Macroalgae Bioplastics: A Sustainable Shift to Mitigate the Ecological Impact of Petroleum-Based Plastics

Abstract

1. Introduction

2. Plastic Pollution and Its Significant Detrimental Impacts

2.1. Carbon Footprint

2.2. Ecosystem Disruption

2.3. Health Problems

2.4. Economic Lose

2.5. Longevity and Persistence

3. Environmental and Economic Benefits of Macroalgae Bioplastics

Bioplastic Industry: Future Prospective for Economic Growth and Job Creation

4. History of Bioplastic

5. Classification of Bioplastics

6. Macroalgae as Sources of Bioplastic Compounds

6.1. Main Compounds of Bioplastics Produced from Brown Macroalgae

6.1.1. Alginate-Based Bioplastics

6.1.2. Fucoidan-Based Bioplastic

6.1.3. Laminarin-Based Bioplastics

6.2. Main Compounds of Bioplastic Produced from Red Algae

6.2.1. Carrageenan-Based Bioplastic

6.2.2. Agar-Based Bioplastic

6.3. Main Compounds of Bioplastics Produced from Green Macroalgae

6.3.1. Ulvan-Based Bioplastics

6.3.2. Starch-Based Bioplastic

7. Processing of Macroalgae for Bioplastic Production

7.1. Harvesting and Processing of Macroalgae

7.2. Extraction of Polysaccharides from Macroalgae

7.2.1. Extraction of Alginate

7.2.2. Extraction of Laminarin

7.2.3. Extraction of Ulvan

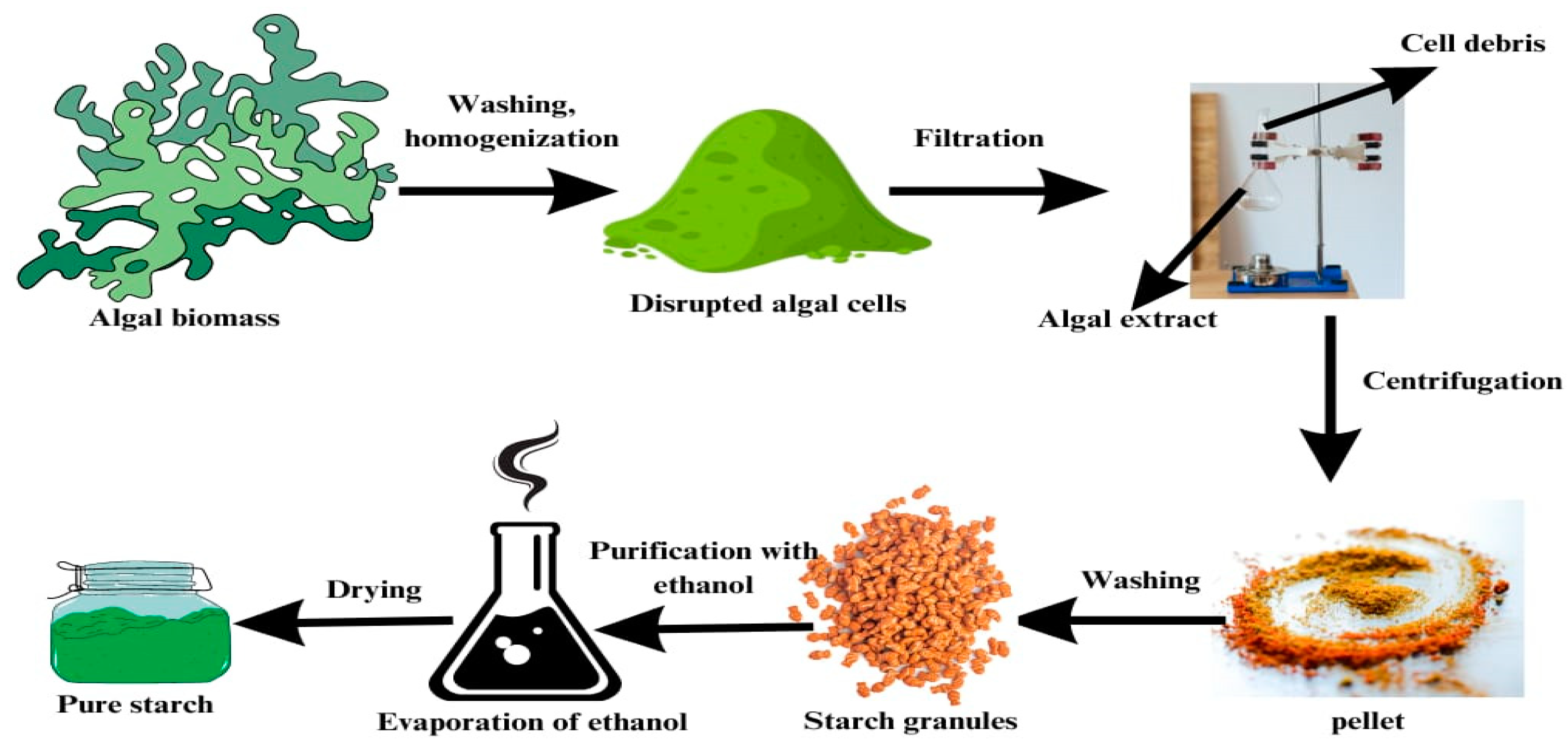

7.2.4. Extraction of Starch

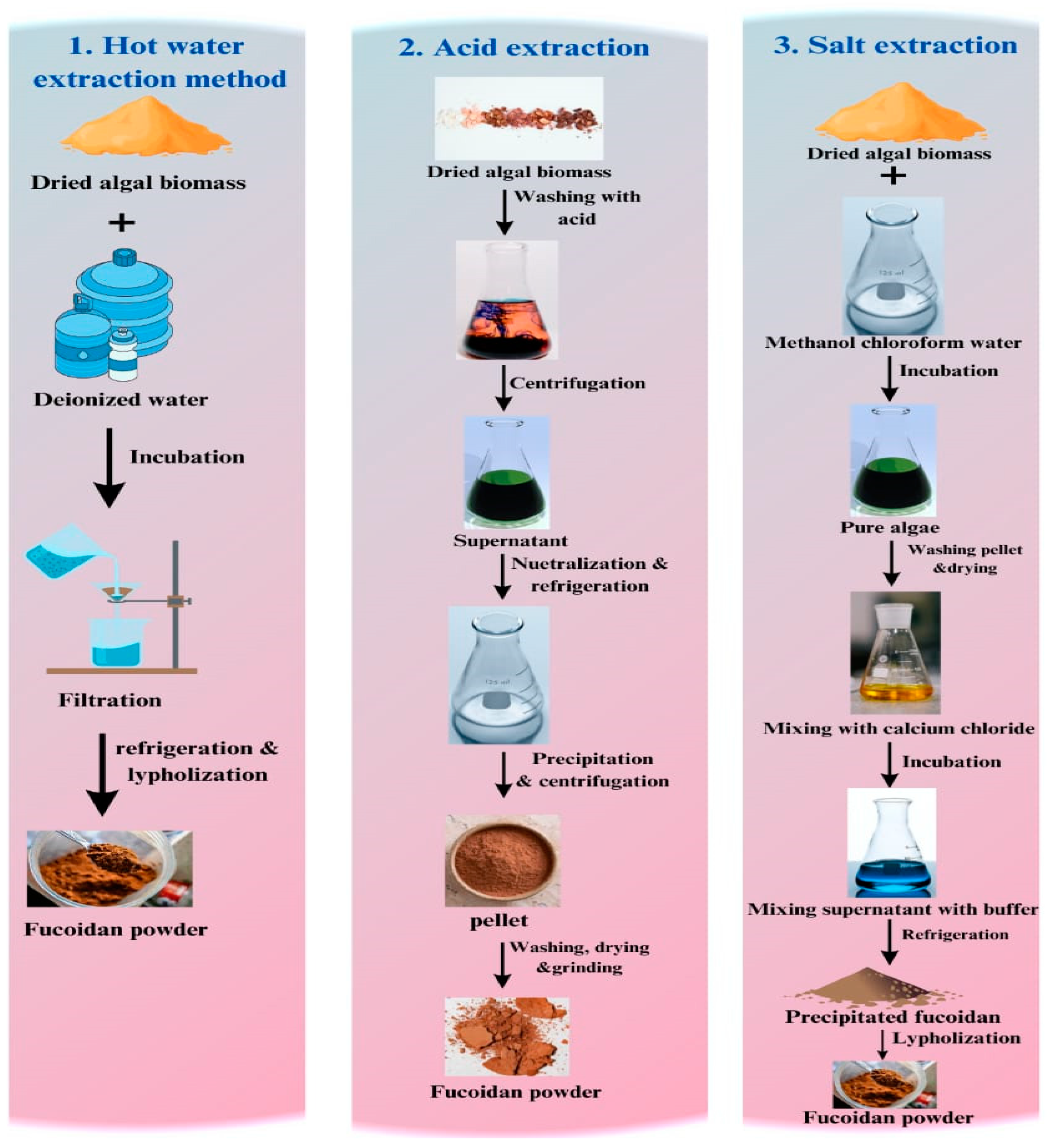

7.2.5. Extraction of Fucoidan

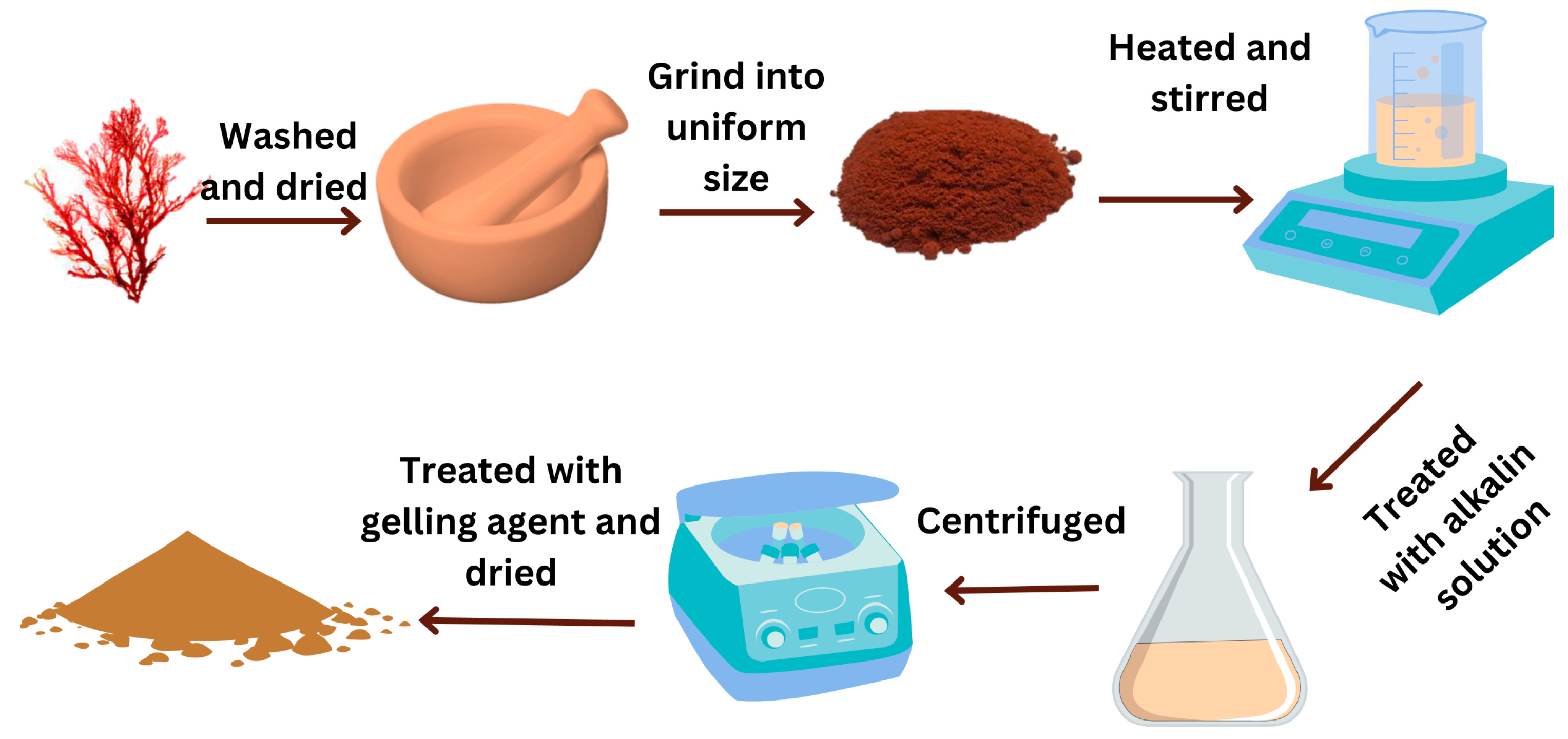

7.2.6. Extraction of Carrageenan

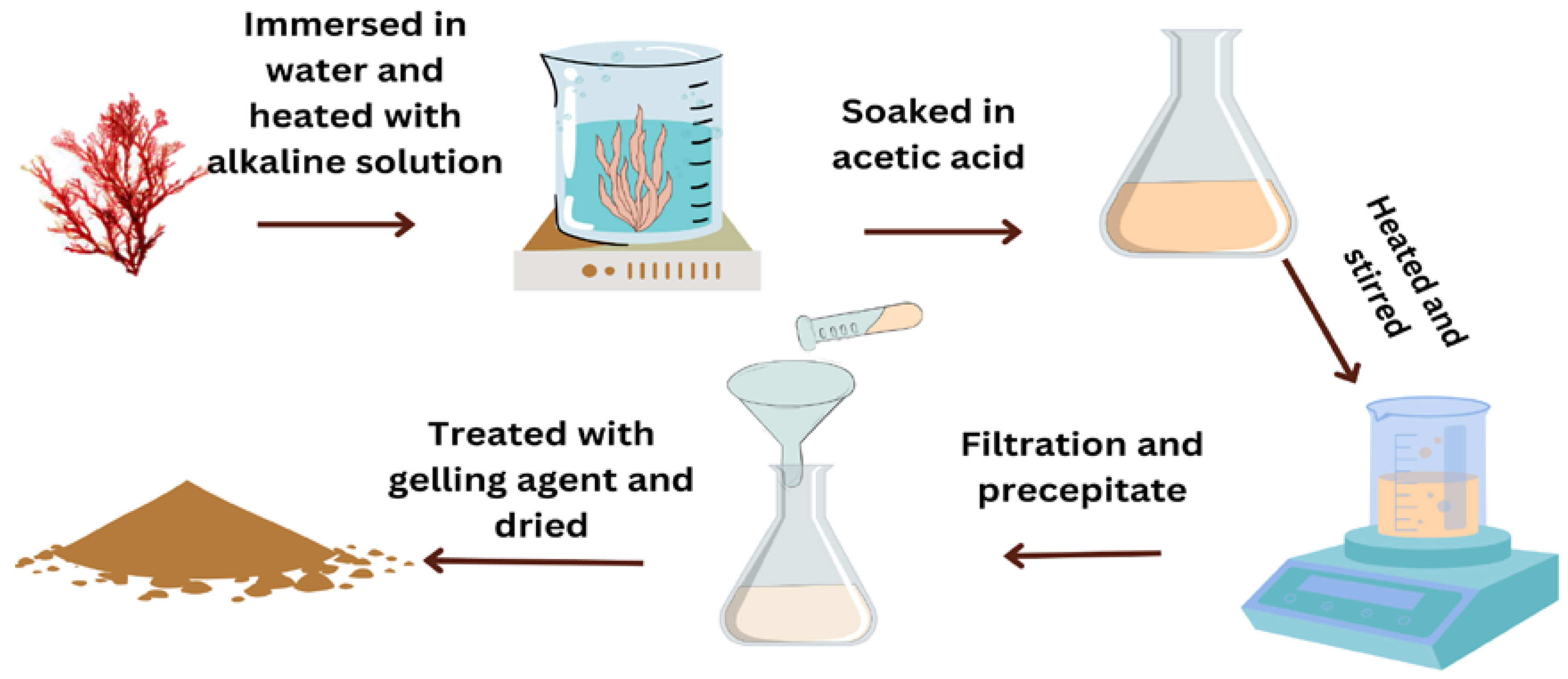

7.2.7. Extraction of Agar

7.3. Formation of Bioplastic

8. Mechanical and Physical Characteristics of Bioplastics

8.1. Tensile Strength (TS) and Elongation at Break (EAB) Properties of Bioplastics

8.2. Thickness Property of Bioplastics

8.3. Thermal Resistance (TR) Property of Bioplastics

8.4. Plasticizers Addition for Improving Bioplastic Properties

9. Biodegradability of Macroalgae Bioplastics

10. Examples of Products Made from Bioplastics

11. Challenges and Limitations of Macroalgae Bioplastic Production

12. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, M.; Sun, Y.; Rathour, R.; Pandey, A.; Thakur, I.S.; Tsang, D.C.W. Algae as Potential Feedstock for the Production of Biofuels and Value-Added Products: Opportunities and Challenges. Sci. Total Environ. 2020, 716, 137116. [Google Scholar] [CrossRef]

- Senousy, H.H.; Khairy, H.M.; El-Sayed, H.S.; Sallam, E.R.; El-Sheikh, M.A.; Elshobary, M.E. Interactive Adverse Effects of Low-Density Polyethylene Microplastics on Marine Microalga Chaetoceros Calcitrans. Chemosphere 2023, 311, 137182. [Google Scholar] [CrossRef]

- Kumar, M.; Xiong, X.; He, M.; Tsang, D.C.W.; Gupta, J.; Khan, E.; Harrad, S.; Hou, D.; Ok, Y.S.; Bolan, N.S. Microplastics as Pollutants in Agricultural Soils. Env. Pollut. 2020, 265, 114980. [Google Scholar] [CrossRef]

- Bishop, G.; Styles, D.; Lens, P.N.L. Environmental Performance Comparison of Bioplastics and Petrochemical Plastics: A Review of Life Cycle Assessment (LCA) Methodological Decisions. Resour. Conserv. Recycl. 2021, 168, 105451. [Google Scholar] [CrossRef]

