Study of Cellulose Dissolution in ZnO/NaOH/Water Solvent Solution and Its Temperature-Dependent Effect Using Molecular Dynamics Simulation

Abstract

1. Introduction

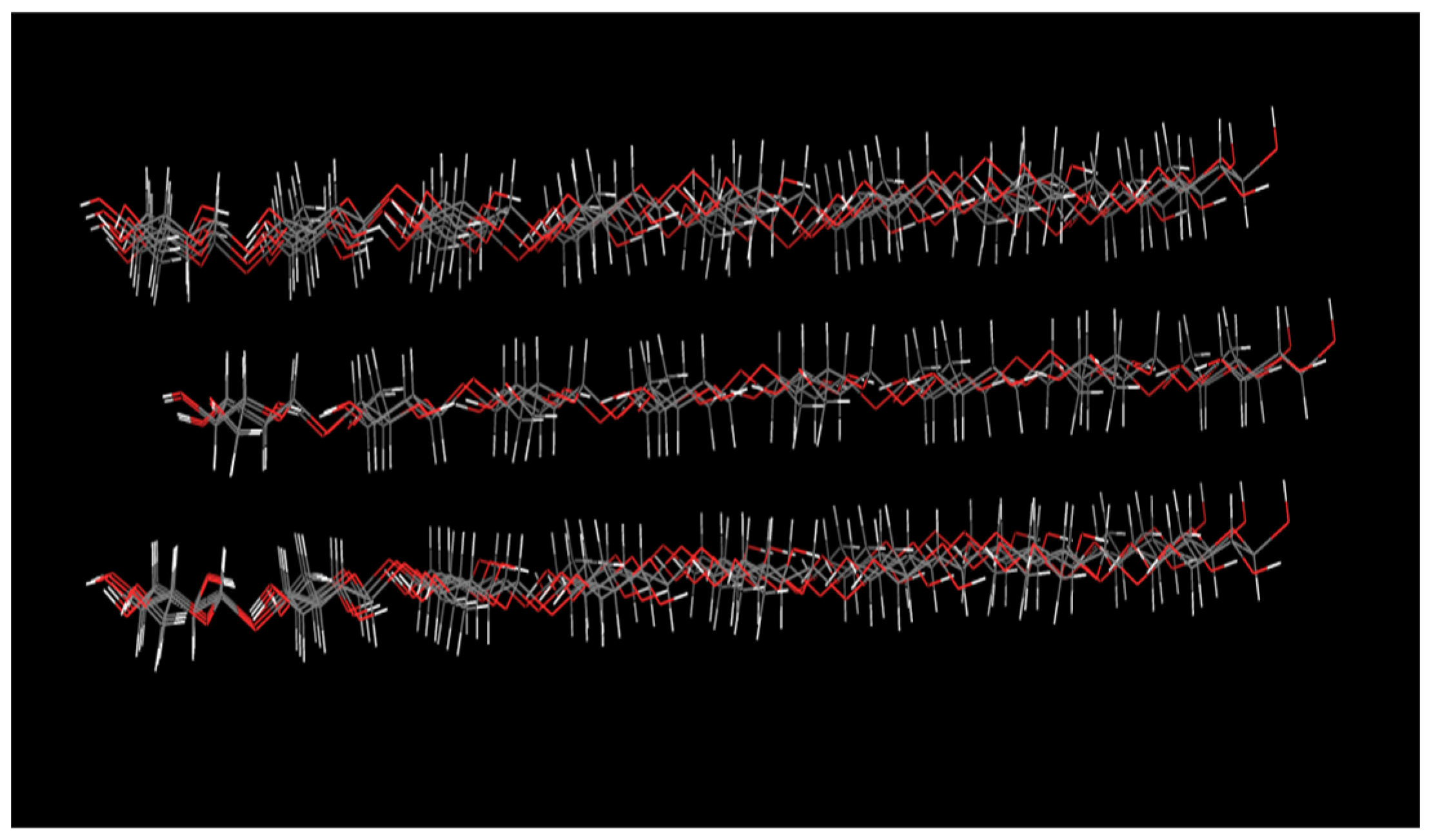

