Analyzing the Potential of Laser Femtosecond Technology for the Mass Production of Cyclic Olefin Copolymer Microfluidic Devices for Biomedical Applications

Abstract

1. Introduction

2. Materials and Methods

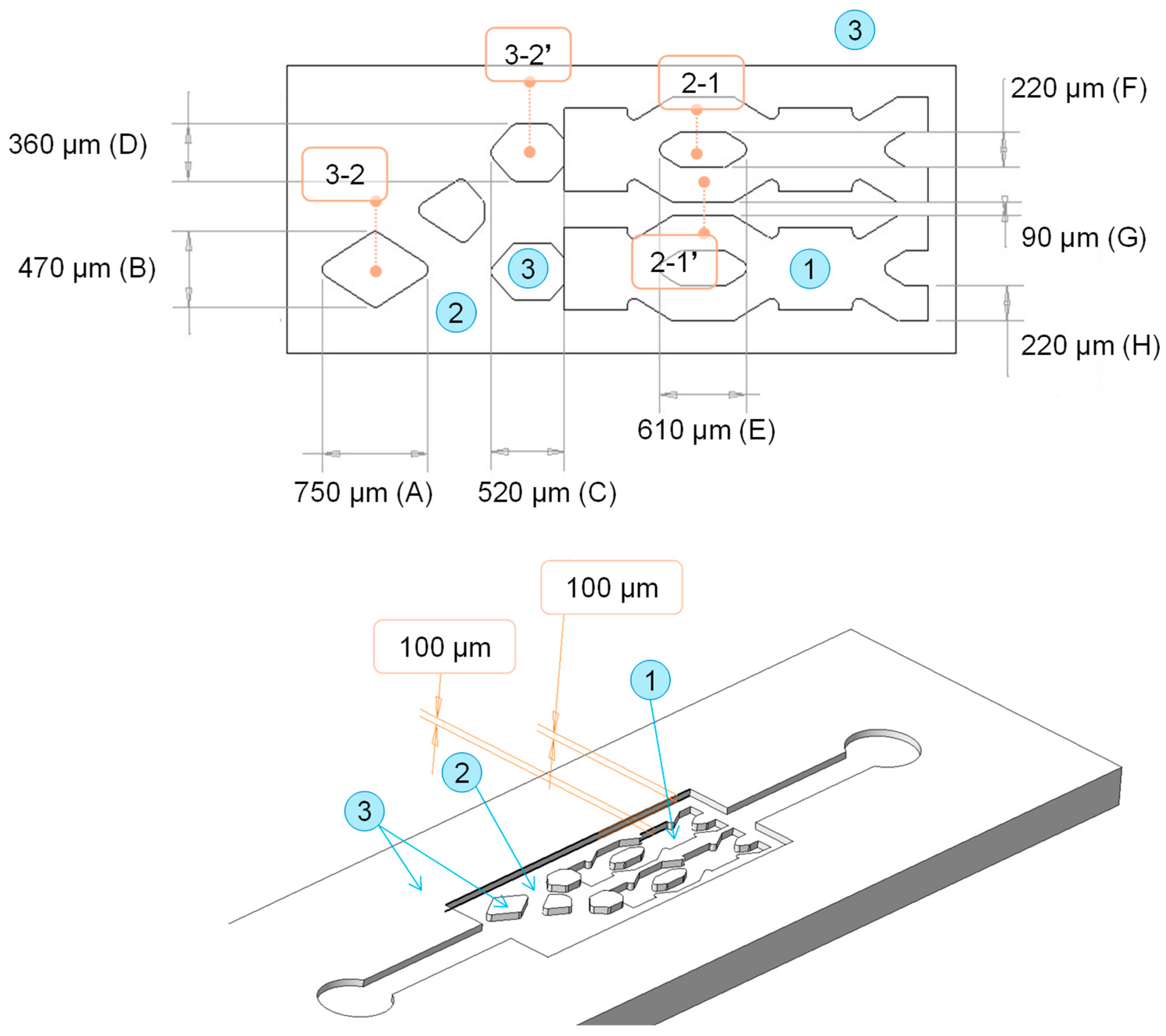

2.1. Microfluidic Design

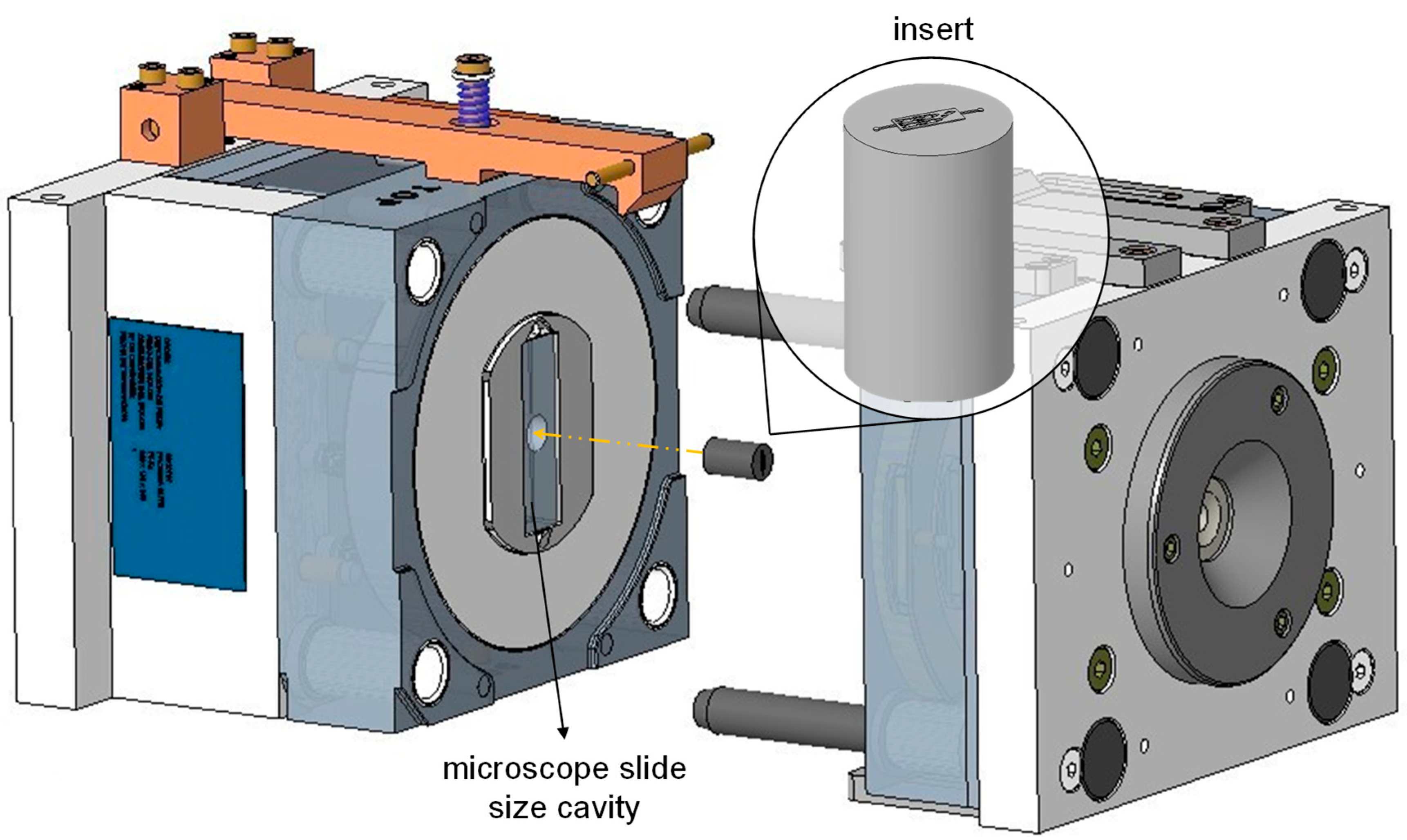

2.2. Metallic Mold Insert Fabrication

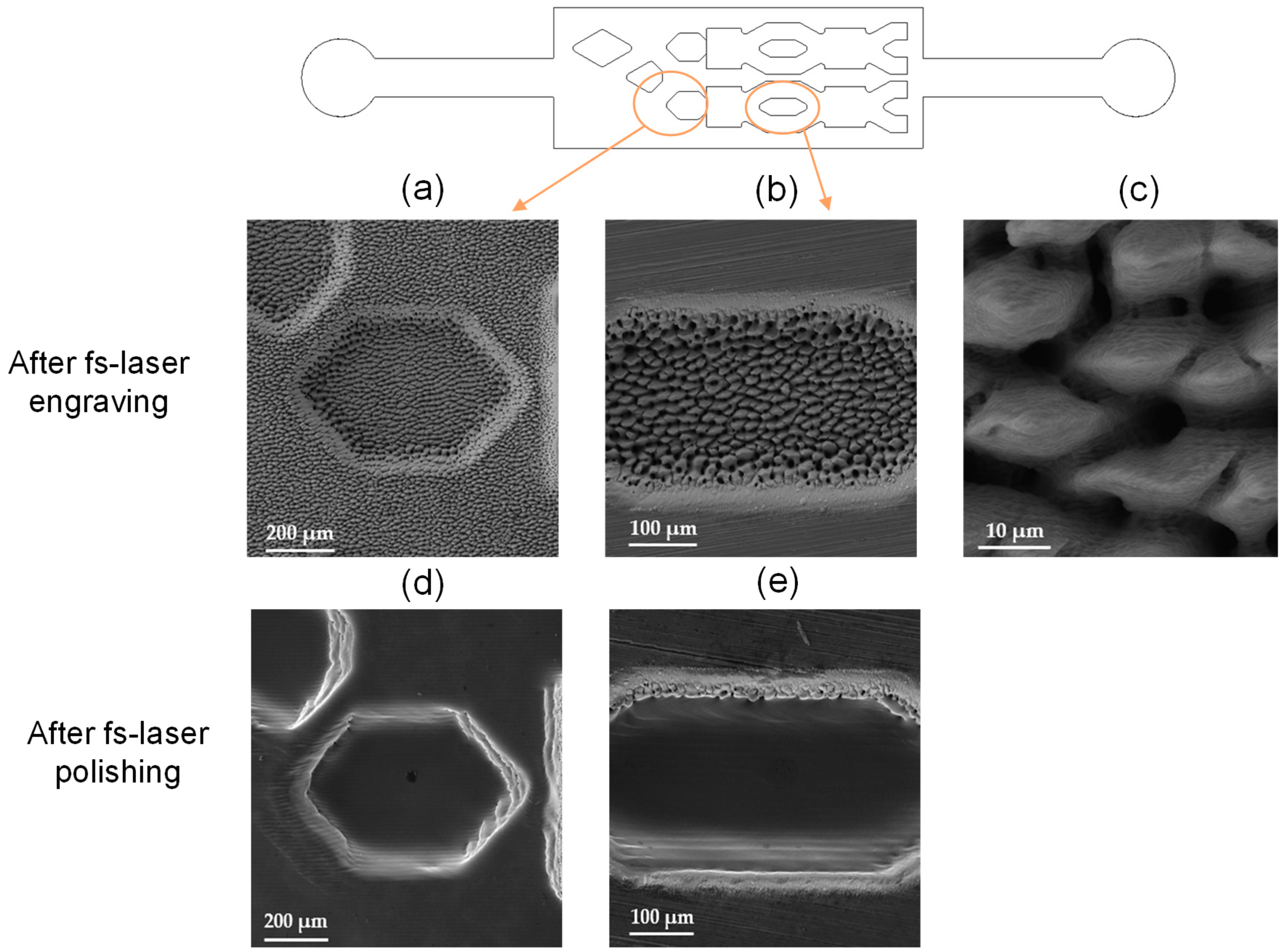

2.3. Manufacturing of Structured Microfluidic Molds by Fs-Laser Processing

2.4. Replication on Polymers by Injection Molding

2.5. Dimensional Characterization of Microstructures and Surface Roughness Analysis

