Experimental Study of Comprehensive Performance Analysis Regarding the Dynamical/Mechanical Aspects of 3D-Printed UAV Propellers and Sound Footprint

Abstract

1. Introduction

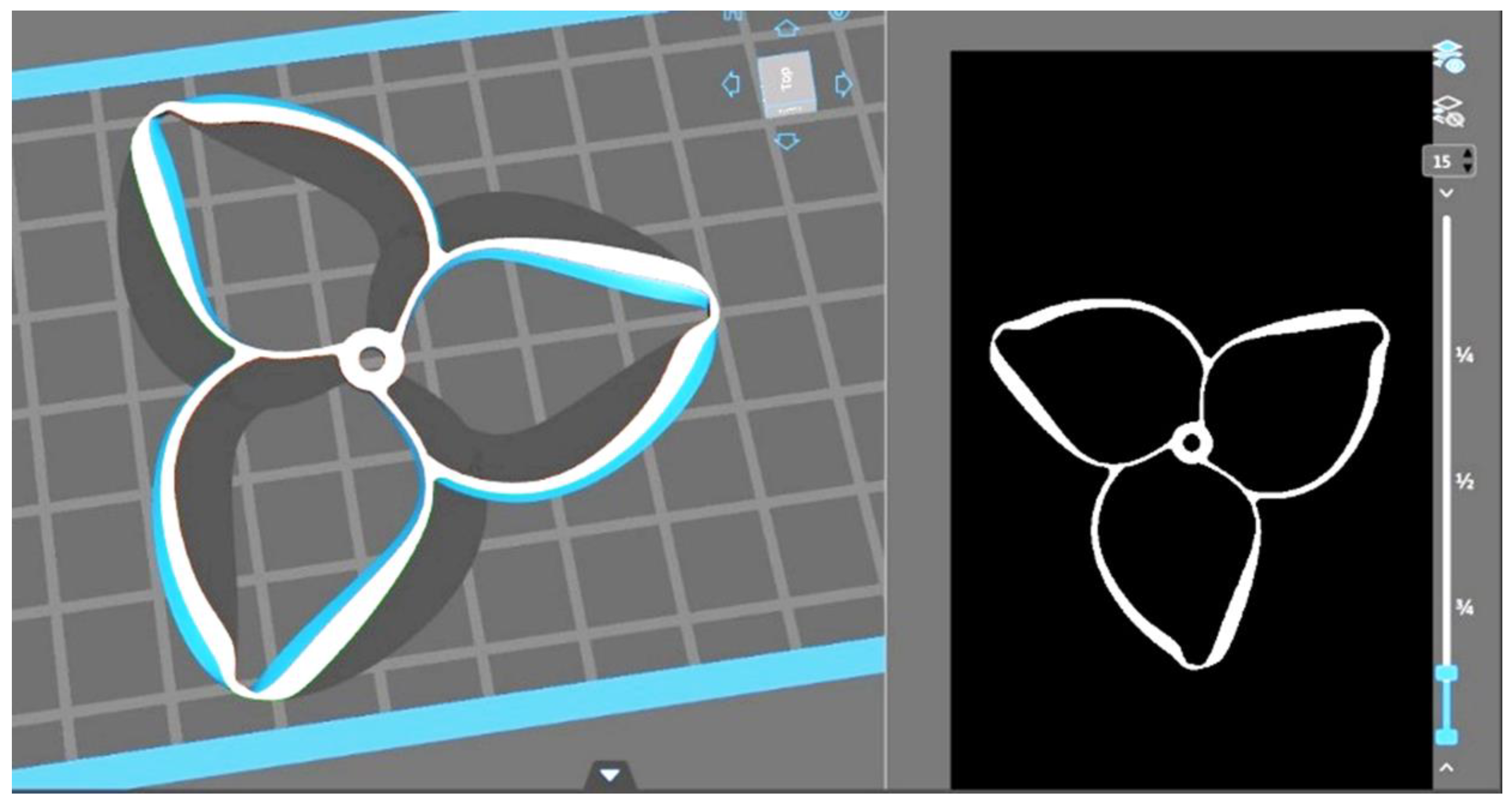

2. Materials and Methods

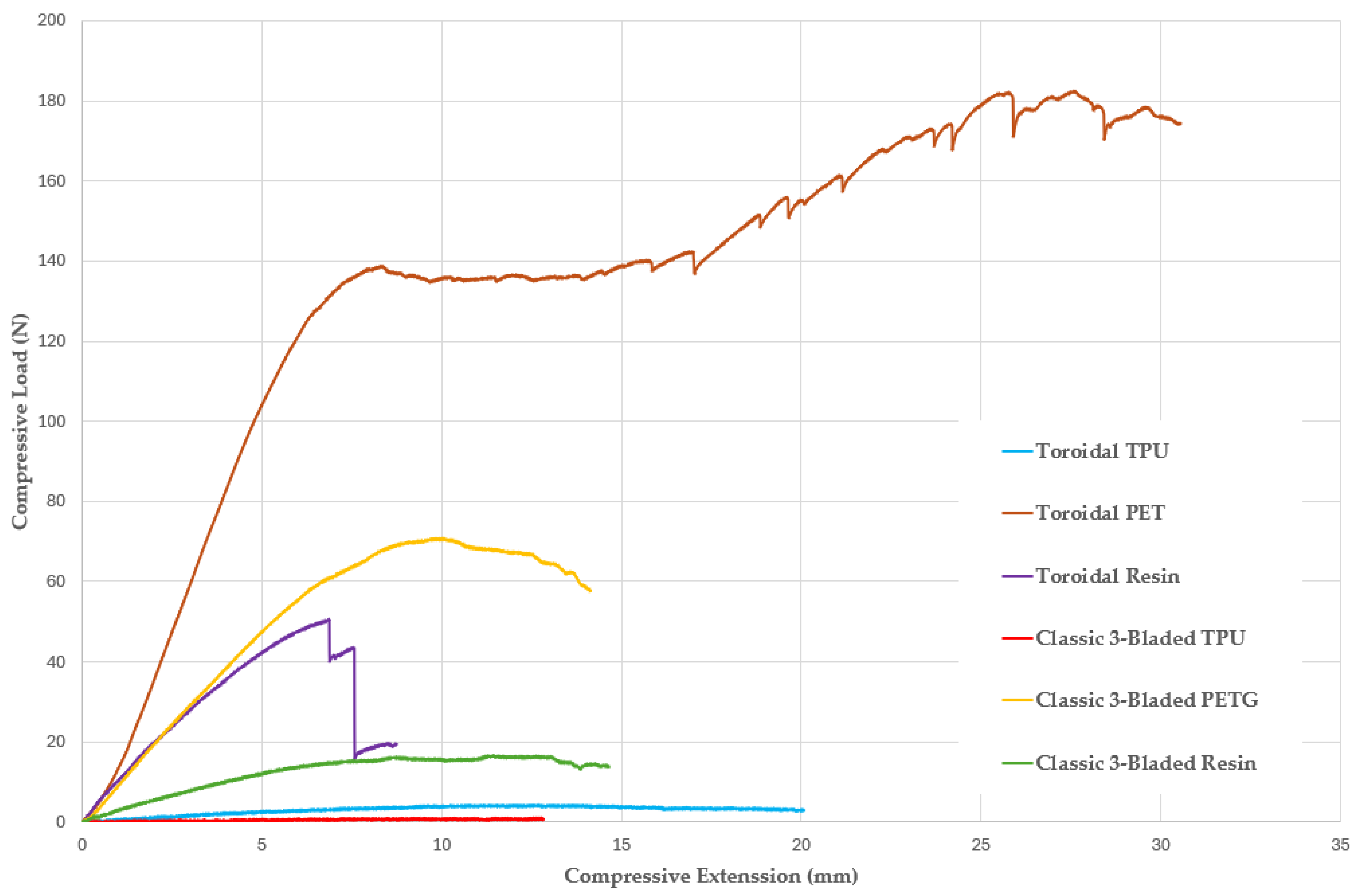

