Damage Monitoring of Regularly Arrayed Short-Fiber-Reinforced Composite Laminates under Tensile Load Based on Acoustic Emission Technology

Abstract

1. Introduction

2. Analysis Procedure

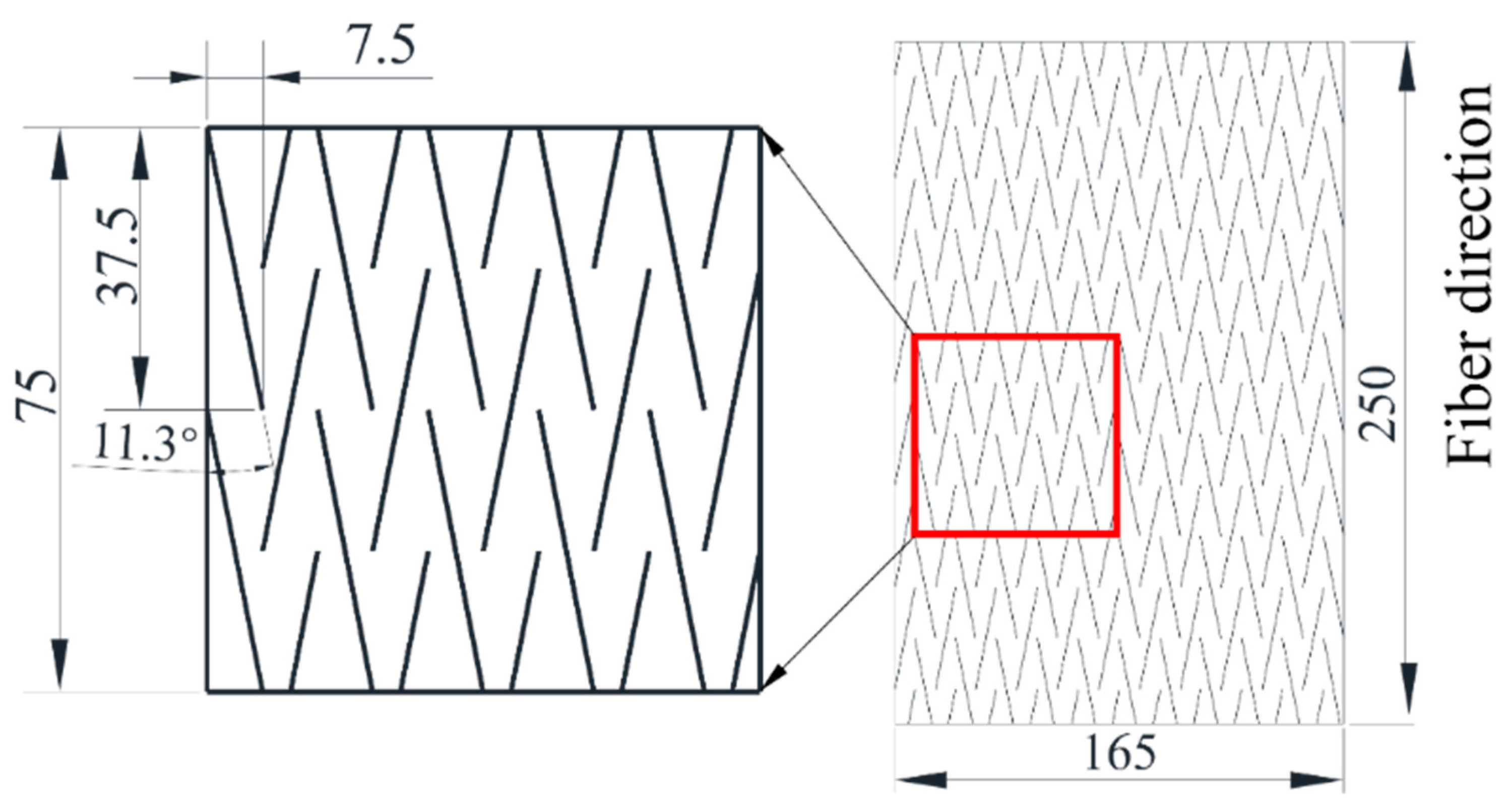

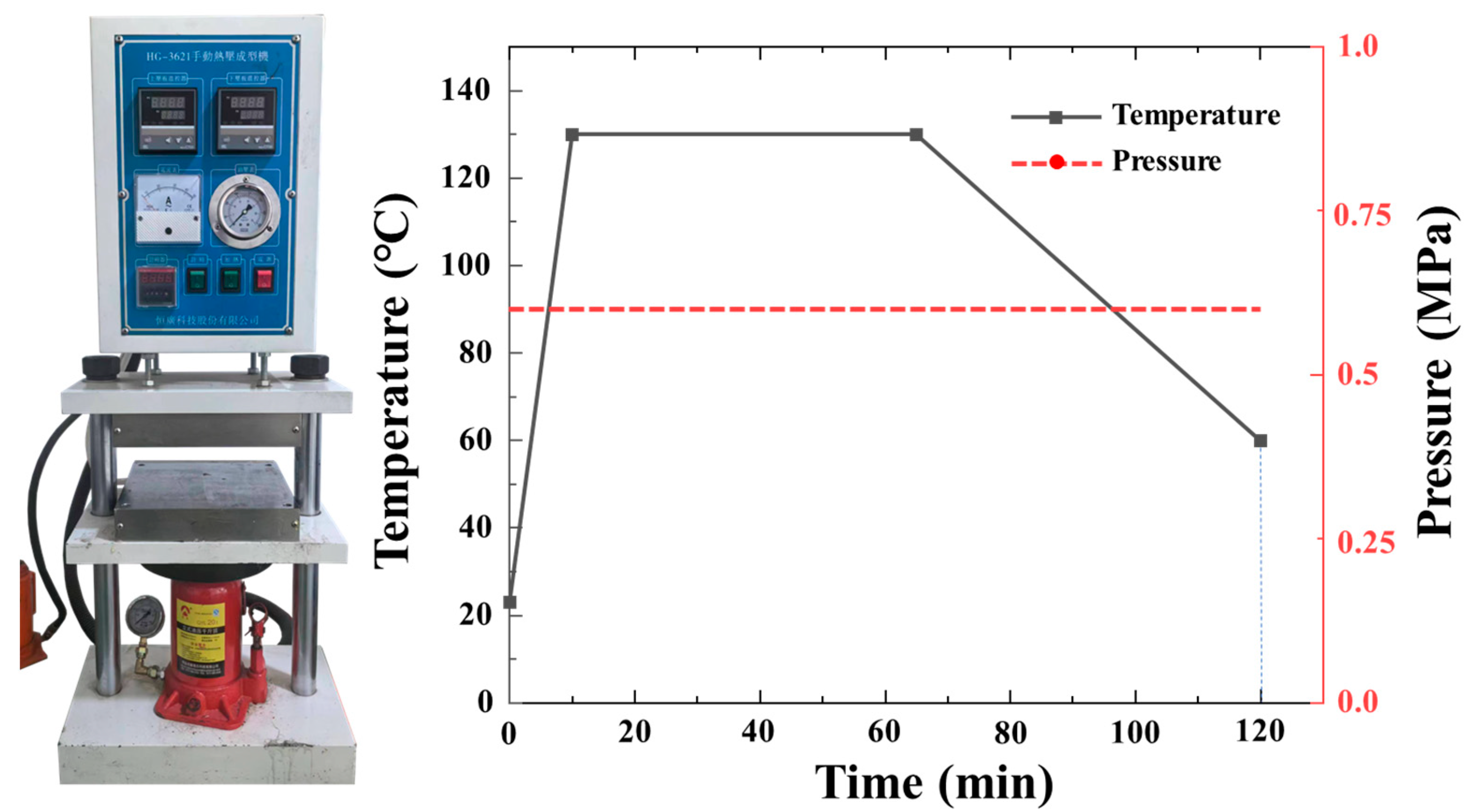

