Possibility of Using Wind Turbine Waste in Particleboard Manufacturing

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- -

- A mix of 40% polymer and 60% pine chips produces a board with satisfactory characteristics.

- -

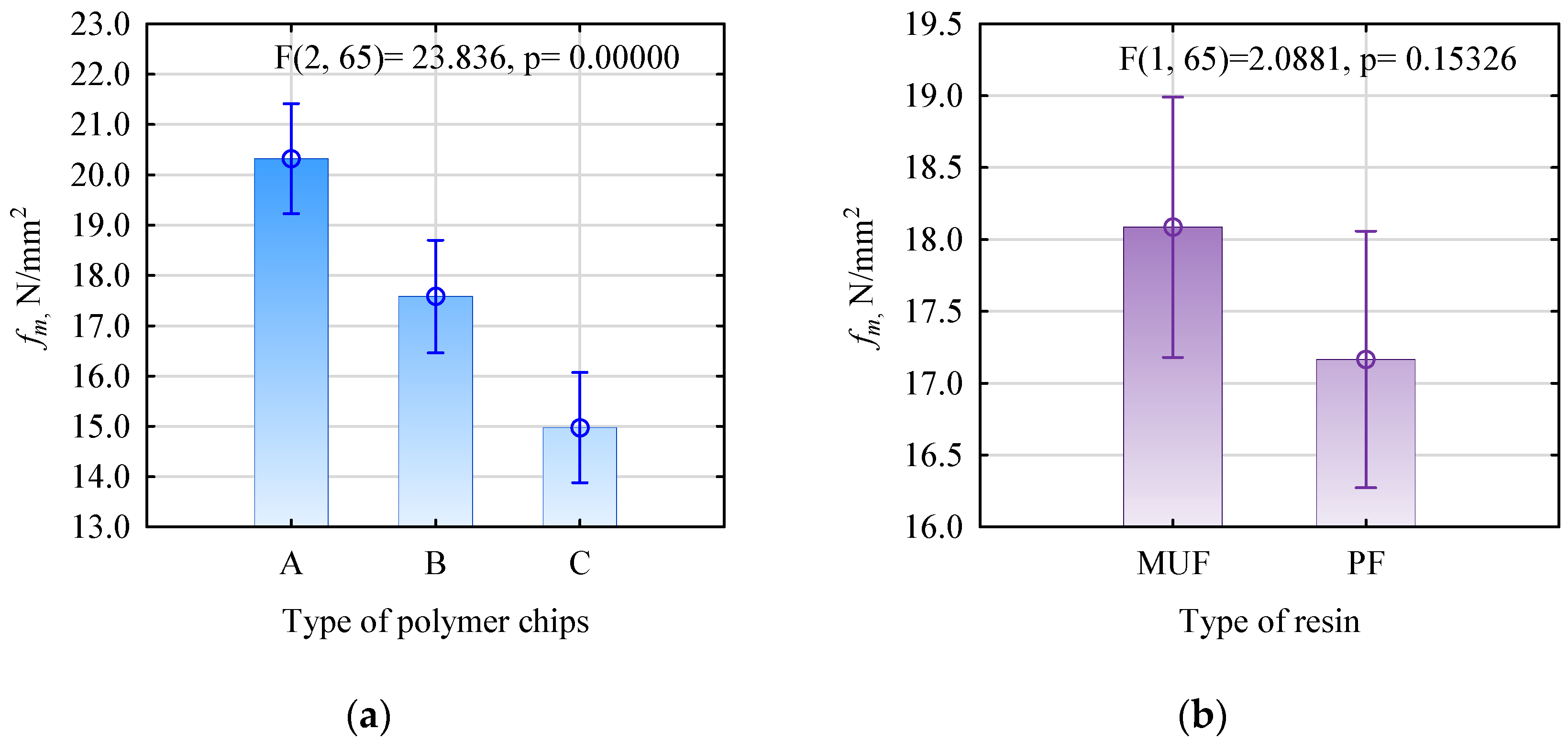

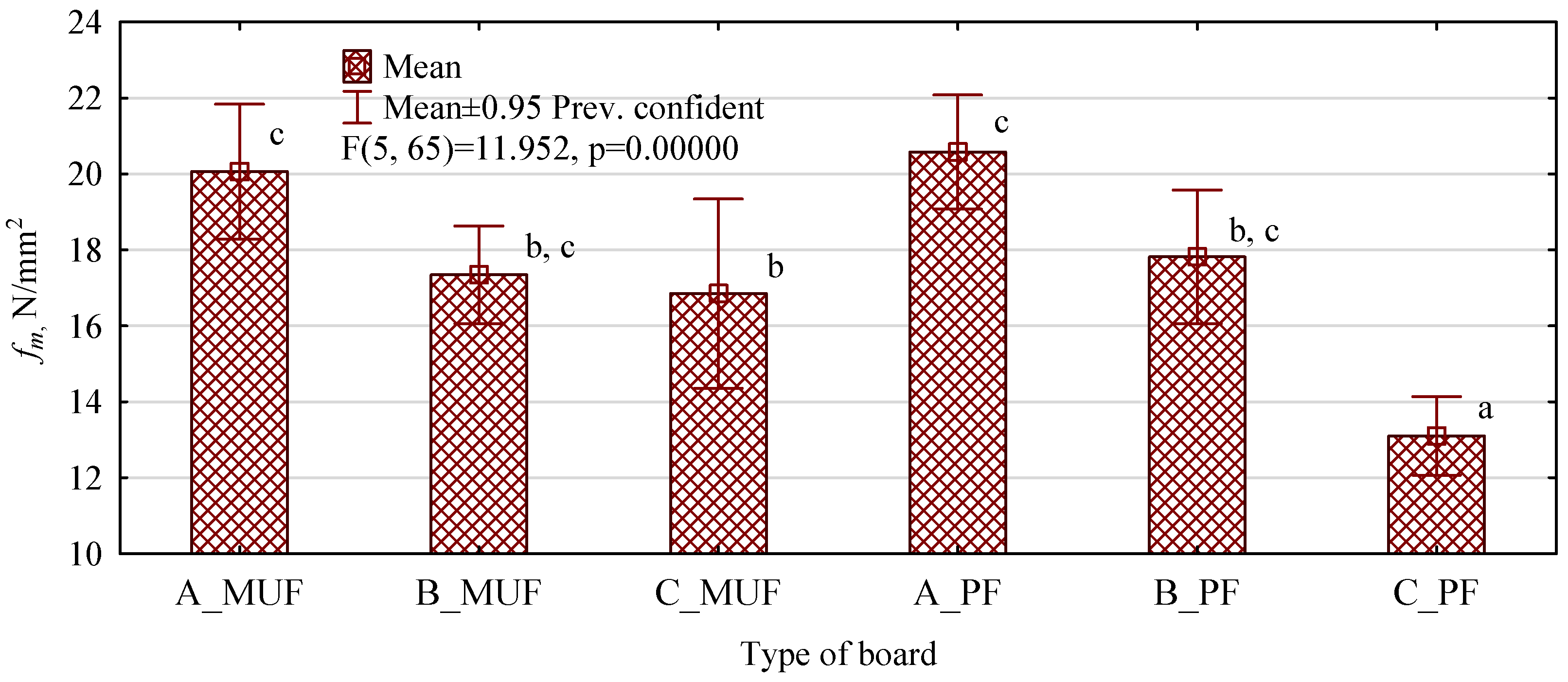

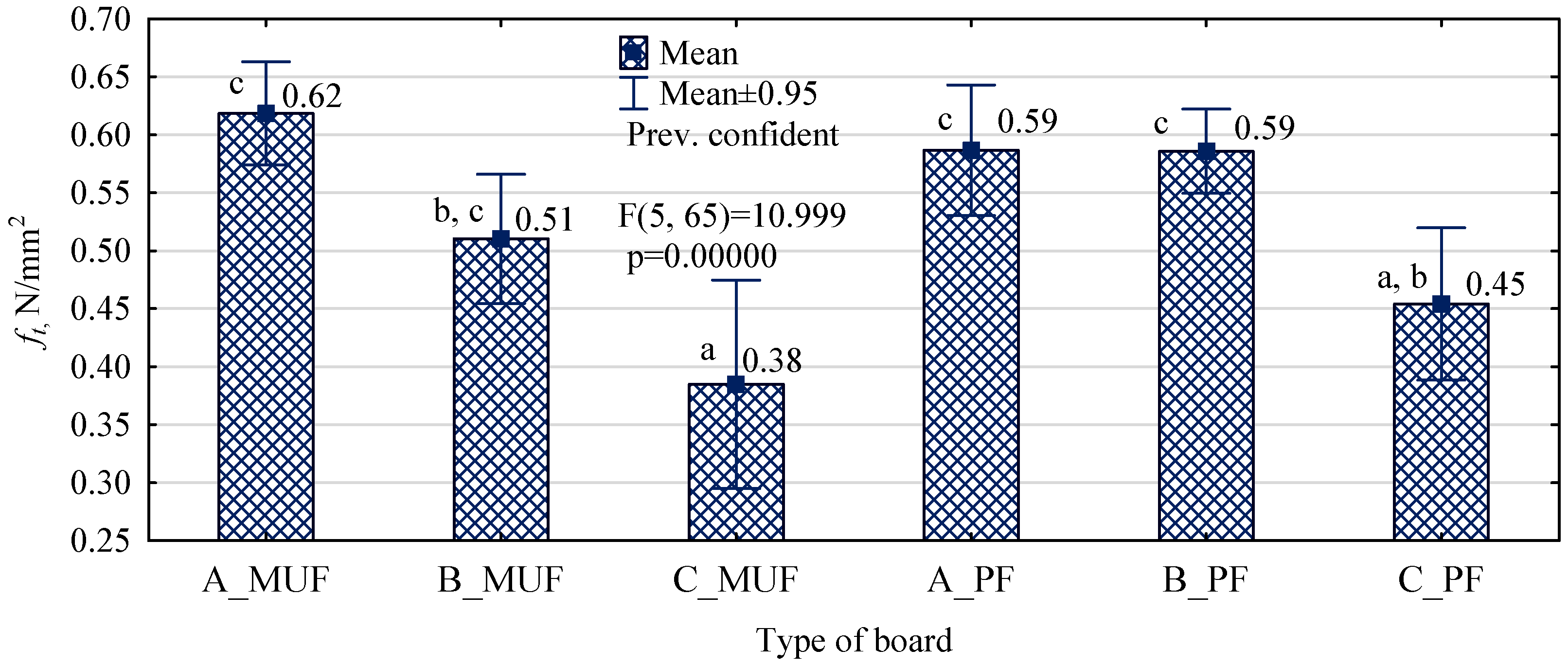

- The method of obtaining the polymer chips and their dimensional structure has a much more significant effect on the values obtained (especially on all the mechanical properties) than the adhesive resin used.

- -

- Slightly better properties, essentially linear elastic modulus, were obtained for mela-mine-urea-formaldehyde resin than for phenol-formaldehyde resin.

