Enhancing Fatigue Performance of Coal Gangue Concrete (CGC) through Polypropylene Fiber Modification: Experimental Evaluation

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Mix Design

2.3. Preparation of Specimens

2.4. Testing Methods

3. Results and Discussion

3.1. Uniaxial Compression Experiments

3.2. Repeated Loading Experiments

3.3. Destroy Form

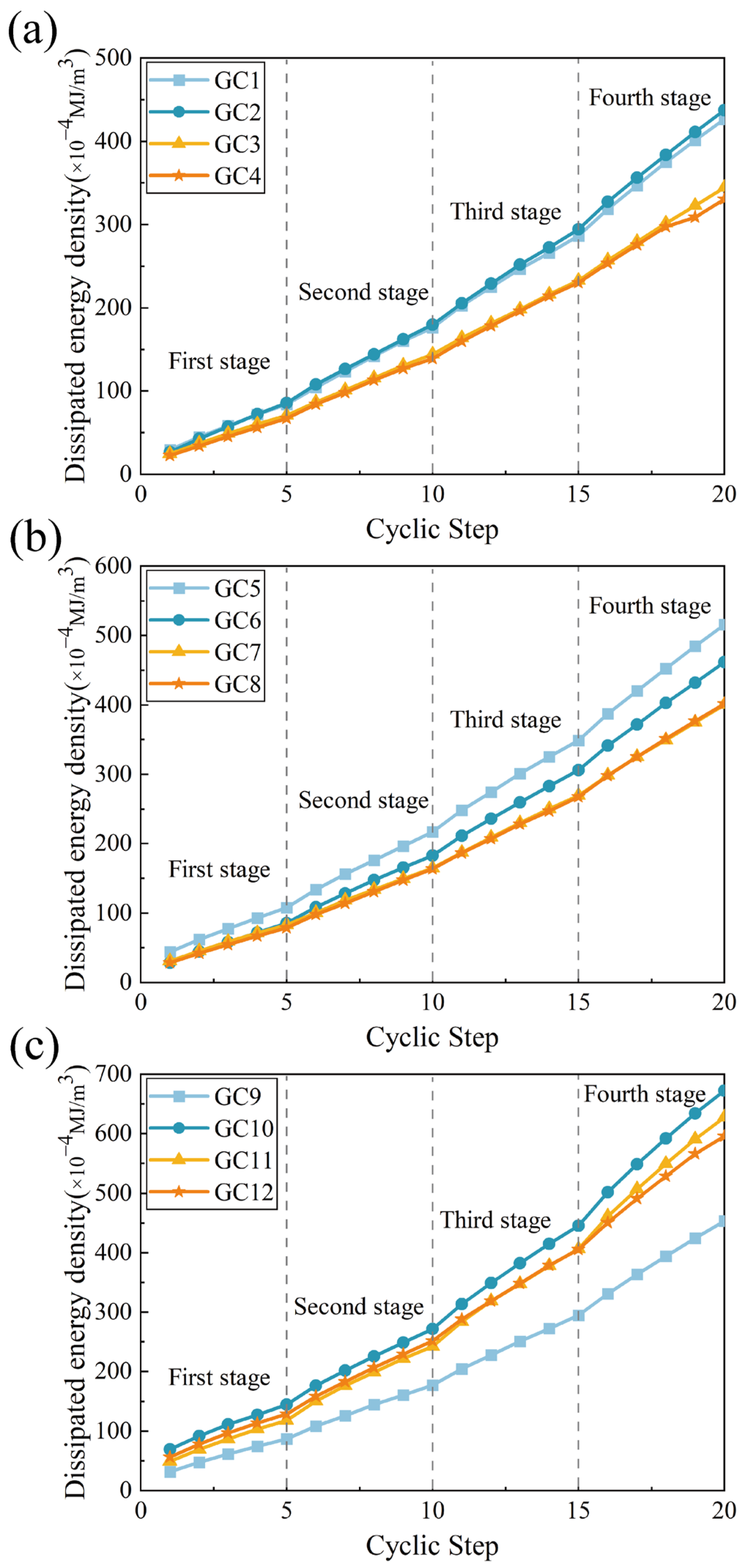

3.4. Energy Evolution

3.5. Residual Strain

3.6. Damage Factors

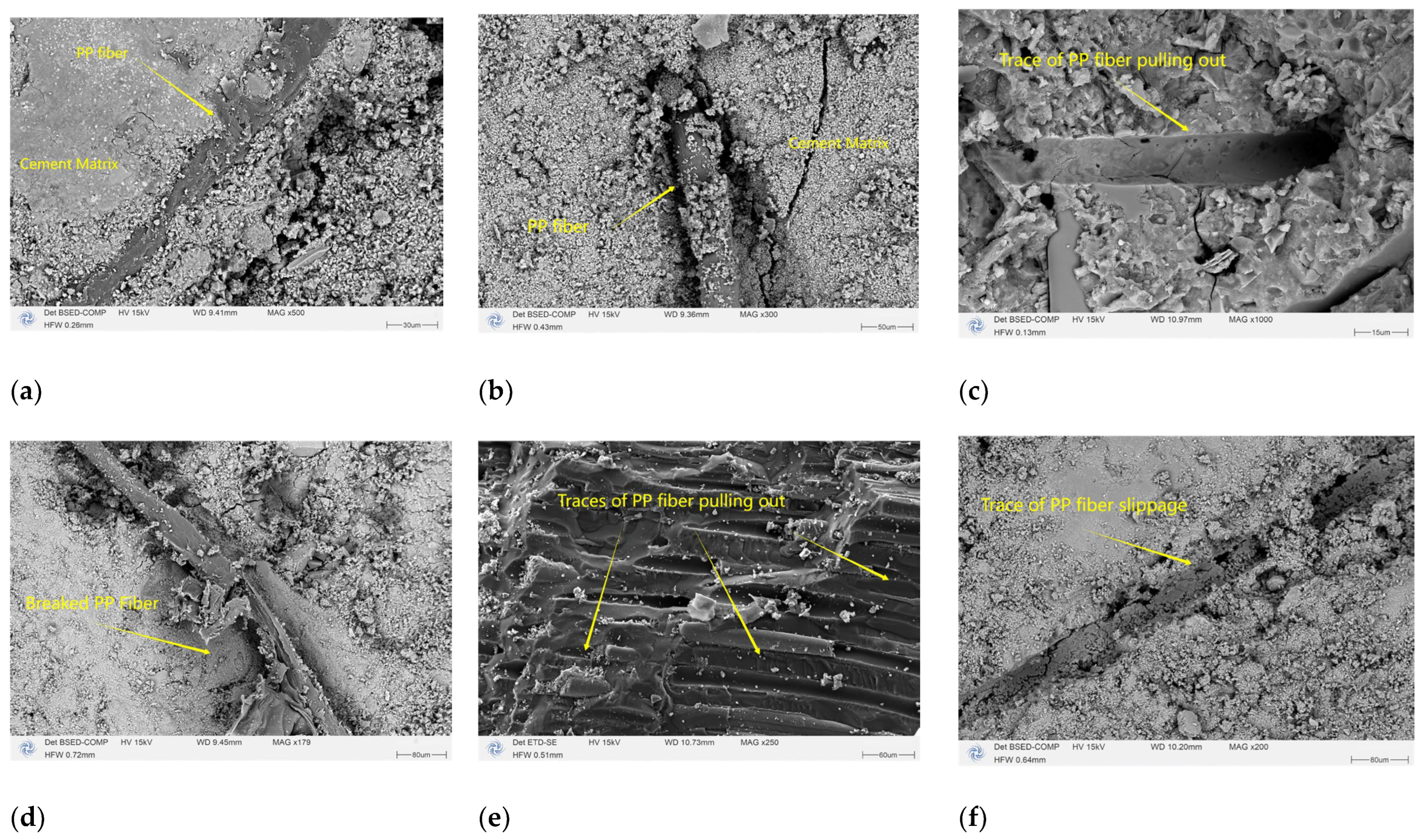

3.7. Microscopic Electron Microscope Analysis

4. Conclusions

- Gangue content inversely affects compressive strength. Fibers enhance strength by crack inhibition, but gangue content remains decisive.