2.6. Sealing of the Structures by Chemically Assisted Bonding

3. Results and Discussion

3.1. Fabrication Time and Cost

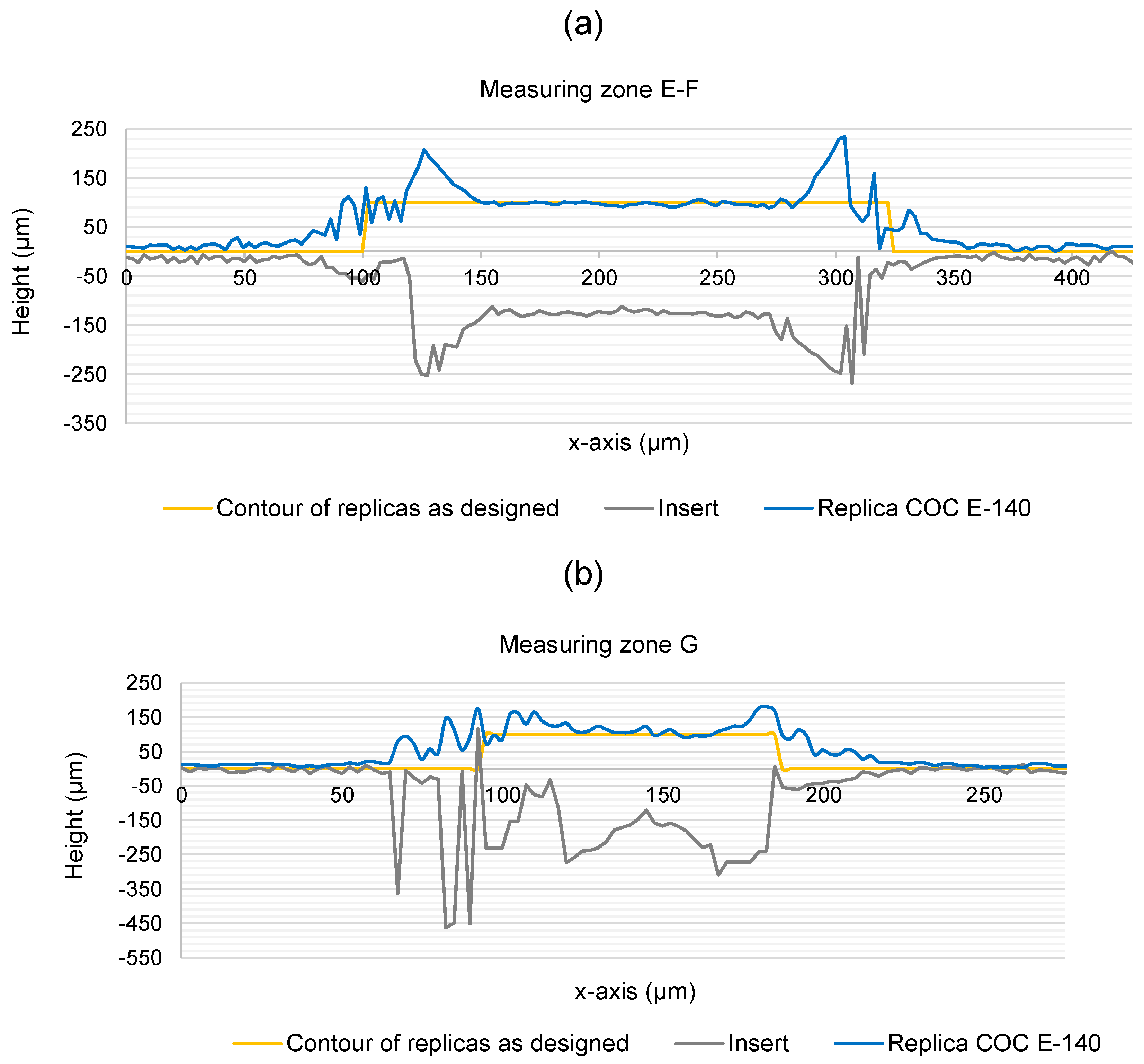

3.2. Dimensional Characterization of the Fabricated Microstructures

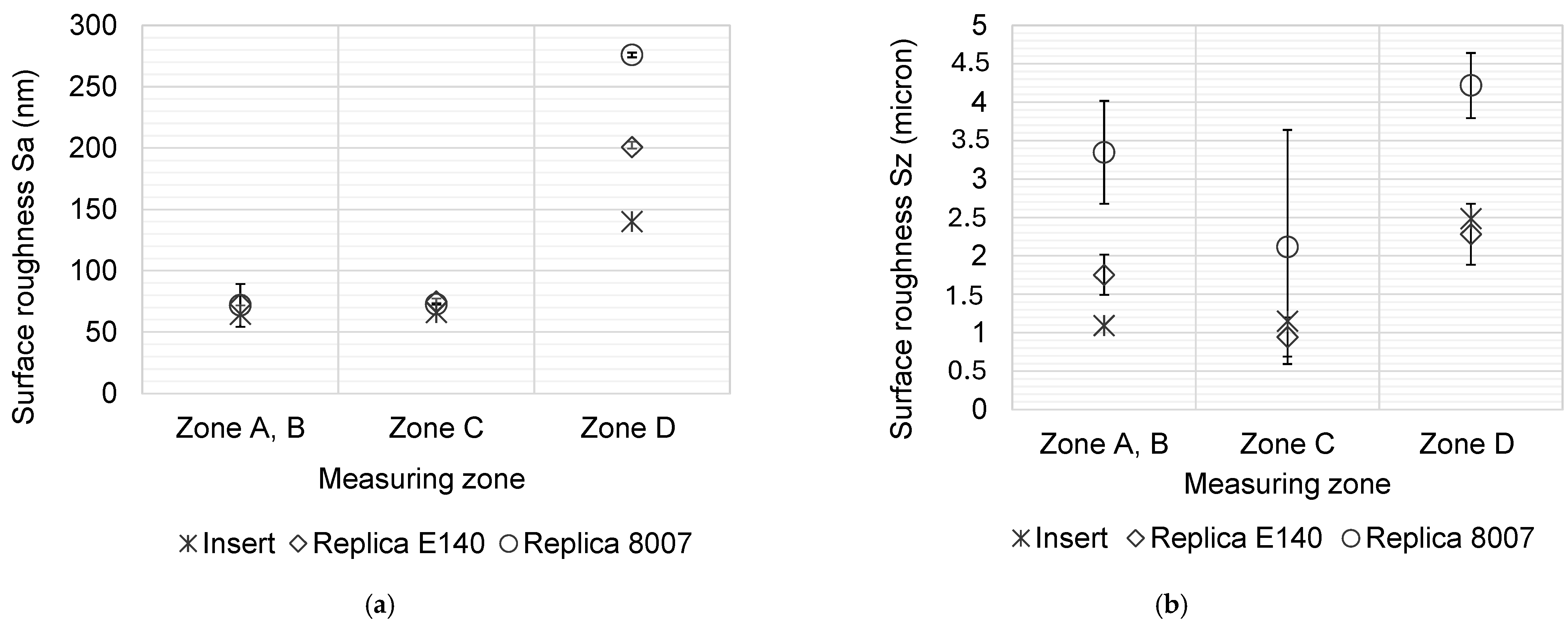

3.3. Analysis of the Surface Roughness

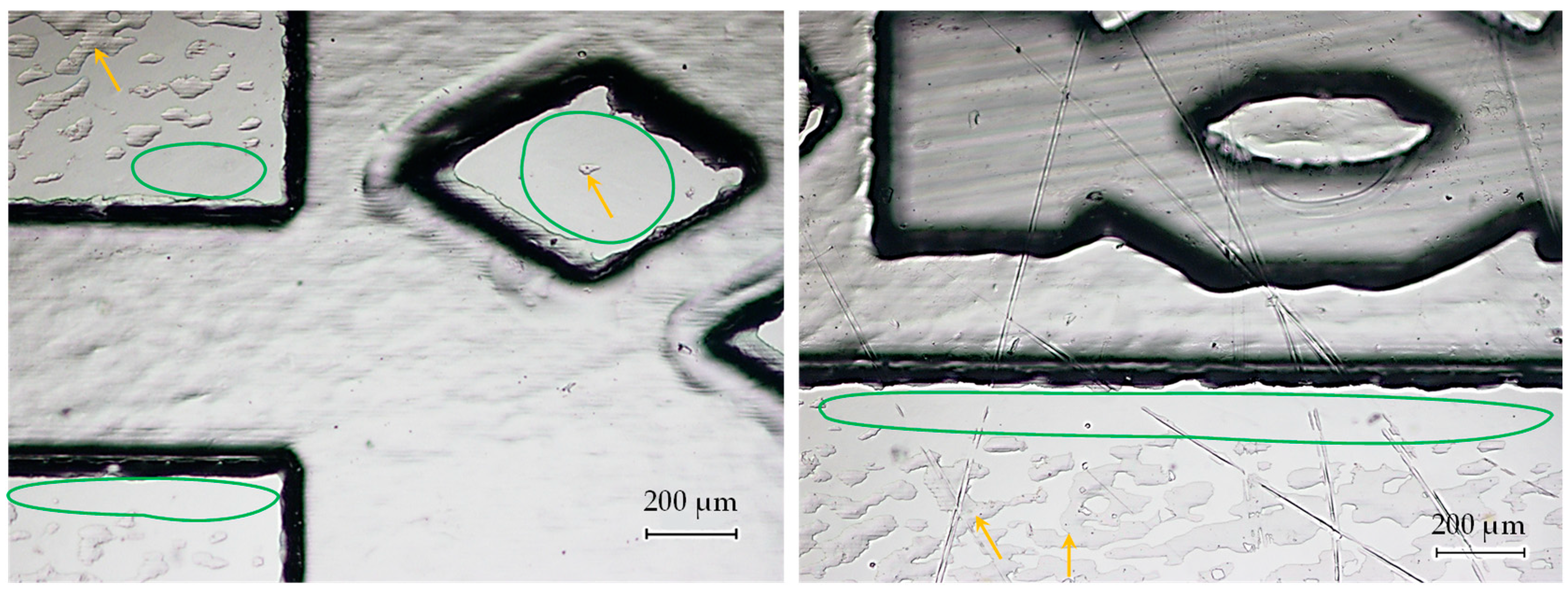

3.4. Structure Sealing and Bonding Coverage

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Berlanda, S.F.; Breitfeld, M.; Dietsche, C.L.; Dittrich, P.S. Recent Advances in Microfluidic Technology for Bioanalysis and Diagnostics. Anal. Chem. 2021, 93, 311–331. [Google Scholar] [CrossRef]

