Investigations into the Material Characteristics of Selected Plastics Manufactured Using SLA-Type Additive Methods

Abstract

1. Introduction

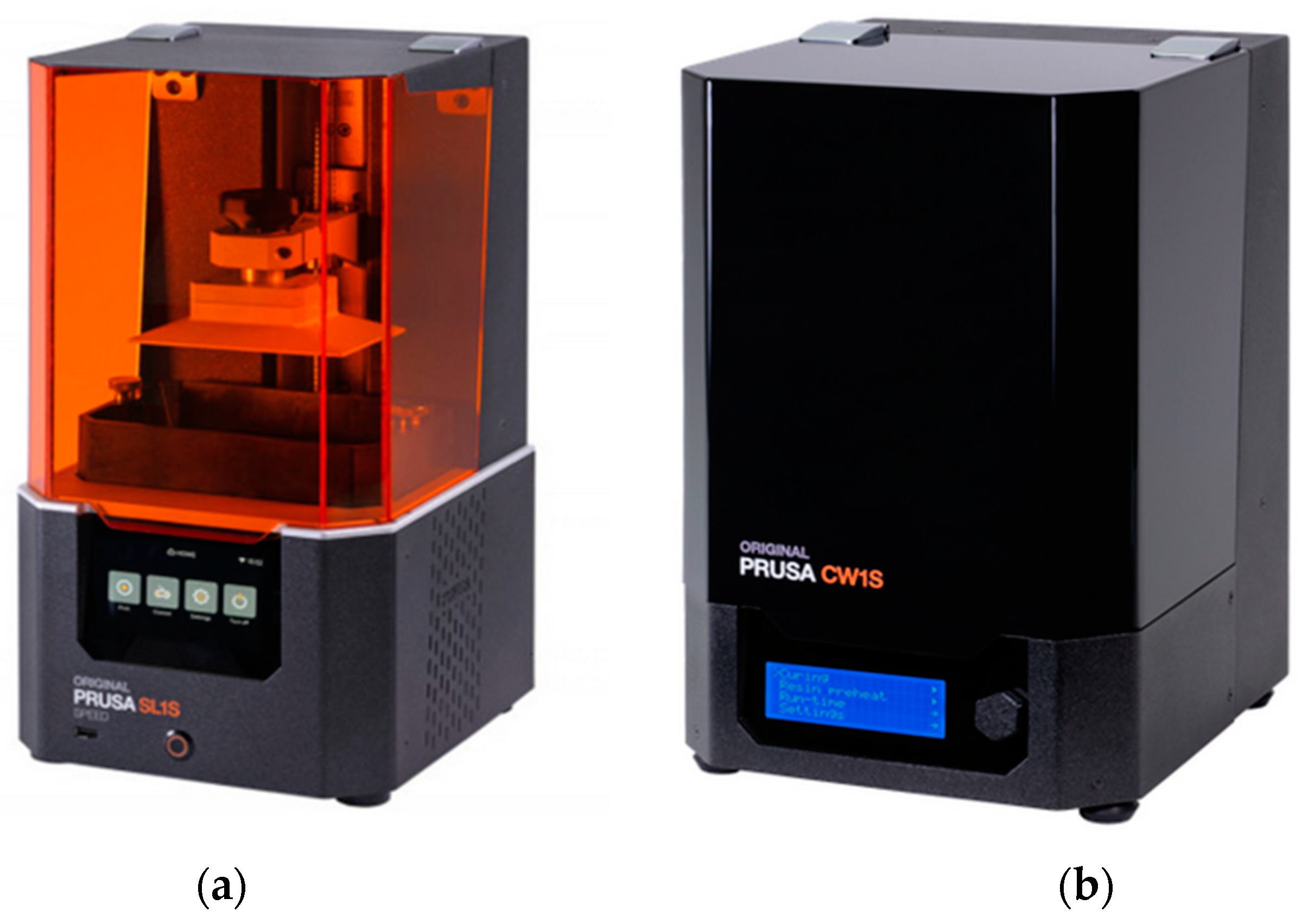

2. Materials and Methods

