Mechanical Properties of Surface-Treated Bamboo Strip-Reinforced Biobased Polyamide Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

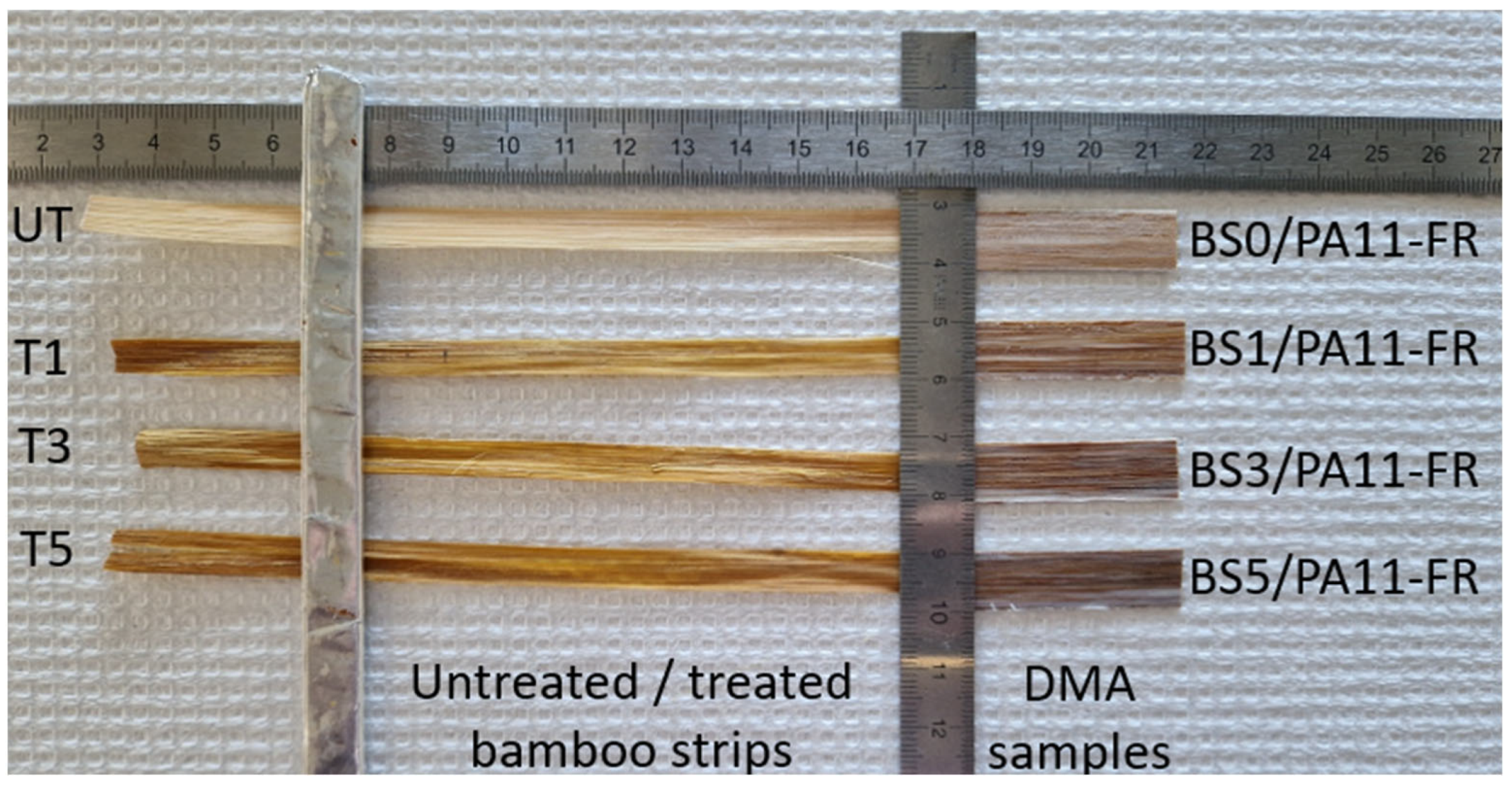

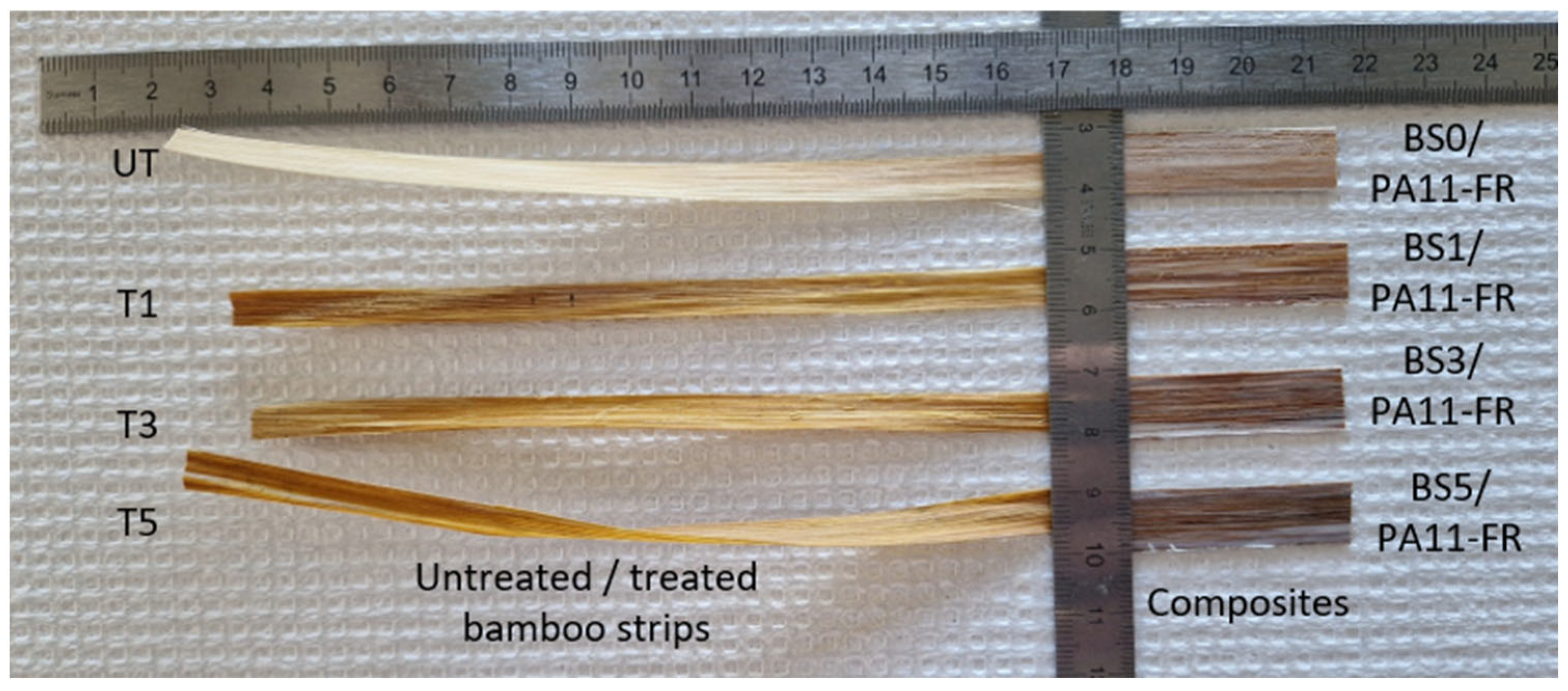

2.1.1. Bamboo Strips

2.1.2. PA11-FR Matrix

2.1.3. Mercerization Treatment

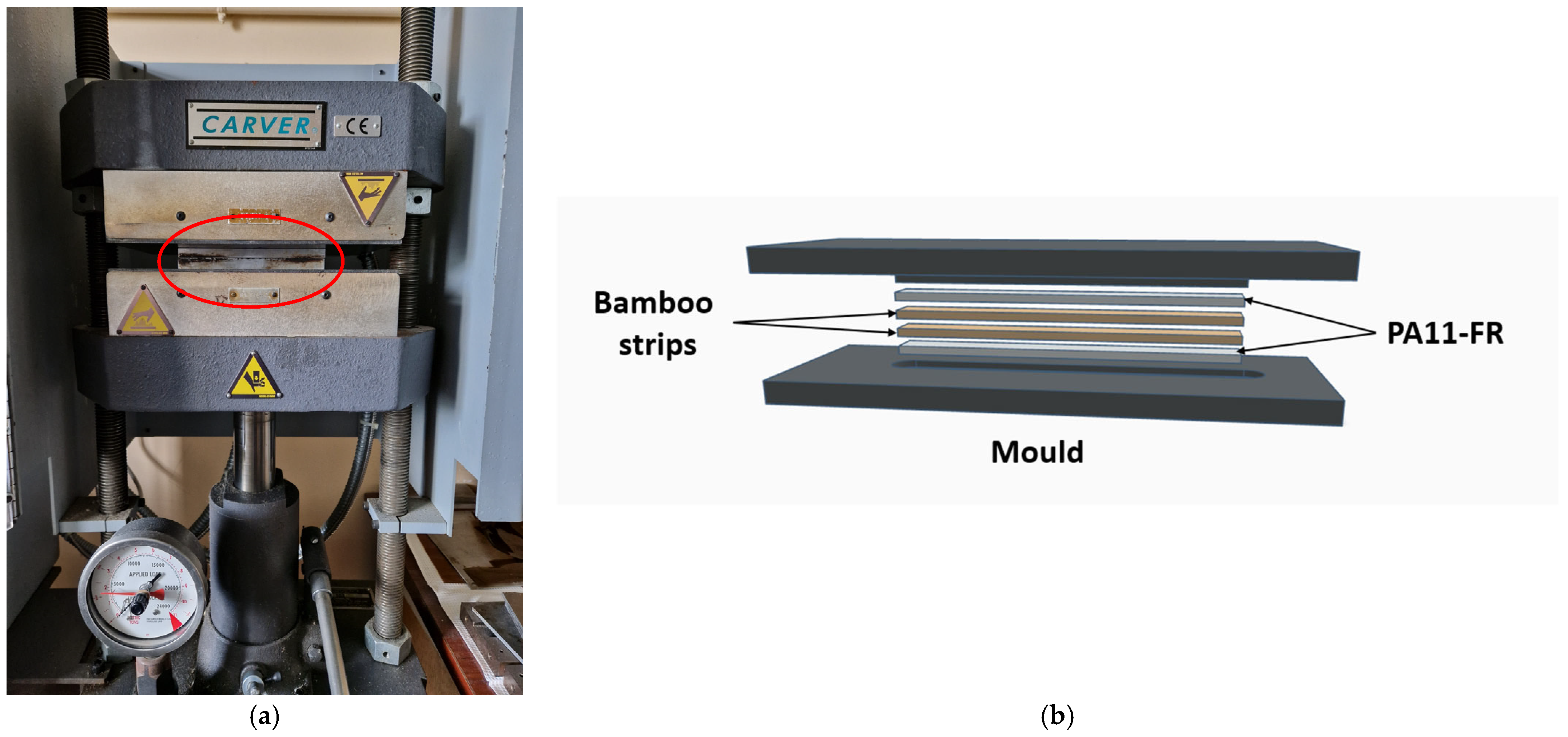

2.1.4. Composite Processing

2.2. Methods

2.2.1. ThermoGravimetric Analysis (TGA)

2.2.2. Tensile Test

2.2.3. Dynamic Mechanical Analysis (DMA)

2.2.4. Water Uptake

3. Results

3.1. Thermal Stability

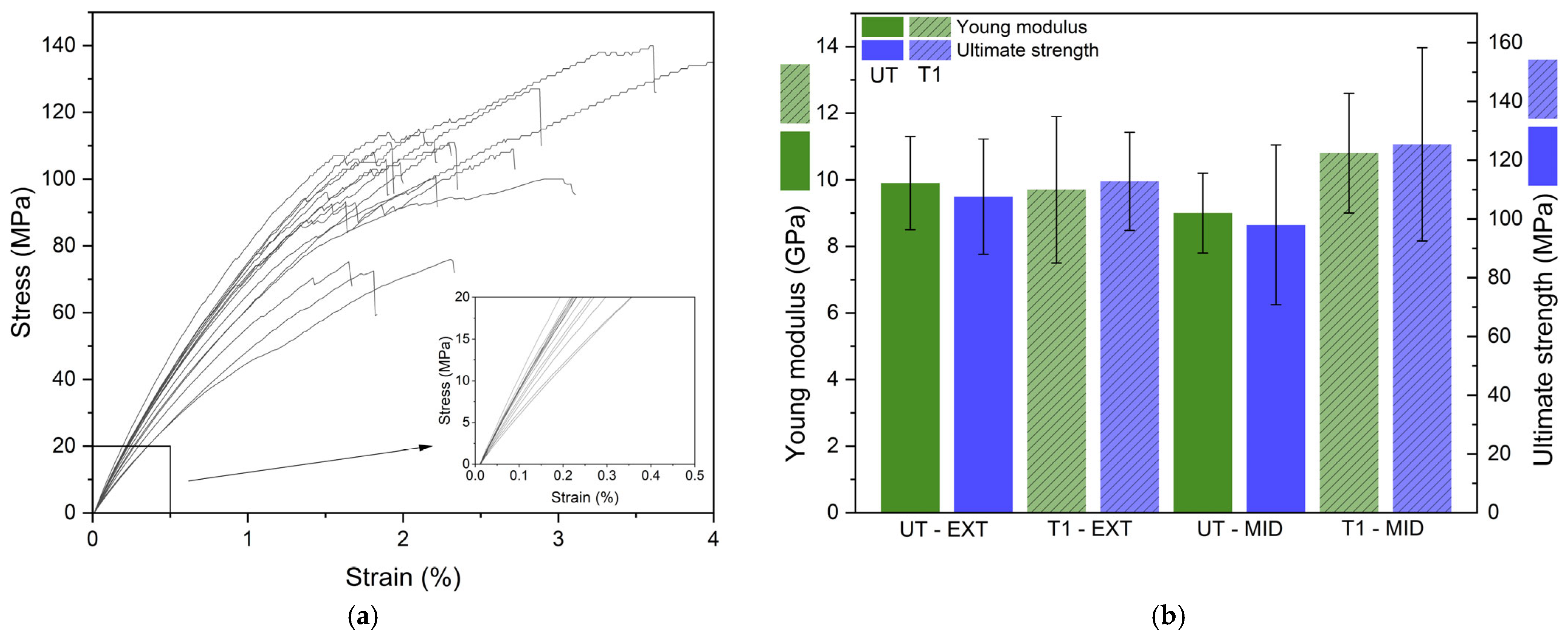

3.2. Tensile Properties

3.3. Dynamic Mechanical Properties

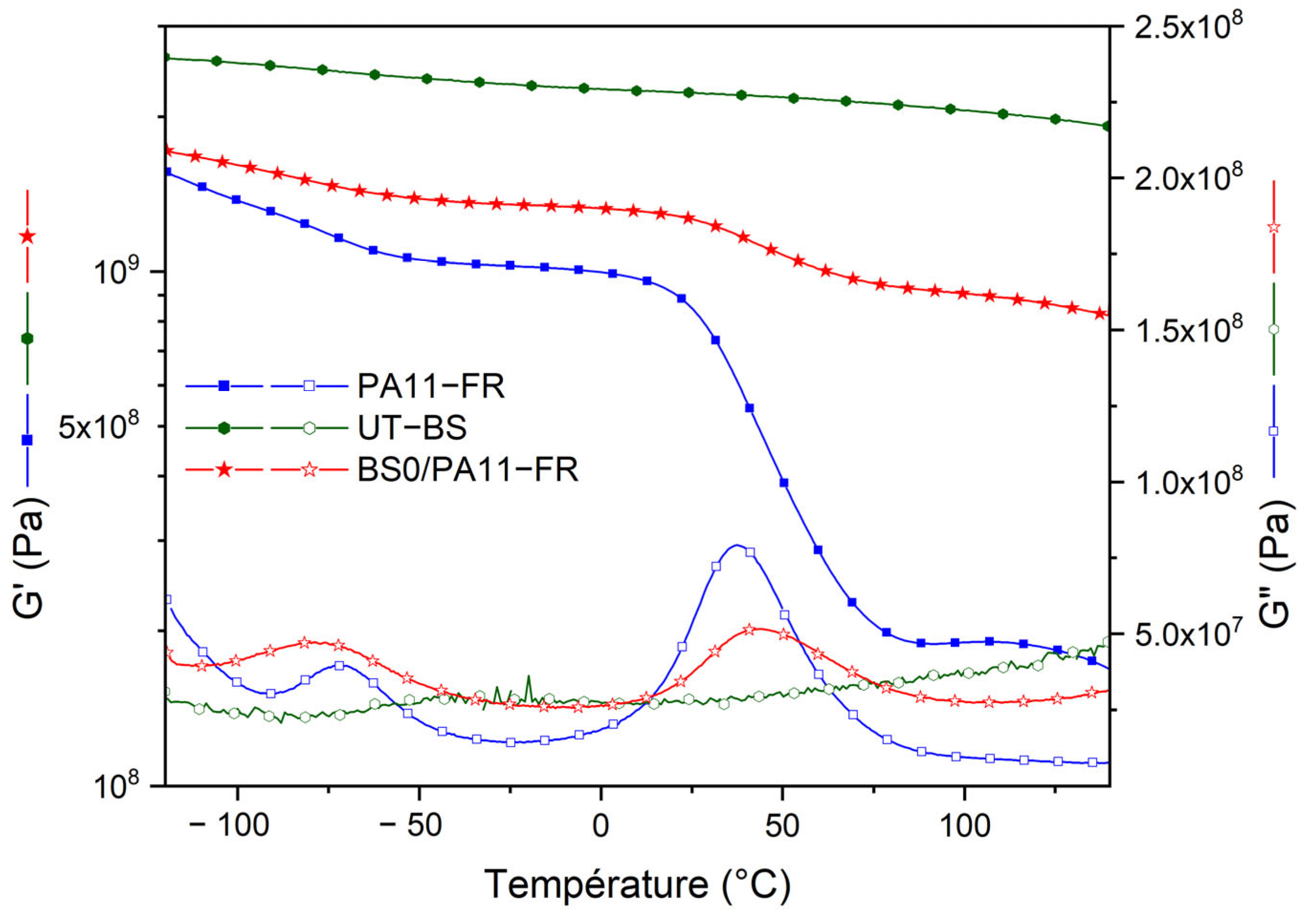

3.3.1. Bamboo Strips

