Dielectric Tailoring of Perovskite-Polymer Composites for High-Performance Triboelectric Nanogenerators

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of MASnCl3 Perovskite Powder

2.3. Fabrication of MASnCl3–PMMA Polymer Composites and TENGs

2.4. Characterization

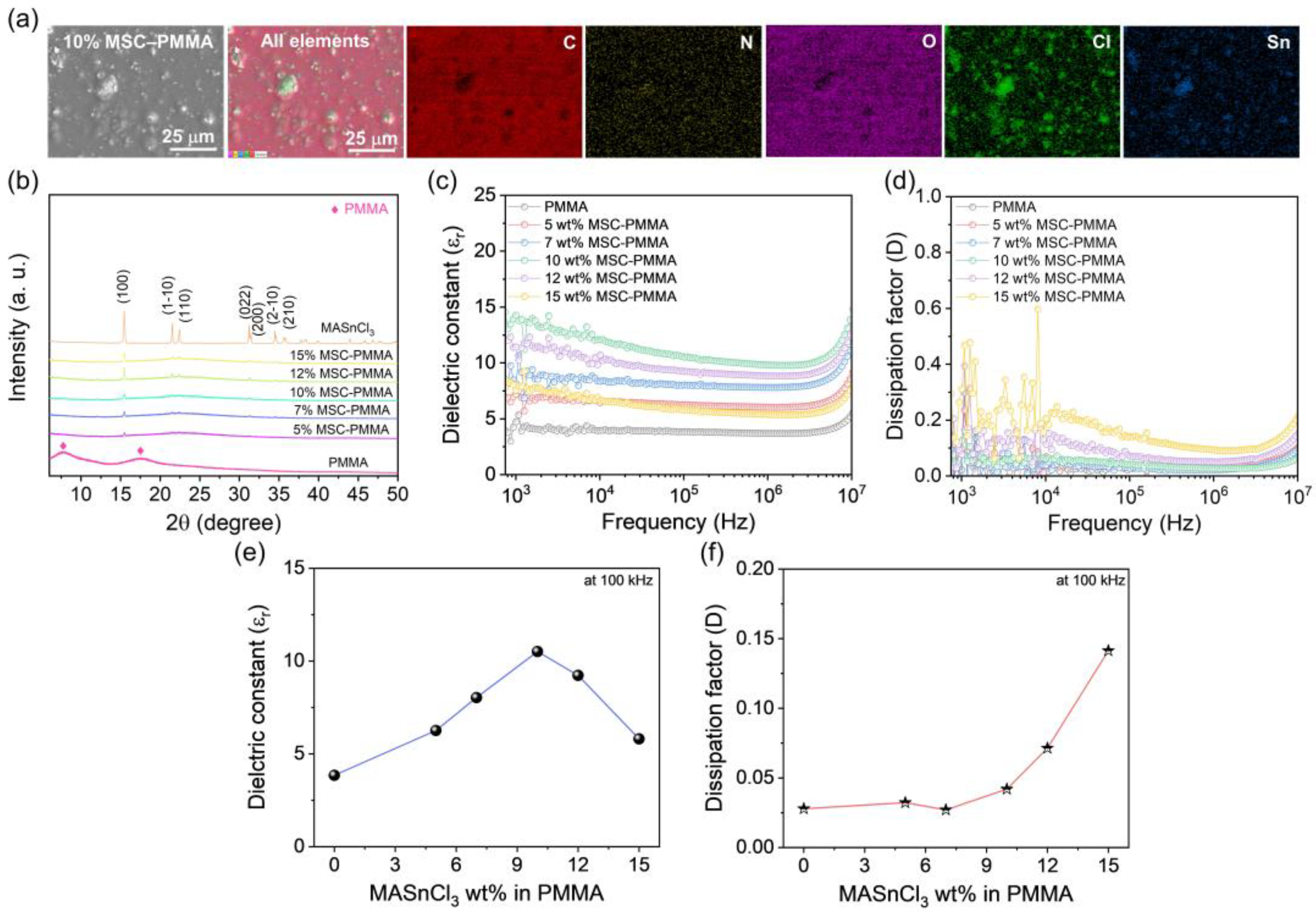

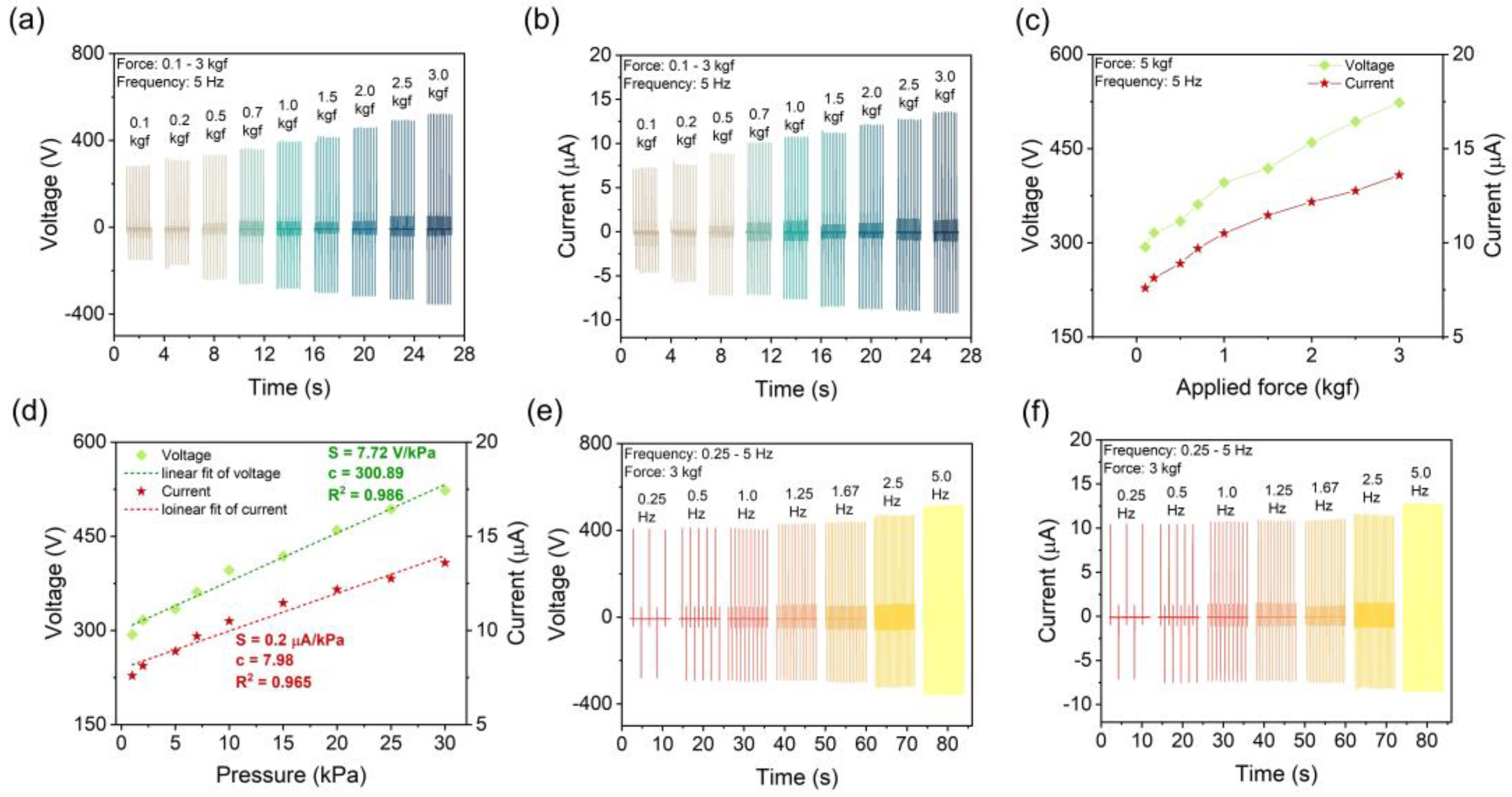

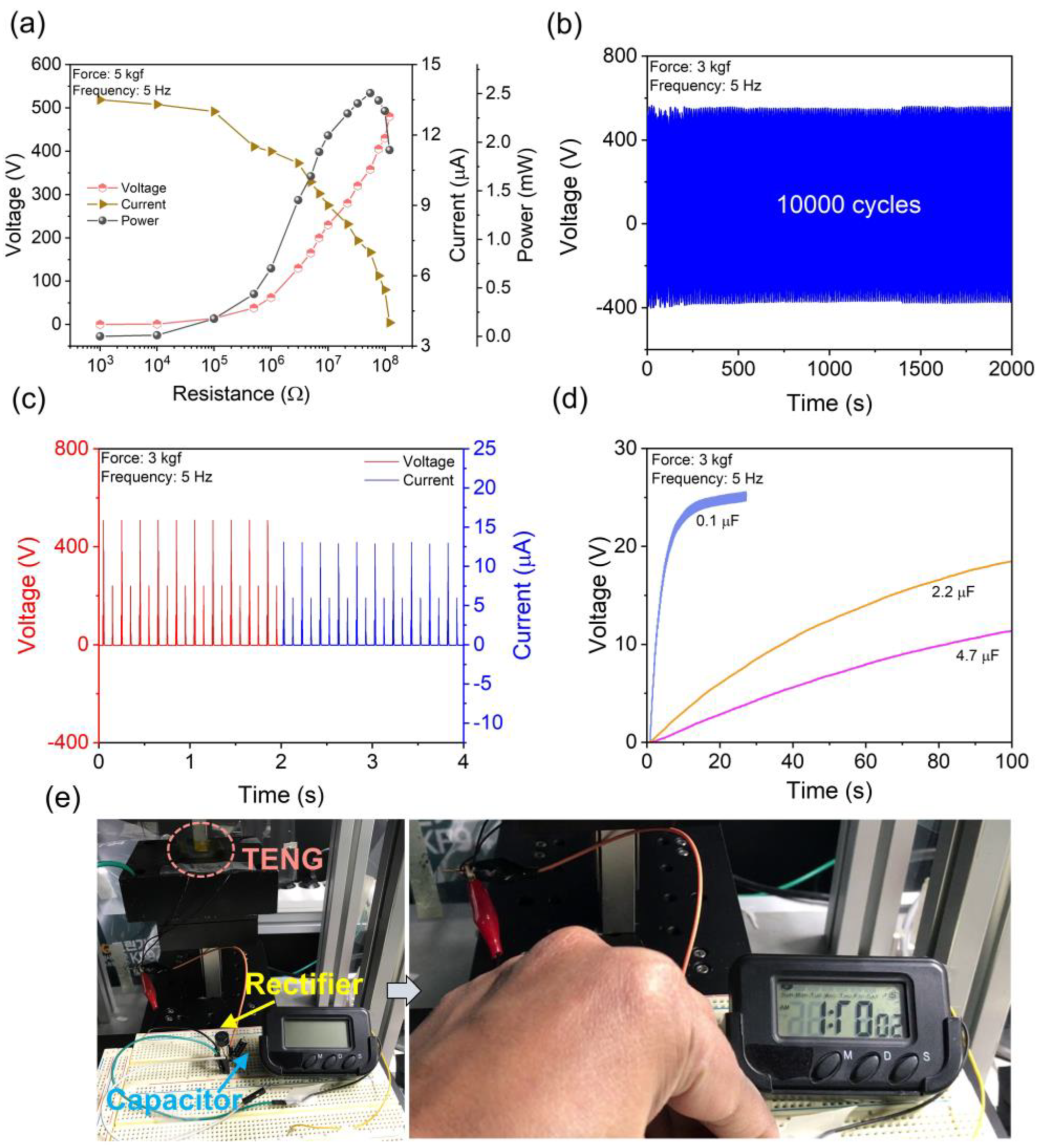

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| IoT | Internet of things |

| PENG | Piezoelectric nanogenerator |

| TENG | Triboelectric nanogenerator |

| PZT | Lead zironate titanate |

| LEDs | Light emitting diodes |

| PMMA | Poly (methyl methacrylate) |

| MACl | Methyl ammonium chloride |

| PTFE | Polytetra fluoroethylene |

| ITO | Indium tin oxide |

| PET | Polyethylene terephthalate |

| ACT | Anti-solvent-assisted collision technique |

| FTO | Florine doped tin oxide |

| MIM | Metal insulator metal |

| MSC | Methyl ammonium stannous chloride |

| XRD | X-ray diffraction |

| SEM | Scanning electron microscopy |

| MWS | Maxwell–Wagner–Sillars |

References

- Pop-Vadean, A.; Pop, P.P.; Latinovic, T.; Barz, C.; Lung, C. Harvesting Energy an Sustainable Power Source, Replace Batteries for Powering WSN and Devices on the IoT. IOP Conf. Ser. Mater. Sci. Eng. 2017, 200, 012043. [Google Scholar] [CrossRef]