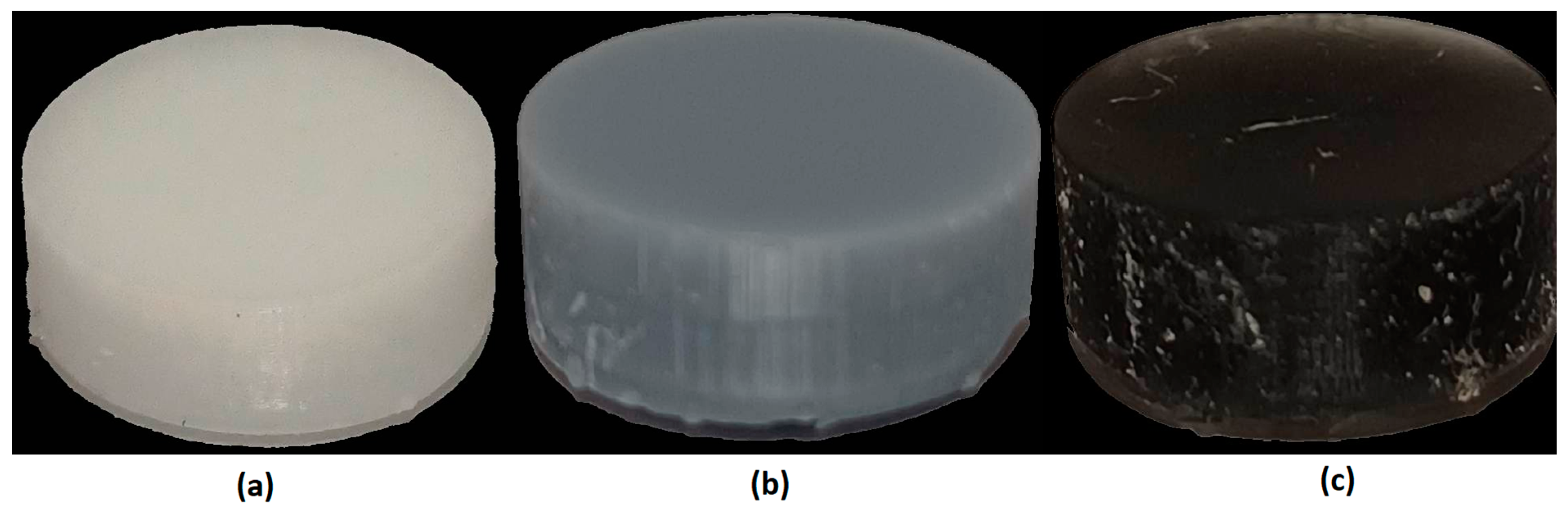

2.1. Characteristics of Printed Materials

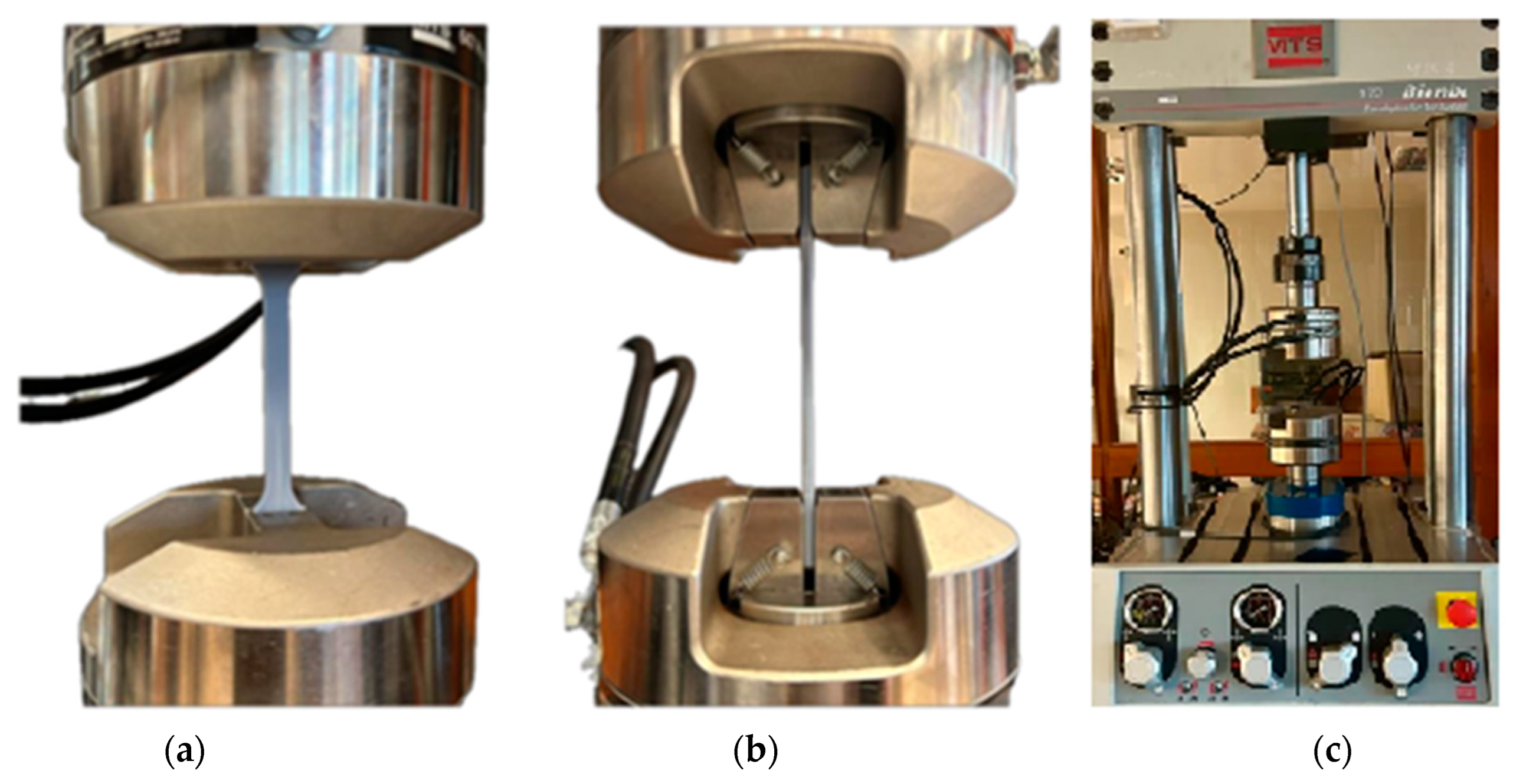

