Advancing Nanogenerators: The Role of 3D-Printed Nanocomposites in Energy Harvesting

Abstract

1. Introduction

2. Fundamentals of Nanogenerators for Flexible Energy Harvesting

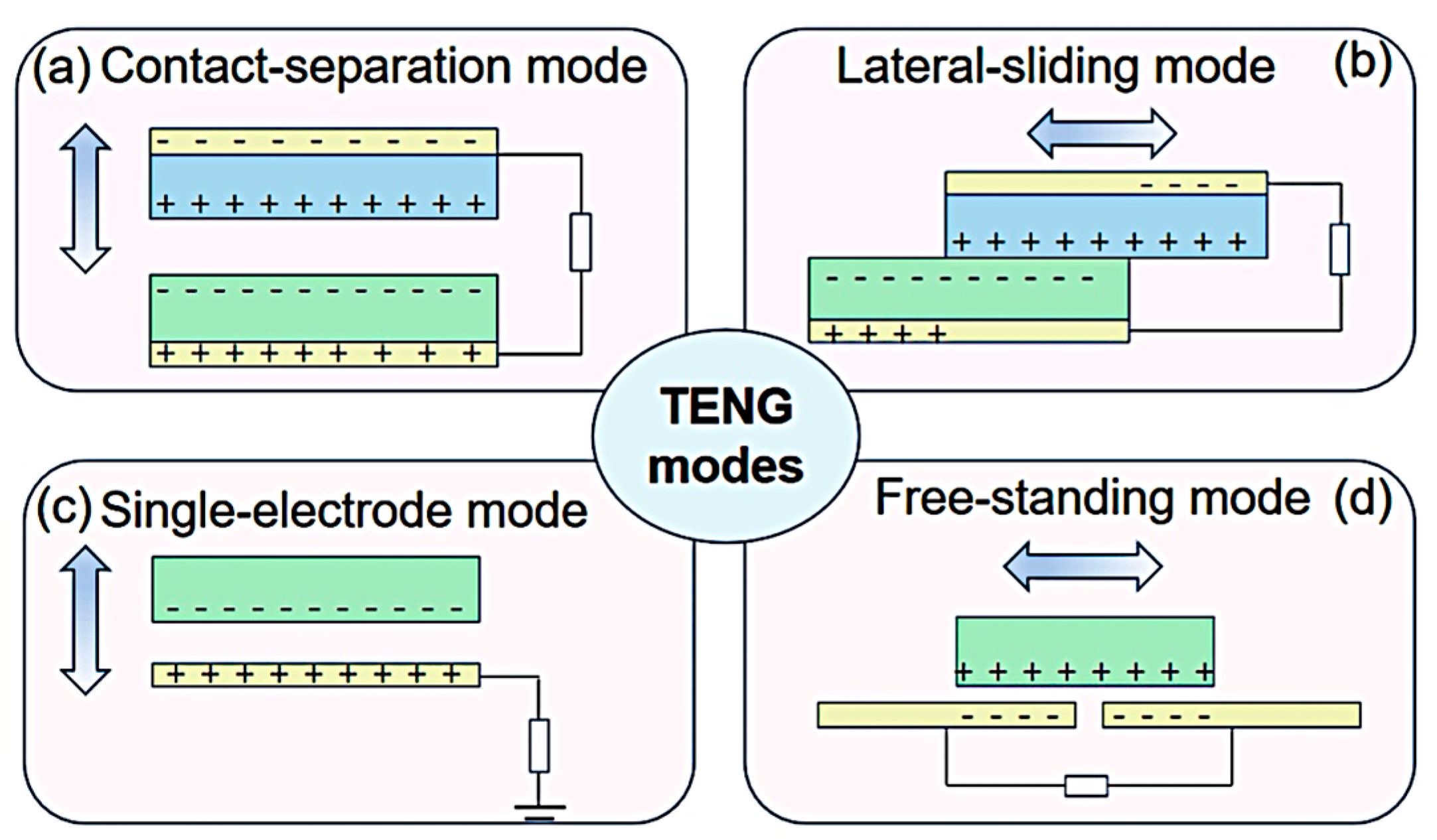

2.1. Triboelectric Nanogenerators [TENGs]

2.2. Piezoelectric Nanogenerators [PENGs]

2.3. Pyroelectric Nanogenerators

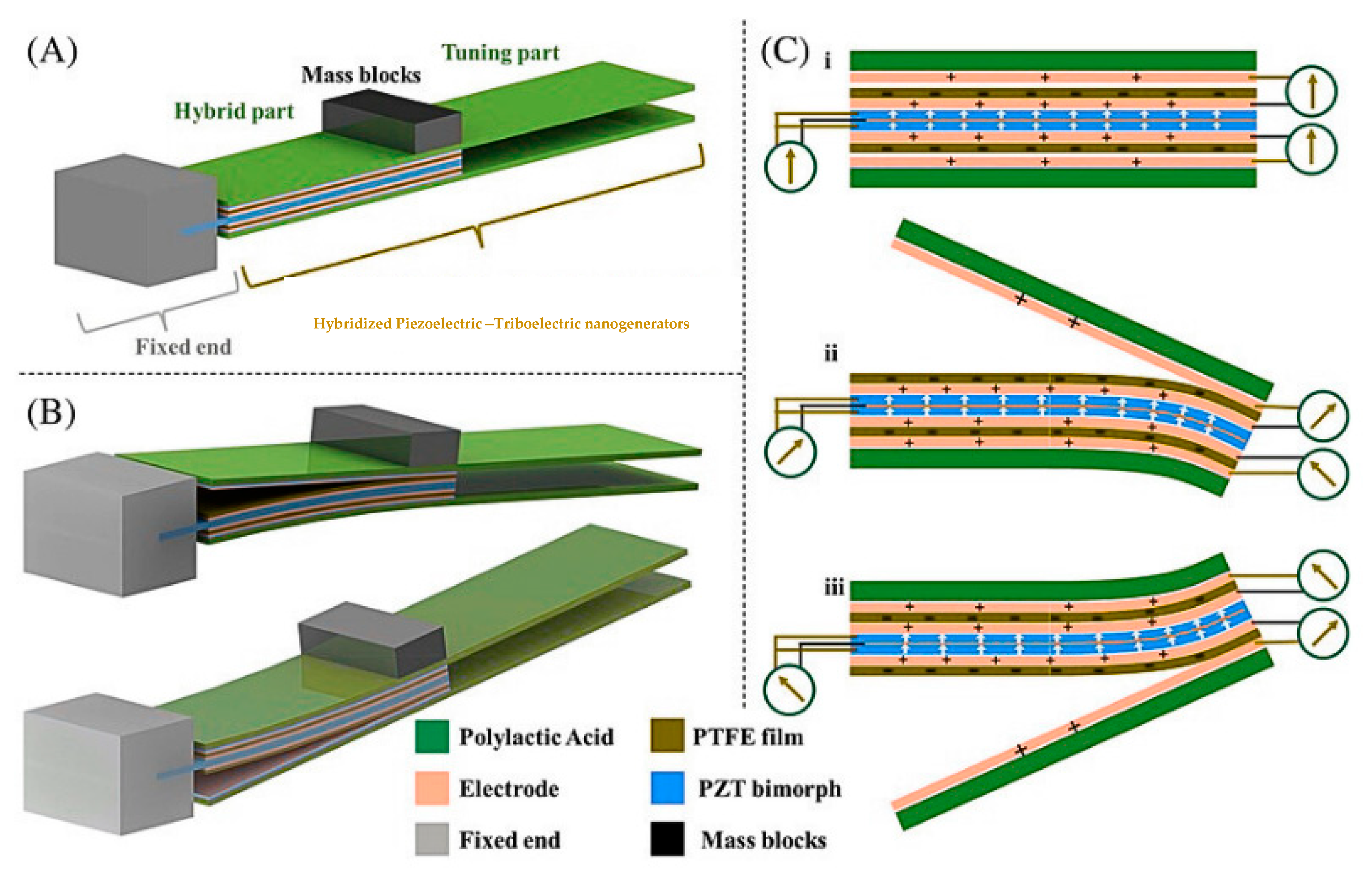

2.4. Hybrid Nanogenerators

3. Nanocomposites in 3D-Printed Nanogenerators: Design and Properties

3.1. Three-Dimensional-Printable Piezoelectric Nanocomposites for Nanogenerators

3.1.1. Polymer-Based Printable Piezoelectric Materials

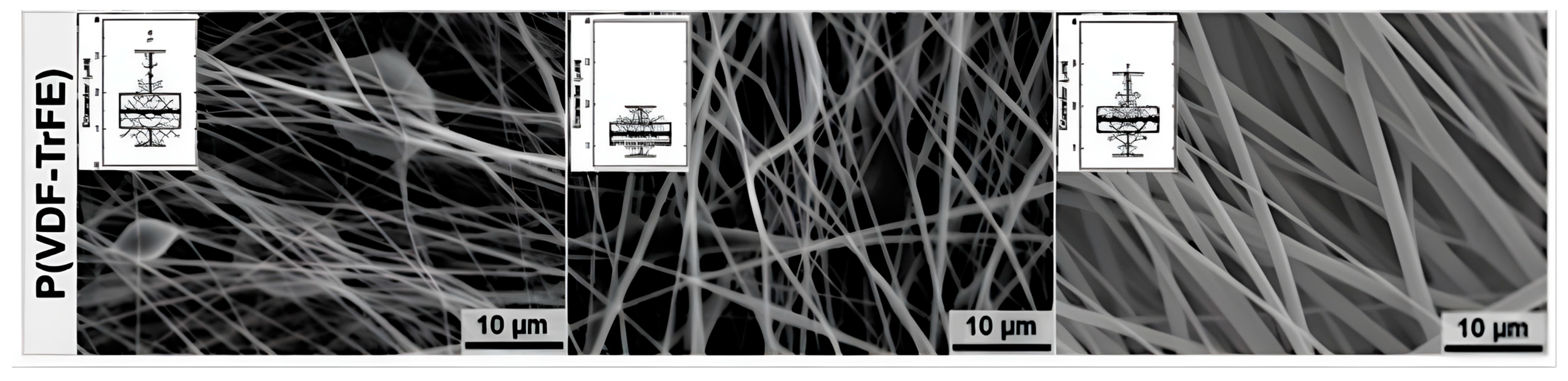

Polyvinylidene Fluoride [PVDF] and P[VDF-TrFE]

Polyurethane [PU] Composites

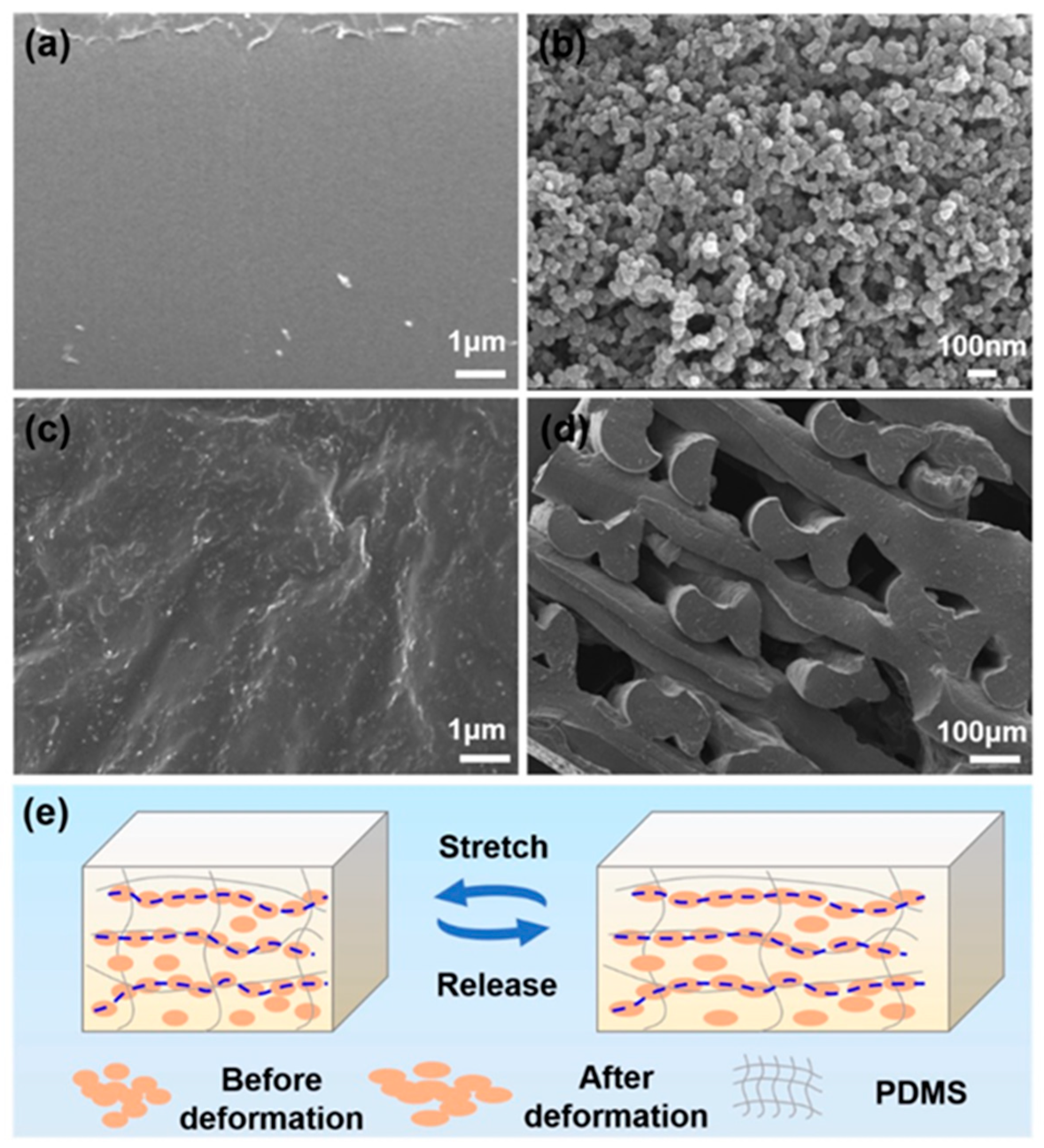

Polydimethylsiloxane [PDMS]

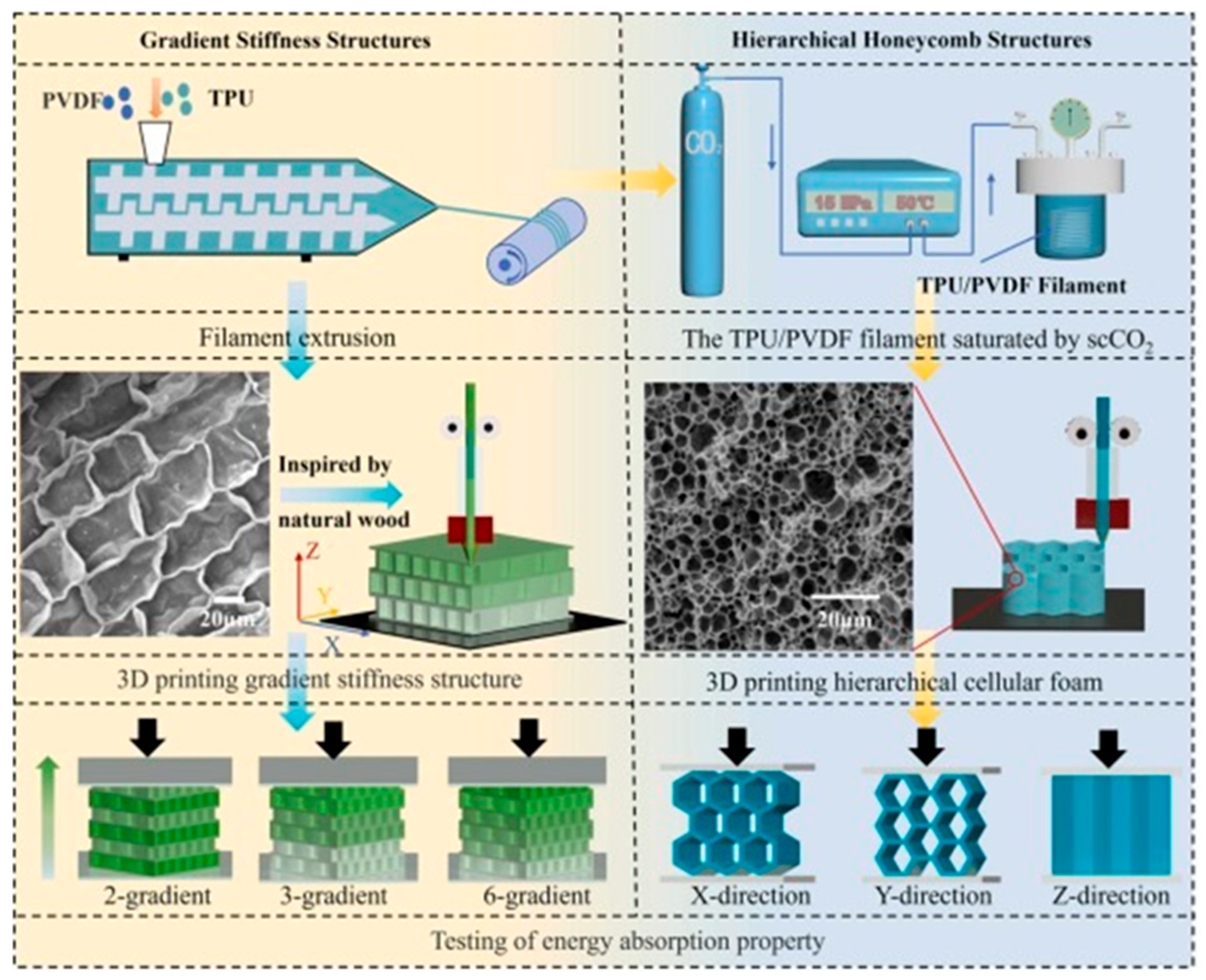

Thermoplastic Polyurethane [TPU]

