Eco-Friendly Polypropylene Composites Reinforced with Cellulose Fibers and Silica Nanoparticles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

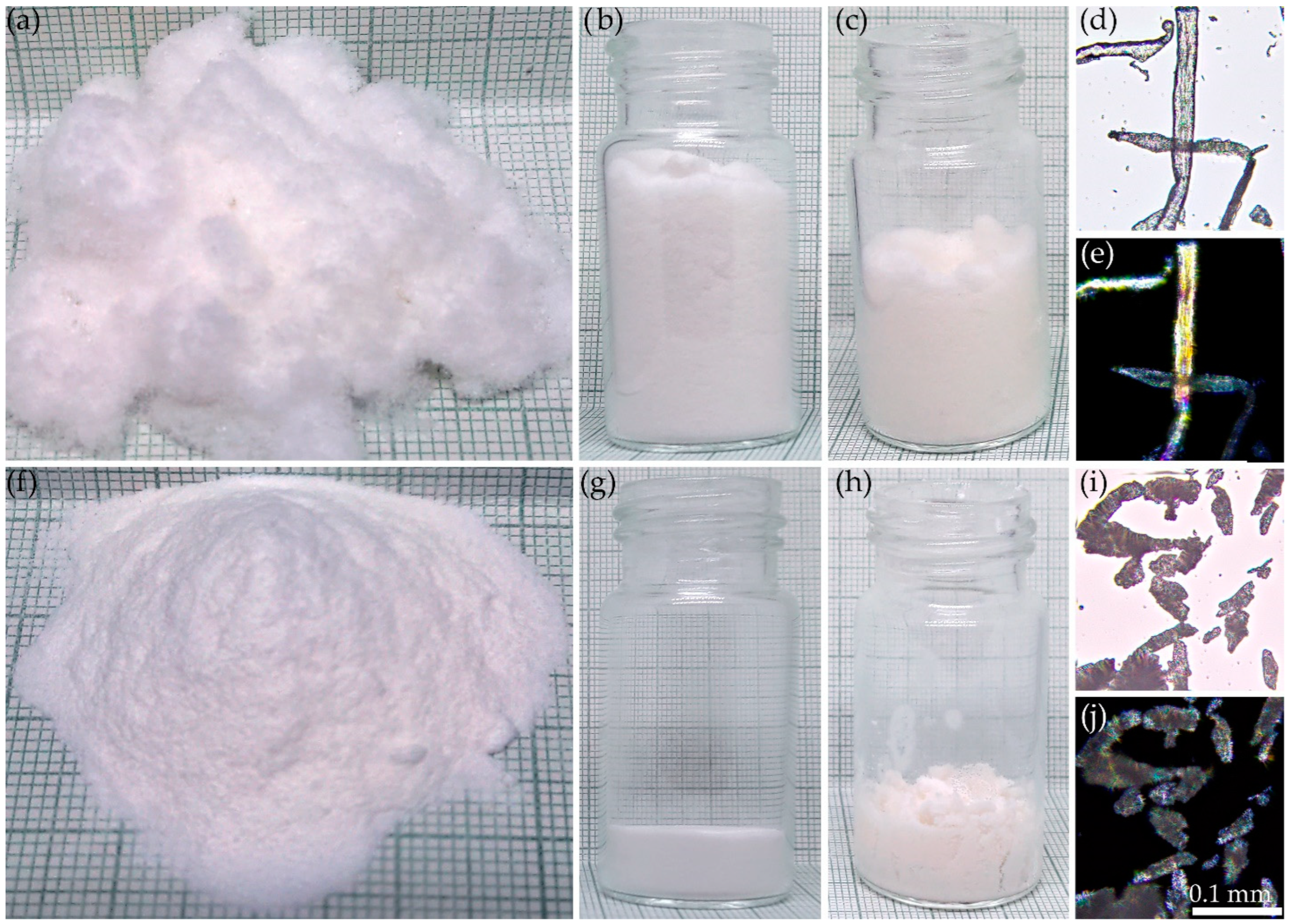

2.2. Sample Preparation

2.3. Rheology

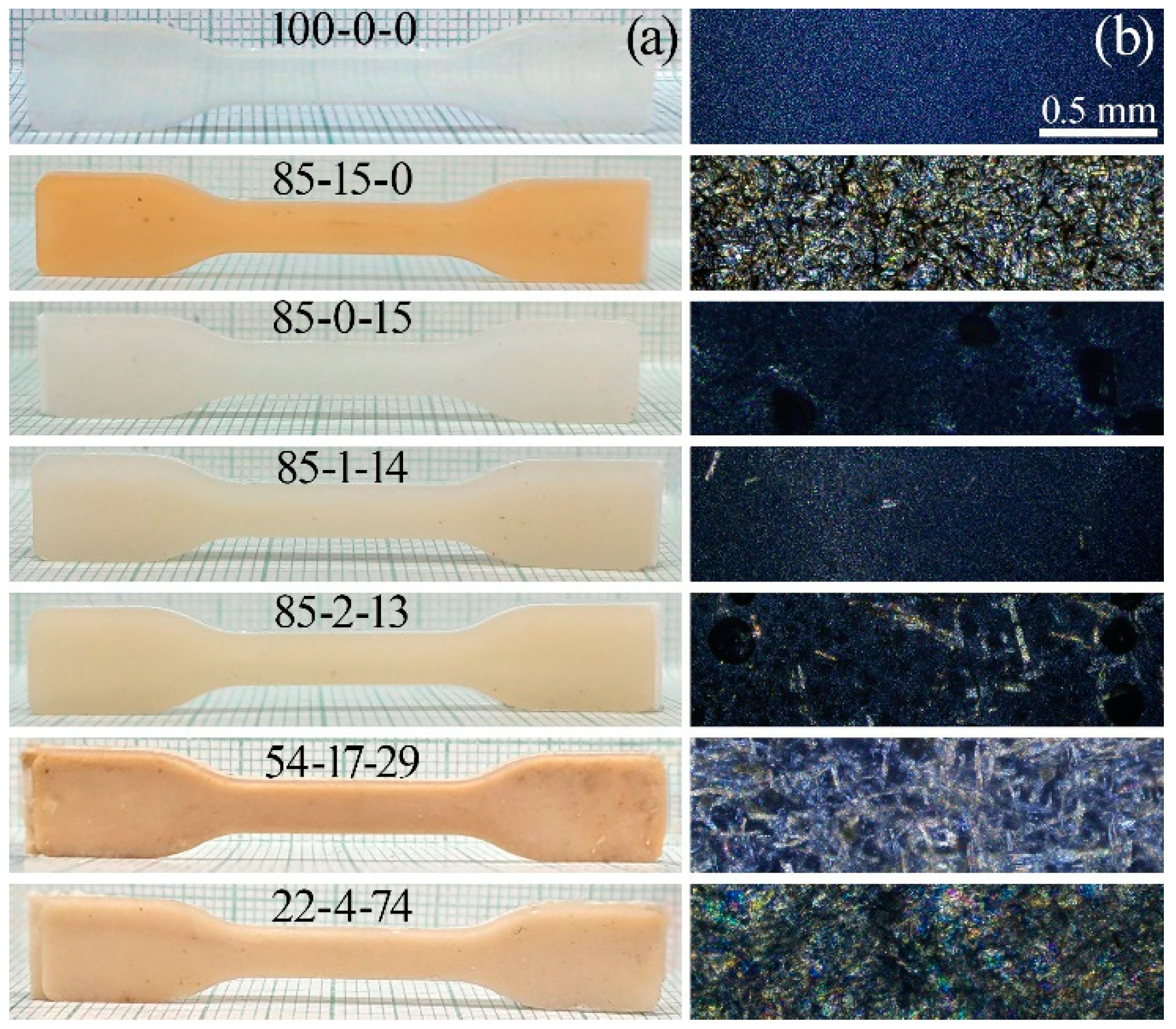

2.4. Microscopy

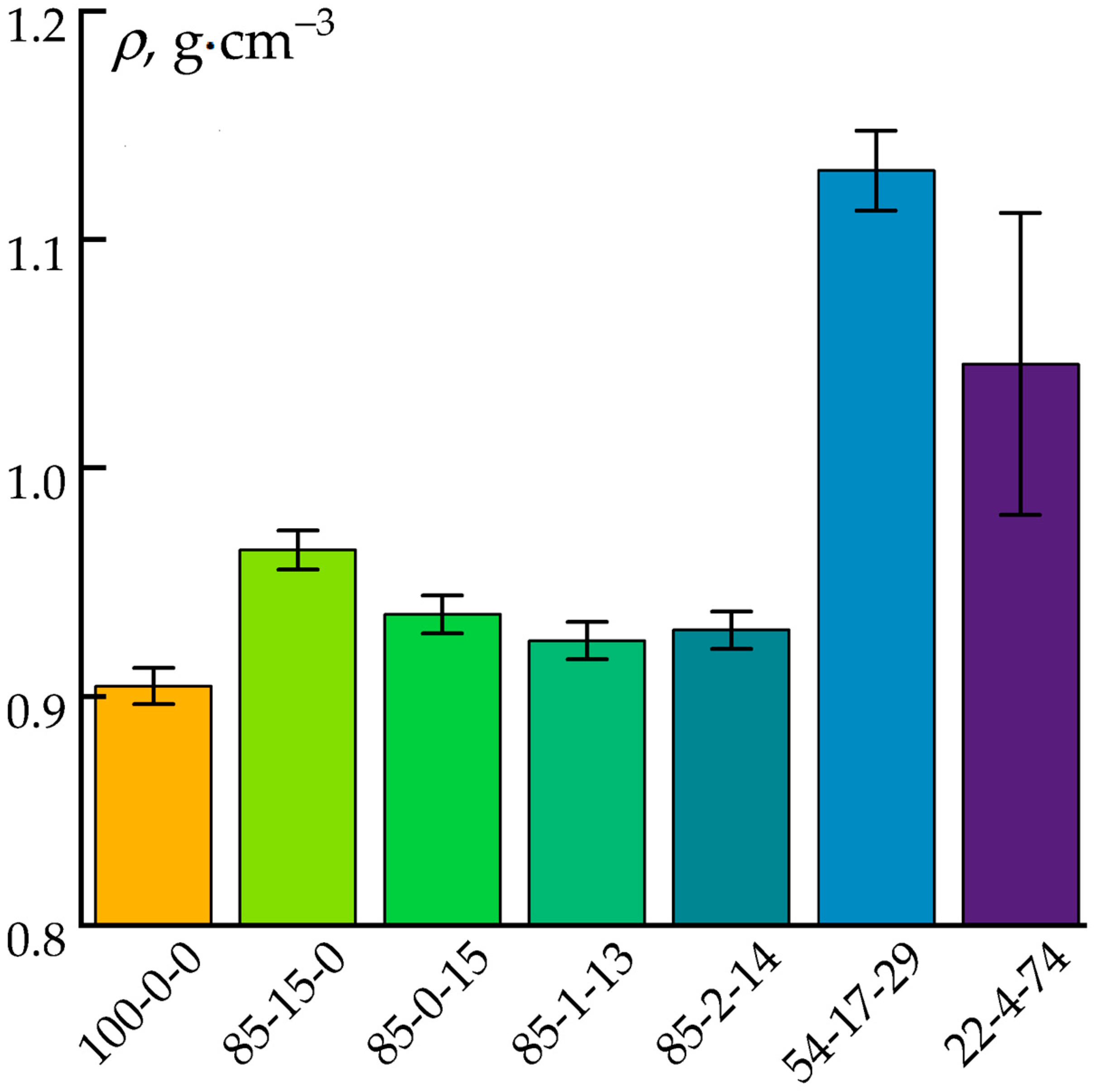

2.5. Density Measurements

2.6. Mechanical Properties

2.7. Pyrolysis

2.8. Scanning Electron Microscopy (SEM)

2.9. X-Ray Phase Analysis

3. Results

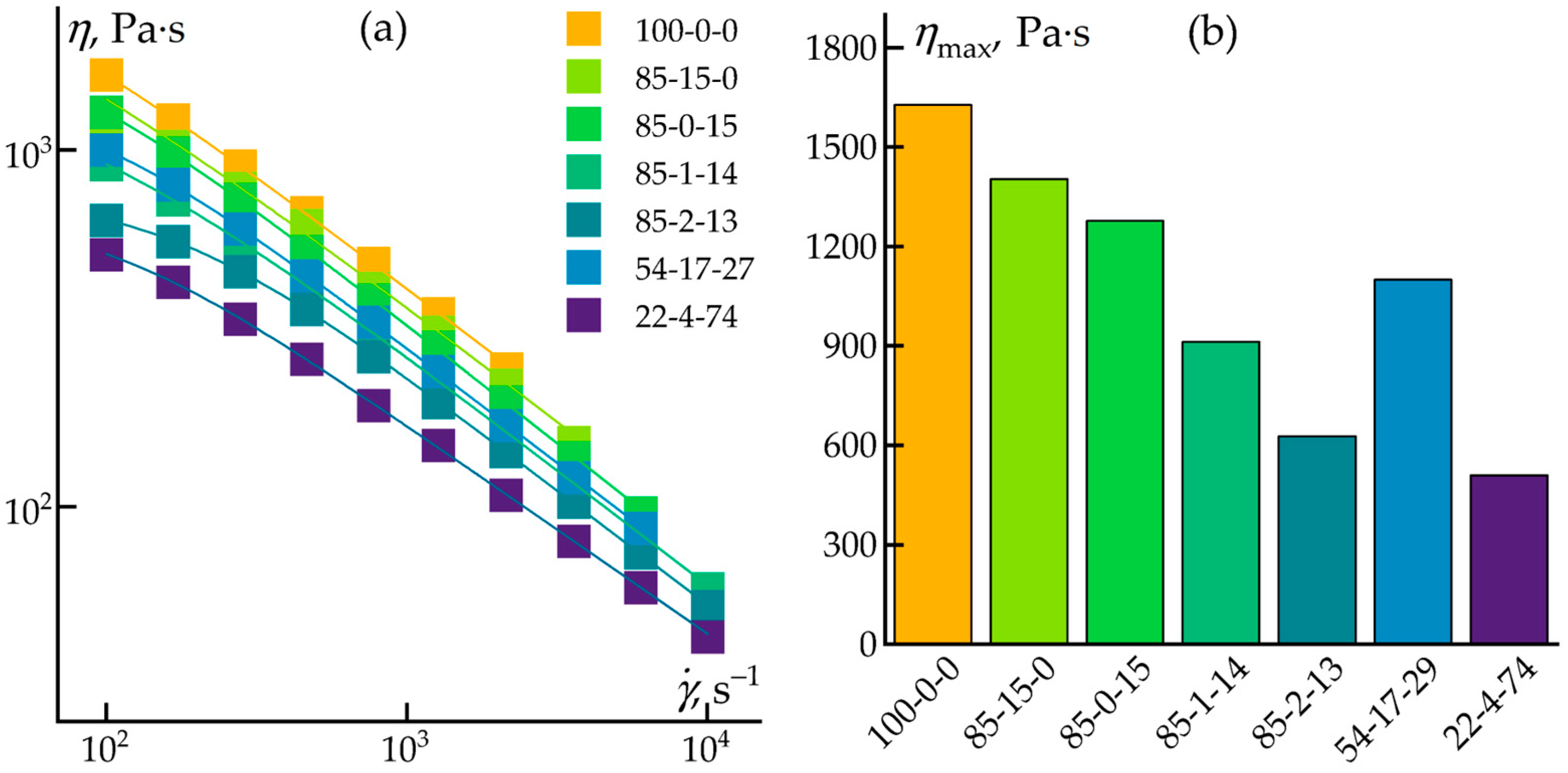

3.1. Rheological Studies

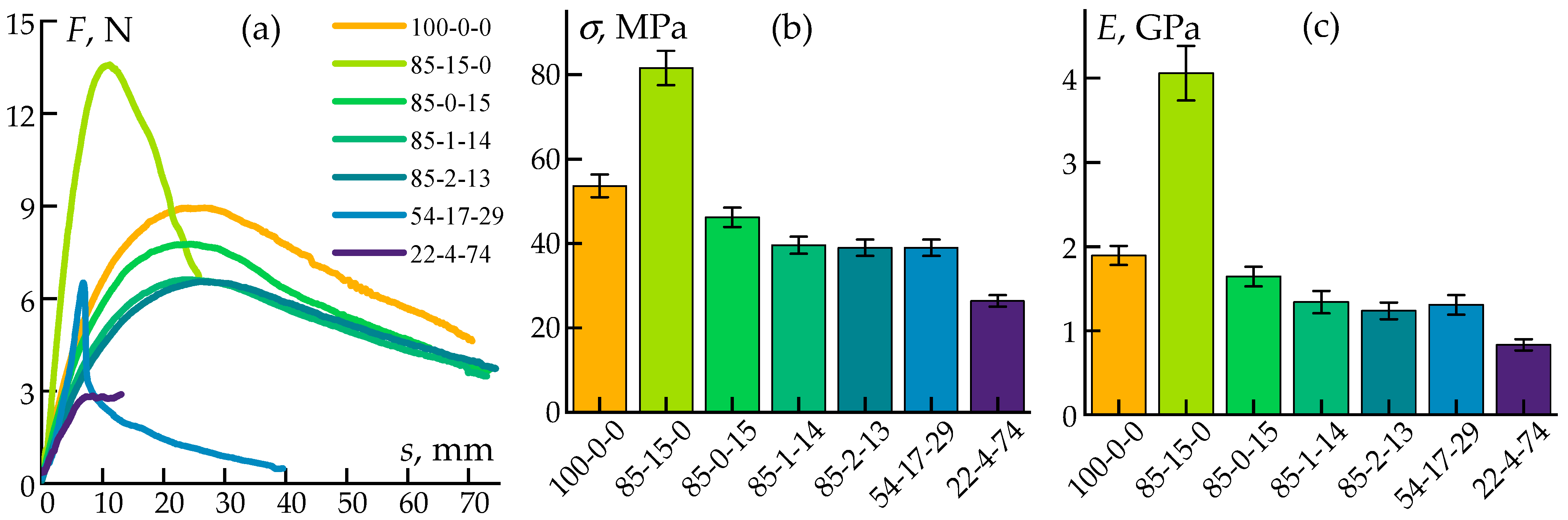

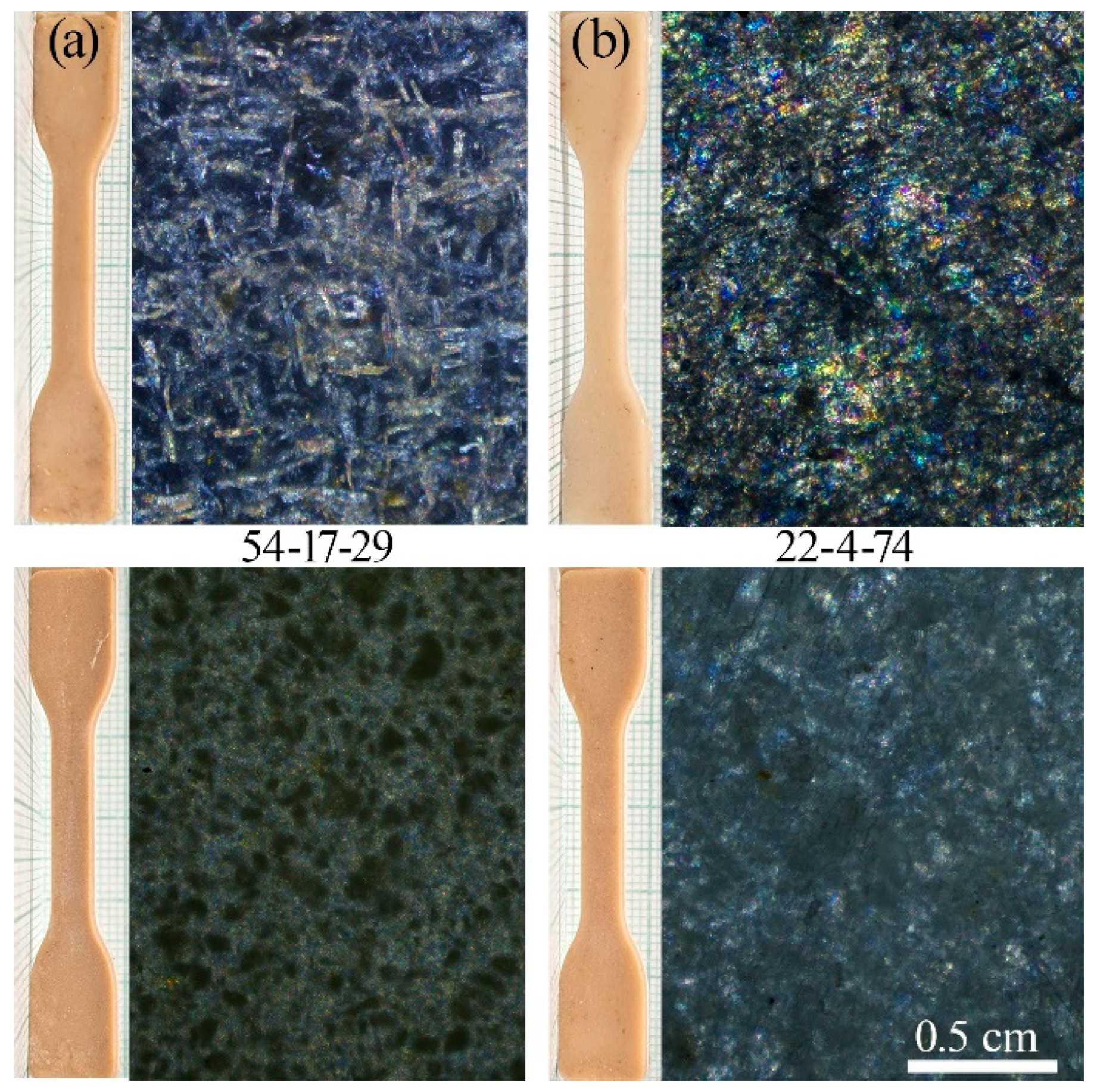

3.2. Molding of Specimens and Their Properties

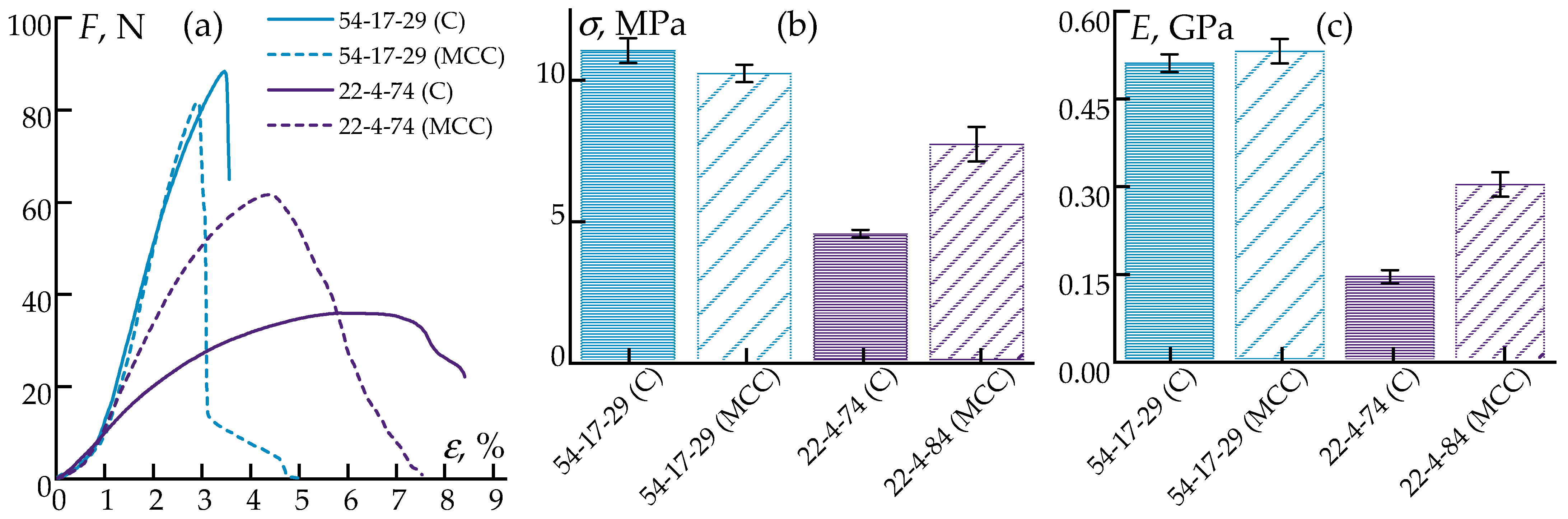

3.3. Microcrystalline Cellulose

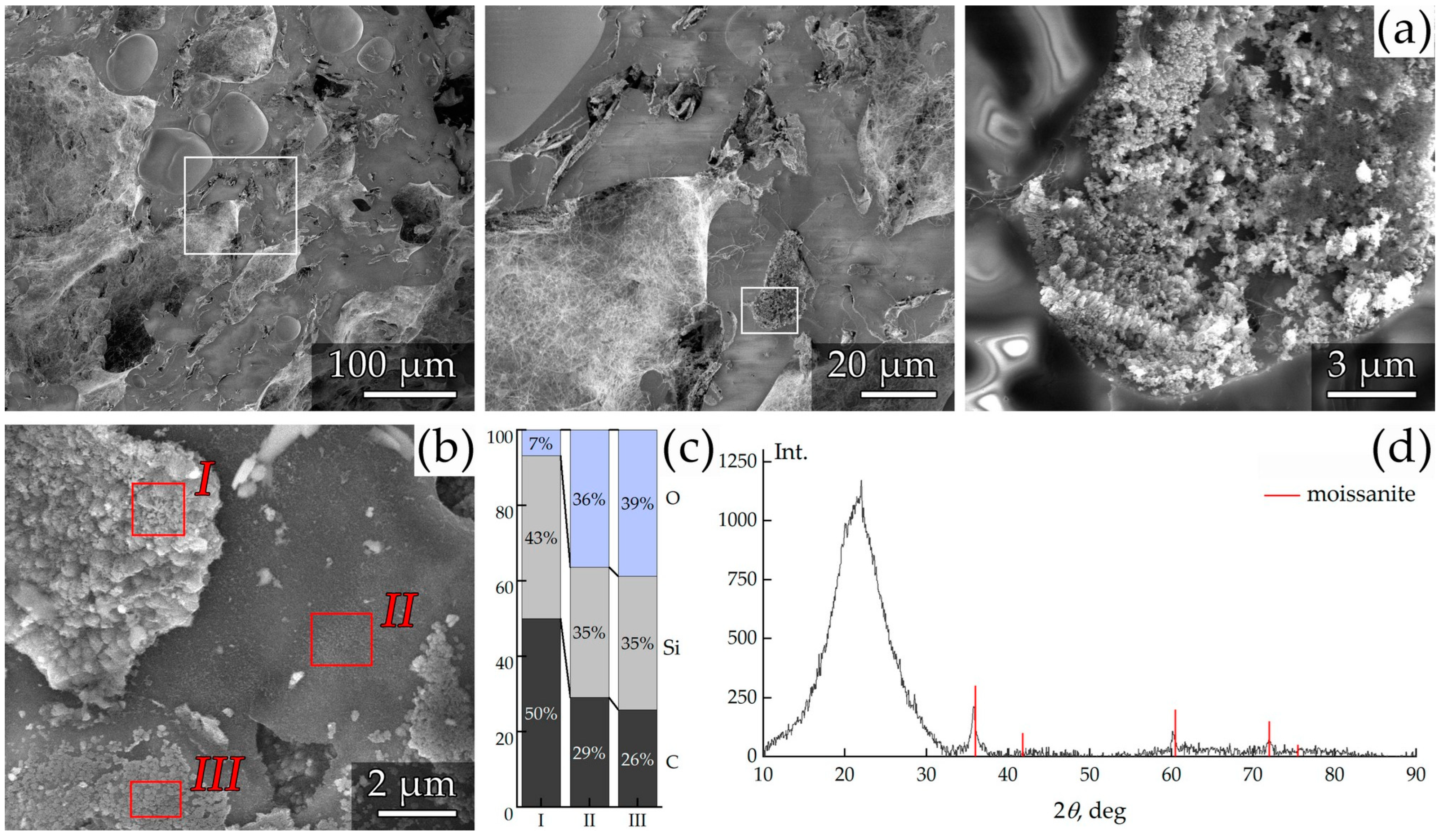

3.4. Carbonization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FDM | Fused Deposition Modeling |

| MCC | Microcrystalline cellulose |