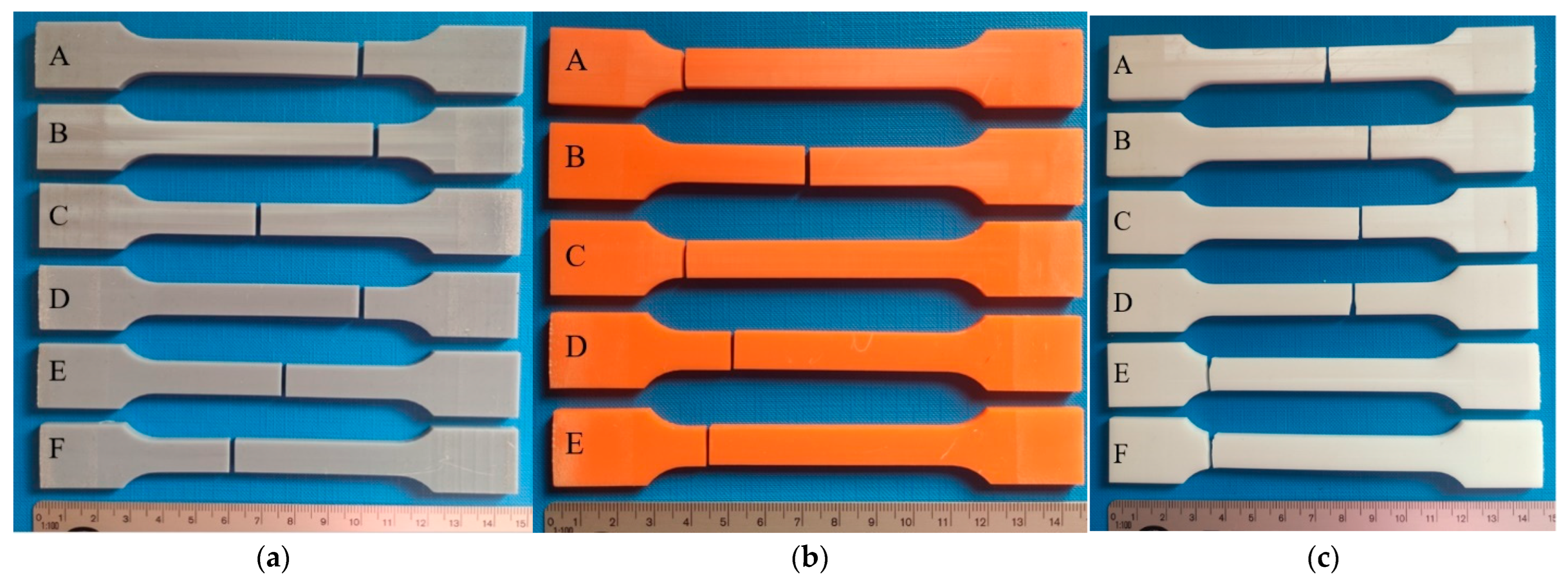

2.2. Testing of Materials Using a Static Tensile Test