- Polypropylene fibers enhance gangue concrete strength under cyclic loading, notably at 20% and 40% gangue substitution fractions.

- Polypropylene fibers reduce dissipated energy in gangue concrete, with varied effects based on content and ratio. Increased stress amplitude causes abrupt residual strain changes, mitigated by polypropylene fibers, enhancing specimen resistance to damage.

- Repeated loading increases the damage factor in concrete specimens. The higher the gangue content, the greater the damage. Polypropylene fiber can reduce the damage, with a maximum reduction of 33.76%.

- SEM tests show that polypropylene fibers are tightly bonded to the cement matrix, bearing loads and transmitting stress.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hao, C.; Zhou, X.; Zhang, Y.; Ma, L. LMDI Decomposition of Coal Consumption in China Based on the Energy Allocation Diagram of Coal Flows: An Update for 2005–2020 with Improved Sectoral Resolutions. Energy 2023, 285, 129266. [Google Scholar] [CrossRef]

- Kang, H.; Gao, F.; Xu, G.; Ren, H. Mechanical Behaviors of Coal Measures and Ground Control Technologies for China’s Deep Coal Mines—A Review. J. Rock Mech. Geotech. Eng. 2023, 15, 37–65. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, R.; Zhang, F.; Shi, G.; Wang, C. Assessing Provincial Coal Reliance for Just Low-Carbon Transition in China. Environ. Impact Assess. Rev. 2023, 102, 107198. [Google Scholar] [CrossRef]

- Dong, Y.; Lu, H.; Lin, H. Comprehensive Study on the Spatial Distribution of Heavy Metals and Their Environmental Risks in High-Sulfur Coal Gangue Dumps in China. J. Environ. Sci. 2024, 136, 486–497. [Google Scholar] [CrossRef] [PubMed]

- Dong, J.; Li, J.; Huang, Y.; Zhong, J.; Dun, K.; Wu, M.; Zhang, L.; Chen, Q.; Pan, B. Understanding the Release, Migration, and Risk of Heavy Metals in Coal Gangue: An Approach by Combining Experimental and Computational Investigations. J. Hazard. Mater. 2024, 461, 132707. [Google Scholar] [CrossRef] [PubMed]

- Kou, B.; He, Y.; Wang, Y.; Qu, C.; Tang, J.; Wu, Y.; Tan, W.; Yuan, Y.; Yu, T. The Relationships between Heavy Metals and Bacterial Communities in a Coal Gangue Site. Environ. Pollut. 2023, 322, 121136. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Zhu, Q.; Xu, J.; Ruan, M. Development of Composite Bactericides for Controlling Acidification Pollution in Coal Gangue Piles and Their Mechanisms of Bacterial Inhibition. Environ. Technol. Innov. 2022, 25, 102094. [Google Scholar] [CrossRef]

- Song, W.; Xu, R.; Li, X.; Min, X.; Zhang, J.; Zhang, H.; Hu, X.; Li, J. Soil Reconstruction and Heavy Metal Pollution Risk in Reclaimed Cultivated Land with Coal Gangue Filling in Mining Areas. Catena 2023, 228, 107147. [Google Scholar] [CrossRef]

- Liu, B.; Tang, Z.; Dong, S.; Wang, L.; Liu, D. Vegetation Recovery and Groundwater Pollution Control of Coal Gangue Fi Eld in a Semi-Arid Area for a Fi Eld Application. Int. Biodeterior. Biodegrad. 2018, 128, 134–140. [Google Scholar] [CrossRef]

- Qin, Q.; Geng, H.; Deng, J.; Su, X.; Chen, M.; Park, C.B. Al and Other Critical Metals Co-Extraction from Coal Gangue through Delamination Pretreatment and Recycling Strategies. Chem. Eng. J. 2023, 477, 147036. [Google Scholar] [CrossRef]

