Substrate-Dependent Performance of ZnTTBPc–PMMA Composite Films on Rigid, Flexible, and Sustainable Materials for Wearable Devices

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

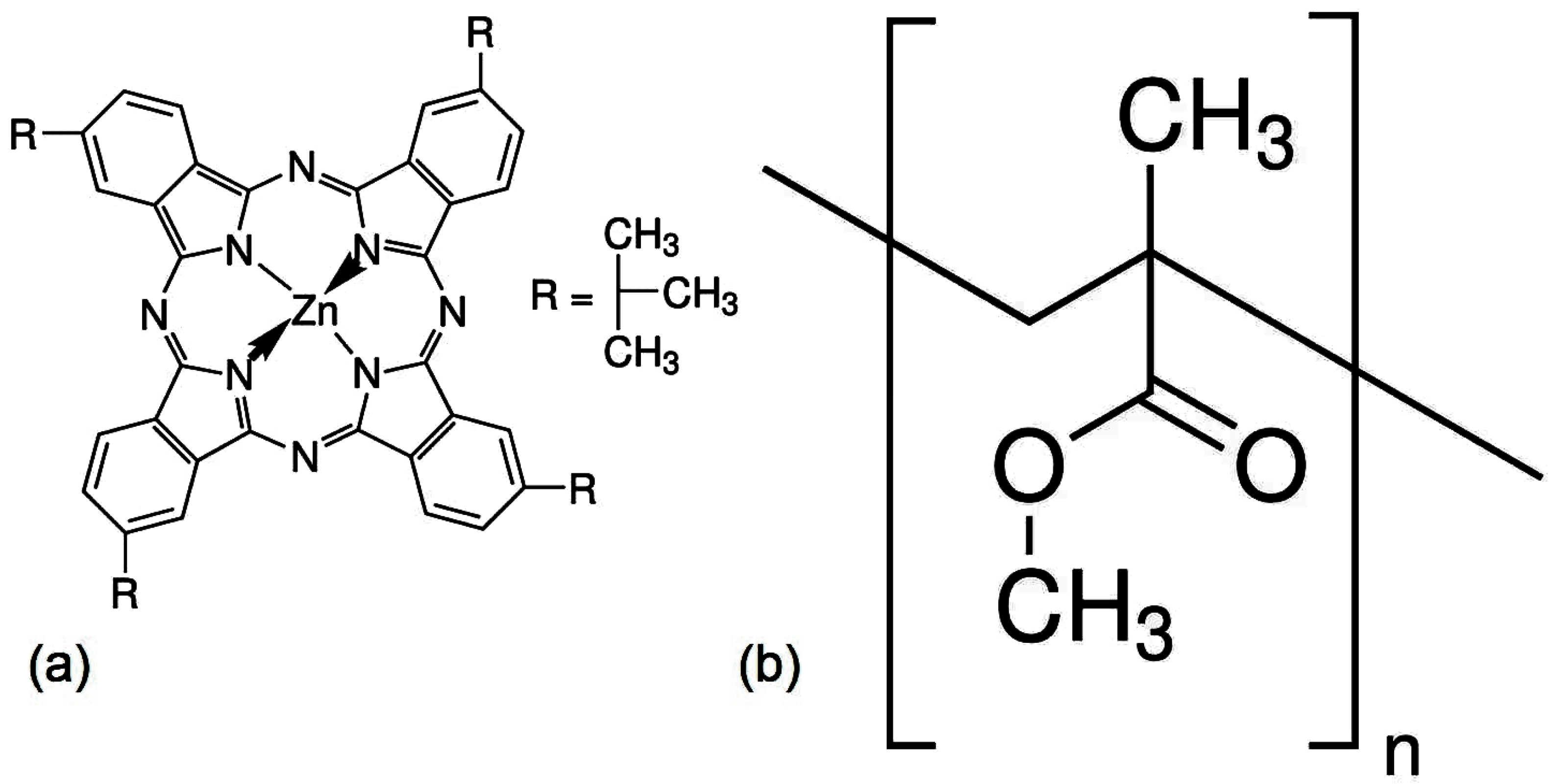

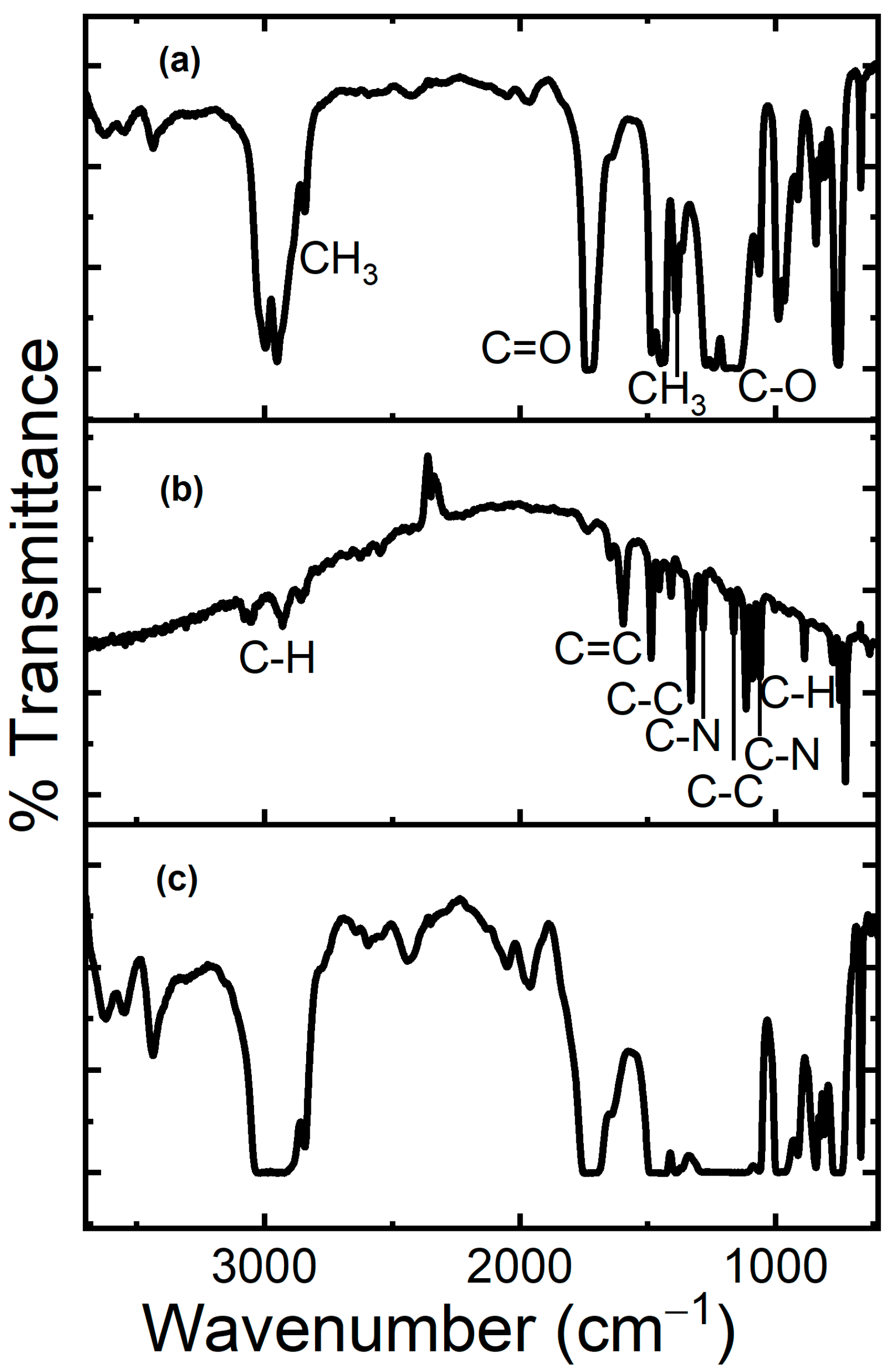

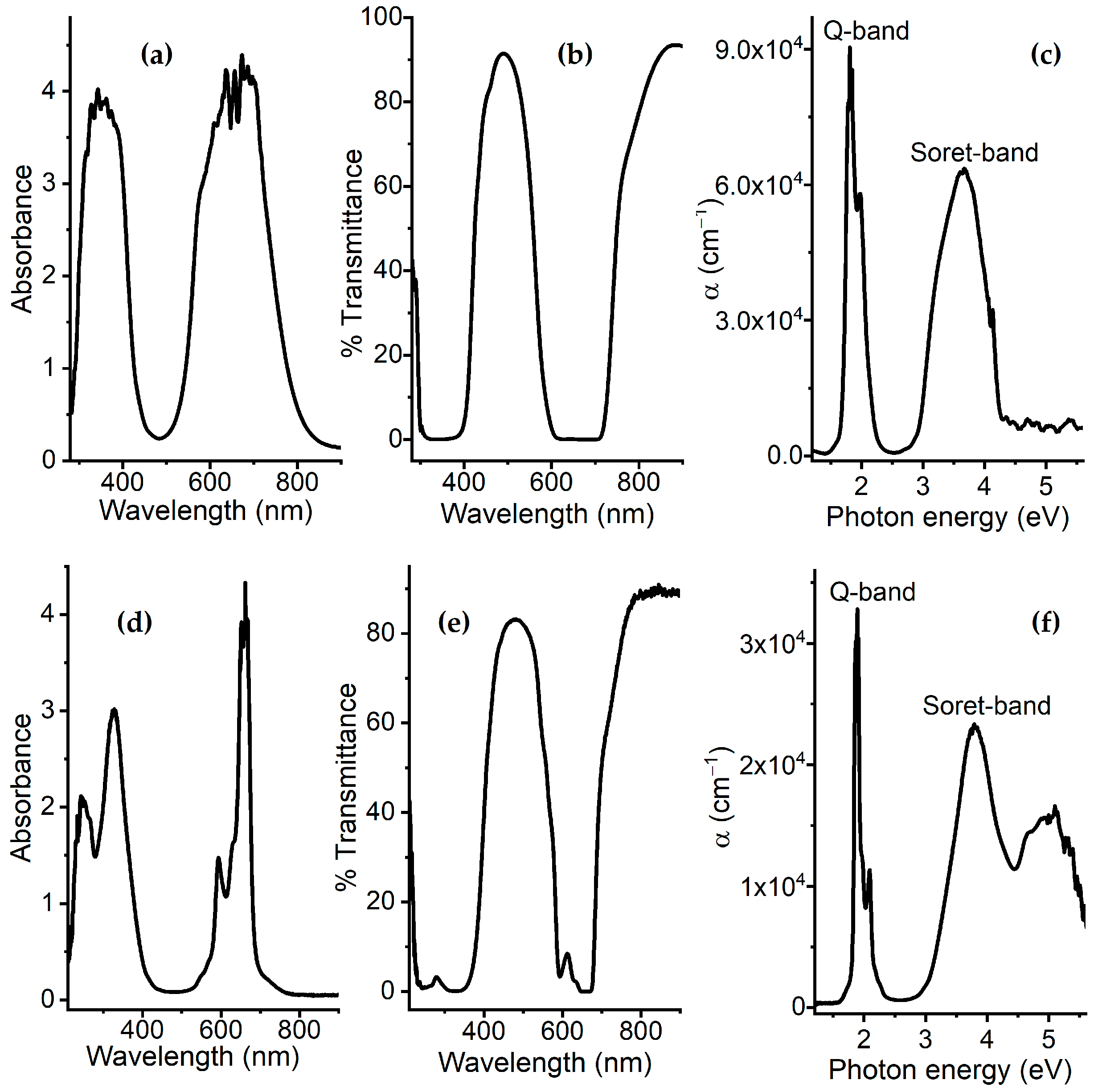

3.1. Structural and Optical Characterization of Pristine ZnTTBPc Film and Composite ZnTTBPc–PMMA Film

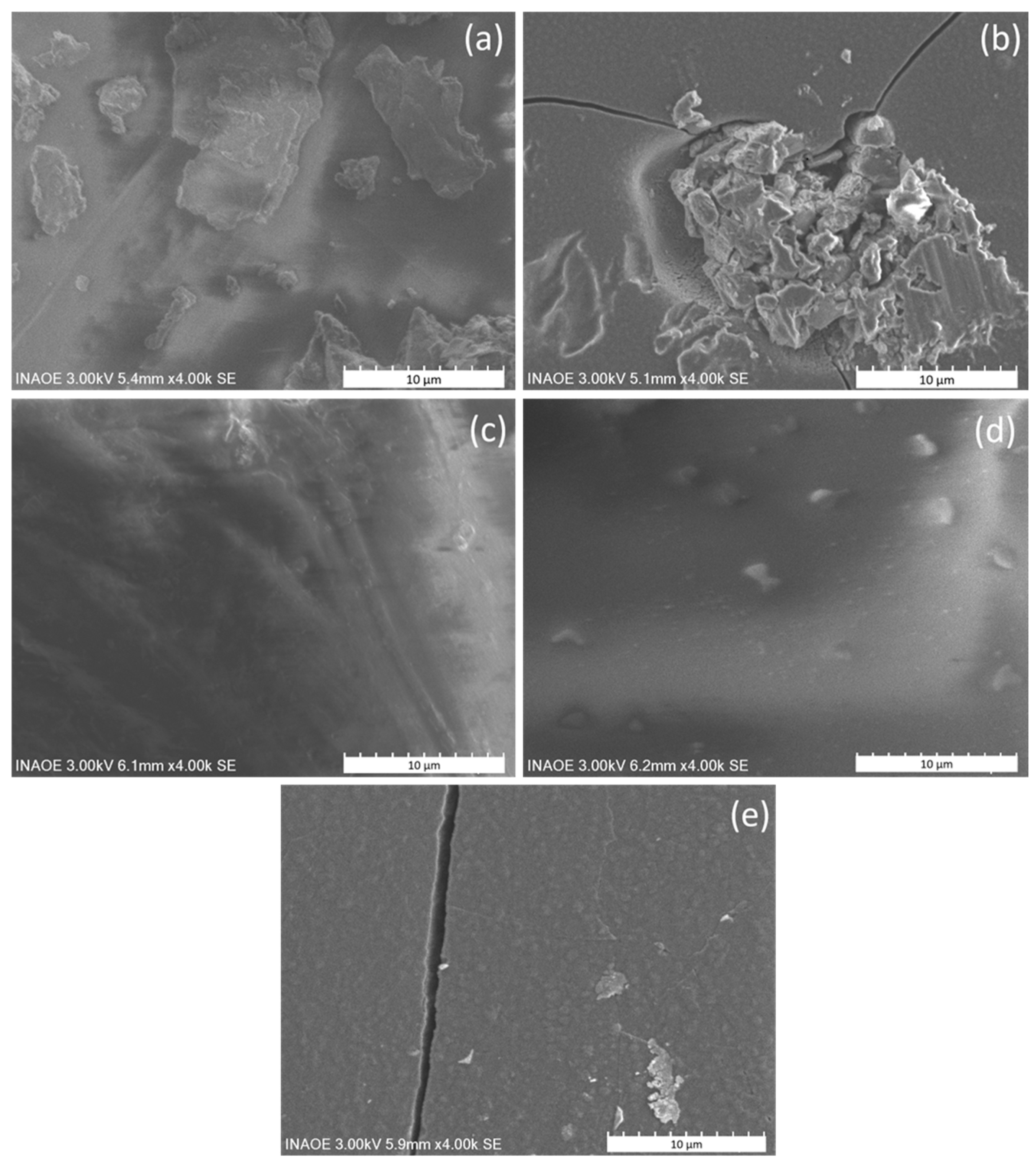

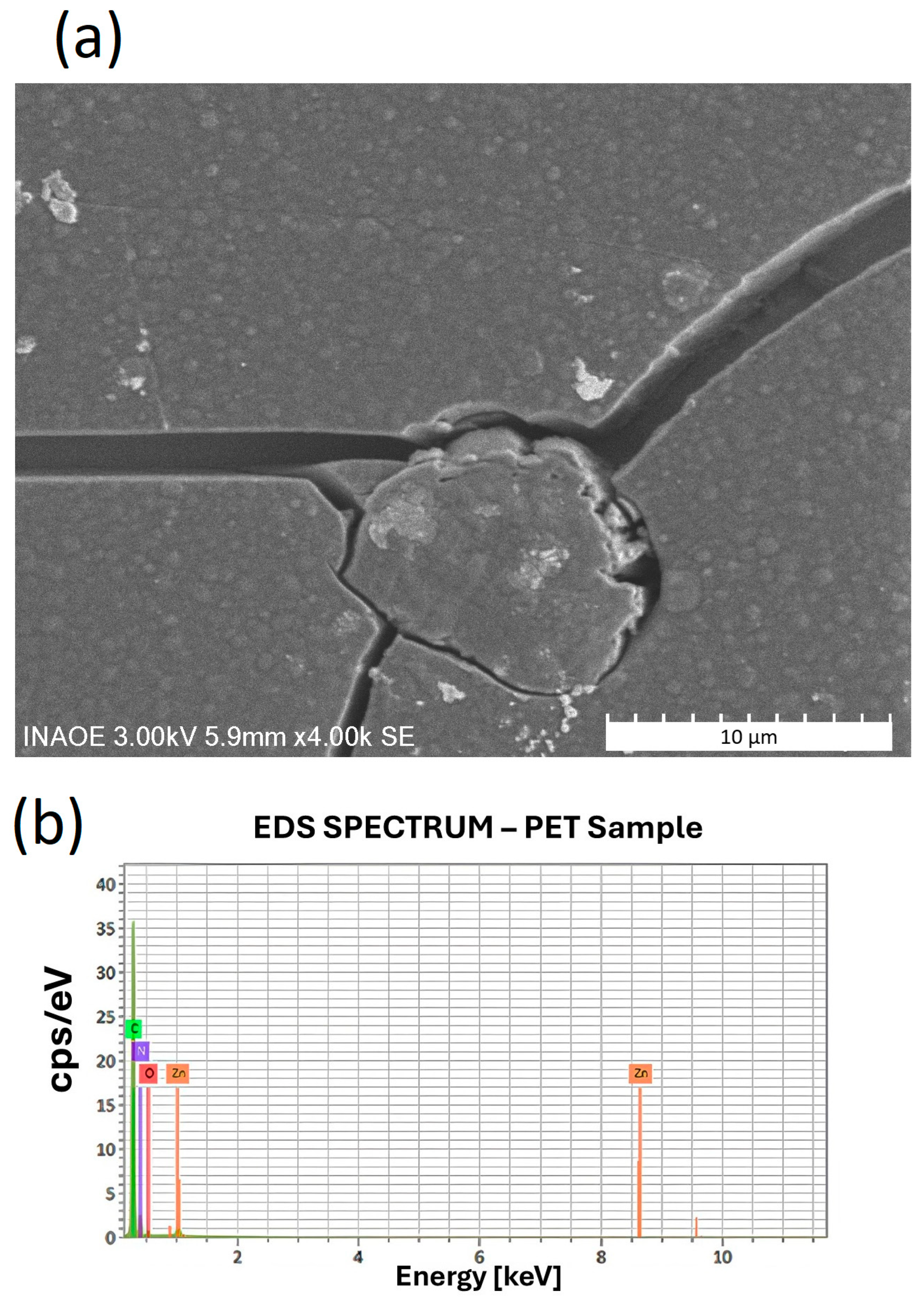

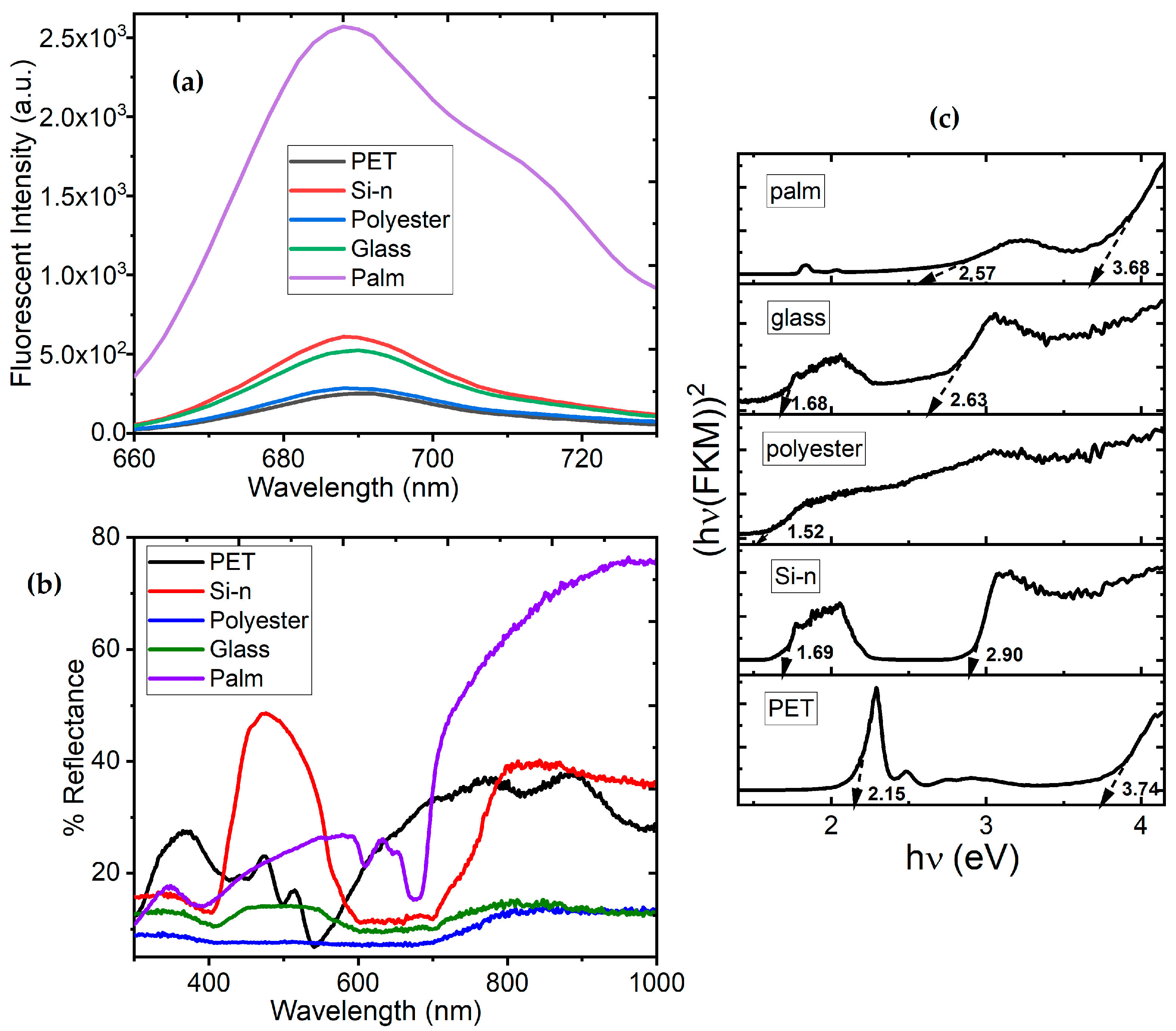

3.2. Study of ZnTTBPc–PMMA Films on Different Substrates