2. Materials and Methods

3. Results and Discussion

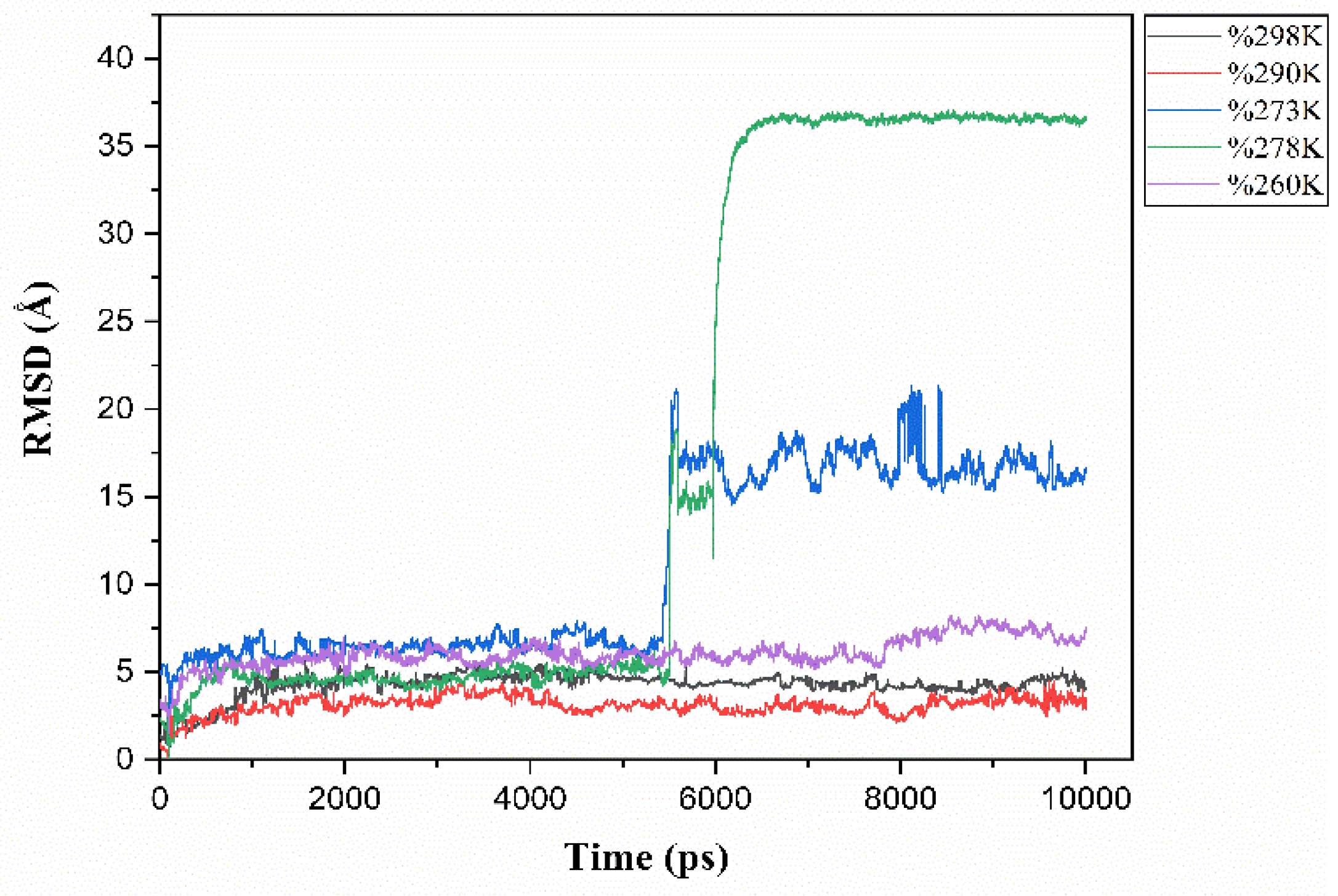

3.1. Root Mean Square Deviation (RMSD)

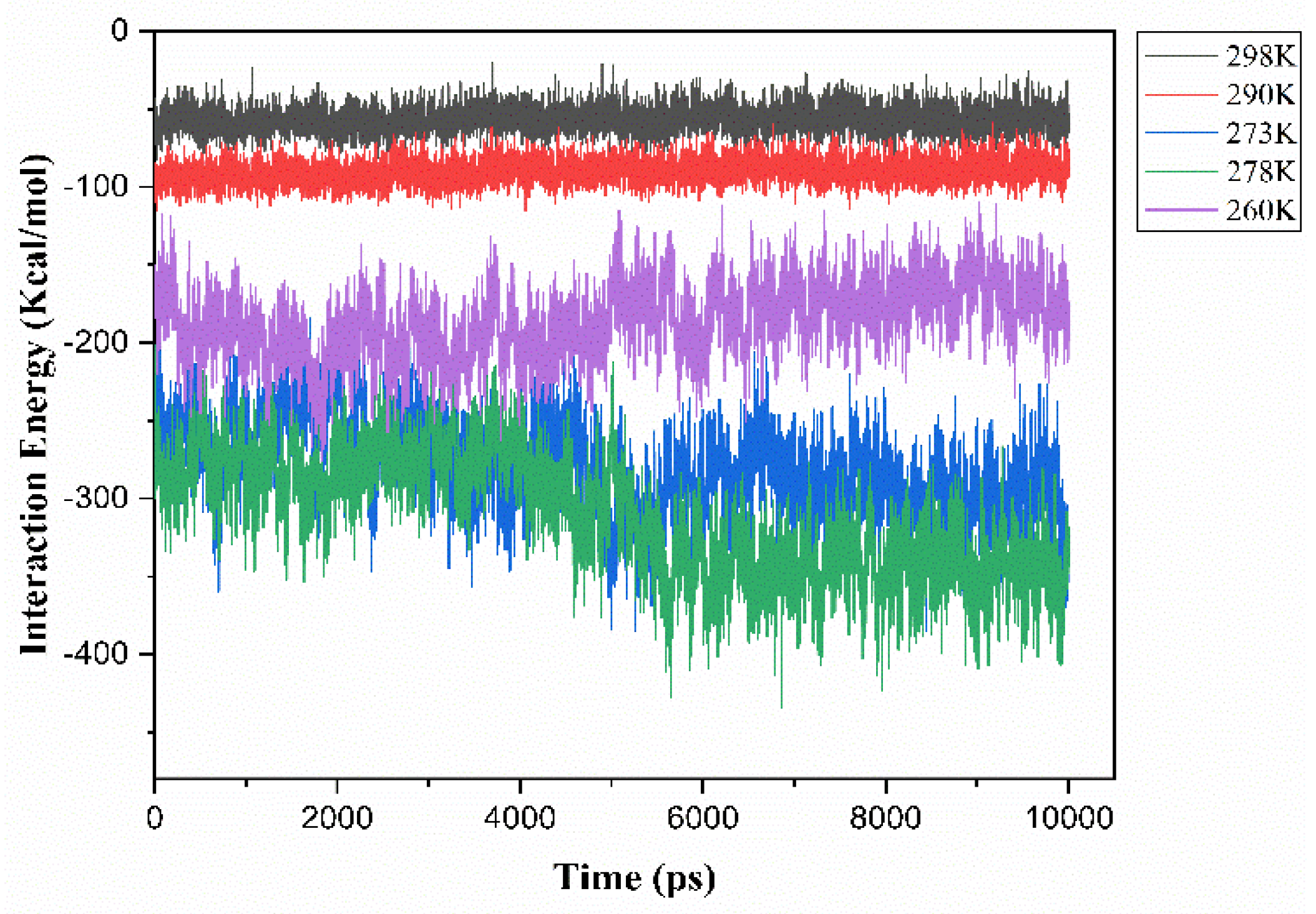

3.2. Interaction Energy

