Study on the Electrospinning Fabrication of PCL/CNTs Fiber Membranes and Their Oil–Water Separation Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Fibrous Membranes

2.2.1. Preparation of Pure PCL Fibrous Membrane

2.2.2. Preparation of PCL/CNTs Composite Fibrous Membrane

2.3. Characterization

2.3.1. Morphological Characterization

2.3.2. Wettability Characterization

2.3.3. Porosity Characterization

2.3.4. Fiber Orientation Quantification (Hermans Orientation Factor)

2.3.5. Oil–Water Separation Performance Evaluation

3. Results and Discussion

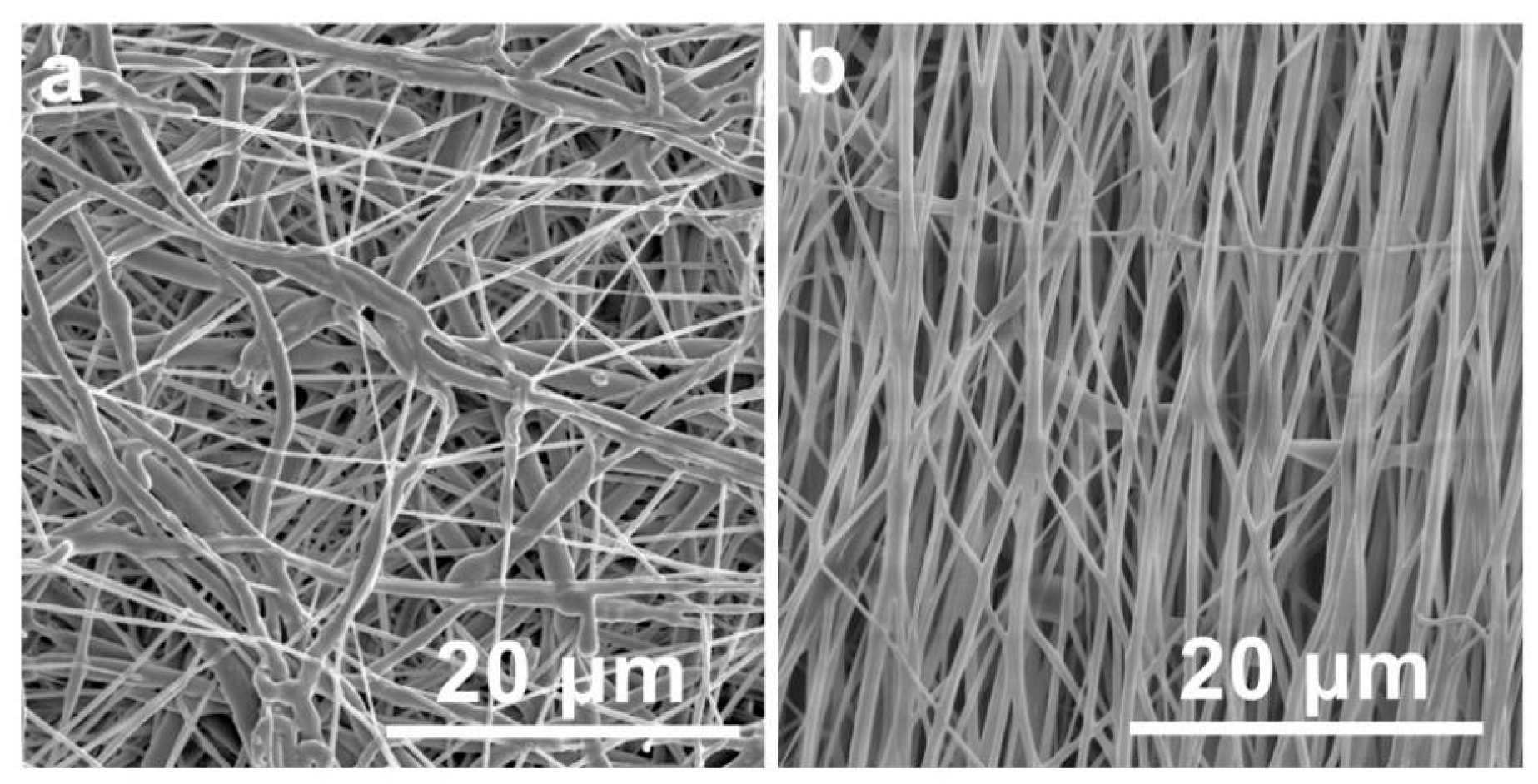

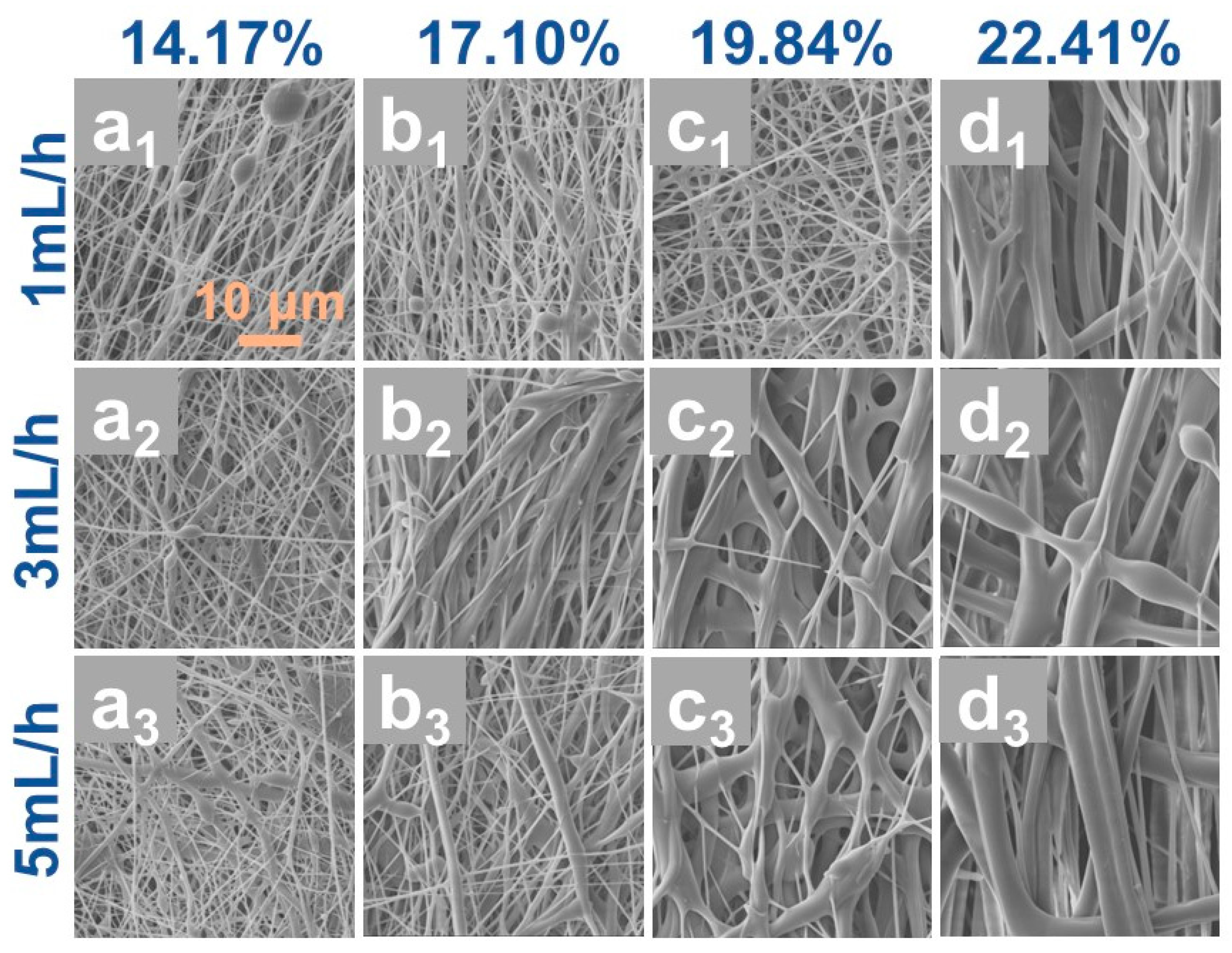

3.1. Study on the Optimal Electrospinning Parameters for PCL