2.1. Materials

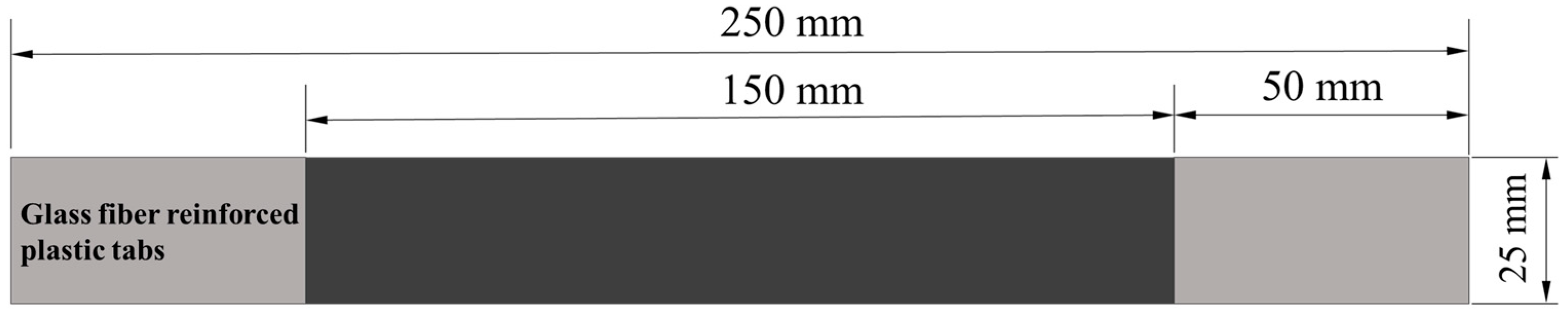

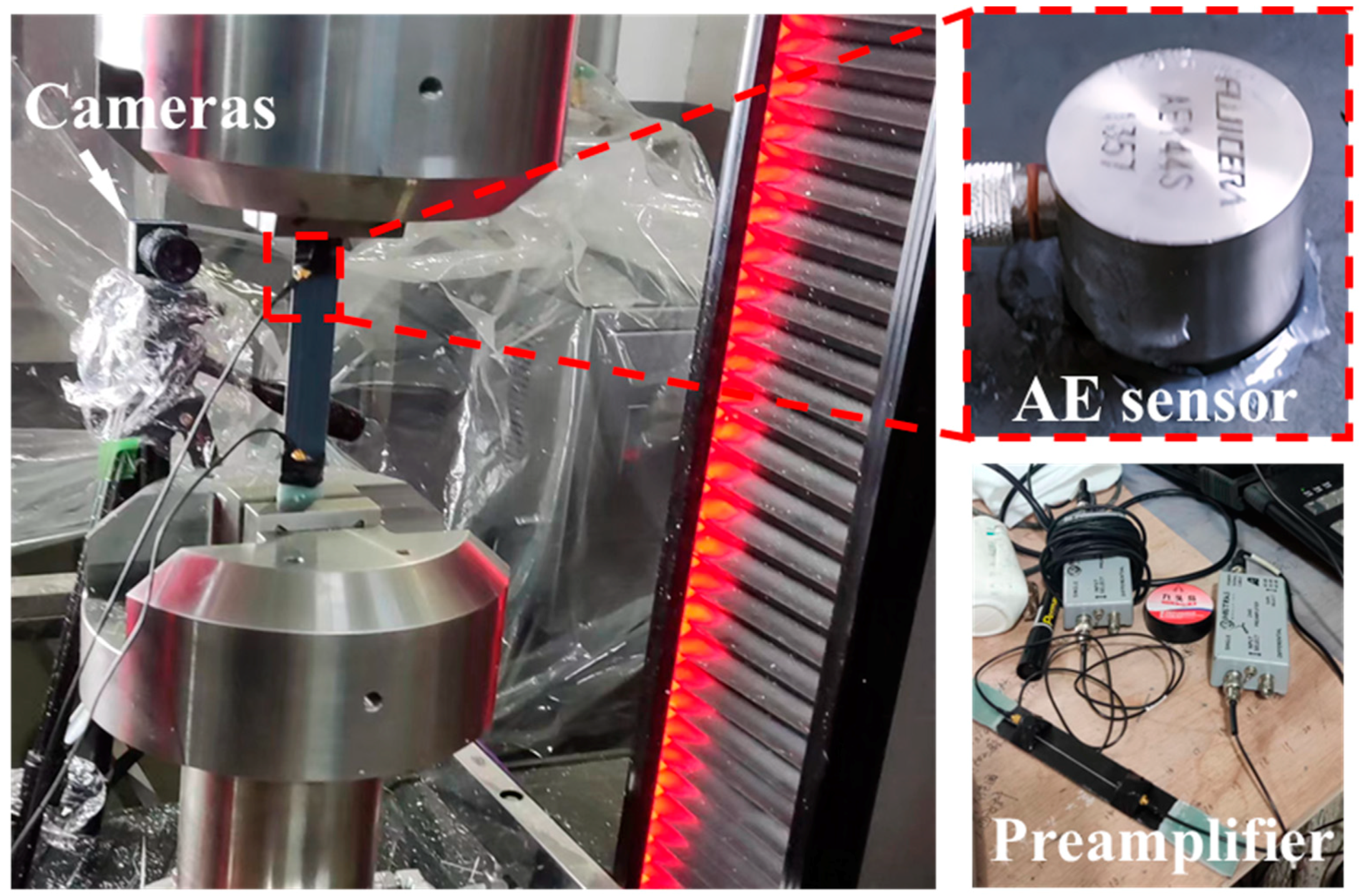

2.2. Tensile Strength Test and Acoustic Emission Detection

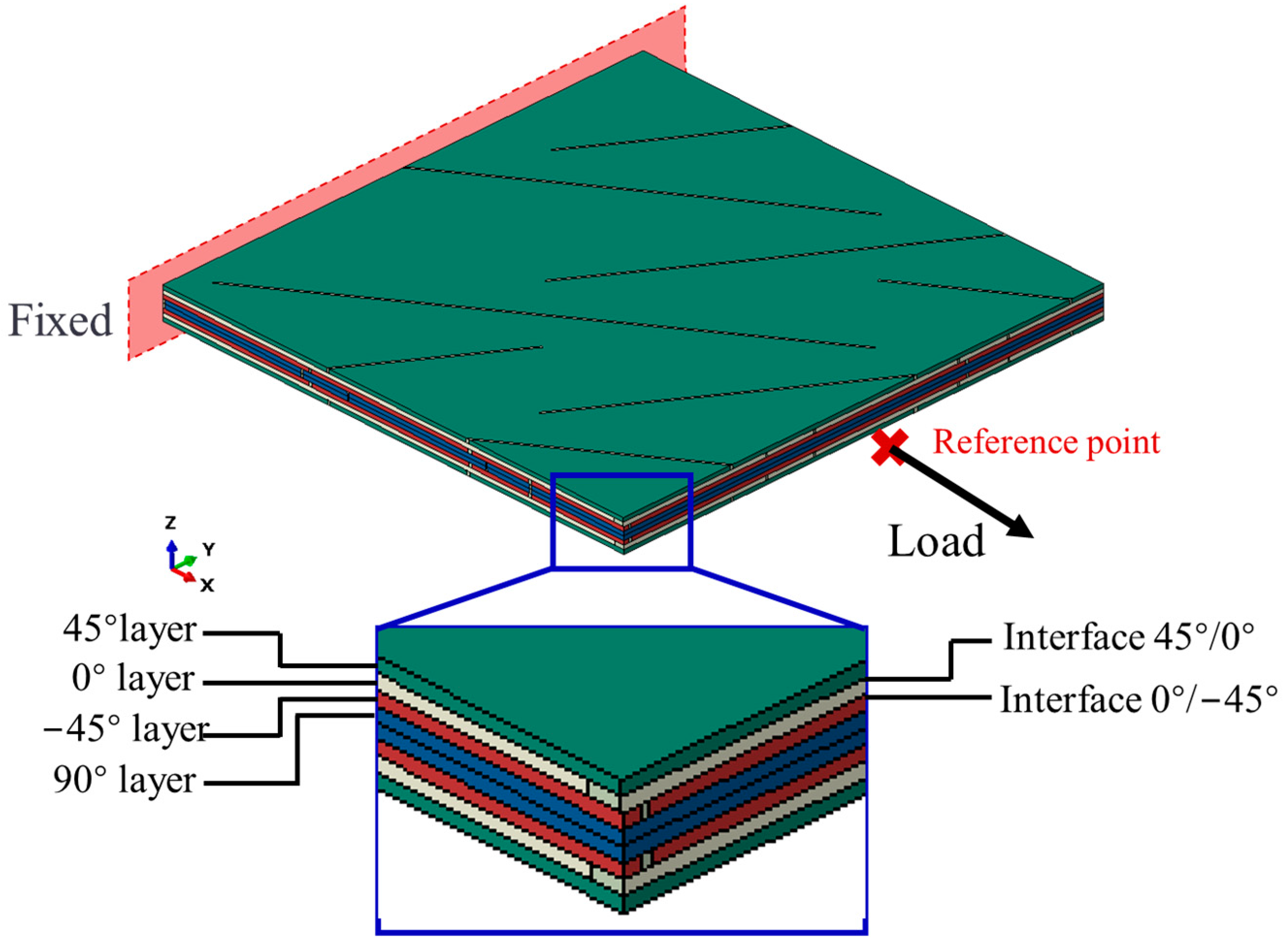

2.3. Finite Element Analysis Model

3. Results and Discussions