3.3.2. PA11-FR Matrix

3.3.3. Untreated Bamboo Strips/PA11-FR Composite

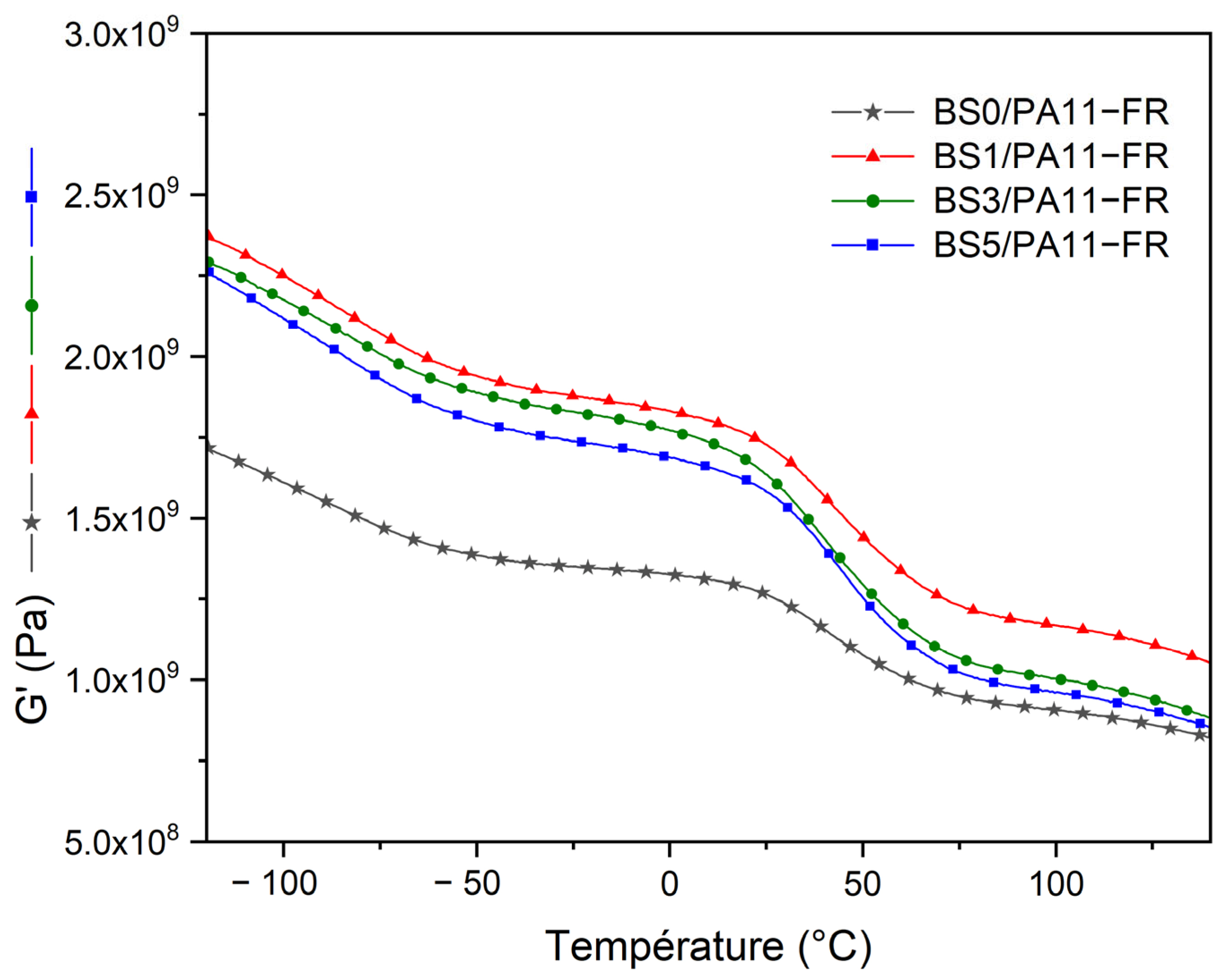

3.3.4. Treated Bamboo Strips/PA11-FR Composite

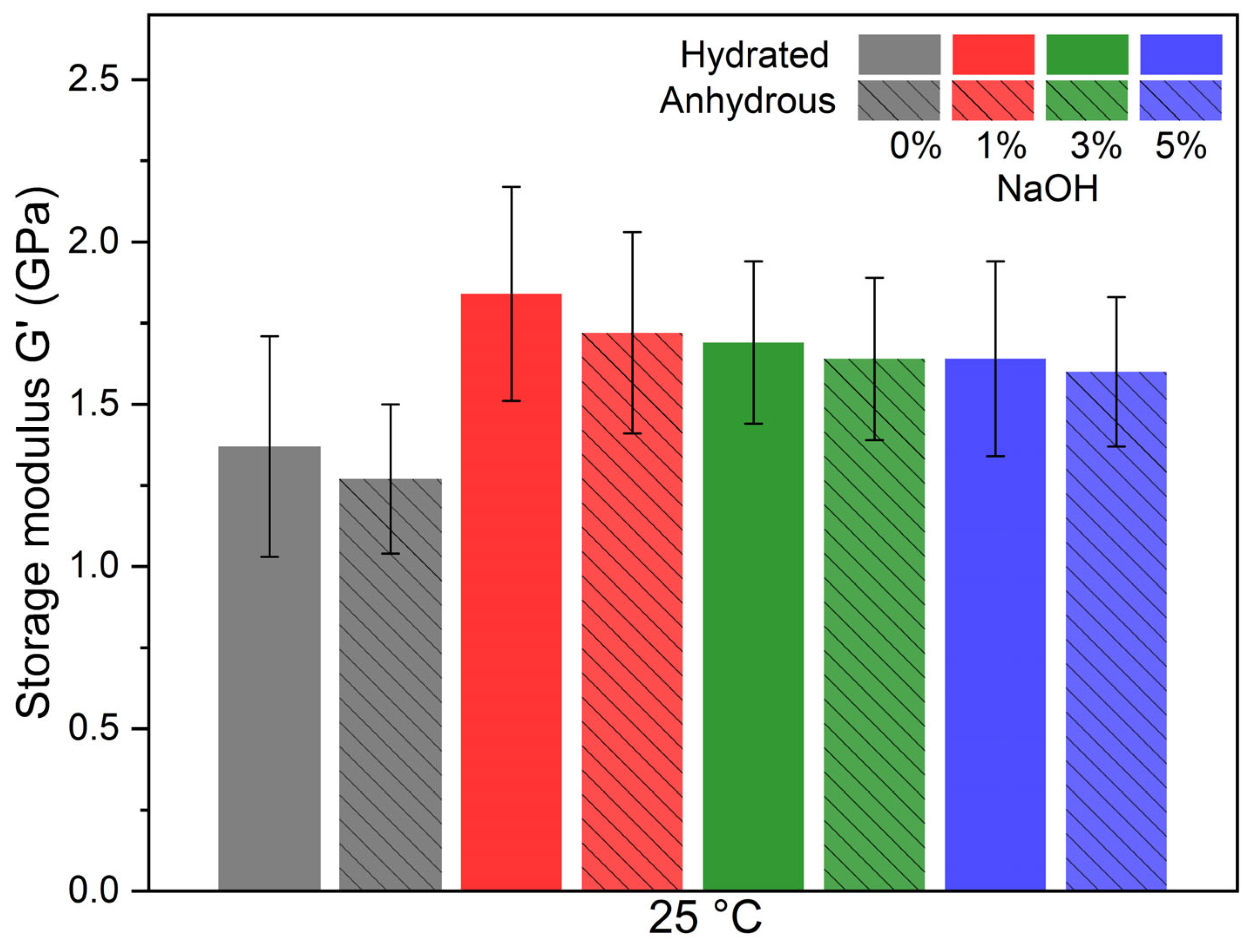

3.4. Water Uptake Influence on Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chang, B.P.; Mohanty, A.K.; Misra, M. Studies on Durability of Sustainable Biobased Composites: A Review. RSC Adv. 2020, 10, 17955–17999. [Google Scholar] [CrossRef] [PubMed]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A Comprehensive Review of Natural Fibers and Their Composites: An Eco-Friendly Alternative to Conventional Materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Progress Report on