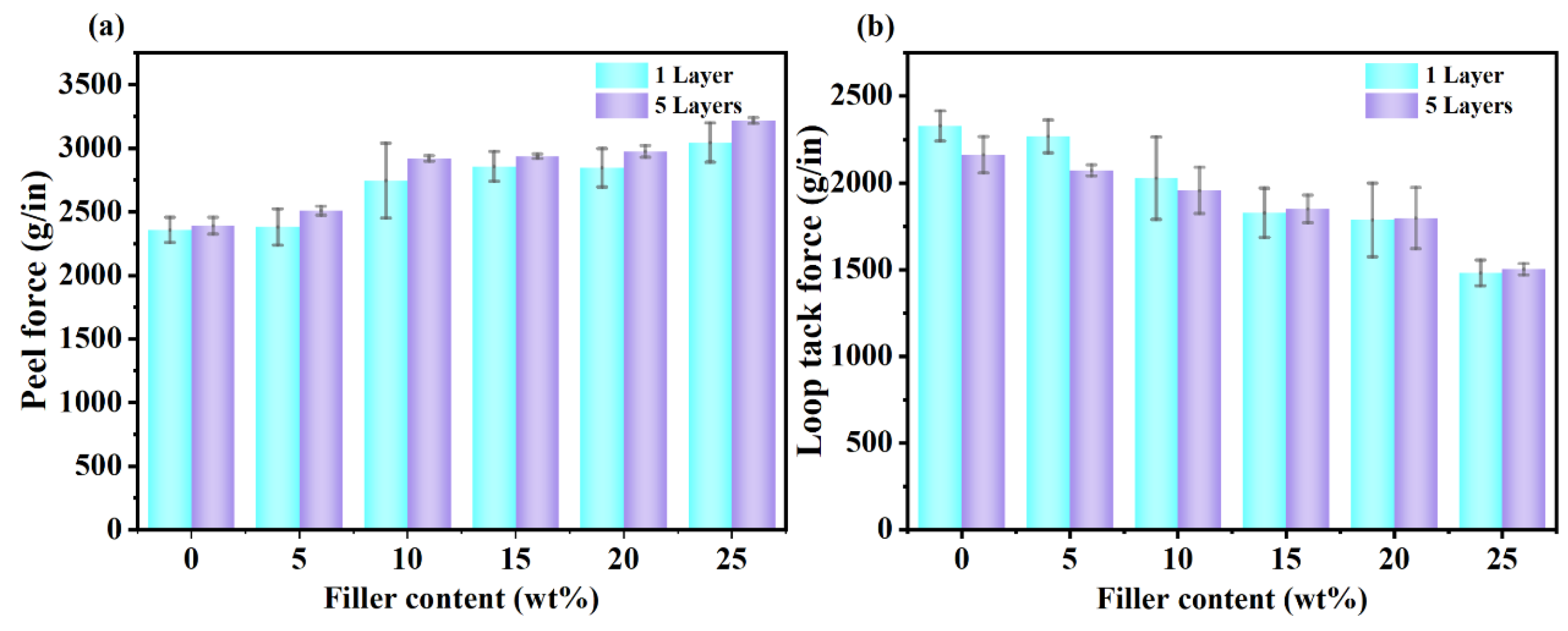

3.8. Mechanical Properties of m-BNNSs/PSAs-Ori Composites

3.9. Electrical Insulation Properties of m-BNNSs/PSAs-Ori Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Ma, X.; Zhou, J.; Du, F.; Teng, C. Bioinspired, high-strength, and flexible MXene/aramid fiber for electromagnetic interference shielding papers with joule heating performance. ACS Nano 2022, 16, 6700–6711. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, Z.; Ruan, K.; Gu, J. Multifunctional Ti3C2T x-(Fe3O4/polyimide) composite films with Janus structure for outstanding electromagnetic interference shielding and superior visual thermal management. Nano Res. 2022, 15, 5601–5609. [Google Scholar] [CrossRef]

- Zhao, C.; Li, Y.; Liu, Y.; Xie, H.; Yu, W. A critical review of the preparation strategies of thermally conductive and electrically insulating polymeric materials and their applications in heat dissipation of electronic devices. Adv. Compos. Hybrid. Mater. 2023, 6, 27. [Google Scholar] [CrossRef]