| SiC | Silicon carbide |

| PAN | Polyacrylonitrile |

| DOAJ | Directory of Open-Access Journals |

| PIM | Powder injection molding |

| ES-40 | Ethyl silicate 40 |

| SEM | Scanning electron microscopy |

| EDS | Energy-dispersive X-ray spectroscopy |

| XRD | X-ray diffraction |

References

- Fernandes, C.; Pontes, A.J.; Viana, J.C.; Gaspar-Cunha, A. Modeling and Optimization of the Injection-Molding Process: A Review. Adv. Polym. Technol. 2018, 37, 429–449. [Google Scholar] [CrossRef]

- Rosato, D.V.; Rosato, M.G. Injection Molding Handbook; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; ISBN 1-4615-4597-8. [Google Scholar]

- Maddah, H.A. Polypropylene as a Promising Plastic: A Review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar]

- Shubhra, Q.T.; Alam, A.M.; Quaiyyum, M.A. Mechanical Properties of Polypropylene Composites: A Review. J. Thermoplast. Compos. Mater. 2013, 26, 362–391. [Google Scholar] [CrossRef]

- Mark, U.C.; Madufor, I.C.; Obasi, H.C.; Mark, U. Influence of Filler Loading on the Mechanical and Morphological Properties of Carbonized Coconut Shell Particles Reinforced Polypropylene Composites. J. Compos. Mater. 2020, 54, 397–407. [Google Scholar] [CrossRef]

- Peng, Y.; Nair, S.S.; Chen, H.; Yan, N.; Cao, J. Effects of Lignin Content on Mechanical and Thermal Properties of Polypropylene Composites Reinforced with Micro Particles of Spray Dried Cellulose Nanofibrils. ACS Sustain. Chem. Eng. 2018, 6, 11078–11086. [Google Scholar] [CrossRef]

- Zolfaghari, S.; Paydayesh, A.; Jafari, M. Mechanical and Thermal Properties of Polypropylene/Silica Aerogel Composites. J. Macromol. Sci. Part B 2019, 58, 305–316. [Google Scholar] [CrossRef]

- Liang, J.; Li, F. Measurement of Thermal Conductivity of Hollow Glass-Bead-Filled Polypropylene Composites. Polym. Test. 2006, 25, 527–531. [Google Scholar] [CrossRef]