- -

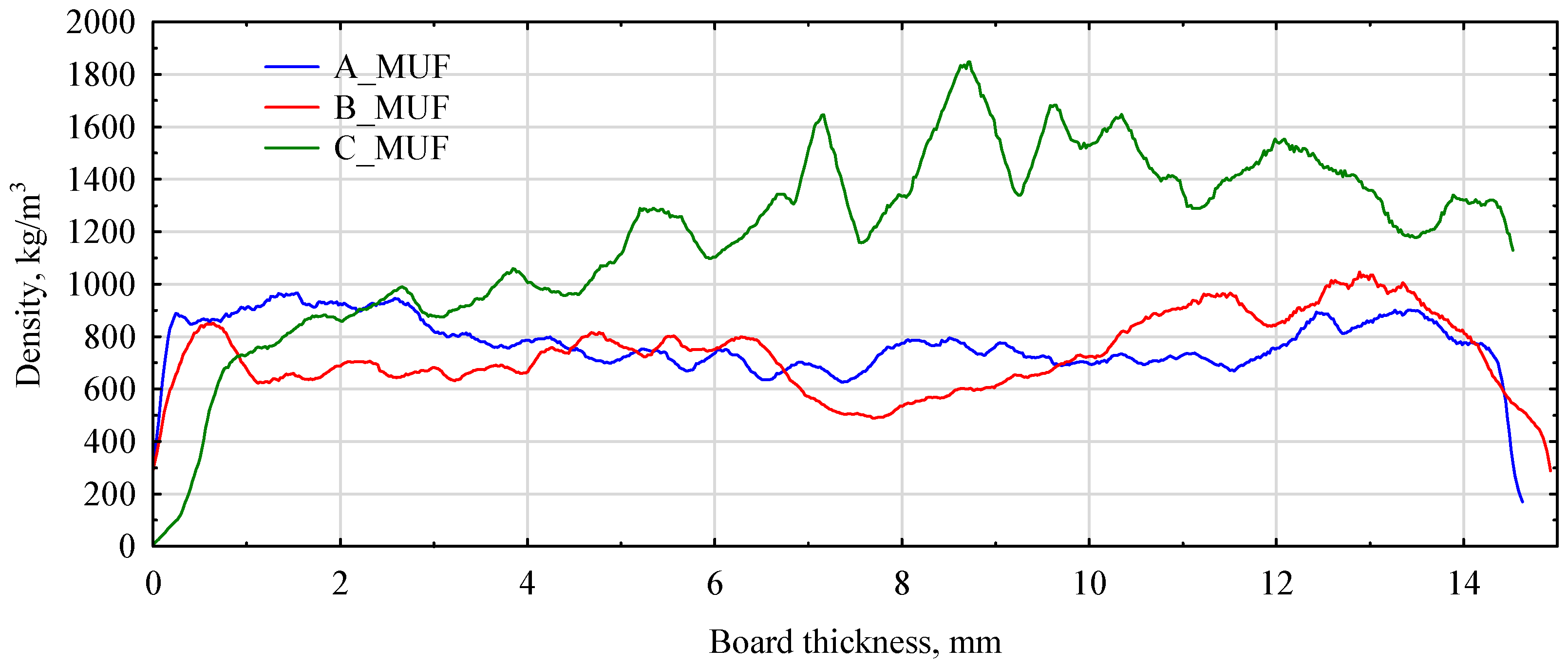

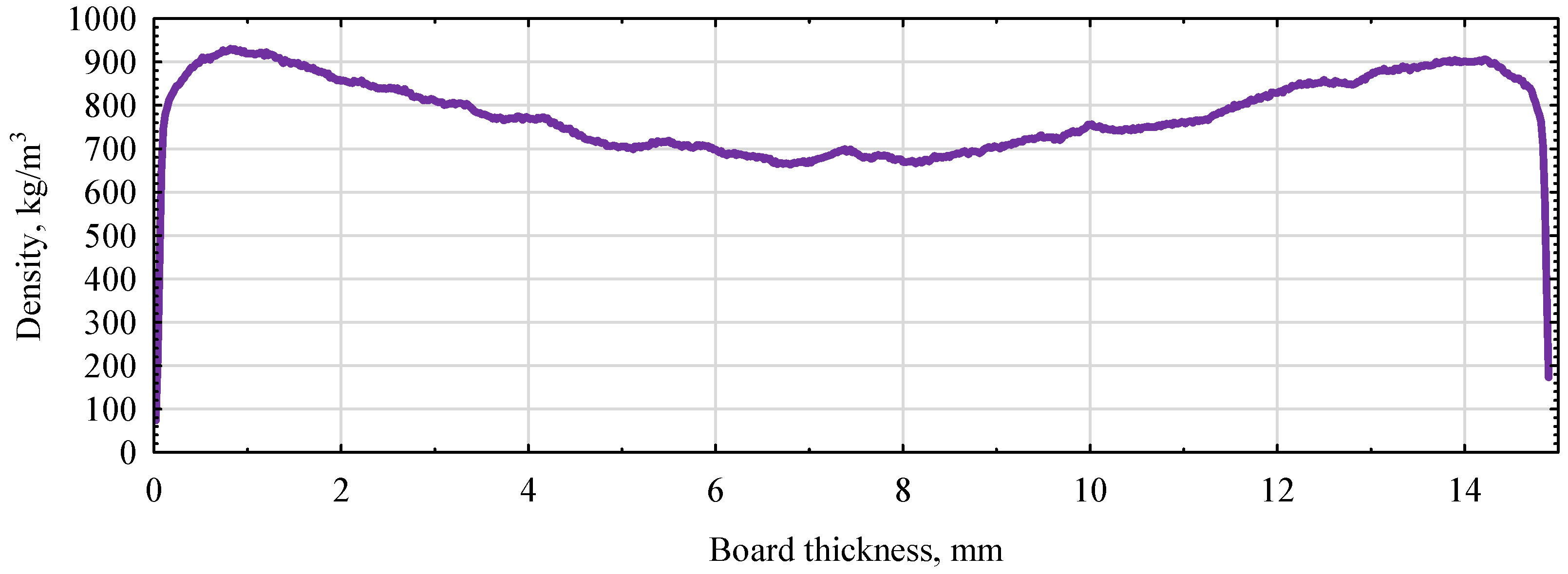

- In order to maintain the contact between the bonded chips, it is necessary to increase the density of the manufactured boards due to the fact that the material with a much higher density than pine chips is introduced into the chip–glue mixture (which results in a higher bulk density).