Natural Fiber Reinforced Composites: Progress Report on Natural Fiber Composites. Macromol. Mater. Eng. 2014, 299, 9–26. [Google Scholar] [CrossRef]

- Ramachandran, A.; Mavinkere Rangappa, S.; Kushvaha, V.; Khan, A.; Seingchin, S.; Dhakal, H.N. Modification of Fibers and Matrices in Natural Fiber Reinforced Polymer Composites: A Comprehensive Review. Macromol. Rapid Commun. 2022, 43, 2100862. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Puttegowda, M.; Mavinkere Rangappa, S.; Siengchin, S. A Review on Extraction, Chemical Treatment, Characterization of Natural Fibers and Its Composites for Potential Applications. Polym. Compos. 2021, 42, 6239–6264. [Google Scholar] [CrossRef]

- Dobrosielska, M.; Dobrucka, R.; Brząkalski, D.; Kozera, P.; Martyła, A.; Gabriel, E.; Kurzydłowski, K.J.; Przekop, R.E. Polyamide 11 Composites Reinforced with Diatomite Biofiller—Mechanical, Rheological and Crystallization Properties. Polymers 2023, 15, 1563. [Google Scholar] [CrossRef]

- Sergi, C.; Vitiello, L.; Dang, P.; Russo, P.; Tirillò, J.; Sarasini, F. Low Molecular Weight Bio-Polyamide 11 Composites Reinforced with Flax and Intraply Flax/Basalt Hybrid Fabrics for Eco-Friendlier Transportation Components. Polymers 2022, 14, 5053. [Google Scholar] [CrossRef]

- Liang, Z.; Jiang, H.; Tan, Y. A Review of Thermal Treatment for Bamboo and Its Composites. Green Process. Synth. 2024, 13, 20230263. [Google Scholar] [CrossRef]