Ecoflex

3.1.2. Ceramic-Based Printable Piezoelectric Materials

Barium Titanate [BaTiO3] Nanoparticles

Zinc Oxide [ZnO] Nanowires

3.2. Printable Triboelectric Materials for Nanogenerators

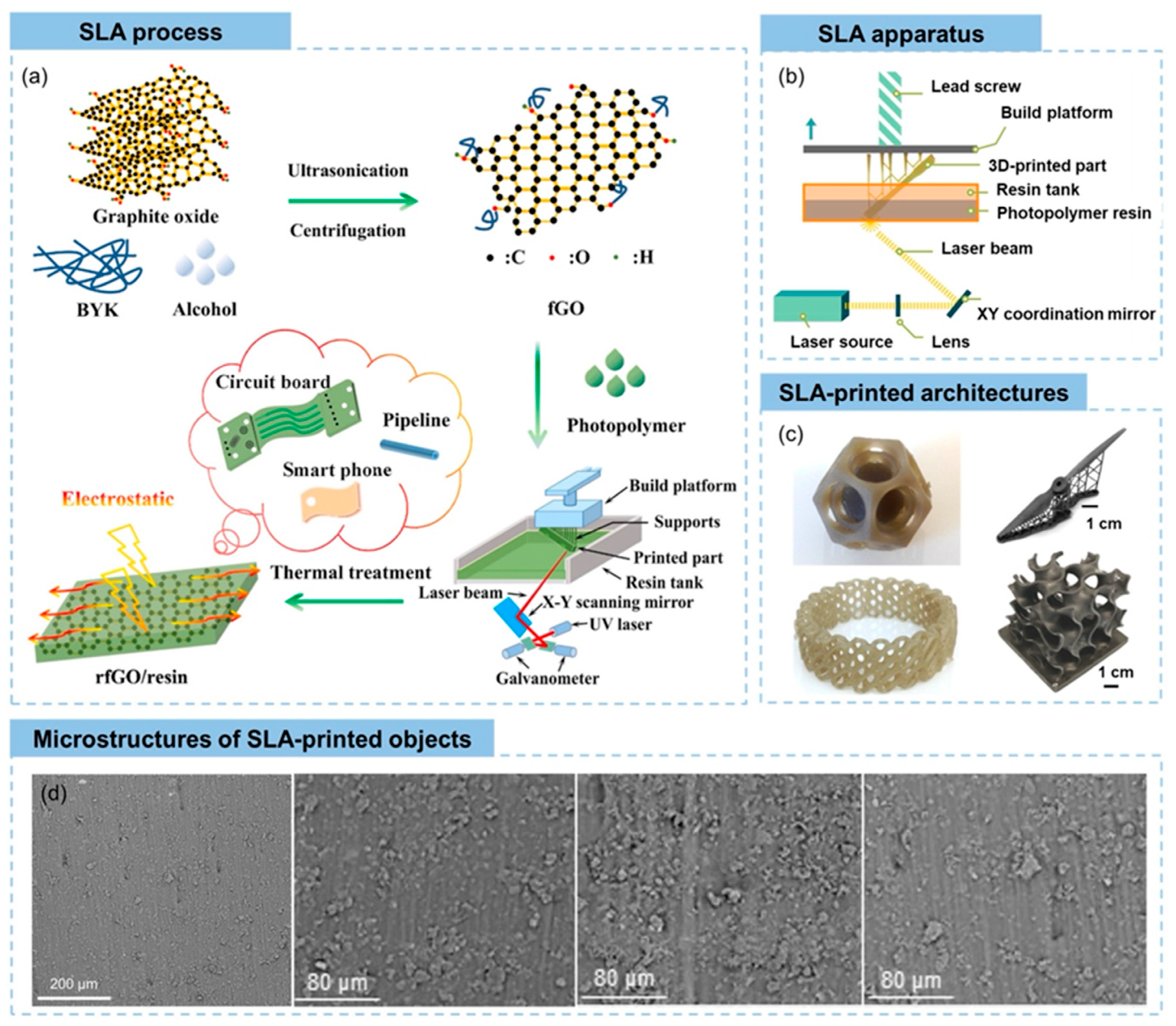

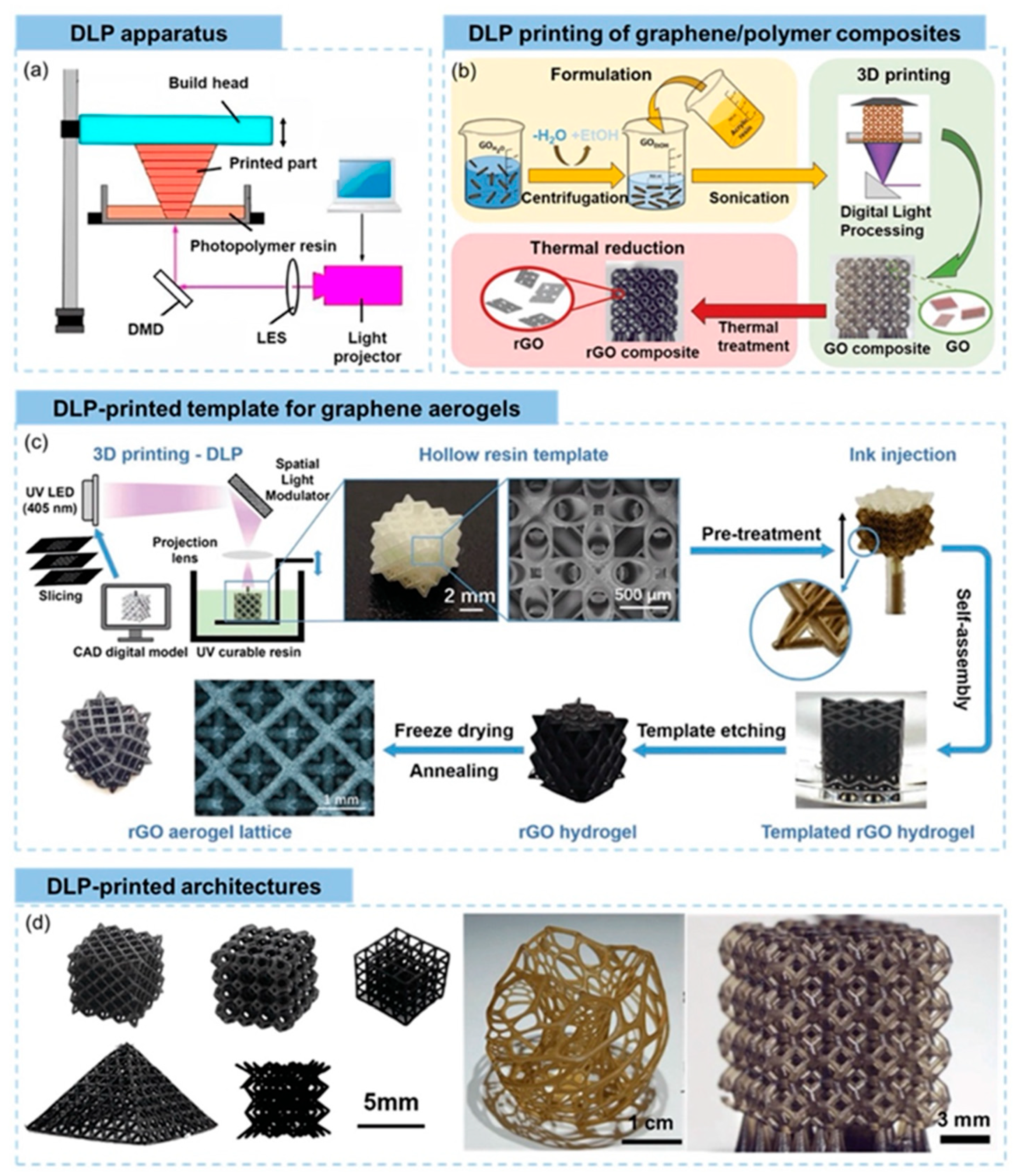

3.2.1. Graphene and Graphene Derivatives

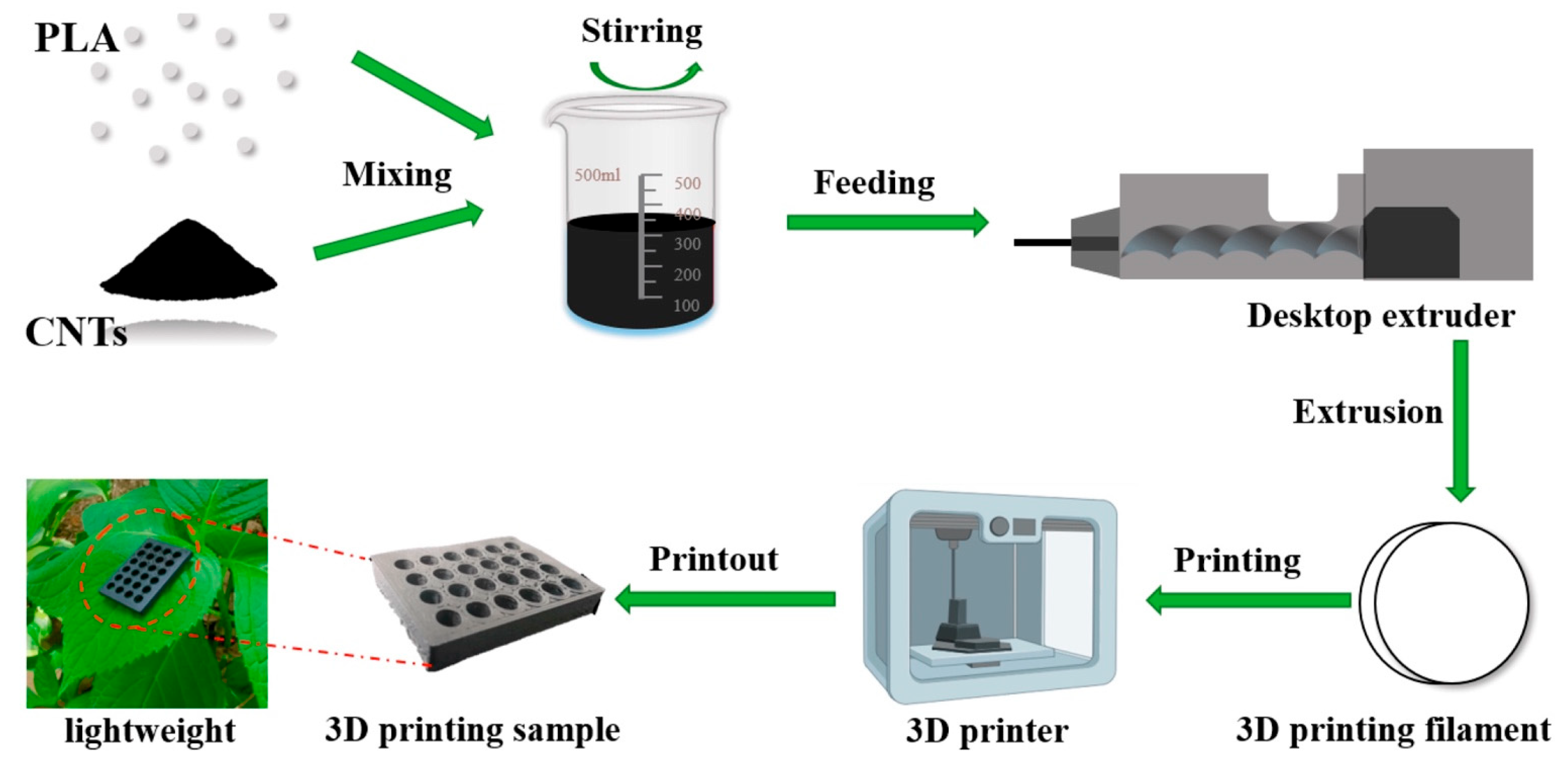

3.2.2. Carbon Nanotubes

3.3. Metal- and Metal Oxide-Based 3D-Printable Materials

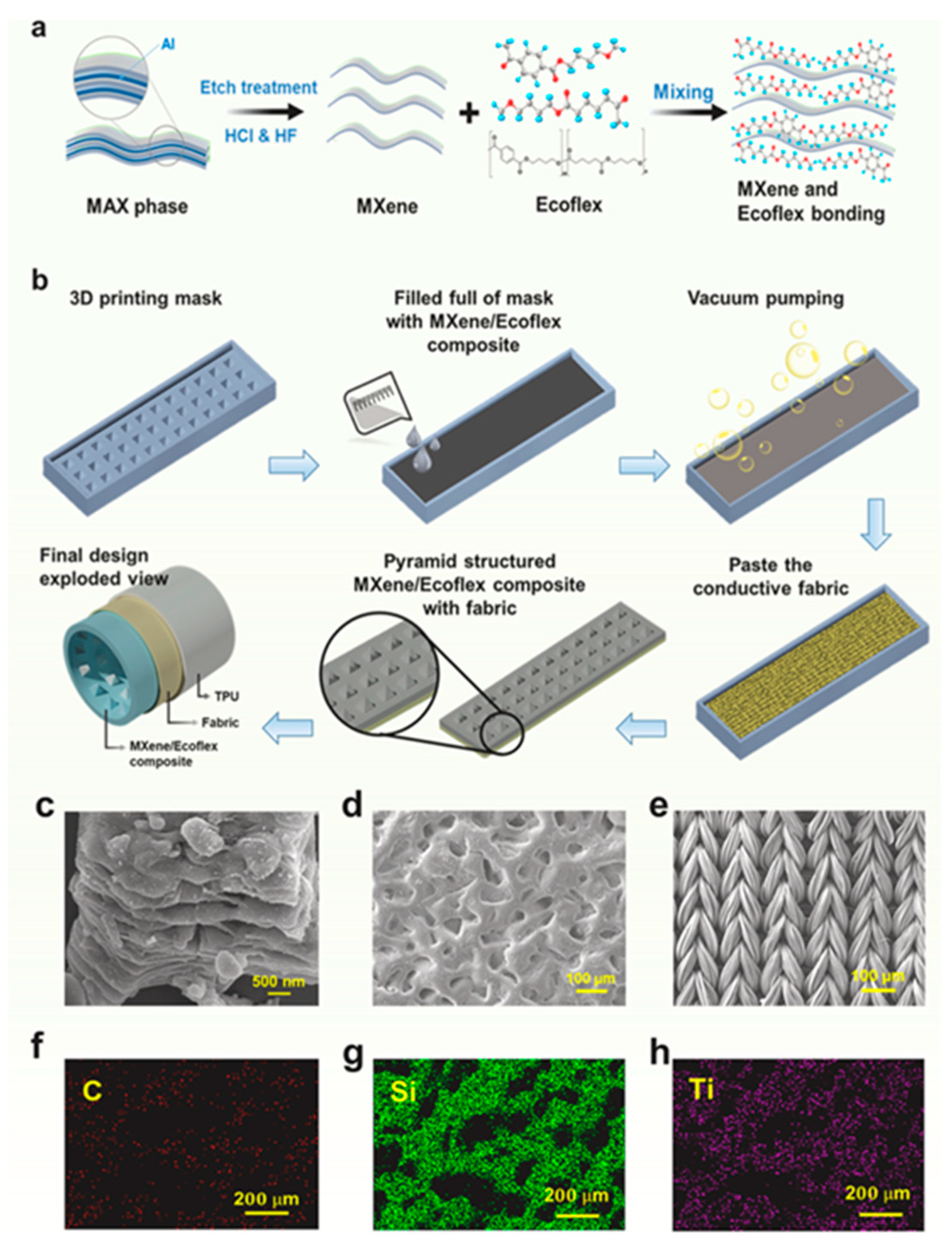

3.3.1. MXenes

3.3.2. Metal Oxides

3.4. Three-Dimensional-Printable Pyroelectric Nanocomposites for Nanogenerators

3.5. Biocompatible and Sustainable Nanocomposites

3.5.1. Nanocellulose

3.5.2. Silk Fibroin and Chitosan-Based Composites

4. Performance Enhancement of 3D-Printed Nanocomposites

4.1. Mechanical Properties Enhancement

4.2. Electrical Properties Enhancement

4.3. Enhancement of Piezoelectric Properties

4.4. Interface Engineering of 3D-Printed Nanogenerators

4.5. Mechanisms of Materials That Enhance the Performance of 3D-Printed Nanogenerators

5. Advantages of 3D-Printed Nanocomposites in Nanogenerators

5.1. Customization and Complex Geometries

5.2. Material Versatility and Functionalization

5.3. Scalability and Cost-Effectiveness

5.4. Enhanced Mechanical and Environmental Adaptability

5.5. Biocompatibility and Clinical Integration

6. Challenges of 3D-Printed Nanocomposites in Nanogenerators

6.1. Material Limitations and Printability

6.2. Mechanical and Environmental Stability

6.3. Energy Conversion Efficiency and Performance Optimization

7. Three-Dimensional Printing in Flexible Nanogenerators

7.1. Three-Dimensional Printing Technologies Utilized in Nanogenerators

7.2. Advantages of 3D Printing in Fabricating Flexible Energy-Harvesting Devices

7.3. Challenges in Integrating 3D-Printed Structures with Flexible Substrates

8. Recent Advances in 3D-Printed Nanocomposite Nanogenerators

8.1. Three-Dimensional-Printed Piezoelectric Nanogenerators [PENGs]

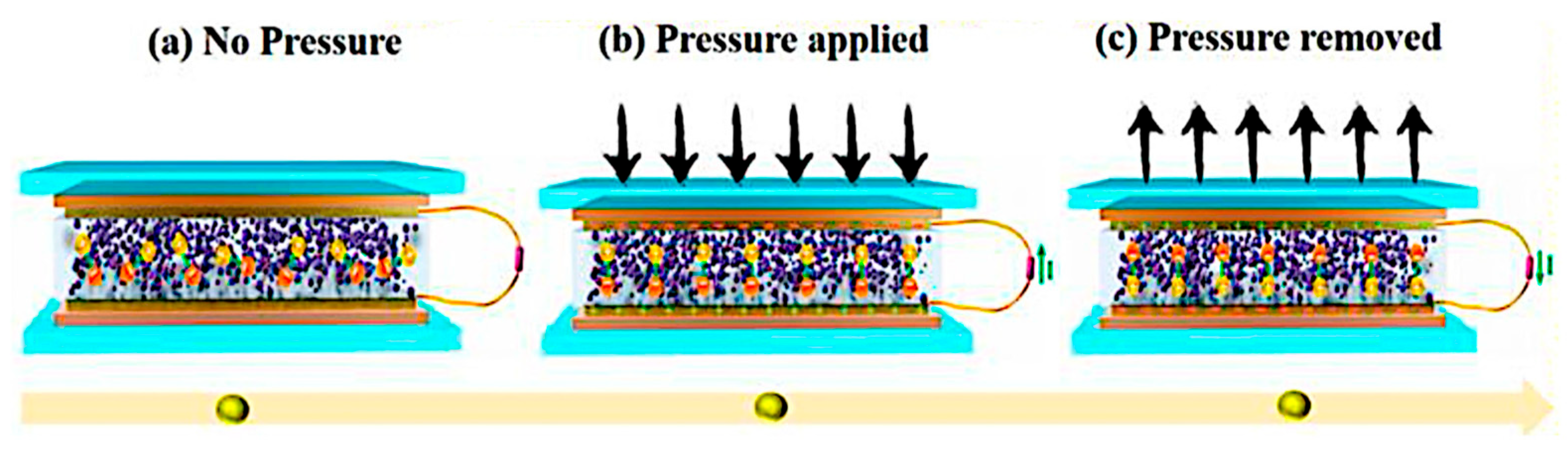

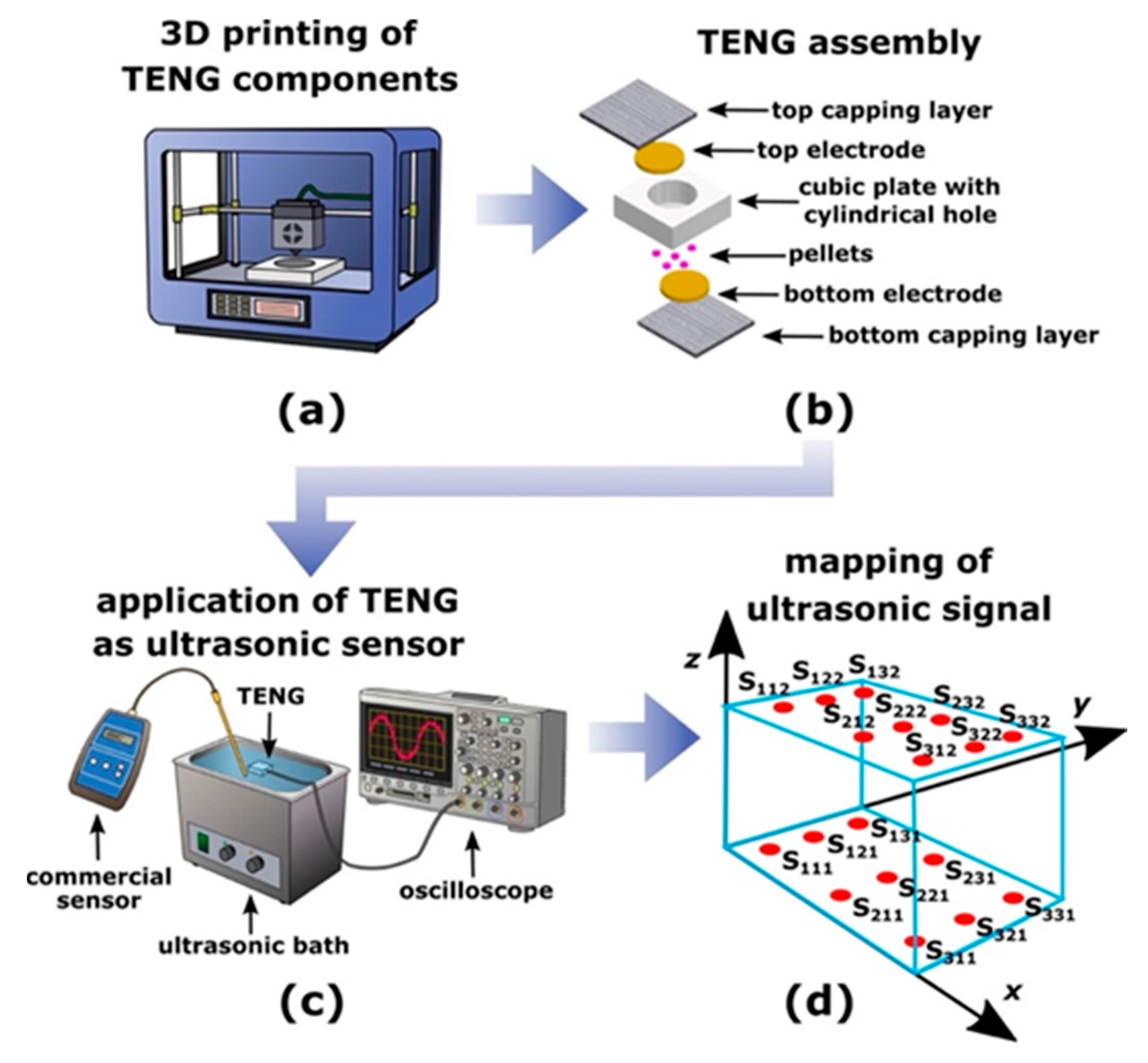

8.2. Three-Dimensional-Printed Triboelectric Nanogenerators [TENGs]

8.3. Three-Dimensional-Printed Hybrid Nanogenerator

9. Comparative Analysis of 3D-Printed Nanogenerators

9.1. Performance Metrics: Voltage, Power Density, and Efficiency

9.2. Material and Processing Cost Analysis

9.3. Mechanical Durability—Flexibility and Biocompatibility

10. Current Challenges in 3D-Printed Nanogenerators

10.1. Material Selection and Ink Formulation Challenges

10.2. Scalability and Manufacturing Limitations

10.3. Long-Term Stability and Degradation Issues

10.4. Environmental Impact and Sustainability Consideration

10.5. Interface Engineering Challenges

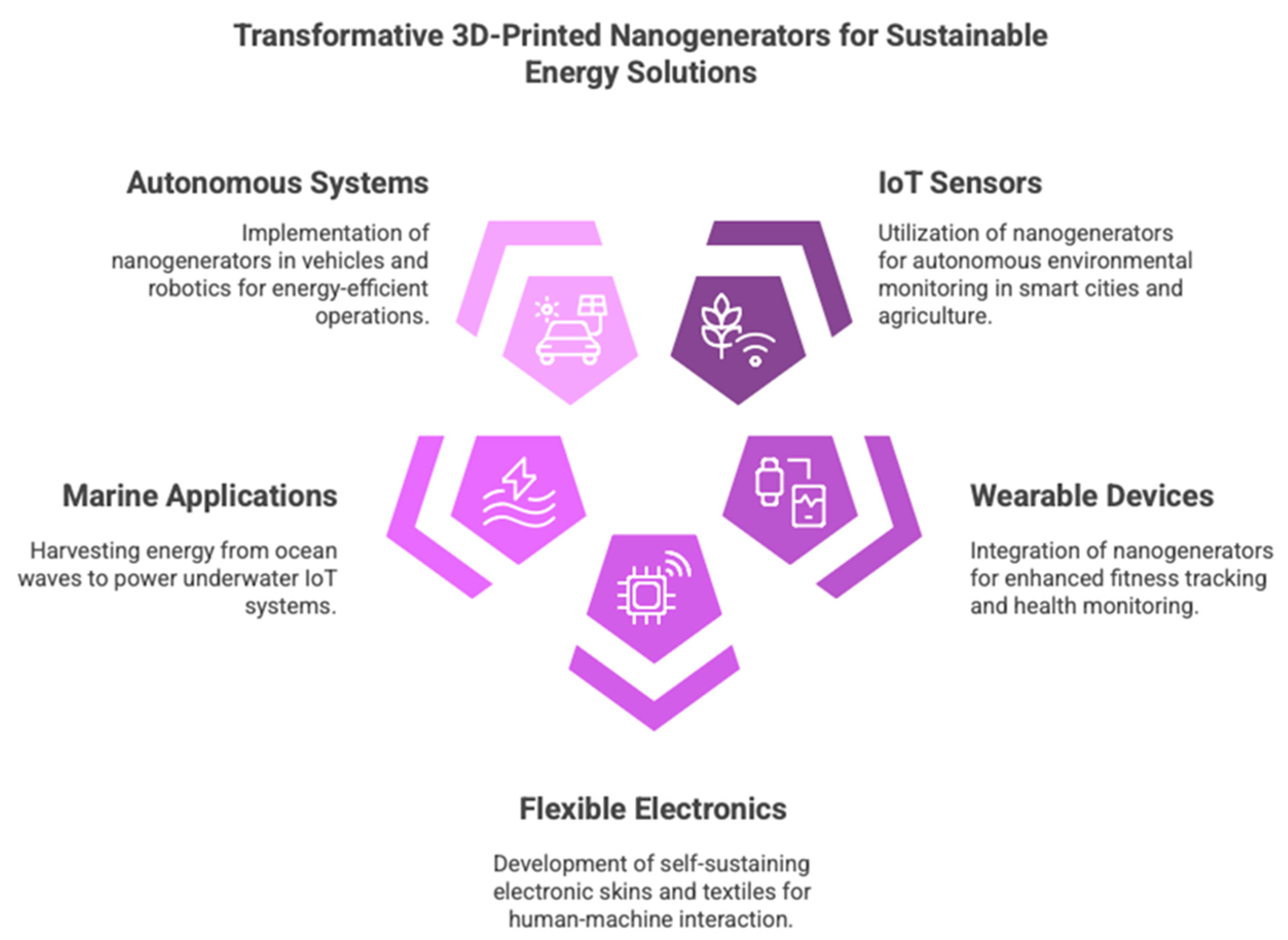

11. Application of 3D-Printed Nanogenerators as Energy-Harvesting Devices

11.1. IoT Sensors for Smart Cities and Agriculture

11.2. Wearable Devices: Fitness Trackers and Smartwatches

11.3. Flexible and Stretchable Electronics

11.4. Marine and Underwater Applications

11.5. Autonomous Vehicles and Robotics

12. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Q.; Soham, D.; Liang, Z.; Wan, J. Advances in wearable energy storage and harvesting systems. Med-X 2025, 3, 3. [Google Scholar] [CrossRef]

- Huang, Y.; Peng, L.; Lin, S.; Qi, S.; Lv, H.; Van Toan, N.; Xia, Y.; Xia, C.; Wang, Z. Optimized design and performance evaluation of a flexible thermoelectric generator for Low-thermal heat waste energy harvesting. Appl. Therm. Eng. 2025, 264, 125225. [Google Scholar] [CrossRef]

- Kiamansouri, M. Integration of Renewable Energy Sources in Oil and Gas Operations a Sustainable Future. Eurasian J. Chem. Med. Pet. Res. 2025, 4, 111–135. [Google Scholar]

- Barros, A.; Breitner, M.H.; Watson, R.T.; Degirmenci, K. Introduction to the Minitrack on Digital Energy Services and Analytics. In Proceedings of the 58th Hawaii International Conference on System Sciences, Big Island, HI, USA, 7–10 January 2025. [Google Scholar]

- Zhang, Y.; Tang, H.; Li, H.; Wang, S. Unlocking the flexibilities of data centers for smart grid services: Optimal dispatch and design of energy storage systems under progressive loading. Energy 2025, 316, 134511. [Google Scholar] [CrossRef]

- Tharuman, S.; Chen, S.-M. Sustainable energy from nature: Biocompatible next-generation triboelectric nanogenerators and waste-recycling approach. J. Power Sources 2025, 640, 236683. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, L.; Lu, J.; Zhang, X.; Wang, K.; Gan, Z.; Liu, X.; Jing, Z.; Cui, X.; Wang, H. Advances in urban wind resource development and wind energy harvesters. Renew. Sustain. Energy Rev. 2025, 207, 114943. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.; Lee, J.P.; Lee, P.S. Nanogenerators developed based on different physics effects. MRS Bull. 2025, 50, 271–282. [Google Scholar] [CrossRef]

- Prauzek, M.; Gaiova, K.; Kucova, T.; Konecny, J. Fuzzy energy management strategies for energy harvesting IoT nodes based on a digital twin concept. Future Gener. Comput. Syst. 2025, 166, 107717. [Google Scholar] [CrossRef]

- Kacimi, M.A.; Aoughlis, C.; Bakir, T.; Guenounou, O. Efficient and Adaptive Design of RBF Neural Network for Maximum Energy Harvesting from Standalone PV System. Sustain. Comput. Inform. Syst. 2025, 46, 101083. [Google Scholar] [CrossRef]

- Wang, Q.; Hu, D.; Huang, X.; Chen, Z.; Yuan, Z.; Zhong, L.; Sun, Q.; Wang, F.; Xu, S.; Chen, S. Hybrid Triboelectric-Electromagnetic-Electric Field Energy Harvester for Simultaneous Wind and Electric Field Energy Capture in High-Voltage Transmission System. Adv. Energy Mater. 2025, 15, 2403931. [Google Scholar] [CrossRef]

- Lee, S.; Ko, H.-J.; Kim, J. Self-powered gas sensor based on triboelectric nanogenerators [TENG]: A comparative review of sensing mechanisms. Micro Nano Syst. Lett. 2025, 13, 2. [Google Scholar] [CrossRef]

- Zou, Y.; Xu, W.; Yang, W. Durable wind energy harvesting by mode-switch triboelectric nanogenerator for self-powered sensors. Sens. Rev. 2025. ahead of print. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Li, K.; Zhang, S.; Yang, Z.; Zhang, C.; Zhang, J.; Li, Y.; Zhang, D.; Liu, Y.; et al. From Fiber to Power: Recent Advances Toward Electrospun-Based Nanogenerators. Adv. Funct. Mater. 2025, 35, 2418066. [Google Scholar] [CrossRef]