- -

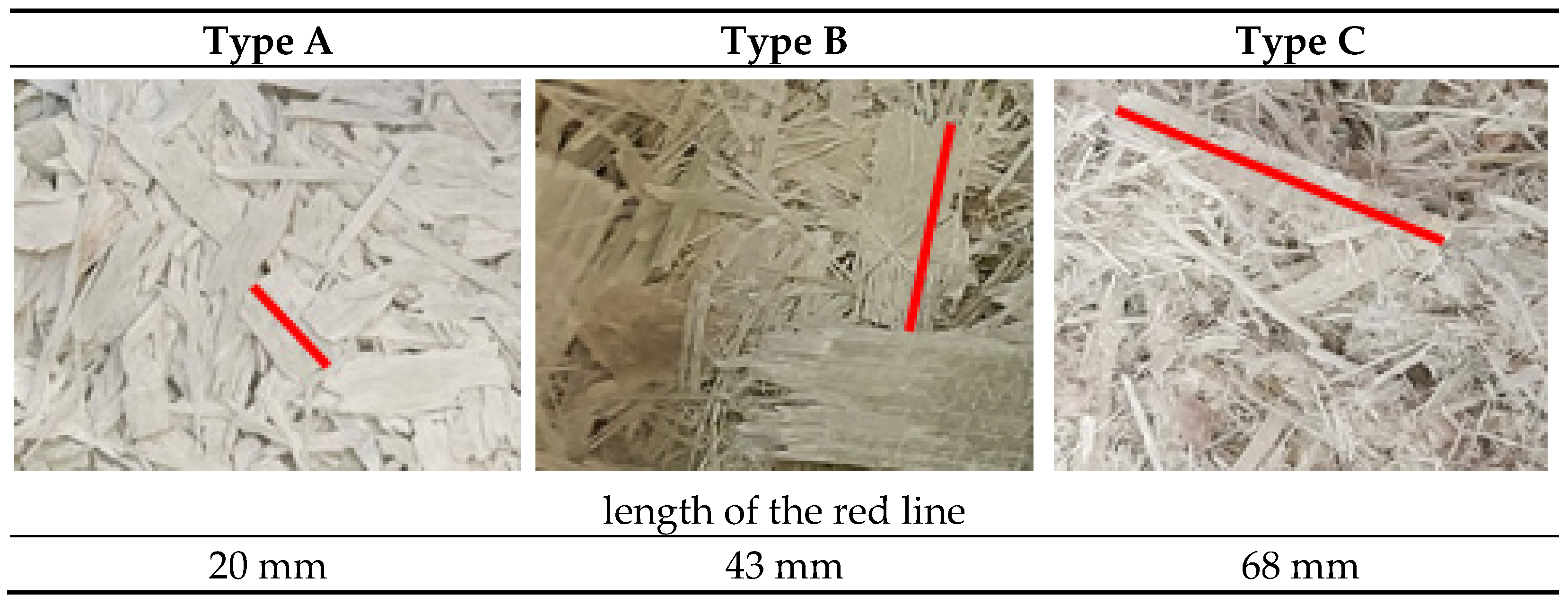

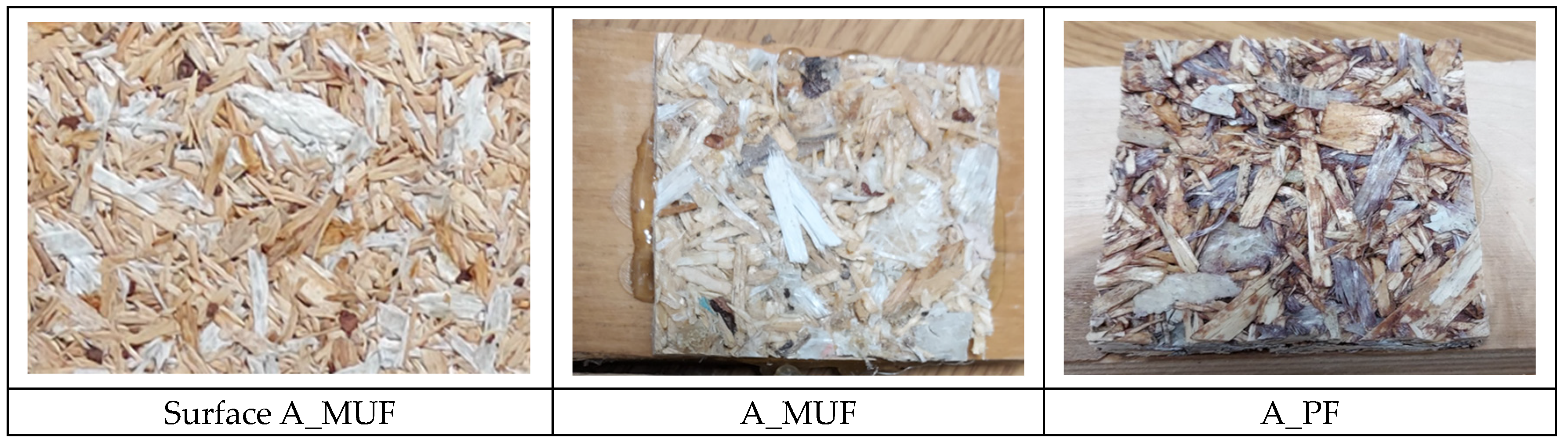

- PW boards with fine polymer chips, similar in size to pine chips, achieved significantly higher strengths than boards manufactured with polymer chips, with very different shapes and linear dimensions.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- European Commission. Communication from the Commission. The European Green Deal. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2019%3A640%3AFIN (accessed on 25 March 2024).