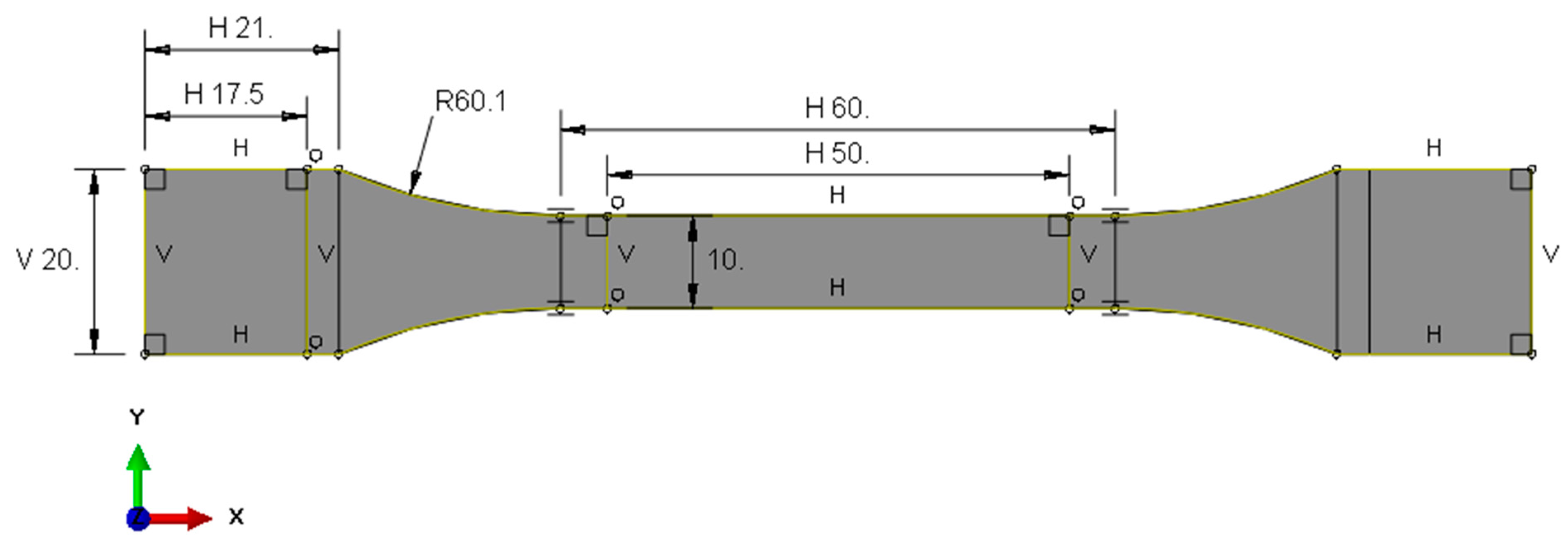

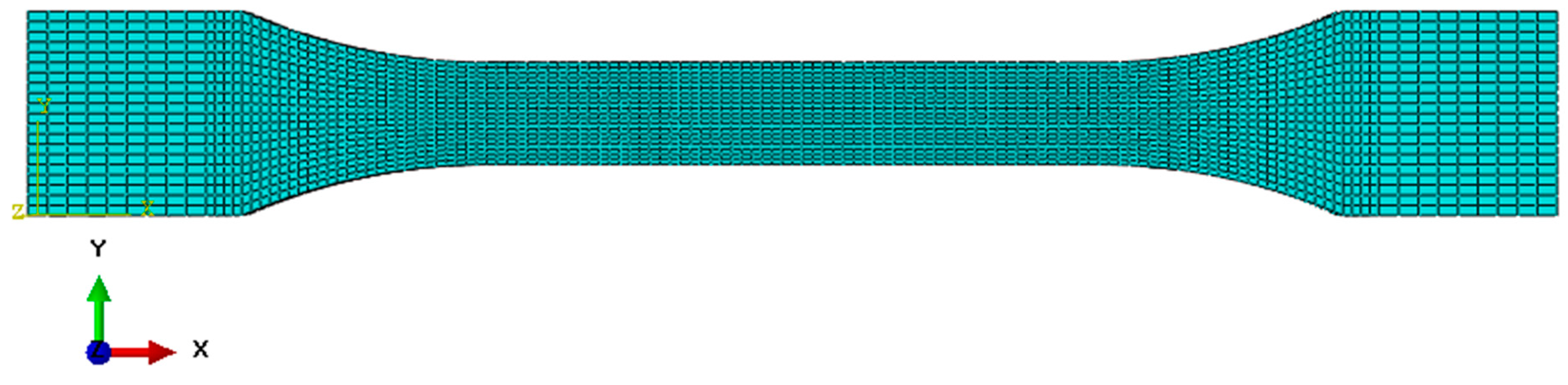

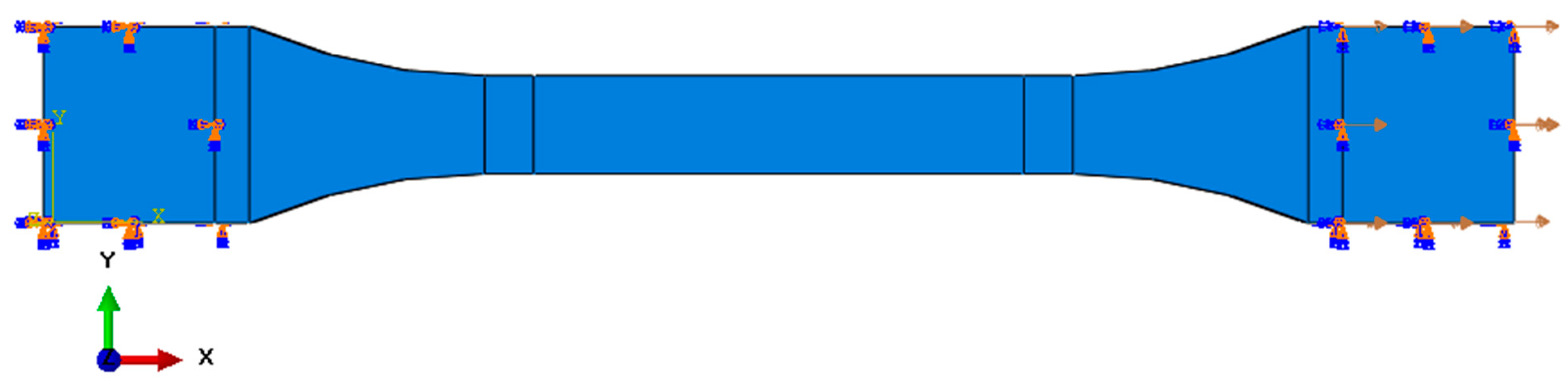