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shuvo, M.M.H.; Titirsha, T.; Amin, N.; Islam, S.K. Energy Harvesting in Implantable and Wearable Medical Devices for Enduring Precision Healthcare. Energies 2022, 15, 7495. [Google Scholar] [CrossRef]

- Murukesh; Sikkander, A.M.; Hemavathy, N.; Theivanathan, G.; Mishra, S.R. Assess of Chemical and Biosensors Chips. YMER 2022, 21, 1455–1462. Available online: https://ymerdigital.com/uploads/YMER2105U2.pdf (accessed on 7 January 2025). [CrossRef]

- Pranav, K.V.R.; Sarma, K.J. An overview of various sensors and their uses. Int. J. Multidiscip. Res. 2022, 4, 27. Available online: https://www.ijfmr.com/papers/2022/5/839.pdf (accessed on 7 January 2025).

- Haleem, A.; Javaid, M.; Singh, R.P.; Suman, R.; Rab, S. Biosensors applications in medical field: A brief review. Sens. Int. 2021, 2, 100100. [Google Scholar] [CrossRef]

- Haj, M.; Can, A.; Erarslan, A.; Basaran, Y.; Ciftci, F. Biomedical Applications of wearable biosensors. Next Mater. 2024, 3, 100084. [Google Scholar] [CrossRef]

- Polat, E.O.; Cetin, M.N.; Tabak, A.F.; Güven, E.B.; Uysal, B.Ö.; Arsan, T.; Kabbani, A.; Hamed, H.; Gül, S.B. Transducer technologies for biosensors and their wearable applications. Biosensors 2022, 12, 385. [Google Scholar] [CrossRef]