- Shah, M.; Rajhans, S.; Himanshu, A.P.; Archana, U. Mankad Bioplastic for Future: A Review Then and Now. World J. Adv. Res. Rev. 2021, 9, 056–067. [Google Scholar] [CrossRef]

- Lim, C.; Yusoff, S.; Ng, C.G.; Lim, P.E.; Ching, Y.C. Bioplastic Made from Seaweed Polysaccharides with Green Production Methods. J. Environ. Chem. Eng. 2021, 9, 105895. [Google Scholar] [CrossRef]

- Ashour, M.; Al-Souti, A.S.; Hassan, S.M.; Ammar, G.A.G.; Goda, A.M.A.-S.; El-Shenody, R.; Abomohra, A.E.-F.; El-Haroun, E.; Elshobary, M.E. Commercial Seaweed Liquid Extract as Strawberry Biostimulants and Bioethanol Production. Life 2023, 13, 85. [Google Scholar] [CrossRef]

- Barakat, K.M.; Ismail, M.M.; Abou El Hassayeb, H.E.; El Sersy, N.A.; Elshobary, M.E. Chemical Characterization and Biological Activities of Ulvan Extracted from Ulva fasciata (Chlorophyta). Rend. Fis. Acc. Lincei 2022, 33, 829–841. [Google Scholar] [CrossRef]

- El-Sapagh, S.; El-Shenody, R.; Pereira, L.; Elshobary, M. Unveiling the Potential of Algal Extracts as Promising Antibacterial and Antibiofilm Agents against Multidrug-Resistant Pseudomonas Aeruginosa: In Vitro and In Silico Studies Including Molecular Docking. Plants 2023, 12, 3324. [Google Scholar] [CrossRef]

- El-Shenody, R.A.; Elshobary, M.E.; Ragab, G.A.; Huo, S.; Essa, D. Towards Biorefinery: Exploring the Potential of Seaweed-Derived Biodiesel and Its Residual Biomass in Improving the Traits of Eruca vesicaria (L.) Cav. S. Afr. J. Bot. 2023, 155, 361–371. [Google Scholar] [CrossRef]

- Osman, M.E.H.; Abo-Shady, A.M.; Elshobary, M.E.; Abd El-Ghafar, M.O.; Abomohra, A.E.-F. Screening of Seaweeds for Sustainable Biofuel Recovery through Sequential Biodiesel and Bioethanol Production. Env. Sci. Pollut. Res. 2020, 27, 32481–32493. [Google Scholar] [CrossRef] [PubMed]

- Osman, M.E.H.; Abo-Shady, A.M.; Elshobary, M.E.; Abd El-Ghafar, M.O.; Hanelt, D.; Abomohra, A. Exploring the Prospects of Fermenting/Co-Fermenting Marine Biomass for Enhanced Bioethanol Production. Fermentation 2023, 9, 934. [Google Scholar] [CrossRef]

- Huo, S.; Wang, H.; Chen, J.; Hu, X.; Zan, X.; Zhang, C.; Qian, J.; Zhu, F.; Ma, H.; Elshobary, M. A Preliminary Study on Polysaccharide Extraction, Purification, and Antioxidant Properties of Sugar-Rich Filamentous Microalgae Tribonema Minus. J. Appl. Phycol. 2022, 34, 2755–2767. [Google Scholar] [CrossRef]

- Ji, Y.; Gao, K. Effects of Climate Change Factors on Marine Macroalgae: A Review. Adv. Mar. Biol. 2021, 88, 91–136. [Google Scholar] [CrossRef] [PubMed]

- Kostas, E.; Adams, J.; Ruiz, H.; Duran-Jimenez, G.; Lye, G. Macroalgal Biorefinery Concepts for the Circular Bioeconomy: A Review on Biotechnological Developments and Future Perspectives. Renew. Sustain. Energy Rev. 2021, 151, 111553. [Google Scholar] [CrossRef]

- Sharma, S.; Sharma, A.; Mulla, S.I.; Pant, D.; Sharma, T.; Kumar, A. Lignin as Potent Industrial Biopolymer: An Introduction. In Lignin: Biosynthesis and Transformation for Industrial Applications; Springer: Cham, Switzerland, 2020; pp. 1–15. [Google Scholar]