- Vuong, V.-H.; Pammi, S.V.N.; Ippili, S.; Jella, V.; Nguyen Thi, T.; Sairam Pasupuleti, K.; Kim, M.-D.; Ji Jeong, M.; Jeong, J.-R.; Sik Chang, H.; et al. Flexible, Stable, and Self-Powered Photodetectors Embedded with Chemical Vapor Deposited Lead-Free Bismuth Mixed Halide Perovskite Films. Chem. Eng. J. 2023, 458, 141473. [Google Scholar] [CrossRef]

- Ippili, S.; Kim, J.H.; Jella, V.; Behera, S.; Vuong, V.-H.; Jung, J.-S.; Cho, Y.; Ahn, J.; Kim, I.-D.; Chang, Y.H.; et al. Halide Double Perovskite-Based Efficient Mechanical Energy Harvester and Storage Devices for Self-Charging Power Unit. Nano Energy 2023, 107, 108148. [Google Scholar] [CrossRef]

- Nayak, P.K.; Mahesh, S.; Snaith, H.J.; Cahen, D. Photovoltaic Solar Cell Technologies: Analysing the State of the Art. Nat. Rev. Mater. 2019, 4, 269–285. [Google Scholar] [CrossRef]

- Du, T.; Dong, F.; Xi, Z.; Zhu, M.; Zou, Y.; Sun, P.; Xu, M. Recent Advances in Mechanical Vibration Energy Harvesters Based on Triboelectric Nanogenerators. Small 2023, 19, e2300401. [Google Scholar] [CrossRef]

- Jella, V.; Ippili, S.; Eom, J.-H.; Kim, Y.-J.; Kim, H.-J.; Yoon, S.-G. A Novel Approach to Ambient Energy (Thermoelectric, Piezoelectric and Solar-TPS) Harvesting: Realization of a Single Structured TPS-Fusion Energy Device Using MAPbI3. Nano Energy 2018, 52, 11–21. [Google Scholar] [CrossRef]

- Abbasipour, M.; Khajavi, R.; Akbarzadeh, A.H. A Comprehensive Review on Piezoelectric Polymeric and Ceramic Nanogenerators. Adv. Eng. Mater. 2022, 24, 2101312. [Google Scholar] [CrossRef]

- Wu, C.; Wang, A.C.; Ding, W.; Guo, H.; Wang, Z.L. Triboelectric Nanogenerator: A Foundation of the Energy for the New Era. Adv. Energy Mater. 2019, 9, 1802906. [Google Scholar] [CrossRef]

- Kim, W.-G.; Kim, D.-W.; Tcho, I.-W.; Kim, J.-K.; Kim, M.-S.; Choi, Y.-K. Triboelectric Nanogenerator: Structure, Mechanism, and Applications. ACS Nano 2021, 15, 258–287. [Google Scholar] [CrossRef]

- Zhou, Y.; Shen, M.; Cui, X.; Shao, Y.; Li, L.; Zhang, Y. Triboelectric Nanogenerator Based Self-Powered Sensor for Artificial Intelligence. Nano Energy 2021, 84, 105887. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; Wang, Z.L. Triboelectric Nanogenerators as Flexible Power Sources. NPJ Flex. Electron. 2017, 1, 10. [Google Scholar] [CrossRef]

- Guo, W.-T.; Lei, Y.; Zhao, X.-H.; Li, R.; Lai, Q.-T.; Liu, S.-Z.; Chen, H.; Fan, J.-C.; Xu, Y.; Tang, X.-G.; et al. Printed-Scalable Microstructure BaTiO3/Ecoflex Nanocomposite for High-Performance Triboelectric Nanogenerators and Self-Powered Human-Machine Interaction. Nano Energy 2024, 131, 110324. [Google Scholar] [CrossRef]

- Li, D.; Wu, C.; Ruan, L.; Wang, J.; Qiu, Z.; Wang, K.; Liu, Y.; Zhang, Y.; Guo, T.; Lin, J.; et al. Electron-Transfer Mechanisms for Confirmation of Contact-Electrification in ZnO/Polyimide-Based Triboelectric Nanogenerators. Nano Energy 2020, 75, 104818. [Google Scholar] [CrossRef]

- Zhang, J.-H.; Zhang, Y.; Sun, N.; Li, Y.; Du, J.; Zhu, L.; Hao, X. Enhancing Output Performance of Triboelectric Nanogenerator via Large Polarization Difference Effect. Nano Energy 2021, 84, 105892. [Google Scholar] [CrossRef]

- Ma, N.; Yang, Y. Enhanced Self-Powered UV Photoresponse of Ferroelectric BaTiO3 Materials by Pyroelectric Effect. Nano Energy 2017, 40, 352–359. [Google Scholar] [CrossRef]