- Cooperman, A.; Eberle, A.; Lantz, E. Wind turbine blade material in the United States: Quantities, costs, and end-of-life options. Resour. Conserv. Recycl. 2021, 168, 105439. [Google Scholar] [CrossRef]

- Liu, P.; Meng, F.; Barlow, C.Y. Wind turbine blade end-of-life options: An eco-audit comparison. J. Clean. Prod. 2019, 212, 268–1281. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A review on recycling and reuse methods for carbon fiber/glass fiber composites waste from wind turbine blades. Compos. Part B Eng. 2021, 215, 108768. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Hossain, M.; Umer, R. Recycling of wind turbine blades through modern recycling technologies: A road to zero waste. Renew. Energy Focus 2023, 44, 373–389. [Google Scholar] [CrossRef]

- Jani, H.K.; Kachhwaha, S.S.; Nagababu, G.; Das, A. A brief review on recycling and reuse of wind turbine blade materials. Mater. Today Proc. 2022, 62, 7124–7130. [Google Scholar] [CrossRef]

- Jensen, J.P.; Skelton, K. Wind turbine blade recycling: Experiences, challenges and possibilities in a circular economy. Renew. Sustain. Energy Rev. 2018, 97, 165–176. [Google Scholar] [CrossRef]

- Anment. Available online: https://www.anmet.com.pl/ (accessed on 25 March 2024).

- Cousins, D.S.; Suzuki, Y.; Murray, R.E.; Samaniuk, J.R.; Stebner, A.P. Recycling glass fiber thermoplastic composites from wind turbine blades. J. Clean. Prod. 2019, 209, 1252–1263. [Google Scholar] [CrossRef]

- Deeney, P.; Nagle, A.J.; Gough, F.; Lemmertz, H.; Delaney, E.L.; McKinley, J.M.; Graham, C.; Leahy, P.G.; Dunphy, N.P.; Mullally, G. End-of-Life alternatives for wind turbine blades: Sustainability Indices based on the UN sustainable development goals. Resour. Conserv. Recycl. 2021, 171, 105642. [Google Scholar] [CrossRef]

- Grigaitienė, G.; Uscila, R.; Valinčius, V.; Kėželis, R.; Mileška, M.; Gimžauskaitė, D.; Snapkauskienė, V.; Kavaliauskas, Ž. Possibility of recycling wind turbine blades using plasma technology. WIT Trans. Ecol. Environ. 2022, 257, 65–71. [Google Scholar]

- Liu, P.; Barlow, C.Y. Wind turbine blade waste in 2050. Waste Manag. 2017, 62, 229–240. [Google Scholar] [CrossRef]

- Tazi, N.; Kim, J.; Bouzidi, Y.; Chatelet, E.; Liu, G. Waste and material flow analysis in the end-of-life wind energy system. Resour. Conserv. Recycl. 2019, 145, 199–207. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr. Recycling of wind turbine blades: Recent developments. Curr. Opin. Green. Sustain. Chem. 2023, 39, 100746. [Google Scholar]

- Global Wind Energy Council. Global Wind Report 2022. Available online: https://gwec.net/category/annual-global-wind-reports/ (accessed on 25 March 2024).

- Gil-García, I.C.; Fernández-Guillamón, A.; García-Cascales, M.S.; Molina-García, A. A Multi-Factorial Review of Repowering Wind Generation Strategies. Energies 2021, 14, 6280. [Google Scholar] [CrossRef]

- Gil García, I.C.; Fernández-Guillamón, A.; García-Cascales, M.S.; Molina-García, Á. Multi-factorial methodology for Wind Power Plant repowering optimization: A Spanish case study. Energy Rep. 2024, 11, 179–196. [Google Scholar] [CrossRef]

- Włodarczyk, R. Analysis of the Photovoltaic Waste-Recycling Process in Polish Conditions—A Short Review. Sustainability 2022, 14, 4739. [Google Scholar] [CrossRef]

- Wong, K.; Rudd, C.; Pickering, S.; Liu, X. Composites recycling solutions for the aviation industry. Sci. China Technol. Sci. 2017, 60, 1291–1300. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Seidlitz, H.; Krenz, J.; Goracy, K.; Urbaniak, M.; Rösch, J.J. Recycling of Carbon Fiber Reinforced Composite Polymers—Review—Part 2: Recovery and Application of Recycled Carbon Fibers. Polymers 2020, 12, 3003. [Google Scholar] [CrossRef] [PubMed]

- Bledzki, A.K.; Seidlitz, H.; Goracy, K.; Urbaniak, M.; Rösch, J.J. Recycling of Carbon Fiber Reinforced Composite Polymers—Review—Part 1: Volume of Production, Recycling Technologies, Legislative Aspects. Polymers 2021, 13, 300. [Google Scholar] [CrossRef]