- Farghali, M.; Mohamed, I.M.A.; Osman, A.I.; Rooney, D.W. Seaweed for Climate Mitigation, Wastewater Treatment, Bioenergy, Bioplastic, Biochar, Food, Pharmaceuticals, and Cosmetics: A Review. Environ. Chem. Lett. 2023, 21, 97–152. [Google Scholar] [CrossRef]

- Devadas, V.V.; Khoo, K.S.; Chia, W.Y.; Chew, K.W.; Munawaroh, H.S.H.; Lam, M.-K.; Lim, J.-W.; Ho, Y.-C.; Lee, K.T.; Show, P.L. Algae Biopolymer towards Sustainable Circular Economy. Bioresour. Technol. 2021, 325, 124702. [Google Scholar] [CrossRef] [PubMed]

- Sarwer, A.; Hamed, S.M.; Osman, A.I.; Jamil, F.; Al-Muhtaseb, A.H.; Alhajeri, N.S.; Rooney, D.W. Algal Biomass Valorization for Biofuel Production and Carbon Sequestration: A Review. Environ. Chem. Lett. 2022, 20, 2797–2851. [Google Scholar] [CrossRef]

- Coppola, G.; Gaudio, M.T.; Lopresto, C.G.; Calabro, V.; Curcio, S.; Chakraborty, S. Bioplastic from Renewable Biomass: A Facile Solution for a Greener Environment. Earth Syst. Environ. 2021, 5, 231–251. [Google Scholar] [CrossRef]

- Altahi, T.I. Handbook of Bioplastics and Biocomposites Engineering Applications, 2nd ed.; Wiley: Hoboken, NJ, USA, 2022. [Google Scholar] [CrossRef]

- Peters, S. Material Revolution: Sustainable and Multi-Purpose Materials for Design and Architecture. In Material Revolution; Birkhäuser: Basel, Switzerland, 2012; ISBN 978-3-0346-1077-3. [Google Scholar]

- Madadi, R.; Maljaee, H.; Serafim, L.S.; Ventura, S.P.M. Microalgae as Contributors to Produce Biopolymers. Mar. Drugs 2021, 19, 466. [Google Scholar] [CrossRef]

- Carina, D.; Sharma, S.; Jaiswal, A.K.; Jaiswal, S. Seaweeds Polysaccharides in Active Food Packaging: A Review of Recent Progress. Trends Food Sci. Technol. 2021, 110, 559–572. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Su, L.; Ma, C.; Feng, Z.; Shi, H. Plastic Debris in Coastal Macroalgae. Environ. Res. 2022, 205, 112464. [Google Scholar] [CrossRef] [PubMed]

- Jaikumar, G.; Baas, J.; Brun, N.R.; Vijver, M.G.; Bosker, T. Acute Sensitivity of Three Cladoceran Species to Different Types of Microplastics in Combination with Thermal Stress. Environ. Pollut. 2018, 239, 733–740. [Google Scholar] [CrossRef] [PubMed]

- Jaikumar, G.; Brun, N.R.; Vijver, M.G.; Bosker, T. Reproductive Toxicity of Primary and Secondary Microplastics to Three Cladocerans during Chronic Exposure. Environ. Pollut. 2019, 249, 638–646. [Google Scholar] [CrossRef] [PubMed]

- Materić, D.; Holzinger, R.; Niemann, H. Nanoplastics and Ultrafine Microplastic in the Dutch Wadden Sea—The Hidden Plastics Debris? Sci. Total Environ. 2022, 846, 157371. [Google Scholar] [PubMed]

- Mitrano, D.M.; Wick, P.; Nowack, B. Placing Nanoplastics in the Context of Global Plastic Pollution. Nat. Nanotechnol. 2021, 16, 491–500. [Google Scholar] [CrossRef] [PubMed]

- Bergmann, M.; Almroth, B.C.; Brander, S.M.; Dey, T.; Green, D.S.; Gundogdu, S.; Krieger, A.; Wagner, M.; Walker, T.R. A Global Plastic Treaty Must Cap Production. Science 2022, 376, 469–470. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Suh, S. Strategies to Reduce the Global Carbon Footprint of Plastics. Nat. Clim. Chang. 2019, 9, 374–378. [Google Scholar] [CrossRef]

- Sharma, S.; Sharma, V.; Chatterjee, S. Contribution of Plastic and Microplastic to Global Climate Change and Their Conjoining Impacts on the Environment—A Review. Sci. Total Environ. 2023, 875, 162627. [Google Scholar]

- Awuchi, C.; Awuchi, C. Impacts of Plastic Pollution on the Sustainability of Seafood Value Chain and Human Health. Int. J. Adv. Acad. Res. 2019, 5, 46–138. [Google Scholar]

- Villarrubia-Gómez, P.; Cornell, S.E.; Fabres, J. Marine Plastic Pollution as a Planetary Boundary Threat—The Drifting Piece in the Sustainability Puzzle. Mar. Policy 2018, 96, 213–220. [Google Scholar] [CrossRef]

- Nava, V.; Leoni, B. A Critical Review of Interactions between Microplastics, Microalgae and Aquatic Ecosystem Function. Water Res. 2021, 188, 116476. [Google Scholar] [CrossRef] [PubMed]

- Tekman, M.B.; Walther, B.; Peter, C.; Gutow, L.; Bergmann, M. Impacts of Plastic Pollution in the Oceans on Marine Species, Biodiversity and Ecosystems; WWW Germany: Berlin, Germany, 2022; ISBN 3-946211-46-1. [Google Scholar]

- Lamb, J.B.; Willis, B.L.; Fiorenza, E.A.; Couch, C.S.; Howard, R.; Rader, D.N.; True, J.D.; Kelly, L.A.; Ahmad, A.; Jompa, J.; et al. Plastic Waste Associated with Disease on Coral Reefs. Science 2018, 359, 460–462. [Google Scholar] [CrossRef] [PubMed]

- Caron, A.G.M.; Thomas, C.R.; Berry, K.L.E.; Motti, C.A.; Ariel, E.; Brodie, J.E. Ingestion of Microplastic Debris by Green Sea Turtles (Chelonia Mydas) in the Great Barrier Reef: Validation of a Sequential Extraction Protocol. Mar. Pollut. Bull. 2018, 127, 743–751. [Google Scholar] [CrossRef] [PubMed]

- McCormick, A.R.; Hoellein, T.J.; London, M.G.; Hittie, J.; Scott, J.W.; Kelly, J.J. Microplastic in Surface Waters of Urban Rivers: Concentration, Sources, and Associated Bacterial Assemblages. Ecosphere 2016, 7, e01556. [Google Scholar] [CrossRef]

- Schuyler, Q.A.; Wilcox, C.; Townsend, K.; Hardesty, B.D.; Marshall, N.J. Mistaken Identity? Visual Similarities of Marine Debris to Natural Prey Items of Sea Turtles. BMC Ecol. 2014, 14, 14. [Google Scholar] [CrossRef] [PubMed]

- Cordova, M.R.; Riani, E.; Shiomoto, A. Microplastics Ingestion by Blue Panchax Fish (Aplocheilus Sp.) from Ciliwung Estuary, Jakarta, Indonesia. Mar. Pollut. Bull. 2020, 161, 111763. [Google Scholar] [CrossRef] [PubMed]

- Hale, R.C.; Seeley, M.E.; La Guardia, M.J.; Mai, L.; Zeng, E.Y. A Global Perspective on Microplastics. J. Geophys. Res. Ocean. 2020, 125, e2018JC014719. [Google Scholar] [CrossRef]

- Samal, K.; Kar, S.; Trivedi, S. Ecological Floating Bed (EFB) for Decontamination of Polluted Water Bodies: Design, Mechanism and Performance. J. Environ. Manag. 2019, 251, 109550. [Google Scholar] [CrossRef]

- Garrido Gamarro, E.; Ryder, J.; Elvevoll, E.; Olsen, R. Microplastics in Fish and Shellfish—A Threat to Seafood Safety? J. Aquat. Food Prod. Technol. 2020, 29, 417–425. [Google Scholar] [CrossRef]

- Neto, J.G.B.; Rodrigues, F.L.; Ortega, I.; Rodrigues, L.D.S.; Lacerda, A.L.D.F.; Coletto, J.L.; Kessler, F.; Cardoso, L.G.; Madureira, L.; Proietti, M.C. Ingestion of Plastic Debris by Commercially Important Marine Fish in Southeast-South Brazil. Environ. Pollut. 2020, 267, 115508. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.H.; Warren, S.H.; Kooter, I.; Williams, W.C.; George, I.J.; Vance, S.A.; Hays, M.D.; Higuchi, M.A.; Gavett, S.H.; DeMarini, D.M.; et al. Chemistry, Lung Toxicity and Mutagenicity of Burn Pit Smoke-Related Particulate Matter. Part. Fibre Toxicol. 2021, 18, 45. [Google Scholar] [CrossRef] [PubMed]

- Alabi, O.; Ologbonjaye, K.; Awosolu, O.; Alalade, O. Public and Environmental Health Effects of Plastic Wastes Disposal: A Review. J. Toxicol. Risk Assess. 2019, 5, 1–13. [Google Scholar] [CrossRef]

- Biemann, R.; Blüher, M.; Isermann, B. Exposure to Endocrine-Disrupting Compounds Such as Phthalates and Bisphenol A Is Associated with an Increased Risk for Obesity. Best. Pract. Res. Clin. Endocrinol. Metab. 2021, 35, 101546. [Google Scholar] [CrossRef] [PubMed]

- Carrington, D. Microplastic Particles Now Discoverable in Human Organs; The Guardian: London, UK, 2020; Available online: https://www.theguardian.com/environment/2020/aug/17/microplastic-particles-discovered-in-human-organs?CMP=share_btn_url (accessed on 3 November 2023).

- Nelms, S.E.; Easman, E.; Anderson, N.; Berg, M.; Coates, S.; Crosby, A.; Eisfeld-Pierantonio, S.; Eyles, L.; Flux, T.; Gilford, E.; et al. The Role of Citizen Science in Addressing Plastic Pollution: Challenges and Opportunities. Environ. Sci. Policy 2022, 128, 14–23. [Google Scholar] [CrossRef]

- Anguiano, D. California Passes First Sweeping US Law to Reduce Single-Use Plastic; The Guardian: London, UK, 2022. [Google Scholar]

- Thushari, G.G.N.; Senevirathna, J.D.M. Plastic Pollution in the Marine Environment. Heliyon 2020, 6, e04709. [Google Scholar] [CrossRef] [PubMed]

- Portman, M.E.; Brennan, R.E. Marine Litter from Beach-Based Sources: Case Study of an Eastern Mediterranean Coastal Town. Waste Manag. 2017, 69, 535–544. [Google Scholar] [CrossRef] [PubMed]

- McIlgorm, A.; Raubenheimer, K.; McIlgorm, D.E. Update of 2009 APEC Report on Economic Costs of Marine Debris to APEC Economies. Available online: https://www.apec.org/publications/2020/03/update-of-2009-apec-report-on-economic-costs-of-marine-debris-to-apec-economies (accessed on 3 November 2023).