- Jella, V.; Ippili, S.; Eom, J.-H.; Pammi, S.V.N.; Jung, J.-S.; Tran, V.-D.; Nguyen, V.H.; Kirakosyan, A.; Yun, S.; Kim, D.; et al. A Comprehensive Review of Flexible Piezoelectric Generators Based on Organic-Inorganic Metal Halide Perovskites. Nano Energy 2019, 57, 74–93. [Google Scholar] [CrossRef]

- Li, M.; Jiao, B.; Peng, Y.; Zhou, J.; Tan, L.; Ren, N.; Ye, Y.; Liu, Y.; Yang, Y.; Chen, Y.; et al. High-Efficiency Perovskite Solar Cells with Improved Interfacial Charge Extraction by Bridging Molecules. Adv. Mater. 2024, 36, e2406532. [Google Scholar] [CrossRef]

- Cao, Y.B.; Zhang, D.; Zhang, Q.; Qiu, X.; Zhou, Y.; Poddar, S.; Fu, Y.; Zhu, Y.; Liao, J.-F.; Shu, L.; et al. High-Efficiency, Flexible and Large-Area Red/Green/Blue All-Inorganic Metal Halide Perovskite Quantum Wires-Based Light-Emitting Diodes. Nat. Commun. 2023, 14, 4611. [Google Scholar] [CrossRef]

- Zhang, Q.; Shang, Q.; Su, R.; Do, T.T.H.; Xiong, Q. Halide Perovskite Semiconductor Lasers: Materials, Cavity Design, and Low Threshold. Nano Lett. 2021, 21, 1903–1914. [Google Scholar] [CrossRef]

- Ippili, S.; Jella, V.; Thomas, A.M.; Yoon, S.-G. The Recent Progress on Halide Perovskite-Based Self-Powered Sensors Enabled by Piezoelectric and Triboelectric Effects. Nanoenergy Adv. 2021, 1, 3–31. [Google Scholar] [CrossRef]

- Ippili, S.; Jella, V.; Kim, J.; Hong, S.; Kim, H.-S.; Yoon, S.-G. High-Power Nanogenerator of 2D-Layered Perovskite in a Polymer Matrix for Self-Charging Battery-Powered Electronics. Nano Energy 2022, 103, 107781. [Google Scholar] [CrossRef]

- Li, Y.; Xu, M.; Xia, Y.; Wu, J.; Sun, X.; Wang, S.; Hu, G.; Xiong, C. Multilayer Assembly of Electrospun/Electrosprayed PVDF-Based Nanofibers and Beads with Enhanced Piezoelectricity and High Sensitivity. Chem. Eng. J. 2020, 388, 124205. [Google Scholar] [CrossRef]

- Chen, L.; He, M.; Li, L.; Yuan, S.; Chen, A.; Chen, M.; Wang, Y.; Sun, L.; Wei, L.; Zhang, T.; et al. Hydrochromic CsPbBr3-KBr Microcrystals for Flexible Anti-Counterfeiting and Wearable Self-Powered Biomechanical Monitoring. Chem. Eng. J. 2022, 450, 138279. [Google Scholar] [CrossRef]

- Jiang, F.; Zhou, X.; Lv, J.; Chen, J.; Chen, J.; Kongcharoen, H.; Zhang, Y.; Lee, P.S. Stretchable, Breathable, and Stable Lead-Free Perovskite/Polymer Nanofiber Composite for Hybrid Triboelectric and Piezoelectric Energy Harvesting. Adv. Mater. 2022, 34, e2200042. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.A.; Rana, M.M.; Wang, S.; Al Fattah, M.F.; Kayaharman, M.; Zhang, K.; Benedict, S.; Goldthorpe, I.; Zhou, Y.N.; Sargent, E.H.; et al. Control of Halogen Atom in Inorganic Metal-Halide Perovskites Enables Large Piezoelectricity for Electromechanical Energy Generation. Small 2023, 19, e2303366. [Google Scholar] [CrossRef] [PubMed]

- Aktas, E.; Rajamanickam, N.; Pascual, J.; Hu, S.; Aldamasy, M.H.; Di Girolamo, D.; Li, W.; Nasti, G.; Martínez-Ferrero, E.; Wakamiya, A.; et al. Challenges and Strategies toward Long-Term Stability of Lead-Free Tin-Based Perovskite Solar Cells. Commun. Mater. 2022, 3, 104. [Google Scholar] [CrossRef]