- Kavaliauskas, Ž.; Kėželis, R.; Grigaitienė, V.; Marcinauskas, L.; Milieška, M.; Valinčius, V.; Uscila, R.; Snapkauskienė, V.; Gimžauskaitė, D.; Baltušnikas, A. Recycling of Wind Turbine Blades into Microfiber Using Plasma Technology. Materials 2023, 16, 3089. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Karl, C.W.; Gagani, A.I.; Jørgensen, J.K. Composite Material Recycling Technology—State-of-the-Art and Sustainable Development for the 2020s. J. Compos. Sci. 2021, 5, 28. [Google Scholar] [CrossRef]

- Korey, M.; Sproul, E.; Renchecka, M.L.; Ennis, B.L. Development of wind turbine blade recycling baselines in the United States. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1293, 012018. [Google Scholar] [CrossRef]

- Mattsson, C.; André, A.; Juntikka, M.; Tränkle, T.; Sott, R. Chemical recycling of End-of-Life wind turbine blades by solvolysis/HTL. IOP Conf. Ser. Mater. Sci. Eng. 2020, 942, 012013. [Google Scholar] [CrossRef]

- Muzyka, R.; Sobek, S.; Korytkowska-Wałach, A.; Drewniak, Ł.; Sajdak, M. Recycling of both resin and fibre from wind turbine blade waste via small molecule-assisted dissolution. Sci. Rep. 2023, 13, 9270. [Google Scholar] [CrossRef]

- Smoleń, J.; Olesik, P.; Jała, J.; Adamcio, A.; Kurtyka, K.; Godzierz, M.; Kozera, R.; Kozioł, M.; Boczkowska, A. The Use of Carbon Fibers Recovered by Pyrolysis from End-of-Life Wind Turbine Blades in Epoxy-Based Composite Panels. Polymers 2022, 14, 2925. [Google Scholar] [CrossRef] [PubMed]

- Sorte, S.; Martins, N.; Oliveira, M.S.A.; Vela, G.L.; Relvas, C. Unlocking the Potential of Wind Turbine Blade Recycling: Assessing Techniques and Metrics for Sustainability. Energies 2023, 16, 7624. [Google Scholar] [CrossRef]

- Utekar, S.; Suriya, V.K.; More, N.; Rao, A. Comprehensive study of recycling of thermosetting polymer composites—Driving force, challenges and methods. Compos. Part. B Eng. 2021, 207, 108596. [Google Scholar] [CrossRef]

- Xu, M.; Ji, H.; Wu, Y.; Di, J.; Meng, X.; Jiang, H.; Lu, Q. The pyrolysis of end-of-life wind turbine blades under different atmospheres and their effects on the recovered glass fibers. Compos. Part. B Eng. 2023, 251, 110493. [Google Scholar] [CrossRef]

- Zero Waste Blade Research Project. Available online: https://www.irt-jules-verne.fr/en/projets/zero-waste-blade-research-project/ (accessed on 25 March 2024).

- Siemens Gamesa RecyclableBlade. Available online: https://www.siemensgamesa.com/explore/journal/recyclable-blade (accessed on 25 March 2024).

- Lee, H.L.; Lum, W.C.; Boon, J.G.; Kristak, L.; Antov, P.; Pędzik, M.; Rogoziński, T.; Taghiyari, H.R.; Lubis, M.A.R.; Fatriasari, W.; et al. Particleboard from agricultural biomass and recycled wood waste: A review. J. Mater. Res. Technol. 2022, 20, 4630–4658. [Google Scholar] [CrossRef]

- Mirski, R.; Dziurka, D.; Banaszak, A. Properties of particleboards produced from various lignocellulosic particles. BioResources 2018, 13, 7758–7765. [Google Scholar] [CrossRef]

- Mirski, R.; Banaszak, A.; Bekhta, P. Selected Properties of Formaldehyde-Free Polymer-Straw Boards Made from Different Types of Thermoplastics and Different Kinds of Straw. Materials 2021, 14, 1216. [Google Scholar] [CrossRef]

- Banaszak, A.; Woźniak, M.; Dziurka, D.; Mirski, R. Annual Plants and Thermoplastics in the Production of Polymer and Lignocellulose Boards. Materials 2023, 16, 4400. [Google Scholar] [CrossRef]

- Mirski, R.; Derkowski, A.; Dziurka, D. Dimensional stability of OSB panels subjected to variable relative humidity: Core layer made with fine wood chips. BioResources 2013, 8, 6448–6459. [Google Scholar] [CrossRef][Green Version]

- Borysiuk, P.; Auriga, R.; Kośka, P. Influence of the filler on the density profile of wood polymer composites. Ann. Wars. Univ. Life Sci.-SGGW For. Wood Technol. 2019, 106, 31–37. [Google Scholar] [CrossRef]