- Litvinova, O.; Eitenberger, M.; Bilir, A.; Yeung, A.W.K.; Parvanov, E.D.; Sundaram, A.M.; Horbańczuk, O.J.; Atanasov, A.G.; Willschke, H. Patent analysis of digital sensors for continuous glucose monitoring. Front. Public Health 2023, 11, 1205903. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Rab, S.; Singh, R.P.; Suman, R. Sensors for daily life: A review. Sens. Int. 2021, 2, 100121. [Google Scholar] [CrossRef]

- Christin, D.; Mogre, P.S.; Hollick, M. Survey on Wireless Sensor Network Technologies for Industrial Automation: The Security and Quality of Service Perspectives. Future Internet 2010, 2, 96–125. [Google Scholar] [CrossRef]

- Sabban, A. Novel Meta-Fractal Wearable Sensors and Antennas for Medical, Communication, 5G, and IoT Applications. Fractal Fract. 2024, 8, 100. [Google Scholar] [CrossRef]

- Kumar, D.; Verma, C.; Dahiya, S.; Singh, P.K.; Raboaca, M.S.; Illés, Z.; Bakariya, B. Cardiac Diagnostic Feature and Demographic Identification (CDF-DI): An IoT Enabled Healthcare Framework Using Machine Learning. Sensors 2021, 21, 6584. [Google Scholar] [CrossRef] [PubMed]

- Kozitsina, A.N.; Svalova, T.S.; Malysheva, N.N.; Okhokhonin, A.V.; Vidrevich, M.B.; Brainina, K.Z. Sensors Based on Bio and Biomimetic Receptors in Medical Diagnostic, Environment, and Food Analysis. Biosensors 2018, 8, 35. [Google Scholar] [CrossRef] [PubMed]