- Han, J.; Du, G.; Gao, W.; Bai, H. An anisotropically high thermal conductive boron nitride/epoxy composite based on nacre-mimetic 3D network. Adv. Funct. Mater. 2019, 29, 1900412. [Google Scholar] [CrossRef]

- Chen, J.; Wei, H.; Bao, H.; Jiang, P.; Huang, X. Millefeuille-inspired thermally conductive polymer nanocomposites with overlapping BN nanosheets for thermal management applications. ACS Appl. Mater. Interfaces 2019, 11, 31402–31410. [Google Scholar] [CrossRef]

- Han, Y.; Shi, X.; Yang, X.; Guo, Y.; Zhang, J.; Kong, J.; Gu, J. Enhanced thermal conductivities of epoxy nanocomposites via incorporating in-situ fabricated hetero-structured SiC-BNNS fillers. Compos. Sci. Technol. 2020, 187, 107944. [Google Scholar] [CrossRef]

- Xu, X.; Chen, J.; Zhou, J.; Li, B. Thermal conductivity of polymers and their nanocomposites. Adv. Mater. 2018, 30, 1705544. [Google Scholar] [CrossRef]

- Feng, C.-P.; Chen, L.-B.; Tian, G.-L.; Wan, S.-S.; Bai, L.; Bao, R.-Y.; Liu, Z.-Y.; Yang, M.-B.; Yang, W. Multifunctional thermal management materials with excellent heat dissipation and generation capability for future electronics. ACS Appl. Mater. Interfaces 2019, 11, 18739–18745. [Google Scholar] [CrossRef]

- Feng, C.P.; Bai, L.; Bao, R.-Y.; Wang, S.-W.; Liu, Z.; Yang, M.-B.; Chen, J.; Yang, W. Superior thermal interface materials for thermal management. Compos. Commun. 2019, 12, 80–85. [Google Scholar] [CrossRef]

- Feng, C.-P.; Chen, L.-B.; Tian, G.-L.; Bai, L.; Bao, R.-Y.; Liu, Z.-Y.; Ke, K.; Yang, M.-B.; Yang, W. Robust polymer-based paper-like thermal interface materials with a through-plane thermal conductivity over 9 W/m-1·K-1. Chem. Eng. J. 2020, 392, 123784. [Google Scholar] [CrossRef]

- Chung, S.-H.; Kim, H.; Jeong, S.W. Improved thermal conductivity of carbon-based thermal interface materials by high-magnetic-field alignment. Carbon. 2018, 140, 24–29. [Google Scholar] [CrossRef]

- Ma, J.; Shang, T.; Ren, L.; Yao, Y.; Zhang, T.; Xie, J.; Zhang, B.; Zeng, X.; Sun, R.; Xu, J.-B. Through-plane assembly of carbon fibers into 3D skeleton achieving enhanced thermal conductivity of a thermal interface material. Chem. Eng. J. 2020, 380, 122550. [Google Scholar] [CrossRef]

- Jensen, A.T.; Gambetta, R.; Machado, F. A versatile route to the synthesis of pressure-sensitive adhesives and polyHIPE-like microparticles: An experimental study on glycerol valorization. Mater. Today Commun. 2020, 25, 101407. [Google Scholar] [CrossRef]

- Lim, D.; Baek, M.-J.; Kim, H.-S.; Baig, C.; Lee, D.W. Carboxyethyl acrylate incorporated optically clear adhesives with outstanding adhesion strength and immediate strain recoverability for stretchable electronics. Chem. Eng. J. 2022, 437, 135390. [Google Scholar] [CrossRef]

- Czech, Z. Solvent-based pressure-sensitive adhesives for removable products. Int. J. Adhes. Adhes. 2006, 26, 414–418. [Google Scholar] [CrossRef]

- Tobing, S.D.; Klein, A. Molecular parameters and their relation to the adhesive performance of acrylic pressure-sensitive adhesives. J. Appl. Polym. Sci. 2001, 79, 2230–2244. [Google Scholar] [CrossRef]

