Understanding the Molecular Arrangement and Orientation Characteristics of Mesophase Pitch and Its Fibers via a Polarized Light Microscope

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of MP-Derived Fibers

2.3. Characterization of MP and MP-Derived Fibers

3. Results and Discussion

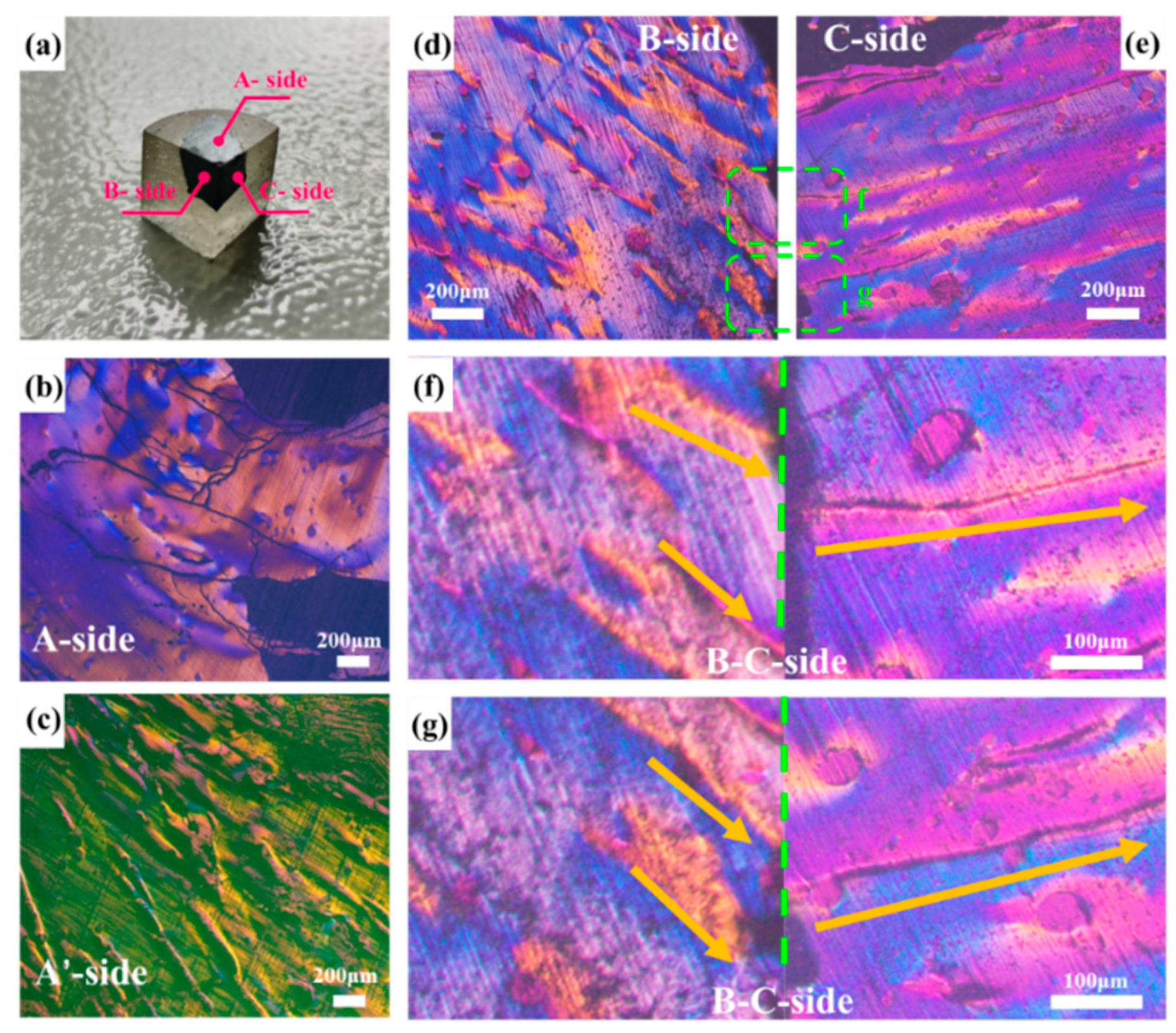

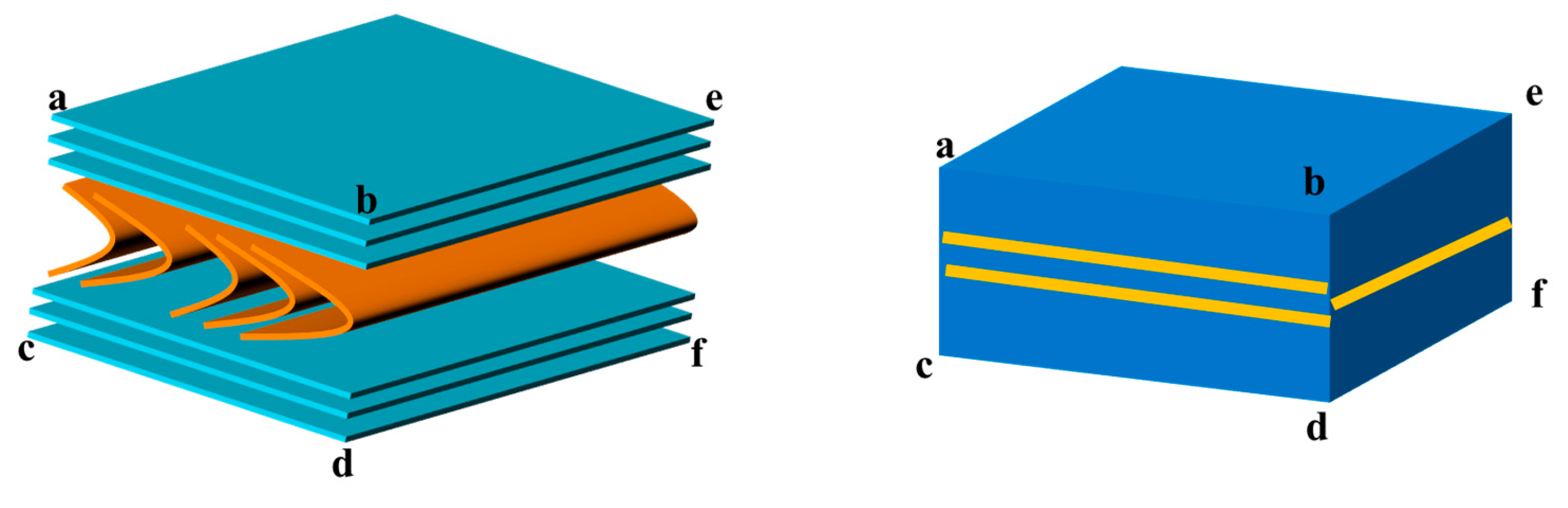

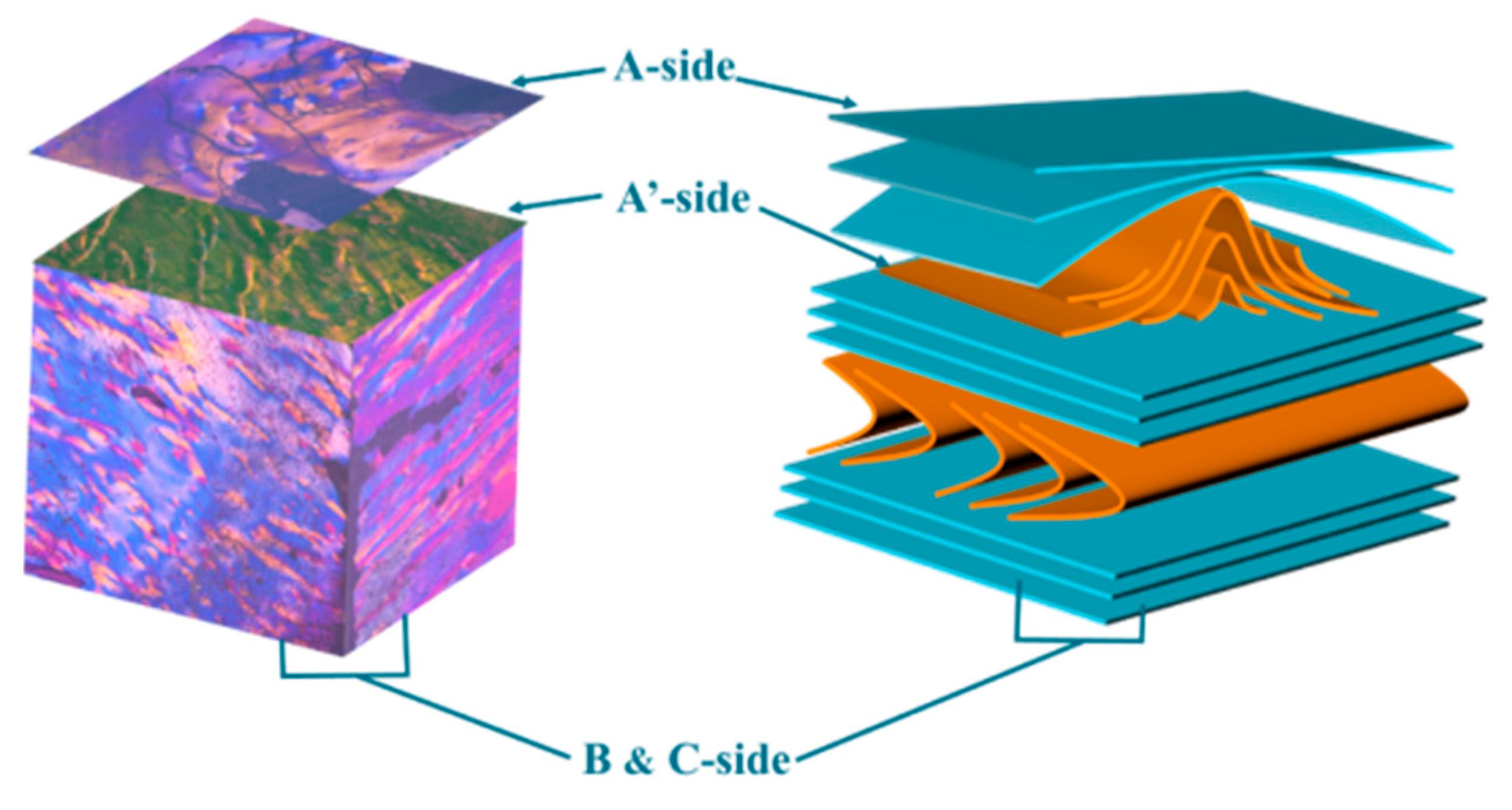

3.1. The Optical Textures of MP

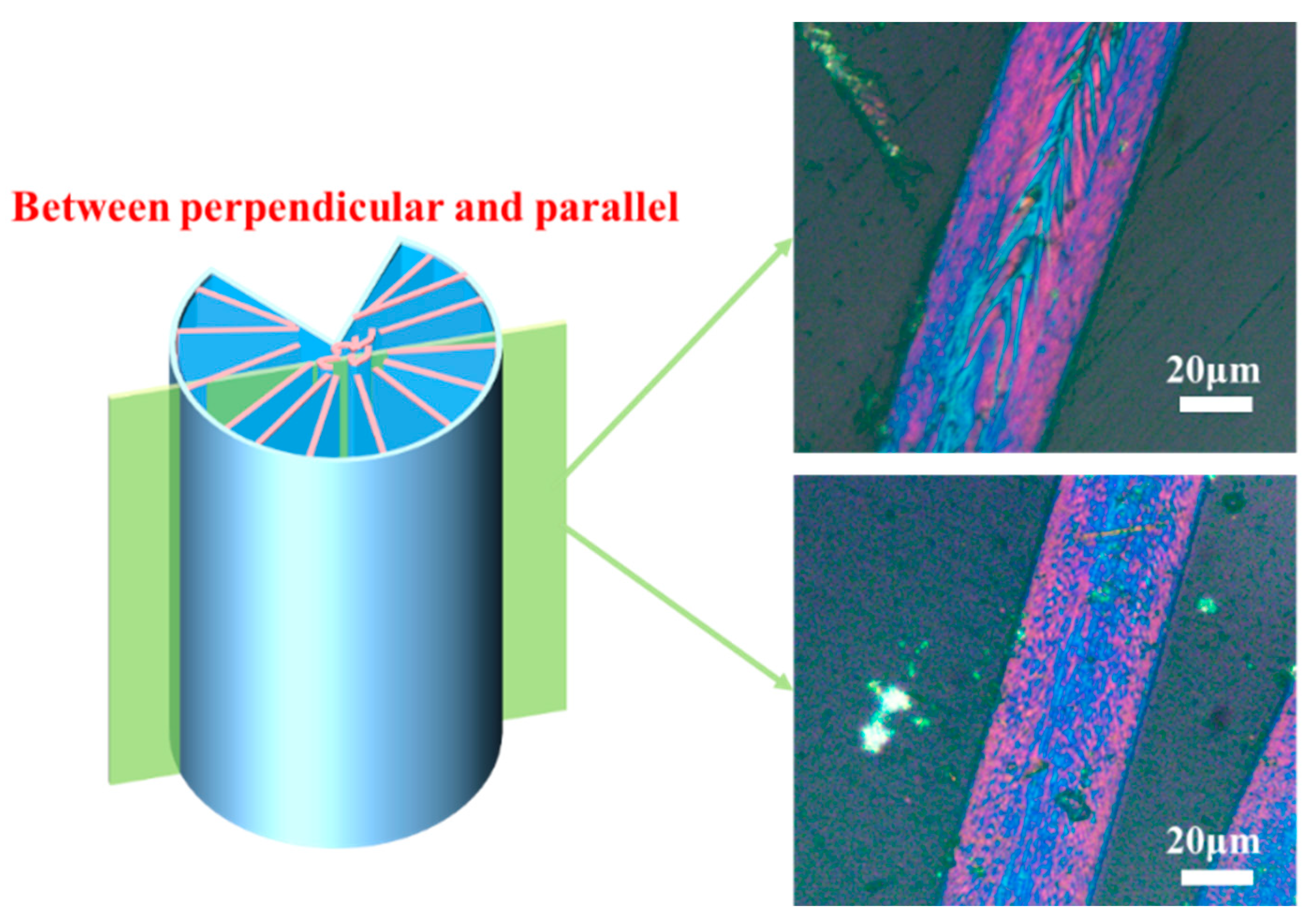

3.2. The Optical Textures of MP-Derived Fibers

3.3. The Microcrystalline Structure of MP-Derived Fibers

3.4. The Microstructure of MP-Derived GFs

3.5. The Interpretation of Structural Evolution between the Optical Structure and Microstructure of MP-Derived Fibers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Klett, J.W.; McMillan, A.D.; Gallego, N.C.; Burchell, T.D.; Walls, C.A. Effects