- Zhou, T.; Zhang, T. Recent Progress of Nanostructured Sensing Materials from 0D to 3D: Overview of Structure–Property-Application Relationship for Gas Sensors. Small Methods 2021, 5, 2100515. [Google Scholar] [CrossRef] [PubMed]

- Haghi, M.; Thurow, K.; Habil; Stoll, R. Wearable Devices in Medical Internet of Things: Scientific Research and Commercially Available Devices. Healthc. Inform. Res. 2017, 23, 4–15. Available online: https://e-hir.org/upload/pdf/hir-23-4.pdf (accessed on 13 January 2025). [CrossRef]

- Guk, K.; Han, G.; Lim, J.; Jeong, K.; Kang, Y.; Lim, E.-K.; Jung, J. Evolution of Wearable Devices with Real-Time Disease Monitoring for Personalized Healthcare. Nanomaterials 2019, 9, 813. [Google Scholar] [CrossRef]

- Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X.-M. Fiber-based Wearable Electronics: A Review of Materials, Fabrication, Devices and Applications. Adv. Mater. 2014, 26, 5310–5336. [Google Scholar] [CrossRef]

- Bao, Z.; Chen, X. Flexible and Stretchable Devices. Adv. Mater. 2016, 28, 4177–4179. [Google Scholar] [CrossRef]

- Varma, S.J.; Kumar, K.S.; Seal, S.; Rajaraman, S.; Thomas, J. Fiber-Type Solar Cells, Nanogenerators, Batteries, and Supercapacitors for Wearable Applications. Adv. Sci. 2018, 5, 32. [Google Scholar] [CrossRef]

- Gao, W.; Ota, H.; Kiriya, D.; Takei, K.; Javey, A. Flexible Electronics toward Wearable Sensing. Acc. Chem. Res. 2019, 52, 523–533. [Google Scholar] [CrossRef]

- Koydemir, H.C.; Ozcan, A. Wearable, and Implantable Sensors for Biomedical Applications. Annu. Rev. 2018, 11, 127–146. [Google Scholar] [CrossRef]

- Babu, M.; Lautman, Z.; Lin, X.; Sobota, M.H.B.; Snyder, M.P. Wearable Devices: Implications for Precision Medicine and the Future of Health Care. Annu. Rev. 2024, 75, 401–415. [Google Scholar] [CrossRef] [PubMed]

- Klyamer, D.; Bonegardt, D.; Basova, T. Fluoro-Substituted Metal Phthalocyanines for Active Layers of Chemical Sensors. Chemosensors 2021, 9, 133. [Google Scholar] [CrossRef]

- Demir, E.; Silah, H.; Uslu, B. Phthalocyanine Modified Electrodes in Electrochemical Analysis. Crit. Rev. Anal. Chem. 2020, 52, 425–461. [Google Scholar] [CrossRef]

- Schmidt, A.M.; Calvete, M.J.F. Phthalocyanines: An Old Dog Can Still Have New (Photo) Tricks. Molecules 2021, 26, 2823. [Google Scholar] [CrossRef]

- Sánchez-Vergara, M.E.; Hamui, L.; González Habib, S. New Approaches in Flexible Organic Field-Effect Transistors (FETs) Using InClPc. Materials 2019, 12, 1712. [Google Scholar] [CrossRef]

- Klyamer, D.; Sukhikh, A.; Bonegardt, D.; Krasnov, P.; Popovetskiy, P.; Basova, T. Thin Films of Chlorinated Vanadyl Phthalocyanines as Active Layers of Chemiresistive Sensors for the Detection of Ammonia. Micromachines 2023, 14, 1773. [Google Scholar] [CrossRef]

- Wumaier, K.; Mamtmin, G.; Ma, Q. Zinc Phthalocyanine Thin Film-Based Optical Waveguide H2S Gas Sensor. Photonic Sens. 2021, 12, 74–83. [Google Scholar] [CrossRef]

- Gil-Martínez, A.; Hernández, A.; Galiana-Roselló, C. Development and application of metallo-phthalocyanines as potent G-quadruplex DNA binders and photosensitizers. JBIC J. Biol. Inorg. Chem. 2023, 28, 495–507. [Google Scholar] [CrossRef]

- Xu, Z.; Romankov, V.; Doll, A.; Dreiser, J. Orienting dilute thin films of non-planar spin-1/2 vanadyl–phthalocyanine complexes. Mater. Adv. 2022, 3, 4938–4946. Available online: https://pubs.rsc.org/en/content/articlepdf/2022/ma/d2ma00157h (accessed on 19 January 2025). [CrossRef]

- Kakade, S.; Ghosh, R.; Palit, D.K. Excited State Dynamics of Zinc–Phthalocyanine Nanoaggregates in Strong Hydrogen Bonding Solvents. J. Phys. Chem. C 2012, 116, 15155–15166. [Google Scholar] [CrossRef]

- El-Khouly, M.E.; El-Said, W.A.; Yildirim, E.; El-Shafei, A. Influence of cationic dimeric and trimeric-type surfactants on the aggregation behavior of water-soluble phthalocyanine: A combined experimental and computational study. J. Mol. Liq. 2024, 400, 124581. [Google Scholar] [CrossRef]

- Mizuno, H.; Nagano, K.; Tomita, S.; Yanagi, H.; Hiromitsu, I. Organic photovoltaic cells with onion-like carbon thin films as hole collection layers. Thin Solid Film. 2018, 654, 69–76. [Google Scholar] [CrossRef]