- Shivanna, K.G.G.; Thammannagowda, V.K.; Shankaregowda, S.A.; Panier, S.; Kalappa, P. Poly [lactic acid]-Based Triboelectric Nanogenerators: Pathways Toward Sustainable Energy Harvesting. Hybrid Adv. 2025, 9, 100395. [Google Scholar] [CrossRef]

- Liu, S.; Manshaii, F.; Chen, J.; Wang, X.; Wang, S.; Yin, J.; Yang, M.; Chen, X.; Yin, X.; Zhou, Y. Unleashing the potential of electroactive hybrid biomaterials and self-powered systems for bone therapeutics. Nano-Micro Lett. 2025, 17, 44. [Google Scholar] [CrossRef]

- Yang, Y.; Lee, J.-H. Hybridized nanogenerators: Materials and structural design for improving energy harvesting. MRS Bull. 2025, 50, 416–427. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, F.; Ma, Y.; Ma, S.; Wang, L. Recent Advances in Polyvinylidene Fluoride with Multifunctional Properties in Nanogenerators. Small 2025, 21, 2412476. [Google Scholar] [CrossRef]

- Ba, Y.Y.; Chang, Y.M.; Mu, F.Y.; Deng, H.T.; Zhang, X.R.; Shi, S.; Zhang, X.S. Self-powered real-time fall alarm microsystem based on reconfigurable paper-like piezoelectric nanogenerator. Nano Energy 2025, 137, 110803. [Google Scholar] [CrossRef]

- Sharma, M.; Kumar, M. Bibliometric Analysis of Biomedical IOT Devices for Remote Diagnosis and Monitoring. In Role of Science and Technology for Sustainable Future: Volume 2-Applied Sciences and Technologies; Springer Nature Singapore: Singapore, 2025; pp. 189–203. [Google Scholar]

- Hua, M.; Jiang, R.; Lu, Y.; Su, Y.; Zhao, Y. Self-Powered Electrochemical Protection for Marine Corrosion and Fouling Control: Principles, Advances, and Prospects. Nano Energy 2025, 135, 110676. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, Z.; Zhao, Z.; Zhang, D.; Feng, J.; Yu, L.; Lin, Z.; Guo, Q.; Huang, J.; Mao, J.; et al. 3D printing of micro-nano devices and their applications. Microsyst. Nanoeng. 2025, 11, 35. [Google Scholar] [CrossRef]

- Ra, Y.; Song, M.; Lee, D.; Jang, S.; Kim, Y.-S.; Chae, J.; Cho, S.; Kam, D.; Lee, D.; Lee, G.; et al. Recent progress in triboelectric platforms: Engineering materials to industrial applications from the perspective of manufacturing. Int. J. Extrem. Manuf. 2025, 7, 032007. [Google Scholar] [CrossRef]

- Jain, N.; Waidi, Y.O. The Multifaceted Role of 3D Printed Conducting Polymers in Next-Generation Energy Devices: A Critical Perspective. JACS Au 2025, 5, 411–425. [Google Scholar] [CrossRef]

- Zhong, Q.; Mao, Y.; Zhou, B.; Hu, W. All-textile 3D triboelectric nanogenerator derived from bidirectional cross-weaving binary-yarns for bio-motion energy harvesting and sensing. Chem. Eng. J. 2025, 504, 158871. [Google Scholar] [CrossRef]

- Gulahmadov, O.; Gahramanli, L.; Muradov, M.; Musayeva, N.; Gilev, J.B.; Bellucci, S. Fabricating nylon/multiwalled carbon nanotube [MWCNT] nanocomposites for potential use in triboelectric nanogenerators [TENGs]. Fuller. Nanotub. Carbon Nanostructures 2025, 1–10. [Google Scholar] [CrossRef]

- Ali, S.M.; Noghanian, S.; Khan, Z.U.; Alzahrani, S.; Alharbi, S.; Alhartomi, M.; Alsulami, R. Wearable and Flexible Sensor Devices: Recent Advances in Designs, Fabrication Methods, and Applications. Sensors 2025, 25, 1377. [Google Scholar] [CrossRef]

- Latief, U.; Mondal, S.; Aishwarya, A.; Bhattacharjee, N.; Bhattacharyya, A.R. Hybrid Fillers of Barium Titanate and Functionalized Multi-Walled Carbon Nanotubes Incorporated Poly [vinylidene fluoride] Nanocomposites for Piezoelectric Nanogenerators. ACS Appl. Nano Mater. 2025, 8, 4784–4800. [Google Scholar] [CrossRef]

- Arefin, N.; Moni, H.E.; Espinosa, D.; Cong, W.; Zeng, M. Multi-material additive manufacturing of energy storage and conversion devices: Recent progress and future prospects. Appl. Phys. Rev. 2025, 12, 011330. [Google Scholar] [CrossRef]

- Li, H.; Xu, Z.; Zhang, J.; Li, S.; Li, S.; Chen, X.; Lu, L.; Pan, Z.; Mao, Y. Recent progress of flexible electrospun nanofibers based triboelectric nanogenerators for self-powered electronics. J. Phys. Condens. Matter 2025, 37, 183001. [Google Scholar] [CrossRef]

- Basharat, A.; Huma, Z. Advancements in Wearable Biomedical Devices for Real-Time Health Monitoring. East. Eur. J. Multidiscip. Res. 2024, 3, 106–112. [Google Scholar]

- Shafik, W. Smart biomedical devices for smart healthcare. In Machine Learning Models and Architectures for Biomedical Signal Processing; Academic Press: Cambridge, MA, USA, 2025; pp. 421–448. [Google Scholar]

- Batra, R.; Pourjafarian, N.; Chang, S.; Tsai, M.; Revelo, J.; Kao, C.H.L. tex TENG: Fabricating Wearable Textile-Based Triboelectric Nanogenerators. arXiv 2025, arXiv:2503.12628. [Google Scholar]

- Slobodian, P.; Riha, P.; Hausnerova, B. Unsorted Postconsumer Plastic Waste in Energy Conversion Using Piezoelectric, Triboelectric, and Pyroelectric Generation Mechanisms. ACS Sustain. Chem. Eng. 2025, 13, 2683–2693. [Google Scholar]

- Revankar, S.S.; Yashaswini, V.L.; Manjunatha, A.S.; Kavya, R.; Gowda, K.M.; Manjushree, N.; Unnikrishanan, G.; Rumana Farheen, S.M.; M.A., S.; Sachith, B.M.; et al. Fluorescent CsPbBr3@ Cs4PbBr6/PU polymer nanocomposite-based triboelectric nanogenerator for self-powered UV sensing. Mater. Today Chem. 2025, 44, 102601. [Google Scholar] [CrossRef]

- Turar, Z.; Sembay, M.; Mubarak, A.; Belgibayeva, A.; Kong, L.; Kalimuldina, G. Advances in Porous Structure Design for Enhanced Piezoelectric and Triboelectric Nanogenerators: A Comprehensive Review. Glob. Chall. 2025, 9, 2400224. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Li, Z.; Hu, H.; Chen, B.; Wang, Y.; Mao, Y.; Li, H.; Zhang, B. Recent Progress in Self-Healing Triboelectric Nanogenerators for Artificial Skins. Biosensors 2025, 15, 37. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Wen, J.; Qin, Y. Development and outlook of high output piezoelectric nanogenerators. Nano Energy 2021, 86, 106080. [Google Scholar] [CrossRef]

- Cheng, T.; Shao, J.; Wang, Z.L. Triboelectric nanogenerators. Nat. Rev. Methods Primers 2023, 3, 39. [Google Scholar] [CrossRef]

- Deng, W.; Zhou, Y.; Libanori, A.; Chen, G.; Yang, W.; Chen, J. Piezoelectric nanogenerators for personalized healthcare. Chem. Soc. Rev. 2022, 51, 3380–3435. [Google Scholar] [CrossRef]

- Pang, Y.; Cao, Y.; Derakhshani, M.; Fang, Y.; Wang, Z.L.; Cao, C. Hybrid energy-harvesting systems based on triboelectric nanogenerators. Matter 2021, 4, 116–143. [Google Scholar] [CrossRef]

- Lone, S.A.; Lim, K.C.; Kaswan, K.; Chatterjee, S.; Fan, K.-P.; Choi, D.; Lee, S.; Zhang, H.; Cheng, J.; Lin, Z.-H. Recent advancements for improving the performance of triboelectric nanogenerator devices. Nano Energy 2022, 99, 107318. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Nie, S.; Lin, Z. Recent Advance of Triboelectric Nanogenerator-Based Electrical Stimulation in Healthcare. Electronics 2023, 12, 4477. [Google Scholar] [CrossRef]

- Kim, W.G.; Kim, D.W.; Tcho, I.W.; Kim, J.K.; Kim, M.S.; Choi, Y.K. Triboelectric nanogenerator: Structure, mechanism, and applications. ACS Nano 2021, 15, 258–287. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Cai, H.; Xu, L.; Ji, L.; Wang, D.; Zheng, Y.; Feng, Y.; Sui, X.; Guo, Y.; Guo, W.; et al. Macro-superlubric triboelectric nanogenerator based on tribovoltaic effect. Matter 2022, 5, 1532–1546. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric nanogenerator [TENG]—Sparking an energy and sensor revolution. Adv. Energy Mater. 2020, 10, 2000137. [Google Scholar] [CrossRef]

- Fu, X.; Pan, X.; Liu, Y.; Li, J.; Zhang, Z.; Liu, H.; Gao, M. Non-contact triboelectric nanogenerator. Adv. Funct. Mater. 2023, 33, 2306749. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhou, L.; Li, S.; Liu, D.; Li, Y.; Gao, Y.; Liu, Y.; Dai, Y.; Wang, J.; Wang, Z.L. Selection rules of triboelectric materials for direct-current triboelectric nanogenerator. Nat. Commun. 2021, 12, 4686. [Google Scholar] [CrossRef]

- Luo, J.; Wang, Z.L. Recent progress of triboelectric nanogenerators: From fundamental theory to practical applications. EcoMat 2020, 2, e12059. [Google Scholar] [CrossRef]

- Zhou, Y.; Deng, W.; Xu, J.; Chen, J. Engineering materials at the nanoscale for triboelectric nanogenerators. Cell Rep. Phys. Sci. 2020, 1, 100142. [Google Scholar] [CrossRef]

- Shao, J.; Willatzen, M.; Wang, Z.L. Theoretical modeling of triboelectric nanogenerators [TENGs]. Journal of Applied Physics 2020, 128, 111101. [Google Scholar] [CrossRef]

- Zhang, C.; Fan, W.; Wang, S.; Wang, Q.; Zhang, Y.; Dong, K. Recent progress of wearable piezoelectric nanogenerators. ACS Appl. Electron. Mater. 2021, 3, 2449–2467. [Google Scholar] [CrossRef]

- Bhadwal, N.; Mrad, R.B.; Behdinan, K. Review of zinc oxide piezoelectric nanogenerators: Piezoelectric properties, composite structures and power output. Sensors 2023, 23, 3859. [Google Scholar] [CrossRef]

- Mariello, M. Recent advances on hybrid piezo-triboelectric bio-nanogenerators: Materials, architectures and circuitry. Nanoenergy Adv. 2022, 2, 64–109. [Google Scholar] [CrossRef]

- Dong, L.; Tang, Q.; Zhao, C.; Hu, G.; Qu, S.; Liu, Z.; Yang, Y. Flag-type hybrid nanogenerator utilizing flapping wakes for consistent high performance over an ultra-broad wind speed range. Nano Energy 2024, 119, 109057. [Google Scholar] [CrossRef]

- Panigrahi, B.K.; Ahmed, R.; Mehmood, M.U.; Park, J.C.; Kim, Y.; Chun, W. Operation of a low-temperature differential heat engine for power generation via hybrid nanogenerators. Appl. Energy 2021, 285, 116385. [Google Scholar]

- Afsarimanesh, N.; Nag, A.; e Alahi, M.E.; Sarkar, S.; Mukhopadhyay, S.; Sabet, G.S.; Altinsoy, M.E. A critical review of the recent progress on carbon nanotubes-based nanogenerators. Sens. Actuators A Phys. 2022, 344, 113743. [Google Scholar] [CrossRef]

- Panda, S.; Hajra, S.; Oh, Y.; Oh, W.; Lee, J.; Shin, H.; Vivekananthan, V.; Yang, Y.; Mishra, Y.K.; Kim, H.J. Hybrid nanogenerators for ocean energy harvesting: Mechanisms, designs, and applications. Small 2023, 19, 2300847. [Google Scholar] [CrossRef]

- Shanbedi, M.; Ardebili, H.; Karim, A. Polymer-based triboelectric nanogenerators: Materials, characterization, and applications. Prog. Polym. Sci. 2023, 144, 101723. [Google Scholar] [CrossRef]

- Pandey, R.K.; Dutta, J.; Brahma, S.; Rao, B.; Liu, C.P. Review on ZnO-based piezotronics and piezoelectric nanogenerators: Aspects of piezopotential and screening effect. J. Phys. Mater. 2021, 4, 044011. [Google Scholar] [CrossRef]

- Cao, X.; Xiong, Y.; Sun, J.; Zhu, X.; Sun, Q.; Wang, Z.L. Piezoelectric nanogenerators derived self-powered sensors for multifunctional applications and artificial intelligence. Adv. Funct. Mater. 2021, 31, 2102983. [Google Scholar] [CrossRef]

- Prajesh, N.; Sharma, V.B.; Rajput, S.S.; Singh, C.K.; Dixit, P.; Praveenkumar, B.; Zarȩba, J.K.; Kabra, D.; Ogale, S.; Boomishankar, R. Flexible Piezoelectric Nanogenerators Based on One-Dimensional Neutral Coordination Network Composites. ACS Sustain. Chem. Eng. 2022, 10, 9911–9920. [Google Scholar] [CrossRef]

- Bairagi, S.; Shahadat, M.; Mulvihill, D.M.; Ali, W. Mechanical energy harvesting and self-powered electronic applications of textile-based piezoelectric nanogenerators: A systematic review. Nano Energy 2023, 111, 108414. [Google Scholar] [CrossRef]

- Shee, C.; Banerjee, S.; Bairagi, S.; Baburaj, A.; Naveen, K.S.K.; Aliyana, A.K.; Mulvihill, D.M.; Alagirusamy, R.; Ali, S.W. A critical review on polyvinylidene fluoride (PVDF)/zinc oxide (ZnO)-based piezoelectric and triboelectric nanogenerators. J. Phys. Energy 2024, 6, 032001. [Google Scholar] [CrossRef]

- Wu, P.; Chen, P.; Xu, C.; Wang, Q.; Zhang, F.; Yang, K.; Jiang, W.; Feng, J.; Luo, Z. Ultrasound-driven in vivo electrical stimulation based on biodegradable piezoelectric nanogenerators for enhancing and monitoring the nerve tissue repair. Nano Energy 2022, 102, 107707. [Google Scholar] [CrossRef]

- Sahu, M.; Hajra, S.; Lee, K.; Deepti, P.L.; Mistewicz, K.; Kim, H.J. Piezoelectric nanogenerator based on lead-free flexible PVDF-barium titanate composite films for driving low power electronics. Crystals 2021, 11, 85. [Google Scholar] [CrossRef]

- Yang, Y. Hybridized and Coupled Nanogenerators: Design, Performance, and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Sriphan, S.; Vittayakorn, N. Hybrid piezoelectric-triboelectric nanogenerators for flexible electronics: Recent advances and perspectives. J. Sci. Adv. Mater. Devices 2022, 7, 100461. [Google Scholar] [CrossRef]

- Korkmaz, S.; Kariper, İ.A. Pyroelectric nanogenerators [PyNGs] in converting thermal energy into electrical energy: Fundamentals and current status. Nano Energy 2021, 84, 105888. [Google Scholar] [CrossRef]

- Sivasubramanian, R.; Vaithilingam, C.A.; Indira, S.S.; Paiman, S.; Misron, N.; Abubakar, S. A review on photovoltaic and nanogenerator hybrid system. Mater. Today Energy 2021, 20, 100772. [Google Scholar] [CrossRef]

- Yaseen, H.M.A.; Park, S. P(VDF-TrFE)/BaTiO3 nanocomposite Langmuir-Schaefer thin film for piezoelectric nanogenerator. J. Alloys Compd. 2023, 952, 169940. [Google Scholar] [CrossRef]

- Padha, B.; Verma, S.; Mahajan, P.; Sundramoorthy, A.K.; Arya, S. An Insight into the Wearable Technologies Based on Novel Hybrid Piezoelectric-Triboelectric Nanogenerators. Energy Technol. 2023, 11, 2300224. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, D.; Xu, Z.; Zhang, X.; Yang, Y.; Guo, J.; Zhang, B.; Zhao, W. Diversiform sensors and sensing systems driven by triboelectric and piezoelectric nanogenerators. Coord. Chem. Rev. 2021, 427, 213597. [Google Scholar] [CrossRef]

