Sustainable Production of Microcrystalline and Nanocrystalline Cellulose from Textile Waste Using HCl and NaOH/Urea Treatment

Abstract

1. Introduction

- (i)

- Discarded fabrics as reinforcement;

- (ii)

- Shoddy fibrous materials produced from shredded textile waste;

- (iii)

- Yarn and woven/nonwoven materials generated from textile waste;

- (iv)

- Nano- and microstructures derived from waste textiles [14].

2. Materials and Methods

2.1. MCC Production

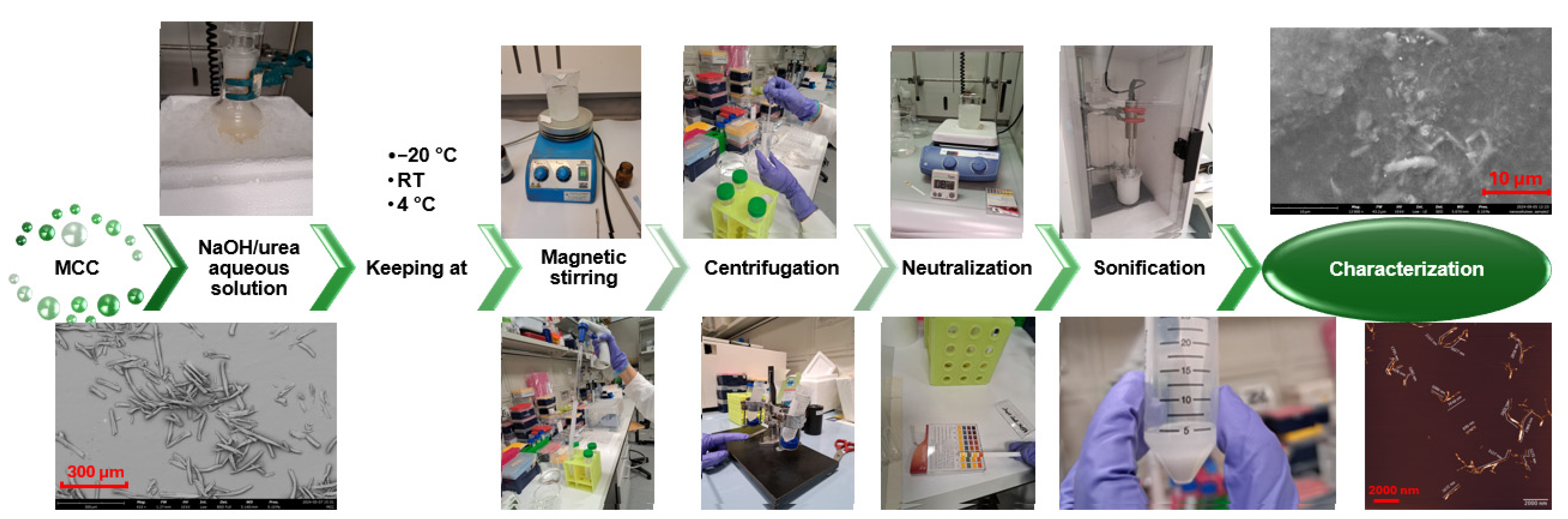

2.2. NCC Production

- (a)

- Kept in the freezer at −20 °C for 16 h;

- (b)

- Kept at 4 °C for 16 h;

- (c)

- Kept at room temperature (RT) for 16 h.