- Uttiya, S.; Pratontep, S.; Bhanthumnavin, W.; Buntem, R.; Kerdcharoen, T. Volatile organic compound sensor arrays based on zinc phthalocyanine and zinc porphyrin thin films. In Proceedings of the 2nd IEEE International Nanoelectronics Conference, 24–27 March 2008; pp. 618–623. [Google Scholar] [CrossRef]

- Tamošiūnaitė, J.; Streckaitė, S.; Chmeliov, J.; Valkunas, L.; Gelzinis, A. Concentration quenching of fluorescence in thin films of zinc-phthalocyanine. Chem. Phys. 2023, 572, 111949. Available online: https://www.sciencedirect.com/science/article/pii/S0301010423001313?via%3Dihub#fig1 (accessed on 21 January 2025). [CrossRef]

- Catania, F.; de Souza Oliveira, H.; Lugoda, P.; Cantarella, G.; Münzenrieder, N. Thin-film electronics on active substrates: Review of materials, technologies and applications. J. Phys. D Appl. Phys. 2022, 55, 323002. [Google Scholar] [CrossRef]

- Harris, K.D.; Elias, A.L.; Chung, H.-J. Flexible electronics under strain: A review of mechanical characterization and durability enhancement strategies. J. Mater. Sci. 2016, 51, 2771–2805. [Google Scholar] [CrossRef]

- Münzenrieder, N.; Cantarella, G.; Vogt, C.; Petti, L.; Büthe, L.; Salvatore, G.A.; Fang, Y.; Andri, R.; Lam, Y.; Libanori, R.; et al. Stretchable and conformable oxide thin-film electronics. Adv. Electron. Mater. 2015, 1, 1400038. [Google Scholar] [CrossRef]

- Walker, J.; Gabriel, K.; Mehregany, M. Thin-film processing of TiNi shape memory alloy. Sens. Actuators A 1990, 21, 243–246. [Google Scholar] [CrossRef]

- Ze, Q.; Kuang, X.; Wu, S.; Wong, J.; Montgomery, S.M.; Zhang, R.; Kovitz, J.M.; Yang, F.; Qi, H.J.; Zhao, R. Magnetic shape memory polymers with integrated multifuncitional shape manipulation. Adv. Mater. 2020, 32, 1906657. [Google Scholar] [CrossRef]

- Dong, Z.-Q.; Cao, Y.; Yuan, Q.-J.; Wang, Y.-F.; Li, J.-H.; Li, B.-J.; Zhang, S. Redox-and Glucose-Induced Shape-Memory Polymers. Macromol. Rapid. Commun. 2013, 34, 867–872. [Google Scholar] [CrossRef]

- Yu, K.; Kuzum, D.; Hwang, S.W.; Kim, B.H.; Juul, H.; Kim, N.H.; Won, S.M.; Chiang, K.; Trumpis, M.; Richardson, A.G.; et al. Bioresorbable silicon electronics for transient spatiotemporal mapping of electrical activity from the cerebral cortex. Nat. Mater. 2016, 15, 782–791. [Google Scholar] [CrossRef]

- Hughes-Riley, T.; Dias, T.; Cork, C. A historical review of the development of electronic textiles. Fibers 2018, 6, 34. [Google Scholar] [CrossRef]

- Lee, M.-H.; Teng, K.-H.; Liang, Y.-Y.; Ding, C.-F.; Chen, Y.-C. Flexible biodegradable wearables based on conductive leaf networks. Sustain. Mater. Technol. 2025, 43, e01263. [Google Scholar] [CrossRef]

- Guo, Z.; Liu, J.; Li, Y.; Lin, H.; Wang, H.; Tam, K.C.H.; Liu, G. Effects of dispersion techniques on the emulsion polymerization of methyl methacrylate. Colloid Polym. Sci. 2021, 299, 1147–1159. [Google Scholar] [CrossRef]

- Yuan, L.; Wang, Y.; Pan, M.; Rempel, G.L.; Pan, Q. Synthesis of poly(methyl methacrylate) nanoparticles via differential microemulsion polymerization. Eur. Polym. J. 2013, 49, 41–48. [Google Scholar] [CrossRef]

- Aziz, S.B.; Abdullah, G.O.; Brza, M.A.; Azawy, A.K.; Tahir, D.A. Effect of carbon nano-dots (CNDs) on structural and optical properties of PMMA polymer composite. Results Phys. 2019, 15, 102776. [Google Scholar] [CrossRef]

- Soman, V.V.; Kelkar, D.S. FTIR studies of doped PMMA–PVC blend system. Macromol. Symp. 2009, 277, 152–161. [Google Scholar] [CrossRef]

- Islam, Z.U.; Tahir, M.; Syed, W.A.; Aziz, F.; Wahab, F.; Said, S.M.; Sarker, M.R.; Ali, S.H.M.; Sabri, M.F.M. Fabrication and Photovoltaic Properties of Organic Solar Cell Based on Zinc Phthalocyanine. Energies 2020, 13, 962. [Google Scholar] [CrossRef]

- Socol, M.; Preda, N.; Costas, A.; Breazu, C.; Stanculescu, A.; Rasoga, O.; Popescu-Pelin, G.; Mihailescu, A.; Socol, G. Hybrid organic-inorganic thin films based on zinc phthalocyanine and zinc oxide deposited by MAPLE. Appl. Surf. Sci. 2020, 503, 144317. [Google Scholar] [CrossRef]