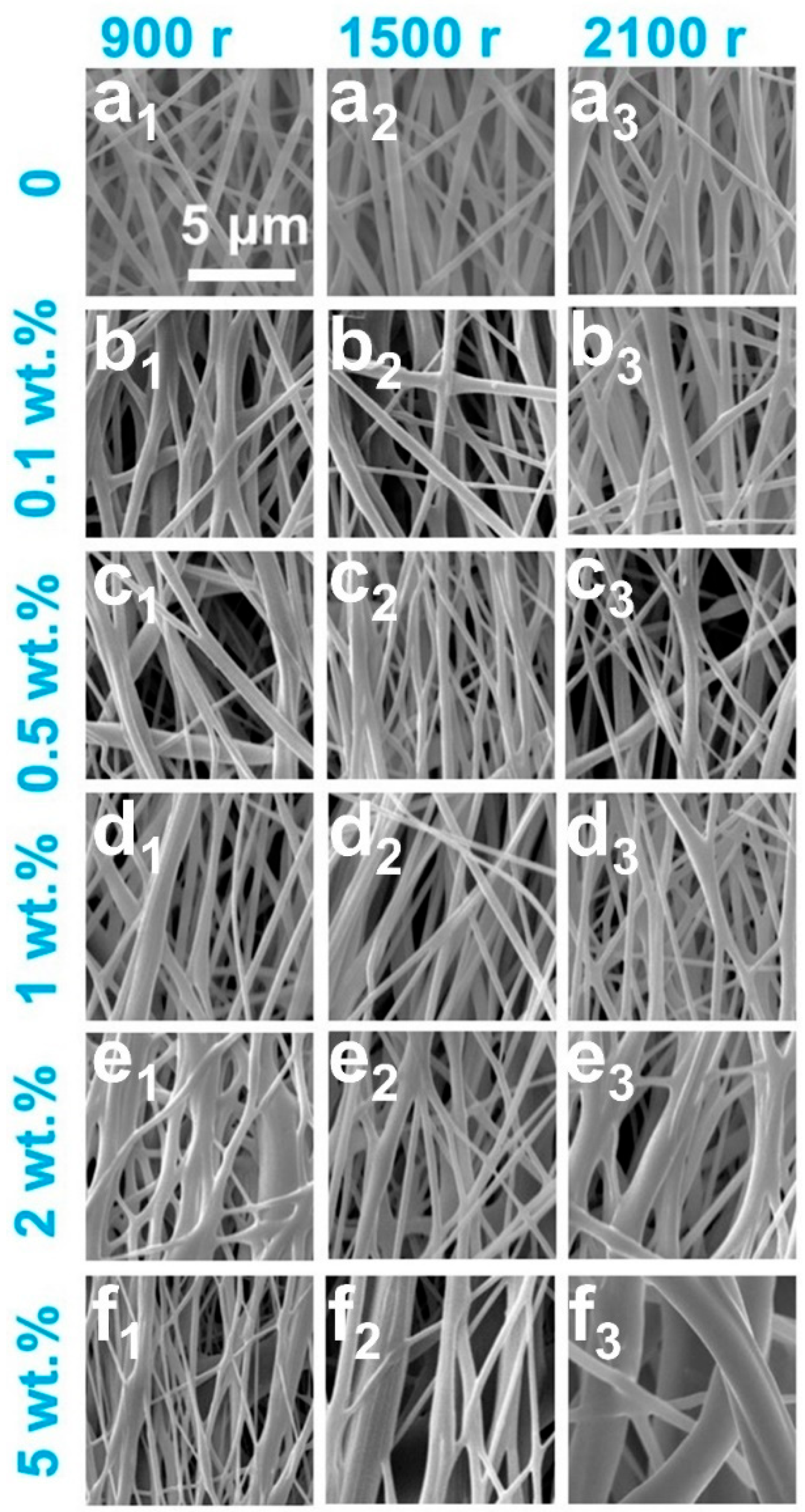

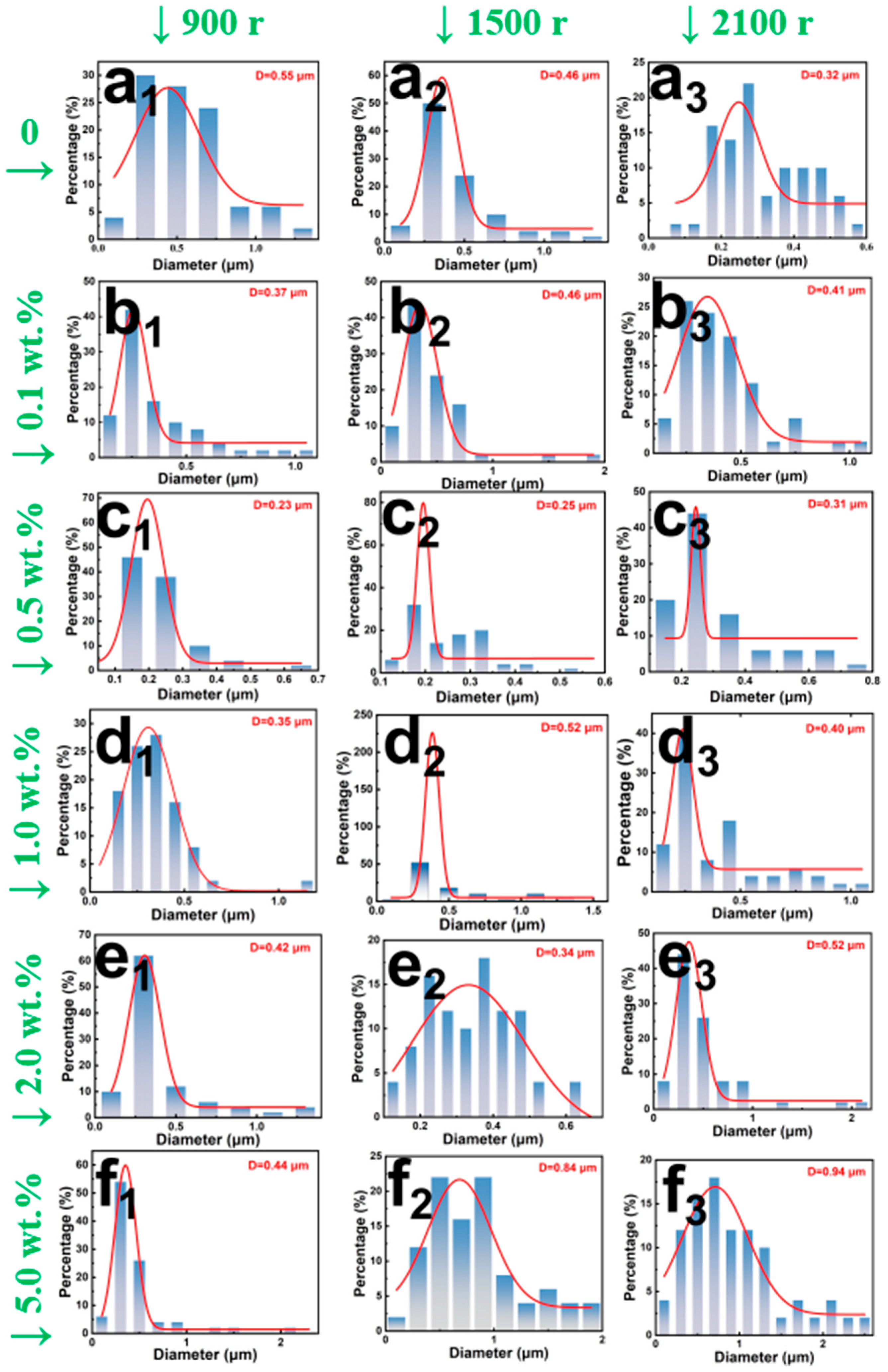

3.2. Influence of CNTs Content on the Morphology of Fiber Membranes

3.3. Impact of CNTs Content on Hydrophobic Properties of Different Fiber Membranes

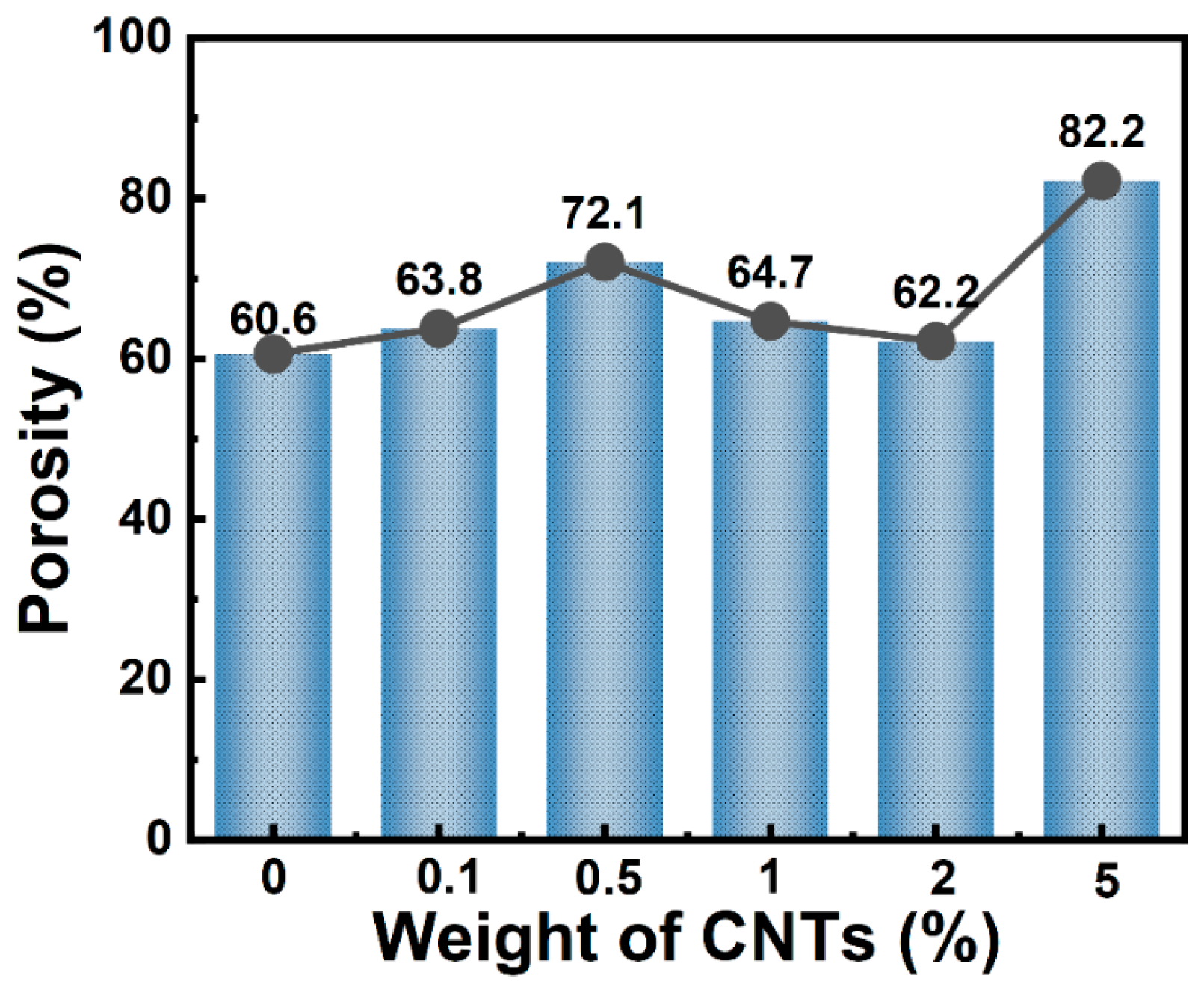

3.4. Porosity Evolution with CNTs Incorporation in Fiber Membranes

3.5. Evaluation of Oil–Water Separation Efficacy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gupta, P.; Rajput, M.; Singla, N.; Kumar, V.; Lahiri, D. Electric field and current assisted alignment of CNT inside polymer matrix and its effects on electrical and mechanical properties. Polymer 2016, 89, 119–127. [Google Scholar] [CrossRef]