2.3. Characterization of MCC and NCC

2.3.1. Microscopy Analysis

2.3.2. Dynamic Light Scattering (DLS)

2.3.3. Fourier Transform Infrared (FTIR)

2.3.4. Atomic Force Microscopy (AFM)

3. Results and Discussion

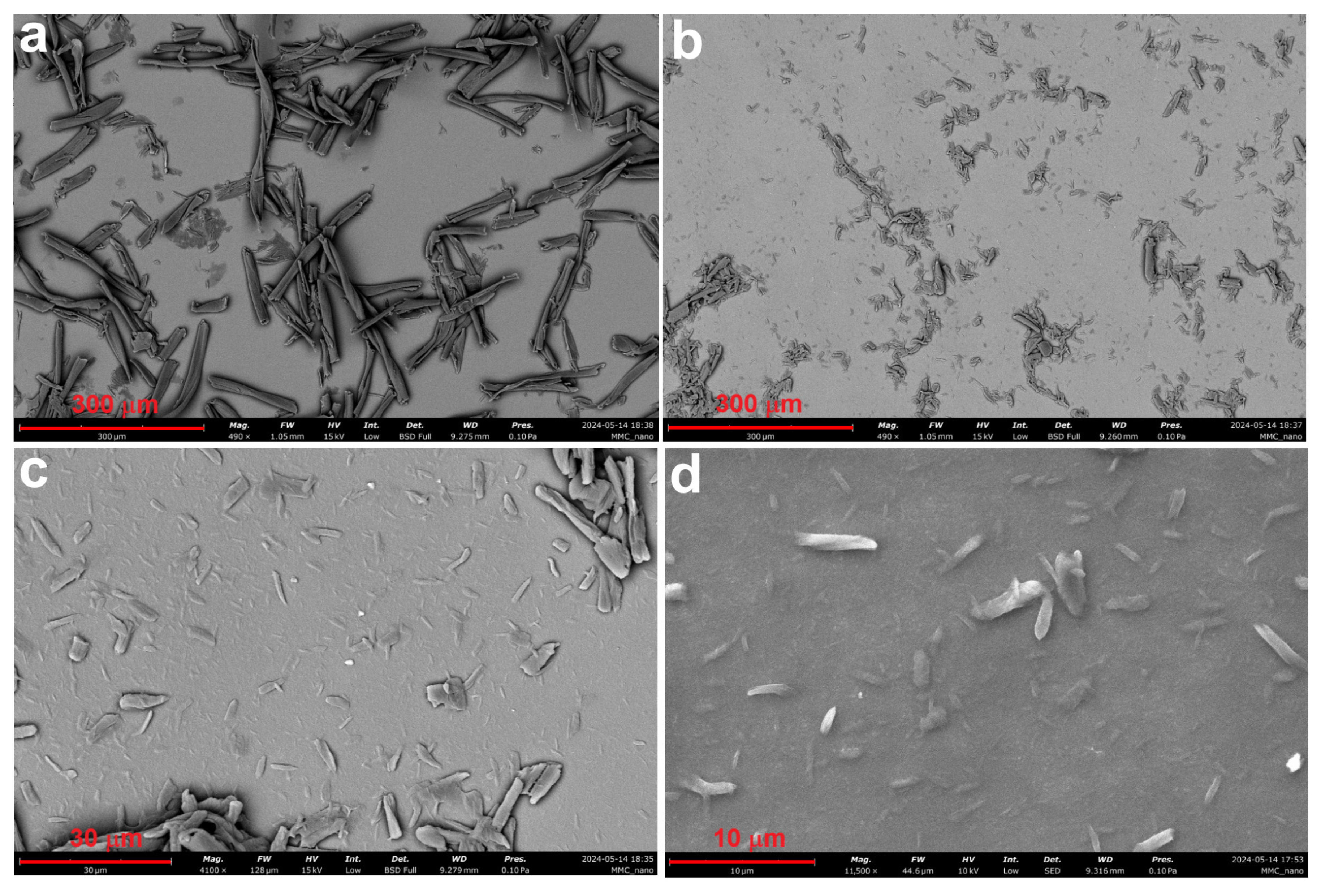

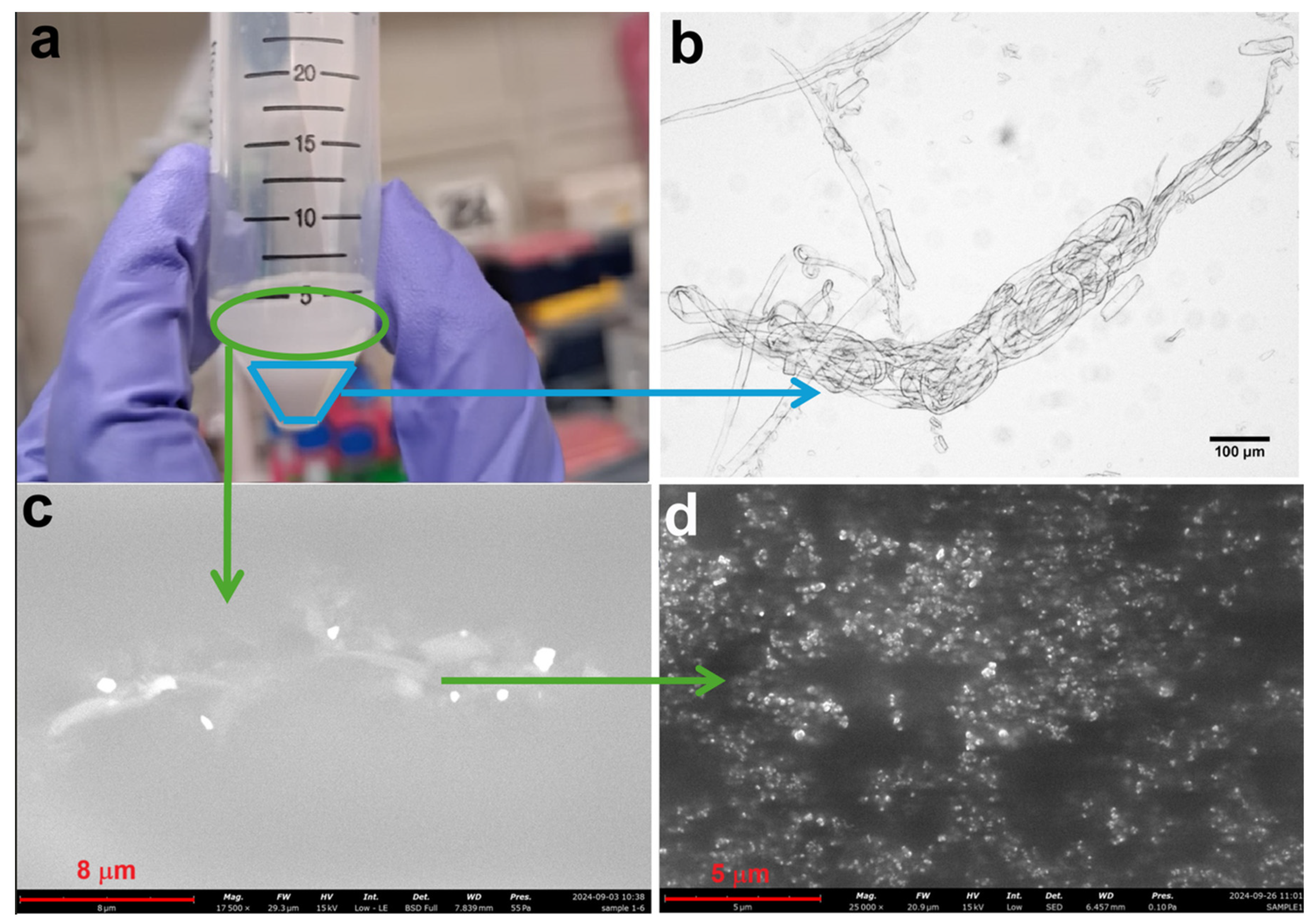

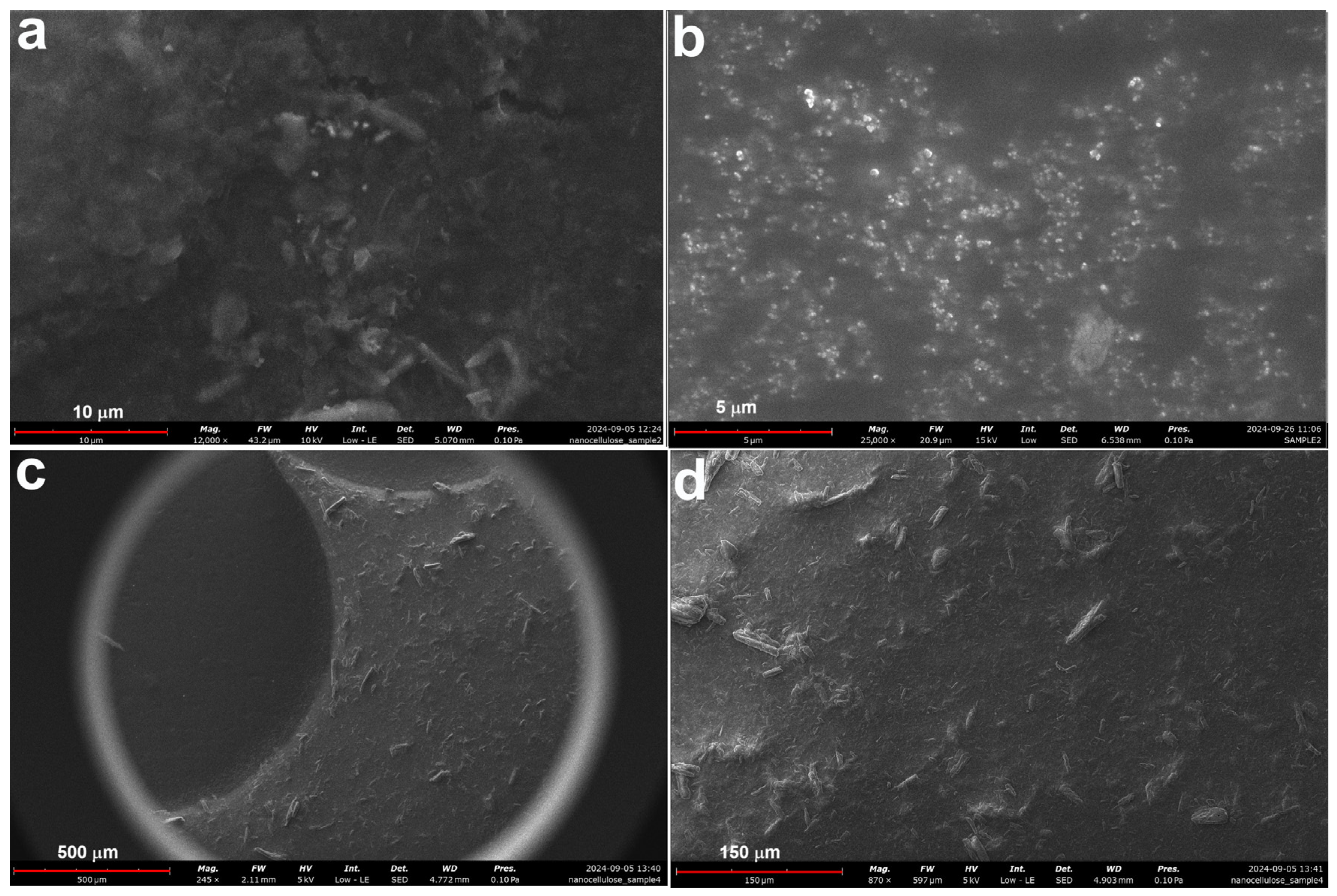

3.1. Size and Morphology Analysis by SEM Images and Optical Microscope

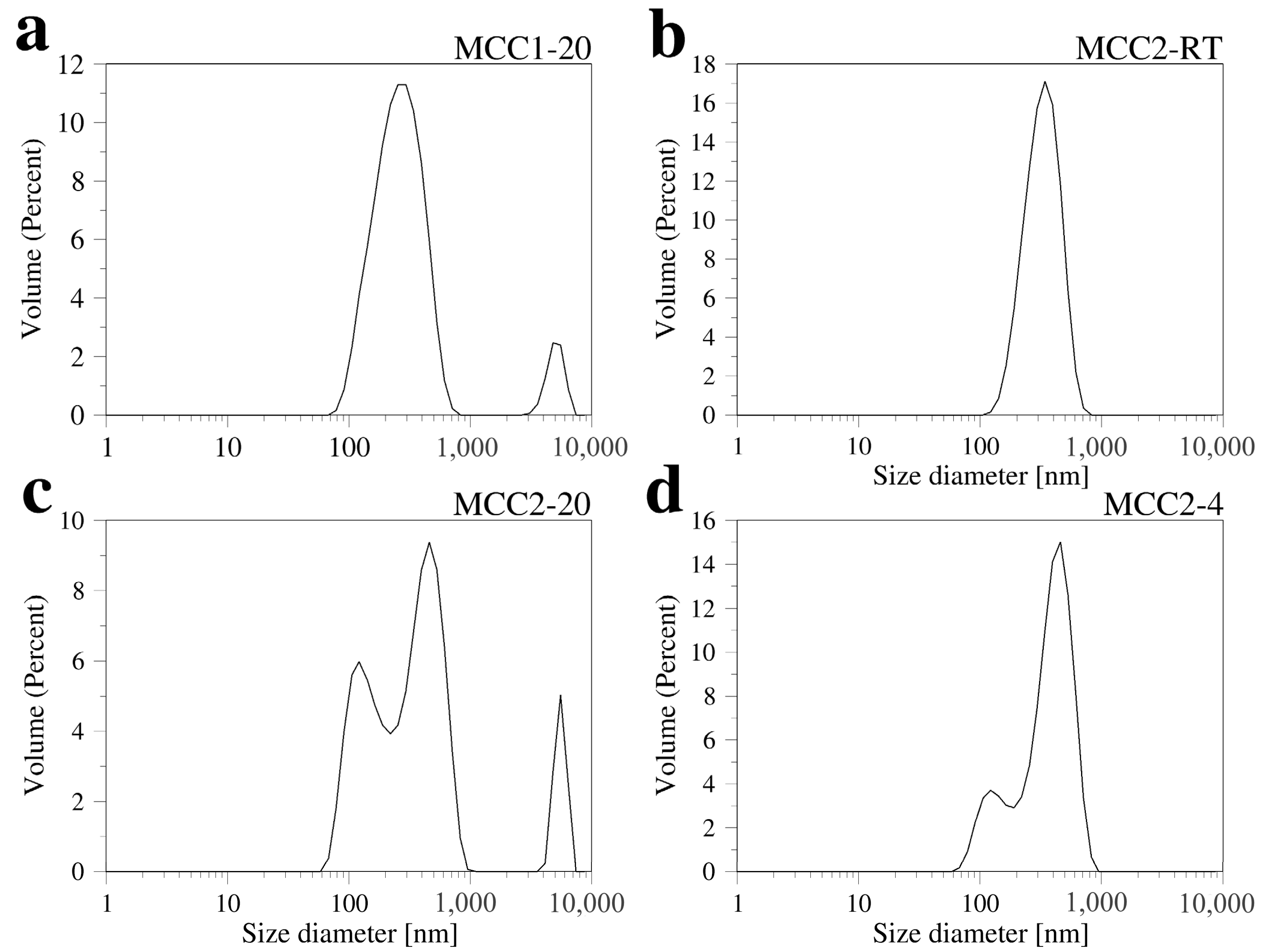

3.2. Size Analysis by Dynamic Light Scattering (DLS)

3.3. Fourier Transformed Infrared (FTIR) Analysis

3.4. Atomic Force Microscopy (AFM) Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, X.; Wu, W.; Wang, J.; Tian, Z.; Jiang, S. Hydrogen-Bonding-Aided Fabrication of Wood Derived Cellulose Scaffold/Aramid Nanofiber into High-Performance Bulk Material. Materials 2021, 14, 5444. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Wang, Z.; Ding, L.; Chen, L.; Wang, F.; Pu, J.; Jiang, S. Water Molecule-Induced Hydrogen Bonding between Cellulose Nanofibers toward Highly Strong and Tough Materials from Wood Aerogel. Chin. Chem. Lett. 2021, 32, 3105–3108. [Google Scholar] [CrossRef]

