The Effect of Nano-Biochar Derived from Olive Waste on the Thermal and Mechanical Properties of Epoxy Composites

Abstract

1. Introduction

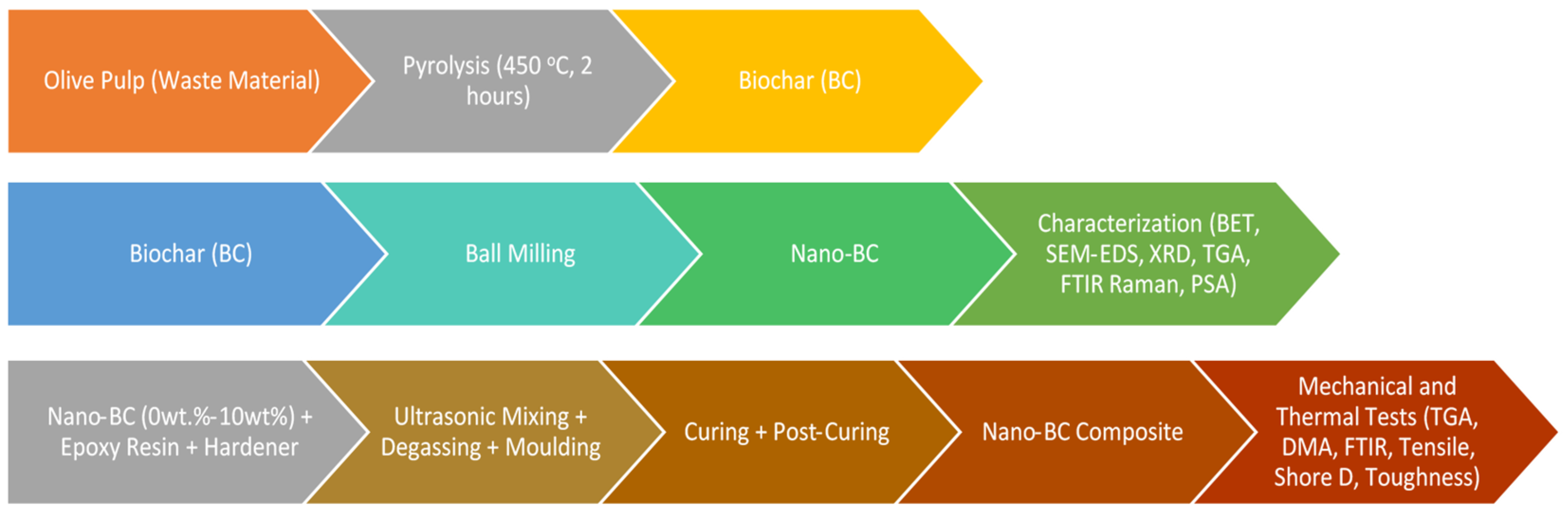

2. Materials and Methods

2.1. Production of the Nano-BC via Ball Milling

2.2. Characterization of the Nano-BC

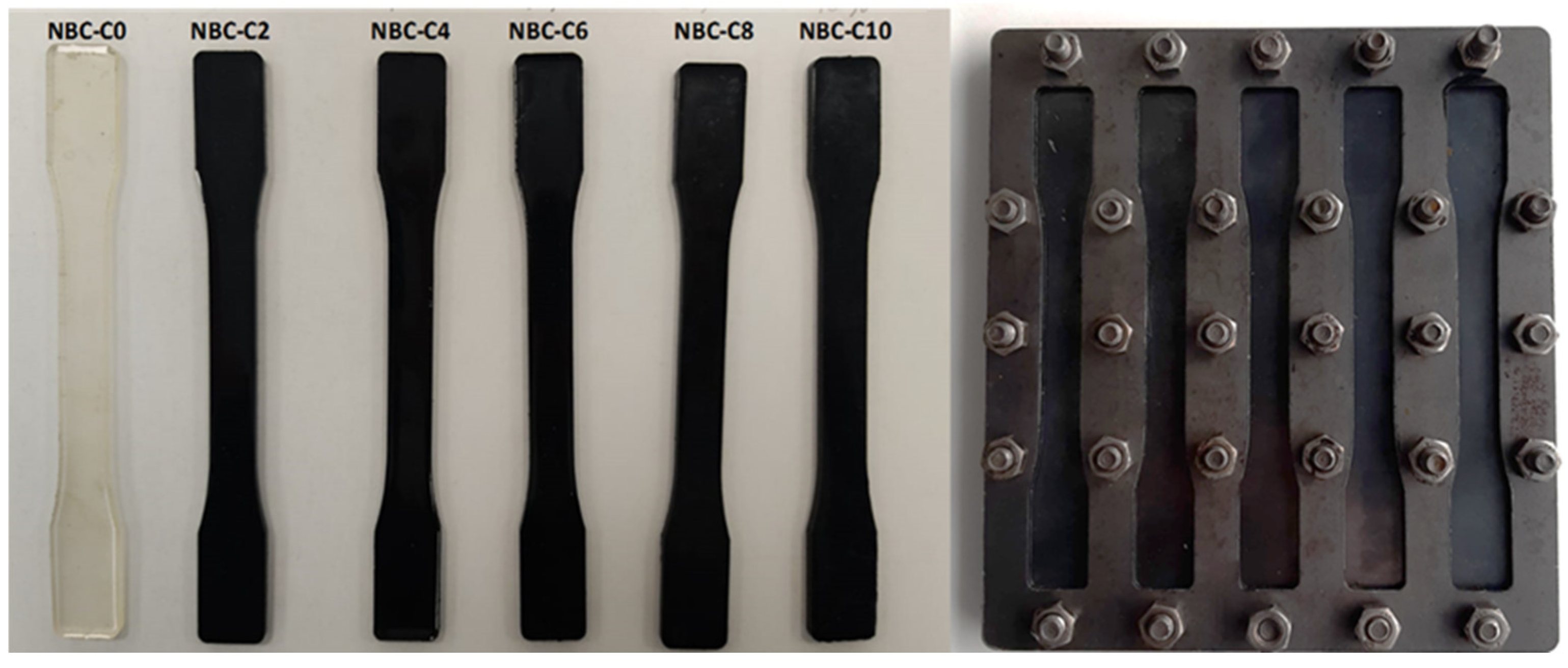

2.3. Preparation of the Nano-BC Composite Samples

3. Results and Discussion

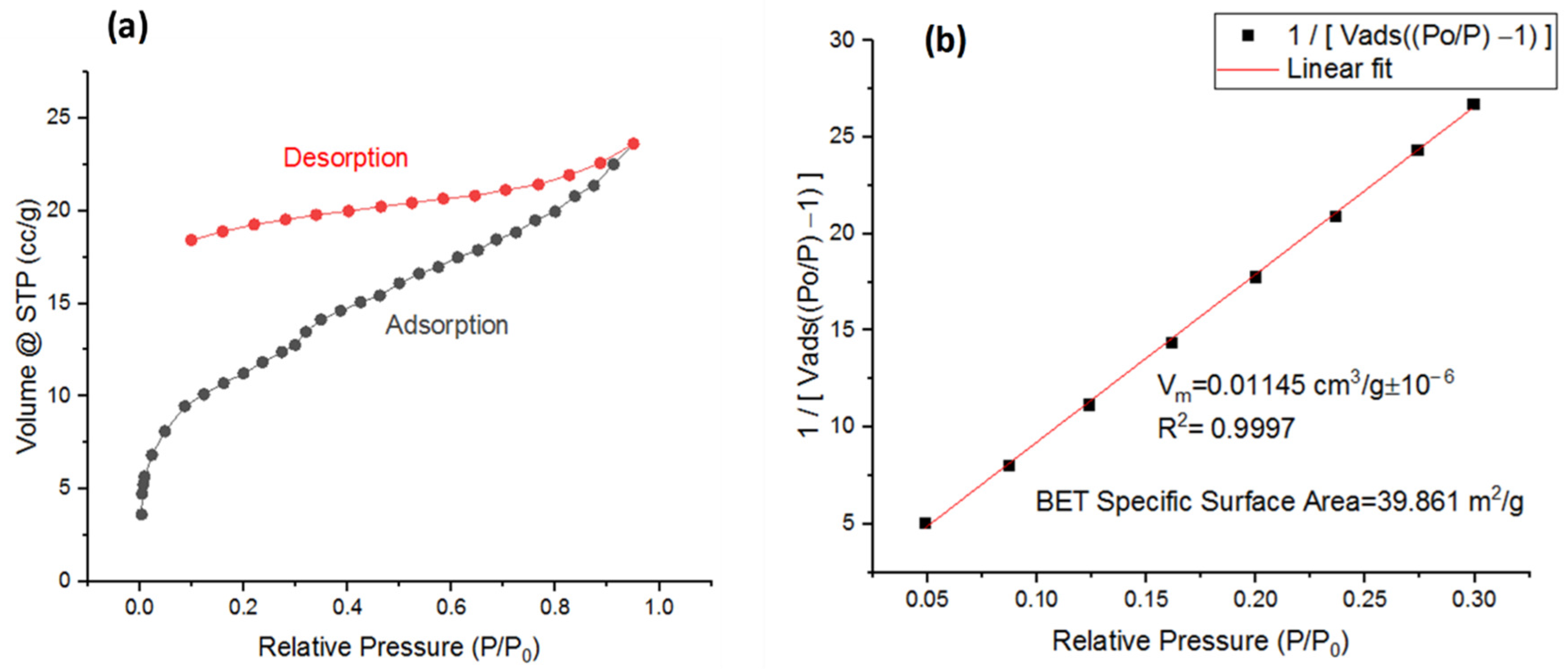

3.1. Brunauer–Emmett–Teller (BET) Analysis

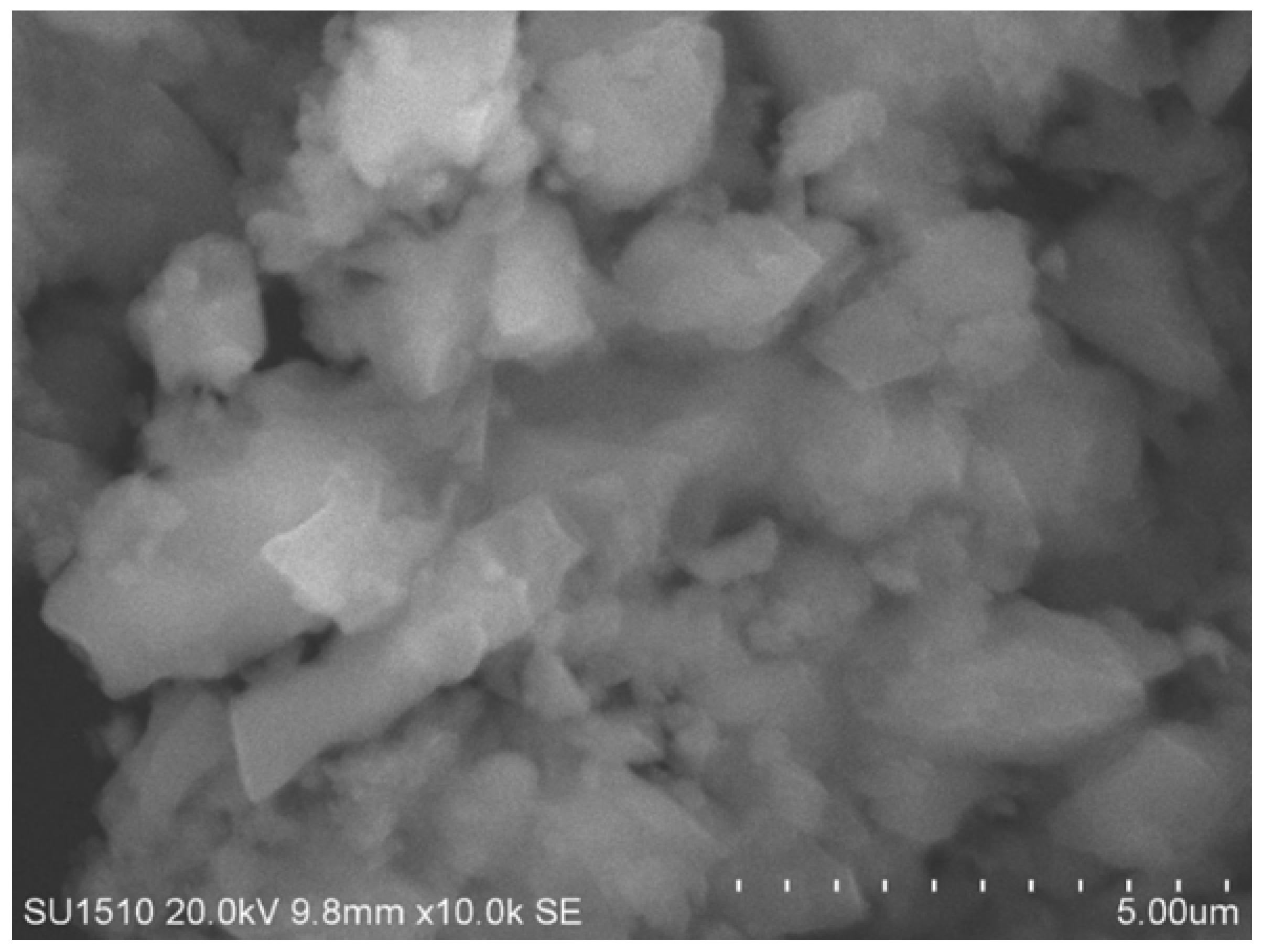

3.2. SEM-EDS Analysis of the Nano-BC

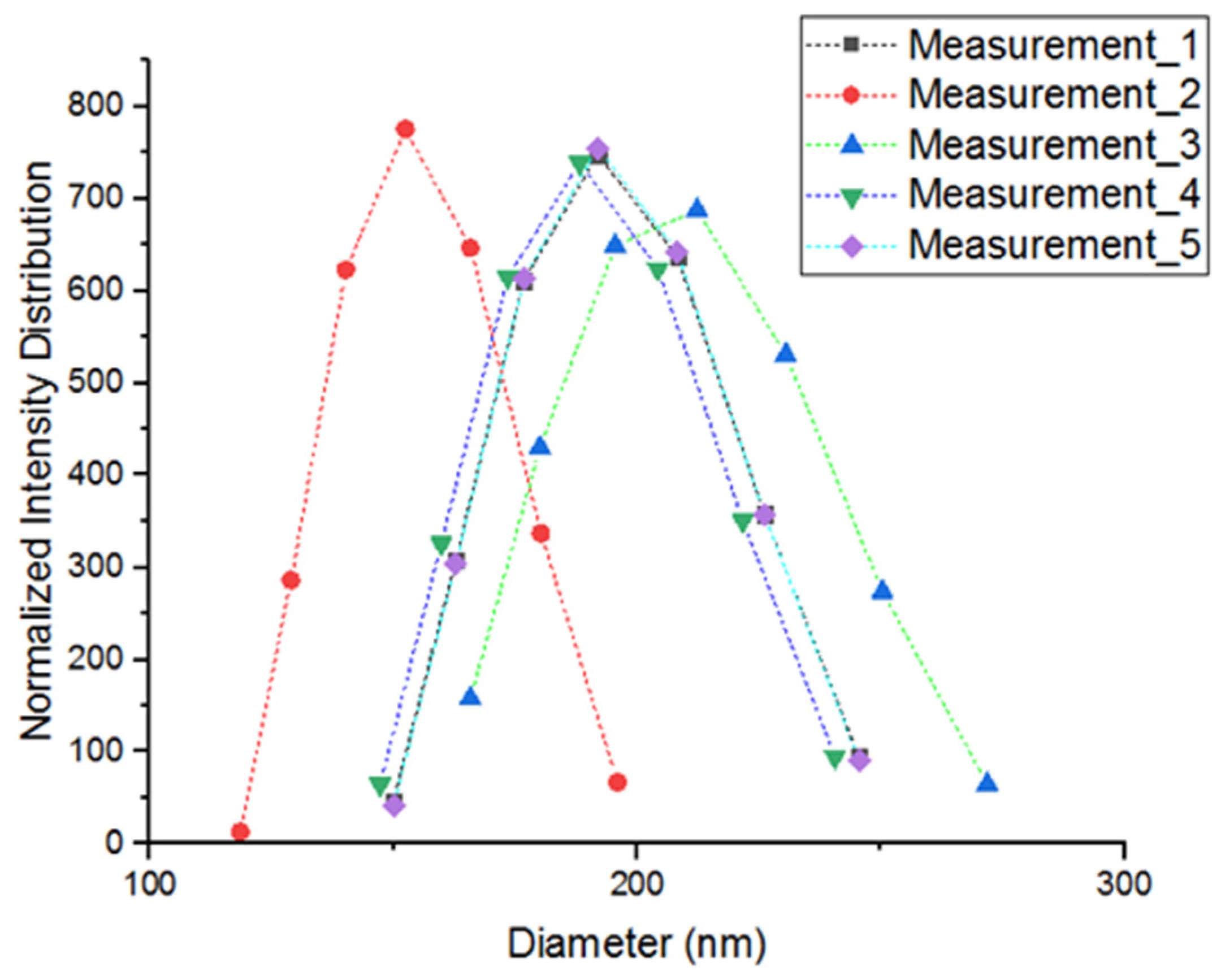