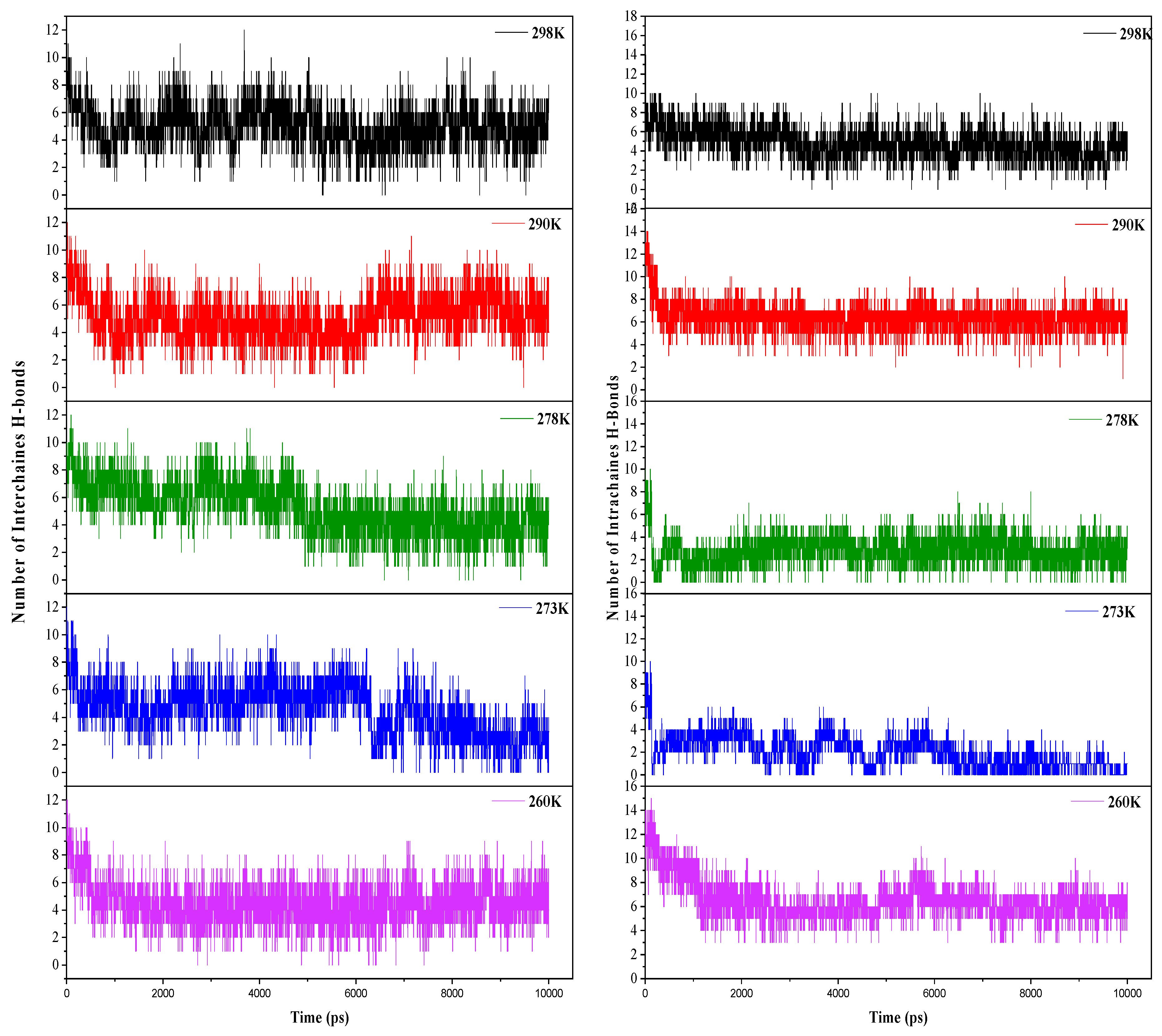

3.3. Hydrogen Bonds

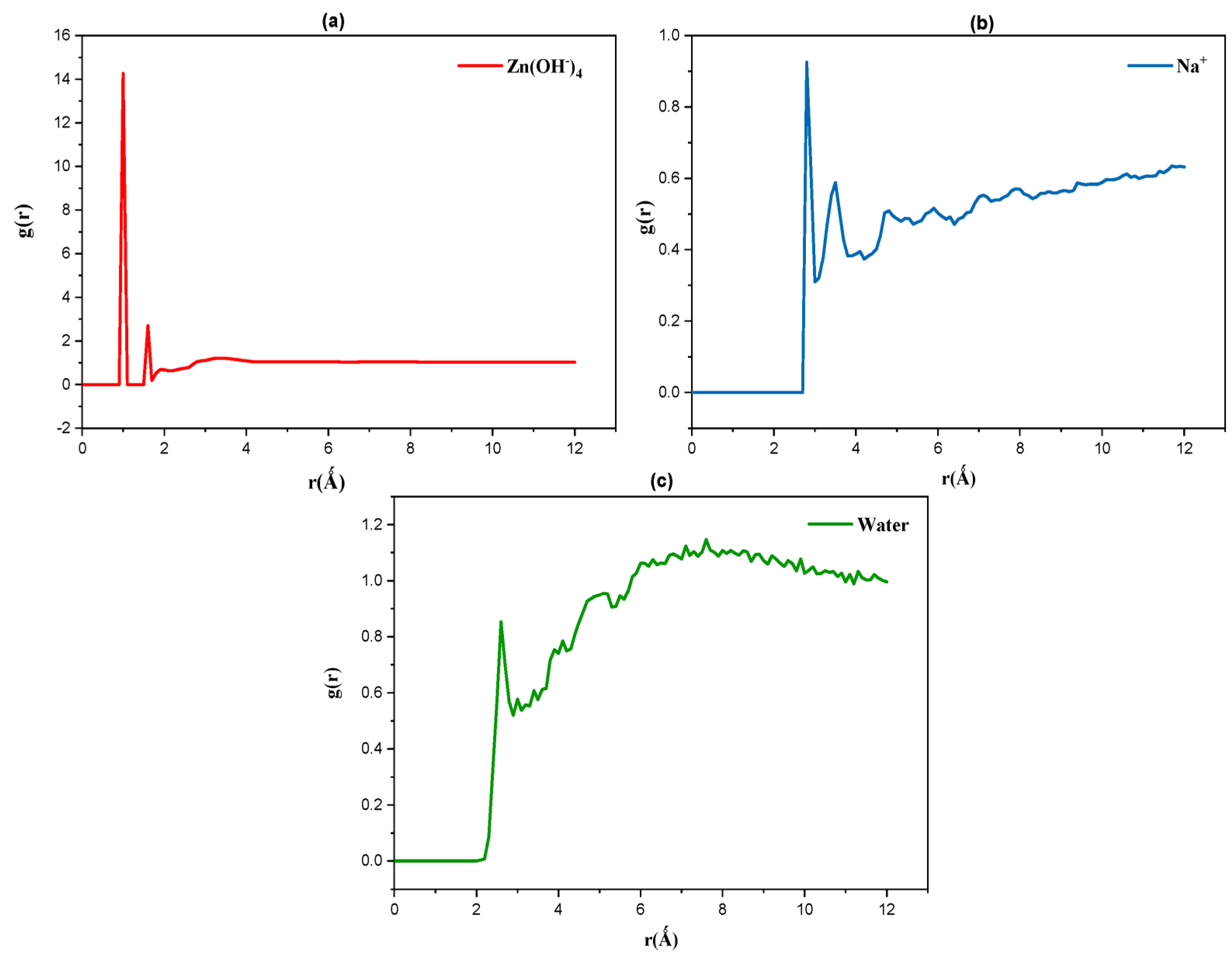

3.4. Radial Distribution Function (RDF)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Thongsomboon, W.; Serra, D.O.; Possling, A.; Hadjineophytou, C.; Hengge, R.; Cegelski, L. Phosphoethanolamine Cellulose: A naturally Produced Chemically Modified Cellulose. Science 2018, 359, 334–338. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, L.; Chen, P.; Zhang, L.; Lu, A. Cationic hydrophobicity promotes dissolution of cellulose in aqueous basic solution by freezing-thawing. Phys. Chem. Chem. Phys. 2018, 20, 14223–14233. [Google Scholar] [CrossRef]