- European Environment Agency. Available online: https://www.eea.europa.eu/en/topics/in-depth/plastics (accessed on 5 July 2024).

- Alves, B. Projected Plastic Waste Generation in the European Union 2019–2060. Available online: https://www.statista.com/topics/5141/plastic-waste-in-europe/ (accessed on 5 July 2024).

- Vroman, I.; Tighzert, L. Biodegradable Polymers. Materials 2009, 2, 307–344. [Google Scholar] [CrossRef]

- Ribba, L.; Lopretti, M.; de Oca-Vásquez, G.M.; Batista, D.; Goyanes, S.; Vega-Baudrit, J.R. Biodegradable Plastics in Aquatic Ecosystems: Latest Findings, Research Gaps, and Recommendations. Environ. Res. Lett. 2022, 17, 033003. [Google Scholar] [CrossRef]

- Petzold Pauli, F.; Silva Freitas, C.; Ribeiro Pereira, P.; Magalhães, A.; de Carvalho da Silva, F.; Paschoalin, V.M.F.; Ferreira, V.F. Exploring the Antimicrobial and Antitumoral Activities of Naphthoquinone-Grafted Chitosans. Polymers 2023, 15, 1430. [Google Scholar] [CrossRef]

- Ansari, F.; Berglund, L.A. Toward Semistructural Cellulose Nanocomposites: The Need for Scalable Processing and Interface Tailoring. Biomacromolecules 2018, 19, 2341–2350. [Google Scholar] [CrossRef]