- Chen, X.; Wang, X.; Luo, X.; Chen, L.; Li, Y.; Xu, J.; Liu, Z.; Dai, C.; Miao, H.; Liu, H. Bamboo as a Naturally-Optimized Fiber-Reinforced Composite: Interfacial Mechanical Properties and Failure Mechanisms. Compos. Part B Eng. 2024, 279, 111458. [Google Scholar] [CrossRef]

- Hu, F.; Li, L.; Wu, Z.; Yu, L.; Liu, B.; Cao, Y.; Xu, H. Surface Characteristics of Thermally Modified Bamboo Fibers and Its Utilization Potential for Bamboo Plastic Composites. Materials 2022, 15, 4481. [Google Scholar] [CrossRef]

- Richmond, T.; Lods, L.; Dandurand, J.; Dantras, E.; Lacabanne, C.; Durand, J.-M.; Sherwood, E.; Ponteins, P. Thermal and Mechanical Performances of Bamboo Strip. Mater. Res. Express 2021, 8, 025502. [Google Scholar] [CrossRef]

- Chen, H.; Cheng, H.; Wang, G.; Yu, Z.; Shi, S.Q. Tensile Properties of Bamboo in Different Sizes. J. Wood Sci. 2015, 61, 552–561. [Google Scholar] [CrossRef]

- Andrew, J.J.; Dhakal, H.N. Sustainable Biobased Composites for Advanced Applications: Recent Trends and Future Opportunities—A Critical Review. Compos. Part C Open Access 2022, 7, 100220. [Google Scholar] [CrossRef]

- Van Cong, D.; Giang, N.V.; Trung, T.H.; Hoang, T.; Lam, T.D.; Tham, D.Q.; Huong, N.T. Biocomposites from Polyamide 11 Reinforced by Organic Silane Modified Jute Fibers: Fabrication and Characterization. J. Appl. Polym. Sci. 2022, 139, 51795. [Google Scholar] [CrossRef]