- Ippili, S.; Jella, V.; Eom, J.-H.; Kim, J.; Hong, S.; Choi, J.-S.; Tran, V.-D.; Van Hieu, N.; Kim, Y.-J.; Kim, H.-J.; et al. An Eco-Friendly Flexible Piezoelectric Energy Harvester That Delivers High Output Performance Is Based on Lead-Free MASnI3 Films and MASnI3-PVDF Composite Films. Nano Energy 2019, 57, 911–923. [Google Scholar] [CrossRef]

- Ippili, S.; Jella, V.; Kim, J.; Hong, S.; Yoon, S.-G. Unveiling Predominant Air-Stable Organotin Bromide Perovskite toward Mechanical Energy Harvesting. ACS Appl. Mater. Interfaces 2020, 12, 16469–16480. [Google Scholar] [CrossRef]

- Nguyen-Tran, T.; An, N.M.; Nguyen, K.D.; Nguyen, T.D.; Truong, T.T. Synthesis of Organo Tin Halide Perovskites via Simple Aqueous Acidic Solution-Based Method. J. Sci. Adv. Mater. Devices 2018, 3, 471–477. [Google Scholar] [CrossRef]

- Kumar, S.; Ansari, M.Z.; Khare, N. Transparent CH3NH3SnCl3/Al-ZnO p-n Heterojunction Diode. AIP Conf. Proc. 2016, 1731, 120025. [Google Scholar] [CrossRef]

- Mosca, R.; Ferro, P.; Besagni, T.; Calestani, D.; Chiarella, F.; Licci, F. Effect of Humidity on the a.c. Impedance of CH3NH3SnCl3 Hybrid Films. Appl. Phys. A 2011, 104, 1181–1187. [Google Scholar] [CrossRef]

- Sahoo, G.; Sarkar, N.; Sahu, D.; Swain, S.K. Nano Gold Decorated Reduced Graphene Oxide Wrapped Polymethylmethacrylate for Supercapacitor Applications. RSC Adv. 2017, 7, 2137–2150. [Google Scholar] [CrossRef]

- Jella, V.; Ippili, S.; Eom, J.-H.; Choi, J.; Yoon, S.-G. Enhanced Output Performance of a Flexible Piezoelectric Energy Harvester Based on Stable MAPbI3-PVDF Composite Films. Nano Energy 2018, 53, 46–56. [Google Scholar] [CrossRef]

- Ippili, S.; Jella, V.; Kim, J.; Hong, S.; Yoon, S.-G. Enhanced Piezoelectric Output Performance via Control of Dielectrics in Fe2+-Incorporated MAPbI3 Perovskite Thin Films: Flexible Piezoelectric Generators. Nano Energy 2018, 49, 247–256. [Google Scholar] [CrossRef]

- Ippili, S.; Jella, V.; Thomas, A.M.; Yoon, C.; Jung, J.-S.; Yoon, S.-G. ZnAl–LDH-Induced Electroactive β-Phase and Controlled Dielectrics of PVDF for a High-Performance Triboelectric Nanogenerator for Humidity and Pressure Sensing Applications. J. Mater. Chem. A Mater. 2021, 9, 15993–16005. [Google Scholar] [CrossRef]

- Ippili, S.; Jella, V.; Lee, J.M.; Jung, J.-S.; Lee, D.-H.; Yang, T.-Y.; Yoon, S.-G. ZnO–PTFE-based Antimicrobial, Anti-Reflective Display Coatings and High-Sensitivity Touch Sensors. J. Mater. Chem. A Mater. 2022, 10, 22067–22079. [Google Scholar] [CrossRef]

- Ippili, S.; Jung, J.-S.; Thomas, A.M.; Vuong, V.-H.; Lee, J.-M.; Sha, M.S.; Sadasivuni, K.K.; Jella, V.; Yoon, S.-G. An Overview of Polymer Composite Films for Antibacterial Display Coatings and Sensor Applications. Polymers 2023, 15, 3791. [Google Scholar] [CrossRef]

- Li, Y.; Luo, Y.; Deng, H.; Shi, S.; Tian, S.; Wu, H.; Tang, J.; Zhang, C.; Zhang, X.; Zha, J.; et al. Advanced Dielectric Materials for Triboelectric Nanogenerators: Principles, Methods, and Applications. Adv. Mater. 2024, 36, e2314380. [Google Scholar] [CrossRef]