- Liu, L.; Shi, Q.; Guo, X.; Zhang, Z.; Lee, C. A facile frequency tuning strategy to realize vibration-based hybridized piezoelectric-triboelectric nanogenerators. EcoMat 2023, 5, e12279. [Google Scholar] [CrossRef]

- Mukherjee, A.; Dasgupta Ghosh, B.; Ghosh, A.; Roy, S. Polyvinylidene fluoride nanocomposites as piezoelectric nanogenerator: Properties, fabrication and market applications. Adv. Eng. Mater. 2024, 26, 2400445. [Google Scholar] [CrossRef]

- Mishra, D.; Tiwari, M. Polymer Composites for Use in Nano-Generators for Energy Harvesting. In Polymer Composites: Fundamentals and Applications; Springer Nature Singapore: Singapore, 2024; pp. 399–423. [Google Scholar]

- Han, Z.; Zheng, S.; Huang, S.; Wang, Y.; Pan, D.; Liu, H.; Liu, C. Advances in electrically functional nanocomposites: Classification and future prospects. Adv. Compos. Hybrid Mater. 2024, 7, 252. [Google Scholar] [CrossRef]

- Mustakim, N.S.M.; Kamaruzaman, D.; Abdullah, M.H.; Malek, M.F.; Parimon, N.; Ahmad, M.K.; Abu Bakar, S.; Vasimalai, N.; Ramakrishna, S.; Mamat, M.H. Review of recent advances in piezoelectric material for nanogenerator application: Preparation methods, material selection, performance, applications, and future outlook. J. Mater. Sci. 2024, 59, 19380–19423. [Google Scholar] [CrossRef]

- Mohamadbeigi, N.; Rafiefard, N.; Ejehi, F.; Mohammadpour, R.; Iraji Zad, A. Triboelectric Nanogenerator-Enabled 3D Microporous Polydimethylsiloxane–Graphene Oxide Nanocomposite for Flexible Self-Powered Humidity Sensing Applications. Energy Technol. 2024, 12, 2301136. [Google Scholar] [CrossRef]

- Lemine, A.S.; Bhadra, J.; Sadasivuni, K.K.; Popelka, A.; Yempally, S.; Ahmad, Z.; Al-Thani, N.J.; Hasan, A. 3D printing flexible Ga-doped ZnO films for wearable energy harvesting: Thermoelectric and piezoelectric nanogenerators. J. Mater. Sci. Mater. Electron. 2024, 35, 1639. [Google Scholar] [CrossRef]

- Mahmud, M.P.; Adhikary, P.; Zolfagharian, A.; Adams, S.; Kaynak, A.; Kouzani, A.Z. Advanced design, fabrication, and applications of 3D-printable piezoelectric nanogenerators. Electron. Mater. Lett. 2022, 18, 129–144. [Google Scholar] [CrossRef]

- Pei, H.; Jing, J.; Chen, Y.; Guo, J.; Chen, N. 3D printing of PVDF-based piezoelectric nanogenerator from programmable metamaterial design: Promising strategy for flexible electronic skin. Nano Energy 2023, 109, 108303. [Google Scholar] [CrossRef]

- Lian, H.; Xue, M.; Ma, K.; Mo, D.; Wang, L.; Cui, Z.; Chen, X. Three-dimensional printed carbon black/PDMS composite flexible strain sensor for human motion monitoring. Micromachines 2022, 13, 1247. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Y.; Zhang, X.; Yu, C.; Xu, K.; Qin, J.; Zhang, G.; Shi, X. 3D-printed thermoplastic polyurethane/polyvinylidene fluoride gradient stiffness and hierarchical cellular structures with tailored energy absorption behavior. Addit. Manuf. 2024, 83, 104062. [Google Scholar] [CrossRef]

- Zhang, S.; Rana, S.S.; Bhatta, T.; Pradhan, G.B.; Sharma, S.; Song, H.; Jeong, S.; Park, J.Y. 3D printed smart glove with pyramidal MXene/Ecoflex composite-based toroidal triboelectric nanogenerators for wearable human-machine interaction applications. Nano Energy 2023, 106, 108110. [Google Scholar] [CrossRef]

- Wu, Y.; An, C.; Guo, Y. 3D printed graphene and graphene/polymer composites for multifunctional applications. Materials 2023, 16, 5681. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Dou, T.; Wang, Y.; Zuo, H.; Chen, X.; Zhang, M.; Zou, L. Three-dimensional-printed carbon nanotube/polylactic acid composite for efficient electromagnetic interference shielding. Polymers 2023, 15, 3080. [Google Scholar] [CrossRef] [PubMed]

- Patel, D.K.; Dutta, S.D.; Hexiu, J.; Ganguly, K.; Lim, K.T. 3D-printable chitosan/silk fibroin/cellulose nanoparticle scaffolds for bone regeneration via M2 macrophage polarization. Carbohydr. Polym. 2022, 281, 119077. [Google Scholar] [CrossRef]

- Lv, N.; Liu, S.; Liu, G.; Liu, X. Direct Ink Writing of Highly Conductive and Strongly Adhesive PEDOT: PSS-EP Coatings for Antistatic Applications. Colloids Interfaces 2024, 8, 48. [Google Scholar] [CrossRef]

- Zhou, X.; Parida, K.; Halevi, O.; Liu, Y.; Xiong, J.; Magdassi, S.; Lee, P.S. All 3D-printed stretchable piezoelectric nanogenerator with non-protruding kirigami structure. Nano Energy 2020, 72, 104676. [Google Scholar] [CrossRef]

- Chen, F.; An, Z.; Chen, Y.; Li, Y.; Liu, X.; Chen, N.; Ru, Y.; Gao, D. Multi-material 3D printing of piezoelectric and triboelectric integrated nanogenerators with voxel structure. Chem. Eng. J. 2023, 471, 144770. [Google Scholar] [CrossRef]

- Zhou, X.; Parida, K.; Chen, J.; Xiong, J.; Zhou, Z.; Jiang, F.; Xin, Y.; Magdassi, S.; Lee, P.S. 3D printed auxetic structure-assisted piezoelectric energy harvesting and sensing. Adv. Energy Mater. 2023, 13, 2301159. [Google Scholar] [CrossRef]

- Maity, K.; Mondal, A.; Saha, M.C. Cellulose nanocrystal-based all-3D-printed pyro-piezoelectric nanogenerator for hybrid energy harvesting and self-powered cardiorespiratory monitoring toward the human–machine interface. ACS Appl. Mater. Interfaces 2023, 15, 13956–13970. [Google Scholar] [CrossRef]

- Shao, B.; Chen, Z.; Su, H.; Peng, S.; Song, M. The Latest Advances in Ink-Based Nanogenerators: From Materials to Applications. Int. J. Mol. Sci. 2024, 25, 6152. [Google Scholar] [CrossRef]

- Pei, H.; Xie, Y.; Xiong, Y.; Lv, Q.; Chen, Y. A novel polarization-free 3D printing strategy for fabrication of poly [Vinylidene fluoride] based nanocomposite piezoelectric energy harvester. Compos. Part B Eng. 2021, 225, 109312. [Google Scholar] [CrossRef]

- Li, C.; Huang, Z.; Zhang, L.; Song, Z.; Chen, Y.; Chang, X.; Hu, P. 3D printing enhanced piezoelectricity of MXene/P [VDF-TrFE] composites for energy harvesting and force sensing. Compos. Sci. Technol. 2024, 258, 110881. [Google Scholar] [CrossRef]

- Song, S.; Li, Y.; Wang, Q.; Zhang, C. Boosting piezoelectric performance with a new selective laser sintering 3D printable PVDF/graphene nanocomposite. Compos. Part A Appl. Sci. Manuf. 2021, 147, 106452. [Google Scholar] [CrossRef]

- Koroglu, L.; Ayas, E.; Ay, N. 3D printing of polyvinylidene fluoride based piezoelectric nanocomposites: An overview. Macromol. Mater. Eng. 2021, 306, 2100277. [Google Scholar] [CrossRef]

- Miranda, B.H.S.; Bagnis, D.; Oréfice, R.L. Towards the fabrication of fully printed flexible P [VDF-TrFE]-based piezoelectric sensors. Sens. Actuators A Phys. 2024, 372, 115379. [Google Scholar] [CrossRef]

- Gryshkov, O.; Al Halabi, F.; Kuhn, A.I.; Leal-Marin, S.; Freund, L.J.; Förthmann, M.; Meier, N.; Barker, S.A.; Haastert-Talini, K.; Glasmacher, B. PVDF and P (VDF-TrFE) electrospun scaffolds for nerve graft engineering: A comparative study on piezoelectric and structural properties, and in vitro biocompatibility. Int. J. Mol. Sci. 2021, 22, 11373. [Google Scholar] [CrossRef] [PubMed]

- Lozano Montero, K.; Calvo Guzman, R.; Tewari, A.; Zou, H.; Wang, Z.L.; Mäntysalo, M.; Laurila, M.M. Printed and Stretchable Triboelectric Energy Harvester Based on P [VDF-TrFE] Porous Aerogel. Adv. Funct. Mater. 2024, 34, 2312881. [Google Scholar] [CrossRef]

- Ahbab, N.; Naz, S.; Xu, T.B.; Zhang, S. A Comprehensive Review of Piezoelectric PVDF Polymer Fabrications and Characteristics. Micromachines 2025, 16, 386. [Google Scholar] [CrossRef]

- Han, S.; Li, S.; Fu, X.; Han, S.; Chen, H.; Zhang, L.; Wang, J.; Sun, G. Research progress of flexible piezoresistive sensors based on polymer porous materials. ACS Sens. 2024, 9, 3848–3863. [Google Scholar] [CrossRef]

- Gong, S.; Lu, Y.; Yin, J.; Levin, A.; Cheng, W. Materials-driven soft wearable bioelectronics for connected healthcare. Chem. Rev. 2024, 124, 455–553. [Google Scholar] [CrossRef]

- Park, J.; Hanif, A.; Kim, D.S.; Jeong, U. Fibrillar Strings for Wearable Sensor Applications. Korean J. Chem. Eng. 2025, 1–22. [Google Scholar] [CrossRef]

- Kim, H.; Zan, G.; Seo, Y.; Lee, S.; Park, C. Stimuli-Responsive Liquid Metal Hybrids for Human-Interactive Electronics. Adv. Funct. Mater. 2024, 34, 2308703. [Google Scholar] [CrossRef]

- Wu, X.; Ye, Y.; Sun, M.; Mei, Y.; Ji, B.; Wang, M.; Song, E. Recent progress of soft and bioactive materials in flexible bioelectronics. Cyborg Bionic Syst. 2025, 6, 0192. [Google Scholar] [CrossRef]

- Joo, H.; Cho, S. Comparative studies on polyurethane composites filled with polyaniline and graphene for DLP-type 3D printing. Polymers 2020, 12, 67. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.; Peng, T.; Zhang, B.; Wu, Y.; Huang, Z.; Guan, Q. Zinc oxide bridges the nanofillers to enhance the wear resistance and stability of triboelectric nanogenerators. Chem. Eng. J. 2024, 493, 152532. [Google Scholar] [CrossRef]

- Missaoui, S.; Bouhamed, A.; Nouri, H.; Jȯhrmann, N.; Wunderle, B.; Khemakhem, H.; Kanoun, O. Sustainable and Flexible Piezoelectric Nanogenerator with Hybrid Nanocomposites Based on High-Performance Synthesized BCZT Powder. ACS Appl. Electron. Mater. 2024, 6, 5608–5625. [Google Scholar] [CrossRef]

- Das, T.; Yadav, M.K.; Dev, A.; Kar, M. Double perovskite-based wearable ternary nanocomposite piezoelectric nanogenerator for self-charging, human health monitoring and temperature sensor. Chem. Eng. J. 2024, 496, 153926. [Google Scholar] [CrossRef]

- Chen, Y.; Shi, J.; Yang, G.; Zhu, N.; Zhang, L.; Yang, D.; Yao, N.; Zhang, W.; Li, Y.; Guo, Q.; et al. High-performance sono-piezoelectric nanocomposites enhanced by interfacial coupling effects for implantable nanogenerators and actuators. Mater. Horiz. 2024, 11, 995–1007. [Google Scholar] [CrossRef]

- Kumar, M.; Kulkarni, N.D.; Saha, A.; Kumari, P. Using multi-criteria decision-making approach for material alternatives in TiO2/P [VDF-TrFE]/PDMS based hybrid nanogenerator as a wearable device. Sens. Actuators A Phys. 2024, 372, 115331. [Google Scholar] [CrossRef]

- Panda, S.; Hajra, S.; Kumar, R.R.; Kumar, K.U.; Borrás, A.; Mishra, Y.K.; Kim, H.J. Nanostructures for energy harvesting. In Advances in Nanostructures; Elsevier: Amsterdam, The Netherlands, 2025; pp. 251–323. [Google Scholar]

- Tao, D.; Su, P.; Chen, A.; Gu, D.; Eginligil, M.; Huang, W. Electro-spun nanofibers-based triboelectric nanogenerators in wearable electronics: Status and perspectives. NPJ Flex. Electron. 2025, 9, 4. [Google Scholar] [CrossRef]

- Eltoukhy, K.A.; Aly, M.F.; Sarquella, M.; Langreo, C.; Serry, M. Fabrication and Optimization of Additively Manufactured Hybrid Nanogenerators for Wearable Devices. Nanomaterials 2025, 15, 159. [Google Scholar] [CrossRef]

- Venkatesan, H.M.; Arun, A.P. High-performance triboelectric nanogenerators based on Ag-doped ZnO loaded electrospun PVDF nanofiber mats for energy harvesting and healthcare monitoring. Sci. Rep. 2025, 15, 3347. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhai, H.; Zhang, Q.; Hu, X.; Li, Y.; Xiong, X.; Ma, R.; Wang, J.; Chang, Y.; Wu, L. Trends in Flexible Sensing Technology in Smart Wearable Mechanisms–Materials–Applications. Nanomaterials 2025, 15, 298. [Google Scholar] [CrossRef] [PubMed]

- Hanif, A.; Kim, D.S. Micro/Nanofibers for Flexible, Stretchable, and Strain-Insensitive Wearable Electronics-A Review. Adv. Sens. Res. 2025, 4, 2400133. [Google Scholar] [CrossRef]

- Tiruneh, D.M.; Ryu, H. Recent advances in nanogenerators for wearable electronic devices. APL Electron. Devices 2025, 1, 011501. [Google Scholar] [CrossRef]

- Sun, Y.; Huang, Y.; Lu, X.; Song, H.; Wang, G. Preparation and Application of Hydrophobic and Breathable Carbon Nanocoils/Thermoplastic Polyurethane Flexible Strain Sensors. Nanomaterials 2025, 15, 457. [Google Scholar] [CrossRef]

- Jung, Y.H.; Wang, S.; Lee, K.J.; Zi, Y. Nanogenerators for flexible and wearable electronics toward healthcare applications. MRS Bull. 2025, 50, 482–490. [Google Scholar] [CrossRef]

- Luo, L.; Zhang, B.; Lei, Y.; Chai, D.; Zhang, D.; Xu, K.; Chen, N.; Hu, S.; Peng, H.-L.; Wang, H. Interface-Engineered Porous PDMS-MWCNTs Composites through HPC-Mediated Sponge Pump Absorption Strategy for High-Performance Triboelectric Nanogenerators. Mater. Today Commun. 2025, 44, 112192. [Google Scholar] [CrossRef]

- Lakra, H.; Aishwarya, A.; Mondal, S.; Bhattacharjee, N.; Bhattacharyya, A.R. Nanogenerators of acid-functionalized multiwalled carbon nanotubes incorporated poly [vinylidene fluoride] nanocomposites with enhanced piezoelectric performance towards bio-mechanical motion energy harvesting. Polym. Compos. 2025. [Google Scholar] [CrossRef]

- Vinodhini, J.; Harish, S.; Ikeda, H.; Navaneethan, M. Interfacial engineering of flexible Ag2-xSnxS on carbon fabric for enhanced wearable thermoelectric generator. J. Colloid Interface Sci. 2025, 679, 422–434. [Google Scholar] [CrossRef]

- Zhou, L.; Yang, T.; Guo, C.; Wang, K.; Wang, E.; Zhu, L.; Wang, H.; Cao, S.; Chou, K.C.; Hou, X. PVDF/6H-SiC composite fiber films with enhanced piezoelectric performance by interfacial engineering for diversified applications. J. Mater. Sci. Technol. 2024, 170, 238–245. [Google Scholar] [CrossRef]

- Damamme, R.; Seveyrat, L.; Borta-Boyon, A.; Nguyen, V.C.; Le, M.Q.; Cottinet, P.J. 3D printing of doped barium-titanate using robocasting-Toward new generation lead-free piezoceramic transducers. J. Eur. Ceram. Soc. 2023, 43, 3297–3306. [Google Scholar] [CrossRef]