- Moshood, T.D.; Nawanir, G.; Mahmud, F. Sustainability of Biodegradable Plastics: A Review on Social, Economic, and Environmental Factors. Crit. Rev. Biotechnol. 2022, 42, 892–912. [Google Scholar] [CrossRef]

- Barrowclough, D.; Birkbeck, C.D. Transforming the Global Plastics Economy: The Role of Economic Policies in the Global Governance of Plastic Pollution. Soc. Sci. 2022, 11, 26. [Google Scholar] [CrossRef]

- Moshood, T.D.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.H.; Abdul Ghani, A. Expanding Policy for Biodegradable Plastic Products and Market Dynamics of Bio-Based Plastics: Challenges and Opportunities. Sustainability 2021, 13, 6170. [Google Scholar] [CrossRef]

- Chung, M.R.W.Y.; Tan, I.S.; Foo, H.C.Y.; Lam, M.K.; Lim, S. Potential of Macroalgae-Based Biorefinery for Lactic Acid Production from Exergy Aspect. Biomass Conv. Bioref. 2023, 13, 2623–2653. [Google Scholar] [CrossRef]

- Vieira, V.; Cadoret, J.-P.; Acien, F.G.; Benemann, J. Clarification of Most Relevant Concepts Related to the Microalgae Production Sector. Processes 2022, 10, 175. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044; Environmental management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Omura, T.; Isobe, N.; Miura, T.; Ishii, S.; Mori, M.; Ishitani, Y.; Kimura, S.; Hidaka, K.; Komiyama, K.; Suzuki, M.; et al. Microbial Decomposition of Biodegradable Plastics on the Deep-Sea Floor. Nat. Commun. 2024, 15, 568. [Google Scholar] [CrossRef] [PubMed]

- Ahsan, W.A.; Hussain, A.; Lin, C.; Nguyen, M.K. Biodegradation of Different Types of Bioplastics through Composting—A Recent Trend in Green Recycling. Catalysts 2023, 13, 294. [Google Scholar] [CrossRef]

- Williams, A.T.; Rangel-Buitrago, N. The Past, Present, and Future of Plastic Pollution. Mar. Pollut. Bull. 2022, 176, 113429. [Google Scholar] [CrossRef] [PubMed]

- Bauer, F.; Ericsson, K.; Hasselbalch, J.; Nielsen, T.; Nilsson, L.J. Climate Innovations in the Plastic Industry: Prospects for Decarbonisation; IMES/EEES Report Series; Miljö- och Energisystem, LTH; Lunds Universitet: Lund, Sweden, 2018; ISBN 978-91-86961-37-4. [Google Scholar]

- Imbert, E.; Ladu, L.; Morone, P.; Quitzow, R. Comparing Policy Strategies for a Transition to a Bioeconomy in Europe: The Case of Italy and Germany. Energy Res. Soc. Sci. 2017, 33, 70–81. [Google Scholar] [CrossRef]

- Friedrich, D. Market and Business-Related Key Factors Supporting the Use of Compostable Bioplastics in the Apparel Industry: A Cross-Sector Analysis. J. Clean. Prod. 2021, 297, 126716. [Google Scholar] [CrossRef]

- Gupta, D.K. Saurabh Bioplastics: Origin, Types and Applications. In Basic Concepts in Environmental Biotechnology; CRC Press: Boca Raton, FL, USA, 2021; ISBN 978-1-00-313142-7. [Google Scholar]

- Shlush, E.; Davidovich-Pinhas, M. Bioplastics for Food Packaging. Trends Food Sci. Technol. 2022, 125, 66–80. [Google Scholar] [CrossRef]

- Degli Esposti, M.; Morselli, D.; Fava, F.; Bertin, L.; Cavani, F.; Viaggi, D.; Fabbri, P. The Role of Biotechnology in the Transition from Plastics to Bioplastics: An Opportunity to Reconnect Global Growth with Sustainability. FEBS Open Bio 2021, 11, 967–983. [Google Scholar] [CrossRef]

- Adam, I.; Walker, T.R.; Bezerra, J.C.; Clayton, A. Policies to Reduce Single-Use Plastic Marine Pollution in West Africa. Mar. Policy 2020, 116, 103928. [Google Scholar] [CrossRef]

- Xanthos, D.; Walker, T.R. International Policies to Reduce Plastic Marine Pollution from Single-Use Plastics (Plastic Bags and Microbeads): A Review. Mar. Pollut. Bull. 2017, 118, 17–26. [Google Scholar] [CrossRef] [PubMed]

- Cristi, M.A.; Holzapfel, C.; Nehls, M.; De Veer, D.; González, C.; Holtmann, G.; Honorato Zimmer, D.; Kiessling, T.; Leyton Muñoz, A.; Narváez Reyes, S.; et al. The Rise and Demise of Plastic Shopping Bags in Chile—Broad and Informal Coalition Supporting Ban as a First Step to Reduce Single-Use Plastics. Ocean. Coast. Manag. 2020, 187, 105079. [Google Scholar] [CrossRef]

- Walker, T.R.; McGuinty, E.; Charlebois, S.; Music, J. Single-Use Plastic Packaging in the Canadian Food Industry: Consumer Behavior and Perceptions. Humanit. Soc. Sci. Commun. 2021, 8, 80. [Google Scholar] [CrossRef]

- Nanda, S.; Patra, B.R.; Patel, R.; Bakos, J.; Dalai, A.K. Innovations in Applications and Prospects of Bioplastics and Biopolymers: A Review. Environ. Chem. Lett. 2022, 20, 379–395. [Google Scholar] [CrossRef] [PubMed]

- Cosma, I.G. Bio-Plastic—Between Current Practices and the Challenges of a Sustainable Future. Manag. J. 2018, 27, 51–63. [Google Scholar]

- Rafiqah, S.A.; Khalina, A.; Harmaen, A.S.; Tawakkal, I.A.; Zaman, K.; Asim, M.; Nurrazi, M.N.; Lee, C.H. A Review on Properties and Application of Bio-Based Poly(Butylene Succinate). Polymers 2021, 13, 1436. [Google Scholar] [CrossRef]

- Teixeira, L.V.; Bomtempo, J.V.; Oroski, F.d.A.; Coutinho, P.L.d.A. The Diffusion of Bioplastics: What Can We Learn from Poly(Lactic Acid)? Sustainability 2023, 15, 4699. [Google Scholar] [CrossRef]

- Gahlawat, G.; Kumari, P.; Bhagat, N.R. Technological Advances in the Production of Polyhydroxyalkanoate Biopolymers. Curr. Sustain. Energy Rep. 2020, 7, 73–83. [Google Scholar] [CrossRef]

- Siracusa, V.; Blanco, I. Bio-Polyethylene (Bio-PE), Bio-Polypropylene (Bio-PP) and Bio-Poly(Ethylene Terephthalate) (Bio-PET): Recent Developments in Bio-Based Polymers Analogous to Petroleum-Derived Ones for Packaging and Engineering Applications. Polymers 2020, 12, 1641. [Google Scholar] [CrossRef]

- Pathak, S.; Sneha, C.L.R.; Mathew, B.B. Bioplastics: Its Timeline Based Scenario & Challenges. J. Polym. Biopolym. Phys. Chem. 2014, 2, 84–90. [Google Scholar]

- Dróżdż, D.; Malińska, K.; Postawa, P.; Stachowiak, T.; Nowak, D. End-of-Life Management of Biodegradable Plastic Dog Poop Bags through Composting of Green Waste. Materials 2022, 15, 2869. [Google Scholar] [CrossRef]

- Rahman, M.H.; Bhoi, P. An Overview of Non-Biodegradable Bioplastics. J. Clean. Prod. 2021, 294, 126218. [Google Scholar] [CrossRef]

- Joniver, C.F.H.; Photiades, A.; Moore, P.J.; Winters, A.L.; Woolmer, A.; Adams, J.M.M. The Global Problem of Nuisance Macroalgal Blooms and Pathways to Its Use in the Circular Economy. Algal Res. 2021, 58, 102407. [Google Scholar] [CrossRef]

- Guedes, A.; Amaro, H.; Sousa Pinto, I.; Malcata, F. Algal Spent Biomass—A Pool of Applications. In Biofuels from Algae, 2nd ed.; Pandey, A., Chang, J.-S., Soccol, C.R., Lee, D.-J., Chisti, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 397–433. ISBN 978-0-444-64192-2. [Google Scholar]

- Gomaa, M.; Fawzy, M.A.; Hifney, A.F.; Abdel-Gawad, K.M. Use of the Brown Seaweed Sargassum Latifolium in the Design of Alginate-Fucoidan Based Films with Natural Antioxidant Properties and Kinetic Modeling of Moisture Sorption and Polyphenolic Release. Food Hydrocoll. 2018, 82, 64–72. [Google Scholar] [CrossRef]

- Cajnko, M.M.; Novak, U.; Likozar, B. Cascade Valorization Process of Brown Alga Seaweed Laminaria Hyperborea by Isolation of Polyphenols and Alginate. J. Appl. Phycol. 2019, 31, 3915–3924. [Google Scholar] [CrossRef]

- Aleksanyan, K.V. Polysaccharides for Biodegradable Packaging Materials: Past, Present, and Future (Brief Review). Polymers 2023, 15, 451. [Google Scholar] [CrossRef] [PubMed]

- Menshova, R.V.; Shevchenko, N.M.; Imbs, T.I.; Zvyagintseva, T.N.; Malyarenko, O.S.; Zaporoshets, T.S.; Besednova, N.N.; Ermakova, S.P. Fucoidans from Brown Alga Fucus Evanescens: Structure and Biological Activity. Front. Mar. Sci. 2016, 3, 129. [Google Scholar] [CrossRef]

- Alazaiza, M.Y.D.; Albahnasawi, A.; Eyvaz, M.; Al Maskari, T.; Nassani, D.E.; Abu Amr, S.S.; Abujazar, M.S.S.; Bashir, M.J.K. An Overview of Green Bioprocessing of Algae-Derived Biochar and Biopolymers: Synthesis, Preparation, and Potential Applications. Energies 2023, 16, 791. [Google Scholar] [CrossRef]

- Cesário, M.T.; da Fonseca, M.M.R.; Marques, M.M.; de Almeida, M.C.M.D. Marine Algal Carbohydrates as Carbon Sources for the Production of Biochemicals and Biomaterials. Biotechnol. Adv. 2018, 36, 798–817. [Google Scholar] [CrossRef]

- Tong, K.T.X.; Tan, I.S.; Foo, H.C.Y.; Lam, M.K.; Lim, S.; Lee, K.T. Advancement of Biorefinery-Derived Platform Chemicals from Macroalgae: A Perspective for Bioethanol and Lactic Acid. Biomass Conv. Bioref. 2022, 14, 1443–1479. [Google Scholar] [CrossRef] [PubMed]

- Zargarzadeh, M.; Amaral, A.J.R.; Custódio, C.A.; Mano, J.F. Biomedical Applications of Laminarin. Carbohydr. Polym. 2020, 232, 115774. [Google Scholar] [CrossRef] [PubMed]

- Ismail, M.M.; Ismail, G.A.; Elshobary, M.E. Morpho-Anatomical, and Chemical Characterization of Some Calcareous Mediterranean Red Algae Species. Bot. Stud. 2023, 64, 10. [Google Scholar] [CrossRef] [PubMed]