- Lee, J.-H.; Lee, T.-H.; Shim, K.-S.; Park, J.-W.; Kim, H.-J.; Kim, Y.; Jung, S. Effect of crosslinking density on adhesion performance and flexibility properties of acrylic pressure sensitive adhesives for flexible display applications. Int. J. Adhes. Adhes. 2017, 74, 137–143. [Google Scholar] [CrossRef]

- Feng, X.; Li, G. UV curable, flame retardant, and pressure-sensitive adhesives with two-way shape memory effect. Polymer 2022, 249, 124835. [Google Scholar] [CrossRef]

- Zhang, F.; Feng, Y.; Feng, W. Three-dimensional interconnected networks for thermally conductive polymer composites: Design, preparation, properties, and mechanisms. Mater. Sci. Eng. R. 2020, 142, 100580. [Google Scholar] [CrossRef]

- Zhang, F.; Feng, Y.; Qin, M.; Gao, L.; Li, Z.; Zhao, F.; Zhang, Z.; Lv, F.; Feng, W. Stress controllability in thermal and electrical conductivity of 3D elastic graphene-crosslinked carbon nanotube sponge/polyimide nanocomposite. Adv. Funct. Mater. 2019, 29, 1901383. [Google Scholar] [CrossRef]

- Dai, W.; Lv, L.; Ma, T.; Wang, X.; Ying, J.; Yan, Q.; Tan, X.; Gao, J.; Xue, C.; Yu, J. Multiscale structural modulation of anisotropic graphene framework for polymer composites achieving highly efficient thermal energy management. Adv. Sci. 2021, 8, 2003734. [Google Scholar] [CrossRef] [PubMed]

- Yan, Q.; Alam, F.E.; Gao, J.; Dai, W.; Tan, X.; Lv, L.; Wang, J.; Zhang, H.; Chen, D.; Nishimura, K. Soft and self-adhesive thermal interface materials based on vertically aligned, covalently bonded graphene nanowalls for efficient microelectronic cooling. Adv. Funct. Mater. 2021, 31, 2104062. [Google Scholar] [CrossRef]

- Wang, P.; Xiang, R.; Maruyama, S. Thermal conductivity of carbon nanotubes and assemblies. Adv. Heat. Transf. 2018, 50, 43–122. [Google Scholar]

- Guerra, V.; Wan, C.; McNally, T. Thermal conductivity of 2D nano-structured boron nitride (BN) and its composites with polymers. Prog. Mater. Sci. 2019, 100, 170–186. [Google Scholar] [CrossRef]

- Guo, Y.; Ruan, K.; Shi, X.; Yang, X.; Gu, J. Factors affecting thermal conductivities of the polymers and polymer composites: A review. Compos. Sci. Technol. 2020, 193, 108134. [Google Scholar] [CrossRef]

- Yu, C.; Gong, W.; Tian, W.; Zhang, Q.; Xu, Y.; Lin, Z.; Hu, M.; Fan, X.; Yao, Y. Hot-pressing induced alignment of boron nitride in polyurethane for composite films with thermal conductivity over 50 W/m−1·K−1. Compos. Sci. Technol. 2018, 160, 199–207. [Google Scholar] [CrossRef]

- Cao, M.; Shu, J.; Chen, P.; Xia, R.; Yang, B.; Miao, J.; Qian, J. Orientation of boron nitride nanosheets in CM/EPDM Co-continuous blends and their thermal conductive properties. Polym. Test. 2018, 69, 208–213. [Google Scholar] [CrossRef]

- Song, Q.; Zhu, W.; Deng, Y.; Hai, F.; Wang, Y.; Guo, Z. Enhanced through-plane thermal conductivity and high electrical insulation of flexible composite films with aligned boron nitride for thermal interface material. Compos. Part A 2019, 127, 105654. [Google Scholar] [CrossRef]

- Haruki, M.; Tada, J.; Funaki, R.; Onishi, H.; Tada, Y. Enhancing thermal conductivities of hexagonal boron nitride/fluorinated polyimide composite materials using direct current electrical fields. Thermochim. Acta 2020, 684, 178491. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, J. Fabrication of Fe3O4 coated boron nitride nanoplatelets by liquid-phase exfoliation for thermally enhanced epoxy composites via magnetic alignment. Compos. Sci. Technol. 2020, 188, 107961. [Google Scholar] [CrossRef]