- Ali, A.; Iqbal, S.; Chen, X. Recent advances in piezoelectric wearable energy harvesting based on human motion: Materials, design, and applications. Energy Strategy Rev. 2024, 53, 101422. [Google Scholar] [CrossRef]

- Tsikriteas, Z.M.; Roscow, J.I.; Bowen, C.R.; Khanbareh, H. Exploring lead-free materials for screen-printed piezoelectric wearable devices. Cell Rep. Phys. Sci. 2024, 5, 101962. [Google Scholar] [CrossRef]

- Wang, Y.; Bu, Y.; Wang, X. Advances in 3D printing of structural and functional ceramics: Technologies, properties, and applications. J. Eur. Ceram. Soc. 2024, 44, 116653. [Google Scholar] [CrossRef]

- Dang, T.B.; Truong, T.A.; Nguyen, C.C.; Listyawan, M.; Sapers, J.S.; Zhao, S.; Truong, D.P.; Zhang, J.; Do, T.N.; Phan, H.-P. Flexible, Wearable Mechano-Acoustic Sensors for Body Sound Monitoring Applications. Nanoscale 2025, 17, 9652–9685. [Google Scholar] [CrossRef] [PubMed]

- Mi, X.; Liu, L.; Yang, S.; Wu, P.; Zhan, W.; Ji, X.; Liang, J. Ink formulation of functional nanowires with hyperbranched stabilizers for versatile printing of flexible electronics. Nat. Commun. 2025, 16, 2590. [Google Scholar] [CrossRef] [PubMed]

- De Pamphilis, L.; Ma, S.; Dahiya, A.S.; Christou, A.; Dahiya, R. Site-Selective Nanowire Synthesis and Fabrication of Printed Memristor Arrays with Ultralow Switching Voltages on Flexible Substrate. ACS Appl. Mater. Interfaces 2024, 16, 60394–60403. [Google Scholar] [CrossRef]

- Ding, Y.; Xiong, S.; Sun, L.; Wang, Y.; Zhou, Y.; Li, Y.; Peng, J.; Fukuda, K.; Someya, T.; Liu, R.; et al. Metal nanowire-based transparent electrode for flexible and stretchable optoelectronic devices. Chem. Soc. Rev. 2024, 53, 7784–7827. [Google Scholar] [CrossRef]

- Ma, S.; Dahiya, A.S.; Christou, A.; De Pamphilis, L.; Dahiya, R. All-Printed ZnO Nanowire-Based High Performance Flexible Ultraviolet Photodetectors. IEEE J. Flex. Electron. 2023, 2, 216–222. [Google Scholar] [CrossRef]

- Han, X.; Lin, X.; Sun, Y.; Huang, L.; Huo, F.; Xie, R. (Advancements in Flexible Electronics Fabrication: Film Formation, Patterning, and Interface Optimization for Cutting-Edge Healthcare Monitoring Devices. ACS Appl. Mater. Interfaces 2024, 16, 54976–55010. [Google Scholar] [CrossRef]

- Hema, S.; Sreelekshmi, C.; Chandran, G.U.; Sajith, M.; Ajitha, A.R.; Sambhudevan, S. Hybrid nanofillers and triboelectric generators. In Hybrid Nanofillers for Polymer Reinforcement; Elsevier: Amsterdam, The Netherlands, 2024; pp. 477–499. [Google Scholar]

- Gebrekrstos, A.; Muzata, T.S.; Elias, A.; Ray, S.S. Tailoring the Properties of 2D Nanomaterial-Polymer Composites for Electromagnetic Interference Shielding and Energy Storage by 3D Printing—A Review. Adv. Eng. Mater. 2024, 27, 2402179. [Google Scholar] [CrossRef]

- Liao, J.; Shamshina, J.L.; Wang, Y.; Sun, D.; Shen, X.; Zhao, D.; Sun, Q. Emerging cellulosic materials for sustainable mechanosensing and energy harvesting devices: Advances and prospect. Nano Today 2024, 56, 102232. [Google Scholar] [CrossRef]

- Roy, A.; Afshari, R.; Jain, S.; Zheng, Y.; Lin, M.-H.; Zenkar, S.; Yin, J.; Chen, J.; Peppas, N.A.; Annabi, N. Advances in conducting nanocomposite hydrogels for wearable biomonitoring. Chem. Soc. Rev. 2025, 54, 2595–2652. [Google Scholar] [CrossRef] [PubMed]

- Sayyad, P.W.; Al-Nashash, H.; Al-Othman, A.; Al-Sayah, M.H. Emerging trends in system-integrated wearable epidermal and flexible electrodes: Material design and applications in physiological monitoring. IEEE Trans. Compon. Packag. Manuf. Technol. 2025, 15, 905–937. [Google Scholar] [CrossRef]

- Mirasadi, K.; Rahmatabadi, D.; Ghasemi, I.; Khodaei, M.; Baniassadi, M.; Bodaghi, M.; Baghani, M. 3D and 4D printing of PETG–ABS–Fe3O4 nanocomposites with supreme remotely driven magneto-thermal shape-memory performance. Polymers 2024, 16, 1398. [Google Scholar] [CrossRef] [PubMed]

- Farzin, M.A.; Naghib, S.M.; Rabiee, N. Advancements in bio-inspired self-powered wireless sensors: Materials, mechanisms, and biomedical applications. ACS Biomater. Sci. Eng. 2024, 10, 1262–1301. [Google Scholar] [CrossRef]

- Li, K.; Wang, Y.; Li, M.; Li, J.; Du, F.; Wang, C.; Fang, J.; Sun, L.; Wang, X. 3D printed ultrahigh aspect ratio lead zirconate titanate [PZT] nanostructures for nano-Newton force sensing. J. Eur. Ceram. Soc. 2024, 44, 4646–4656. [Google Scholar] [CrossRef]

- Li, S.; Shan, Y.; Chen, J.; Chen, X.; Shi, Z.; Zhao, L.; He, R.; Li, Y. 3D printing and biomedical applications of piezoelectric composites: A critical review. Adv. Mater. Technol. 2025, 10, 2401160. [Google Scholar] [CrossRef]

- Pei, H.; Chen, Y.; Lv, Q.; Peng, Z.; Wang, X.; Chen, N.; Zhang, H. A novel microwave assisted multi-material 3D printing strategy to architect lamellar piezoelectric generators for intelligent sensing. Compos. Part B Eng. 2024, 280, 111529. [Google Scholar] [CrossRef]

- Patil, I.G.; Thakur, K.; Nath, S.S.; Sundriyal, P. 3D Printed Energy Harvesting Devices for Flexible and Wearable Electronics. Sustain. Energy Fuels 2024, 8, 5731–5767. [Google Scholar] [CrossRef]

- Shi, J.; Ju, K.; Chen, H.; Mirabolghasemi, A.; Akhtar, S.; Sasmito, A.; Akbarzadeh, A. 3D printed architected shell-based ferroelectric metamaterials with programmable piezoelectric and pyroelectric properties. Nano Energy 2024, 123, 109385. [Google Scholar] [CrossRef]

- Wajahat, M.; Kouzani, A.Z.; Khoo, S.Y.; Mahmud, M.P. Development of triboelectric nanogenerators using novel 3D printed polymer materials. Adv. Eng. Mater. 2024, 26, 2301897. [Google Scholar] [CrossRef]

- Hasan, S.; Mahmud, M.A.; Kouzani, A.Z. Additively Manufactured Biomedical Energy Harvesters. In Additive Manufacturing in Biomedical Applications; ASM International: Materials Park, OH, USA, 2022. [Google Scholar]

- Balpande, S.; Khan, M.J.; Nikhade, G. 3D printing technology for next-generation energy harvesters. In 3D Printed Smart Sensors and Energy Harvesting Devices: Concepts, Fabrication and Applications; IOP Publishing: Bristol, UK, 2024; pp. 8-1–8-19. [Google Scholar]

- Vu, C.C. Embedded-machine learning and soft, flexible sensors for wearable devices-viewing from an ai engineer. Mater. Today Phys. 2024, 42, 101376. [Google Scholar] [CrossRef]

- Vaseghi, A.; Sadeghizadeh, M.; Herb, M.; Grumme, D.; Demidov, Y.; Remmler, T.; Maleki, H.H. 3D Printing of Biocompatible and Antibacterial Silica–Silk–Chitosan-Based Hybrid Aerogel Scaffolds Loaded with Propolis. ACS Appl. Bio Mater. 2024, 7, 7917–7935. [Google Scholar] [CrossRef]

- Gan, N.; Wei, M.; Zhou, Q.; Dong, K.; Gao, B. Silk Fibroin-Based Triboelectric Nanogenerators for Energy Harvesting and Biomedical Applications. ACS Appl. Nano Mater. 2024, 7, 8407–8423. [Google Scholar] [CrossRef]

- Hao, Y.; Zhang, C.; Su, W.; Zhang, H.; Qin, Y.; Wang, Z.L.; Li, X. Sustainable materials systems for triboelectric nanogenerator. SusMat 2024, 4, e244. [Google Scholar] [CrossRef]

- Zhu, Q.; Sun, E.; Sun, Y.; Cao, X.; Wang, N. Biomaterial Promotes Triboelectric Nanogenerator for Health Diagnostics and Clinical Application. Nanomaterials 2024, 14, 1885. [Google Scholar] [CrossRef]

- Sanandiya, N.D.; Pai, A.R.; Seyedin, S.; Tang, F.; Thomas, S.; Xie, F. Chitosan-based electroconductive inks without chemical reaction for cost-effective and versatile 3D printing for electromagnetic interference [EMI] shielding and strain-sensing applications. Carbohydr. Polym. 2024, 337, 122161. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Feng, Z.; Yin, T.; Wan, T.; Guan, P.; Li, M.; Hu, L.; Lin, C.H.; Han, Z.; Xu, H.; et al. Multi-Interface Engineering of MXenes for Self-Powered Wearable Devices. Adv. Mater. 2024, 36, 2403791. [Google Scholar] [CrossRef]

- Huong, V.T.; Van Duc, B.; An, N.T.; Anh, T.T.P.; Aminabhavi, T.M.; Vasseghian, Y.; Joo, S.W. 3D-Printed WO3-UiO-66@ reduced graphene oxide nanocomposites for photocatalytic degradation of sulfamethoxazole. Chem. Eng. J. 2024, 483, 149277. [Google Scholar] [CrossRef]

- Gupta, S.P.; Bhardwaj, A. Green Nano-Composites for Energy Conversion and Storage. In Materials for Boosting Energy Storage. Volume 2: Advances in Sustainable Energy Technologies; American Chemical Society: Washington, DC, USA, 2024; pp. 299–319. [Google Scholar]

- Bai, J.; Li, H.; Vivegananthan, P.; Tian, X.; Dong, Y.; Sun, J.; Dai, Z.; Zhou, K. Interface engineering for 3D printed energy storage materials and devices. Adv. Energy Mater. 2024, 14, 2303035. [Google Scholar] [CrossRef]

- Tran, T.P.A.; Vu, T.H.; Dao, T.P.; Aminabhavi, T.M.; Vasseghian, Y.; Joo, S.W. Integrating 3D-printed Mo2CTx-UiO-66@ rGQDs nanocatalysts with semiconducting BiVO4 to improve interfacial charge transfer and photocatalytic degradation of atrazine. Appl. Catal. B Environ. Energy 2025, 365, 124924. [Google Scholar]

- Cheng, Z.; Zhou, J.; Liu, Y.; Yan, J.; Wang, S.; Tao, J.; Zou, K.; Tan, R.; Yao, Z. 3D printed composites based on the magnetoelectric coupling of Fe/FeCo@ C with multiple heterogeneous interfaces for enhanced microwave absorption. Chem. Eng. J. 2024, 480, 148188. [Google Scholar] [CrossRef]

- Hu, Q.; Guo, J.; Zhao, X.; Guan, C.; Wang, S.; Zhao, Z. Enhanced thermoelectric properties of 3D printed Bi2Te2. 7Se0. 3 by atomic interface engineering. J. Alloys Compd. 2024, 1004, 175770. [Google Scholar] [CrossRef]

- Liacouras, P.C.; Huo, E.; Mitsouras, D. 3D Printing Technologies and Materials. In 3D Printing at Hospitals and Medical Centers: A Practical Guide for Medical Professionals; Springer International Publishing: Cham, Switzerland, 2024; pp. 47–69. [Google Scholar]

- Swetha, S.; Sahiti, T.J.; Priya, G.S.; Harshitha, K.; Anil, A. Review on digital light processing [DLP] and effect of printing parameters on quality of print. Interactions 2024, 245, 178. [Google Scholar] [CrossRef]

- Hussain, M.I.; Xia, M.; Ren, X.; Ge, C.; Jamil, M.; Gupta, M.K. Digital light processing 3D printing of ceramic materials: A review on basic concept, challenges, and applications. Int. J. Adv. Manuf. Technol. 2024, 130, 2241–2267. [Google Scholar] [CrossRef]

- Yi, J.; Yang, S.; Yue, L.; Lei, I.M. Digital light processing 3D printing of flexible devices: Actuators, sensors and energy devices. Microsyst. Nanoeng. 2025, 11, 51. [Google Scholar] [CrossRef]

- He, L.; Liu, X.; Han, C.; Wang, D.; Wang, Q.; Deng, X.; Zhang, C. 3D printing architecting β-PVDF reservoirs for preferential ZnO epitaxial growth toward advanced piezoelectric energy harvesting. Small Methods 2024, 8, 2301707. [Google Scholar] [CrossRef]

- Saeed, G.; Kang, T.; Byun, J.S.; Min, D.; Kim, J.S.; Sadavar, S.V.; Park, H.S. Two-dimensional [2D] materials for 3D printed micro-supercapacitors and micro-batteries. Energy Mater. 2024, 4, 400023. [Google Scholar] [CrossRef]

- Chen, L.; Yao, P.; Li, W.; Huang, Q.; Chen, J.; Zhang, H.; Wang, X. 3D-Printed Flexible and Integrable Asymmetric Microsupercapacitors with High-Areal-Energy-Density. ACS Appl. Mater. Interfaces 2025, 17, 18666–18676. [Google Scholar] [CrossRef]

- Djurović, S.; Lazarević, D.; Mišić, M.; Stojčetović, B.; Blagojević, M.; Biočanin, S. 3D Printing Technologies: Process, Materials, Advantages, Disadvantages and Application. In Proceedings of the International Conference of Experimental and Numerical Investigations and New Technologies, Belgrade, Serbia, 24–27 June 2024; Springer Nature Switzerland: Cham, Switzerland, 2024. [Google Scholar]

- Lin, H.; Shen, Q.; Ma, M.; Ji, R.; Guo, H.; Qi, H.; Xing, W.; Tang, H. 3D printing of porous ceramics for enhanced thermal insulation properties. Adv. Sci. 2025, 12, 2412554. [Google Scholar] [CrossRef] [PubMed]

- Cho, S.; Khawar, M.R.; Ra, Y.; Jang, S.; Lee, D.; Kam, D.; Shah, S.A.; Yoo, D.; Javed, Y.; Ahmad, A.; et al. Advances in 3D-printed triboelectric nanogenerators and supercapacitors for self-sustainable energy systems. Mater. Today 2025, 85, 189–211. [Google Scholar] [CrossRef]

- Hari, A.S.; Patadiya, J.; Kandasubramanian, B. Recent advancements in 3D printing methods of optical glass fabrication: A technical perspective. Hybrid Adv. 2024, 7, 100289. [Google Scholar] [CrossRef]

- Cho, H.C.; Latif, M.; Jiang, Y.; Kim, J. Environment-Friendly Triboelectric Nanogenerator Based on 3D-Printed Nanocellulose Films for Human Motion Monitoring. ACS Appl. Energy Mater. 2024, 8, 267–275. [Google Scholar] [CrossRef]

- Mohapatra, A.; Divakaran, N.; PV, A.K.; Mohanty, S. The significant role of CNT-ZnO core-shell nanostructures in the development of FDM-based 3D-printed triboelectric nanogenerators. Mater. Today Nano 2023, 22, 100313. [Google Scholar] [CrossRef]

- Ribeiro, C.; Sencadas, V.; Correia, D.M.; Lanceros-Méndez, S. Piezoelectric polymers as biomaterials for tissue engineering applications. Colloids Surf. B Biointerfaces 2015, 136, 46–55. [Google Scholar] [CrossRef] [PubMed]

- Kwon, S.; Kwon, Y.T.; Kim, Y.S.; Lim, H.R.; Mahmood, M.; Yeo, W.H. Skin-conformal, soft material-enabled bioelectronic system with minimized motion artifacts for reliable health and performance monitoring of athletes. Biosens. Bioelectron. 2020, 151, 111981. [Google Scholar] [CrossRef]