- Shi, D.; He, P.; Lian, J.; Chaud, X.; Bud’ko, S.L.; Beaugnon, E.; Wang, L.M.; Ewing, R.C.; Tournier, R. Magnetic alignment of carbon nanofibers in polymer composites and anisotropy of mechanical properties. J. Appl. Phys. 2005, 97, 064312. [Google Scholar] [CrossRef]

- Robinson, A.J.; Perez-Nava, A.; Ali, S.C.; Gonzalez-Campos, J.B.; Holloway, J.L.; Cosgriff-Hernandez, E.M. Comparative Analysis of Fiber Alignment Methods in Electrospinning. Matter 2021, 4, 821–844. [Google Scholar] [CrossRef]

- Stachewicz, U.; Dijksman, J.F.; Soudani, C.; Tunnicliffe, L.B.; Busfield, J.J.C.; Barber, A.H. Surface free energy analysis of electrospun fibers based on Rayleigh-Plateau/Weber instabilities. Eur. Polym. J. 2017, 91, 368–375. [Google Scholar] [CrossRef]

- Ray, S.S.; Chen, S.-S.; Li, C.-W.; Nguyen, N.C.; Nguyen, H.T. A comprehensive review: Electrospinning technique for fabrication and surface modification of membranes for water treatment application. RSC Adv. 2016, 6, 85495–85514. [Google Scholar] [CrossRef]

- Ali, A.; Rahimian Koloor, S.S.; Alshehri, A.H.; Arockiarajan, A. Carbon nanotube characteristics and enhancement effects on the mechanical features of polymer-based materials and structures—A review. J. Mater. Res. Technol. 2023, 24, 6495–6521. [Google Scholar] [CrossRef]

- Long, J.C.; Zhan, H.; Wu, G.; Zhang, Y.; Wang, J.N. High-strength carbon nanotube/epoxy resin composite film from a controllable cross-linking reaction. Compos. Part A Appl. Sci. Manuf. 2021, 146, 106409. [Google Scholar] [CrossRef]

- Pichtel, J. Oil and Gas Production Wastewater: Soil Contamination and Pollution Prevention. Appl. Environ. Soil Sci. 2016, 2016, 2707989. [Google Scholar] [CrossRef]

- Stickland, A.D.; Burgess, C.; Dixon, D.R.; Harbour, P.J.; Scales, P.J.; Studer, L.J.; Usher, S.P. Fundamental dewatering properties of wastewater treatment sludges from filtration and sedimentation testing. Chem. Eng. Sci. 2008, 63, 5283–5290. [Google Scholar] [CrossRef]

- Rashid, R.; Shafiq, I.; Akhter, P.; Iqbal, M.J.; Hussain, M. A state-of-the-art review on wastewater treatment techniques: The effectiveness of adsorption method. Env. Sci. Pollut. Res. Int. 2021, 28, 9050–9066. [Google Scholar] [CrossRef]