- Lao, X.; Tu, Z.; Xu, X.; Jiang, W.; Liang, J. An Energy-Saving and Cleaner Method for Recycling Coal Gangue and Aluminium Chips: Preparing in-Situ Nitride Whiskers Reinforced Ceramics for Thermal Storage. J. Clean. Prod. 2023, 383, 135383. [Google Scholar] [CrossRef]

- Yao, C.; Shen, Z.; Wang, Y.; Mei, N.; Li, C.; Liu, Y.; Ma, W. Tracing and Quantifying the Source of Heavy Metals in Agricultural Soils in a Coal Gangue Stacking Area: Insights from Isotope Fi Ngerprints and Receptor Models. Sci. Total Environ. 2023, 863, 160882. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Zhou, Y.; Sun, Y.; Chen, X.; Yuan, L. Coal Gangue-Based Magnetic Porous Material for Simultaneous Remediation of Arsenic and Cadmium in Contaminated Soils: Performance and Mechanisms. Chemosphere 2023, 338, 139380. [Google Scholar] [CrossRef] [PubMed]

- Feng, D.; Wang, J.; Wang, Y.; Xiao, X.; Hou, W.; Liang, S. Alkali-Activated Geopolymer Materials Prepared from Coal Gangue and Municipal Solid Waste Incineration Byproducts. J. Build. Eng. 2023, 80, 108074. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, J.; Lü, G.; Zhang, T.; Gong, Y. Kinetics of Alumina Extraction from Coal Gangue by Hydrochloric Acid Leaching. Trans. Nonferrous Met. Soc. China 2023, 33, 1932–1942. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Nian, P.; Wang, W.; Wei, D.; Xu, N.; Wu, Z.; Zhu, T.; Wei, Y. Reaction-Bonded Robust SiC Ceramic Membranes Sintered at Low Temperature with Coal Gangue. Ceram. Int. 2023, 49, 19798–19805. [Google Scholar] [CrossRef]

- Sun, J.; Liu, S.; Ma, Z.; Qian, H.; Wang, Y. Mechanical Properties Prediction of Lightweight Coal Gangue Shotcrete. J. Build. Eng. 2023, 80, 108088. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, H.; Tang, J.; Gao, S. Ur Na Oo F. J. Build. Eng. 2024, 84, 108488. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, X.; Du, G.; Ma, Y.; Fan, J. Shrinkage Model for Concrete Incorporating Coal Gangue Coarse and Fine Aggregates. J. Build. Eng. 2023, 80, 107865. [Google Scholar] [CrossRef]

- Zhang, X.; Feng, X.; Wang, Z.; Jian, J.; Chen, S.; Luo, W. Experimental Study on the Physico-Mechanical Properties and Microstructure of Foam Concrete Mixed with Coal Gangue. Constr. Build. Mater. 2022, 359, 129428. [Google Scholar] [CrossRef]

- Wen, B.; Huang, D.; Zhang, L.; Song, Q.; Gao, G.; Huo, D. Study on Mechanical Properties and Size Effect of Coal CGC at Mesoscale. Constr. Build. Mater. 2022, 360, 129551. [Google Scholar] [CrossRef]

- Qiu, J.; Zhou, Y.; Ivanovich, N.; Guan, X.; Sultanov, S. Damage Constitutive Model of Coal CGC under Freeze-Thaw Cycles. Constr. Build. Mater. 2020, 264, 120720. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, S.; Wang, R.; Shen, L.; Wang, Q. Utilization of Raw Coal Gangue as Coarse Aggregates in Pavement Concrete. Constr. Build. Mater. 2023, 378, 131062. [Google Scholar] [CrossRef]

- Gao, S.; Zhao, G.; Guo, L.; Zhou, L.; Yuan, K. Utilization of Coal Gangue as Coarse Aggregates in Structural Concrete. Constr. Build. Mater. 2021, 268, 121212. [Google Scholar] [CrossRef]