- Çelebi, H. Thermal Conductivity and Tensile Properties of Hollow Glass Microsphere/Polypropylene Composites. Anadolu Univ. J. Sci. Technol. A-Appl. Sci. Eng. 2017, 18, 746–753. [Google Scholar] [CrossRef]

- Gao, W.; Zheng, Y.; Shen, J.; Guo, S. Electrical Properties of Polypropylene-Based Composites Controlled by Multilayered Distribution of Conductive Particles. ACS Appl. Mater. Interfaces 2015, 7, 1541–1549. [Google Scholar] [CrossRef]

- Panwar, V.; Park, J.; Park, S.; Kumar, S.; Mehra, R. Electrical, Dielectric, and Electromagnetic Shielding Properties of Polypropylene-graphite Composites. J. Appl. Polym. Sci. 2010, 115, 1306–1314. [Google Scholar] [CrossRef]

- Cordin, M.; Bechtold, T.; Pham, T. Effect of Fibre Orientation on the Mechanical Properties of Polypropylene–Lyocell Composites. Cellulose 2018, 25, 7197–7210. [Google Scholar] [CrossRef]

- Sanadi, A.R.; Calufield, D.; Rowell, R.M. Reinforcing Polypropylene with Natural Fibers. Plast. Eng. (USA) 1994, 50, 27–28. [Google Scholar] [CrossRef]

- Unterweger, C.; Brüggemann, O.; Fürst, C. Effects of Different Fibers on the Properties of Short-Fiber-Reinforced Polypropylene Composites. Compos. Sci. Technol. 2014, 103, 49–55. [Google Scholar] [CrossRef]

- Bataille, P.; Ricard, L.; Sapieha, S. Effects of Cellulose Fibers in Polypropylene Composites. Polym. Compos. 1989, 10, 103–108. [Google Scholar] [CrossRef]

- Arutchelvi, J.; Sudhakar, M.; Arkatkar, A.; Doble, M.; Bhaduri, S.; Uppara, P.V. Biodegradation of Polyethylene and Polypropylene. Indian J. Biotechnol. 2008, 7, 9–22. [Google Scholar]

- Chattopadhyay, S.K.; Singh, S.; Pramanik, N.; Niyogi, U.; Khandal, R.; Uppaluri, R.; Ghoshal, A.K. Biodegradability Studies on Natural Fibers Reinforced Polypropylene Composites. J. Appl. Polym. Sci. 2011, 121, 2226–2232. [Google Scholar] [CrossRef]