- Abuhasel, K.; Kchaou, M.; Alquraish, M.; Munusamy, Y.; Jeng, Y.T. Oily Wastewater Treatment: Overview of Conventional and Modern Methods, Challenges, and Future Opportunities. Water 2021, 13, 980. [Google Scholar] [CrossRef]

- Deng, Y.; Peng, C.; Dai, M.; Lin, D.; Ali, I.; Alhewairini, S.S.; Zheng, X.; Chen, G.; Li, J.; Naz, I. Recent development of super-wettable materials and their applications in oil-water separation. J. Clean. Prod. 2020, 266, 121624. [Google Scholar] [CrossRef]

- Yong, J.; Huo, J.; Chen, F.; Yang, Q.; Hou, X. Oil/water separation based on natural materials with super-wettability: Recent advances. Phys. Chem. Chem. Phys. 2018, 20, 25140–25163. [Google Scholar] [CrossRef]

- Ma, Q.; Cheng, H.; Fane, A.G.; Wang, R.; Zhang, H. Recent Development of Advanced Materials with Special Wettability for Selective Oil/Water Separation. Small 2016, 12, 2186–2202. [Google Scholar] [CrossRef]

- Wang, F.; Liu, K.; Xi, Y.; Li, Z. One-step electrospinning PCL/ph-LPSQ nanofibrous membrane with excellent self-cleaning and oil-water separation performance. Polymer 2022, 249, 124858. [Google Scholar] [CrossRef]

- Cui, C.; Sun, S.; Li, X.; Chen, S.; Wu, S.; Zhou, F.; Ma, J. Optimizing the chitosan-PCL based membranes with random/aligned fiber structure for controlled ciprofloxacin delivery and wound healing. Int. J. Biol. Macromol. 2022, 205, 500–510. [Google Scholar] [CrossRef]

- Mochane, M.J.; Motsoeneng, T.S.; Sadiku, E.R.; Mokhena, T.C.; Sefadi, J.S. Morphology and Properties of Electrospun PCL and Its Composites for Medical Applications: A Mini Review. Appl. Sci. 2019, 9, 2205. [Google Scholar] [CrossRef]

- Niezabitowska, E.; Smith, J.; Prestly, M.R.; Akhtar, R.; von Aulock, F.W.; Lavallee, Y.; Ali-Boucetta, H.; McDonald, T.O. Facile production of nanocomposites of carbon nanotubes and polycaprolactone with high aspect ratios with potential applications in drug delivery. RSC Adv. 2018, 8, 16444–16454. [Google Scholar] [CrossRef]

- Yang, W.; Li, C.; Han, L. Mechanical properties of polycaprolactone bone scaffolds reinforced with carbon nanotube-modified tricalcium phosphate. Carbon Lett. 2024, 35, 267–276. [Google Scholar] [CrossRef]

- Scaffaro, R.; Gammino, M. 3D wet-electrospun “branch leaf” graphene oxide polycaprolactone fibers structure for enhancing oil-water separation treatment performance in a multi-scale design. Sustain. Mater. Technol. 2025, 43, e01200. [Google Scholar] [CrossRef]

- Scaffaro, R.; Gammino, M.; Maio, A. Hierarchically Structured Hybrid Membranes for Continuous Wastewater Treatment via the Integration of Adsorption and Membrane Ultrafiltration Mechanisms. Polymers 2022, 15, 156. [Google Scholar] [CrossRef] [PubMed]

- Alfaro De Prá, M.A.; Ribeiro-do-Valle, R.M.; Maraschin, M.; Veleirinho, B. Effect of collector design on the morphological properties of polycaprolactone electrospun fibers. Mater. Lett. 2017, 193, 154–157. [Google Scholar] [CrossRef]

- Van der Schueren, L.; De Schoenmaker, B.; Kalaoglu, Ö.I.; De Clerck, K. An alternative solvent system for the steady state electrospinning of polycaprolactone. Eur. Polym. J. 2011, 47, 1256–1263. [Google Scholar] [CrossRef]

- Khan, M.T.; Mamun, M.A. Effect of Different Solvent Systems on Fiber Morphology and Property of Electrospun PCL Nano Fibers. Tekst. Muhendis 2021, 28, 61–76. [Google Scholar] [CrossRef]

- Li, X.; Li, Z.; Wang, L.; Ma, G.; Meng, F.; Pritchard, R.H.; Gill, E.L.; Liu, Y.; Huang, Y.Y. Low-Voltage Continuous Electrospinning Patterning. ACS Appl. Mater. Interfaces 2016, 8, 32120–32131. [Google Scholar] [CrossRef]

- Cramariuc, B.; Cramariuc, R.; Scarlet, R.; Manea, L.R.; Lupu, I.G.; Cramariuc, O. Fiber diameter in electrospinning process. J. Electrost. 2013, 71, 189–198. [Google Scholar] [CrossRef]