- Heinze, T. Cellulose: Structure and properties. Adv. Polym. Sci. 2015, 271, 1–52. [Google Scholar] [CrossRef]

- Väisänen, S.; Ajdary, R.; Altgen, M.; Nieminen, K.; Kesari, K.K.; Ruokolainen, J.; Rojas, O.J.; Vuorinen, T. Cellulose dissolution in aqueous NaOH–ZnO: Cellulose reactivity and the role of ZnO. Cellulose 2021, 28, 1267–1281. [Google Scholar] [CrossRef]

- Seddiqi, H.; Oliaei, E.; Honarkar, H.; Jin, J.; Geonzon, L.C.; Bacabac, R.G.; Klein-Nulend, J. Cellulose and its derivatives: Towards biomedical applications. Cellulose 2021, 28, 1893–1931. [Google Scholar] [CrossRef]

- Fu, L.H.; Qi, C.; Ma, M.G.; Wan, P. Multifunctional cellulose-based hydrogels for biomedical applications. J. Mater. Chem. B 2019, 7, 1541–1562. [Google Scholar] [CrossRef]

- Ruel, K.; Nishiyama, Y.; Joseleau, J.P. Crystalline and amorphous cellulose in the secondary walls of Arabidopsis. Plant Sci. 2012, 193–194, 48–61. [Google Scholar] [CrossRef]

- Emenike, E.C.; Iwuozor, K.O.; Saliu, O.D.; Ramontja, J.; Adeniyi, A.G. Advances in the extraction, classification, modification, emerging and advanced applications of crystalline cellulose: A review. Carbohydr. Polym. Technol. Appl. 2023, 6, 100337. [Google Scholar] [CrossRef]

- Liu, R.; Yu, H.; Huang, Y. Structure and morphology of cellulose in wheat straw. Cellulose 2005, 12, 25–34. [Google Scholar] [CrossRef]

- Poletto, M.; Pistor, V.; Zattera, A.J. Structural Characteristics and Thermal Properties of Native Cellulose. In Cellulose—Fundamental Aspects; InTech: Rio Grande do Sul, Brazil, 2013. [Google Scholar] [CrossRef]

- Bochek, A.M. Effect of Hydrogen Bonding on Cellulose Solubility in Aqueous and Nonaqueous Solvents. Russ. J. Appl. Chem. 2003, 76, 1711–1719. [Google Scholar] [CrossRef]

- Heise, K.; Koso, T.; King, A.W.T.; Nypelö, T.; Penttilä, P.; Tardy, B.L.; Beaumont, M. Spatioselective surface chemistry for the production of functional and chemically anisotropic nanocellulose colloids. J. Mater. Chem. A 2022, 10, 23413–23432. [Google Scholar] [CrossRef] [PubMed]

- Bali, G.; Meng, X.; Deneff, J.I.; Sun, Q.; Ragauskas, A.J. The effect of alkaline pretreatment methods on cellulose structure and accessibility. ChemSusChem 2015, 8, 275–279. [Google Scholar] [CrossRef] [PubMed]

- Malaspina, D.C.; Faraudo, J. Molecular insight into the wetting behavior and amphiphilic character of cellulose nanocrystals. Adv. Colloid Interface Sci. 2019, 267, 15–25. [Google Scholar] [CrossRef] [PubMed]

- Biermann, O.; Hädicke, E.; Koltzenburg, S.; Müller-Plathe, F.; Müller-Plathe, F. Hydrophilicity and Lipophilicity of Cellulose Crystal Surfaces. Angew. Chem. Int. Ed. 2001, 40, 3822–3825. [Google Scholar] [CrossRef]

- Isogai, A.; Hänninen, T.; Fujisawa, S.; Saito, T. Review: Catalytic oxidation of cellulose with nitroxyl radicals under aqueous conditions. Prog. Polym. Sci. 2018, 86, 122–148. [Google Scholar] [CrossRef]