- Gharib, G.; Bütün, İ.; Muganlı, Z.; Kozalak, G.; Namlı, İ.; Sarraf, S.S.; Ahmadi, V.E.; Toyran, E.; van Wijnen, A.J.; Koşar, A. Biomedical Applications of Microfluidic Devices: A Review. Biosensors 2022, 12, 1023. [Google Scholar] [CrossRef]

- Niculescu, A.-G.; Chircov, C.; Bîrcă, A.C.; Grumezescu, A.M. Fabrication and Applications of Microfluidic Devices: A Review. Int. J. Mol. Sci. 2021, 22, 2011. [Google Scholar] [CrossRef]

- Sharma, B.; Sharma, A. Microfluidics: Recent Advances Toward Lab-on-Chip Applications in Bioanalysis. Adv. Eng. Mater. 2022, 24, 2100738. [Google Scholar] [CrossRef]

- Bhatia, S.N.; Ingber, D.E. Microfluidic Organs-on-Chips. Nat. Biotechnol. 2014, 32, 760–772. [Google Scholar] [CrossRef]

- Enders, A.; Grünberger, A.; Bahnemann, J. Towards Small Scale: Overview and Applications of Microfluidics in Biotechnology. Mol. Biotechnol. 2024, 66, 365–377. [Google Scholar] [CrossRef]

- Pattanayak, P.; Singh, S.K.; Gulati, M.; Vishwas, S.; Kapoor, B.; Chellappan, D.K.; Anand, K.; Gupta, G.; Jha, N.K.; Gupta, P.K.; et al. Microfluidic Chips: Recent Advances, Critical Strategies in Design, Applications and Future Perspectives. Microfluid. Nanofluidics 2021, 25, 99. [Google Scholar] [CrossRef]

- Cong, H.; Zhang, N. Perspectives in Translating Microfluidic Devices from Laboratory Prototyping into Scale-up Production. Biomicrofluidics 2022, 16, 021301. [Google Scholar] [CrossRef]

- Stampone, B.; Deniz, K.I.; Foscarini, A.; Turco, A.; Chiriacò, M.S.; Ferrara, F.; Giorleo, L.; Trotta, G. Rapid Tooling for Microinjection Moulding of Proof-of-Concept Microfluidic Device: Resin Insert Capability and Preliminary Validation. Appl. Sci. 2024, 14, 3157. [Google Scholar] [CrossRef]