- Gozdecki, C.; Wilczyński, A.; Kociszewski, M.; Zajchowski, S. Properties of wood–plastic composites made of milled particleboard and polypropylene. Eur. J. Wood Prod. 2015, 73, 87–95. [Google Scholar] [CrossRef]

- Gozdecki, C.; Wilczyński, A. Acoustic emission generated from wood-polypropylene composites. Ann. Wars. Univ. Life Sci.-SGGW. For. Wood Technol. 2015, 91, 70–75. [Google Scholar]

- Gozdecki, C.; Wilczyński, A. Effect of wood flour type on flexural properties of wood-plastic composites. Ann. Wars. Univ. Life Sci.-SGGW. For. Wood Technol. 2015, 89, 65–69. [Google Scholar]

- Gozdecki, C.; Zajchowski, S.; Kociszewski, M.; Wilczyński, A.D.; Mirowski, J. Effect of wood particle size on mechanical properties of industrial wood particle-polyethylene composites. Polimery 2011, 56, 375–380. Available online: https://polimery.ichp.vot.pl/index.php/p/article/view/927927 (accessed on 15 March 2024). [CrossRef]

- Kociszewski, M.; Gozdecki, C.; Wilczyński, A.; Zajchowski, S.; Mirowski, J. Effect of industrial wood particle size on mechanical properties of wood-polyvinyl chloride composites. Eur. J. Wood Prod. 2012, 70, 113–118. [Google Scholar] [CrossRef]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. Natural rubber biocomposites containing corn, barley and wheat straw. Polym. Test. 2017, 63, 84–91. [Google Scholar] [CrossRef]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. Influence of wheat, rye, and triticale straw on the properties of natural rubber composites. Adv. Polym. Technol. 2018, 37, 2866–2878. [Google Scholar] [CrossRef]

- Kuliński, M.; Walkiewicz, J.; Dukarska, D.; Dziurka, D.; Mirski, R. Properties of Particle Boards Containing Polymer Waste. Materials 2023, 16, 4774. [Google Scholar] [CrossRef] [PubMed]

- EN 310; Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 319; Particleboards and Fibreboards. Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 317; Particleboards and Fibreboards. Determination of Swelling in Thickness after Immersion in Water. European Committee for Standardization: Brussels, Belgium, 1993.

- Mamanpush, S.H.; Tabatabaei, A.T.; Li, H.; Englund, K. Data on the mechanical properties of recycled wind turbine blade composites. Data Brief. 2018, 19, 230–235. [Google Scholar] [CrossRef] [PubMed]

- Mamanpush, S.H.; Tabatabaei, A.T.; Li, H.; Englund, K. Experimental data on the mechanical and thermal properties of extruded composites from recycled wind turbine blade material. Data Brief. 2019, 25, 104253. [Google Scholar] [CrossRef] [PubMed]

| Publication | Type of Resin | Variant | Density | fm | Em | ft |

|---|---|---|---|---|---|---|

| kg/m3 | N/mm2 | N/mm2 | N/mm2 | |||

| Mirski * [46] | UF | 2S65 | 650 | 12.3 | 2625 | 0.57 |

| Mamanpush * [50] | pMDI ** | 10/5/12.7 | 1030 | 40.7 | 5110 | 2.34 |

| 6/3/12.7 | 985 | 28.9 | 4215 | 1.56 | ||

| 3/5/12.7 | 1020 | 21.2 | 3480 | 0.82 | ||

| Mamanpush * [51] | HDPE *** | 7 | 1120 | 25.0 | 2030 | - |

| 23 | 1150 | 24.2 | 2072 | - | ||

| 25 | 1095 | 23.3 | 1928 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Derkowski, A.; Dziurka, D.; Antonowicz, R.; Chuda-Kowalska, M.; Mirski, R. Possibility of Using Wind Turbine Waste in Particleboard Manufacturing. Polymers 2024, 16, 1210. https://doi.org/10.3390/polym16091210

Derkowski A, Dziurka D, Antonowicz R, Chuda-Kowalska M, Mirski R. Possibility of Using Wind Turbine Waste in Particleboard Manufacturing. Polymers. 2024; 16(9):1210. https://doi.org/10.3390/polym16091210

Chicago/Turabian StyleDerkowski, Adam, Dorota Dziurka, Ryszard Antonowicz, Monika Chuda-Kowalska, and Radoslaw Mirski. 2024. "Possibility of Using Wind Turbine Waste in Particleboard Manufacturing" Polymers 16, no. 9: 1210. https://doi.org/10.3390/polym16091210

APA StyleDerkowski, A., Dziurka, D., Antonowicz, R., Chuda-Kowalska, M., & Mirski, R. (2024). Possibility of Using Wind Turbine Waste in Particleboard Manufacturing. Polymers, 16(9), 1210. https://doi.org/10.3390/polym16091210