- Rutledge, G.C.; Fridrikh, S.V. Formation of fibers by electrospinning. Adv. Drug Deliv. Rev. 2007, 59, 1384–1391. [Google Scholar] [CrossRef]

- Baji, A.; Mai, Y.-W.; Wong, S.-C.; Abtahi, M.; Chen, P. Electrospinning of polymer nanofibers: Effects on oriented morphology, structures and tensile properties. Compos. Sci. Technol. 2010, 70, 703–718. [Google Scholar] [CrossRef]

- Chinnappan, B.A.; Krishnaswamy, M.; Xu, H.; Hoque, M.E. Electrospinning of Biomedical Nanofibers/Nanomembranes: Effects of Process Parameters. Polymers 2022, 14, 3719. [Google Scholar] [CrossRef]

- Ghaderpour, A.; Hoseinkhani, Z.; Yarani, R.; Mohammadiani, S.; Amiri, F.; Mansouri, K. Altering the characterization of nanofibers by changing the electrospinning parameters and their application in tissue engineering, drug delivery, and gene delivery systems. Polym. Adv. Technol. 2021, 32, 1924–1950. [Google Scholar] [CrossRef]

- Ye, D.; Ding, Y.; Duan, Y.; Su, J.; Yin, Z.; Huang, Y.A. Large-Scale Direct-Writing of Aligned Nanofibers for Flexible Electronics. Small 2018, 14, e1703521. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Bu, X.; Wang, X.; Ni, C.; Ma, G.; Sun, Y.; Xie, G.; Bilal, M.; Alheshibri, M.; Hassanzadeh, A.; et al. Effects of surface roughness on the hydrophilic particles-air bubble attachment. J. Mater. Res. Technol. 2022, 18, 3884–3893. [Google Scholar] [CrossRef]

- Langley, K.R.; Li, E.Q.; Vakarelski, I.U.; Thoroddsen, S.T. The air entrapment under a drop impacting on a nano-rough surface. Soft Matter 2018, 14, 7586–7596. [Google Scholar] [CrossRef]

- Yan, K.-K.; Jiao, L.; Lin, S.; Ji, X.; Lu, Y.; Zhang, L. Superhydrophobic electrospun nanofiber membrane coated by carbon nanotubes network for membrane distillation. Desalination 2018, 437, 26–33. [Google Scholar] [CrossRef]

- Tijing, L.D.; Woo, Y.C.; Shim, W.-G.; He, T.; Choi, J.-S.; Kim, S.-H.; Shon, H.K. Superhydrophobic nanofiber membrane containing carbon nanotubes for high-performance direct contact membrane distillation. J. Membr. Sci. 2016, 502, 158–170. [Google Scholar] [CrossRef]

- Xu, H.; Liu, H.; Huang, Y.; Xiao, C. Three-dimensional structure design of tubular polyvinyl chloride hybrid nanofiber membranes for water-in-oil emulsion separation. J. Membr. Sci. 2021, 620, 118905. [Google Scholar] [CrossRef]

- Gao, J.; Wang, J.; Xu, Q.; Wu, S.; Chen, Y. Regenerated cellulose strongly adhered by a supramolecular adhesive onto the PVDF membrane for a highly efficient oil/water separation. Green Chem. 2021, 23, 5633–5646. [Google Scholar] [CrossRef]

- Deng, W.; Fan, T.; Li, Y. In situ biomineralization-constructed superhydrophilic and underwater superoleophobic PVDF-TiO2 membranes for superior antifouling separation of oil-in-water emulsions. J. Membr. Sci. 2021, 622, 119030. [Google Scholar] [CrossRef]

- Asad, A.; Rastgar, M.; Sameoto, D.; Sadrzadeh, M. Gravity assisted super high flux microfiltration polyamide-imide membranes for oil/water emulsion separation. J. Membr. Sci. 2021, 621, 119019. [Google Scholar] [CrossRef]

- Xiong, Z.; He, Z.; Mahmud, S.; Yang, Y.; Zhou, L.; Hu, C.; Zhao, S. Simple Amphoteric Charge Strategy to Reinforce Superhydrophilic Polyvinylidene Fluoride Membrane for Highly Efficient Separation of Various Surfactant-Stabilized Oil-in-Water Emulsions. ACS Appl. Mater. Interfaces 2020, 12, 47018–47028. [Google Scholar] [CrossRef]

- Faraji, M.; Nabavi, S.R.; Salimi-Kenari, H. Fabrication of a PAN–PA6/PANI membrane using dual spinneret electrospinning followed byin situpolymerization for separation of oil-in-water emulsions. New J. Chem. 2020, 44, 13488–13500. [Google Scholar] [CrossRef]