- Yang, G.; Zhang, X.; Shang, Y.; Xu, P.; Pan, D.; Su, F.; Ji, Y.; Feng, Y.; Liu, Y.; Liu, C. Highly thermally conductive polyvinyl alcohol/boron nitride nanocomposites with interconnection oriented boron nitride nanoplatelets. Compos. Sci. Technol. 2021, 201, 108521. [Google Scholar] [CrossRef]

- Liu, J.; Guo, Y.; Weng, C.; Zhang, H.; Zhang, Z. High thermal conductive epoxy based composites fabricated by multi-material direct ink writing. Compos. Part A 2020, 129, 105684. [Google Scholar] [CrossRef]

- Yao, Y.; Sun, J.; Zeng, X.; Sun, R.; Xu, J.B.; Wong, C.P. Construction of 3D skeleton for polymer composites achieving a high thermal conductivity. Small 2018, 14, 1704044. [Google Scholar] [CrossRef] [PubMed]

- Yuan, C.; Duan, B.; Li, L.; Xie, B.; Huang, M.; Luo, X. Thermal conductivity of polymer-based composites with magnetic aligned hexagonal boron nitride platelets. ACS Appl. Mater. Interfaces 2015, 7, 13000–13006. [Google Scholar] [CrossRef] [PubMed]

- Yin, Z.; Guo, J.; Jiang, X. Significantly improved thermal conductivity of silicone rubber and aligned boron nitride composites by a novel roll-cutting processing method. Compos. Sci. Technol. 2021, 209, 108794. [Google Scholar] [CrossRef]

- Zhong, B.; Zou, J.; An, L.; Ji, C.; Huang, X.; Liu, W.; Yu, Y.; Wang, H.; Wen, G.; Zhao, K. The effects of the hexagonal boron nitride nanoflake properties on the thermal conductivity of hexagonal boron nitride nanoflake/silicone rubber composites. Compos. Part A 2019, 127, 105629. [Google Scholar] [CrossRef]

- Liu, Z.; Xiang, Y.; Fang, X.; Sun, Z.; Wang, J.; Fu, X.; Liu, Q.; Hu, S.; Hu, C.; Wong, C.P. Transposable, highly thermal conductive silicone rubber/boron nitride composites with enhanced orientation of BN by multilayer stacked hot pressing according to rheological control. Polym. Test. 2023, 117, 107835. [Google Scholar] [CrossRef]

- Guo, F.; Shen, X.; Zhou, J.; Liu, D.; Zheng, Q.; Yang, J.; Jia, B.; Lau, A.K.; Kim, J.K. Highly thermally conductive dielectric nanocomposites with synergistic alignments of graphene and boron nitride nanosheets. Adv. Funct. Mater. 2020, 30, 1910826. [Google Scholar] [CrossRef]

- Song, N.; Wang, P.; Jin, L.; Zhang, F.; Wang, Z.; Ding, P. Tunable oriented cellulose/BNNSs films designed for high-performance thermal management. Chem. Eng. J. 2022, 437, 135404. [Google Scholar] [CrossRef]

- Agari, Y.; Uno, T. Estimation on thermal conductivities of filled polymers. J. Appl. Polym. Sci. 1986, 32, 5705–5712. [Google Scholar] [CrossRef]

- Ridzuan, M.; Majid, M.A.; Afendi, M.; Mazlee, M.; Gibson, A. Thermal behaviour and dynamic mechanical analysis of Pennisetum purpureum/glass-reinforced epoxy hybrid composites. Compos. Struct. 2016, 152, 850–859. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.A.; Alattas, O.S. Woven hybrid biocomposites: Dynamic mechanical and thermal properties. Compos. Part A 2012, 43, 288–293. [Google Scholar] [CrossRef]

- Júnior, J.H.S.A.; Júnior, H.L.O.; Amico, S.C.; Amado, F.D.R. Study of hybrid intralaminate curaua/glass composites. Mater. Des. 2012, 42, 111–117. [Google Scholar] [CrossRef]

- Ahmad, M.A.A.; Majid, M.A.; Ridzuan, M.; Mazlee, M.; Gibson, A. Dynamic mechanical analysis and effects of moisture on mechanical properties of interwoven hemp/polyethylene terephthalate (PET) hybrid composites. Constr. Build. Mater. 2018, 179, 265–276. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; ElayaPerumal, A. Mechanical and water absorption properties of woven jute/banana hybrid composites. Fibers Polym. 2012, 13, 907–914. [Google Scholar] [CrossRef]