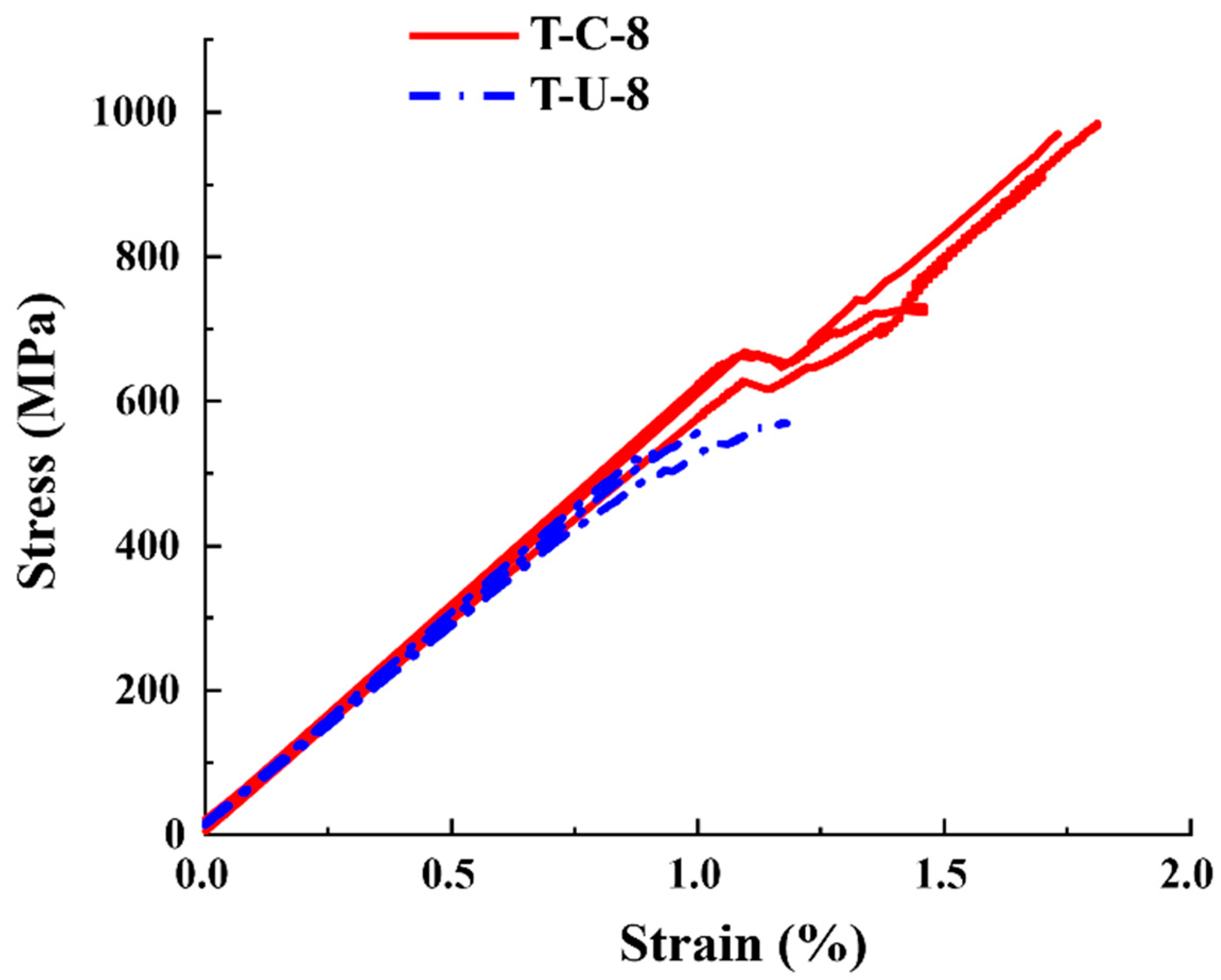

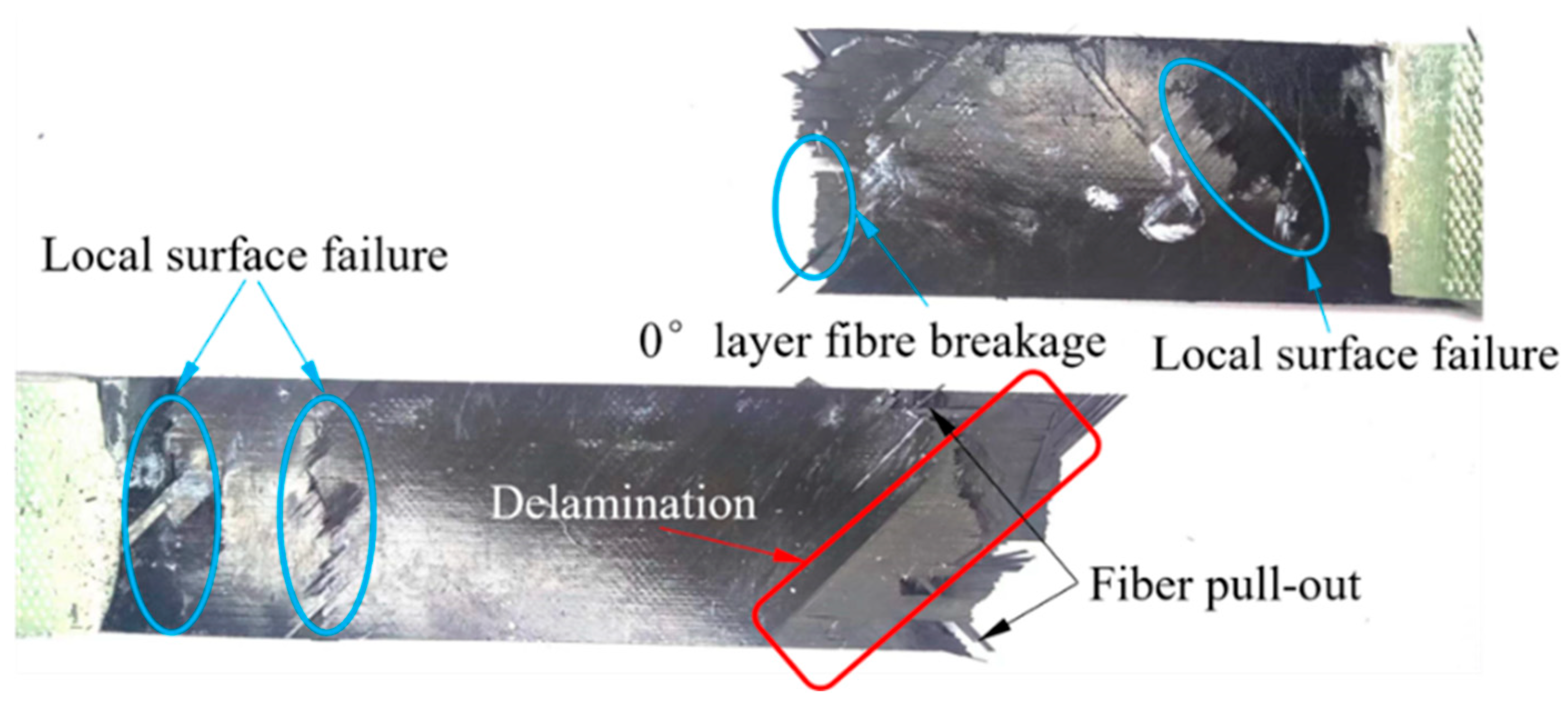

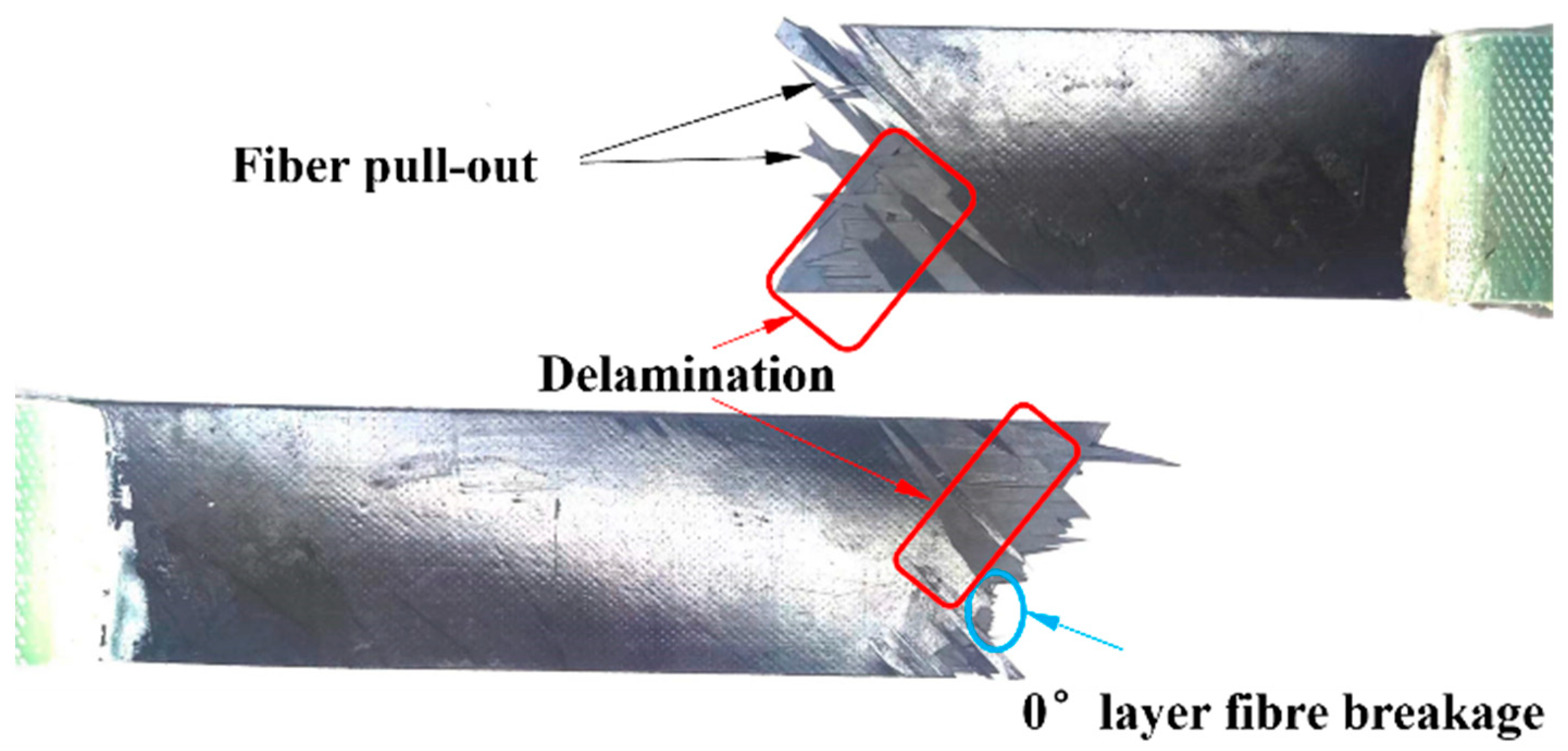

3.1. Results of Tensile Tests

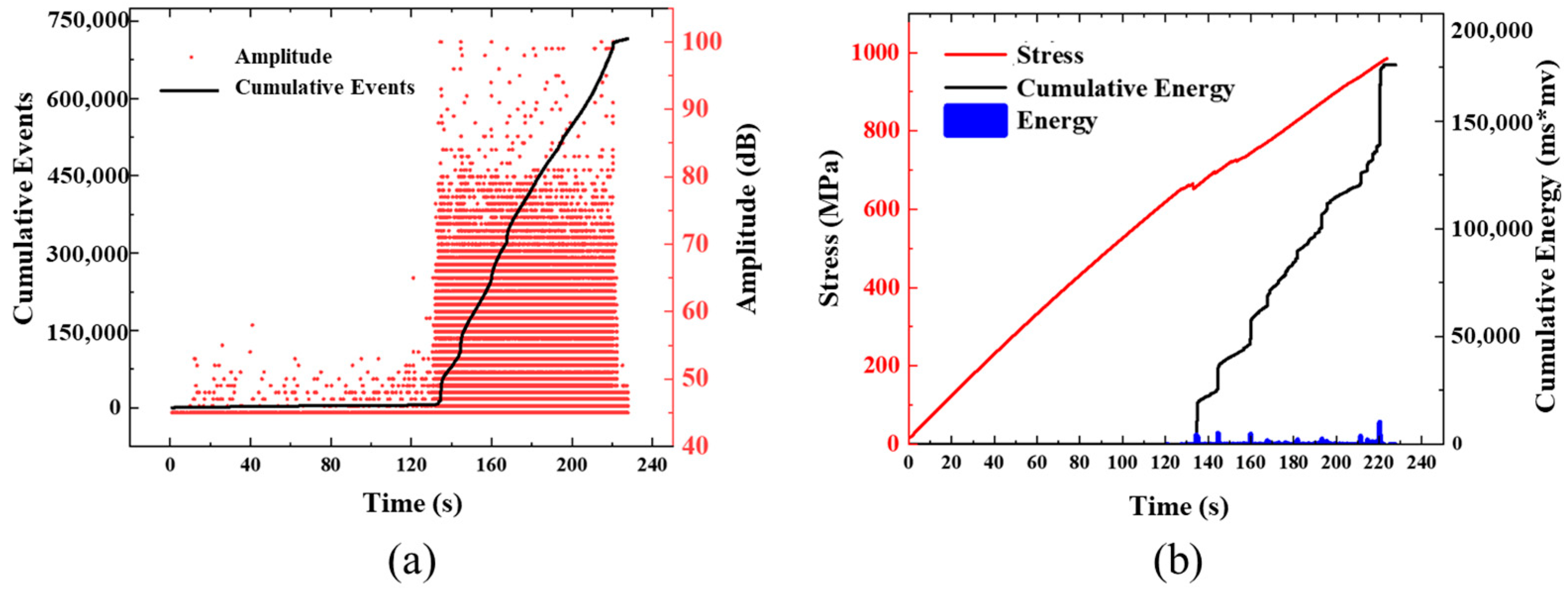

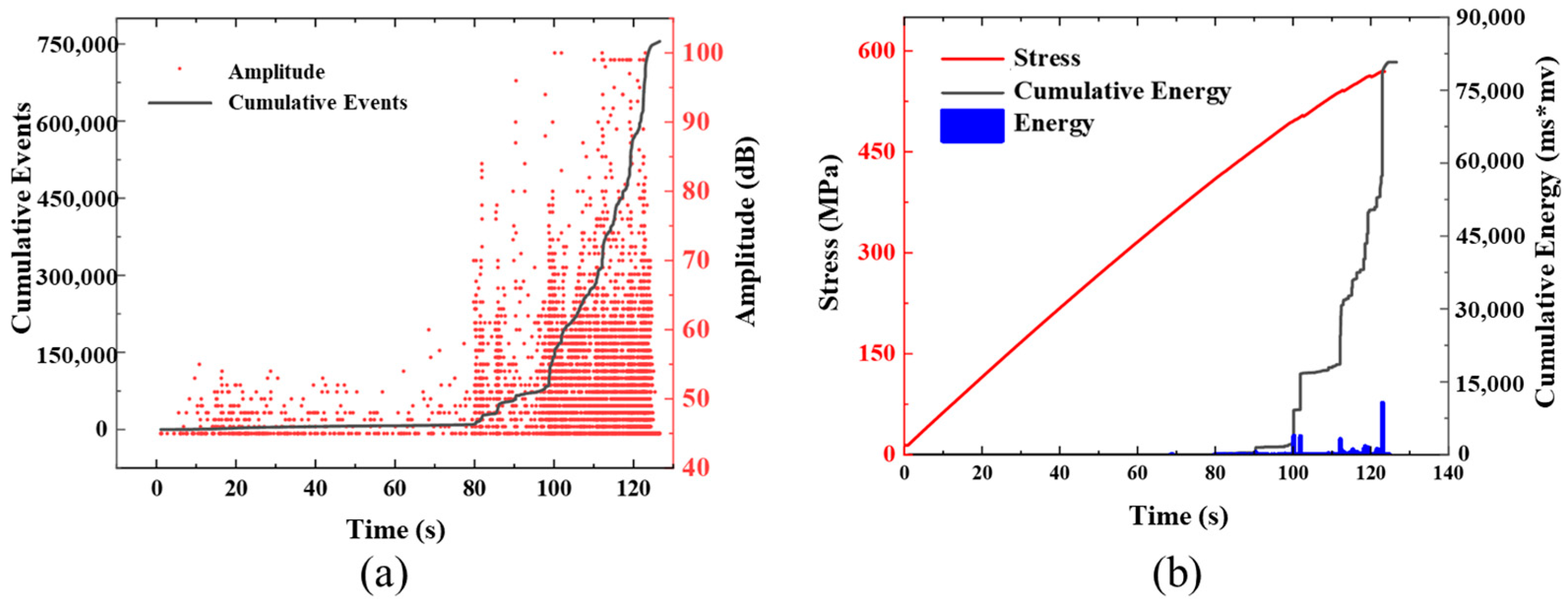

3.2. Results of Acoustic Emission Detection