- Chen, X.; Chen, D.; Li, N.; Xu, Q.; Li, H.; He, J.; Lu, J. Modified-MOF-808-Loaded Polyacrylonitrile Membrane for Highly Efficient, Simultaneous Emulsion Separation and Heavy Metal Ion Removal. ACS Appl. Mater. Interfaces 2020, 12, 39227–39235. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Shen, Y.; Li, M.; Zhu, G.; Feng, H.; Li, J. Egg Shell Powders-Coated Membrane for Surfactant-Stabilized Crude Oil-in-Water Emulsions Efficient Separation. ACS Sustain. Chem. Eng. 2019, 7, 10880–10887. [Google Scholar] [CrossRef]

- Khodadousti, S.; Zokaee Ashtiani, F.; Karimi, M.; Fouladitajar, A. Preparation and characterization of novel PES-(SiO2-g-PMAA) membranes with antifouling and hydrophilic properties for separation of oil-in-water emulsions. Polym. Adv. Technol. 2019, 30, 2221–2232. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, G.; Bai, R.; Shen, S.; Zhou, X.; Wyman, I. Fabrication of superhydrophilic and underwater superoleophobic membranes via an in situ crosslinking blend strategy for highly efficient oil/water emulsion separation. J. Membr. Sci. 2019, 569, 60–70. [Google Scholar] [CrossRef]

- Xu, S.; Ren, L.F.; Zhou, Q.; Bai, H.; Li, J.; Shao, J. Facile ZIF-8 functionalized hierarchical micronanofiber membrane for high-efficiency separation of water-in-oil emulsions. J. Appl. Polym. Sci. 2018, 135, 46462. [Google Scholar] [CrossRef]

| 0 | 0.1 wt.% | 0.5 wt.% | 1.0 wt.% | 2.0 wt.% | 5.0 wt.% | |

|---|---|---|---|---|---|---|

| 900 rpm | 0.80 | 0.82 | 0.84 | 0.90 | 0.76 | 0.77 |

| 1500 rpm | 0.89 | 0.92 | 0.80 | 0.83 | 0.88 | 0.79 |

| 2100 rpm | 0.91 | 0.84 | 0.74 | 0.80 | 0.80 | 0.80 |

| Material | Permeation Flux (LMH) | Separation Efficiency (%) | Type of Emulsion | Number of Cycles | Reference |

|---|---|---|---|---|---|

| PCL/CNTs | 1000 | >90 | O/W | 10 | This work |

| PVC/SiO2 | 358 | 95 | O/W | 10 | [36] |

| PVDF/PVA | 318 | 99.9 | O/W | 30 | [37] |

| PVDF/TiO2 | 400 | 99.7 | O/W | 5 | [38] |

| PAI/HFPS | 440 | 99.9 | O/W | 18 | [39] |

| PVDF/PDA/PEI | 233 | 85 | O/W | 3 | [40] |

| PAN-PA6/PANI | 326 | 97.8 | O/W | 5 | [41] |

| PAN/MOF | 380 | 99.97 | O/W | 10 | [42] |

| PVDF/ESP | 229 | 99.5 | O/W | 10 | [43] |

| PES/SiO2-g-PMAA | 143 | 98 | O/W | - | [44] |

| PMMA/PEI/PVDF | 90 | 99.3 | O/W | 10 | [45] |

| PVDF/ZnO | 1.11 | 93 | O/W | - | [46] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, D.; Li, Y.; Zheng, Y.; Chen, J.; Zhang, X.; Li, K.; Shen, J.; Guo, X. Study on the Electrospinning Fabrication of PCL/CNTs Fiber Membranes and Their Oil–Water Separation Performance. Polymers 2025, 17, 1705. https://doi.org/10.3390/polym17121705

Feng D, Li Y, Zheng Y, Chen J, Zhang X, Li K, Shen J, Guo X. Study on the Electrospinning Fabrication of PCL/CNTs Fiber Membranes and Their Oil–Water Separation Performance. Polymers. 2025; 17(12):1705. https://doi.org/10.3390/polym17121705

Chicago/Turabian StyleFeng, Desheng, Yanru Li, Yanjun Zheng, Jinlong Chen, Xiaoli Zhang, Kun Li, Junfang Shen, and Xiaoqin Guo. 2025. "Study on the Electrospinning Fabrication of PCL/CNTs Fiber Membranes and Their Oil–Water Separation Performance" Polymers 17, no. 12: 1705. https://doi.org/10.3390/polym17121705

APA StyleFeng, D., Li, Y., Zheng, Y., Chen, J., Zhang, X., Li, K., Shen, J., & Guo, X. (2025). Study on the Electrospinning Fabrication of PCL/CNTs Fiber Membranes and Their Oil–Water Separation Performance. Polymers, 17(12), 1705. https://doi.org/10.3390/polym17121705