- Ferreira, R.R.; Souza, A.G.; Barbosa, R.F.S.; Marciano, J.S.; Marques, F.A.S.; Mitra, S.K.; Rosa, D.S. The Synergistic Effect of Nanocellulose and Nanocapsules into Poly(Butylene Adipate-Co-Butylene Terephthalate) Films for Active Packaging. Food Packag. Shelf Life 2023, 35, 100996. [Google Scholar] [CrossRef]

- Omran, A.A.B.; Mohammed, A.A.B.A.; Sapuan, S.M.; Ilyas, R.A.; Asyraf, M.R.M.; Koloor, S.S.R.; Petrů, M. Micro- and Nanocellulose in Polymer Composite Materials: A Review. Polymers 2021, 13, 231. [Google Scholar] [CrossRef]

- Samrot, A.V.; Ngaakudzwe, K.T.; Rajalakshmi, D.; Prakash, P.; Suresh Kumar, S.; Chandramohan, M.; Alex Anand, D.; Lilly Mercy, J.; Simon, Y.; Saigeetha, S. Waste-Derived Cellulosic Fibers and Their Applications. Adv. Mater. Sci. Eng. 2022, 2022, 7314694. [Google Scholar] [CrossRef]

- European Commission. New Circular Economy Action Plan; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- The European Environment Agency (EEA). Textiles and the Environment: The Role of Design in Europe’s Circular Economy. Available online: https://www.eea.europa.eu/publications/textiles-and-the-environment-the (accessed on 25 August 2024).