3.3. Particle Size Distribution of the Nano-BC

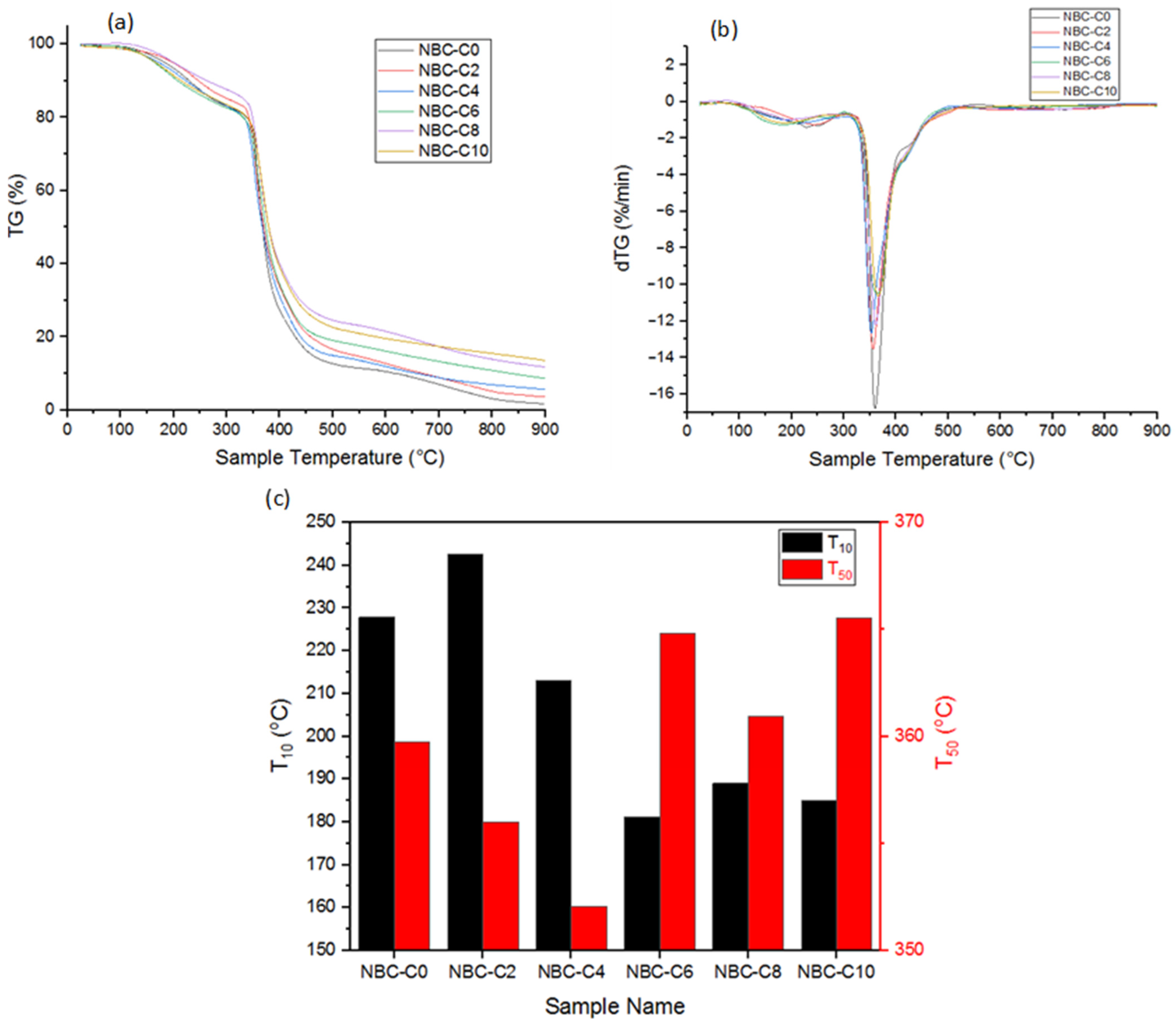

3.4. Thermogravimetric Analysis (TGA)

3.5. Fourier-Transform Infrared Spectroscopy (FTIR)

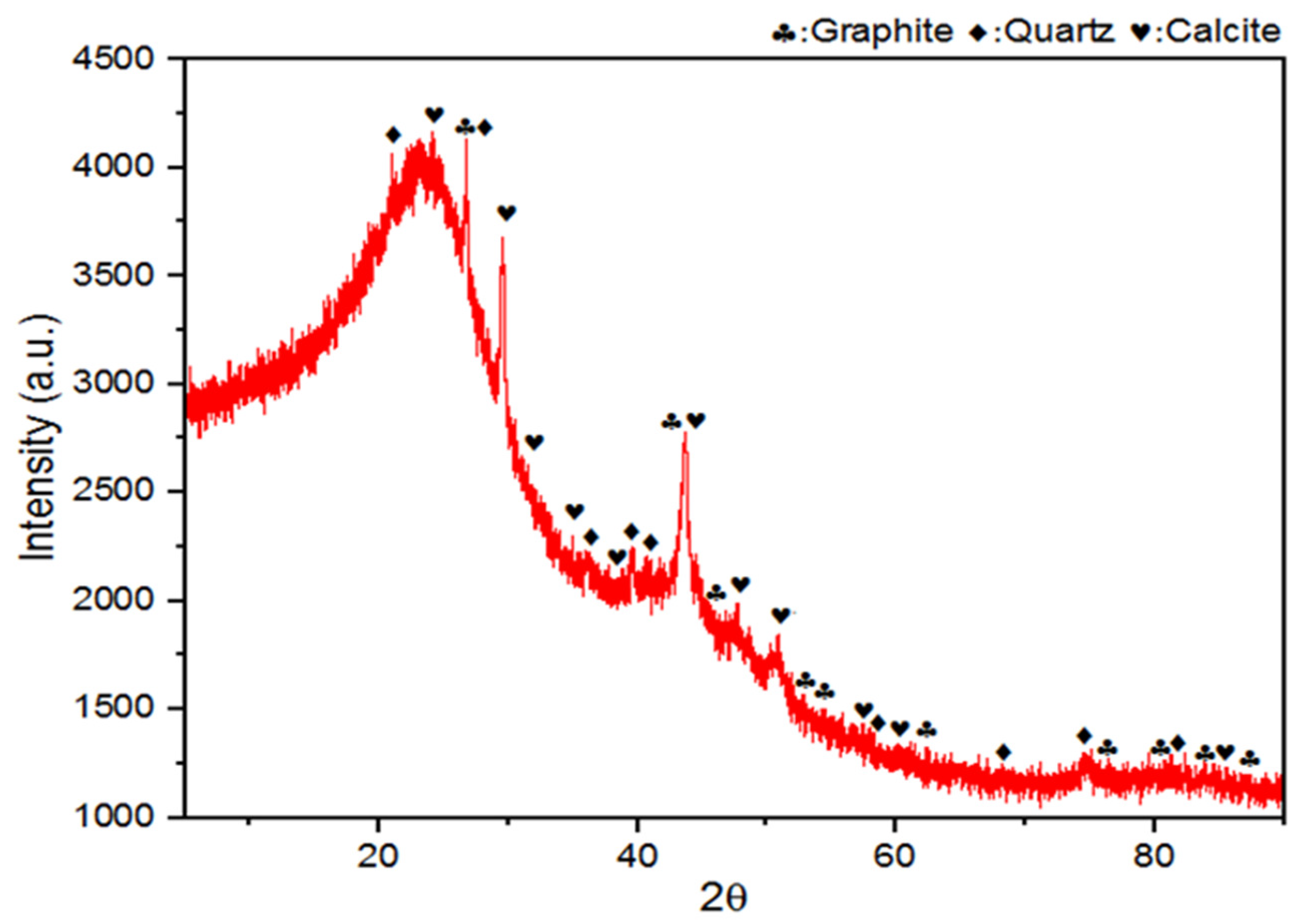

3.6. X-Ray Diffraction (XRD)

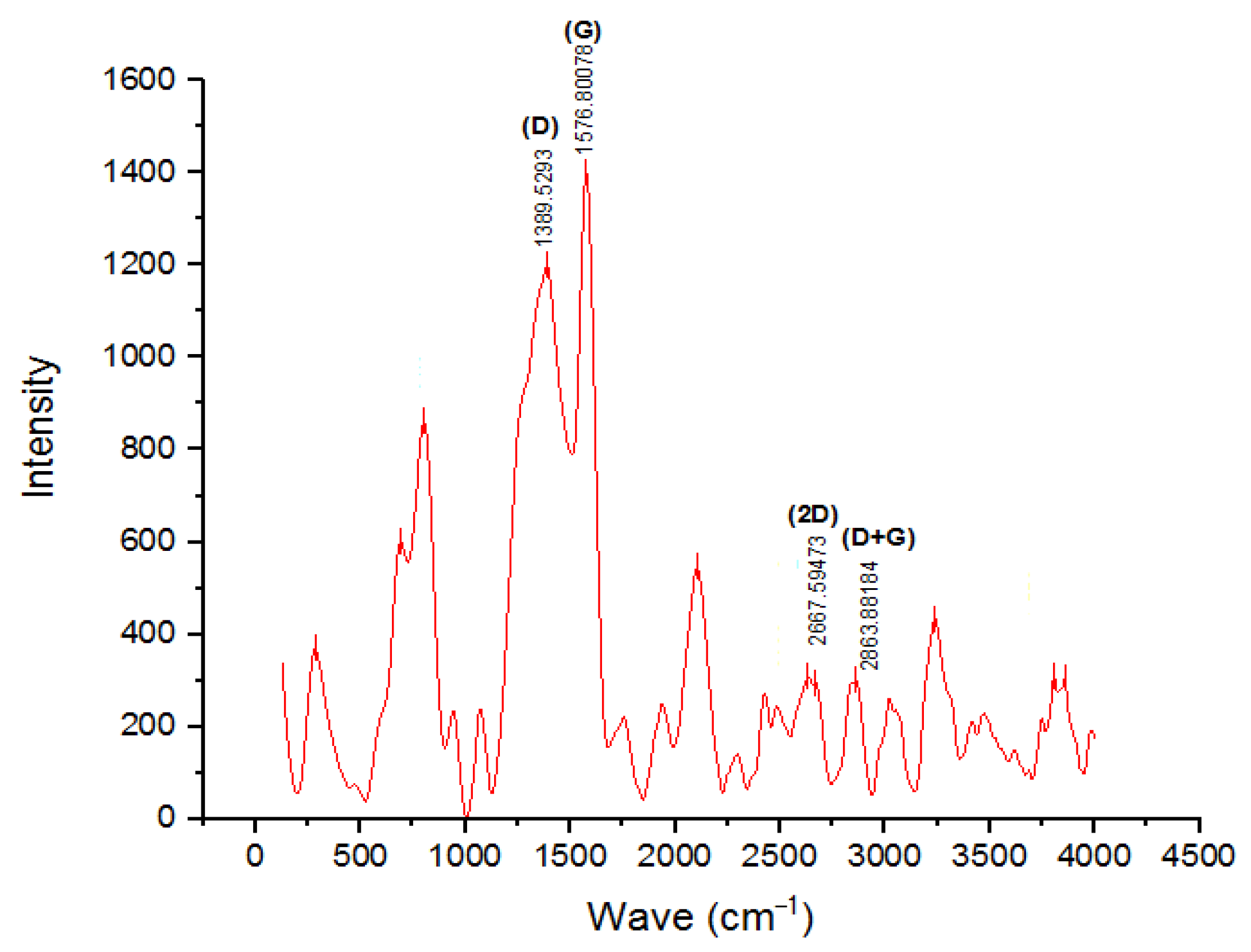

3.7. Raman Spectroscopy Analysis

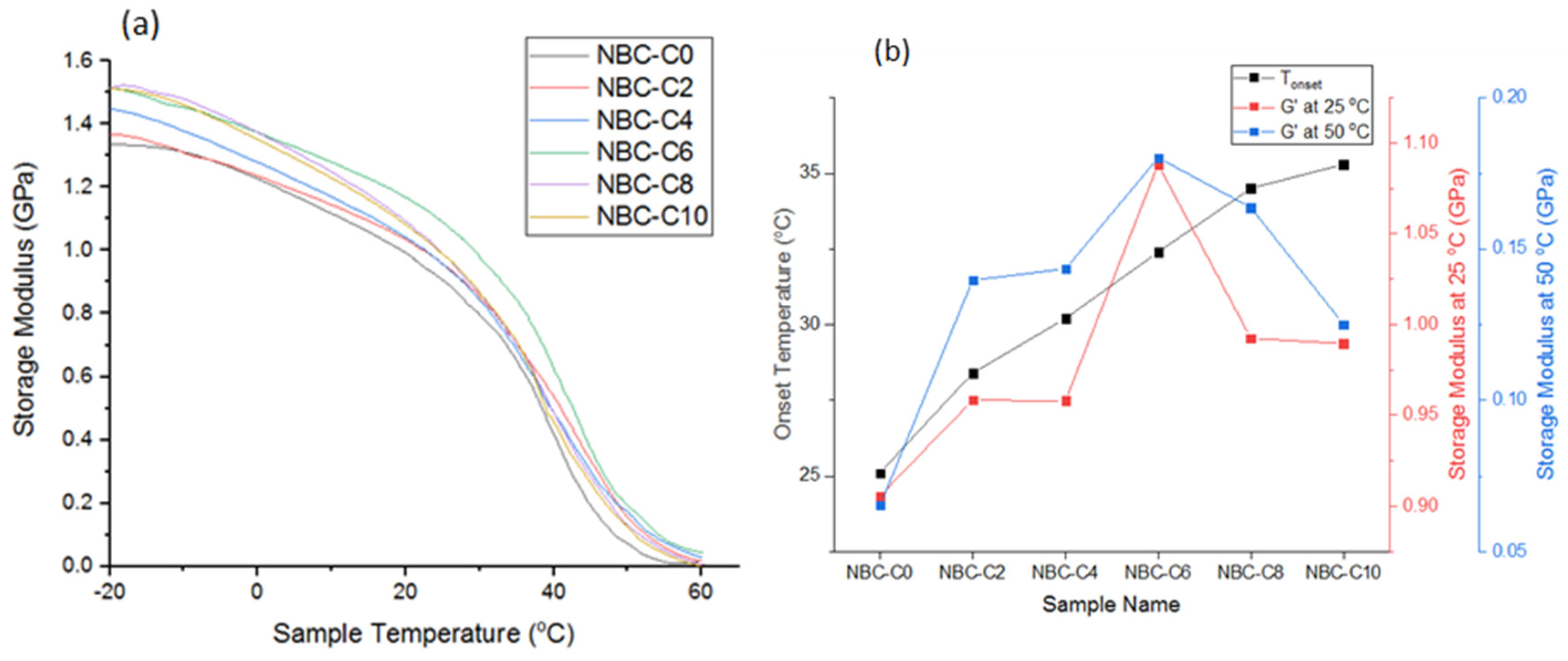

3.8. Characterization of the Nano-BC Using DMA Analysis

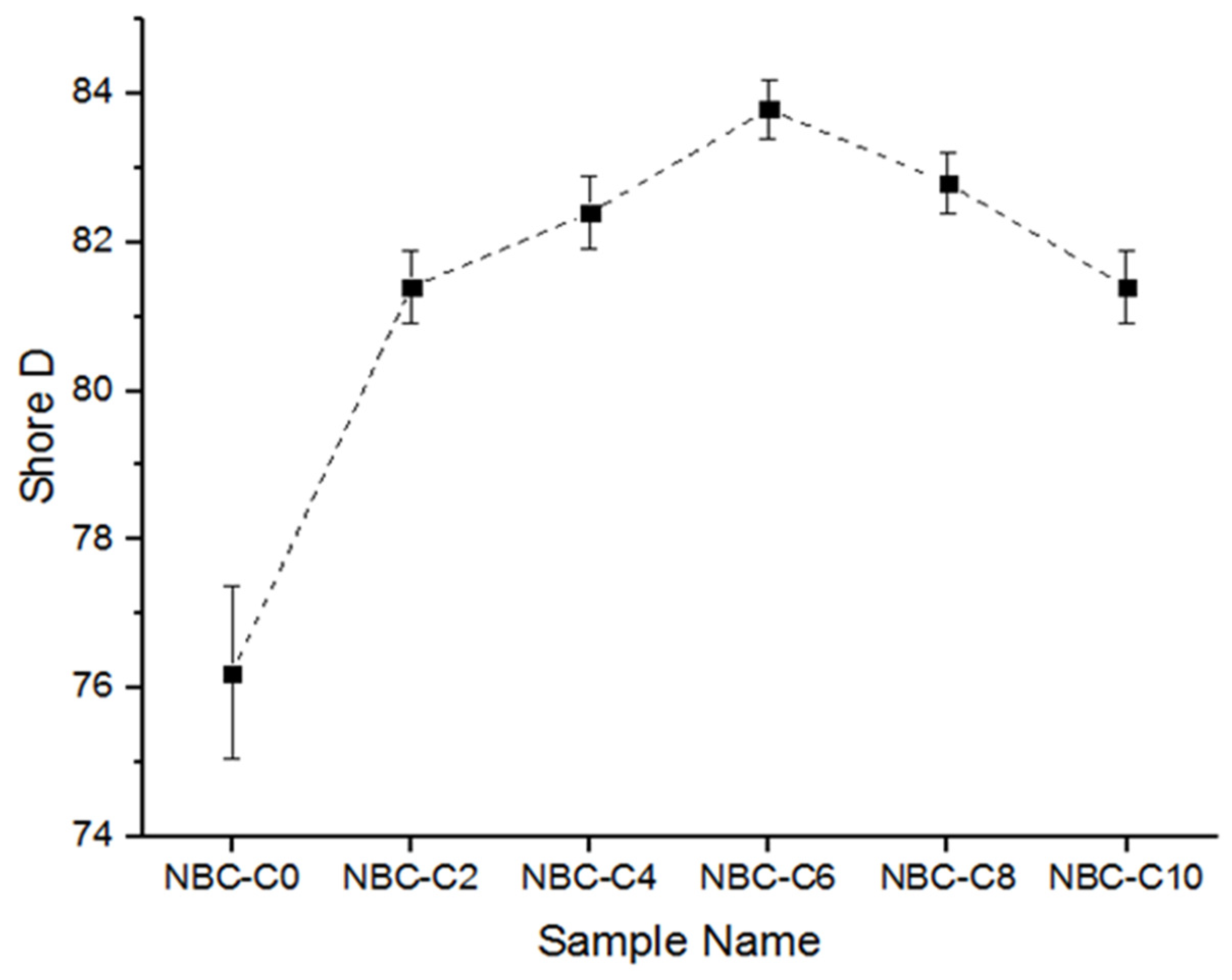

3.9. Hardness Test of the Composites

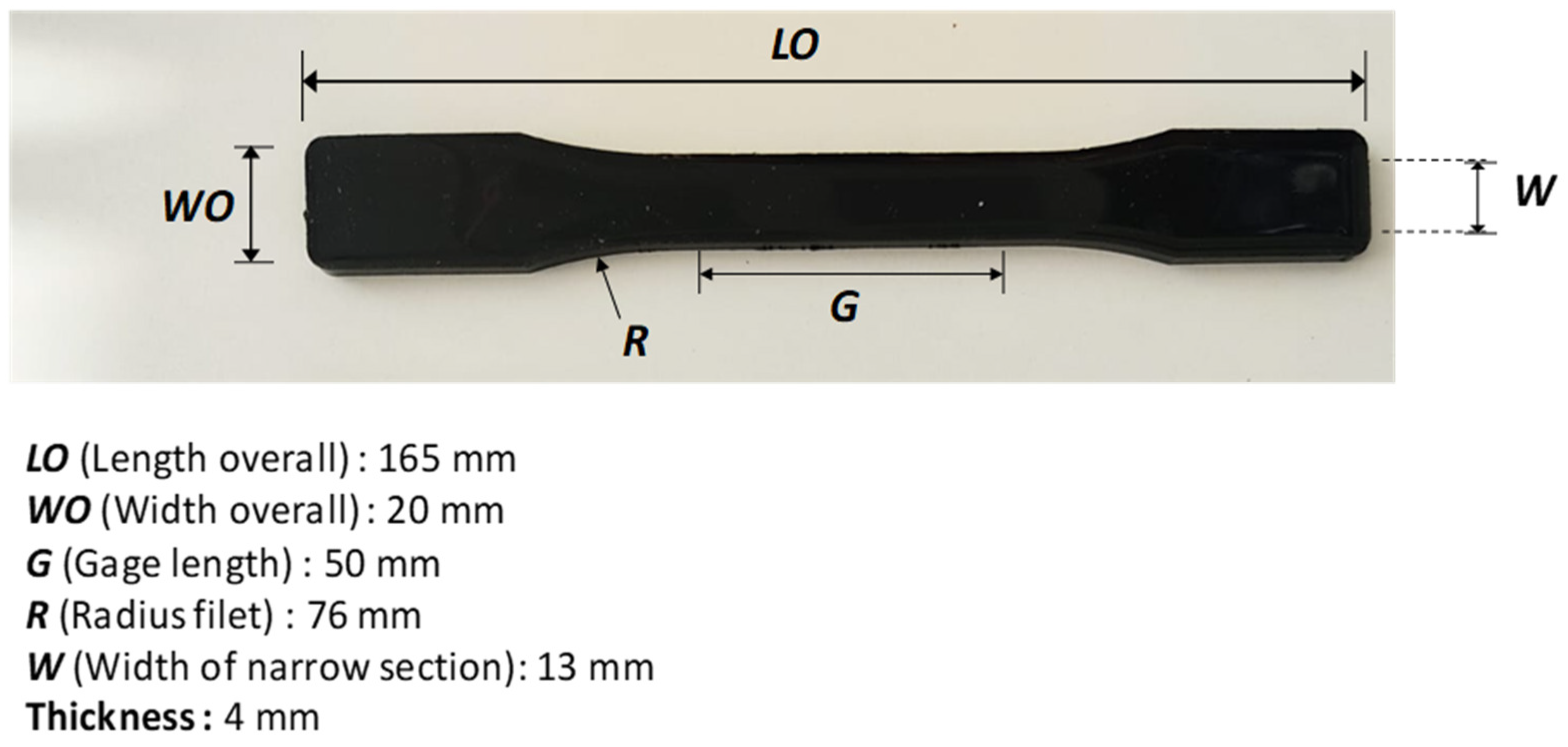

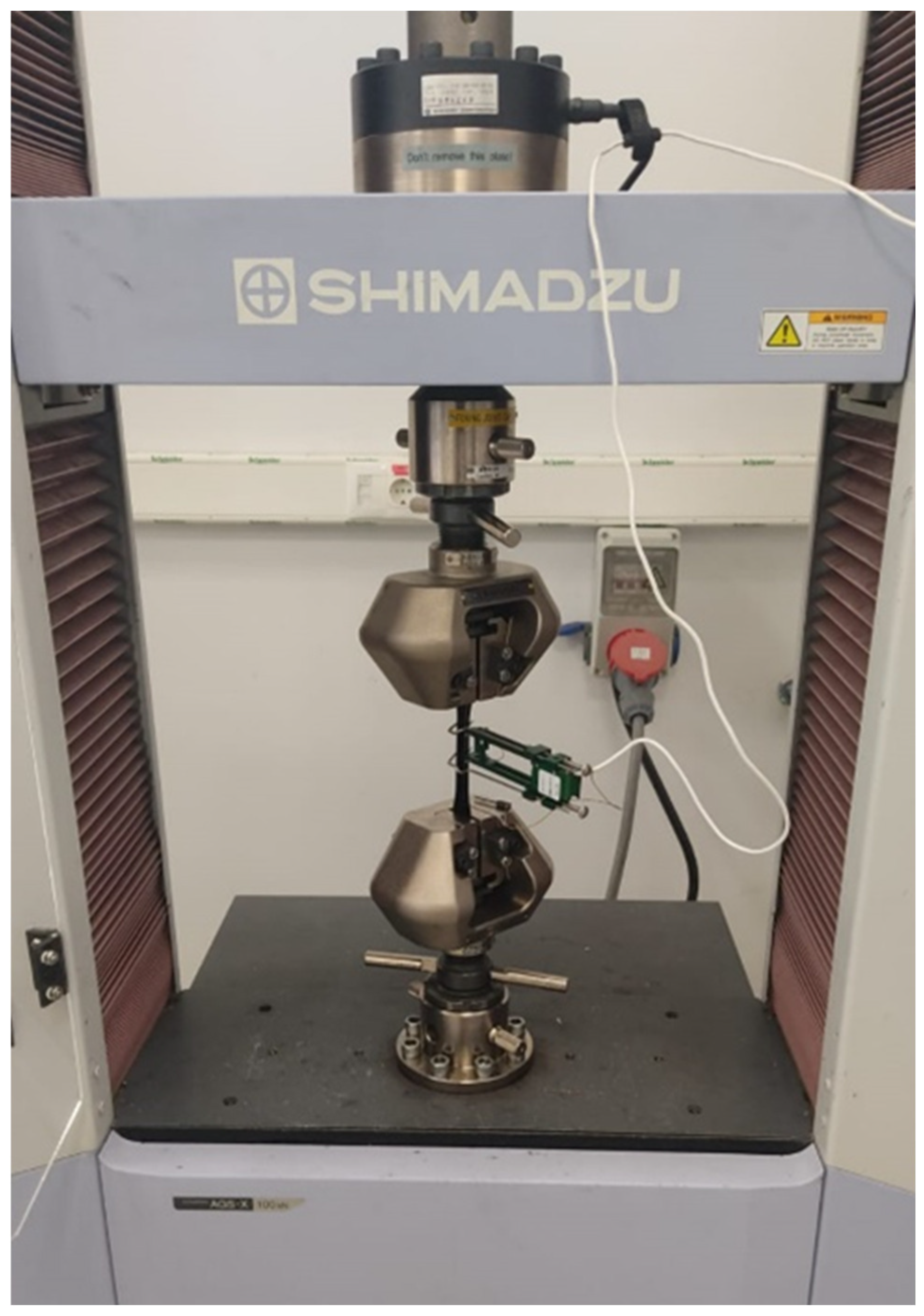

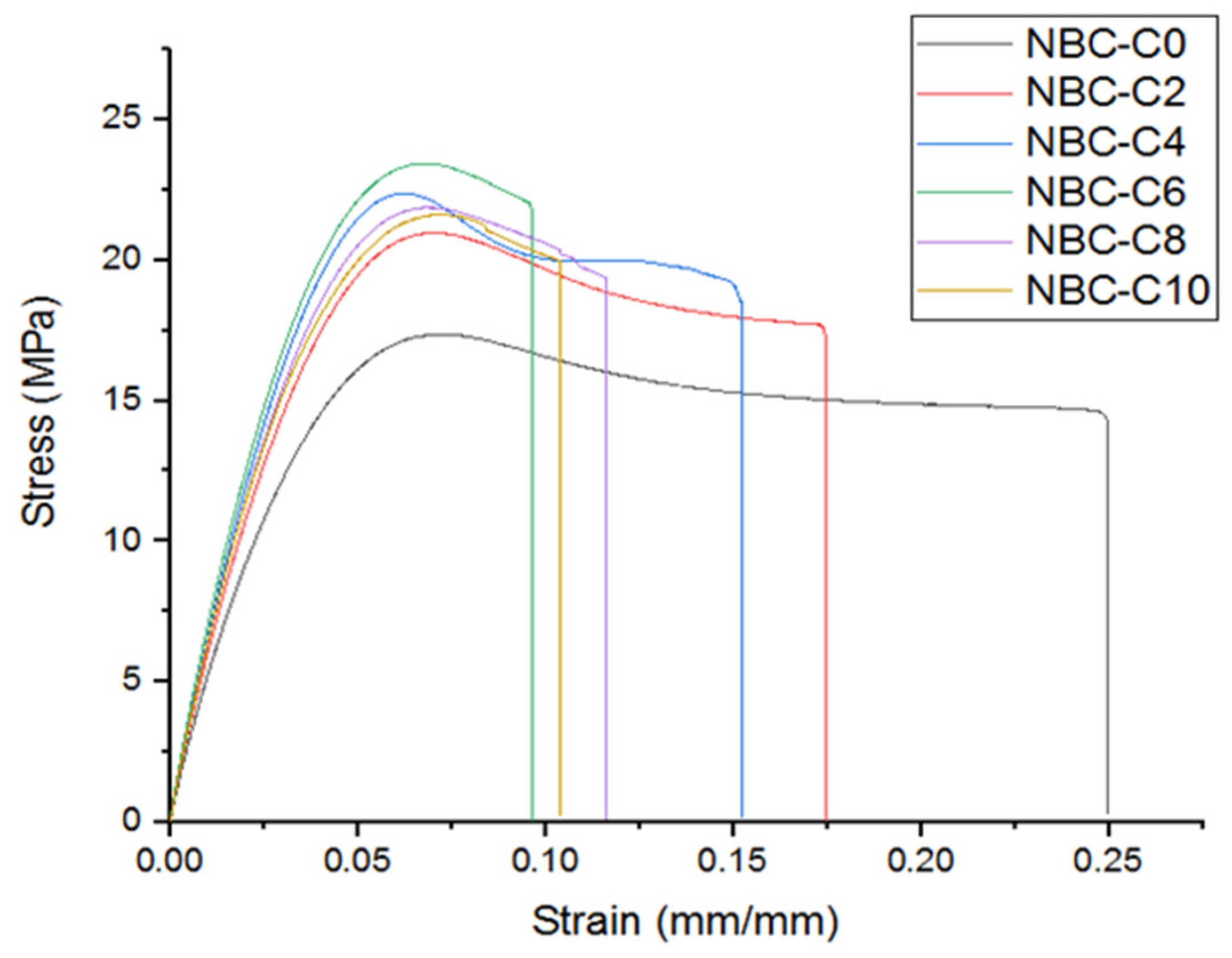