- Jella, V.; Ippili, S.; Yoon, S.-G. Halide (Cl/Br)-Incorporated Organic–Inorganic Metal Trihalide Perovskite Films: Study and Investigation of Dielectric Properties and Mechanical Energy Harvesting Performance. ACS Appl. Electron. Mater. 2020, 2, 2579–2590. [Google Scholar] [CrossRef]

- Ippili, S.; Kumar, G.S.; Sharma, A.; Ko, Y.; Hong, S.; Goddati, M.; Saini, H.; Lee, J.; Yang, T.; Siddhanta, S.; et al. Advancing Charge Density in Temperature-Dependent Amphiphile Metal–Organic Polyhedra-Based Triboelectric Nanogenerators. Adv. Energy Mater. 2024, 14, 2402260. [Google Scholar] [CrossRef]

- Jella, V.; Behera, S.; Ippili, S.; Joo, S.; Kwon, K.; Hong, S.; Kim, H.; Yoon, S. Self-Charging Power System Empowered by Bismuth Halide Perovskite-Based Hybrid Nanogenerator and Lithium-ion Battery. Small 2024, e202400824. [Google Scholar] [CrossRef]

- Ippili, S.; Jella, V.; Eom, S.; Hong, S.; Yoon, S.-G. Light-Driven Piezo- and Triboelectricity in Organic–Inorganic Metal Trihalide Perovskite toward Mechanical Energy Harvesting and Self-Powered Sensor Application. ACS Appl. Mater. Interfaces 2020, 12, 50472–50483. [Google Scholar] [CrossRef]

- Yoon, C.; Ippili, S.; Thomas, A.M.; Buyantogtokh, B.; Hong, S.; Jella, V.; Tran, V.-D.; Yoon, S.-G. Harnessing Flexoelectric and Piezoelectric Effects for Self-Charging Power Systems. ACS Energy Lett. 2023, 8, 4634–4642. [Google Scholar] [CrossRef]

- Yoon, C.; Ippili, S.; Jella, V.; Thomas, A.M.; Jung, J.-S.; Han, Y.; Yang, T.-Y.; Yoon, S.-G.; Yoon, G. Synergistic Contribution of Flexoelectricity and Piezoelectricity towards a Stretchable Robust Nanogenerator for Wearable Electronics. Nano Energy 2022, 91, 106691. [Google Scholar] [CrossRef]

- Sriphan, S.; Vittayakorn, N. Hybrid Piezoelectric-Triboelectric Nanogenerators for Flexible Electronics: Recent Advances and Perspectives. J. Sci. Adv. Mater. Devices 2022, 7, 100461. [Google Scholar] [CrossRef]

- Wang, Y.; Duan, J.; Yang, X.; Liu, L.; Zhao, L.; Tang, Q. The Unique Dielectricity of Inorganic Perovskites toward High-Performance Triboelectric Nanogenerators. Nano Energy 2020, 69, 104418. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, Y.; Kong, M.; Ge, J.; Hu, Z.; Peng, X.; Xu, W.; Ding, Y.; Hou, H.; Peng, X. High Dielectric CsPbBr3/RGO/Polyimide Composite Prepared via in-Situ Conversion of Fillers. J. Mater. Sci. Mater. Electron. 2021, 32, 12414–12423. [Google Scholar] [CrossRef]

- Jiao, Y.; Lin, Z.; Ma, X.; Zhou, L.; Guo, X.; Hu, Z.; Hu, X.; Zhao, X.; Ding, L.; Hao, Y.; et al. High-Performance Triboelectric Nanogenerators Based on Blade-Coating Lead Halide Perovskite Film and Electrospinning PVDF/Graphene Nanofiber. Chem. Eng. J. 2024, 483, 149442. [Google Scholar] [CrossRef]

- Wang, M.; Duan, J.; Yang, X.; Wang, Y.; Duan, Y.; Tang, Q. Interfacial Electric Field Enhanced Charge Density for Robust Triboelectric Nanogenerators by Tailoring Metal/Perovskite Schottky Junction. Nano Energy 2020, 73, 104747. [Google Scholar] [CrossRef]

- Xie, G.; Yang, X.; Duan, J.; Duan, Y.; Tang, Q. Bulk Pt/CsPbBr 3 Schottky Junctions for Charge Boosting in Robust Triboelectric Nanogenerators. J. Mater. Chem. A Mater. 2020, 8, 11966–11975. [Google Scholar] [CrossRef]