- Yadav, R.; Kamble, Z. Textile Waste-Based Cellulose Composites: A Review. J. Mater. Sci. 2024, 59, 7147–7168. [Google Scholar] [CrossRef]

- Sathasivam, T.; Sugiarto, S.; Pek, M.; Yew, Y.; Oh, X.Y.; Chan, S.Y.; Qi, B.; Chan, Y.; Tim, M.J.; Kai, D. Transforming Textile Waste into Nanocellulose for a Circular Future. Nanoscale 2024, 16, 14168. [Google Scholar] [CrossRef] [PubMed]

- Vanzetto, A.B.; Beltrami, L.V.R.; Zattera, A.J. Textile Waste as Precursors in Nanocrystalline Cellulose Synthesis. Cellulose 2021, 28, 6967–6981. [Google Scholar] [CrossRef]

- Singhal, S.; Agarwal, S.; Kumar, A.; Kumar, V.; Prajapati, S.K.; Kumar, T.; Singhal, N. Waste Clothes to Microcrystalline Cellulose: An Experimental Investigation. J. Polym. Environ. 2023, 31, 358–372. [Google Scholar] [CrossRef]

- Tribot, A.; Amer, G.; Abdou Alio, M.; de Baynast, H.; Delattre, C.; Pons, A.; Mathias, J.D.; Callois, J.M.; Vial, C.; Michaud, P.; et al. Wood-Lignin: Supply, Extraction Processes and Use as Bio-Based Material. Eur. Polym. J. 2019, 112, 228–240. [Google Scholar] [CrossRef]

- Kumar, A.P.; Depan, D.; Singh Tomer, N.; Singh, R.P. Nanoscale Particles for Polymer Degradation and Stabilization—Trends and Future Perspectives. Prog. Polym. Sci. 2009, 34, 479–515. [Google Scholar] [CrossRef]

- Damayanti, D.; Wulandari, L.A.; Bagaskoro, A.; Rianjanu, A.; Wu, H.S. Possibility Routes for Textile Recycling Technology. Polymers 2021, 13, 3834. [Google Scholar] [CrossRef]

- Chuayjuljit, S.; Su-Uthai, S.; Charuchinda, S. Poly(Vinyl Chloride) Film Filled with Microcrystalline Cellulose Prepared from Cotton Fabric Waste: Properties and Biodegradability Study. Waste Manag. Res. 2010, 28, 109–117. [Google Scholar] [CrossRef]

- Maciel, M.M.Á.D.; Benini, K.C.C. de C.; Voorwald, H.J.C.; Cioffi, M.O.H. Obtainment and Characterization of Nanocellulose from an Unwoven Industrial Textile Cotton Waste: Effect of Acid Hydrolysis Conditions. Int. J. Biol. Macromol. 2019, 126, 496–506. [Google Scholar] [CrossRef]

- Chuayjuljit, S.; Su-Uthai, S.; Tunwattanaseree, C.; Charuchinda, S. Preparation of Microcrystalline Cellulose from Waste-Cotton Fabric for Biodegradability Enhancement of Natural Rubber Sheets. J. Reinf. Plast. Compos. 2008, 28, 1245–1254. [Google Scholar] [CrossRef]

- Costa, C.; Viana, A.; Silva, C.; Marques, E.F.; Azoia, N.G. Recycling of Textile Wastes, by Acid Hydrolysis, into New Cellulosic Raw Materials. Waste Manag. 2022, 153, 99–109. [Google Scholar] [CrossRef]

- Abou-Yousef, H.; Kamel, S. Physico-Mechanical Properties of All-Cellulose Composites Prepared by Different Approaches from Micro-Fibrillated Bagasse Pulp Fibers. Mater. Today Commun. 2023, 35, 105672. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Zheng, Q.; Chen, L.; Huang, L.; Ni, Y.; Ouyang, X. Urea/NaOH System for Enhancing the Removal of Hemicellulose from Cellulosic Fibers. Cellulose 2019, 26, 6393–6400. [Google Scholar] [CrossRef]

- Qi, H.; Yang, Q.; Zhang, L.; Liebert, T.; Heinze, T. The Dissolution of Cellulose in NaOH-Based Aqueous System by Two-Step Process. Cellulose 2011, 18, 237–245. [Google Scholar] [CrossRef]

- Ho, Y.S.; Fahad Halim, A.F.M.; Islam, M.T. The Trend of Bacterial Nanocellulose Research Published in the Science Citation Index Expanded From 2005 to 2020: A Bibliometric Analysis. Front. Bioeng. Biotechnol. 2022, 9, 795341. [Google Scholar] [CrossRef]

- Jing, L.; Shi, T.; Chang, Y.; Meng, X.; He, S.; Xu, H.; Yang, S.; Liu, J. Cellulose-Based Materials in Environmental Protection: A Scientometric and Visual Analysis Review. Sci. Total Environ. 2024, 929, 172576. [Google Scholar] [CrossRef]

- Abdelhamid, H.N. Nanocellulose-Based Materials for Water Pollutant Removal: A Review. Int. J. Mol. Sci. 2024, 25, 8529. [Google Scholar] [CrossRef]

- Fernández-Silva, S.D.; Delgado, M.A.; Roman, C.; García-Morales, M. Rheological and Tribological Properties of Nanocellulose-Based Ecolubricants. Nanomaterials 2021, 11, 2987. [Google Scholar] [CrossRef]

- Rashid, A.B.; Hoque, M.E.; Kabir, N.; Rifat, F.F.; Ishrak, H.; Alqahtani, A.; Chowdhury, M.E.H. Synthesis, Properties, Applications, and Future Prospective of Cellulose Nanocrystals. Polymers 2023, 15, 4070. [Google Scholar] [CrossRef]

- Satyamurthy, P.; Jain, P.; Balasubramanya, R.H.; Vigneshwaran, N. Preparation and Characterization of Cellulose Nanowhiskers from Cotton Fibres by Controlled Microbial Hydrolysis. Carbohydr. Polym. 2011, 83, 122–129. [Google Scholar] [CrossRef]

- Wang, Z.; Yao, Z.J.; Zhou, J.; Zhang, Y. Reuse of Waste Cotton Cloth for the Extraction of Cellulose Nanocrystals. Carbohydr. Polym. 2017, 157, 945–952. [Google Scholar] [CrossRef]

- Nada, A.M.A.; El-Kady, M.Y.; El-Sayed, E.S.A.; Amine, F.M. Preparation and characterization of microcrystalline cellulose (MCC). BioResources 2009, 4, 1359–1371. [Google Scholar] [CrossRef]

- Chauhan, Y.P.; Sapkal, R.S.; Sapkal, V.S.; Zamre, G.S. Microcrystalline Cellulose from Cotton Rags (Waste from Garment and Hosiery Industries). Int. J. Chem. Sci. 2009, 7, 681–688. [Google Scholar]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 Years of Image Analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- GitHub—AFMiJ/AFMiJ: Plugins to Read and Eleborate AFM Data in ImageJ. Available online: https://github.com/AFMiJ/AFMiJ (accessed on 2 December 2024).