- Qiu, J.; Zhang, R.; Guan, X.; Cheng, K.; Gao, Y.; Xiao, Z. Deterioration Characteristics of Coal CGC under the Combined Action of Cyclic Loading and Freeze-Thaw Cycles. J. Build. Eng. 2022, 60, 105165. [Google Scholar] [CrossRef]

- Xiao, G.; Yang, G.; Jixi, C.; Ruyi, Z. Deterioration Mechanism of Coal CGC under the Coupling Action of Bending Load and Freeze—Thaw. Constr. Build. Mater. 2022, 338, 127265. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, Y.; Wang, Q.; Kato, A. Experimental Study and Machine Learning Prediction on Compressive Strength of Spontaneous-Combustion Coal Gangue Aggregate Concrete. J. Build. Eng. 2023, 71, 106518. [Google Scholar] [CrossRef]

- Chen, P.; Zhang, L.; Wang, Y.; Fang, Y.; Zhang, F.; Xu, Y. Case Studies in Construction Materials Environmentally Friendly Utilization of Coal Gangue as Aggregates for Shotcrete Used in the Construction of Coal Mine Tunnel. Case Stud. Constr. Mater. 2021, 15, e00751. [Google Scholar] [CrossRef]

- Cai, C.; Li, F.; Fan, S.; Yan, D.; Sun, Q.; Jin, H. Investigation on Deterioration Mechanism of Geopolymer Cemented Coal Gangue-Fly Ash Backfill under Combined Action of High Temperature and Salt Corrosion Environment. Constr. Build. Mater. 2023, 398, 132518. [Google Scholar] [CrossRef]

- Yang, Y.; Lai, X.; Zhang, Y.; Shan, P. Strength Deterioration and Energy Dissipation Characteristics of Cemented Backfill with Different Gangue Particle Size Distributions. J. Mater. Res. Technol. 2023, 25, 5122–5135. [Google Scholar] [CrossRef]

- Cai, B.; Li, K.; Fu, F. Flexural Behavior of Steel Fiber-Reinforced Coal Gangue Aggregate Concrete Beams. Structures 2023, 52, 131–145. [Google Scholar] [CrossRef]

- Wang, H.; Feng, G.; Qi, T.; Gao, X.; Wang, C. Influence of the Use of Corn Straw Fibers to Connect the Interfacial Transition Zone with the Mechanical Properties of Cemented Coal Gangue Backfill. Constr. Build. Mater. 2023, 367, 130334. [Google Scholar] [CrossRef]

- Zhu, M.; Qiu, J.; Chen, J. Effect and Mechanism of Coal CGC Modification by Basalt Fiber. Constr. Build. Mater. 2022, 328, 126601. [Google Scholar] [CrossRef]

- Zhang, N.; Zhao, Z.; Zheng, C. Compression Behavior of GFRP—Coal CGC—Steel Tubular Columns. Int. J. Press. Vessel. Pip. 2022, 197, 104650. [Google Scholar] [CrossRef]

- Guan, H.; Yu, J.; Wang, J.; Pi, J. Experimental and Analytical Model of CFRP-Confined Spontaneous Combustion Coal Gangue Aggregate Concrete. Constr. Build. Mater. 2023, 404, 133261. [Google Scholar] [CrossRef]

- Xia, S.; Liu, H.; Fu, G.; Zhang, J.; Lei, M.; Chen, Z. Axial Compression Property Test of GFRP Tube-Confined Coal Gangue Steel Fiber Short Concrete Column. Polymers 2022, 14, 4528. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Kazemi, S. Investigating the Fracture Parameters of Lightweight Geopolymer Concrete Reinforced with Steel and Polypropylene Fibers. Theor. Appl. Fract. Mech. 2024, 129, 104223. [Google Scholar] [CrossRef]

- Liang, N.; Geng, S.; Mao, J.; Liu, X.; Zhou, X. Investigation on Cracking Resistance Mechanism of Basalt-Polypropylene Fiber Reinforced Concrete Based on SEM Test. Constr. Build. Mater. 2024, 411, 134102. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Y.; Zhou, B.; Wang, L.; Fang, Y. Influence of Polypropylene Fibers on the Mechanical Properties of Radiation Shielding Concrete with Barite Aggregates. J. Build. Eng. 2023, 79, 107820. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, X.; Ma, L.; Li, Z. Effects of Polypropylene Fibers and Aggregate Contents on the Impact Performance of Coral Aggregate Concrete. J. Build. Eng. 2024, 81, 108140. [Google Scholar] [CrossRef]