- Argyropoulos, D.S.; Menachem, S.B. Lignin; Springer: Berlin/Heidelberg, Germany, 1997; ISBN 3-540-61868-6. [Google Scholar]

- Kaczmarek, H.; Ołdak, D.; Malanowski, P.; Chaberska, H. Effect of Short Wavelength UV-Irradiation on Ageing of Polypropylene/Cellulose Compositions. Polym. Degrad. Stab. 2005, 88, 189–198. [Google Scholar] [CrossRef]

- Makarov, I.S.; Golova, L.K.; Smyslov, A.G.; Vinogradov, M.I.; Palchikova, E.E.; Legkov, S.A. Flax Noils as a Source of Cellulose for the Production of Lyocell Fibers. Fibers 2022, 10, 45. [Google Scholar] [CrossRef]

- Yu, M.; Mishra, D.; Cui, Z.; Wang, X.; Lu, Q. Recycling Papermill Waste Lignin into Recyclable and Flowerlike Composites for Effective Oil/Water Separation. Compos. Part B Eng. 2021, 216, 108884. [Google Scholar] [CrossRef]

- Liu, W.; Liu, J.; Zhu, M.; Wang, W.; Wang, L.; Xie, S.; Wang, L.; Yang, X.; He, X.; Sun, Y. Recycling of Lignin and Si Waste for Advanced Si/C Battery Anodes. ACS Appl. Mater. Interfaces 2020, 12, 57055–57063. [Google Scholar] [CrossRef]

- Mikhaylov, P.A.; Zuev, K.V.; Golubev, Y.V.; Kulichikhin, V.G. Fully Aromatic Thermotropic Copolyesters Based on Vanillic, Hydroxybenzoic, and Hydroxybiphenylcarboxylic Acids. Polymers 2024, 16, 1501. [Google Scholar] [CrossRef]

- Agustiany, E.A.; Rasyidur Ridho, M.; Rahmi, D.N.M.; Madyaratri, E.W.; Falah, F.; Lubis, M.A.R.; Solihat, N.N.; Syamani, F.A.; Karungamye, P.; Sohail, A.; et al. Recent Developments in Lignin Modification and Its Application in Lignin-based Green Composites: A Review. Polym. Compos. 2022, 43, 4848–4865. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K.; Raghavan, P.; Kessler, M.R. Progress in Green Polymer Composites from Lignin for Multifunctional Applications: A Review. ACS Sustain. Chem. Eng. 2014, 2, 1072–1092. [Google Scholar] [CrossRef]

- Faruk, O.; Sain, M. Lignin in Polymer Composites; William Andrew: Norwich, NY, USA, 2015; ISBN 0-323-35566-8. [Google Scholar]

- Chen, F.; Dai, H.; Dong, X.; Yang, J.; Zhong, M. Physical Properties of Lignin-based Polypropylene Blends. Polym. Compos. 2011, 32, 1019–1025. [Google Scholar] [CrossRef]

- Toriz, G.; Denes, F.; Young, R.A. Lignin-polypropylene Composites. Part 1: Composites from Unmodified Lignin and Polypropylene. Polym. Compos. 2002, 23, 806–813. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, Y.; Sun, J.; Huang, Y.; Hu, H.; Jiang, R.; Gai, W.; Li, G.; Zhi, C. Polyurethane/Cotton/Carbon Nanotubes Core-Spun Yarn as High Reliability Stretchable Strain Sensor for Human Motion Detection. ACS Appl. Mater. Interfaces 2016, 8, 24837–24843. [Google Scholar] [CrossRef]

- Bourmaud, A.; Pimbert, S. Investigations on Mechanical Properties of Poly(Propylene) and Poly(Lactic Acid) Reinforced by Miscanthus Fibers. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1444–1454. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Biocomposite Consisting of Miscanthus Fiber and Biodegradable Binary Blend Matrix: Compatibilization and Performance Evaluation. RSC Adv. 2017, 7, 27538–27548. [Google Scholar] [CrossRef]

- Makarov, I.S.; Golova, L.K.; Vinogradov, M.I.; Levin, I.S.; Shandryuk, G.A.; Arkharova, N.A.; Golubev, Y.V.; Berkovich, A.K.; Eremin, T.V.; Obraztsova, E.D. The Effect of Alcohol Precipitants on Structural and Morphological Features and Thermal Properties of Lyocell Fibers. Fibers 2020, 8, 43. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, C.; Duan, C.; Hu, H.; Li, H.; Li, J.; Liu, Y.; Ma, X.; Stavik, J.; Ni, Y. Regenerated Cellulose by the Lyocell Process, a Brief Review of the Process and Properties. BioResources 2018, 13, 4577–4592. [Google Scholar] [CrossRef]

- Rosenau, T.; Potthast, A.; Sixta, H.; Kosma, P. The Chemistry of Side Reactions and Byproduct Formation in the System NMMO/Cellulose (Lyocell Process). Prog. Polym. Sci. 2001, 26, 1763–1837. [Google Scholar] [CrossRef]

- Makarov, I.; Vinogradov, M.; Mironova, M.; Shandryuk, G.; Golubev, Y.; Berkovich, A. The Thermal Behavior of Lyocell Fibers Containing Bis(Trimethylsilyl)Acetylene. Polymers 2021, 13, 537. [Google Scholar] [CrossRef] [PubMed]

- Smith, D.; Bampton, R.; Alexander, W. Use of New Solvents for Evaluating Chemical Cellulose for the Viscose Process. Ind. Eng. Chem. Process Des. Dev. 1963, 2, 57–62. [Google Scholar] [CrossRef]

- Wilkes, A.G. The Viscose Process. In Regenerated Cellulose Fibres, 1st ed.; Woodings, C., Ed.; Woodhead publishing Ltd.: Cambridge, UK, 2001; pp. 37–61. [Google Scholar] [CrossRef]

- Mitchell, R. Viscose Processing of Cellulose. Ind. Eng. Chem. 1949, 41, 2197–2201. [Google Scholar] [CrossRef]

- Klemm, D.; Schumann, D.; Kramer, F.; Heßler, N.; Hornung, M.; Schmauder, H.-P.; Marsch, S. Nanocelluloses as Innovative Polymers in Research and Application. In Polysaccharides II; Klemm, D., Ed.; Advances in Polymer Science; Springer: Berlin/Heidelberg, Germany, 2006; Volume 205, pp. 49–96. ISBN 978-3-540-37102-1. [Google Scholar]

- Wang, W.; Mozuch, M.D.; Sabo, R.C.; Kersten, P.; Zhu, J.Y.; Jin, Y. Production of Cellulose Nanofibrils from Bleached Eucalyptus Fibers by Hyperthermostable Endoglucanase Treatment and Subsequent Microfluidization. Cellulose 2015, 22, 351–361. [Google Scholar] [CrossRef]