3.3. Results of Finite Element Analysis

4. Conclusions

- (1)

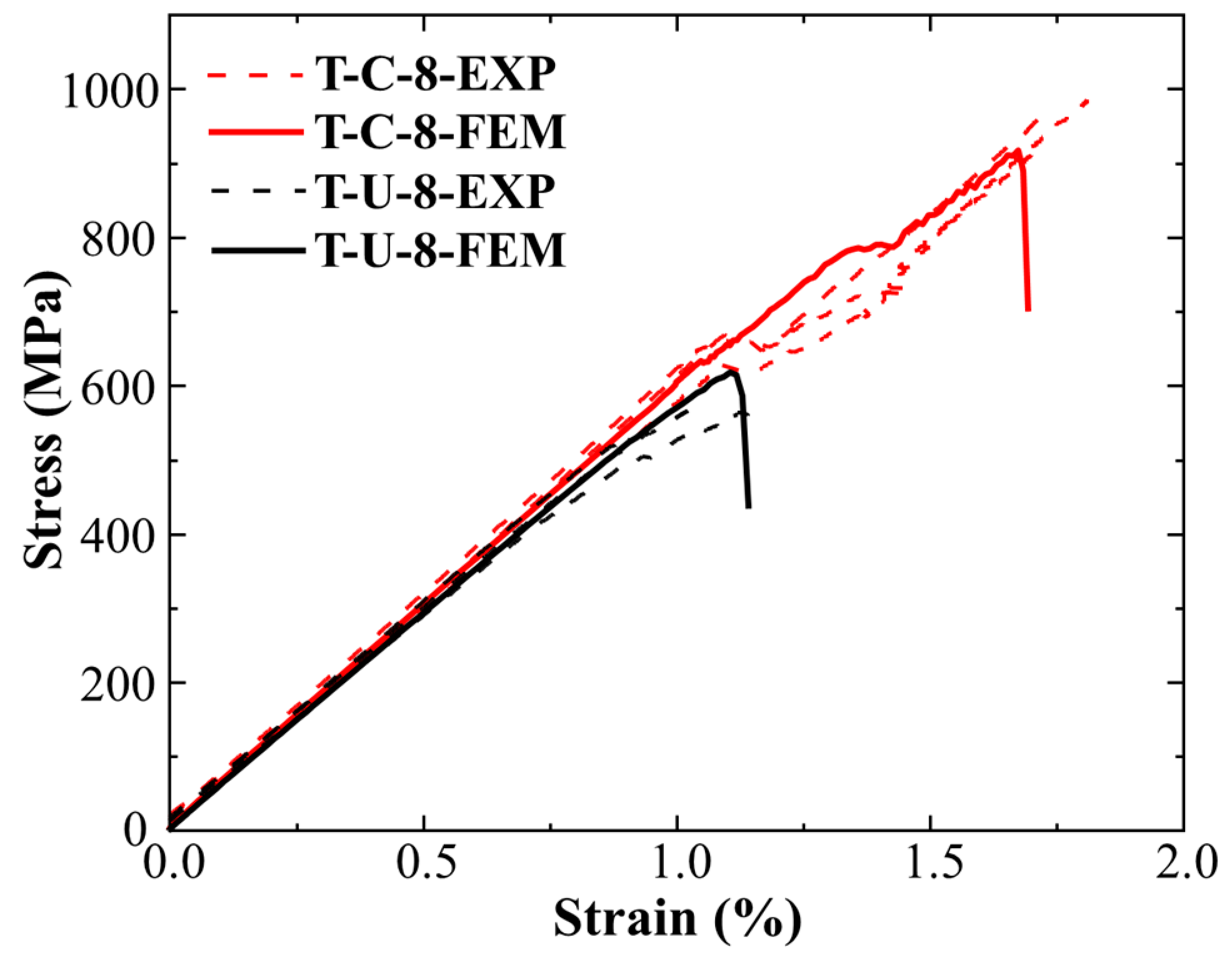

- The tensile strength and elastic modulus of the continuous fiber laminates are 951.66 MPa and 60.282 GPa, and these values are 551.43 MPa and 59.241 GPa for UACS laminates. Slits inhibit the delamination of UACS laminates and cause it to have an obvious nonlinear response before the final failure.

- (2)

- The high-decibel impact events of continuous fiber specimens are concentrated in the last 41% of the tensile test, while that of the UACS specimen is concentrated in the last 30%, and the overall decibel level of impact events is low. This indicates that the damage of UACS laminates is mostly matrix damage and delamination because this damage exhibits lower energy and occurs to a smaller degree.

- (3)