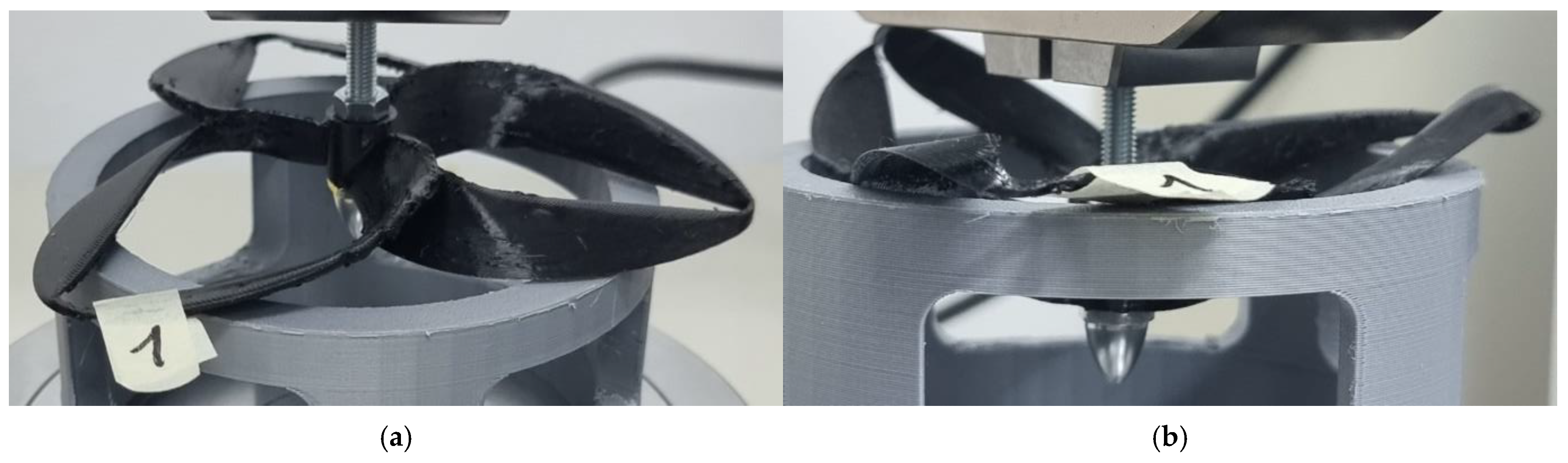

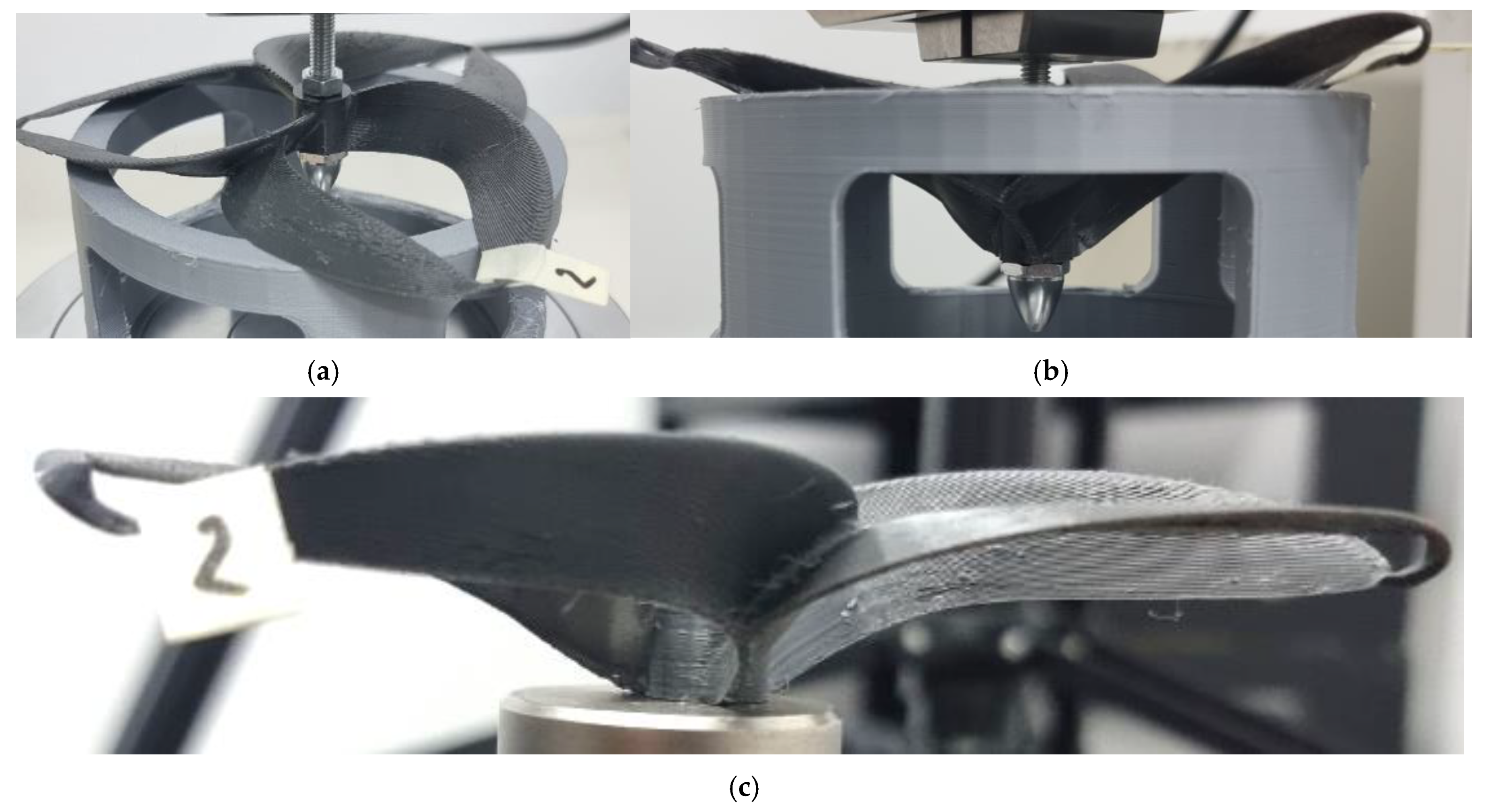

3. Results and Discussion

- The probe is mounted onto the motor shaft.

- Calibration is performed by recording the zero value.

- The pre-measured weight is applied, and the measurement is recorded.