- Lods, L.; Richmond, T.; Dandurand, J.; Dantras, E.; Lacabanne, C.; Durand, J.-M.; Sherwood, E.; Hochstetter, G.; Ponteins, P. Thermal Stability and Mechanical Behavior of Technical Bamboo Fibers/Bio-Based Polyamide Composites. J. Therm. Anal. Calorim. 2022, 147, 1097–1106. [Google Scholar] [CrossRef]

- Hou, W.; Fu, Y.; Zeng, C.; Liu, N.; Yin, C. Enhancement of Flame Retardancy and Mechanical Properties of Polyamide 6 by Incorporating Melamine Cyanurate Combined with Attapulgite. J. Appl. Polym. Sci. 2020, 137, 47298. [Google Scholar] [CrossRef]

- Zhan, J.; Wang, J.; Lin, J.; Zhao, G.; Ji, S.; Li, X.; Li, J.; Wang, G.; Chen, L.; Guan, Y.; et al. Flame-retardant, Thermal and Mechanical Properties of PLA/Ramie Fiber Composites. Polym. Compos. 2022, 43, 4244–4254. [Google Scholar] [CrossRef]

- Negrell, C.; Frénéhard, O.; Sonnier, R.; Dumazert, L.; Briffaud, T.; Flat, J.-J. Self-Extinguishing Bio-Based Polyamides. Polym. Degrad. Stab. 2016, 134, 10–18. [Google Scholar] [CrossRef]

- Liu, X.; Liu, J.; Dong, Y.; Hughes, M.; Wu, M.; Li, J. Evaluation of Natural Weathering and Thermal Degradation Behavior of Furfurylated Bamboo Strips at Different Weight Percent Gain. Eur. J. Wood Wood Prod. 2022, 80, 289–299. [Google Scholar] [CrossRef]

- Kaima, J.; Preechawuttipong, I.; Peyroux, R.; Jongchansitto, P.; Kaima, T. Experimental Investigation of Alkaline Treatment Processes (NaOH, KOH and Ash) on Tensile Strength of the Bamboo Fiber Bundle. Results Eng. 2023, 18, 101186. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical Treatments on Plant-Based Natural Fibre Reinforced Polymer Composites: An Overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Budtova, T.; Navard, P. Cellulose in NaOH–Water Based Solvents: A Review. Cellulose 2016, 23, 5–55. [Google Scholar] [CrossRef]

- Mohanta, S.; Mahalik, P.; Hota, G.P.; Sahoo, B.B.; Pradhan, S.S.; Mohanty, S.P. Influence of Surface-treatment of Bamboo Fiber on the Physico-mechanical Properties of Bamboo Fiber Composites with Virgin and Recycled High-density Polyethylene. Polym. Compos. 2024, 45, 914–923. [Google Scholar] [CrossRef]

- Nirmal Kumar, K.; Dinesh Babu, P.; Surakasi, R.; Kumar, P.M.; Ashokkumar, P.; Khan, R.; Alfozan, A.; Gebreyohannes, D.T. Mechanical and Thermal Properties of Bamboo Fiber–Reinforced PLA Polymer Composites: A Critical Study. Int. J. Polym. Sci. 2022, 2022, 1332157. [Google Scholar] [CrossRef]

- Sánchez, M.L.; Patiño, W.; Cárdenas, J. Physical-Mechanical Properties of Bamboo Fibers-Reinforced Biocomposites: Influence of Surface Treatment of Fibers. J. Build. Eng. 2020, 28, 101058. [Google Scholar] [CrossRef]

- Noori, A.; Lu, Y.; Saffari, P.; Liu, J.; Ke, J. The Effect of Mercerization on Thermal and Mechanical Properties of Bamboo Fibers as a Biocomposite Material: A Review. Constr. Build. Mater. 2021, 279, 122519. [Google Scholar] [CrossRef]

- Saha, A.; Kulkarni, N.D.; Kumar, M.; Kumari, P. The Structural, Dielectric, and Dynamic Properties of NaOH-Treated Bambusa Tulda Reinforced Biocomposites—An Experimental Investigation. Biomass Convers. Biorefin. 2024, 14, 26247–26266. [Google Scholar] [CrossRef]

- Sethu, S.; Kalimuthu, M.; Nagarajan, R.; Ismail, S.O.; Devi, K.; Muthukannan, M.; Murali, M.; Mohammad, F.; Al-Lohedan, H.A. Thermal, Chemical, Tensile and Morphological Characterization Studies of Bamboo Fibre Extracted from the Indian Species Bambusa Bambos. Mater. Res. Express 2023, 10, 105501. [Google Scholar] [CrossRef]

- Fuentes, C.A.; Brughmans, G.; Tran, L.Q.N.; Dupont-Gillain, C.; Verpoest, I.; Van Vuure, A.W. Mechanical Behaviour and Practical Adhesion at a Bamboo Composite Interface: Physical Adhesion and Mechanical Interlocking. Compos. Sci. Technol. 2015, 109, 40–47. [Google Scholar] [CrossRef]