- Quintard, C.; Tubbs, E.; Jonsson, G.; Jiao, J.; Wang, J.; Werschler, N.; Laporte, C.; Pitaval, A.; Bah, T.-S.; Pomeranz, G.; et al. A Microfluidic Platform Integrating Functional Vascularized Organoids-on-Chip. Nat. Commun. 2024, 15, 1452. [Google Scholar] [CrossRef]

- Etxeberria, L.; Messelmani, T.; Badiola, J.H.; Llobera, A.; Fernandez, L.; Vilas-Vilela, J.L.; Leclerc, E.; Legallais, C.; Jellali, R.; Zaldua, A.M. Validation of HepG2/C3A Cell Cultures in Cyclic Olefin Copolymer Based Microfluidic Bioreactors. Polymers 2022, 14, 4478. [Google Scholar] [CrossRef] [PubMed]

- Aghvami, S.A.; Opathalage, A.; Zhang, Z.K.; Ludwig, M.; Heymann, M.; Norton, M.; Wilkins, N.; Fraden, S. Rapid Prototyping of Cyclic Olefin Copolymer (COC) Microfluidic Devices. Sens. Actuators B Chem. 2017, 247, 940–949. [Google Scholar] [CrossRef]

- Rodrigues, R.G.; Condelipes, P.G.M.; Rosa, R.R.; Chu, V.; Conde, J.P. Scalable Processing of Cyclic Olefin Copolymer (COC) Microfluidic Biochips. Micromachines 2023, 14, 1837. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, S.; Kamalakshakurup, G.; Lee, A.P.; Ahn, C.H. A Mass Manufacturable Thermoplastic Based Microfluidic Droplet Generator on Cyclic Olefin Copolymer. J. Micromech. Microeng. 2019, 29, 055009. [Google Scholar] [CrossRef]

- Prada, J.; Cordes, C.; Harms, C.; Lang, W. Design and Manufacturing of a Disposable, Cyclo-Olefin Copolymer, Microfluidic Device for a Biosensor †. Sensors 2019, 19, 1178. [Google Scholar] [CrossRef] [PubMed]

- Azouz, A.B.; Murphy, S.; Karazi, S.; Vázquez, M.; Brabazon, D. Fast Fabrication Process of Microfluidic Devices Based on Cyclic Olefin Copolymer. Mater. Manuf. Process. 2014, 29, 93–99. [Google Scholar] [CrossRef]

- Shakeri, A.; Khan, S.; Jarad, N.A.; Didar, T.F. The Fabrication and Bonding of Thermoplastic Microfluidics: A Review. Materials 2022, 15, 6478. [Google Scholar] [CrossRef]

- Martínez Vázquez, R.; Trotta, G.; Volpe, A.; Bernava, G.; Basile, V.; Paturzo, M.; Ferraro, P.; Ancona, A.; Fassi, I.; Osellame, R. Rapid Prototyping of Plastic Lab-on-a-Chip by Femtosecond Laser Micromachining and Removable Insert Microinjection Molding. Micromachines 2017, 8, 328. [Google Scholar] [CrossRef]

- Zhao, B.; Wu, W.; Zhou, M.; Jiang, B.; Ziegmann, G. Highly Dynamic Tempered In-Mold Thermocompression Bonding of Microfluidic Chips: Process Characteristics and Bonding Performances. J. Mater. Res. Technol. 2023, 24, 639–652. [Google Scholar] [CrossRef]

- Scott, S.M.; Ali, Z. Fabrication Methods for Microfluidic Devices: An Overview. Micromachines 2021, 12, 319. [Google Scholar] [CrossRef]

- Chang, W.-L.; Luo, X.-C.; Ritchie, J.M.; Sun, J.-N.; Mark, C. Fabrication of Microfluidic Injection Moulds by a Hybrid Micromachining Process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 458–462. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, B.; Zhang, Z.; Guo, M.; Wang, J.; Wang, C. Process Chain for the Mass Production of Polymeric Microfluidic Chips. Int. J. Adv. Manuf. Technol. 2023, 127, 3665–3680. [Google Scholar] [CrossRef]

- Malinauskas, M.; Žukauskas, A.; Hasegawa, S.; Hayasaki, Y.; Mizeikis, V.; Buividas, R.; Juodkazis, S. Ultrafast Laser Processing of Materials: From Science to Industry. Light Sci. Appl. 2016, 5, e16133. [Google Scholar] [CrossRef]

- Audouard, E.; Tropheme, B.; Pouysegur, J.; Basin, F.; Sanabaria, J.; Nillon, J.; Delaigue, M.; Hönninger, C.; Mottay, E.; Mincuzzi, G.; et al. Extended Application Field in Femtosecond Processing with 300 W Lasers. In Proceedings of the Frontiers in Ultrafast Optics: Biomedical, Scientific, and Industrial Applications XXII, San Francisco, CA, USA, 22–27 January 2022; SPIE: Washington, DC, USA, 2022; Volume PC11991, p. PC119910A. [Google Scholar]