- Kalasariya, H.S.; Yadav, V.K.; Yadav, K.K.; Tirth, V.; Algahtani, A.; Islam, S.; Gupta, N.; Jeon, B.-H. Seaweed-Based Molecules and Their Potential Biological Activities: An Eco-Sustainable Cosmetics. Molecules 2021, 26, 5313. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, D.N.; Inácio, A.R.; Sousa, R.O.; Reis, R.L.; Silva, T.H. Seaweed Polysaccharides as Sustainable Building Blocks for Biomaterials in Tissue Engineering. In Sustainable Seaweed Technologies; Elsevier: Amsterdam, The Netherlands, 2020; pp. 543–587. [Google Scholar]

- Abdou, E. Sorour, manal (PDF) Preparation and Characterization of Starch/Carrageenan Edible Films. Int. Food Res. J. 2014, 21, 189–193. [Google Scholar]

- Chiovitti, A.; Bacic, A.; Craik, D.J.; Kraft, G.T.; Liao, M.-L. A Nearly Idealized 6′-O-Methylated η-Carrageenan from the Australian Red Alga Claviclonium ovatum (Acrotylaceae, Gigartinales). Carbohydr. Res. 2004, 339, 1459–1466. [Google Scholar] [CrossRef]

- Falshaw, R.; Furneaux, R.H.; Stevenson, D.E. Structural Analysis of Carrageenans from the Red Alga, Callophyllis hombroniana Mont. Kütz (Kallymeniaceae, Rhodophyta). Carbohydr. Res. 2005, 340, 1149–1158. [Google Scholar] [CrossRef]

- Noseda, M.D.; Cerezo, A.S. Alkali Modification of Carrageenans—II. The Cyclization of Model Compounds Containing Nonsulfated β-d-Galactose Units. Carbohydr. Polym. 1995, 26, 1–3. [Google Scholar] [CrossRef]

- Viana, A.; Noseda, M.; Duarte, M.; Cerezo, A. Alkali Modification of Carrageenans. Part V. The Iota?Nu Hybrid Carrageenan from and Its Cyclization to Iota-Carrageenan. Carbohydr. Polym. 2004, 58, 455–460. [Google Scholar] [CrossRef]

- Zablackis, E.; Santos, G.A. The Carrageenan of Catenella nipae Zanard., a Marine Red Alga. J. Bot. Mar. 1986, 29, 319–322. [Google Scholar] [CrossRef]

- Kadar, N.A.H.A.; Rahim, N.S.; Yusof, R.; Nasir, N.A.H.A.; Hamid, H.A. A Review on Potential of Algae in Producing Biodegradable Plastic. Int. J. Eng. Adv. Res. 2021, 3, 13–26. [Google Scholar]

- Parveen, I.; Maraz, K.M.; Mahmud, I.; Khan, R.A. Seaweed Based Bio Polymeric Film and Their Application: A Review on Hydrocolloid Polysaccharides. Sci. Rev. 2019, 5, 93–102. [Google Scholar] [CrossRef]

- Litaay, C.; Arfah, H.; Rugebregt, M.J.; Opier, R.D.A. Species Diversity, Density, Phosphate Concentration and the Utilization of Algae as a Food Material. IOP Conf. Ser. Earth Environ. Sci. 2021, 777, 012004. [Google Scholar] [CrossRef]

- Rashad, S.; El-Chaghaby, G.A. Marine Algae in Egypt: Distribution, Phytochemical Composition and Biological Uses as Bioactive Resources (a Review). Egypt. J. Aquat. Biol. Fish. 2020, 24, 147–160. [Google Scholar] [CrossRef]

- Gomaa, M. Biodegradable Plastics Based on Algal Polymers: Recent Advances and Applications. In Handbook of Biodegradable Materials; Ali, G.A.M., Makhlouf, A.S.H., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 1–31. ISBN 978-3-030-83783-9. [Google Scholar]

- Manikandan, N.; Lens, P.N.L. Green Extraction and Esterification of Marine Polysaccharide (Ulvan) from Green Macroalgae Ulva Sp. Using Citric Acid for Hydrogel Preparation. J. Clean. Prod. 2022, 366, 132952. [Google Scholar] [CrossRef]

- Tziveleka, L.-A.; Ioannou, E.; Roussis, V. Ulvan, a Bioactive Marine Sulphated Polysaccharide as a Key Constituent of Hybrid Biomaterials: A Review. Carbohydr. Polym. 2019, 218, 355–370. [Google Scholar] [CrossRef] [PubMed]

- Tudu, M.; Samanta, A. Natural Polysaccharides: Chemical Properties and Application in Pharmaceutical Formulations. Eur. Polym. J. 2023, 184, 111801. [Google Scholar] [CrossRef]

- Surendren, A.; Mohanty, A.K.; Liu, Q.; Misra, M. A Review of Biodegradable Thermoplastic Starches, Their Blends and Composites: Recent Developments and Opportunities for Single-Use Plastic Packaging Alternatives. Green Chem. 2022, 24, 8606–8636. [Google Scholar] [CrossRef]

- Sagnelli, D.; Hebelstrup, K.H.; Leroy, E.; Rolland-Sabaté, A.; Guilois, S.; Kirkensgaard, J.J.K.; Mortensen, K.; Lourdin, D.; Blennow, A. Plant-Crafted Starches for Bioplastics Production. Carbohydr. Polym. 2016, 152, 398–408. [Google Scholar] [CrossRef]

- Tagliapietra, B.L.; Borges, L.A.; Ferreira, N.L.B.; Clerici, M.T.P.S. Seaweed as a Potential New Source for Starch, Produced in the Sea: A Short Review. Starch Stärke 2023, 75, 2200130. [Google Scholar] [CrossRef]

- Prabhu, M.; Chemodanov, A.; Gottlieb, R.; Kazir, M.; Nahor, O.; Gozin, M.; Israel, A.; Livney, Y.D.; Golberg, A. Starch from the Sea: The Green Macroalga Ulva Ohnoi as a Potential Source for Sustainable Starch Production in the Marine Biorefinery. Algal Res. 2019, 37, 215–227. [Google Scholar] [CrossRef]

- Gomez-Zavaglia, A.; Prieto Lage, M.A.; Jimenez-Lopez, C.; Mejuto, J.C.; Simal-Gandara, J. The Potential of Seaweeds as a Source of Functional Ingredients of Prebiotic and Antioxidant Value. Antioxidants 2019, 8, 406. [Google Scholar] [CrossRef] [PubMed]

- Araújo, R.; Vázquez Calderón, F.; Sánchez López, J.; Azevedo, I.C.; Bruhn, A.; Fluch, S.; Garcia Tasende, M.; Ghaderiardakani, F.; Ilmjärv, T.; Laurans, M.; et al. Current Status of the Algae Production Industry in Europe: An Emerging Sector of the Blue Bioeconomy. Front. Mar. Sci. 2021, 7, 1247. [Google Scholar] [CrossRef]

- Kumar, M.D.; Kavitha, S.; Tyagi, V.K.; Rajkumar, M.; Bhatia, S.K.; Kumar, G.; Banu, J.R. Macroalgae-Derived Biohydrogen Production: Biorefinery and Circular Bioeconomy. Biomass Convers. Biorefinery 2022, 12, 769–791. [Google Scholar] [CrossRef]

- Liu, J.; Dickson, R.; Niaz, H.; Van Hal, J.; Dijkstra, J.W.; Fasahati, P. Production of Fuels and Chemicals from Macroalgal Biomass: Current Status, Potentials, Challenges, and Prospects. Renew Sustain. Energy Rev. 2022, 169, 112954. [Google Scholar] [CrossRef]

- André, R.; Pacheco, R.; Bourbon, M.; Serralheiro, M.L. Brown Algae Potential as a Functional Food against Hypercholesterolemia: Review. Foods 2021, 10, 234. [Google Scholar] [CrossRef]

- Łabowska, M.B.; Michalak, I.; Detyna, J. Methods of Extraction, Physicochemical Properties of Alginates and Their Applications in Biomedical Field—A Review. Open Chem. 2019, 17, 738–762. [Google Scholar] [CrossRef]

- Lim, J.-Y.; Siew Ling, H.; Chee, S.-Y.; Wong, C.-L. Sargassum Siliquosum, J. Agardh Extract as Potential Material for Synthesis of Bioplastic Film. J. Appl. Phycol. 2018, 30, 3285–3297. [Google Scholar] [CrossRef]

- Saji, S.; Hebden, A.; Goswami, P.; Du, C. A Brief Review on the Development of Alginate Extraction Process and Its Sustainability. Sustainability 2022, 14, 5181. [Google Scholar] [CrossRef]

- Rhim, J.W. Physical and Mechanical Properties of Water Resistant Sodium Alginate Films. LWT-Food Sci. Technol. 2004, 37, 323–330. [Google Scholar] [CrossRef]

- Goh, C.H.; Heng, P.W.S.; Chan, L.W. Cross-Linker and Non-Gelling Na+ Effects on Multi-Functional Alginate Dressings. Carbohydr. Polym. 2012, 87, 1796–1802. [Google Scholar] [CrossRef]

- Olivas, G.I.; Barbosa-Cánovas, G.V. Alginate–Calcium Films: Water Vapor Permeability and Mechanical Properties as Affected by Plasticizer and Relative Humidity. LWT-Food Sci. Technol. 2008, 41, 359–366. [Google Scholar] [CrossRef]

- Costa, M.J.; Marques, A.M.; Pastrana, L.M.; Teixeira, J.A.; Sillankorva, S.M.; Cerqueira, M.A. Physicochemical Properties of Alginate-Based Films: Effect of Ionic Crosslinking and Mannuronic and Guluronic Acid Ratio. Food Hydrocoll. 2018, 81, 442–448. [Google Scholar] [CrossRef]

- Li, J.; He, J.; Huang, Y.; Li, D.; Chen, X. Improving Surface and Mechanical Properties of Alginate Films by Using Ethanol as a Co-Solvent during External Gelation. Carbohydr. Polym. 2015, 123, 208–216. [Google Scholar] [CrossRef] [PubMed]

- Gao, C.; Pollet, E.; Avérous, L. Properties of Glycerol-Plasticized Alginate Films Obtained by Thermo-Mechanical Mixing. Food Hydrocoll. 2017, 63, 414–420. [Google Scholar] [CrossRef]

- Alves, A.; Pinho, E.D.; Neves, N.M.; Sousa, R.A.; Reis, R.L. Processing Ulvan into 2D Structures: Cross-Linked Ulvan Membranes as New Biomaterials for Drug Delivery Applications. Int. J. Pharm. 2012, 426, 76–81. [Google Scholar] [CrossRef] [PubMed]

- Pereira, R.; Carvalho, A.; Vaz, D.C.; Gil, M.H.; Mendes, A.; Bártolo, P. Development of Novel Alginate Based Hydrogel Films for Wound Healing Applications. Int. J. Biol. Macromol. 2013, 52, 221–230. [Google Scholar] [CrossRef] [PubMed]

- Jia, L.-C.; Sun, W.-J.; Zhou, C.-G.; Yan, D.-X.; Zhang, Q.-C.; Li, Z.-M. Integrated Strength and Toughness in Graphene/Calcium Alginate Films for Highly Efficient Electromagnetic Interference Shielding. J. Mater. Chem. C 2018, 6, 9166–9174. [Google Scholar] [CrossRef]