2.3. Methodology of Numerical Simulation

2.4. Methodology of SEM Observations

2.5. Biological Assessment of Samples

3. Results

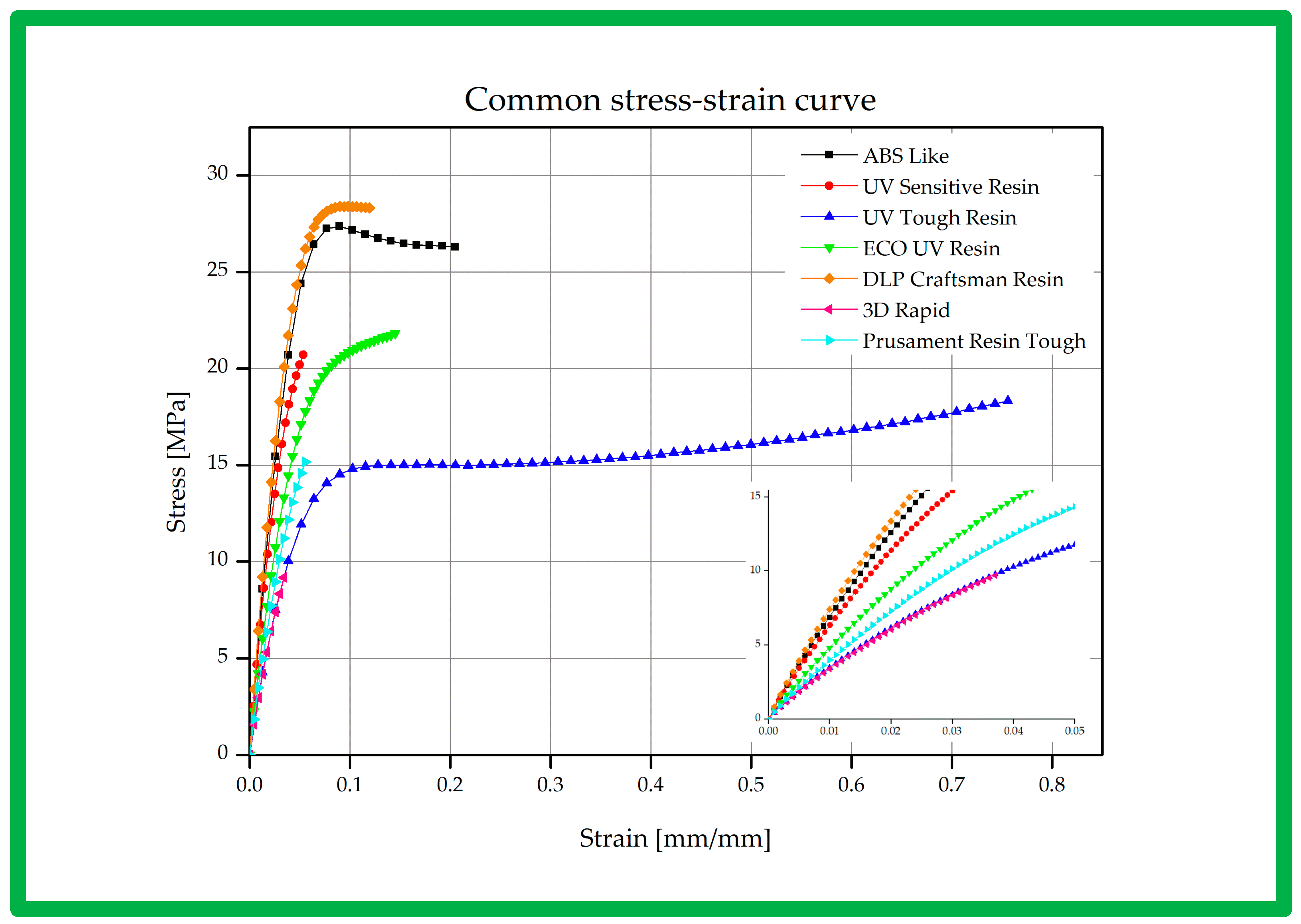

3.1. Static Tensile Test