of heat treatment conditions on the thermal properties of mesophase pitch-derived graphitic foams. Carbon 2004, 42, 1849–1852. [Google Scholar] [CrossRef]

- Tian, Y.C.; Huang, Y.; Yu, X.L.; Gao, F.; Gao, S.H.; Wang, F.L.; Li, D.; Xu, X.; Cui, L.W.; Fan, X.Y.; et al. Co-carbonization of medium- and low- temperature coal tar pitch and coal-based hydrogenated diesel oil prepare mesophase pitch for needle coke precursor. Adv. Eng. Mater. 2021, 23, 2001523. [Google Scholar] [CrossRef]

- Shi, J.L.; Ma, C. Preparation and characterization of spinnable mesophase pitches: A review. New Carbon Mater. 2019, 34, 211–219. [Google Scholar] [CrossRef]

- Yao, Y.B.; Chen, J.M.; Liu, L.; Dong, Y.M.; Liu, A.H. Tailoring structures and properties of mesophase pitch-based carbon fibers based on isotropic/mesophase incompatible blends. J. Mater. Sci. 2012, 47, 5509–5516. [Google Scholar] [CrossRef]

- Pei, R.S.; Chen, G.Q.; Wang, Y.P.; Zhao, M.; Wu, G.H. Effect of interfacial microstructure on the thermal-mechanical properties of mesophase pitch-based carbon fiber reinforced aluminum composites. J. Alloys Compd. 2018, 756, 8–18. [Google Scholar] [CrossRef]

- Shimanoe, H.; Mashino, T.; Nakabayashi, K.; Inoue, I.; Hamaguchi, M.; Miyawaki, J.; Mochida, I.; Yoon, S.H. Manufacturing spinnable mesophase pitch using direct coal extracted fraction and its derived mesophase pitch based carbon fiber. Carbon 2020, 158, 922–929. [Google Scholar] [CrossRef]

- Emmerich, F.G. Young’s modulus, thermal conductivity, electrical resistivity and coefficient of thermal expansion of mesophase pitch-based carbon fibers. Carbon 2014, 79, 274–293. [Google Scholar] [CrossRef]

- Salim, O.; Tapas, K.M. NMR spectroscopy analysis of asphaltenes. Energy Fuels 2019, 33, 10391–10414. [Google Scholar] [CrossRef]

- Yang, J.; Nakabayashi, K.; Miyawaki, J.; Yoon, S.H. Preparation of pitch based carbon fibers using Hyper-coal as a raw material. Carbon 2016, 106, 28–36. [Google Scholar] [CrossRef]

- Khushboo, K.; Sonu, R.; Pankaj, K. Study of mesophase pitch based carbon fibers: Structural changes as a function of anisotropic content. J. Anal. Appl. Pyrolysis 2023, 171, 105961. [Google Scholar] [CrossRef]

- Peng, Y.; Yang, J.; Shi, K.; Guo, J.; Zhu, H.; Li, X. Effects of the degree of oxidation of pitch fibers on their stabilization and carbonization behaviors. New Carbon Mater. 2020, 35, 722–730. [Google Scholar] [CrossRef]

- Haruki, O.; Robert, J.Y.; Daniel, W.; Fumihiko, T.; Go, Y.; Tomonaga, O. Investigating nanostructures in carbon fibres using Raman spectroscopy. Carbon 2018, 130, 178–184. [Google Scholar] [CrossRef]