- Ahmad, A.; Collins, R. FTIR characterization of triclinic phthalocyanine. J. Phys. D Appl. Phys. 1991, 24, 1894–1897. [Google Scholar] [CrossRef]

- Svorcik, V.; Lyutakov, O.; Huttel, I. Thickness dependence of refractive index and optical gap of PMMA layers prepared under electrical field. J. Mater. Sci. Mater. Electron. 2008, 19, 363–367. [Google Scholar] [CrossRef]

- Elimat, Z.M.; Zihlif, A.M.; Avella, M. Thermal and optical properties of poly(methyl methacrylate)/calcium carbonate nanocomposite. J. Exp. Nanosci. 2008, 3, 259–269. [Google Scholar] [CrossRef]

- Aziz, S.B.; Ahmed, H.M.; Hussein, A.M.; Fathulla, A.B.; Wsw, R.M.; Hussein, R.T. Tuning the absorption of ultraviolet spectra and optical parameters of aluminium doped PVA based solid polymer composites. J. Mater. Sci. Mater. Electron. 2015, 26, 8022–8028. [Google Scholar] [CrossRef]

- Alharbi, S.R.; Darwish, A.A.A.; Al Garni, S.E.; El Saeedy, H.I.; Abd El-Rahman, K.F. Influence of thickness and annealing on linear and nonlinear optical properties of manganese (III) chloride tetraphenyl porphine (MnTPPCl) organic thin films. Infrared Phys. Technol. 2016, 78, 77–83. [Google Scholar] [CrossRef]

- Abdulwahid, R.T.; Abdullah, O.G.; Aziz, S.B.; Hussein, S.A.; Muhammad, F.F.; Yahya, M.Y. The study of structural and optical properties of PVA:PbO2 based solid polymer nano-composites. J. Mater. Sci. Mater. Electron. 2016, 27, 12112–12118. [Google Scholar] [CrossRef]

- Bdewi, S.F.; Abdullah, O.G.; Aziz, B.K.; Mutar, A.A.R. Synthesis, structural and optical characterization of MgO nanocrystalline embedded in PVA matrix. J. Inorg. Organomet. Polym. Mater. 2016, 26, 326–334. [Google Scholar] [CrossRef]

- Abdulla, O.G.; Aziz, S.B.; Saber, D.R. Characterizations of pure and Pb2 + ion doped methylcellulose based biopolymer electrolyte films: Optical and electrical properties. Int. J. Electrochem. Sci. 2018, 13, 11931–11952. [Google Scholar] [CrossRef]

- Zidan, H.M.; Abu-Elnader, M. Structural and optical properties of pure PMMA and metal chloride-doped PMMA films. Phys. B 2005, 355, 308–317. [Google Scholar] [CrossRef]

- Zanfolim, A.A.; Volpati, D.; Olivati, C.A.; Job, A.E.; Constantino, C.J.L. Structural and Electric-Optical Properties of Zinc Phthalocyanine Evaporated Thin Films: Temperature and Thickness Effects. J. Phys. Chem. C 2010, 114, 12290–12299. [Google Scholar] [CrossRef]

- Ogunsipe, A.; Maree, D.; Nyokong, T. Solvent effects on the photochemical and fluorescence properties of zinc phthalocyanine derivatives. J. Mol. Struct. 2003, 650, 131–140. [Google Scholar] [CrossRef]

- Martin, W.E. Leaf scattering polarimetry and chlorophyll fluorescence. J. Quant. Spectrosc. Radiat. Transf. 2020, 242, 106760. [Google Scholar] [CrossRef]

- Tauc, J.; Menth, A. States in the gap. J. Non-Cryst. Solids 1972, 8, 569–585. [Google Scholar] [CrossRef]

| Substrate | Maximum Fluorescence Intensity | Maximum Reflectance (%) | EK-M (eV) |

|---|---|---|---|

| PET | 253 | 38% at 887 nm | 2.15, 3.74 |

| Polyester | 290 | 13% at 840 nm | 1.52 |

| Glass | 521 | 15% at 809 nm | 1.68, 2.63 |

| Si-n | 612 | 48% at 472 nm | 1.69, 2.90 |

| Palm | 2573 | 75% at 960 nm | 2.57, 3.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez Vergara, M.E.; Cosme, I.; Álvarez Bada, J.R. Substrate-Dependent Performance of ZnTTBPc–PMMA Composite Films on Rigid, Flexible, and Sustainable Materials for Wearable Devices. Polymers 2025, 17, 1574. https://doi.org/10.3390/polym17111574

Sánchez Vergara ME, Cosme I, Álvarez Bada JR. Substrate-Dependent Performance of ZnTTBPc–PMMA Composite Films on Rigid, Flexible, and Sustainable Materials for Wearable Devices. Polymers. 2025; 17(11):1574. https://doi.org/10.3390/polym17111574

Chicago/Turabian StyleSánchez Vergara, María Elena, Ismael Cosme, and José Ramón Álvarez Bada. 2025. "Substrate-Dependent Performance of ZnTTBPc–PMMA Composite Films on Rigid, Flexible, and Sustainable Materials for Wearable Devices" Polymers 17, no. 11: 1574. https://doi.org/10.3390/polym17111574

APA StyleSánchez Vergara, M. E., Cosme, I., & Álvarez Bada, J. R. (2025). Substrate-Dependent Performance of ZnTTBPc–PMMA Composite Films on Rigid, Flexible, and Sustainable Materials for Wearable Devices. Polymers, 17(11), 1574. https://doi.org/10.3390/polym17111574