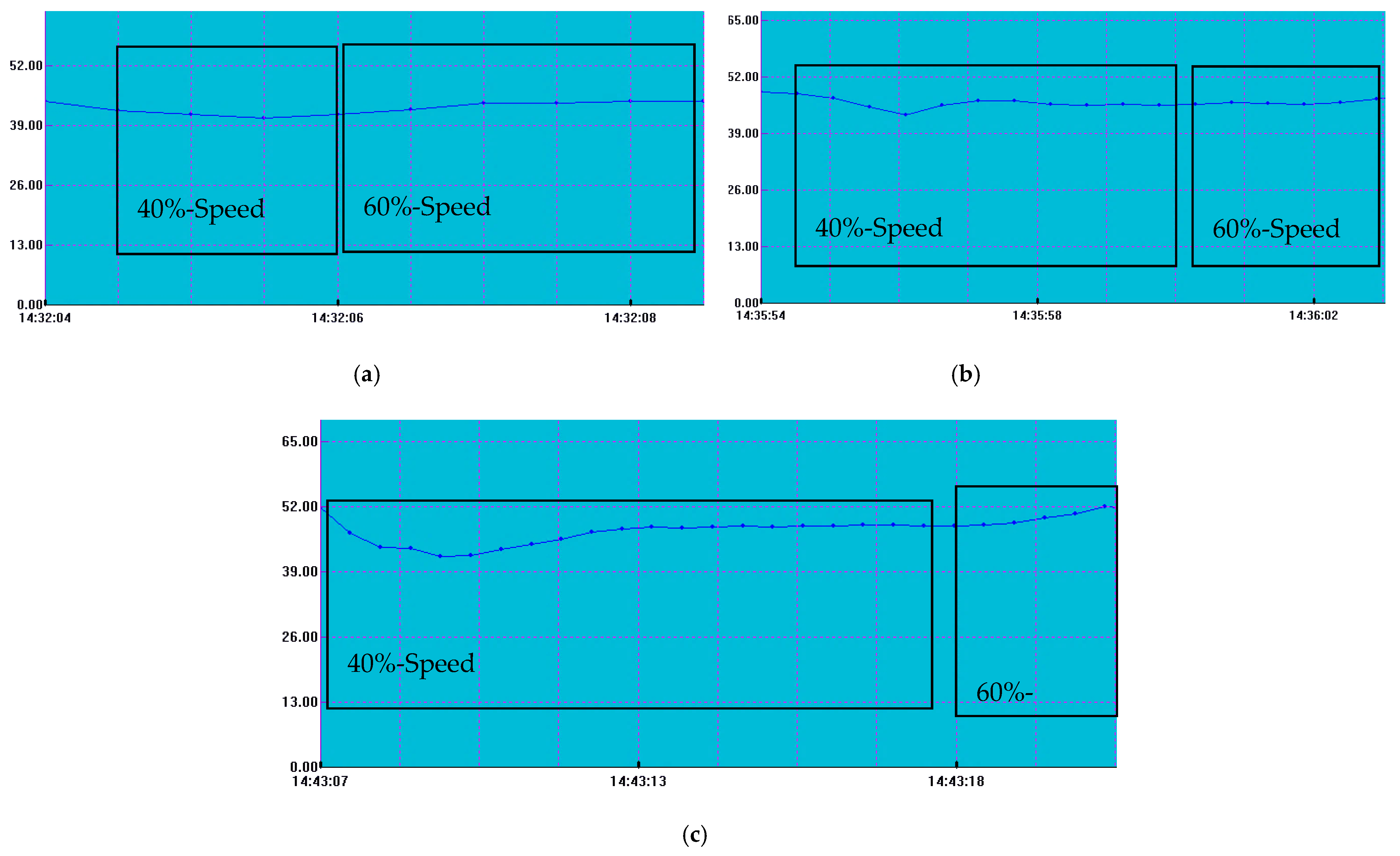

- The motor operates at 40% of its maximum RPM, and the thrust is recorded.

- The RPM is increased to 60%, and the corresponding thrust is recorded.

- The motor is deactivated, and the process is repeated for the next propeller.