- Brooks, J.D.; Taylor, G.H. The formation of graphitizing carbons from the liquid phase. Carbon 1965, 3, 185–187. [Google Scholar] [CrossRef]

- Zimmer, J.E.; White, J.L. Disclination structures in the carbonaceous mesophase. Adv. Liq. Cryst. 1982, 5, 157–213. [Google Scholar] [CrossRef]

- Chen, L.; Fan, X.H.; Jiang, Z.; Ouyang, T.; Fei, Y.Q. Observation of “in-contact” characteristics of Brooks-Taylor mesophase spheres obtained by high-temperature centrifugation. Carbon 2016, 103, 421–424. [Google Scholar] [CrossRef]

- Kundu, S.; Ogale, A.A. Microstructural effects on the dynamic rheology of a discotic mesophase pitch. Rheol. Acta 2007, 46, 1211–1222. [Google Scholar] [CrossRef]

- Kundu, S.; Ogale, A.A. Rheostructural studies of a discotic mesophase pitch at processing flow conditions. Rheol. Acta 2010, 49, 845–854. [Google Scholar] [CrossRef]

- Kundu, S.; Grecov, D.; Ogale, A.A.; Rey, A.D. Shear flow induced microstructure of a synthetic mesophase pitch. J. Rheol. 2009, 53, 85–113. [Google Scholar] [CrossRef]

- Kundu, S.; Ogale, A.A. Rheostructural studies on a synthetic mesophase pitch during transient shear flow. Carbona 2006, 44, 2224–2235. [Google Scholar] [CrossRef]

- Mochida, I.; Korai, Y.; Ku, C.H.; Watanabe, F.; Sakai, Y. Chemistry of synthesis, structure, preparation and application of aromatic-derived mesophase pitch. Carbon 2000, 38, 305–328. [Google Scholar] [CrossRef]

- Gerald, G.J.D.; Pennock, G.M.; Taylor, G.H. Domain structure in mesophase pitch-based fibres. Carbon 1991, 29, 139–164. [Google Scholar] [CrossRef]

- Mochida, I.; Yoon, S.H.; Takano, N.; Fortin, F.; Korai, Y.; Yokogawa, K. Microstructure of mesophase pitch-based carbon fiber and its control. Carbon 1996, 34, 941–956. [Google Scholar] [CrossRef]

- Hong, S.H.; Korai, Y.; Mochida, I. Development of mesoscopic textures in transverse cross-section of mesophase pitch-based carbon fibers. Carbon 1999, 37, 917–930. [Google Scholar] [CrossRef]

- Hong, S.H.; Korai, Y.; Mochida, I. Mesoscopic texture at the skin area of mesophase pitch-based carbon fiber. Carbon 2000, 38, 805–815. [Google Scholar] [CrossRef]

- Peng, Y.; Tan, R.; Liu, Y.; Yang, J.; Li, Y.; Li, J.; Fan, Z.; Shi, K. Mesophase pitch-based carbon fibers: Accelerated stabilization of pitch fibers under effective plasma irradiation-assisted modification. Materials 2021, 14, 6382. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Tang, X.; Qin, J.; Yang, J.; Wu, X.; Wei, Y.; He, X.; Huang, Z. Understanding the Molecular Arrangement and Orientation Characteristics of Mesophase Pitch and Its Fibers via a Polarized Light Microscope. Polymers 2024, 16, 1114. https://doi.org/10.3390/polym16081114

Li J, Tang X, Qin J, Yang J, Wu X, Wei Y, He X, Huang Z. Understanding the Molecular Arrangement and Orientation Characteristics of Mesophase Pitch and Its Fibers via a Polarized Light Microscope. Polymers. 2024; 16(8):1114. https://doi.org/10.3390/polym16081114

Chicago/Turabian StyleLi, Jingpan, Ximing Tang, Ji Qin, Jianxiao Yang, Xiao Wu, Yuxin Wei, Xubin He, and Zujian Huang. 2024. "Understanding the Molecular Arrangement and Orientation Characteristics of Mesophase Pitch and Its Fibers via a Polarized Light Microscope" Polymers 16, no. 8: 1114. https://doi.org/10.3390/polym16081114

APA StyleLi, J., Tang, X., Qin, J., Yang, J., Wu, X., Wei, Y., He, X., & Huang, Z. (2024). Understanding the Molecular Arrangement and Orientation Characteristics of Mesophase Pitch and Its Fibers via a Polarized Light Microscope. Polymers, 16(8), 1114. https://doi.org/10.3390/polym16081114