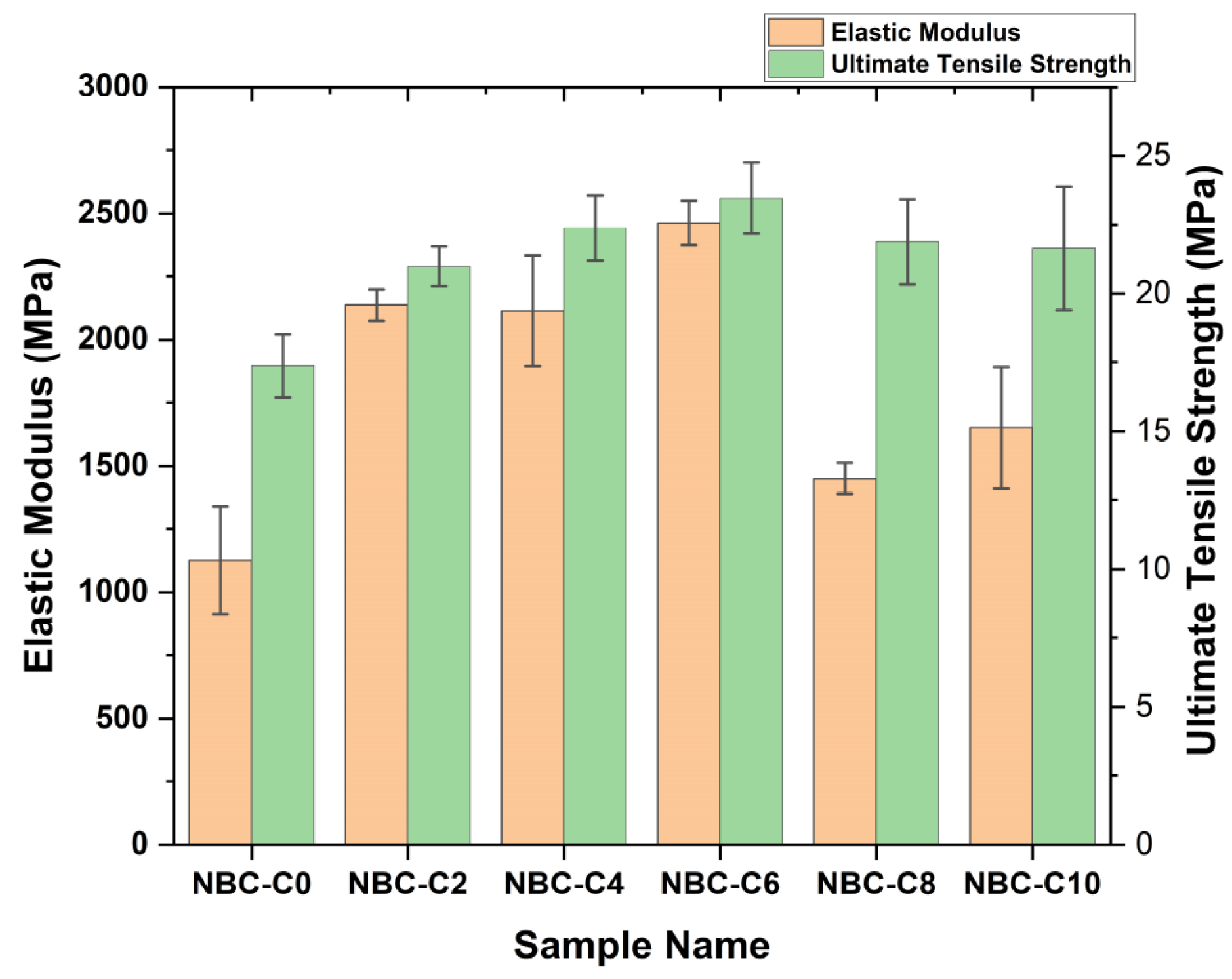

3.10. Ultimate Tensile Strength of the Nano-BC Composites

3.11. Static Toughness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Jamróz, E.; Kulawik, P.; Kopel, P. The Effect of Nanofillers on the Functional Properties of Biopolymer-Based Films: A Review. Polymers 2019, 11, 675. [Google Scholar] [CrossRef] [PubMed]

- Morreale, M.; Liga, A.; Mistretta, M.C.; Ascione, L.; Mantia, F.P.L. Mechanical, Thermomechanical and Reprocessing Behavior of Green Composites from Biodegradable Polymer and Wood Flour. Materials 2015, 8, 7536–7548. [Google Scholar] [CrossRef] [PubMed]