- Specimen 1—Toroidal—TPU

- Specimen 2—Toroidal—PETG

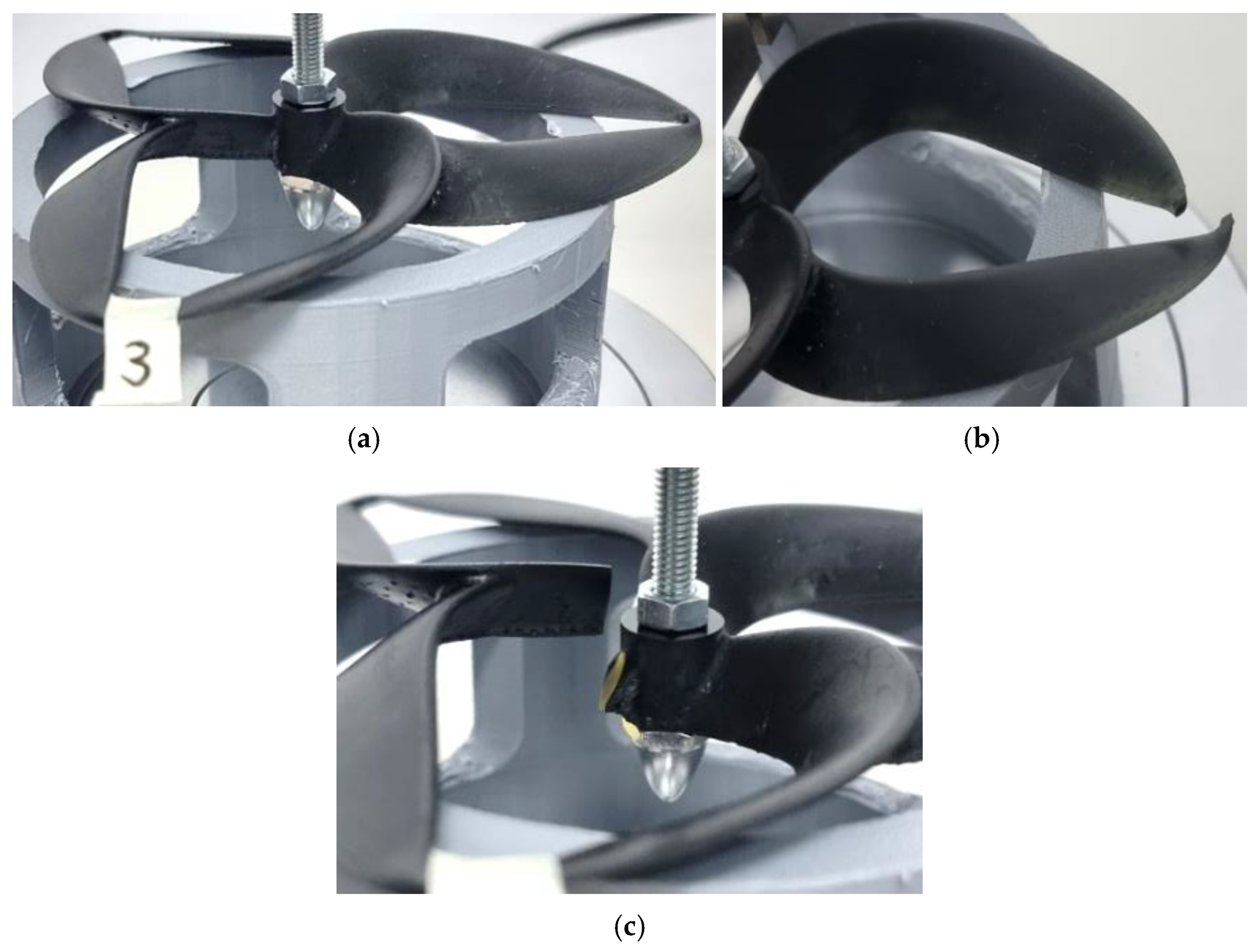

- Specimen 3—Toroidal—Resin

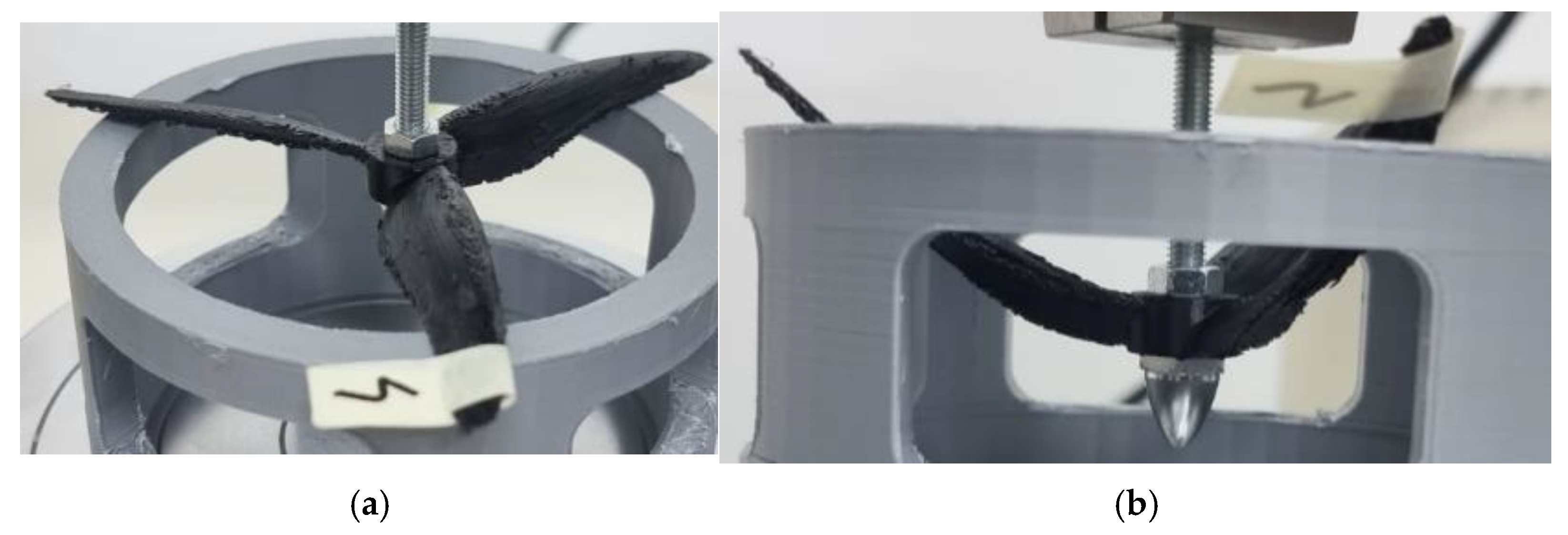

- Specimen 4—classic 3-bladed propeller—TPU

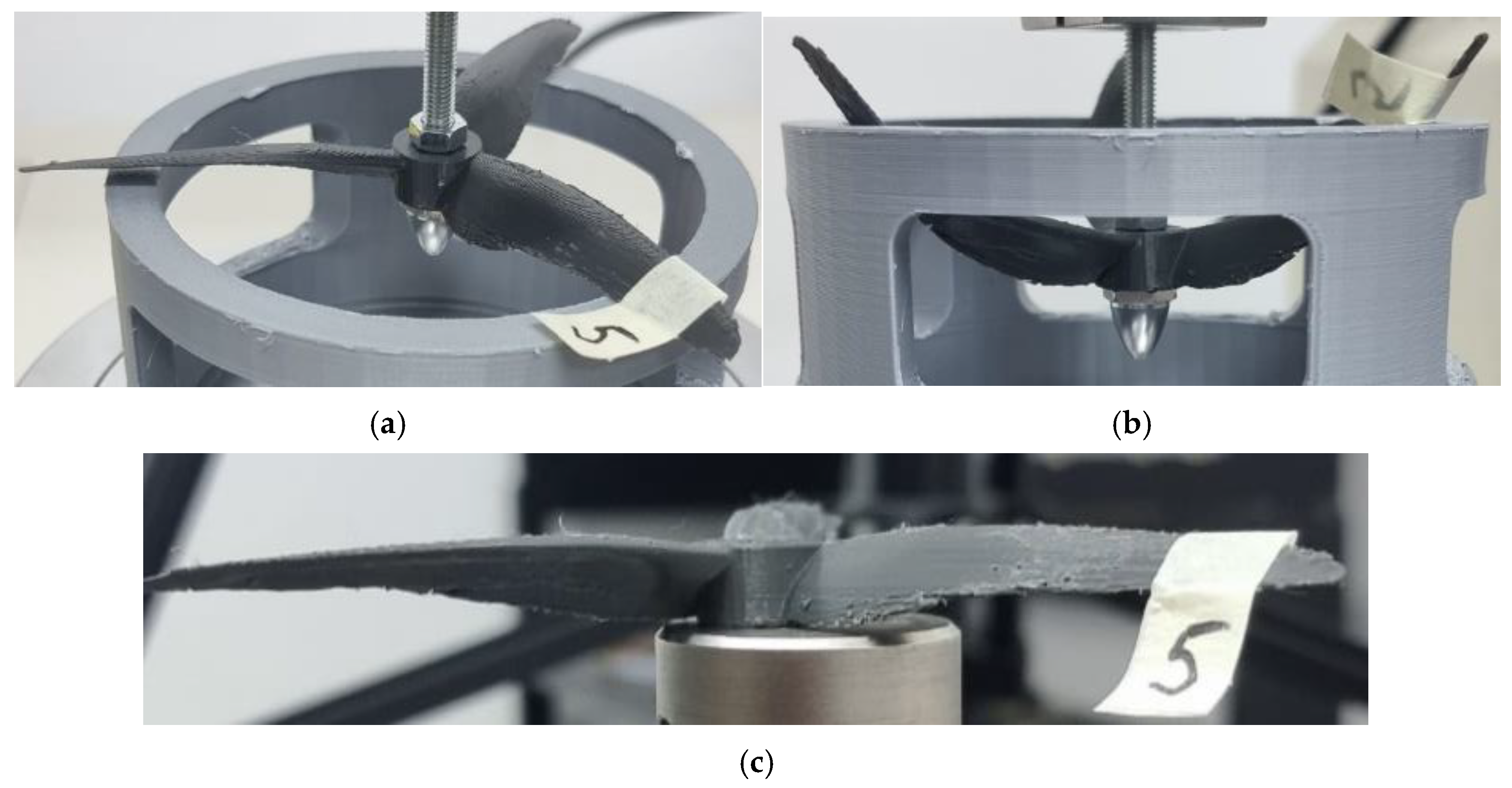

- Specimen 5—classic 3-bladed propeller—PETG

- Specimen 6—classic 3-bladed propeller—Resin

- The temperature of the motor windings is measured using the thermal camera. If the winding temperature matches the reference value, the trial can proceed.