- Liling, G.; Di, Z.; Jiachao, X.; Xin, G.; Xiaoting, F.; Qing, Z. Effects of Ionic Crosslinking on Physical and Mechanical Properties of Alginate Mulching Films. Carbohydr. Polym. 2016, 136, 259–265. [Google Scholar] [CrossRef]

- Mohammed, C.; Mahabir, S.; Mohammed, K.; John, N.; Lee, K.-Y.; Ward, K. Calcium Alginate Thin Films Derived from Sargassum Natans for the Selective Adsorption of Cd2+, Cu2+, and Pb2+ Ions. Ind. Eng. Chem. Res. 2019, 58, 1417–1425. [Google Scholar] [CrossRef]

- Abraham, R.E.; Su, P.; Puri, M.; Raston, C.L.; Zhang, W. Optimisation of Biorefinery Production of Alginate, Fucoidan and Laminarin from Brown Seaweed Durvillaea Potatorum. Algal Res. 2019, 38, 101389. [Google Scholar] [CrossRef]

- Sterner, M.; Gröndahl, F. Extraction of Laminarin from Saccharina Latissima Seaweed Using Cross-Flow Filtration. J. Appl. Phycol. 2021, 33, 1825–1844. [Google Scholar] [CrossRef]

- Cindana Mo’o, F.R.; Wilar, G.; Devkota, H.P.; Wathoni, N. Ulvan, a Polysaccharide from Macroalga Ulva Sp.: A Review of Chemistry, Biological Activities and Potential for Food and Biomedical Applications. Appl. Sci. 2020, 10, 5488. [Google Scholar] [CrossRef]

- Kidgell, J.T.; Magnusson, M.; de Nys, R.; Glasson, C.R.K. Ulvan: A Systematic Review of Extraction, Composition and Function. Algal Res. 2019, 39, 101422. [Google Scholar] [CrossRef]

- January, G.; Naidoo, R.; Kirby-McCullough, B.; Bauer, R. Assessing Methodologies for Fucoidan Extraction from South African Brown Algae. Algal Res. 2019, 40, 101517. [Google Scholar] [CrossRef]

- Moses, J.; Anandhakumar, R.; Shanmugam, M. Effect of Alkaline Treatment on the Sulfate Content and Quality of Semi-Refined Carrageenan Prepared from Seaweed Kappaphycus Alvarezii Doty (Doty) Farmed in Indian Waters. Afr. J. Biotechnol. 2015, 14, 1584–1589. [Google Scholar] [CrossRef]

- Rupert, R.; Rodrigues, K.F.; Thien, V.Y.; Yong, W.T.L. Carrageenan from Kappaphycus alvarezii (Rhodophyta, Solieriaceae): Metabolism, Structure, Production, and Application. Front. Plant Sci. 2022, 13, 859635. [Google Scholar] [CrossRef]

- Hussein, M.H. Extraction of Agar from Gelidium Sp (Rhodophyta) and Green Synthesis of Agar/Silver Nanoparticles. J. Agric. Chem. Biotechnol. 2015, 6, 419–434. [Google Scholar] [CrossRef]

- Dang, B.-T.; Bui, X.-T.; Tran, D.P.H.; Hao Ngo, H.; Nghiem, L.D.; Hoang, T.-K.-D.; Nguyen, P.-T.; Nguyen, H.H.; Vo, T.-K.-Q.; Lin, C.; et al. Current Application of Algae Derivatives for Bioplastic Production: A Review. Bioresour. Technol. 2022, 347, 126698. [Google Scholar] [CrossRef]

- Leong, Y.K.; Chang, J.S. Bioprocessing for Production and Applications of Bioplastics from Algae. In Algae-Based Biomaterials for Sustainable Development; Elsevier: Amsterdam, The Netherlands, 2022; pp. 105–132. ISBN 978-0-323-96143-1. [Google Scholar]

- Gomaa, M.; Hifney, A.F.; Fawzy, M.A.; Issa, A.A.; Abdel-Gawad, K.M. Biodegradation of Palisada perforata (Rhodophyceae) and Sargassum Sp. (Phaeophyceae) Biomass by Crude Enzyme Preparations from Algicolous Fungi. J. Appl. Phycol. 2015, 27, 2395–2404. [Google Scholar] [CrossRef]

- Kadam, S.U.; Pankaj, S.K.; Tiwari, B.K.; Cullen, P.J.; O’Donnell, C.P. Development of Biopolymer-Based Gelatin and Casein Films Incorporating Brown Seaweed Ascophyllum Nodosum Extract. Food Packag. Shelf Life 2015, 6, 68–74. [Google Scholar] [CrossRef]

- Matche, R.S.; Anup, G.J.; Mrudula, G. Development of Biodegradable Films from Marine Ingredients Incorporated with Natural Antimicrobial Agents for Food Packaging. J. Package Technol. Res. 2020, 4, 45–55. [Google Scholar] [CrossRef]

- Nogueira, L.F.B.; Maniglia, B.C.; Pereira, L.S.; Tapia-Blácido, D.R.; Ramos, A.P. Formation of Carrageenan-CaCO3 Bioactive Membranes. Mater. Sci. Eng. C 2016, 58, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Paula, G.A.; Benevides, N.M.B.; Cunha, A.P.; de Oliveira, A.V.; Pinto, A.M.B.; Morais, J.P.S.; Azeredo, H.M.C. Development and Characterization of Edible Films from Mixtures of κ-Carrageenan, ι-Carrageenan, and Alginate. Food Hydrocoll. 2015, 47, 140–145. [Google Scholar] [CrossRef]

- Ismail, A.; Hammami, W.; Mensi, F.; Ktari, L. Bioplastic from Agar: Hydrophilic and Thermo-Mecanical Properties. INSTM Bull. Mar. Freshw. Sci. 2015, 42, 17–19. [Google Scholar]

- Mostafavi, F.S.; Zaeim, D. Agar-Based Edible Films for Food Packaging Applications—A Review. Int. J. Biol. Macromol. 2020, 159, 1165–1176. [Google Scholar] [CrossRef] [PubMed]

- Russ, N.; Zielbauer, B.I.; Koynov, K.; Vilgis, T.A. Influence of Nongelling Hydrocolloids on the Gelation of Agarose. Biomacromolecules 2013, 14, 4116–4124. [Google Scholar] [CrossRef] [PubMed]

- Guidara, M.; Yaich, H.; Richel, A.; Blecker, C.; Boufi, S.; Attia, H.; Garna, H. Effects of Extraction Procedures and Plasticizer Concentration on the Optical, Thermal, Structural and Antioxidant Properties of Novel Ulvan Films. Int. J. Biol. Macromol. 2019, 135, 647–658. [Google Scholar] [CrossRef]

- Morelli, A.; Betti, M.; Puppi, D.; Chiellini, F. Design, Preparation and Characterization of Ulvan Based Thermosensitive Hydrogels. Carbohydr. Polym. 2016, 136, 1108–1117. [Google Scholar] [CrossRef] [PubMed]

- Díaz-Montes, E. Polysaccharides: Sources, Characteristics, Properties, and Their Application in Biodegradable Films. Polysaccharides 2022, 3, 480–501. [Google Scholar] [CrossRef]

- Jiang, J.; Yao, C.; Cao, X.; Liu, Y.; Xue, S. Characterization of Starch Phosphorylase from the Marine Green Microalga (Chlorophyta) Tetraselmis Subcordiformis Reveals Its Potential Role in Starch Biosynthesis. J. Plant Physiol. 2017, 218, 84–93. [Google Scholar] [CrossRef]

- Sudhakar, M.P.; Magesh Peter, D.; Dharani, G. Studies on the Development and Characterization of Bioplastic Film from the Red Seaweed (Kappaphycus alvarezii). Environ. Sci. Pollut. Res. 2021, 28, 33899–33913. [Google Scholar] [CrossRef] [PubMed]

- Budiman, M.; Tarman, K. A Review on the Difference of Physical and Mechanical Properties of Bioplastic from Seaweed Hydrocolloids with Various Plasticizers; IOP Publishing: Bristol, UK, 2022; Volume 967, p. 012012. [Google Scholar]

- Kanagesan, K.; Abdulla, R.; Derman, E.; Sabullah, M.K.; Govindan, N.; Gansau, J.A. A Sustainable Approach to Green Algal Bioplastics Production from Brown Seaweeds of Sabah, Malaysia. J. King Saud. Univ. -Sci. 2022, 34, 102268. [Google Scholar] [CrossRef]

- Ili Balqis, A.M.; Nor Khaizura, M.a.R.; Russly, A.R.; Nur Hanani, Z.A. Effects of Plasticizers on the Physicochemical Properties of Kappa-Carrageenan Films Extracted from Eucheuma Cottonii. Int. J. Biol. Macromol. 2017, 103, 721–732. [Google Scholar] [CrossRef] [PubMed]

- Rasheed, I.; Riaz, S.; Shafique, S. Seaweed as Natural Raw Material for Industrial Applications; Extraction, Physio-Chemical Characterization and Antioxidant Potential of Alginate Based Biofilm. Pak. J. Pharm. Sci. 2023, 36, 1241–1248. [Google Scholar]

- Hanry, E.L.; Surugau, N. Characterization of Bioplastics Developed from Whole Seaweed Biomass (Kappaphycus sp.) Added with Commercial Sodium Alginate. J. Appl. Phycol. 2023; 1–10. [Google Scholar] [CrossRef]

- El-Sheekh, M.M.; Alwaleed, E.A.; Ibrahim, A.; Saber, H. Preparation and Characterization of Bioplastic Film from the Green Seaweed Halimeda opuntia. Int. J. Biol. Macromol. 2024, 259, 129307. [Google Scholar] [CrossRef] [PubMed]

- Chia, W.Y.; Tang, D.; Khoo, K.S.; Lup, A.; Kit Wayne, C. Nature’s Fight against Plastic Pollution: Algae for Plastic Biodegradation and Bioplastics Production. Environ. Sci. Ecotechnol. 2020, 4, 100065. [Google Scholar] [CrossRef]

- Accinelli, C.; Saccà, M.L.; Mencarelli, M.; Vicari, A. Deterioration of Bioplastic Carrier Bags in the Environment and Assessment of a New Recycling Alternative. Chemosphere 2012, 89, 136–143. [Google Scholar] [CrossRef]

- Bacha, A.-U.-R.; Nabi, I.; Zaheer, M.; Jin, W.; Yang, L. Biodegradation of Macro- and Micro-Plastics in Environment: A Review on Mechanism, Toxicity, and Future Perspectives. Sci. Total Environ. 2023, 858, 160108. [Google Scholar]

- Dalal, S.R.; El-Naggar, N.E.-A.; El Naeem, G.A. Biosynthesis of Sustainable Biodegradable Bioplastics Using Alginate Extracted from Padina Pavonica, Optimization and Characterization. Algal Res. 2023, 76, 103325. [Google Scholar] [CrossRef]

- Husseiny, S.; Elgiddawy, N.; El-Sayyad, G.; El Rouby, W. Recent Advances in Microbial Biodegradation. In Handbook of Biodegradable Materials; Springer International Publishing: Cham, Switzerland, 2023; pp. 111–136. ISBN 978-3-031-09709-6. [Google Scholar]

- Ramu Ganesan, A.; Shanmugam, M.; Bhat, R. Producing Novel Edible Films from Semi Refined Carrageenan (SRC) and Ulvan Polysaccharides for Potential Food Applications. Int. J. Biol. Macromol. 2018, 112, 1164–1170. [Google Scholar] [CrossRef] [PubMed]