- Mehmandoust, M.; Li, G.; Erk, N. Biomass-derived carbon materials as an emerging platform for advanced electrochemical sensors: Recent advances and future perspectives. Ind. Eng. Chem. Res. 2022, 62, 4628–4635. [Google Scholar] [CrossRef]

- Nasir, S.; Hussein, M.Z.; Zainal, Z.; Yusof, N.A. Carbon-Based Nanomaterials/Allotropes: A Glimpse of Their Synthesis, Properties and Some Applications. Materials 2018, 11, 295. [Google Scholar] [CrossRef] [PubMed]

- Rajak, D.K.; Wagh, P.H.; Linul, E. A Review on Synthetic Fibers for Polymer Matrix Composites: Performance, Failure Modes and Applications. Materials 2022, 15, 4790. [Google Scholar] [CrossRef]

- Paolillo, S.; Bose, R.K.; Santana, M.H.; Grande, A.M. Intrinsic Self-Healing Epoxies in Polymer Matrix Composites (PMCs) for Aerospace Applications. Polymers 2021, 13, 201. [Google Scholar] [CrossRef]

- Saska, S.; Pilatti, L.; Blay, A.; Shibli, J.A. Bioresorbable Polymers: Advanced Materials and 4D Printing for Tissue Engineering. Polymers 2021, 13, 563. [Google Scholar] [CrossRef]

- Ali, A.; Andriyana, A.; Hassan, S.B.A.; Ang, B.C. Fabrication and Thermo-Electro and Mechanical Properties Evaluation of Helical Multiwall Carbon Nanotube-Carbon Fiber/Epoxy Composite Laminates. Polymers 2021, 13, 1437. [Google Scholar] [CrossRef]