- Belgacem, M.N.; Gandini, A. The Surface Modification of Cellulose Fibres for Use as Reinforcing Elements in Composite Materials. Compos. Interfaces 2005, 12, 41–75. [Google Scholar] [CrossRef]

- Ito, H.; Hattori, H.; Hirai, S.; Okamoto, T.; Takatani, M. Effect of Spherical Silica on the Molding and Properties of Cellulose/Plastic Composite with High Cellulose Content. J. Wood Chem. Technol. 2010, 30, 175–185. [Google Scholar] [CrossRef]

- Li, Y.; He, H.; Huang, B.; Zhou, L.; Yu, P.; Lv, Z. In Situ Fabrication of Cellulose Nanocrystal-silica Hybrids and Its Application in UHMWPE: Rheological, Thermal, and Wear Resistance Properties. Polym. Compos. 2018, 39, E1701–E1713. [Google Scholar] [CrossRef]

- Alcock, B.; Cabrera, N.O.; Barkoula, N.-M.; Loos, J.; Peijs, T. The Mechanical Properties of Unidirectional All-Polypropylene Composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 716–726. [Google Scholar] [CrossRef]

- Orouji, M.; Zahrai, S.M.; Najaf, E. Effect of Glass Powder & Polypropylene Fibers on Compressive and Flexural Strengths, Toughness and Ductility of Concrete: An Environmental Approach. Structures 2021, 33, 4616–4628. [Google Scholar] [CrossRef]

- Serenko, O.A.; Shevchenko, V.G.; Zhiltsov, A.S.; Chuprakov, V.E.; Zaderenko, T.V.; Gritsenko, O.T.; Mironova, M.V.; Gorbatsevich, O.B.; Kazakova, V.V.; Kulichikhin, V.G.; et al. Structure and Properties of Composites Based on Polyethylene Oxide and Molecular Silicasol. Nanotechnol. Russ. 2013, 8, 81–91. [Google Scholar] [CrossRef]

- Serenko, O.A.; Mironova, M.V.; Novozhilova, N.A.; Strashnov, P.V.; Getmanova, E.V.; Askadskii, A.A.; Shevchenko, V.G.; Kulichikhin, V.G.; Muzafarov, A.M. Effect of the Rigid Core of the Filler on the Properties of Melt-Mixed Polystyrene/Core–Shell Particle Nanocomposites. Mater. Chem. Phys. 2015, 156, 16–28. [Google Scholar] [CrossRef]

- Fan, Y.; Zhu, Z.; Luan, J.; Liu, Y. Exploring the Application Method of Bamboo Powder in Promoting the Development of Sustainable Outdoor Furniture. Sustainability 2024, 16, 11282. [Google Scholar] [CrossRef]

- Ge, S.; Ouyang, H.; Ye, H.; Shi, Y.; Sheng, Y.; Peng, W. High-Performance and Environmentally Friendly Acrylonitrile Butadiene Styrene/Wood Composite for Versatile Applications in Furniture and Construction. Adv. Compos. Hybrid Mater. 2023, 6, 44. [Google Scholar] [CrossRef]

- Dybka-Stępień, K.; Antolak, H.; Kmiotek, M.; Piechota, D.; Koziróg, A. Disposable Food Packaging and Serving Materials—Trends and Biodegradability. Polymers 2021, 13, 3606. [Google Scholar] [CrossRef] [PubMed]

- Renner, J.; Evans, B.; Hirth, G. On the Rheologically Critical Melt Fraction. Earth Planet. Sci. Lett. 2000, 181, 585–594. [Google Scholar] [CrossRef]

- Costa, A. Viscosity of High Crystal Content Melts: Dependence on Solid Fraction. Geophys. Res. Lett. 2005, 32, 2005GL024303. [Google Scholar] [CrossRef]

- Skvortsov, I.Y.u.; Varfolomeeva, L.A.; Kulichikhin, V.G. The Effect of Tetraethoxysilane on the Phase State, Rheological Properties, and Coagulation Features of Polyacrylonitrile Solutions. Colloid J. 2019, 81, 165–175. [Google Scholar] [CrossRef]

- Varfolomeeva, L.A.; Skvortsov, I.Y.u.; Levin, I.S.; Shandryuk, G.A.; Patsaev, T.D.; Kulichikhin, V.G. Polyacrylonitrile Fibers with a Gradient Silica Distribution as Precursors of Carbon-Silicon-Carbide Fibers. Polymers 2023, 15, 2579. [Google Scholar] [CrossRef]

- Yashiro, S.; Sasaki, H.; Sakaida, Y. Particle Simulation for Predicting Fiber Motion in Injection Molding of Short-Fiber-Reinforced Composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1754–1764. [Google Scholar] [CrossRef]

- Park, S.J.; Ahn, S.; Kang, T.G.; Chung, S.-T.; Kwon, Y.-S.; Chung, S.H.; Kim, S.-G.; Kim, S.; Atre, S.V.; Lee, S. A Review of Computer Simulations in Powder Injection Molding. Int. J. Powder Met. 2010, 46, 37–46. [Google Scholar]

- Park, J.M.; Park, S.J. Modeling and Simulation of Fiber Orientation in Injection Molding of Polymer Composites. Math. Probl. Eng. 2011, 2011, 105637. [Google Scholar] [CrossRef]

- Annicchiarico, D.; Alcock, J.R. Review of Factors That Affect Shrinkage of Molded Part in Injection Molding. Mater. Manuf. Process. 2014, 29, 662–682. [Google Scholar] [CrossRef]

- Karacaer, Ö.; Polat, T.N.; Tezvergıl, A.; Lassıla, L.V.J.; Vallıttu, P.K. The Effect of Length and Concentration of Glass Fibers on the Mechanical Properties of an Injection- and a Compression-Molded Denture Base Polymer. J. Prosthet. Dent. 2003, 90, 385–393. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Park, O.O. Effect of Fiber Length on Mechanical Properties of Injection Molded Long-Fiber-Reinforced Thermoplastics. Macromol. Res. 2020, 28, 433–444. [Google Scholar] [CrossRef]

- Jansen, K.M.B.; Van Dijk, D.J.; Husselman, M.H. Effect of Processing Conditions on Shrinkage in Injection Molding. Polym. Eng. Sci 1998, 38, 838–846. [Google Scholar] [CrossRef]

- Pomerleau, J.; Sanschagrin, B. Injection Molding Shrinkage of PP: Experimental Progress. Polym. Eng. Sci 2006, 46, 1275–1283. [Google Scholar] [CrossRef]

- Shambilova, G.K.; Iskakov, R.M.; Bukanova, A.S.; Kairliyeva, F.B.; Kalauova, A.S.; Kuzin, M.S.; Novikov, E.M.; Gerasimenko, P.S.; Makarov, I.S.; Skvortsov, I.Y. Polypropylene Crystallinity Reduction through the Synergistic Effects of Cellulose and Silica Formed via Sol–Gel Synthesis. Polymers 2024, 16, 2855. [Google Scholar] [CrossRef]