- Trotta, G.; Martínez Vázquez, R.; Volpe, A.; Modica, F.; Ancona, A.; Fassi, I.; Osellame, R. Disposable Optical Stretcher Fabricated by Microinjection Moulding. Micromachines 2018, 9, 388. [Google Scholar] [CrossRef] [PubMed]

- Saadat, M.; Taylor, M.; Hughes, A.; Hajiyavand, A.M. Rapid Prototyping Method for 3D PDMS Microfluidic Devices Using a Red Femtosecond Laser. Adv. Mech. Eng. 2020, 12, 1687814020982713. [Google Scholar] [CrossRef]

- Agha, A.; Waheed, W.; Alamoodi, N.; Mathew, B.; Alnaimat, F.; Abu-Nada, E.; Abderrahmane, A.; Alazzam, A. A Review of Cyclic Olefin Copolymer Applications in Microfluidics and Microdevices. Macromol. Mater. Eng. 2022, 307, 2200053. [Google Scholar] [CrossRef]

- 1.2083/1.2083 ESR Steel for Through Hardening at Meusburger. Available online: https://www.meusburger.com/en-gb/all-products/plates-and-bars/material-grades/12083-esu-steel-for-through-hardening (accessed on 22 October 2024).

- Kočica, J.J.; Mur, J.; Didierjean, J.; Guillossou, A.; Saby, J.; Petelin, J.; Mincuzzi, G.; Petkovšek, R. Pulse-on-Demand Operation for Precise High-Speed UV Laser Microstructuring. Micromachines 2023, 14, 843. [Google Scholar] [CrossRef]

- Shin, S.; Lee, W.; Kab Park, J. Wavelength Selection for Femtosecond Laser Processing of Materials: Comparison of Ablation Efficiency and Surface Quality. Opt. Laser Technol. 2024, 171, 110428. [Google Scholar] [CrossRef]

- Metzner, D.; Lickschat, P.; Weißmantel, S. High-Quality Surface Treatment Using GHz Burst Mode with Tunable Ultrashort Pulses. Appl. Surf. Sci. 2020, 531, 147270. [Google Scholar] [CrossRef]

- Technical Datasheet TOPAS Elastomer E-140. Available online: https://topas.com/wp-content/uploads/2023/05/TDS_Elastomer-E-140_english-units.pdf (accessed on 22 November 2024).

- Technical Datasheet TOPAS COC 8007-S04. Available online: https://topas.com/wp-content/uploads/2023/05/TDS_8007S_04_e.pdf (accessed on 22 November 2024).

- Gao, P.; MacKay, I.; Gruber, A.; Krantz, J.; Piccolo, L.; Lucchetta, G.; Pelaccia, R.; Orazi, L.; Masato, D. Wetting Characteristics of Laser-Ablated Hierarchical Textures Replicated by Micro Injection Molding. Micromachines 2023, 14, 863. [Google Scholar] [CrossRef]

- Etxeberria, L.; Badiola, J.H.; Astigarraga, M.; Garitaonandia, F.; Zaldua, A.M. Comparison between Injection Molding (IM) and Injection-Compression Molding (ICM) for Mass Manufacturing of Thermoplastic Microfluidic Devices. Macromol. Mater. Eng. 2024, 309, 2300231. [Google Scholar] [CrossRef]

- Tsibidis, G.D.; Fotakis, C.; Stratakis, E. From Ripples to Spikes: A Hydrodynamical Mechanism to Interpret Femtosecond Laser-Induced Self-Assembled Structures. Phys. Rev. B 2015, 92, 041405. [Google Scholar] [CrossRef]

- Fu, G.; Tor, S.B.; Loh, N.H.; Hardt, D.E. Fabrication of Robust Tooling for Mass Production of Polymeric Microfluidic Devices. J. Micromech. Microeng. 2010, 20, 085019. [Google Scholar] [CrossRef]

- Orazi, L.; Siciliani, V.; Pelaccia, R.; Oubellaouch, K.; Reggiani, B. Ultrafast Laser Micromanufacturing of Microfluidic Devices. Procedia CIRP 2022, 110, 122–127. [Google Scholar] [CrossRef]

- Etxeberria Aizpuru, L. Different Approaches for Mass Production of Thermoplastic Microfluidic Devices. Ph.D. Thesis, University of the Basque Country (EHU/UPV), Bilbao, Spain, 2022. [Google Scholar]

- Jun, I.; Choi, H.; Kim, H.; Chan Choi, B.; Chang, H.J.; Kim, Y.; Cho, S.W.; Edwards, J.R.; Hwang, S.-W.; Kim, Y.-C.; et al. Exploring the Potential of Laser-Textured Metal Alloys: Fine-Tuning Vascular Cells Responses through in Vitro and Ex Vivo Analysis. Bioact. Mater. 2025, 43, 181–194. [Google Scholar] [CrossRef]