- Pathak, R.; Punetha, V.D.; Bhatt, S.; Punetha, M. Carbon nanotube-based biocompatible polymer nanocomposites as an emerging tool for biomedical applications. Eur. Polym. J. 2023, 196, 112257. [Google Scholar] [CrossRef]

- Bartoli, M.; Arrigo, R.; Malucelli, G.; Tagliaferro, A.; Duraccio, D. Recent Advances in Biochar Polymer Composites. Polymers 2022, 14, 2506. [Google Scholar] [CrossRef]

- Kumar, A.; Bhattacharya, T. Biochar: A sustainable solution. Environ. Dev. Sustain. 2021, 23, 6642–6680. [Google Scholar] [CrossRef]

- Aboughaly, M.; Babaei-Ghazvini, A.; Dhar, P.; Patel, R.; Acharya, B. Enhancing the Potential of Polymer Composites Using Biochar as a Filler: A Review. Polymers 2023, 15, 3981. [Google Scholar] [CrossRef]

- Yameen, M.Z.; Naqvi, S.R.; Juchelková, D.; Khan, M.N.A. Harnessing the power of functionalized biochar: Progress, challenges, and future perspectives in energy, water treatment, and environmental sustainability. Biochar 2024, 6, 25. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Ananova, O.; Chernil’nik, A.; El’shaeva, D.; Pogrebnyak, A.; Dubinkin, I.; Madenci, E.; Aksoylu, C.; et al. Performance Assessment of a Novel Green Concrete Using Coffee Grounds Biochar Waste. Recycling 2024, 9, 94. [Google Scholar] [CrossRef]