- A timer is set for 5 min, and the first propeller probe is mounted and securely fastened onto the motor’s shaft.

- Simultaneously, the timer and the motor are started, with the motor running at 60% of its maximum rotational speed.

- The motor is stopped when the timer ends, and the temperature of the windings is immediately measured using the thermal camera.

- The propeller is removed, and the motor’s temperature is gradually brought back to the reference value.

- The experiment is repeated with a different propeller.

4. Conclusions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Telli, K.; Kraa, O.; Himeur, Y.; Ouamane, A.; Boumehraz, M.; Atalla, S.; Mansoor, W. A Comprehensive Review of Recent Research Trends on Unmanned Aerial Vehicles (UAVs). Systems 2023, 11, 400. [Google Scholar] [CrossRef]

- Palmer, M.; Laliberte, J. Effects of non-planar slicing techniques and carbon fibre material additives on the mechanical properties of 3D-printed drone propellers. Drone Syst. Appl. 2023, 11, 1–11. [Google Scholar] [CrossRef]

- Krmela, J.; Bakosova, A.; Krmelova, V.; Sadjiep Tchuigwa, B.S. Drone propeller blade material optimization using modern computational method. In Proceedings of the 20th International Scientific Conference on Engineering for Rural Development, Jelgava, Latvia, 26–28 May 2021. [Google Scholar] [CrossRef]

- Kiss-Nagy, K.; Simongáti, G.; Ficzere, P. Investigation of 3D Printed Underwater Thruster Propellers Using CFD and Structural Simulations. Period. Polytech. Mech. Eng. 2024, 68, 70–77. [Google Scholar] [CrossRef]

- Schuschnigg, S.; Hufnagl, M.; Holzer, C.; Eder, F.; Kroke, E.; Schallmeiner, S.; Seidler, K. Novel Additive Manufacturing Materials for Waste Heat Deduction. Adv. Eng. Mater. 2022, 25, 2200671. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Chen, J.-Y.; Chang, Y.-H. Optimization of Process Parameters for Fabricating Polylactic Acid Filaments Using Design of Experiments Approach. Polymers 2021, 13, 1222. [Google Scholar] [CrossRef]

- Baltić, M.Z.; Vasić, M.R.; Vorkapić, M.D.; Bajić, D.M.; Piteľ, J.; Svoboda, P.; Vencl, A. PETG as an Alternative Material for the Production of Drone Spare Parts. Polymers 2024, 16, 2976. [Google Scholar] [CrossRef]

- MIT Lincoln Laboratory. Toroidal Propeller. Available online: https://www.ll.mit.edu/sites/default/files/other/doc/2022-09/TVO_Technology_Highlight_41_Toroidal_Propeller.pdf (accessed on 27 October 2024).

- Gemfan Hobby. Product Details: Gemfan 51466-3 Propeller. Available online: https://www.gfprops.com/products/gemfan-hurricane-mck-51466-3.html (accessed on 16 October 2024).

- Sun, J.; Yonezawa, K.; Shima, E.; Liu, H. Experimental Investigations on Aerodynamic and Psychoacoustic Characteristics of Three-Blade Looprop Propeller. J. Acoust. Soc. Am. 2023, 154 (Suppl. 4), A144. [Google Scholar] [CrossRef]

- Nohut, S.; Schwentenwein, M. Vat Photopolymerization Additive Manufacturing of Functionally Graded Materials: A Review. J. Manuf. Mater. Process. 2022, 6, 17. [Google Scholar] [CrossRef]

- Sun, J.; Yonezawa, K.; Shima, E.; Liu, H. Integrated Evaluation of the Aeroacoustics and Psychoacoustics of a Single Propeller. Int. J. Environ. Res. Public Health 2023, 20, 1955. [Google Scholar] [CrossRef]

- Aminuddin, A.; Salim, S. Aerodynamic Analysis of Propeller for Heavy Lifting Drone Applications Using Blade Element Momentum Analysis. Prog. Aerosp. Aviat. Technol. 2022, 2, 24–32. [Google Scholar] [CrossRef]

- Darvishpoor, S.; Roshanian, J.; Raissi, A.; Hassanalian, M. Configurations, Flight Mechanisms, and Applications of Unmanned Aerial Systems: A Review. Prog. Aerosp. Sci. 2020, 121, 100694. [Google Scholar] [CrossRef]

- Zhang, Y. Aeroacoustics analysis of propeller blades. J. Phys. Conf. Ser. 2023, 2569, 012026. [Google Scholar] [CrossRef]

- Salmi, M. Design and Applications of Additive Manufacturing and 3D Printing. Designs 2022, 6, 6. [Google Scholar] [CrossRef]

- Balakrishnan, H.; Badar, F.; Doeven, E.; Novak, J.; Merenda, A.; Dumée, L.; Loy, J.; Guijt, R. 3D Printing: An Alternative Microfabrication Approach with Unprecedented Opportunities in Design. Anal. Chem. 2020, 93, 350–366. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, M.; Yonezawa, A.; Takeda, K.; Yamada, A. Evaluation of the Deterioration of the Mechanical Properties of Poly(lactic acid) Structures Fabricated by a Fused Filament Fabrication 3D Printer. Inventions 2019, 4, 21. [Google Scholar] [CrossRef]