- Chaiwutthinan, P.; Pimpan, V.; Chuayjuljit, S.; Leejarkpai, T. Biodegradable Plastics Prepared from Poly(Lactic Acid), Poly(Butylene Succinate) and Microcrystalline Cellulose Extracted from Waste-Cotton Fabric with a Chain Extender. J. Polym. Environ. 2015, 23, 114–125. [Google Scholar] [CrossRef]

- Crews, K.; Huntley, C.; Cooley, D.; Phillips, B.; Curry, M. Influence of Cellulose on the Mechanical and Thermal Stability of ABS Plastic Composites. Int. J. Polym. Sci. 2016, 2016, 9043086. [Google Scholar] [CrossRef]

- Jayasinghe, J.R.; Samarasekara, A.M.P.B.; Amarasinghe, D.A.S. Synthesis and Characterization of Microcrystalline from Cotton Textile Waste. In Proceedings of the Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 28–30 July 2020; pp. 187–192. [Google Scholar]

- Kale, R.D.; Bansal, P.S.; Gorade, V.G. Extraction of Microcrystalline Cellulose from Cotton Sliver and Its Comparison with Commercial Microcrystalline Cellulose. J. Polym. Environ. 2018, 26, 355–364. [Google Scholar] [CrossRef]

- Das, K.; Ray, D.; Bandyopadhyay, N.R.; Ghosh, T.; Mohanty, A.K.; Misra, M. A Study of the Mechanical, Thermal and Morphological Properties of Microcrystalline Cellulose Particles Prepared from Cotton Slivers Using Different Acid Concentrations. Cellulose 2009, 16, 783–793. [Google Scholar] [CrossRef]

- Karchangi, Z.; BioResources, R.B. Preparation of Microcrystalline Cellulose Using Cotton Yarn Waste from the Textile Industry and Evaluation of Its Characteristics. Bioresources 2023, 18, 1115–1127. [Google Scholar] [CrossRef]

- Tan, W.Y.; Gopinath, S.C.B.; Anbu, P.; Velusamy, P.; Gunny, A.A.N.; Chen, Y.; Subramaniam, S. Generation of Microcrystalline Cellulose from Cotton Waste and Its Properties. Bioresources 2023, 18, 4884–4896. [Google Scholar] [CrossRef]

- Hou, W.; Ling, C.; Shi, S.; Yan, Z. Preparation and Characterization of Microcrystalline Cellulose from Waste Cotton Fabrics by Using Phosphotungstic Acid. Int. J. Biol. Macromol. 2019, 123, 363–368. [Google Scholar] [CrossRef]

- Rehman, M.M.; Zeeshan, M.; Shaker, K.; Nawab, Y. Effect of Micro-Crystalline Cellulose Particles on Mechanical Properties of Alkaline Treated Jute Fabric Reinforced Green Epoxy Composite. Cellulose 2019, 26, 9057–9069. [Google Scholar] [CrossRef]

- Chaiwutthinan, P.; Chuayjuljit, S.; Leejarkpai, T. Use of Microcrystalline Cellulose Prepared from Cotton Fabric Waste to Prepare Poly(Butylene Succinate) Composites. Adv. Mater. Res. 2012, 356–360, 430–434. [Google Scholar] [CrossRef]

- Shi, S.; Zhang, M.; Ling, C.; Hou, W.; Yan, Z. Extraction and Characterization of Microcrystalline Cellulose from Waste Cotton Fabrics via Hydrothermal Method. Waste Manag. 2018, 82, 139–146. [Google Scholar] [CrossRef] [PubMed]

- Hoo, D.Y.; Low, Z.L.; Low, D.Y.S.; Tang, S.Y.; Manickam, S.; Tan, K.W.; Ban, Z.H. Ultrasonic Cavitation: An Effective Cleaner and Greener Intensification Technology in the Extraction and Surface Modification of Nanocellulose. Ultrason. Sonochem. 2022, 90, 106176. [Google Scholar] [CrossRef]

- Barbash, V.A.; Yaschenko, O.V.; Shniruk, O.M. Preparation and Properties of Nanocellulose from Organosolv Straw Pulp. Nanoscale Res. Lett. 2017, 12, 1–8. [Google Scholar] [CrossRef]

- Pandi, N.; Sonawane, S.H.; Anand Kishore, K. Synthesis of Cellulose Nanocrystals (CNCs) from Cotton Using Ultrasound-Assisted Acid Hydrolysis. Ultrason. Sonochem. 2021, 70, 105353. [Google Scholar] [CrossRef]

- Martins, M.A.; Teixeira, E.M.; Corrêa, A.C.; Ferreira, M.; Mattoso, L.H.C. Extraction and Characterization of Cellulose Whiskers from Commercial Cotton Fibers. J. Mater. Sci. 2011, 46, 7858–7864. [Google Scholar] [CrossRef]

- Rahbar Shamskar, K.; Heidari, H.; Rashidi, A. Preparation and Evaluation of Nanocrystalline Cellulose Aerogels from Raw Cotton and Cotton Stalk. Ind. Crops. Prod. 2016, 93, 203–211. [Google Scholar] [CrossRef]