- Alves, Z.; Ferreira, N.M.; Mendo, S.; Ferreira, P.; Nunes, C. Design of Alginate-Based Bionano-composites with Electrical Conductivity for Active Food Packaging. Int. J. Mol. Sci. 2021, 22, 9943. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.; Xu, J.; Gao, X.; Fu, X.; Zheng, D. Factors Affecting Water Resistance of Alginate/Gellan Blend Films on Paper Cups for Hot Drinks. Carbohydr. Polym. 2017, 156, 435–442. [Google Scholar] [CrossRef] [PubMed]

- Bergonzi, C.; d’Ayala, G.G.; Elviri, L.; Laurienzo, P.; Bandiera, A.; Catanzano, O. Alginate/Human Elastin-like Polypeptide Composite Films with Antioxidant Properties for Potential Wound Healing Application. Int. J. Biol. Macromol. 2020, 164, 586–596. [Google Scholar] [CrossRef] [PubMed]

- Polat, T.G.; Duman, O.; Tunç, S. Agar/κ-Carrageenan/Montmorillonite Nanocomposite Hydrogels for Wound Dressing Applications. Int. J. Biol. Macromol. 2020, 164, 4591–4602. [Google Scholar] [CrossRef] [PubMed]

- Sezer, A.D.; Hatipoğlu, F.; Cevher, E.; Oğurtan, Z.; Baş, A.L.; Akbuğa, J. Chitosan Film Containing Fucoidan as a Wound Dressing for Dermal Burn Healing: Preparation and in Vitro/in Vivo Evaluation. AAPS PharmSciTech 2007, 8, 39. [Google Scholar] [CrossRef] [PubMed]

- Sedayu, B.B.; Cran, M.J.; Bigger, S.W. A Review of Property Enhancement Techniques for Carrageenan-Based Films and Coatings. Carbohydr. Polym. 2019, 216, 287–302. [Google Scholar] [CrossRef] [PubMed]

- Don, T.-M.; Liu, L.-M.; Chen, M.; Huang, Y.-C. Crosslinked Complex Films Based on Chitosan and Ulvan with Antioxidant and Whitening Activities. Algal Res. 2021, 58, 102423. [Google Scholar] [CrossRef]

- Jo, S.; Oh, Y.; Park, S.; Kan, E.; Lee, S. Cellulose/Carrageenan/TiO2 Nanocomposite for Adsorption and Photodegradation of Cationic Dye. Biotechnol. Bioprocess. Eng. 2017, 22, 734–738. [Google Scholar] [CrossRef]

- Shamsudin, M.; Farhan binti Azha, S.; Sellaoui, L.; Badawi, M.; Bonilla-Petriciolet, A.; Ismail, S.; Shamsudin, M. Performance and Interactions of Diclofenac Adsorption Using Alginate/Carbon-Based Films: Experimental Investigation and Statistical Physics Modelling. Chem. Eng. J. 2021, 428, 131929. [Google Scholar] [CrossRef]

- Alshahrani, A.; Alharbi, A.; Alnasser, S.; Almihdar, M.; Alsuhybani, M.; AlOtaibi, B. Enhanced Heavy Metals Removal by a Novel Carbon Nanotubes Buckypaper Membrane Containing a Mixture of Two Biopolymers: Chitosan and i-Carrageenan. Sep. Purif. Technol. 2021, 276, 119300. [Google Scholar] [CrossRef]

- Ugur Nigiz, F. Graphene Oxide-sodium Alginate Membrane for Seawater Desalination through Pervaporation. Desalination 2020, 485, 114465. [Google Scholar] [CrossRef]

- Merino, D.; Salcedo, M.F.; Mansilla, A.Y.; Casalongué, C.A.; Alvarez, V.A. Development of Sprayable Sodium Alginate-Seaweed Agricultural Mulches with Nutritional Benefits for Substrates and Plants. Waste Biomass Valor. 2021, 12, 6035–6043. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, J.; Zhang, X.; Tian, D.; Zhan, Z.; Lu, C. Ultrathin MXene/Calcium Alginate Aerogel Film for High-Performance Electromagnetic Interference Shielding. Adv. Mater. Interfaces 2019, 6, 1802040. [Google Scholar] [CrossRef]

- Ohm, Y.; Pan, C.; Ford, M.; Huang, X.; Liao, J.; Majidi, C. An Electrically Conductive Silver–Polyacrylamide–Alginate Hydrogel Composite for Soft Electronics. Nat. Electron. 2021, 4, 1–8. [Google Scholar] [CrossRef]

- Jumaah, F.N.; Mobarak, N.; Ahmad, A.; Ghani, M.A.; Rahman, M.Y.A. Derivative of Iota-Carrageenan as Solid Polymer Electrolyte. Ionics 2015, 21, 1311–1320. [Google Scholar] [CrossRef]

- Wen, X.; Zeng, Q.; Guan, J.; Wen, W.; Chen, P.; Li, Z.; Liu, Y.; Chen, A.; Liu, X.; Liu, W.; et al. 3D Structural Lithium Alginate-Based Gel Polymer Electrolytes with Superior High-Rate Long Cycling Performance for High-Energy Lithium Metal Batteries. J. Mater. Chem. A 2022, 10, 707–718. [Google Scholar] [CrossRef]

- Song, Q.; Li, A.; Shi, L.; Qian, C.; Feric, T.G.; Fu, Y.; Zhang, H.; Li, Z.; Wang, P.; Li, Z.; et al. Thermally Stable, Nano-Porous and Eco-Friendly Sodium Alginate/Attapulgite Separator for Lithium-Ion Batteries. Energy Storage Mater. 2019, 22, 48–56. [Google Scholar] [CrossRef]

- Tan, L.; Li, Z.; Shi, R.; Quan, F.; Wang, B.; Ma, X.; Ji, Q.; Tian, X.; Xia, Y. Preparation and Properties of an Alginate-Based Fiber Separator for Lithium-Ion Batteries. ACS Appl. Mater. Interfaces 2020, 12, 38175–38182. [Google Scholar] [CrossRef]

- Pasini Cabello, S.D.; Mollá, S.; Ochoa, N.A.; Marchese, J.; Giménez, E.; Compañ, V. New Bio-Polymeric Membranes Composed of Alginate-Carrageenan to Be Applied as Polymer Electrolyte Membranes for DMFC. J. Power Sources 2014, 265, 345–355. [Google Scholar] [CrossRef]

- Xue, Z.; Zhang, W.; Yan, M.; Liu, J.; Wang, B.; Xia, Y. Pyrolysis Products and Thermal Degradation Mechanism of Intrinsically Flame-Retardant Carrageenan Fiber. RSC Adv. 2017, 7, 25253–25264. [Google Scholar] [CrossRef]

- Rudhziah, S.; Ahmad, A.; Ahmad, I.; Mohamed, N.S. Biopolymer Electrolytes Based on Blend of Kappa-Carrageenan and Cellulose Derivatives for Potential Application in Dye Sensitized Solar Cell. Electrochim. Acta 2015, 175, 162–168. [Google Scholar] [CrossRef]

- Sreenikethanam, A.; Bajhaiya, A.; Sreenikethanam, A.; Bajhaiya, A. Algae Based Bio-Plastics: Future of Green Economy. In Biorefineries-Selected Processes; IntechOpen: Rijeka, Croatia, 2021; ISBN 978-1-83969-735-7. [Google Scholar]

| Bioplastic | Processing Methods | Details | References |

|---|---|---|---|

| Alginate | Casting | Sodium alginate is dissolved in water, glycerol or other plasticizers can be added, the solution is cast onto a surface like glass or plastic, and the solvent evaporates, leaving an alginate film. | [124] |

| External gelation | Films are first cast from sodium alginate, as above. Then, the dried films are immersed in a CaCl2 solution, which diffuses into the film, crosslinks the alginate chains, and improves film properties. Time in calcium solution can be optimized to control the extent of crosslinking. | [126,128] | |

| Compression molding | Alginate and plasticizers are premixed and heated to increase viscous flow, then pressed between mold plates at specific pressures and temperatures. Allows incorporation of thermoplastics. | [129] | |

| Fucoidan | Blending | Fucoidan lacks gel-forming ability alone, so it is blended with polymers like alginate or chitosan. They can be dissolved together in aqueous solutions before casting films. | [145] |

| Laminarin | Thermo-reversible gelation | Laminarin gelatinized when cooled below 40 °C, which can produce films. | [146] |

| Blending | Laminarin blending with other polymers like glycerol, chitosan, or crosslinking improves moisture and mechanical properties. | [147] | |

| Carrageenan | Casting | Carrageenan powder is dissolved in water along with plasticizers, then poured or spread onto a surface for solvent evaporation. | [148] |

| Ionic crosslinking | Divalent cations like Ca+2 are added to ι-carrageenan solutions, or K+ is added to κ-carrageenan, which induces helix formation and gelation. Crosslinking cations can be optimized. | [149] | |

| Blending | Blending with glycerol increases the plasticizer content, and the tensile strength decreases, but the elongation break increases, water vapors transmission, and oxygen transmission. | [150] | |

| Casting | Hot agar solution is poured onto a warm surface above its gel point. As water evaporates, hydrogen bonding between agar chains allows film formation. Silicone casting surfaces can help prevent sticking. | [151] | |

| Agar | Thermo-reversible gelation | Agar powder is added to water and heated to 90–100 °C to dissolve. Upon cooling to 32–40 °C, the agar chains transition from random coils to double helices, inducing gelation. | [152] |

| Blending | Blending agar with silky, clear, and firm glycerol for both commercial and algal agar. They lose weight by heating but still have the same texture. Algal agar has a higher water-holding capacity than commercial agar. They can be maintained for nine months. | [150] | |

| Ulvan | Casting | Similar to carrageenan, ulvan powder is dissolved in water, plasticizers are added, and then cast into films. | [153] |

| Thermo-reversible gelation | Aqueous ulvan solutions form gels upon heating and cooling cycles between 25 and 80 °C. Gel strength depends on ulvan molecular weight. | [154] | |

| Starch | Casting | Algal starch is dissolved in water with plasticizers like glycerol and cast into films similarly to other polysaccharides. | [155] |

| Heating in water | Starch can be gelatinized by heating in excess water, and then retrograded by cooling to make films. | [156] | |

| Blending | Ulvan and starch show good miscibility and interact synergistically when blended. Glycerol plasticization further improves green algal starch film properties. | [115] | |

| Compression molding | Heat and pressure can be used to produce thermoplastic starch bioplastic objects. | [144] |

| Bioplastic | Plasticizer | Thickness (mm) | Tensile Strength (TS) (MPa) | Elongation at Break (EAB) (%) | Ref. |

|---|---|---|---|---|---|

| Alginate | ــــــــــــ | 0.023 | ــــــــــــ | ــــــــــــ | [161] |

| Sorbitol | 0.23: 0.676 | ||||

| Glycerol | 0.113: 0.27 | ||||

| Whole biomass Kappaphycus sp. + sodium alginate | Glycerol | 0.054 | 7.91 ± 0.45 | ــــــــــــ | [162] |