- Guerra Silva, R.; Torres, M.J.; Zahr Viñuela, J.; Zamora, A.G. Manufacturing and Characterization of 3D Miniature Polymer Lattice Structures Using Fused Filament Fabrication. Polymers 2021, 13, 635. [Google Scholar] [CrossRef]

- Syrlybayev, D.; Zharylkassyn, B.; Seisekulova, A.; Akhmetov, M.; Perveen, A.; Talamona, D. Optimisation of Strength Properties of FDM Printed Parts—A Critical Review. Polymers 2021, 13, 1587. [Google Scholar] [CrossRef]

- Hassan, M.H.; Omar, A.M.; Daskalakis, E.; Hou, Y.; Huang, B.; Strashnov, I.; Grieve, B.D.; Bártolo, P. The Potential of Polyethylene Terephthalate Glycol as Biomaterial for Bone Tissue Engineering. Polymers 2020, 12, 3045. [Google Scholar] [CrossRef]

- Oliveira, T.; de Oliveira, M.; Oliveira, L.; Silva, L. Evaluation of Polymers for Upper Limb Orthosis Through Computer Simulation. Res. Soc. Dev. 2022, 11, e585111234937. [Google Scholar] [CrossRef]

- Haryńska, A.; Carayon, I.; Kosmela, P.; Brillowska-Dąbrowska, A.; Łapiński, M.; Kucińska-Lipka, J.; Janik, H. Processing of Polyester-Urethane Filament and Characterization of FFF 3D Printed Elastic Porous Structures with Potential in Cancellous Bone Tissue Engineering. Materials 2020, 13, 4457. [Google Scholar] [CrossRef]

- Fenollosa, F.; Jorand, L.; Otero, A.T.; Lustig, P.; Romero-Sabat, G.; Medel, S.; Uceda, R. Soft 3D printing of thermoplastic polyurethane: Preliminary study. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2023, 237, 1128–1135. [Google Scholar] [CrossRef]

- Bertana, V.; De Pasquale, G.; Ferrero, S.; Scaltrito, L.; Catania, F.; Nicosia, C.; Marasso, S.L.; Cocuzza, M.; Perrucci, F. 3D Printing with the Commercial UV-Curable Standard Blend Resin: Optimized Process Parameters towards the Fabrication of Tiny Functional Parts. Polymers 2019, 11, 292. [Google Scholar] [CrossRef]

- Ellakany, P.; Fouda, S.M.; Mahrous, A.A.; AlGhamdi, M.A.; Aly, N.M. Influence of CAD/CAM Milling and 3D-Printing Fabrication Methods on the Mechanical Properties of 3-Unit Interim Fixed Dental Prosthesis after Thermo-Mechanical Aging Process. Polymers 2022, 14, 4103. [Google Scholar] [CrossRef]

- Park, S.; Cho, W.; Lee, H.; Bae, J.; Jeong, T.; Huh, J.; Shin, J. Strength and Surface Characteristics of 3D-Printed Resin Crowns for the Primary Molars. Polymers 2023, 15, 4241. [Google Scholar] [CrossRef] [PubMed]

- Khaliq, J.; Gurrapu, D.R.; Elfakhri, F. Effects of Infill Line Multiplier and Patterns on Mechanical Properties of Lightweight and Resilient Hollow Section Products Manufactured Using Fused Filament Fabrication. Polymers 2023, 15, 2585. [Google Scholar] [CrossRef]

- Yang, J.; Yue, H.; Mirihanage, W.; Bartolo, P. Multi-Stage Thermal Modelling of Extrusion-Based Polymer Additive Manufacturing. Polymers 2023, 15, 838. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Korolovych, V.; Muhlbauer, R.; Tsukruk, V. 3D-Printed Polymer Packing Structures: Uniformity of Morphology and Mechanical Properties via Microprocessing Conditions. J. Appl. Polym. Sci. 2020, 137, 49381. [Google Scholar] [CrossRef]

- Valvez, S.; Silva, A.P.; Reis, P.N.B. Optimization of Printing Parameters to Maximize the Mechanical Properties of 3D-Printed PETG-Based Parts. Polymers 2022, 14, 2564. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Printability and Tensile Performance of 3D Printed Polyethylene Terephthalate Glycol Using Fused Deposition Modelling. Polymers 2019, 11, 1220. [Google Scholar] [CrossRef]

- Michailidis, N.; Petousis, M.; Saltas, V.; Papadakis, V.; Spiridaki, M.; Mountakis, N.; Argyros, A.; Valsamos, J.; Nasikas, N.K.; Vidakis, N. Investigation of the Effectiveness of Silicon Nitride as a Reinforcement Agent for Polyethylene Terephthalate Glycol in Material Extrusion 3D Printing. Polymers 2024, 16, 1043. [Google Scholar] [CrossRef]

- Lee, H.; Eom, R.; Lee, Y. Evaluation of the Mechanical Properties of Porous Thermoplastic Polyurethane Obtained by 3D Printing for Protective Gear. Adv. Mater. Sci. Eng. 2019, 2019, 5838361. [Google Scholar] [CrossRef]

- Hanon, M.M.; Ghaly, A.; Zsidai, L.; Szakál, Z.; Szabó, I.; Kátai, L. Investigations of the Mechanical Properties of DLP 3D Printed Graphene/Resin Composites. Acta Polytech. Hung. 2021, 18, 143–161. [Google Scholar] [CrossRef]