- Miyamoto, H.; Umemura, M.; Aoyagi, T.; Yamane, C.; Ueda, K.; Takahashi, K. Structural reorganization of molecular sheets derived from cellulose II by molecular dynamics simulations. Carbohydr. Res. 2009, 344, 1085–1094. [Google Scholar] [CrossRef]

- Medronho, B.; Romano, A.; Miguel, M.G.; Stigsson, L.; Lindman, B. Rationalizing cellulose (in)solubility: Reviewing basic physicochemical aspects and role of hydrophobic interactions. Cellulose 2012, 19, 581–587. [Google Scholar] [CrossRef]

- Mohd, N.; Draman, S.F.S.; Salleh, M.S.N.; Yusof, N.B. Dissolution of cellulose in ionic liquid: A review. AIP Conf. Proc. 2017, 1809, 020035. [Google Scholar] [CrossRef]

- Singh, P.; Duarte, H.; Alves, L.; Antunes, F.; Le Moigne, N.; Dormanns, J.; Duchemin, B.; Staiger, M.P.; Medronho, B. From Cellulose Dissolution and Regeneration to Added Value Applications—Synergism Between Molecular Understanding and Material Development. In Cellulose—Fundamental Aspects and Current Trends; InTech: Rio Grande do Sul, Brazil, 2015. [Google Scholar] [CrossRef]

- Zhang, Y.H.P.; Lynd, L.R. Determination of the number-average degree of polymerization of cellodextrins and cellulose with application to enzymatic hydrolysis. Biomacromolecules 2005, 6, 1510–1515. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Zhang, L.; Liu, S.; Liu, Y.; Xu, X.; Chen, X.; Chu, B.; Guo, X.; Xu, J.; Cheng, H.; et al. Dynamic self-assembly induced rapid dissolution of cellulose at low temperatures. Macromolecules 2008, 41, 9345–9351. [Google Scholar] [CrossRef]

- Medronho, B.; Lindman, B. Brief overview on cellulose dissolution/regeneration interactions and mechanisms. Adv. Colloid Interface Sci. 2015, 222, 502–508. [Google Scholar] [CrossRef]

- Davidson, G.F. 12—The dissolution of chemically modified cotton cellulose in alkaline solutions: Part I—In solutions of sodium hydroxide, particularly at temperatures below the normal. J. Text. Inst. Trans. 1934, 25, T174–T196. [Google Scholar] [CrossRef]

- Egal, M.; Budtova, T.; Navard, P. Structure of aqueous solutions of microcrystalline cellulose/sodium hydroxide below 0 °C and the limit of cellulose dissolution. Biomacromolecules 2007, 8, 2282–2287. [Google Scholar] [CrossRef]

- Yang, Q.; Qi, H.; Lue, A.; Hu, K.; Cheng, G.; Zhang, L. Role of sodium zincate on cellulose dissolution in NaOH/urea aqueous solution at low temperature. Carbohydr. Polym. 2011, 83, 1185–1191. [Google Scholar] [CrossRef]

- Kihlman, M.; Medronho, B.F.; Romano, A.L.; Germgård, U.; Lindman, B. Cellulose dissolution in an alkali based solvent: Influence of additives and pretreatments. J. Braz. Chem. Soc. 2013, 24, 295–303. [Google Scholar] [CrossRef]

- Liu, W.; Budtova, T.; Navard, P. Influence of ZnO on the properties of dilute and semi-dilute cellulose-NaOH-water solutions. Cellulose 2011, 18, 911–920. [Google Scholar] [CrossRef]

- Wang, Y.; Deng, Y. The kinetics of cellulose dissolution in sodium hydroxide solution at low temperatures. Biotechnol. Bioeng. 2009, 102, 1398–1405. [Google Scholar] [CrossRef]

- Bregado, J.L.; Tavares, F.W.; Secchi, A.R.; Segtovich, I.S.V. Molecular dynamics of dissolution of a 36-chain cellulose Iβ microfibril at different temperatures above the critical pressure of water. J. Mol. Liq. 2021, 336, 116271. [Google Scholar] [CrossRef]