- Niu, Q.; Wei, H.; Hsiao, B.S.; Zhang, Y. Biodegradable silk fibroin-based bio-piezoelectric/triboelectric nanogenerators as self-powered electronic devices. Nano Energy 2022, 96, 107101. [Google Scholar] [CrossRef]

- Majumder, C.H.; Chatterjee, K.; Kool, A.; Banerjee, S.K. Advanced Electronic and Energy Applications of Chitin and Chitosan-based Composites. In Advances in Modern and Applied Sciences; Scientific Research Publishing: Wuhan, China, 2022; p. 246. [Google Scholar]

- Wang, Y.; Sun, M.; Kwon, S.H.; Dong, L. Advancements in flexible biomechanical energy harvesting for smart health applications. Chem. Commun. 2025, 61, 2424–2449. [Google Scholar] [CrossRef]

- Wei, X.; Xu, K.; Wang, Y.; Zhang, Z.; Chen, Z. 3D printing of flexible BaTiO3/polydimethylsiloxane piezocomposite with aligned particles for enhanced energy harvesting. ACS Appl. Mater. Interfaces 2024, 16, 11740–11748. [Google Scholar] [CrossRef]

- Pawar, O.Y.; Lim, S. 3D-Printed piezoelectric nanogenerator with aligned graphitic carbon nitrate nanosheets for enhancing piezoelectric performance. J. Colloid Interface Sci. 2024, 654, 868–877. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, S.; Panday, R.; Kothavade, P.; Sharma, V.B.; Sowmiyanarayanan, A.; Praveenkumar, B.; Zaręba, J.K.; Kabra, D.; Shanmuganathan, K.; Boomishankar, R. A Highly Electrostrictive Salt Cocrystal and the Piezoelectric Nanogenerator Application of Its 3D-Printed Polymer Composite. ACS Appl. Mater. Interfaces 2024, 16, 26406–26416. [Google Scholar] [CrossRef]

- Akin, S.; Chang, T.; Abir, S.S.H.; Kim, Y.W.; Xu, S.; Lim, J.; Sim, Y.; Lee, J.; Tsai, J.-T.; Nath, C.; et al. One-step fabrication of functionalized electrodes on 3D-printed polymers for triboelectric nanogenerators. Nano Energy 2024, 129, 110082. [Google Scholar] [CrossRef]

- Tian, X.; Zhao, S.; Gao, Y.; Li, H.; Cao, W.; Xu, B. 3D printing-directed synergistic design of high-performance zinc-ion hybrid capacitors and nanogenerators for all-in-one self-powered energy wristband. Adv. Funct. Mater. 2023, 33, 2300381. [Google Scholar] [CrossRef]

- Kou, L.; Haque, R.; Sadri, R.; Auliya, R.Z.; Kaur, M.; Roberts, E.P.; Gan, W.C.; Mohammad Haniff, M.A.S.; Dee, C.F.; Ooi, P.C. Enhanced Piezoelectric Nanogenerator Based on Tridoped Graphene and Ti3CNT x MXene Quasi-3D Heterostructure. Ind. Eng. Chem. Res. 2024, 63, 15853–15868. [Google Scholar] [CrossRef]

- Han, L.; Li, K.; Wang, Z.; Men, W.; Wu, X.; Sun, X.; Zhang, J.; Cheng, J. 3D Printing Flexible Wearable Electronics with Diversified Environmentally Adaptive for Biomechanical Energy Harvesting and Personal Electromagnetic Safety. Adv. Funct. Mater. 2025, 2424743. [Google Scholar] [CrossRef]

- Wawryniuk, Z.; Brancewicz-Steinmetz, E.; Sawicki, J. Revolutionizing transportation: An overview of 3D printing in aviation, automotive, and space industries. Int. J. Adv. Manuf. Technol. 2024, 134, 3083–3105. [Google Scholar] [CrossRef]

- Yang, J.; Yu, J.; Zhang, K.; Qiao, F.; Yu, G. Laser-Induced Graphene Toward Flexible Energy Harvesting and Storage Electronics. Adv. Mater. Technol. 2024, 9, 2301602. [Google Scholar] [CrossRef]

- Ma, J.; Zheng, S.; Fu, Y.; Wang, X.; Qin, J.; Wu, Z.S. The status and challenging perspectives of 3D-printed micro-batteries. Chem. Sci. 2024, 15, 5451–5481. [Google Scholar] [CrossRef]

- Dahiya, A.S.; Christou, A.; Ma, S.; Dahiya, R. Printed Interconnects for Heterogeneous Systems Integration on Flexible Substrates. Adv. Mater. Technol. 2024, 10, 2401213. [Google Scholar] [CrossRef]

- Son, J.H.; Kim, H.; Choi, Y.; Lee, H. 3D printed energy devices: Generation, conversion, and storage. Microsyst. Nanoeng. 2024, 10, 93. [Google Scholar] [CrossRef] [PubMed]

- Alhosani, M.E.M. The Evolution of 3D Printing in Biomechanical Energy Harvesting: A Focus on Triboelectric Nanogenerator Design and Conductivity. Master’s Thesis, Diss. Khalifa University of Science, Abu Dhabi, United Arab Emirates, 2024. [Google Scholar]

- Zhang, H.B.; Chen, Y.B.; Li, K.K.; Wang, Y.F.; Wang, G.Q. Piezoelectric energy harvester with tip 3D-printed bi-stable asymmetric raceway for effective harvesting of ultralow-frequency and low-level vibration energy. Mech. Syst. Signal Process. 2025, 224, 112054. [Google Scholar] [CrossRef]

- Lemine, A.S.; Bhadra, J.; Maurya, M.R.; Sadasivuni, K.K.; Ahmad, Z.; Al-Thani, N.J.; Hasan, A. Scalable fabrication of flexible thermoelectric generator with non-toxic Ga: ZnO and PEDOT: PSS thermoelements for wearable energy harvesting. Mater. Today Commun. 2025, 42, 111225. [Google Scholar] [CrossRef]

- Vaghasiya, J.V.; Pumera, M. The rise of 3D/4D-printed water harvesting materials. Mater. Today 2024, 78, 46–74. [Google Scholar] [CrossRef]

- Ukoba, K.; Jen, T.-C. Challenges and Opportunities of Thin Films and 3D Printing. In Shaping Tomorrow: Thin Films and 3D Printing in the Fourth Industrial Revolution 1: Fundamentals; Springer: Cham, Switzerland, 2025; pp. 235–325. [Google Scholar]

- Nowacki, B.; Mistewicz, K.; Hajra, S.; Kim, H.J. 3D printed triboelectric nanogenerator for underwater ultrasonic sensing. Ultrasonics 2023, 133, 107045. [Google Scholar] [CrossRef]

- Liang, X.; Gao, J.; Wen, W. A 3D printed serrated contact structure triboelectric nanogenerator for swimming training safety monitoring. Heliyon 2024, 10, e38107. [Google Scholar] [CrossRef]

- Kim, M.; Kim, H.S. Triboelectric nanogenerator of 3D printed textile structure for energy harvesting application. J. Text. Inst. 2024, 115, 939–947. [Google Scholar] [CrossRef]

- Jalali, A.; Rajabi-Abhari, A.; Zhang, H.; Gupta, T.; Dias, O.A.T.; Islam, A.; Filleter, T.; Yan, N.; Sain, M.; Park, C.B. Cultivation of In situ foam 3D-printing: Lightweight and flexible triboelectric nanogenerators employing polyvinylidene fluoride/graphene nanocomposite foams with superior EMI shielding and thermal conductivity. Nano Energy 2025, 134, 110554. [Google Scholar] [CrossRef]

- Paranjape, M.V.; Graham, S.A.; Patnam, H.; Manchi, P.; Yu, J.S. 3D printed bidirectional rotatory hybrid nanogenerator for mechanical energy harvesting. Nano Energy 2021, 88, 106250. [Google Scholar] [CrossRef]

- Meena, K.K.; Arief, I.; Ghosh, A.K.; Liebscher, H.; Hait, S.; Nagel, J.; Heinrich, G.; Fery, A.; Das, A. 3D-printed stretchable hybrid piezoelectric-triboelectric nanogenerator for smart tire: Onboard real-time tread wear monitoring system. Nano Energy 2023, 115, 108707. [Google Scholar] [CrossRef]

- Su, E.; Xu, S.; Wang, Z.; Xu, Z.; Pan, S.; Wang, Z.L.; Cao, L.N. Buoyancy-gravity optimized triboelectric nanogenerators via conductive 3D printing for robust wave energy harvesting. Mater. Sci. Eng. R Rep. 2025, 164, 100953. [Google Scholar] [CrossRef]

- Mappoli, S.; Ghosh, K.; Pumera, M. Multi-material 3D printed smart floor tiles with triboelectric energy generation and security monitoring. Virtual Phys. Prototyp. 2025, 20, e2457580. [Google Scholar] [CrossRef]

- Somkuwar, V.U.; Kumar, B. Influence of the fabric topology on the performance of a textile-based triboelectric nanogenerator for self-powered monitoring. ACS Appl. Polym. Mater. 2023, 5, 2323–2335. [Google Scholar] [CrossRef]

- Dinesh Kumar, A.; Arunachalam, N.; Jayaganthan, R. Additively manufactured triboelectric nanogenerator with enhanced output performance by electrically poled polyvinylidene fluoride for energy harvesting application. J. Mater. Sci. Mater. Electron. 2025, 36, 250. [Google Scholar] [CrossRef]

- Yaw, Z.; Zhang, Y.; Liu, C.; Chen, Z.; Ni, Y.Q.; Lai, S.K. Reconfigurable 3D-printed 1-bit Coding Metasurface for Simultaneous Acoustic Focusing and Ene rgy Harvesting at Low-frequency Regime. Nano Energy 2025, 138, 110874. [Google Scholar] [CrossRef]

- Aliyana, A.K.; Jalajamony, H.M.; De, S.; Bairagi, S.; Mulvihill, D.M.; Fernandez, R.E.; Stylios, G.K. Plasma jet printed AgNP electrodes for high-performance fabric TENGs and adaptive sensing applications. Chem. Eng. J. 2025, 504, 158791. [Google Scholar] [CrossRef]

- Jurinovs, M.; Lapčinskis, L.; Sherrell, P.C.; Gaidukovs, S.; Sútka, A. Printing Bioderived and Biodegradable Triboelectric Nanogenerators via Dual-Head Additive Manufacturing. ACS Sustain. Chem. Eng. 2025, 13, 4641–4650. [Google Scholar] [CrossRef]

- Sun, C.-F.; Zaki, M.F.; Chen, P.-C. DLP 3D-Printed Nanogenerators: Rapid and Robust Fabrication Polymeric Microstructure Nanogenerator for Portable Energy Harvesting and Self-Powered Sensors. In Proceedings of the 2025 IEEE 38th International Conference on Micro Electro Mechanical Systems [MEMS], Kaohsiung, Taiwan, 19–23 January 2025; IEEE: Piscataway, NJ, USA, 2025. [Google Scholar]

- Chakoma, S.; Rajendran, J.; Pei, X.; Ghandehari, A.; Negrete, J.A.T.; Esfandyarpour, R. A flexible self-powered multi-nanomaterials 3D-printed triboelectric nanogenerator-based force sensor. In Proceedings of the Oxide-based Materials and Devices XVI, San Francisco, CA, USA, 25–31 January 2025; SPIE: Bellingham, WA, USA, 2025; Volume 13367. [Google Scholar]

- Lee, C.; Qin, Y.; Wang, Y.-C. Triboelectric nanogenerators for self-powered sensors and other applications. MRS Bull. 2025, 50, 428–438. [Google Scholar] [CrossRef]

- Jiang, Q.; Antwi-Afari, M.F.; Fadaie, S.; Mi, H.Y.; Anwer, S.; Liu, J. Self-powered wearable Internet of Things sensors for human-machine interfaces: A systematic literature review and science mapping analysis. Nano Energy 2024, 131, 110252. [Google Scholar] [CrossRef]

- Javaid, S.; Fahim, H.; Zeadally, S.; He, B. Self-powered sensors: Applications, challenges, and solutions. IEEE Sens. J. 2023, 23, 20483–20509. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, S.; Li, W.; Gao, Q.; Zhao, D.; Wang, Z.L.; Cheng, T. Self-powered sensing for smart agriculture by electromagnetic–triboelectric hybrid generator. ACS Nano 2021, 15, 20278–20286. [Google Scholar] [CrossRef] [PubMed]

- Saini, A.; Tiwari, M.; Mudgal, T.; Bharti, D. Fully Waste-derived Triboelectric Nanogenerators for Real-time Activity Tracking. IEEE Sens. J. 2025, 25, 13904–13911. [Google Scholar] [CrossRef]

- Cao, X.; Xiong, Y.; Sun, J.; Xie, X.; Sun, Q.; Wang, Z.L. Multidiscipline applications of triboelectric nanogenerators for the intelligent era of internet of things. Nano-Micro Lett. 2023, 15, 14. [Google Scholar] [CrossRef]

- Xi, Y.; Tan, P.; Li, Z.; Fan, Y. Self-powered wearable IoT sensors as human-machine interfaces. Soft Sci. 2023, 3, 26. [Google Scholar] [CrossRef]

- Sobianin, I.; Psoma, S.D.; Tourlidakis, A. A 3D-printed piezoelectric microdevice for human energy harvesting for wearable biosensors. Micromachines 2024, 15, 118. [Google Scholar] [CrossRef]

- Ali, A.; Shaukat, H.; Bibi, S.; Altabey, W.A.; Noori, M.; Kouritem, S.A. Recent progress in energy harvesting systems for wearable technology. Energy Strategy Rev. 2023, 49, 101124. [Google Scholar] [CrossRef]

- Chu, H.; Xue, J.; Luo, D.; Zheng, H.; Li, Z. Advances in Wearable Multifunctional Devices Based on Human-Body Energy Harvesting. Adv. Mater. Technol. 2024, 9, 2302068. [Google Scholar] [CrossRef]

- Chu, H.; Xue, J.; Luo, D.; Zheng, H.; Li, Z. Additively manufactured nano-mechanical energy harvesting systems: Advancements, potential applications, challenges and future perspectives. Nano Converg. 2021, 8, 37. [Google Scholar]

- Chen, Y.; Deng, Z.; Ouyang, R.; Zheng, R.; Jiang, Z.; Bai, H.; Xue, H. 3D printed stretchable smart fibers and textiles for self-powered e-skin. Nano Energy 2021, 84, 105866. [Google Scholar] [CrossRef]

- Wang, Z.; Luan, C.; Zhu, Y.; Liao, G.; Liu, J.; Li, X.; Yao, X.; Fu, J. Integrated and shape-adaptable multifunctional flexible triboelectric nanogenerators using coaxial direct ink writing 3D printing. Nano Energy 2021, 90, 106534. [Google Scholar] [CrossRef]

- Yang, J.; Sun, Y.; Zhang, J.; Chen, B.; Wang, Z.L. 3D-printed bearing structural triboelectric nanogenerator for intelligent vehicle monitoring. Cell Rep. Phys. Sci. 2021, 2, 100666. [Google Scholar] [CrossRef]

- Liu, W.; Wang, X.; Yang, L.; Wang, Y.; Xu, H.; Sun, Y.; Nan, Y.; Sun, C.; Zhou, H.; Huang, Y. Swing Origami-Structure-Based Triboelectric Nanogenerator for Harvesting Blue Energy toward Marine Environmental Applications. Adv. Sci. 2024, 11, 2401578. [Google Scholar] [CrossRef]

- Radhakrishnan, S.; Joseph, S.; Jelmy, E.J.; Saji, K.J.; Sanathanakrishnan, T.; John, H. Triboelectric nanogenerators for marine energy harvesting and sensing applications. Results Eng. 2022, 15, 100487. [Google Scholar] [CrossRef]

- Xu, Q.; Shang, C.; Ma, H.; Hong, Q.; Li, C.; Ding, S.; Xue, L.; Sun, X.; Pan, Y.; Sugahara, T.; et al. A guided-liquid-based hybrid triboelectric nanogenerator for omnidirectional and high-performance ocean wave energy harvesting. Nano Energy 2023, 109, 108240. [Google Scholar] [CrossRef]

- Xu, Z.; Chen, L.; Zhang, Z.; Han, J.; Chen, P.; Hong, Z.; Jiang, T.; Wang, Z.L. Durable Roller-Based Swing-Structured Triboelectric Nanogenerator for Water Wave Energy Harvesting. Small 2024, 20, 2307288. [Google Scholar] [CrossRef]