- Jabbar, A.; Militký, J.; Wiener, J.; Kale, B.M.; Ali, U.; Rwawiire, S. Nanocellulose coated woven jute/green epoxy composites: Characterization of mechanical and dynamic mechanical behavior. Compos. Struct. 2017, 161, 340–349. [Google Scholar] [CrossRef]

- Sriromreun, P.; Petchsuk, A.; Opaprakasit, M.; Opaprakasit, P. Miscibility and hydrolytic degradability of polylactic acid/poly (ethylene terephthalate-co-lactic acid) blends. Chiang Mai J. Sci. 2014, 41, 691–703. [Google Scholar]

- Murugan, R.; Ramesh, R.; Padmanabhan, K. Investigation on static and dynamic mechanical properties of epoxy based woven fabric glass/carbon hybrid composite laminates. Procedia Eng. 2014, 97, 459–468. [Google Scholar] [CrossRef]

- Satapathy, S.; Kothapalli, R.V. Mechanical, dynamic mechanical and thermal properties of banana fiber/recycled high density polyethylene biocomposites filled with flyash cenospheres. J. Polym. Environ. 2018, 26, 200–213. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Chandrasekar, M.; Alothman, O.Y.; Fouad, H.; Jawaid, M.; Azeem, M. Flexural, impact and dynamic mechanical analysis of hybrid composites: Olive tree leaves powder/pineapple leaf fibre/epoxy matrix. J. Mater. Res. Technol. 2022, 21, 4241–4252. [Google Scholar] [CrossRef]

- Tanaka, T.; Montanari, G.; Mulhaupt, R. Polymer nanocomposites as dielectrics and electrical insulation-perspectives for processing technologies, material characterization and future applications. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 763–784. [Google Scholar] [CrossRef]

- Kuntman, A.; Kuntman, H. A study on dielectric properties of a new polyimide film suitable for interlayer dielectric material in microelectronics applications. Microelectron. J. 2000, 31, 629–634. [Google Scholar] [CrossRef]

| Composite | Tg Obtained from Tan δ Curves (°C) | E′ (MPa) at 25 °C |

|---|---|---|

| Pure PSAs | −34 | 214 |

| 1 Layer m-BNNSs/PSAs | −30 | 358 |

| 5 Layers m-BNNSs/PSAs | −28 | 604 |

| Sample | T10/°C | T40/°C | Tmax/°C | Residue/% |

|---|---|---|---|---|

| Pure PSAs | 320 | 385 | 403 | 1.03 |

| 1 Layer | 340 | 391 | 403 | 14.18 |

| 5 Layers | 352 | 394 | 405 | 13.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Cao, C.; Zheng, D.; Li, G.; Qu, X. Controllable Preparation of Oriented Boron Nitride Nanosheets/Polyacrylate Pressure-Sensitive Adhesive Composites with Enhanced Thermal Conductivity. Polymers 2025, 17, 1604. https://doi.org/10.3390/polym17121604

Liu Y, Cao C, Zheng D, Li G, Qu X. Controllable Preparation of Oriented Boron Nitride Nanosheets/Polyacrylate Pressure-Sensitive Adhesive Composites with Enhanced Thermal Conductivity. Polymers. 2025; 17(12):1604. https://doi.org/10.3390/polym17121604

Chicago/Turabian StyleLiu, Yuan, Chaochao Cao, De Zheng, Guohua Li, and Xiongwei Qu. 2025. "Controllable Preparation of Oriented Boron Nitride Nanosheets/Polyacrylate Pressure-Sensitive Adhesive Composites with Enhanced Thermal Conductivity" Polymers 17, no. 12: 1604. https://doi.org/10.3390/polym17121604

APA StyleLiu, Y., Cao, C., Zheng, D., Li, G., & Qu, X. (2025). Controllable Preparation of Oriented Boron Nitride Nanosheets/Polyacrylate Pressure-Sensitive Adhesive Composites with Enhanced Thermal Conductivity. Polymers, 17(12), 1604. https://doi.org/10.3390/polym17121604