- Yue, Y.; Zhou, C.; French, A.D.; Xia, G.; Han, G.; Wang, Q.; Wu, Q. Comparative Properties of Cellulose Nano-Crystals from Native and Mercerized Cotton Fibers. Cellulose 2012, 19, 1173–1187. [Google Scholar] [CrossRef]

- Morais, J.P.S.; Rosa, M.D.F.; De Souza Filho, M.D.S.M.; Nascimento, L.D.; Do Nascimento, D.M.; Cassales, A.R. Extraction and Characterization of Nanocellulose Structures from Raw Cotton Linter. Carbohydr. Polym. 2013, 91, 229–235. [Google Scholar] [CrossRef]

- Huang, S.; Tao, R.; Ismail, A.; Wang, Y. Cellulose Nanocrystals Derived from Textile Waste through Acid Hydrolysis and Oxidation as Reinforcing Agent of Soy Protein Film. Polymers 2020, 12, 958. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Caldas, M.X.; Apostolopoulou-Kalkavoura, V.; Hellström, A.K.; Hildenbrand, J.; Larsson, M.; Jaworski, A.; Samec, J.S.M.; Lahtinen, P.; Tammelin, T.; Mathew, A.P. Citrated Cellulose Nanocrystals from Post-Consumer Cotton Textiles. J. Mater. Chem. A Mater. 2023, 11, 6854–6868. [Google Scholar] [CrossRef]

- Xiong, R.; Zhang, X.; Tian, D.; Zhou, Z.; Lu, C. Comparing Microcrystalline with Spherical Nanocrystalline Cellulose from Waste Cotton Fabrics. Cellulose 2012, 19, 1189–1198. [Google Scholar] [CrossRef]

- Mohamed, S.H.; Hossain, M.S.; Kassim, M.H.M.; Ahmad, M.I.; Omar, F.M.; Balakrishnan, V.; Zulkifli, M.; Yahaya, A.N.A. Recycling Waste Cotton Cloths for the Isolation of Cellulose Nanocrystals: A Sustainable Approach. Polymers 2021, 13, 626. [Google Scholar] [CrossRef] [PubMed]

- Chattopadhyay, D.P.; Patel, B.H. Synthesis, Characterization and Application of Nano Cellulose for Enhanced Performance of Textiles. J. Text. Sci. Eng. 2016, 6, 2. [Google Scholar] [CrossRef]

- Lim, Y.H.; Chew, I.M.L.; Choong, T.S.Y.; Tan, M.C.; Tan, K.W. NanoCrystalline Cellulose Isolated from Oil Palm Empty Fruit Bunch and Its Potential in Cadmium Metal Removal. MATEC Web. Conf. 2016, 59. [Google Scholar] [CrossRef]

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose Nanocrystals: Chemistry, Self-Assembly, and Applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef]

- Kumar, S.; Negi, Y.; Lett, J.U. Studies on Characterization of Corn Cob Based Nanoparticles. Adv. Mater. Lett. 2010, 2010, 246–253. [Google Scholar] [CrossRef]

- Kunusa, W.R.; Isa, I.; Laliyo, L.A.R.; Iyabu, H. FTIR, XRD and SEM Analysis of Microcrystalline Cellulose (MCC) Fibers from Corncorbs in Alkaline Treatment. J. Phys. Conf. Ser. 2018, 1028, 012199. [Google Scholar] [CrossRef]

- Kwon, G.-J.; Han, S.-Y.; Park, C.-W.; Park, J.-S.; Lee, E.-A.; Kim, N.-H.; Alle, M.; Bandi, R.; Lee, S.-H. Adsorption Characteristics of Ag Nanoparticles on Cellulose Nanofibrils with Different Chemical Compositions. Polymers 2020, 12, 164. [Google Scholar] [CrossRef]

- Oliveira, R.L.; Vieira, J.G.; Barud, H.S.; Assunção, R.M.N.; Filho, G.R.; Ribeiro, S.J.L.; Messadeqq, Y. Synthesis and Characterization of Methylcellulose Produced from Bacterial Cellulose under Heterogeneous Condition. J. Braz. Chem. Soc. 2015, 26, 1861–1870. [Google Scholar] [CrossRef]

- Helmiyati, H.; Budiman, Y.; Abbas, G.H.; Dini, F.W.; Khalil, M. Highly Efficient Synthesis of Biodiesel Catalyzed by a Cellulose@hematite-Zirconia Nanocomposite. Heliyon 2021, 7, e06622. [Google Scholar] [CrossRef] [PubMed]

- Sumarago, E.C.; dela Cerna, M.F.M.; Leyson, A.K.B.; Tan, N.P.B.; Magsico, K.F. Production and Characterization of Nanocellulose from Maguey (Agave Cantala) Fiber. Polymers 2024, 16, 1312. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Li, X.; Li, Q.; Wang, S.; Luo, Y. Estimation of Aspect Ratio of Cellulose Nanocrystals by Viscosity Measurement: Influence of Aspect Ratio Distribution and Ionic Strength. Polymers 2019, 11, 781. [Google Scholar] [CrossRef]

| Starting Material | Sample | NaOH and Urea Solubilization in an Ice Bath | Kept Time and Temperature | Centrifugation Temperature | Sonication in an Ice Bath |

|---|---|---|---|---|---|

| Children’s clothing | MCC1 | --- | --- | --- | --- |

| Undyed towel | MCC2 | --- | --- | --- | --- |

| MCC1 | MCC1-20 | No | −20 °C for 16 h | RT | --- |

| MCC1-1 | No | −20 °C for 16 h | RT | No | |

| MCC1-2 | No | −20 °C for 16 h | RT | No | |

| MCC1-3 | No | −20 °C for 16 h | RT | No | |

| MCC1-4 | No | −20 °C for 16 h | RT | No | |

| MCC2 | MCC2-RT | Yes | RT for 16 h | 4 °C | Yes |

| MCC2-20 | Yes | −20 °C for 16 h | 4 °C | Yes | |

| MCC2-4 | Yes | 4 °C for 16 h | 4 °C | Yes |

| Raw Materials | Length (µm) | Width/Height/ Diameter (µm) | Methods | References |