- Kumar, P.V.; Gupta, G.S. Study of Formation of Silicon Carbide in the Acheson Process. Steel Res. 2002, 73, 31–38. [Google Scholar] [CrossRef]

- Golova, L.K.; Makarov, I.S.; Bondarenko, G.N.; Mironova, M.V.; Berkovich, A.K.; Shandryuk, G.A.; Vinogradov, M.I.; Bermeshev, M.V.; Kulichikhin, V.G. Composite Fibers Based on Cellulose and Vinyltriethoxysilane as Precursors of Carbon Materials. Polym. Sci. Ser. B 2020, 62, 152–162. [Google Scholar] [CrossRef]

- Lin, Y.-J.; Tsang, C.-P. The Effects of Starting Precursors on the Carbothermal Synthesis of SiC Powders. Ceram. Int. 2003, 29, 69–75. [Google Scholar] [CrossRef]

- Youm, M.R.; Yun, S.-I.; Choi, S.C.; Park, S.W. Synthesis of β-SiC Powders by the Carbothermal Reduction of Porous SiO2–C Hybrid Precursors with Controlled Surface Area. Ceram. Int. 2020, 46, 4870–4877. [Google Scholar] [CrossRef]

- Makarov, I.S.; Golova, L.K.; Mironova, M.V.; Vinogradov, M.I.; Bermeshev, M.V.; Berkovich, A.K.; Kulichikhin, V.G. Structural and Morphological Features of Carbon—Silicon-Carbide Fibers Based on Cellulose and Triethoxyvinylsilane. Fibre Chem. 2018, 50, 79–84. [Google Scholar] [CrossRef]

- Govorov, V.; Malkin, A. Physics of Ceramic Powder Injection Molding Technology. Int. J. Adv. Multidisc. Res. Stud. 2024, 4, 517–524. [Google Scholar] [CrossRef]

- Slonov, A.L.; Zhansitov, A.A.; Musov, K.V.; Tlupov, A.F.; Baykaziev, A.E.; Rzhevskaya, E.V.; Khashirova, S.Y.; Malkin, A.Y. Powder Casting of Polyetheretherketone and Polyphenylene Sulfone: Sintering. Powder Technol. 2025, 451, 120449. [Google Scholar] [CrossRef]

- Siedlecki, K.; Słoma, M.; Skalski, A. Comparison between Micro-Powder Injection Molding and Material Extrusion Additive Manufacturing of Metal Powders for the Fabrication of Sintered Components. Materials 2023, 16, 7268. [Google Scholar] [CrossRef]

- Momeni, V.; Hufnagl, M.; Shahroodi, Z.; Gonzalez-Gutierrez, J.; Schuschnigg, S.; Kukla, C.; Holzer, C. Research Progress on Low-Pressure Powder Injection Molding. Materials 2022, 16, 379. [Google Scholar] [CrossRef]

- ISO 527-5:2009; Plastics—Determination of Tensile Properties—Part 5: Test Conditions for Unidirectional Fibrereinforced Plastics Composites. ISO: Geneva, Switzerland, 2009.

- ISO 604:2002; Plastics—Determination of Compressive Properties. ISO: Geneva, Switzerland, 2002.

- GOST 15139-69; Plastics—Methods for the Determination of Density (Mass Density). State Committee of the Ussr for Standards: Moscow, Russia, 1969.

- GOST P 56810-2015; Polymer Composites. Test Method for Flexural Flat Samples. Standartinform: Moscow, Russia, 2015.

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ISO 178; Plastics—Determination of Flexural Properties. ISO: Geneva, Switzerland, 2010.

- Auras, R.; Harte, B.; Selke, S. An Overview of Polylactides as Packaging Materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef]

- Owen, S.R.; Harper, J.F. Mechanical, Microscopical and Fire Retardant Studies of ABS Polymers. Polym. Degrad. Stab. 1999, 64, 449–455. [Google Scholar] [CrossRef]

- Tunçel, O.; Kahya, Ç.; Tüfekci, K. Optimization of Flexural Performance of PETG Samples Produced by Fused Filament Fabrication with Response Surface Method. Polymers 2024, 16, 2020. [Google Scholar] [CrossRef]

| Sample Abbreviation | Component Concentration, wt.% | ||

|---|---|---|---|

| Polypropylene | Cellulose | ES-40 | |

| 100-0-0 | 100 | 0 | 0 |

| 85-15-0 | 85 | 15 | 0 |

| 85-0-15 | 85 | 0 | 15 |

| 85-1-14 | 85 | 0.8 | 14.2 |

| 85-2-13 | 85 | 1.5 | 13.5 |

| 22-4-74 | 22.1 | 3.9 | 74 |

| 54-17-29 | 54 | 17 | 29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iskakov, R.M.; Bukanova, A.S.; Kalauova, A.S.; Kairliyeva, F.B.; Nauashev, A.N.; Shambilova, G.K.; Obidin, I.M.; Kuzin, M.S.; Chernenko, D.N.; Patsaev, T.D.; et al. Eco-Friendly Polypropylene Composites Reinforced with Cellulose Fibers and Silica Nanoparticles. Polymers 2025, 17, 1290. https://doi.org/10.3390/polym17101290

Iskakov RM, Bukanova AS, Kalauova AS, Kairliyeva FB, Nauashev AN, Shambilova GK, Obidin IM, Kuzin MS, Chernenko DN, Patsaev TD, et al. Eco-Friendly Polypropylene Composites Reinforced with Cellulose Fibers and Silica Nanoparticles. Polymers. 2025; 17(10):1290. https://doi.org/10.3390/polym17101290

Chicago/Turabian StyleIskakov, Rinat M., Aigul S. Bukanova, Altynay S. Kalauova, Fazilat B. Kairliyeva, Alimzhan N. Nauashev, Gulbarshin K. Shambilova, Ivan M. Obidin, Mikhail S. Kuzin, Dmitryi N. Chernenko, Timofey D. Patsaev, and et al. 2025. "Eco-Friendly Polypropylene Composites Reinforced with Cellulose Fibers and Silica Nanoparticles" Polymers 17, no. 10: 1290. https://doi.org/10.3390/polym17101290

APA StyleIskakov, R. M., Bukanova, A. S., Kalauova, A. S., Kairliyeva, F. B., Nauashev, A. N., Shambilova, G. K., Obidin, I. M., Kuzin, M. S., Chernenko, D. N., Patsaev, T. D., Gerasimenko, P. S., Makarov, I. S., & Skvortsov, I. Y. (2025). Eco-Friendly Polypropylene Composites Reinforced with Cellulose Fibers and Silica Nanoparticles. Polymers, 17(10), 1290. https://doi.org/10.3390/polym17101290