- Pang, S.; Zhang, X.; Zhu, K.; Li, J.; Su, L. Study on Mechanical Properties and Micro Characterization of Fibre Reinforced Ecological Cementitious Coal Gangue Materials. Polymers 2023, 15, 700. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Xin, C.; Sun, Y.; Di, J.; Meng, F.; Zhou, X. Experimental Study on the Mechanical Properties of Disposable Mask Waste–Reinforced Gangue Concrete. Materials 2024, 17, 948. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Jing, Y.; Zhang, D. Study on modification of mechanical properties of coal gangue concrete with fiber and mineral admixture. J. Funct. Mater. 2022, 53, 7150–7156. [Google Scholar] [CrossRef]

- JGJ 55-2011; Specification for Mix Proportion Design of Ordinary Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2011. Available online: https://www.chinesestandard.net/PDF/English.aspx/JGJ55-2011 (accessed on 1 April 2024).

| Group | Gangue Content | Cement/g | Sand/g | Stone/g | Gangue/g | Water/g | Water Reducer/g | PP Fiber Content |

|---|---|---|---|---|---|---|---|---|

| GC1 | 20% | 445 | 641 | 911 | 207 | 178 | 3.3 | 0 |

| GC2 | 20% | 445 | 641 | 911 | 207 | 178 | 3.3 | 0.1% |

| GC3 | 20% | 445 | 641 | 911 | 207 | 178 | 3.3 | 0.2% |

| GC4 | 20% | 445 | 641 | 911 | 207 | 178 | 3.3 | 0.3% |

| GC5 | 40% | 445 | 641 | 683 | 414 | 178 | 3.3 | 0 |

| GC6 | 40% | 445 | 641 | 683 | 414 | 178 | 3.3 | 0.1% |

| GC7 | 40% | 445 | 641 | 683 | 414 | 178 | 3.3 | 0.2% |

| GC8 | 40% | 445 | 641 | 683 | 414 | 178 | 3.3 | 0.3% |

| GC9 | 60% | 445 | 641 | 456 | 620 | 178 | 3.3 | 0 |

| GC10 | 60% | 445 | 641 | 456 | 620 | 178 | 3.3 | 0.1% |

| GC11 | 60% | 445 | 641 | 456 | 620 | 178 | 3.3 | 0.2% |

| GC12 | 60% | 445 | 641 | 456 | 620 | 178 | 3.3 | 0.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, D.; Jing, L.; Li, Y.; Ran, T.; Peng, S.; Jing, W. Enhancing Fatigue Performance of Coal Gangue Concrete (CGC) through Polypropylene Fiber Modification: Experimental Evaluation. Polymers 2024, 16, 1096. https://doi.org/10.3390/polym16081096

Wu D, Jing L, Li Y, Ran T, Peng S, Jing W. Enhancing Fatigue Performance of Coal Gangue Concrete (CGC) through Polypropylene Fiber Modification: Experimental Evaluation. Polymers. 2024; 16(8):1096. https://doi.org/10.3390/polym16081096

Chicago/Turabian StyleWu, Di, Laiwang Jing, Yan Li, Tao Ran, Shaochi Peng, and Wei Jing. 2024. "Enhancing Fatigue Performance of Coal Gangue Concrete (CGC) through Polypropylene Fiber Modification: Experimental Evaluation" Polymers 16, no. 8: 1096. https://doi.org/10.3390/polym16081096

APA StyleWu, D., Jing, L., Li, Y., Ran, T., Peng, S., & Jing, W. (2024). Enhancing Fatigue Performance of Coal Gangue Concrete (CGC) through Polypropylene Fiber Modification: Experimental Evaluation. Polymers, 16(8), 1096. https://doi.org/10.3390/polym16081096