- Kumar, S.; Choudhary, V.; Kumar, R. Study on the Compatibility of Unbleached and Bleached Bamboo-Fiber with LLDPE Matrix. J. Therm. Anal. Calorim. 2010, 102, 751–761. [Google Scholar] [CrossRef]

- Reale Batista, M.D.; Drzal, L.T. Surface Modification of Bamboo Fiber with Sodium Hydroxide and Graphene Oxide in Epoxy Composites. Polym. Compos. 2021, 42, 1135–1147. [Google Scholar] [CrossRef]

- Wu, J.; Zhong, T.; Zou, Y.; Li, J.; Zhao, W.; Chen, H. Microstructure, Chemical Composition and Thermal Stability of Alkali-Treated Bamboo Fibers and Parenchyma Cells: Effects of Treatment Time and Temperature. Cellulose 2023, 30, 1911–1925. [Google Scholar] [CrossRef]

- Richmond, T.; Lods, L.; Dandurand, J.; Dantras, E.; Lacabanne, C.; Malburet, S.; Graillot, A.; Durand, J.-M.; Sherwood, E.; Ponteins, P. Physical and Dynamic Mechanical Properties of Continuous Bamboo Reinforcement/Bio-Based Epoxy Composites. Mater. Res. Express 2022, 9, 015505. [Google Scholar] [CrossRef]

- Lods, L.; Richmond, T.; Dandurand, J.; Dantras, E.; Lacabanne, C.; Durand, J.-M.; Sherwood, E.; Hochstetter, G.; Ponteins, P. Continuous Bamboo Fibers/Fire-Retardant Polyamide 11: Dynamic Mechanical Behavior of the Biobased Composite. Polymers 2022, 14, 299. [Google Scholar] [CrossRef]

- ASTM E2550-21; Standard Test Method for Thermal Stability by Thermogravimetry. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM D7028-07(2015); Standard Test Method for Glass Transition Temperature (DMA TGA) of Polymer Matrix Composites by Dynamic Mechanical Analysis (DMA). ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- Wang, S.; Cao, X.; Miao, D.; Pang, L.; Li, J. A Review of In-Flight Thermal Comfort and Air Quality Status in Civil Aircraft Cabin Environments. Buildings 2024, 14, 2001. [Google Scholar] [CrossRef]

- Song, Y.; Jiang, W.; Zhang, Y.; Wang, H.; Zou, F.; Yu, K.; Han, G. A Novel Process of Nanocellulose Extraction from Kenaf Bast. Mater. Res. Express 2018, 5, 085032. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, G.; Chen, L.; Yu, Z.; Smith, L.M.; Chen, F. Hydrothermal Aging Properties of Three Typical Bamboo Engineering Composites. Materials 2019, 12, 1450. [Google Scholar] [CrossRef]

| UT-EXT | T1-EXT | UT-MID | T1-MID | |

|---|---|---|---|---|

| E (GPa) | 9.9 ± (1.4) | 9.7 ± (2) | 9.0 ± (1.2) | 10.8 ± (1.8) |

| Rm (MPa) | 108 ± (20) | 113 ± (17) | 98 ± (27) | 124 ± (33) |

| UT-BS | BS0/PA11FR | BS1/PA11FR | BS3/PA11FR | BS5/PA11FR | |

|---|---|---|---|---|---|

| 65% RH | 8.4 ± 0.8 | 5.9 ± 0.3 | 7.4 ± 0.7 | 7.4 ± 0.6 | 6.5 ± 0.2 |

| Anhydrous | 0.2 ± 0.2 | 0.6 ± 0.3 | 1.3 ± 0.1 | 1.2 ± 0.9 | 1.1 ± 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pébère, C.; Mangeret, G.; Dantras, E.; Lacabanne, C.; Dandurand, J.; Moussiegt, T.; Sherwood, E.; Hochstetter, G. Mechanical Properties of Surface-Treated Bamboo Strip-Reinforced Biobased Polyamide Composites. Polymers 2025, 17, 1379. https://doi.org/10.3390/polym17101379

Pébère C, Mangeret G, Dantras E, Lacabanne C, Dandurand J, Moussiegt T, Sherwood E, Hochstetter G. Mechanical Properties of Surface-Treated Bamboo Strip-Reinforced Biobased Polyamide Composites. Polymers. 2025; 17(10):1379. https://doi.org/10.3390/polym17101379

Chicago/Turabian StylePébère, Clément, Gautier Mangeret, Eric Dantras, Colette Lacabanne, Jany Dandurand, Thomas Moussiegt, Edouard Sherwood, and Gilles Hochstetter. 2025. "Mechanical Properties of Surface-Treated Bamboo Strip-Reinforced Biobased Polyamide Composites" Polymers 17, no. 10: 1379. https://doi.org/10.3390/polym17101379

APA StylePébère, C., Mangeret, G., Dantras, E., Lacabanne, C., Dandurand, J., Moussiegt, T., Sherwood, E., & Hochstetter, G. (2025). Mechanical Properties of Surface-Treated Bamboo Strip-Reinforced Biobased Polyamide Composites. Polymers, 17(10), 1379. https://doi.org/10.3390/polym17101379