- Gezahegn, S.; Lai, R.; Huang, L.; Chen, L.; Huang, F.; Blozowski, N.; Thomas, S.C.; Sain, M.; Tjong, J.; Jaffer, S.; et al. Porous graphitic biocarbon and reclaimed carbon fiber derived environmentally benign lightweight composites. Sci. Total Environ. 2019, 664, 363–373. [Google Scholar] [CrossRef] [PubMed]

- Das, O.; Sarmah, A.K. The love–hate relationship of pyrolysis biochar and water: A perspective. Sci. Total Environ. 2015, 512, 682–685. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, S.N.; Calado, V.; Rodriguez, R.J.; Margem, F.M. Thermogravimetric stability of polymer composites reinforced with less common lignocellulosic fibers–An overview. J. Mater. Res. Technol. 2012, 1, 117–126. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. Biocomposites from waste derived biochars: Mechanical, thermal, chemical, and morphological properties. Waste Manag. 2016, 49, 560–570. [Google Scholar] [CrossRef]

- Nan, N.; DeVallance, D.B.; Xie, X.; Wang, J. The effect of bio-carbon addition on the electrical, mechanical, and thermal properties of polyvinyl alcohol/biochar composites. J. Compos. Mater. 2016, 50, 1161–1168. [Google Scholar] [CrossRef]

- Richard, S.; Rajadurai, J.S.; Manikandan, V. Influence of particle size and particle loading on mechanical and dielectric properties of biochar particulate-reinforced polymer nanocomposites. Int. J. Polym. Anal. Charact. 2016, 21, 462–477. [Google Scholar] [CrossRef]

- Myllytie, P.; Misra, M.; Mohanty, A.K. Carbonized lignin as sustainable filler in biobased poly (trimethylene terephthalate) polymer for injection molding applications. ACS Sustain. Chem. Eng. 2016, 4, 102–110. [Google Scholar] [CrossRef]

- Khan, A.; Savi, P.; Quaranta, S.; Rovere, M.; Giorcelli, M.; Tagliaferro, A.; Rosso, C.; Jia, C.Q. Low-Cost Carbon Fillers to Improve Mechanical Properties and Conductivity of Epoxy Composites. Polymers 2017, 9, 642. [Google Scholar] [CrossRef]

- Giorcelli, M.; Bartoli, M. Development of Coffee Biochar Filler for the Production of Electrical Conductive Reinforced Plastic. Polymers 2019, 11, 1916. [Google Scholar] [CrossRef] [PubMed]

- Bartoli, M.; Nasir, M.A.; Jagdale, P.; Passaglia, E.; Spiniello, R.; Rosso, C.; Giorcelli, M.; Rovere, M.; Tagliaferro, A. Influence of pyrolytic thermal history on olive pruning biochar and related epoxy composites mechanical properties. J. Compos. Mater. 2020, 54, 1863–1873. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. A sustainable and resilient approach through biochar addition in wood polymer composites. Sci. Total Environ. 2015, 512, 326–336. [Google Scholar] [CrossRef] [PubMed]

- Giorcelli, M.; Khan, A.; Pugno, N.M.; Rosso, C.; Tagliaferro, A. Biochar as a cheap and environmental friendly filler able to improve polymer mechanical properties. Biomass Bioenergy 2019, 120, 219–223. [Google Scholar] [CrossRef]

- Sathish, T.; Palani, K.; Natrayan, L.; Merneedi, A.; De Poures, M.V.; Singaravelu, D.K. Synthesis and characterization of polypropylene/ramie fiber with hemp fiber and coir fiber natural biopolymer composite for biomedical application. Int. J. Polym. Sci. 2021, 2021, 2462873. [Google Scholar] [CrossRef]

- Harussani, M.M.; Sapuan, S.M. Carbonization of Biomass and Waste into Biosourced Carbon (BC) Nanofillers for Advanced Composite Applications. In Emerging Sustainable and Renewable Composites; CRC Press: Boca Raton, FL, USA, 2024; pp. 248–292. [Google Scholar]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM D2240-15(2021); Standard Test Method for Rubber Property—Durometer Hardness. ASTM: West Conshohocken, PA, USA, 2021.

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution. Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Takagi, H.; Maruyama, K.; Yoshizawa, N.; Yamada, Y.; Sato, Y. XRD analysis of carbon stacking structure in coal during heat treatment. Fuel 2004, 83, 2427–2433. [Google Scholar] [CrossRef]

- Xu, J.; Liu, J.; Ling, P.; Zhang, X.; Xu, K.; He, L.; Wang, Y.; Su, S.; Hu, S.; Xiang, J. Raman spectroscopy of biochar from the pyrolysis of three typical Chinese biomasses: A novel method for rapidly evaluating the biochar property. Energy 2020, 202, 117644. [Google Scholar] [CrossRef]

- Li, S.; Xu, Y.; Jing, X.; Yilmaz, G.; Li, D.; Turng, L.-S. Effect of carbonization temperature on mechanical properties and biocompatibility of biochar/ultra-high molecular weight polyethylene composites. Compos. Part B Eng. 2020, 196, 108120. [Google Scholar] [CrossRef]

| Sample | Resin (gram) | Hardener (gram) | Nano-BC Filler (gram) |

|---|---|---|---|

| NBC-C0 (Control Sample) | 50 | 25 | 0 |

| NBC-C2 | 49 | 24.5 | 1.5 |

| NBC-C4 | 48 | 24 | 3 |

| NBC-C6 | 47 | 23.5 | 4.5 |

| NBC-C8 | 46 | 23 | 6 |

| NBC-C10 | 45 | 22.5 | 7.5 |

| Map Sum Spectrum | ||||

|---|---|---|---|---|

| Element | Line Type | Weight% | Weight% Sigma | Atomic% |

| C | K series | 81.23 | 0.26 | 86.16 |

| O | K series | 16.36 | 0.26 | 13.02 |

| K | K series | 1.50 | 0.03 | 0.49 |

| Ca | K series | 0.72 | 0.03 | 0.23 |

| Si | K series | 0.12 | 0.01 | 0.05 |

| Mg | K series | 0.08 | 0.02 | 0.04 |

| Total | 100.00 | 100.00 |

| Measurement No. | Ave. Diameter (nm) | Polydispersity Index | Mean. (nm) | D-10% (nm) | D-50% (nm) | D-90% (nm) |

|---|---|---|---|---|---|---|

| 1 | 225.7 | 0.174 | 194.6 | 159.6 | 185.4 | 216.7 |

| 2 | 247.3 | 0.2 | 154.6 | 128 | 147.2 | 171.2 |

| 3 | 225.1 | 0.176 | 209.4 | 169.7 | 199.3 | 234.7 |

| 4 | 206.3 | 0.196 | 190.2 | 155.4 | 181.3 | 212.2 |

| 5 | 223.1 | 0.169 | 194.6 | 159.9 | 185.4 | 216.5 |

| Average | 225.5 | 0.183 | 188.68 | 154.52 | 179.72 | 210.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Özgün, M.İ.; Erci, V.; Madenci, E.; Erci, F. The Effect of Nano-Biochar Derived from Olive Waste on the Thermal and Mechanical Properties of Epoxy Composites. Polymers 2025, 17, 1337. https://doi.org/10.3390/polym17101337

Özgün Mİ, Erci V, Madenci E, Erci F. The Effect of Nano-Biochar Derived from Olive Waste on the Thermal and Mechanical Properties of Epoxy Composites. Polymers. 2025; 17(10):1337. https://doi.org/10.3390/polym17101337

Chicago/Turabian StyleÖzgün, Muhammed İhsan, Vildan Erci, Emrah Madenci, and Fatih Erci. 2025. "The Effect of Nano-Biochar Derived from Olive Waste on the Thermal and Mechanical Properties of Epoxy Composites" Polymers 17, no. 10: 1337. https://doi.org/10.3390/polym17101337

APA StyleÖzgün, M. İ., Erci, V., Madenci, E., & Erci, F. (2025). The Effect of Nano-Biochar Derived from Olive Waste on the Thermal and Mechanical Properties of Epoxy Composites. Polymers, 17(10), 1337. https://doi.org/10.3390/polym17101337