|---|---|---|---|---|

| 100% polyester yarn with fresh raw cotton fibers | 45–65 | 20–30 | H2SO4 hydrolysis | [41] |

| Cotton sliver | 5 | -- | H2SO4 hydrolysis | [42] |

| Cotton sliver | 1–1900 | 0.15–0.020 | H2SO4 hydrolysis | [43] |

| Waste cotton:polyester ~19:1 clothes | 0.5–1 | -- | H2SO4 hydrolysis | [17] |

| Yarn waste | 27 | -- | H2SO4 hydrolysis | [44] |

| Cotton waste | -- | 37.8 | Alkaline treatment and H2SO4 hydrolysis | [45] |

| Cotton/polyester fabric blends | 45–65 | 20–30 | Chemical pretreatment and H2SO4 hydrolysis | [41] |

| Waste-cotton dyed cotton shirt | 0.87–111 | -- | Phosphotungstic acid hydrolysis | [46] |

| Jute fabric | 14.28–181.31 | 2.197–63.73 | Alkaline treatment with NaOH | [47] |

| Cotton garment fabric waste | -- | 32 | HCl hydrolysis | [48] |

| Yarn waste | 25 | -- | HCl hydrolysis | [44] |

| Short staple cotton variety: Bengal desi | 45–53 | -- | HCI hydrolysis | [33] |

| Waste-cotton fabrics | -- | 20–50 | HCI hydrolysis | [49] |

| Cotton children’s clothing | 50–300 | 7–15 | HCl hydrolysis | Present study |

| Cotton towel | 50–400 | 12–17 | HCl hydrolysis | Present study |

| Raw Materials | Length (nm) | Height/Diameter (nm) | Methods | References |

|---|---|---|---|---|

| Commercial cotton balls | 150 ± 50 | 14 ± 5 | Alkali extraction, H2SO4 hydrolysis, centrifugation, neutralization, ultrasonication | [53] |

| Cotton-stalk bleached pulps | 450 | 25 | Treated with synthetic white liquor, bleached cotton pulp using hydrogen peroxide, H2SO4 hydrolysis, sonification, centrifugation | [54] |

| Short staple cotton variety: Bengal desi | 287.24 ± 79.75 | 29.69 ± 5.07 | MMC by HCl hydrolysis; H2SO4 hydrolysis, centrifugation, neutralization, freeze-dried | [33] |

| 120.27 ± 36.25 | 40.74 ± 7.59 | Enzymatic hydrolysis | ||

| Cotton fabrics | 76–159 | 14.2–15 | NaOH solution treatments, neutralization, H2SO4 hydrolysis, centrifugation, neutralization, high-pressure homogenization, ultrasonication | [55] |

| Cotton linters | 177 | 12 | H2SO4 hydrolysis, neutralization, centrifugation | [56] |

| Degreasing cotton | 17–230 | 2–25 | Boiled with NaOH, neutralization, mixed H2SO4 and HCI hydrolysis, neutralization, sonification, centrifugation | [34] |

| Waste-cotton cloth | 28–470 | 3–35 | ||

| Textile waste from factory | 111.76 ± 38.73 | 11.18 ± 2.33 | H2SO4 hydrolysis | [57] |

| 97.25 ± 25.18 | 5.69 ± 2.08 | Three-step oxidization | ||

| Post-consumer cotton fabrics | 218 ± 112 | 12 ± 7 | Citric-acid esterification, sonification, neutralized by NaOH, fibrillated using high-pressure microfluidization | [58] |

| MCC from waste-cotton fabrics | 5–100 | 10–65 | MCC obtained by boiling NaOH, boiling with NaClO, and nitric acid and HCl hydrolysis; H2SO4 hydrolysis, neutralization, sonification, centrifugation | [59] |

| Waste cloths from landfill | 10–30 | 2–6 | Alkali pulping with NaOH, bleaching, and H2SO4 hydrolysis, centrifugation, homogenization, ultrasonication | [60] |

| MCC from cotton towel by HCl hydrolysis | 200–1000 | 2–4 | NaOH/urea solvent system and ultrasonication | Present study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Işıtan, A.; Pasquardini, L.; Bersani, M.; Gök, C.; Fioravanti, S.; Lunelli, L.; Çağlarer, E.; Koluman, A. Sustainable Production of Microcrystalline and Nanocrystalline Cellulose from Textile Waste Using HCl and NaOH/Urea Treatment. Polymers 2025, 17, 48. https://doi.org/10.3390/polym17010048

Işıtan A, Pasquardini L, Bersani M, Gök C, Fioravanti S, Lunelli L, Çağlarer E, Koluman A. Sustainable Production of Microcrystalline and Nanocrystalline Cellulose from Textile Waste Using HCl and NaOH/Urea Treatment. Polymers. 2025; 17(1):48. https://doi.org/10.3390/polym17010048

Chicago/Turabian StyleIşıtan, Arzum, Laura Pasquardini, Massimo Bersani, Cem Gök, Simona Fioravanti, Lorenzo Lunelli, Evren Çağlarer, and Ahmet Koluman. 2025. "Sustainable Production of Microcrystalline and Nanocrystalline Cellulose from Textile Waste Using HCl and NaOH/Urea Treatment" Polymers 17, no. 1: 48. https://doi.org/10.3390/polym17010048

APA StyleIşıtan, A., Pasquardini, L., Bersani, M., Gök, C., Fioravanti, S., Lunelli, L., Çağlarer, E., & Koluman, A. (2025). Sustainable Production of Microcrystalline and Nanocrystalline Cellulose from Textile Waste Using HCl and NaOH/Urea Treatment. Polymers, 17(1), 48. https://doi.org/10.3390/polym17010048