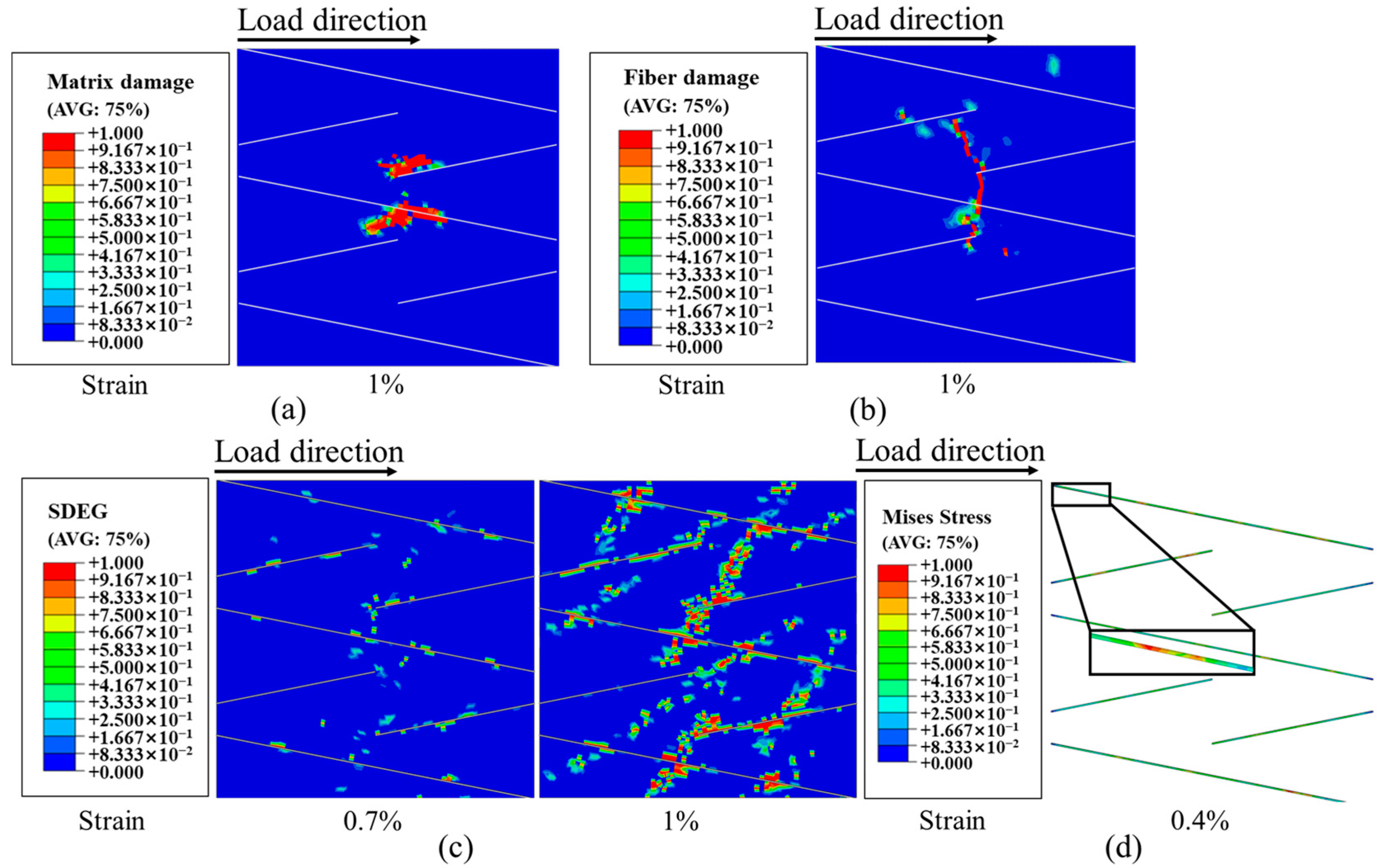

- The errors rates in the strength and modulus of continuous fiber laminates are 3.58% and 2.02%, and those of UACS laminates are 7.9% and 2.04%, respectively. The finite element results show that the continuous fiber laminates experienced extensive delamination damage before final failure affected by ±45°. The failure mode of the 0° layer in UACS laminates is fiber fracture, and the other layers experience matrix damage and local delamination, rather than widespread delamination.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- He, D.; Kim, H.C.; Sommacal, S.; Stojcevski, F.; Soo, V.K.; Lipiński, W.; Morozov, E.; Henderson, L.C.; Compston, P.; Doolan, M. Improving mechanical and life cycle environmental performances of recycled CFRP automotive component by fibre architecture preservation. Compos. Part A Appl. Sci. Manuf. 2023, 175, 107749. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, J.; Yue, G.; Liu, J.; Xue, J. Application of composites in new generation of large civil aircraft. Acta Mater. Compos. Sin. 2015, 32, 317–322. [Google Scholar]

- Fan, X. Application status and development trend of carbon fiber reinforced plastic. Chem. Ind. 2019, 37, 12–16. [Google Scholar]

- Ma, X.; Wang, R.; Hou, J.; Cheng, Z.; Wang, H. Application analysis of CFRP based on automobile lightweight. New Chem. Mater. 2020, 48, 223–226. [Google Scholar]

- Zhang, X.; Hu, J.; Wang, Y.; Chen, D.; Zhang, S.; Qian, R.; Huang, Y.; Thompson, F.; Ma, J.; Lu, W. A New Composite Leaf Spring for In-Board Bogie of New Generation High-Speed Trains. Appl. Compos. Mater. 2023, 30, 1377–1392. [Google Scholar] [CrossRef]

- Wysmulski, P. Numerical and Experimental Study of Crack Propagation in the Tensile Composite Plate with the Open Hole. Adv. Sci. Technol. Res. J. 2023, 17, 249–261. [Google Scholar] [CrossRef] [PubMed]

- El-Zohairy, A.; Salim, H.; Shaaban, H.; Mustafa, S.; El-Shihy, A. Experimental and FE parametric study on continuous steel-concrete composite beams strengthened with CFRP laminates. Constr. Build. Mater. 2017, 157, 885–898. [Google Scholar] [CrossRef]

- Pappas, J.M.; Thakur, A.R.; Leu, M.C.; Dong, X. A Comparative Study of Pellet-Based Extrusion Deposition of Short, Long, and Continuous Carbon Fiber-Reinforced Polymer Composites for Large-Scale Additive Manufacturing. J. Manuf. Sci. Eng. 2021, 143, 071012. [Google Scholar] [CrossRef]

- Fu, Y.; Yao, X. A review on manufacturing defects and their detection of fiber reinforced resin matrix composites. Compos. Part C Open Access 2022, 8, 100276. [Google Scholar] [CrossRef]

- Taketa, I.; Okabe, T.; Kitano, A. A new compression-molding approach using unidirectionally arrayed chopped strands. Compos. Part A 2008, 39, 1884–1890. [Google Scholar] [CrossRef]

- Chang, I.Y. LDF™ Thermoplastic Composites Technology. J. Thermoplast. Compos. Mater. 1991, 4, 227–252. [Google Scholar] [CrossRef]

- Hour, K.-Y. Damage Development in a Short Fiber Reinforced Composite. J. Compos. Mater. 1993, 27, 782–805. [Google Scholar] [CrossRef]

- Johnson, A.F. Comparison of the mechanical properties of SMC with laminated GRP materials. Composites 1986, 17, 233–239. [Google Scholar] [CrossRef]

- Li, H.; Wang, W.-X.; Matsubara, T. Multiscale analysis of damage progression in newly designed UACS laminates. Compos. Part A 2014, 57, 108–117. [Google Scholar] [CrossRef]

- Li, H.; Wang, W.-X.; Takao, Y.; Matsubara, T. New designs of unidirectionally arrayed chopped strands by introducing discontinuous angled slits into prepreg. Compos. Part A 2013, 45, 127–133. [Google Scholar] [CrossRef]