- Du, J.; Yang, X.; Duan, J.; Wang, Y.; Tang, Q. Tailoring All-Inorganic Cesium Lead Halide Perovskites for Robust Triboelectric Nanogenerators. Nano Energy 2020, 70, 104514. [Google Scholar] [CrossRef]

- Du, J.; Duan, J.; Yang, X.; Wang, Y.; Duan, Y.; Tang, Q. Charge Boosting and Storage by Tailoring Rhombus All-Inorganic Perovskite Nanoarrays for Robust Triboelectric Nanogenerators. Nano Energy 2020, 74, 104845. [Google Scholar] [CrossRef]

- Yu, X.; Wang, Y.; Zhang, J.; Duan, J.; Yang, X.; Liu, L.; Tang, Q. Halogen Regulation of Inorganic Perovskites toward Robust Triboelectric Nanogenerators and Charging Polarity Series. J. Mater. Chem. A Mater. 2020, 8, 14299–14307. [Google Scholar] [CrossRef]

- Wei, Z.; Ding, L.; Sun, N.; Dang, L.-Y.; Sun, H.-R.; Han, J.-C.; Zhu, J.-Q.; Wang, G.-G. Lead-Free CsBi3I10 Perovskite Based Photo-Enhanced Triboelectric Nanogenerator. Nano Energy 2023, 108, 108209. [Google Scholar] [CrossRef]

| Perovskite | Pressure/ Frequency | Voltage (V) | Current/Current Density | Power/Power Density (mW/cm2) | Ref. |

|---|---|---|---|---|---|

| Cs3Bi2Br9–PVDF-HFP–SEBS NFs | 30 N/5 Hz | 400 | 1.63 | 0.23 mW/cm2 | [24] |

| CS0.05FA0.7MA0.25PbI3 | 50 N/3 Hz | 200 | 16.3 µA | 1.13 mW/cm2 | [48] |

| MAPbI3-PVDF | 300 kPa/5 Hz | 44.7 | 4.34 µA/cm2 | 0.059 mW/cm2 | [42] |

| CsPbBr3–Au | -/2 Hz | 240 | 4.13 µA/cm2 | 0.331 mW/cm2 | [49] |

| CsPbBr3–Pt (0.5%) | -/- | 273 | 30.3 µA/cm2 | 0.129 mW/cm2 | [50] |

| CsPbBr2.6I0.4 | -/0.5 Hz | 192 | 16.7 µA | 0.12 mW/cm2 | [51] |

| CsPbIBr2 | -/0.5 Hz | 243 | 3.1 µA/cm2 | 0.204 mW/cm2 | [52] |

| CsPb0.91Ba0.09Br3 | -/- | 220 | 2.28 µA/cm2 | 0.307 mW/cm2 | [46] |

| CsPbCl3 | 10 N/- | 257 | 27.87µA/cm2 | 0.304 mW/cm2 | [53] |

| DAPPbI4–PVDF | 30 kPa/5 Hz | 662 | 18.7 µA/cm2 | 4.28 mW/cm2 | [21] |

| CsBi3I10 | 50 N/1 Hz | 158 | 4.55 µA/cm2 | 0.38 mW/cm2 | [54] |

| MA2Bi2I9–SEBS | 20 kPa/5 Hz | 537 | 13.2 µA/cm2 | 3.04 mW/cm2 | [41] |

| MASnCl3–PMMA (10 wt%) | 3 kgf/5 Hz | 525 | 13.6 µA | 2.5 mW or (0.625 mW/cm2) | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jella, V.; Ippili, S.; Yoon, S.-G. Dielectric Tailoring of Perovskite-Polymer Composites for High-Performance Triboelectric Nanogenerators. Polymers 2025, 17, 969. https://doi.org/10.3390/polym17070969

Jella V, Ippili S, Yoon S-G. Dielectric Tailoring of Perovskite-Polymer Composites for High-Performance Triboelectric Nanogenerators. Polymers. 2025; 17(7):969. https://doi.org/10.3390/polym17070969

Chicago/Turabian StyleJella, Venkatraju, Swathi Ippili, and Soon-Gil Yoon. 2025. "Dielectric Tailoring of Perovskite-Polymer Composites for High-Performance Triboelectric Nanogenerators" Polymers 17, no. 7: 969. https://doi.org/10.3390/polym17070969

APA StyleJella, V., Ippili, S., & Yoon, S.-G. (2025). Dielectric Tailoring of Perovskite-Polymer Composites for High-Performance Triboelectric Nanogenerators. Polymers, 17(7), 969. https://doi.org/10.3390/polym17070969