- Lee, H.-E.; Alauddin, M.S.; Mohd Ghazali, M.I.; Said, Z.; Mohamad Zol, S. Effect of Different Vat Polymerization Techniques on Mechanical and Biological Properties of 3D-Printed Denture Base. Polymers 2023, 15, 1463. [Google Scholar] [CrossRef] [PubMed]

- Al-Dulaijan, Y.A.; Alsulaimi, L.; Alotaibi, R.; Alboainain, A.; Alalawi, H.; Alshehri, S.; Khan, S.Q.; Alsaloum, M.; AlRumaih, H.S.; Alhumaidan, A.A.; et al. Comparative Evaluation of Surface Roughness and Hardness of 3D Printed Resins. Materials 2022, 15, 6822. [Google Scholar] [CrossRef] [PubMed]

- Jiang, T.; Yan, B.; Jiang, M.; Xu, B.; Gao, S.; Xu, Y.; Yu, Y.; Ma, T.; Qin, T. Study of Forming Performance and Characterization of DLP 3D Printed Parts. Materials 2023, 16, 3847. [Google Scholar] [CrossRef]

- Schäffer, B.; Pieren, R.; Heutschi, K.; Wunderli, J.M.; Becker, S. Drone noise emission characteristics and noise effects on humans—A systematic review. Int. J. Environ. Res. Public Health 2021, 18, 5940. [Google Scholar] [CrossRef]

- ISO 1:2022; Geometrical Product Specifications (GPS)—Standard Reference Temperature for the Specification of Geometrical and Dimensional Properties. International Organization for Standardization: Geneva, Switzerland, 2022. Available online: https://www.iso.org/standard/80702.html (accessed on 1 November 2024).

- ISO 3382-1:2009; Acoustics—Measurement of Room Acoustic Parameters. International Organization for Standardization: Geneva, Switzerland, 2009. Available online: https://www.iso.org/standard/40979.html (accessed on 16 October 2024).

| Attribute | PETG | TPU | H200 Hard-Tough Resin |

|---|---|---|---|

| Tensile Strength [MPA] | 67.07 | 21–36 | 45.16–49.17 |

| Impact Strength [kJ/m2] | 70 | 120 | 17–35 |

| Flexural Strength [MPa] | 80 | 60–97 | 133.39 |

| Modulus of Elasticity [GPa] | 1.71 | 2.127 | 0.841–0.917 |

| Cost | 20–30 €/kg | 40–70 €/kg | 70–100 €/L |

| Parameter | Creality Ender 3 S1 Pro-TPU | Creality Ender 3 S1 Pro-PETG | AnyCubic Photon-S |

|---|---|---|---|

| Layer Height [mm] | 0.18 | 0.18 | 0.05 |

| Wall Line Count | 4 | 4 | |

| Line Width [mm] | 0.5 | 0.5 | |

| Top/Bottom Thickness [mm] | 0.18 | 0.18 | |

| Infill [%] | 100 | 100 | 100 |

| Lifting Speed [mm/min] | 180 | ||

| Lift Distance [mm] | 6 | ||

| Retract Speed [mm/min] | 180 | ||

| Exposure Time [s] | 6 | ||

| Resolution [px] | X: 1440, Y:2560 | ||

| Printing temperature [ C] | 230 | 250 | |

| Print Speed [mm/s] | 50 | 50 | |

| Fan Speed [%] | 100 | 50 |

| Probe | Measured Thrust Values | ||

|---|---|---|---|

| Case of 40% rpm | Case of 60% rpm | ||

| Toroidal propeller | TPU | 2.9 N | 3.1 N |

| PETG | 2.7 N | 3.4 N | |

| Resin | 2.6 N | 4.4 N | |

| Classic 3-bladed propeller | TPU | 2.9 N | 3.0 N |

| PETG | 2.6 N | 3.0 N | |

| Resin | 3.0 N | 4.1 N | |

| Specimen Label | Maximum Tensile Load (N) | Stress at Max. Compressive Load (MPa) | Tensile Ext. at Max. Load (mm) | |

|---|---|---|---|---|

| 1 | 1 | 4.10 | 0.20228 | 12.20601 |

| 2 | 2 | 178.82 | 8.83064 | 27.61233 |

| 3 | 3 | 49.49 | 2.44414 | 6.87214 |

| 4 | 4 | 0.88 | 0.04352 | 19.01836 |

| 5 | 5 | 69.25 | 3.41991 | 14.95876 |

| 6 | 6 | 16.18 | 0.79889 | 17.06898 |

| Propeller Model | Values of the Measured Temperatures [°C] | ||

|---|---|---|---|

| TPU | PETG | RESIN | |

| Toroidal propeller | 28.9 °C | 29 °C | 28.8 °C |

| Classic 3-bladed propeller | 30.1 °C | 29.8 °C | 29.3 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popișter, F. Experimental Study of Comprehensive Performance Analysis Regarding the Dynamical/Mechanical Aspects of 3D-Printed UAV Propellers and Sound Footprint. Polymers 2025, 17, 1466. https://doi.org/10.3390/polym17111466

Popișter F. Experimental Study of Comprehensive Performance Analysis Regarding the Dynamical/Mechanical Aspects of 3D-Printed UAV Propellers and Sound Footprint. Polymers. 2025; 17(11):1466. https://doi.org/10.3390/polym17111466

Chicago/Turabian StylePopișter, Florin. 2025. "Experimental Study of Comprehensive Performance Analysis Regarding the Dynamical/Mechanical Aspects of 3D-Printed UAV Propellers and Sound Footprint" Polymers 17, no. 11: 1466. https://doi.org/10.3390/polym17111466

APA StylePopișter, F. (2025). Experimental Study of Comprehensive Performance Analysis Regarding the Dynamical/Mechanical Aspects of 3D-Printed UAV Propellers and Sound Footprint. Polymers, 17(11), 1466. https://doi.org/10.3390/polym17111466