- Arifin, A.A.; Wang, W.-X.; Matsubara, T. Experimental investigation on the compression and crush responses of cross-ply laminates with 0° plies of unidirectionally arrayed chopped strand. Compos. Part B 2016, 98, 182–193. [Google Scholar] [CrossRef]

- Wang, X.; Guo, Y.; Zhu, Q.; Liu, Z. Progress in Research of Nondestructive Testing Technique of Composites. Fiber Reinf. Plast. Compos. 2012, S1, 261–265. [Google Scholar]

- Higuchi, R.; Warabi, S.; Yoshimura, A.; Nagashima, T.; Yokozeki, T.; Okabe, T. Experimental and numerical study on progressive damage and failure in composite laminates during open-hole compression tests. Compos. Part A Appl. Sci. Manuf. 2021, 145, 106300. [Google Scholar] [CrossRef]

- Grosse, C.; Ohtsu, M. Acoustic Emission Testing; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Ni, Y.; Yang, Y.; Lv, Y.; Zhang, W. Application status and development trend of acoustic emission in research on damage mechanicsm of composite materials. Fiber Reinf. Plast. Compos. 2019, 8, 115–126. [Google Scholar]

- Wysmulski, P. Load Eccentricity of Compressed Composite Z-Columns in Non-Linear State. Materials 2022, 15, 7631. [Google Scholar] [CrossRef]

- Andraju, L.B.; Raju, G. Damage characterization of CFRP laminates using acoustic emission and digital image correlation: Clustering, damage identification and classification. Eng. Fract. Mech. 2023, 277, 108993. [Google Scholar] [CrossRef]

- Baker, C.; Morscher, G.N.; Pujar, V.V.; Lemanski, J.R. Transverse cracking in carbon fiber reinforced polymer composites: Modal acoustic emission and peak frequency analysis. Compos. Sci. Technol. 2015, 116, 26–32. [Google Scholar] [CrossRef]

- Cheng, X.; Ying, J.; Wu, Z.; Shi, L.; Hu, X. Mode I interlaminar fracture characteristics of CNTs doped woven and unidirectional CFRP via acoustic emission. Theor. Appl. Fract. Mech. 2023, 124, 103812. [Google Scholar] [CrossRef]

- Morokov, E.; Levin, V.; Ryzhova, T.; Dubovikov, E.; Petronyuk, Y.; Gulevsky, I. Bending damage evolution from micro to macro level in CFRP laminates studied by high-frequency acoustic microscopy and acoustic emission. Compos. Struct. 2022, 288, 115427. [Google Scholar] [CrossRef]

- Li, Z.; Gao, Y.; Wang, Y.; Xue, P.; Gong, C.; Wang, W.; Wei, X.; Xiong, J. Failure mechanisms and acoustic emission pattern recognition of all-CFRP cylindrical honeycomb sandwich shell under three-point bending. Compos. Sci. Technol. 2023, 237, 110003. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, K.; Wang, Z.-x.; Li, Z.; Chen, L.; Shi, Q.; Yu, S.; Li, Z.; Zhang, L.; Guo, L. Cross-scale data-based damage identification of CFRP laminates using acoustic emission and deep learning. Eng. Fract. Mech. 2023, 294, 109724. [Google Scholar] [CrossRef]

- Ren, X.-Y.; Wang, J.; Liang, Y.-J.; Ma, L.-H.; Zhou, W. Acoustic emission detection of filament wound CFRP composite structure damage based on Mel spectrogram and deep learning. Thin-Walled Struct. 2024, 198, 111683. [Google Scholar] [CrossRef]

- Zhou, W.; Lv, Z.-H.; Li, Z.-Y.; Song, X. Acoustic emission response and micro-deformation behavior for compressive buckling failure of multi-delaminated composites. J. Strain Anal. Eng. Des. 2016, 51, 397–407. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, W.; Luo, X.; Pang, Y.; Zhou, W. Tensile deformation measurement and acoustic emission monitoring of carbon fiber braided composite. Eng. Plast. Appl. 2017, 45, 97–100. [Google Scholar]

- Wildemann, V.E.; Spaskova, E.V.; Shilova, A.I. Research of the Damage and Failure Processes of Composite Materials Based on Acoustic Emission Monitoring and Method of Digital Image Correlation. Solid State Phenom. 2015, 243, 163–170. [Google Scholar] [CrossRef]

- ASTM D3039M; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2014.

| Parameters | T800/7091(CFRP) |

|---|---|

| Longitudinal Young’s modulus E1 (GPa) | 145 |

| Transverse Young’s modulus E2 = E3 (GPa) | 9.2 |

| In-plane shear modulus G12 = G31 (GPa) | 4.5 |

| Poisson’s ratio | 0.27 |

| Longitudinal tensile strength Xt (MPa) | 2600 |

| Longitudinal compression strength Xc (MPa) | 1150 |

| Transverse tensile strength Yt = Zt (MPa) | 70 |

| Transverse compression strength Yc = Zc (MPa) | 180 |

| Out-of-plane shear strength S23 (MPa) | 55 |

| Parameters | Value |

|---|---|

| Elastic modulus (GPa) | 3 |

| Poisson’s ratio | 0.35 |

| Strengths in normal direction (MPa) | 79 |

| Strengths in first shear direction (MPa) | 55 |

| Strengths in second shear direction (MPa) | 55 |

| Kn * (GPa/mm) | Ks = Kt * (GPa/mm) | * (MPa) | * (MPa) | * (N/mm) | * (N/mm) | η * |

|---|---|---|---|---|---|---|

| 100 | 100 | 40 | 50 | 0.293 | 0.631 | 1.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, H.; Lu, W.; Ma, J.; Huang, Y.; Hu, J. Damage Monitoring of Regularly Arrayed Short-Fiber-Reinforced Composite Laminates under Tensile Load Based on Acoustic Emission Technology. Polymers 2024, 16, 890. https://doi.org/10.3390/polym16070890

Cai H, Lu W, Ma J, Huang Y, Hu J. Damage Monitoring of Regularly Arrayed Short-Fiber-Reinforced Composite Laminates under Tensile Load Based on Acoustic Emission Technology. Polymers. 2024; 16(7):890. https://doi.org/10.3390/polym16070890

Chicago/Turabian StyleCai, Hongda, Wenlong Lu, Jingxuan Ma, Yinyuan Huang, and Junfeng Hu. 2024. "Damage Monitoring of Regularly Arrayed Short-Fiber-Reinforced Composite Laminates under Tensile Load Based on Acoustic Emission Technology" Polymers 16, no. 7: 890. https://doi.org/10.3390/polym16070890

APA StyleCai, H., Lu, W., Ma, J., Huang, Y., & Hu, J. (2024). Damage Monitoring of Regularly Arrayed Short-Fiber-Reinforced Composite Laminates under Tensile Load Based on Acoustic Emission Technology. Polymers, 16(7), 890. https://doi.org/10.3390/polym16070890