| Kappa-carrageenan | ـــــــــــــ | 0.03153 | 69.69 | 3 | [160] |

| Glycerol | 0.05627 | 39 | 13 | ||

| Sorbitol | 0.05567 | 41 | 11 | ||

| PEG-300 | 0.05533 | 39 | 17 | ||

| Kappa-carrageenan (3%) | PEG-300 | 0.806 | 9.13 | 7.1 | [157] |

| Kappa-carrageenan (4%) | 0.097 | 13.78 | 4.72 | ||

| Kappa-carrageenan (5%) | 0.079 | 12.90 | 2.72 | ||

| Alginate (6%) | ــــــــــــ | ــــــــــــ | 14.96 | 0.86 | [159] |

| Inverted sugar | 2.13 | 17.44 | |||

| Halimeda opuntia: PVA films in ratios | Glycerol | [163] | |||

| 0.5:1 | 0.037 | 147.5 | 420.3 | ||

| 1:1 | 0.015 | 127.8 | 363.7 | ||

| 1.5:1 | 0.020 | 157.3 | 440 | ||

| 2:1 | 0.025 | 173.4 | 408.5 | ||

| 3:1 | 0.028 | 181.2 | 436.6 |

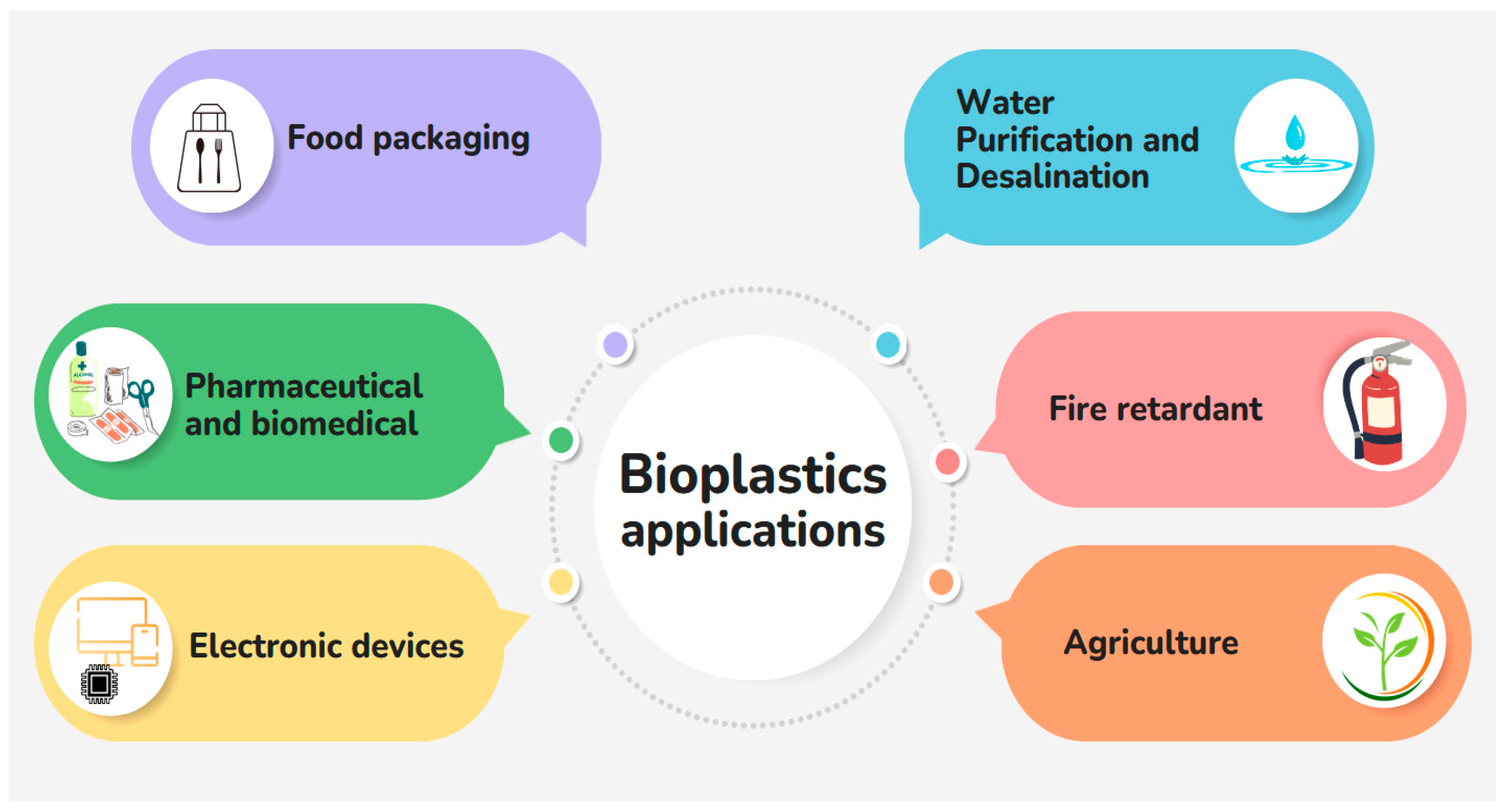

| Field of Application | Polysaccharide | Composite or Transformed Form | Specific Application | Ref. |

|---|---|---|---|---|

| Food packaging and coatings | Crude Alginate | Calcium alginate | Calcium alginate films are rich in co-extracted phlorotannins polyphenols | [87] |

| Carrageenan and Alginate | Carrageenan and calcium alginate | Films with promoted properties | [168] | |

| Alginate and Carrageenan | Alginate with two different types of carrageenan (κ- and ι-carrageenan) | Films with different physical properties | [149] | |

| Carrageenan and Ulvan | Semi-refined carrageenan and ulvan | Edible composite films with antioxidant properties | [169] | |

| Alginate | Graphene oxide and zinc oxide as an electrically conducting and active filler in alginate films and sepiolite for compatibility | Edible films with an electrical conduction property | [170] | |

| Alginate | Alginate/gellan | Water-resistant films as a coat on paper cups for hot drinks by spraying method | [171] | |

| Pharmaceutical and biomedical | Alginate | Human elastin-like polypeptide with alginate and cross-linked with curcumin and CaCl2 | Wound dressing | [172] |

| Ulvan and Chitosan | Ulvan/chitosan layer-by-layer films | Membranes used for neural implants and devices | [168] | |

| Ulvan | Ulvan was cross-linked using 1,4-Butanediol diglycidyl ether | Wound dressing for controlled release of a steroid antiinflammatory drug | [130] | |

| Alginate and Carrageenan | Sodium alginate and κ-carrageenan with potassium ions | Wound dressings with good swelling and bioactivity | [168] | |

| Carrageenan and Agar | κ-carrageenan was blended with agar | Biocompatible wound dressing | [173] | |

| Chitosan and Fucoidan | Chitosan/fucoidan porous film | Wound dressing | [174] | |

| Fucoidan | Collagenfucoidan blend films | Tissue regeneration | [175] | |

| Chitosan and Ulvan | Chitosan/ulvan composite membranes are further crosslinked by tripolyphosphate and glycerol | Wound dressing | [176] | |

| Water purification and desalination | Alginate | Calcium alginate | Films for the removal of heavy metals from an aqueous solution | [134] |

| Cellulose and Carrageenan | Anionic nanocomposite using cellulose, carrageenan, and TiO2 | Nanocomposite catalyzed the removal of methylene blue by photodegradation | [177] | |

| Alginate | Alginate and activated carbon | Membranes removed the analgesic drug diclofenac from solutions | [178] | |

| Carrageenan | κ-carrageenan into polyvinylidene fluoride membrane | Water separation from methyl orange dye solution | [168] | |

| Alginate | Alginate and bacterial cellulose | Separate ethanol/water mixtures | [168] | |

| Chitosan and Carrageenan | Multiwalled carbon nanotubes/chitosan/ι-carrageenan membrane | Remove heavy metals | [179] | |

| Alginate | Graphene oxide in sodium alginate membrane | Water desalination by pervaporation | [180] | |

| Agriculture | Alginate | Alginate crosslinking by Ca2+ | Films are carriers of plant nutrients | [133] |

| Alginate | Na-alginate | Na-alginate mulching coatings for stimulation of plant growth | [181] | |

| Electronic devices | Alginate | Graphene/calcium alginate thin films | Electromagnetic interference shielding | [132] |

| Alginate | Ti3C2Tx/Ca alginate films | Aerogel film provides electromagnetic interference shielding | [182] | |

| Alginate | Alginate hydrogel-polyacrylamide composite embedded with silver flakes | Material for electricity conduction | [183] | |

| Chitosan and Carrageenan | Chitosan/ι-carrageenan composite films with H3PO4 and poly(ethylene glycol) | Electrical double-layer capacitors as separators and electrolytes | [184] | |

| Alginate | Lithium alginate with poly(ethylene oxide) and polyacrylamide | Batteries | [185] | |

| Alginate | Sodium alginate/attapulgite nanofiber | Membrane as a potential separator in lithium-ion batteries | [186] | |

| Alginate and Cellulose | Calcium alginate and cellulose | Membranes with good performance as a separator in batteries | [187] | |

| Alginate and Carrageenan | Alginate and κ-carrageenan | Methanol fuel cells | [188] | |

| Fire retardant | Carrageenan | Carrageenan fibres | Fibers with good flame-retardant properties | [189] |

| Agar and Alginate | Agar and sodium alginate with boric acid | Flame-retardant composite films | [168] | |

| Chitosan and Alginate | Soluble chitosan, sodium alginate, and Cu+2 | Coat for polyester fabric | [168] | |

| Other application | Carrageenan | Carboxymethyl κ-carrageenan, CMC, and ammonium iodide | Polymer electrolyte films | [190] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elkaliny, N.E.; Alzamel, N.M.; Moussa, S.H.; Elodamy, N.I.; Madkor, E.A.; Ibrahim, E.M.; Elshobary, M.E.; Ismail, G.A. Macroalgae Bioplastics: A Sustainable Shift to Mitigate the Ecological Impact of Petroleum-Based Plastics. Polymers 2024, 16, 1246. https://doi.org/10.3390/polym16091246

Elkaliny NE, Alzamel NM, Moussa SH, Elodamy NI, Madkor EA, Ibrahim EM, Elshobary ME, Ismail GA. Macroalgae Bioplastics: A Sustainable Shift to Mitigate the Ecological Impact of Petroleum-Based Plastics. Polymers. 2024; 16(9):1246. https://doi.org/10.3390/polym16091246

Chicago/Turabian StyleElkaliny, Nehal E., Nurah M. Alzamel, Shaaban H. Moussa, Nour I. Elodamy, Engy A. Madkor, Esraa M. Ibrahim, Mostafa E. Elshobary, and Gehan A. Ismail. 2024. "Macroalgae Bioplastics: A Sustainable Shift to Mitigate the Ecological Impact of Petroleum-Based Plastics" Polymers 16, no. 9: 1246. https://doi.org/10.3390/polym16091246

APA StyleElkaliny, N. E., Alzamel, N. M., Moussa, S. H., Elodamy, N. I., Madkor, E. A., Ibrahim, E. M., Elshobary, M. E., & Ismail, G. A. (2024). Macroalgae Bioplastics: A Sustainable Shift to Mitigate the Ecological Impact of Petroleum-Based Plastics. Polymers, 16(9), 1246. https://doi.org/10.3390/polym16091246