- Lutey, A.H.A.; Gemini, L.; Romoli, L.; Lazzini, G.; Fuso, F.; Faucon, M.; Kling, R. Towards Laser-Textured Antibacterial Surfaces. Sci. Rep. 2018, 8, 10112. [Google Scholar] [CrossRef]

| Process | Repetition Rate (kHz) | Scan Speed (m/s) | Power (W) | Number of Successive Scans | Fluence (J/cm2) |

|---|---|---|---|---|---|

| Engraving (depth 100 µm) | 200 | 2 | 18.8 | 55 | 12.45 |

| Engraving (depth 200 µm) | 200 | 2 | 18.8 | 110 | 12.45 |

| Polishing | 1000 (256 ppb) | 1.25 | 30 | 2 | 3.97 (256 ppb total amount) |

| Process Parameters | COC E-140 | COC 8007S-04 |

|---|---|---|

| Melt temperature [°C] | 270 | 220 |

| Mold temperature [°C] | 50 | 50 |

| Injection speed [cm3/s] | 4 | 76 |

| Injection volume [cm3] | 7 | 4 |

| Packing pressure [bar] | 1000 | 1000 |

| Packing time [s] | 6 | 6 |

| Cooling time [s] | 30 | 30 |

| Zone | Designed | Insert | Replica E-140 | Replica 8007S-04 | |||

|---|---|---|---|---|---|---|---|

| Measured | Error | Measured | Error | Measured | Error | ||

| 3-2 | 100 µm | 94.84 µm | 5% | 87.2 ± 1.2 µm | 8% | 84.9 ± 1.6 µm | 10% |

| 3-2′ | 100 µm | 98.21 µm | 2% | 87.1 ± 2.2 µm | 11% | 85.2 ± 1.4 µm | 13% |

| 2-1 | 100 µm | 108.9 µm | 9% | 86.2 ± 1.6 µm | 21% | 88.2 ± 2.8 µm | 19% |

| 2-1′ | 100 µm | 108.8 µm | 9% | 93.4 ± 4.9 µm | 14% | 90.8 ± 4.3 µm | 17% |

| Zone. | Designed | Insert | Replica E-140 | Replica 8007S-04 | |||

|---|---|---|---|---|---|---|---|

| Measured | Error | Measured | Error | Measured | Error | ||

| A | 750 µm | 868.4 µm | 16% | 855.1 ± 2 µm | 2% | 864.6 ± 3.9 µm | 0% |

| B | 470 µm | 552.6 µm | 18% | 546.5 ± 2 µm | 1% | 539.9 ± 1.5 µm | 2% |

| C | 520 µm | 676.6 µm | 30% | 674.1 ± 2.5 µm | 0% | 687.0 ± 1.3 µm | 2% |

| D | 360 µm | 445.1 µm | 24% | 443.1 ± 2.7 µm | 0% | 439.5 ± 1.9 µm | 1% |

| E | 610 µm | 636.6 µm | 4% | 664.1 ± 2.1 µm | 4% | 667.1 ± 1.2 µm | 5% |

| F | 220 µm | 249.6 µm | 13% | 272.1 ± 0.4 µm | 9% | 271.6 ± 1.9 µm | 9% |

| G | 90 µm | 124.8 µm | 39% | 148.0 ± 2.8 µm | 19% | 151.3 ± 1.1 µm | 21% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Varela Leniz, I.; Bakouche, T.; Astigarraga, M.; Husson, F.; Zaldua, A.M.; Gemini, L.; Vilas-Vilela, J.L.; Etxeberria, L. Analyzing the Potential of Laser Femtosecond Technology for the Mass Production of Cyclic Olefin Copolymer Microfluidic Devices for Biomedical Applications. Polymers 2025, 17, 1289. https://doi.org/10.3390/polym17091289

Varela Leniz I, Bakouche T, Astigarraga M, Husson F, Zaldua AM, Gemini L, Vilas-Vilela JL, Etxeberria L. Analyzing the Potential of Laser Femtosecond Technology for the Mass Production of Cyclic Olefin Copolymer Microfluidic Devices for Biomedical Applications. Polymers. 2025; 17(9):1289. https://doi.org/10.3390/polym17091289

Chicago/Turabian StyleVarela Leniz, Irene, Taieb Bakouche, Malen Astigarraga, Florent Husson, Ane Miren Zaldua, Laura Gemini, José Luis Vilas-Vilela, and Leire Etxeberria. 2025. "Analyzing the Potential of Laser Femtosecond Technology for the Mass Production of Cyclic Olefin Copolymer Microfluidic Devices for Biomedical Applications" Polymers 17, no. 9: 1289. https://doi.org/10.3390/polym17091289

APA StyleVarela Leniz, I., Bakouche, T., Astigarraga, M., Husson, F., Zaldua, A. M., Gemini, L., Vilas-Vilela, J. L., & Etxeberria, L. (2025). Analyzing the Potential of Laser Femtosecond Technology for the Mass Production of Cyclic Olefin Copolymer Microfluidic Devices for Biomedical Applications. Polymers, 17(9), 1289. https://doi.org/10.3390/polym17091289