- Bhatta, T.; Faruk, O.; Islam, M.R.; Kim, H.S.; Rana, S.S.; Pradhan, G.B.; Deo, A.; Kwon, D.-S.; Yoo, I.; Park, J.Y. Polymeric multilayered planar spring-based hybrid nanogenerator integrated with a self-powered vibration sensor for automotive vehicles IoT applications. Nano Energy 2024, 127, 109793. [Google Scholar] [CrossRef]

- Arabi, A.A.; Wang, X.; Zhang, Y.; Kim, J. E3D: Harvesting Energy from Everyday Kinetic Interactions Using 3D Printed Attachment Mechanisms. Proc. ACM Interact. Mob. Wearable Ubiquitous Technol. 2023, 7, 1–31. [Google Scholar] [CrossRef]

- Zhao, H.; Ruan, L.; Wang, Z.; Shu, M.; Lyu, C.; Lakshan, B.R.; Ishara, D.; Wu, C.; Ding, W. Flexible nanogenerators for intelligent robotics: Design, manufacturing, and applications. Int. J. Extrem. Manuf. 2024, 7, 022012. [Google Scholar] [CrossRef]

- Hajra, S.; Panda, S.; Khanberh, H.; Vivekananthan, V.; Chamanehpour, E.; Mishra, Y.K.; Kim, H.J. Revolutionizing self-powered robotic systems with triboelectric nanogenerators. Nano Energy 2023, 115, 108729. [Google Scholar] [CrossRef]

- Liang, Z.; He, J.; Hu, C.; Pu, X.; Khani, H.; Dai, L.; Fan, D.; Manthiram, A.; Wang, Z.-L. Next-generation energy harvesting and storage technologies for robots across all scales. Adv. Intell. Syst. 2023, 5, 2200045. [Google Scholar] [CrossRef]

- Zeng, C.; Liu, L.; Xin, X.; Zhao, W.; Lin, C.; Liu, Y.; Leng, J. 4D printed bio-inspired mesh composite materials with high stretchability and reconfigurability. Compos. Sci. Technol. 2024, 249, 110503. [Google Scholar] [CrossRef]

| Material | Fabrication Method | d33 [pC/N] | Reference |

|---|---|---|---|

| PVDF [Polyvinylidene Fluoride] | 3D Printing [FDM] | ~5–15 | [87] |

| PVDF-TrFE | Inkjet Printing | ~20–35 | [88] |

| BaTiO3 [Barium Titanate] Composite | SLA 3D Printing | ~100–120 | [89] |

| PZT [Lead Zirconate Titanate] Composite | Direct Ink Writing | ~250–300 | [90] |

| CBN -Based Ceramic | Traditional | ~10–20 | [85] |

| PLLA nanofiber | 3D Printing | ~20–30 | [86] |

| Material | Strengths | Weakness | Reference |

|---|---|---|---|

| PVDF/P(VDF-TrFE) | High piezoelectricity; flexible; printable; good mechanical properties | Lower output compared to ceramics; requires poling for optimal performance | [94] |

| Ecoflex | Extremely stretchable; highly biocompatible; soft | Low dielectric constant; lower triboelectric output compared to rigid materials | [124] |

| BaTiO3 (Barium Titanate) | High piezoelectric constant; excellent ferroelectric properties | Brittle; difficult to print standalone without polymer matrix | [129] |

| ZnO Nanowires | Good piezoelectricity; compatible with flexible substrates | Mechanical degradation under long-term cycling; lower thermal stability | [135] |

| Carbon Nanotubes (CNTs) | High electrical conductivity; mechanical strength; flexible | Aggregation issues; uniform dispersion is challenging | [109] |

| Graphene/rGO | Exceptional conductivity; high mechanical flexibility | Requires functionalization for good matrix dispersion | [112] |

| MXenes | High conductivity; large surface area; hydrophilic | Susceptible to oxidation; stability concerns in humid environments | [138] |

| TPU (Thermoplastic Polyurethane) | High elasticity; wear resistance; good triboelectric properties | Moderate energy conversion efficiency; softer than some alternatives | [119] |

| PDMS | Excellent elasticity and environmental stability; biocompatible | Low intrinsic conductivity; requires fillers for enhanced properties | [110] |

| Nanocellulose | Renewable; biodegradable; excellent mechanical reinforcement | Poor inherent conductivity; requires blending with active fillers | [152] |

| Silk Fibroin | Biodegradable; biocompatible; mechanically strong | Lower piezoelectric output; needs doping or composites for energy harvesting | [154] |

| Chitosan | Biodegradable; antibacterial; good for biomedical devices | Limited electrical performance; requires functionalization for TENG/PENG applications | [155] |

| Sl. No. | Material System | 3D Printing Technique | Nanogenerator Type | Output Performance | Environmental Conditions | Application | References |

|---|---|---|---|---|---|---|---|

| 1 | BaTiO3-PVDF composite | Direct Ink Writing [DIW] | PENG | 120 V, 1.8 μA/cm2 | Room temperature, in some cases performed under low humidity | Wearable sensors | [80] |

| 2 | ZnO-PDMS nanocomposite | Extrusion-based 3D Printing | PENG | 6 V, 0.5 μA | Ambient temperature and relative humidity of 40–60% | Soft robotics | [81] |

| 3 | MXene-PVDF composite | Inkjet printing | Hybrid PENG-TENG | 30 V, 2.5 μA | Room temperature, relative humidity <40% | Human motion harvesting | [146] |

| 4 | CNT-PDMS composite | SLA 3D printing | TENG | 80 V, 12 μA | Room temperature with minimal ambient interference | Wearable electronics | [78] |

| 5 | AgNW-TPU composite | DIW | TENG | 50 V, 8 μA | ~25 °C, 40–60% relative humidity | Pressure sensors | [79] |

| 6 | BaTiO3-Ecoflex nanocomposite | FDM | PENG | 18 V, 1.2 μA | Ambient temperature, body motion simulation | Biomechanical sensors | [141] |

| 7 | ZnO-MXene-PVDF composite | DIW | Hybrid | 70 V, 3.1 μA | 30–90% relative humidity, stable under humidity variation | Self-powered health monitoring | [114] |

| 8 | CNT-TPU composite | Inkjet printing | TENG | 40 V, 10 μA | Ambient lab conditions | Wearable stretchable devices | [119] |

| 9 | Self-healing hydrogel nanocomposite | DIW | TENG | 35 V, 1.5 μA | Tested from −20 °C to room temperature | Smart textiles | [125] |

| 10 | BaTiO3-PDMS composite | Robocasting | PENG | 100 V, 2.8 μA/cm2 | −10 °C to 60 °C, stable output | Structural monitoring | [31] |

| 11 | Conductive hydrogel-TPU | DIW | TENG | 22 V, 0.8 μA | Physiological conditions | Biomedical sensors | [126] |

| 12 | BaTiO3-rGO-PVDF composite | Inkjet | PENG | 90 V, 3.5 μA | Room temperature, protected against humidity | Wearable electronics | [116] |

| 13 | Chitosan-PVDF nanocomposite | DIW | PENG | 14 V, 0.9 μA | 37 °C (physiological) | Implantable devices | [155] |

| 14 | BaTiO3/PU composite | FDM | PENG | 45 V, 1.0 μA | Mild humidity | Self-powered IoT devices | [127] |

| 15 | MXene-PDMS composite | Inkjet printing | TENG | 60 V, 7 μA | Ambient temperature | Flexible electronics | [109] |

| 16 | Silk fibroin-PVDF | Extrusion printing | TENG | 20 V, 0.5 μA | Biocompatible, 37 °C | Biodegradable energy harvesters | [157] |

| 17 | Waste plastic-graphene composite | FDM | TENG | 25 V, 1 μA | Room temperature | Sustainable TENGs | [34] |

| 18 | BaTiO3-MXene-PVDF composite | DIW | Hybrid | 85 V, 4 μA | Moderate humidity | Multi-source energy harvesting | [130] |

| 19 | CNT-Ecoflex composite | SLA | TENG | 38 V, 0.9 μA | 50–60% RH, room temperature | Flexible wearable systems | [23] |

| 20 | P[VDF-TrFE]-aerogel composite | DIW | PENG | 65 V, 2.0 μA | Room temperature, under minimal temperature fluctuations | Motion sensors | [37] |

| Nanogenerator Type | Material System | 3D Printing Technique | Output Voltage [V] | Output Current [μA] | Power Density | Application | References |

|---|---|---|---|---|---|---|---|

| PENG | BaTiO3-PVDF composite [75] | Direct Ink Writing [DIW] | 120 | 1.8 | 3.5 mW/cm2 | Wearable sensors | [80] |

| PENG | ZnO-PDMS composite [76] | Extrusion-Based 3D Printing | 6 | 0.5 | 0.15 mW/cm2 | Soft robotics | [81] |

| Hybrid [PENG-TENG] | MXene-PVDF composite [77] | Inkjet Printing | 30 | 2.5 | 0.7 mW/cm2 | Human motion harvesting | [82] |

| TENG | CNT-PDMS composite [73] | SLA 3D Printing | 80 | 12 | 2.5 mW/cm2 | Wearable electronics | [78] |

| TENG | CNT-TPU composite [103] | Inkjet Printing | 40 | 10 | 1.2 mW/cm2 | Stretchable wearables | [119] |

| Hybrid | ZnO-MXene-PVDF composite [57] | DIW | 70 | 3.1 | 2.8 mW/cm2 | Self-powered health monitoring | [58] |

| PENG | BaTiO3-TPU composite [31] | Robocasting | 100 | 2.8 | 3.0 mW/cm2 | Structural monitoring | [31] |

| TENG | Self-healing hydrogel-TPU [109] | DIW | 35 | 1.5 | 0.4 mW/cm2 | Smart textiles | [125] |

| PENG | BaTiO3-rGO-PVDF composite [100] | Inkjet Printing | 90 | 3.5 | 3.2 mW/cm2 | Wearable electronics | [116] |

| TENG | MXene-PDMS composite [93] | Inkjet Printing | 60 | 7 | 1.8 mW/cm2 | Flexible electronics | [109] |

| PENG | Chitosan-PVDF composite [137] | DIW | 14 | 0.9 | 0.18 mW/cm2 | Implantable devices | [155] |

| TENG | CNT-Ecoflex composite [23] | SLA | 38 | 0.9 | 0.95 mW/cm2 | Flexible wearable systems | [23] |

| Advantages | Challenges |

|---|---|

| Customization and complex geometries for optimized designs | Limited material printability and nanoparticle dispersion issues |

| Versatility in material selection for enhanced properties | Brittle nature of some functional materials |

| Cost-effective and scalable production | Mechanical degradation under prolonged use |

| Integration of conductive electrodes within the structure | Environmental factors affecting long-term stability |

| Enhanced flexibility and stretchability for wearable applications | Challenges in achieving high energy conversion efficiency |

| Sustainable fabrication with reduced material wastage | Need for multifunctional hybrid designs to enhance performance |

| Property | 3D-Printed Nanocomposites | Nanocomposites |

|---|---|---|

| Fabrication Method | Additive manufacturing, layer-by-layer deposition [165] | Traditional methods like melt blending, electrospinning, and casting [75] |

| Material Integration | Multi-material printing allows for functionalized nanocomposites [176] | Requires multiple processing steps for material integration [76] |

| Structural Complexity | Can produce highly complex and customized designs [166] | Limited by conventional fabrication constraints [76] |

| Mechanical Properties | Improved due to precise microstructural control [167] | Dependent on fabrication technique, may have inconsistencies [78] |

| Energy Harvesting Efficiency | Enhanced due to optimized micro-architectures [174] | Relies on bulk material properties and limited design optimization [79] |

| Piezoelectric Performance | Higher due to well-controlled nanoparticle dispersion [167] | Affected by nanoparticle agglomeration and uneven dispersion [113] |

| Triboelectric Performance | Can be enhanced by precise material layering [94] | Less controlled layering results in variations [111] |

| Scalability | Scalable using advanced printing methods like multi-jet fusion [172] | Requires batch processing, increasing material waste and cost [160] |

| Flexibility | High, especially for wearable applications [168] | Dependent on material properties, usually requires additional processing [138] |

| Electrode Integration | Can be printed directly into the structure [174] | Requires manual assembly and additional processing [160] |

| Environmental Stability | Susceptible to humidity and temperature changes but can be improved with coatings [80] | Material degradation due to exposure to environmental factors [137] |

| Sustainability | Reduced material waste, more eco-friendly fabrication [130] | Higher material consumption and waste generation [139] |

| Cost Efficiency | Lower production costs due to minimal waste and fewer fabrication steps [174] | Higher costs due to multi-step processing and material loss [188] |

| Performance Consistency | High due to precise control over material composition and architecture [185] | Can vary due to non-uniform fabrication methods [140] |

| Hybrid Nanogenerators | Easily integrates multiple energy-harvesting mechanisms [93] | Requires complex assembly for hybrid designs [151] |

| Wearable Applications | Ideal due to conformal and flexible design capabilities [187] | Limited by material rigidity and manufacturing constraints [114] |

| Future Potential | Advancements in additive manufacturing can further enhance properties [17] | Continuous improvements in materials and fabrication techniques required [109] |

| Method | Material Compatibility | Cost | Resolution | Key Advantages | Limitations |

|---|---|---|---|---|---|

| DIW | Broad (inks, nanocomposites, polymers) | Low | ~100 μm | Room temperature processing, good for soft materials | Lower resolution; ink formulation is critical |

| FDM | Thermoplastics (e.g., TPU, PLA, ABS) | Very Low | ~200–300 μm | Simple, low-cost, rapid prototyping | Poor resolution; high temp required |

| SLA | Photocurable resins | Medium | ~50 μm | High resolution, smooth surfaces | Limited resin choices; brittle materials |

| DLP | Photopolymers, composites with nanoparticles | Medium | ~25–50 μm | Faster than SLA, finer details | Resin must be photoactive; post-processing often needed |

| Parameter | 3D-Printed Nanogenerators | Conventional Nanogenerators | Reference[s] |

|---|---|---|---|

| Fabrication Method | Additive manufacturing [e.g., DLP, SLA, FDM] enables rapid prototyping and complex geometries | Conventional methods include photolithography, chemical vapor deposition, and electrospinning, which are labor-intensive and require multiple steps | [39,168,174] |

| Material Selection | Wide range of materials, including biodegradable polymers, nanocomposites, and conductive inks | Primarily relies on pre-synthesized nanomaterials and traditional substrates, limiting flexibility | [169,176,183] |

| Cost Efficiency | Reduced production cost due to minimal material wastage and single-step processing | High fabrication costs due to complex etching, deposition, and assembly processes | [42,149] |

| Energy Output [Voltage and Power Density] | Optimized microstructures and controlled material composition enhance charge transfer, increasing efficiency | Traditional techniques achieve high power output but require post-processing for enhanced triboelectric performance | [44,45,49] |

| Flexibility and Wearability | Highly flexible and stretchable due to printable elastomeric and conductive materials | Limited flexibility, often requiring hybrid structures for enhanced mechanical properties | [52,147,168] |

| Scalability | Scalable manufacturing for mass production using automated 3D printing | Challenging to scale due to reliance on batch processes and complex alignment techniques | [167,190] |

| Integration with Other Systems | Easily integrates with flexible electronics, sensors, and self-powered devices | Requires additional interfacing steps for hybrid system integration | [51,54] |

| Mechanical Durability | Resilient under repeated mechanical stress due to the use of stretchable and self-healing materials | Prone to mechanical degradation under cyclic loading | [64,176] |

| Sustainability and Environmental Impact | Biodegradable and eco-friendly 3D-printed materials reduce environmental footprint | Traditional materials may generate toxic waste and are difficult to recycle | [176,187] |

| Application Versatility | Used in smart textiles, biomedical devices, soft robotics, and self-powered sensors | Primarily employed in energy harvesting and sensor networks, with limited adaptability to wearables | [56,58] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Razack, R.K.; Sadasivuni, K.K. Advancing Nanogenerators: The Role of 3D-Printed Nanocomposites in Energy Harvesting. Polymers 2025, 17, 1367. https://doi.org/10.3390/polym17101367

Razack RK, Sadasivuni KK. Advancing Nanogenerators: The Role of 3D-Printed Nanocomposites in Energy Harvesting. Polymers. 2025; 17(10):1367. https://doi.org/10.3390/polym17101367

Chicago/Turabian StyleRazack, Riyamol Kallikkoden, and Kishor Kumar Sadasivuni. 2025. "Advancing Nanogenerators: The Role of 3D-Printed Nanocomposites in Energy Harvesting" Polymers 17, no. 10: 1367. https://doi.org/10.3390/polym17101367

APA StyleRazack, R. K., & Sadasivuni, K. K. (2025). Advancing Nanogenerators: The Role of 3D-Printed Nanocomposites in Energy Harvesting. Polymers, 17(10), 1367. https://doi.org/10.3390/polym17101367