- Parthasarathi, R.; Balamurugan, K.; Shi, J.; Subramanian, V.; Simmons, B.A.; Singh, S. Theoretical Insights into the Role of Water in the Dissolution of Cellulose Using IL/Water Mixed Solvent Systems. J. Phys. Chem. B 2015, 119, 14339–14349. [Google Scholar] [CrossRef] [PubMed]

- Gomes, T.C.; Skaf, M.S. Cellulose–builder: A toolkit for building crystalline structures of cellulose. J. Comput. Chem. 2012, 33, 1338–1346. [Google Scholar] [CrossRef] [PubMed]

- Kevin, J.B. Scalable Algorithms for Molecular Dynamics Simulations on Commodity Clusters. In Proceedings of the 2006 ACM/IEEE Conference on Supercomputing, Tampa, FL, USA, 11–17 November 2006. [Google Scholar]

- Kang, Y.; Wang, F.; Zhang, Z.; Zhou, J. Dissolution and interaction of cellulose carbamate in naoh/zno aqueous solutions. Polymers 2021, 13, 1092. [Google Scholar] [CrossRef]

- Manna, B.; Ghosh, A. Dissolution of cellulose in ionic liquid and water mixtures as revealed by molecular dynamics simulations. J. Biomol. Struct. Dyn. 2019, 37, 3987–4005. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, Y.; Wan, J.; Wu, Q.; Wei, Z.; Ma, Y. Effects of wet-pressing induced fiber hornification on hydrogen bonds of cellulose and on properties of eucalyptus paper sheets. Holzforschung 2018, 72, 829–837. [Google Scholar] [CrossRef]

- Liu, H.; Sale, K.L.; Simmons, B.A.; Singh, S. Molecular dynamics study of polysaccharides in binary solvent mixtures of an ionic liquid and water. J. Phys. Chem. B 2011, 115, 10251–10258. [Google Scholar] [CrossRef]

- Tian, G.; Du, H.; Yuan, Q. The effects of benzene on the structure and properties of triethylamine hydrochloride/chloroaluminate. Crystals 2021, 11, 1532. [Google Scholar] [CrossRef]

- Gupta, K.M.; Hu, Z.; Jiang, J. Molecular insight into cellulose regeneration from a cellulose/ionic liquid mixture: Effects of water concentration and temperature. RSC Adv. 2013, 3, 4425–4433. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bourassi, L.; El Mrani, M.; Merzouki, M.; Abidi, R.; Bouammali, H.; Bouammali, B.; Elfarh, L.; Touzani, R.; Challioui, A.; Siaj, M. Study of Cellulose Dissolution in ZnO/NaOH/Water Solvent Solution and Its Temperature-Dependent Effect Using Molecular Dynamics Simulation. Polymers 2024, 16, 1211. https://doi.org/10.3390/polym16091211

Bourassi L, El Mrani M, Merzouki M, Abidi R, Bouammali H, Bouammali B, Elfarh L, Touzani R, Challioui A, Siaj M. Study of Cellulose Dissolution in ZnO/NaOH/Water Solvent Solution and Its Temperature-Dependent Effect Using Molecular Dynamics Simulation. Polymers. 2024; 16(9):1211. https://doi.org/10.3390/polym16091211

Chicago/Turabian StyleBourassi, Lamiae, Meriem El Mrani, Mohammed Merzouki, Rania Abidi, Haytham Bouammali, Boufelja Bouammali, Larbi Elfarh, Rachid Touzani, Allal Challioui, and Mohamed Siaj. 2024. "Study of Cellulose Dissolution in ZnO/NaOH/Water Solvent Solution and Its Temperature-Dependent Effect Using Molecular Dynamics Simulation" Polymers 16, no. 9: 1211. https://doi.org/10.3390/polym16091211

APA StyleBourassi, L., El Mrani, M., Merzouki, M., Abidi, R., Bouammali, H., Bouammali, B., Elfarh, L., Touzani, R., Challioui, A., & Siaj, M. (2024). Study of Cellulose Dissolution in ZnO/NaOH/Water Solvent Solution and Its Temperature-Dependent Effect Using Molecular Dynamics Simulation. Polymers, 16(9), 1211. https://doi.org/10.3390/polym16091211