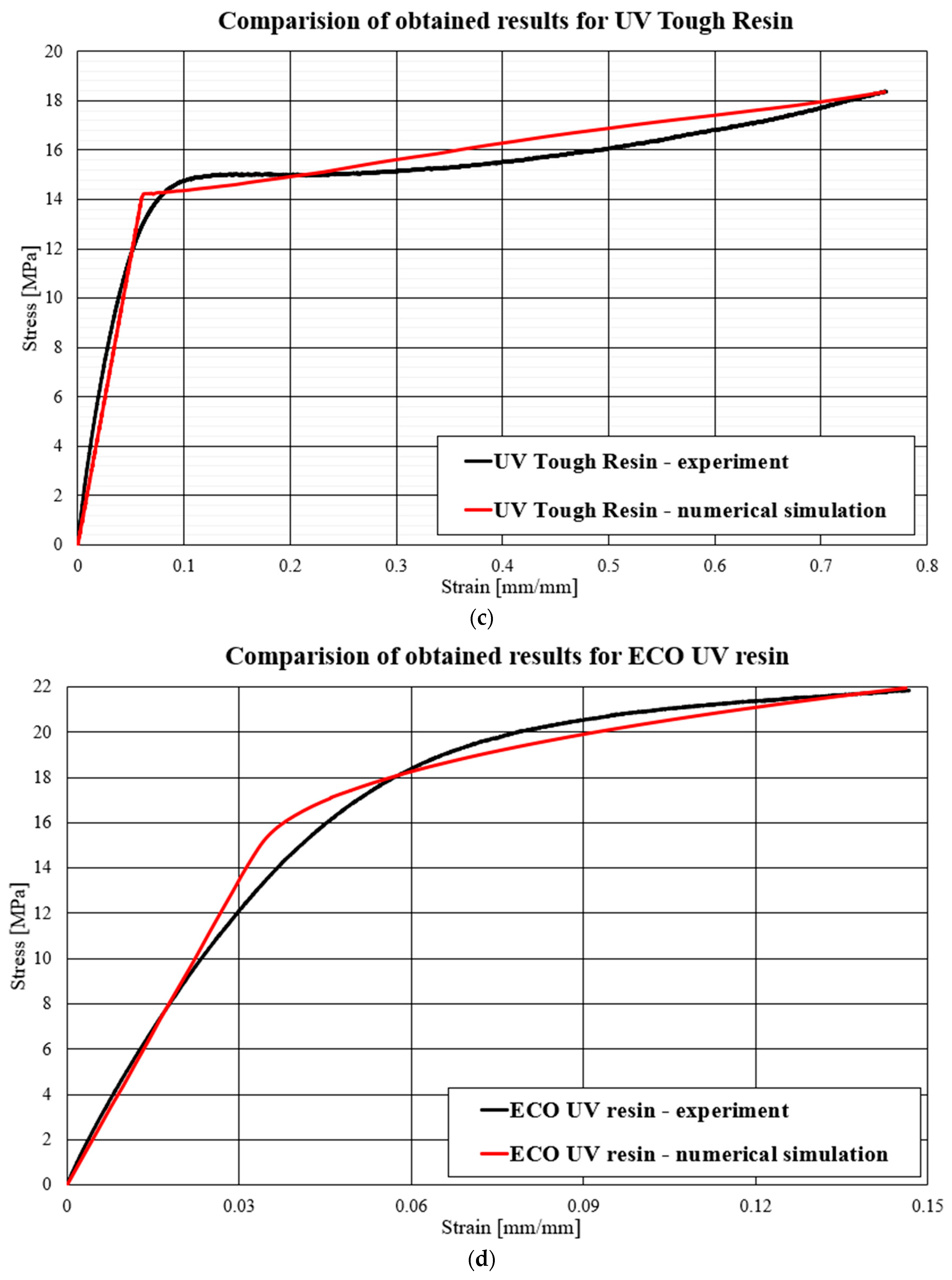

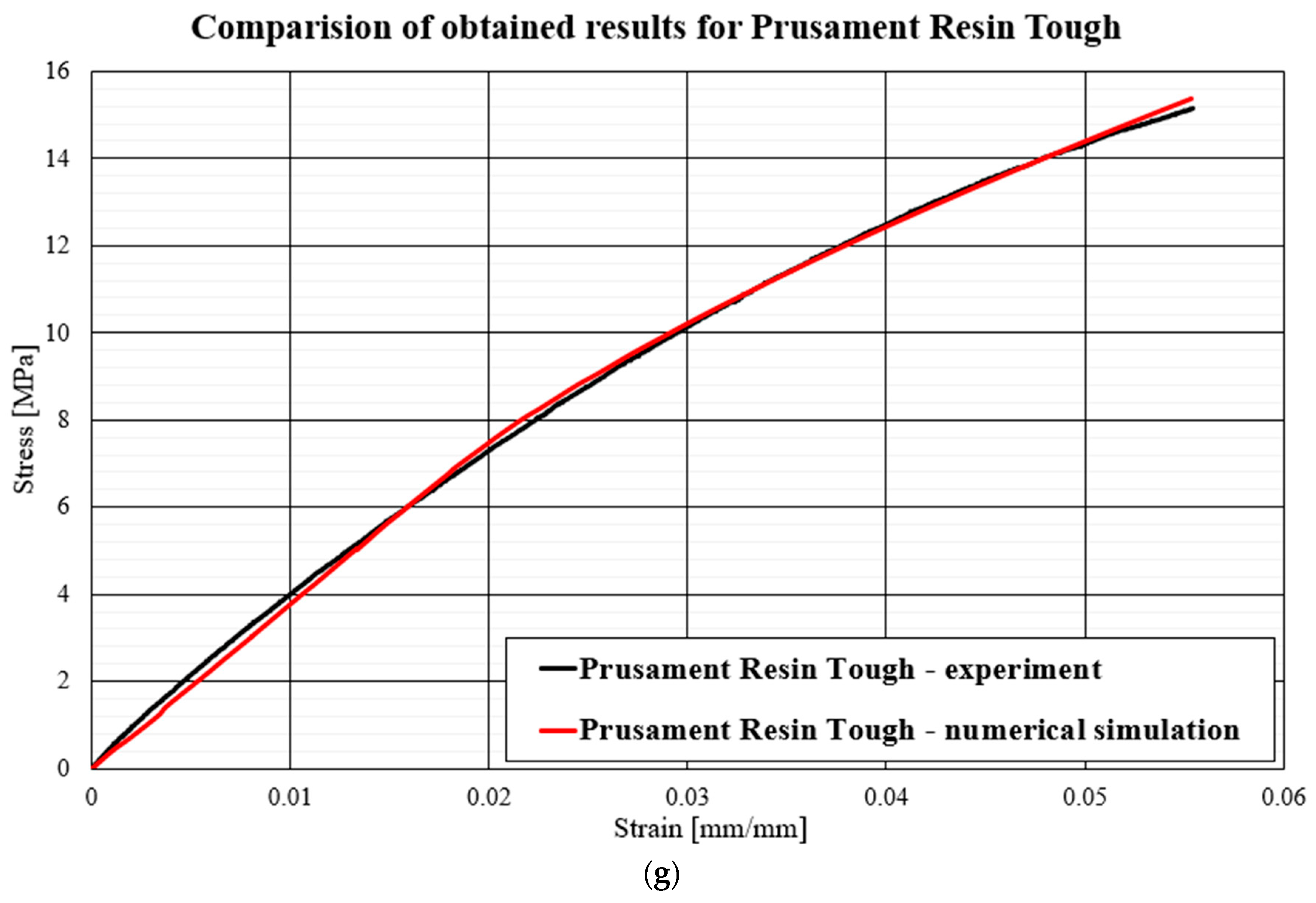

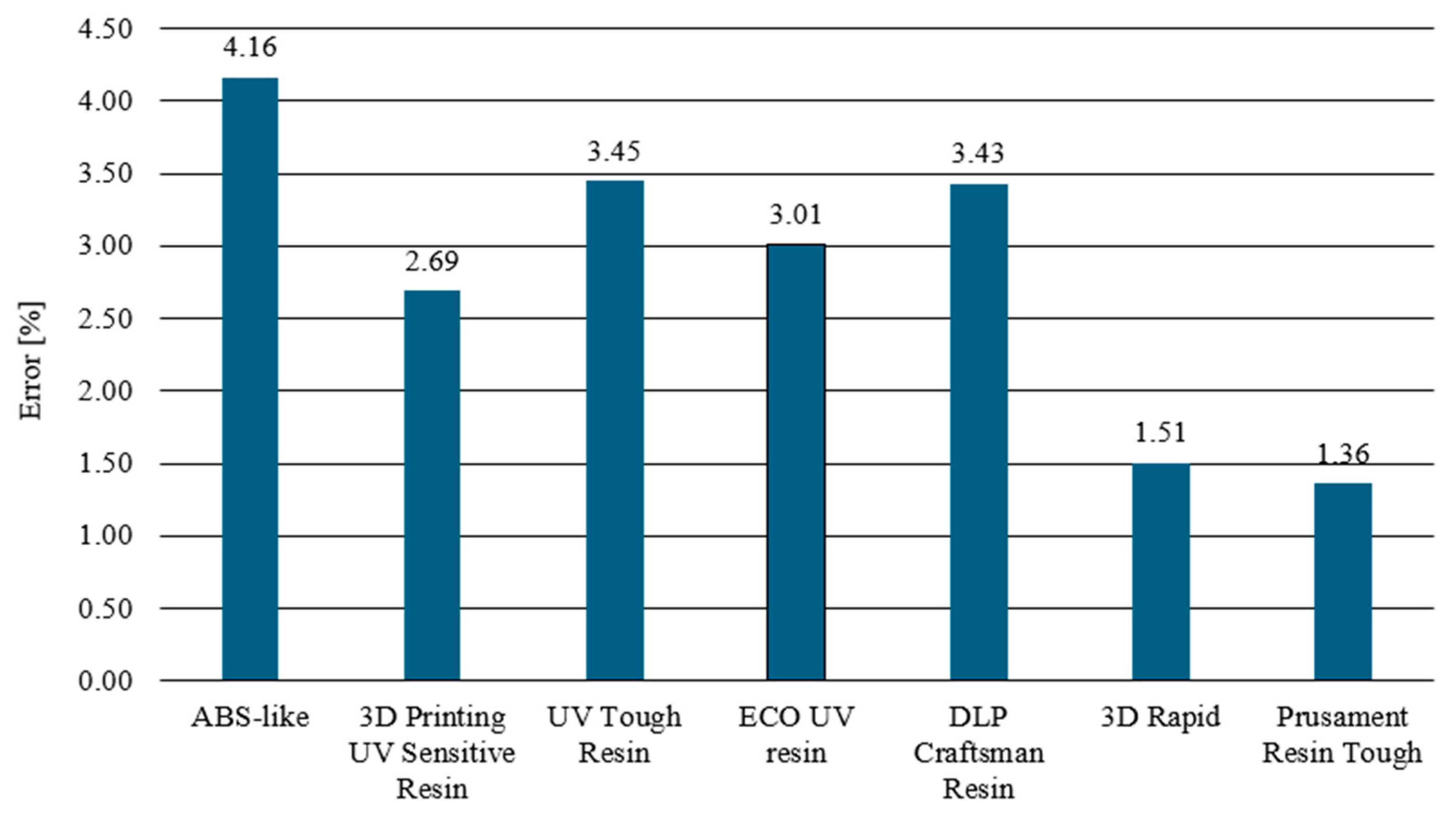

3.2. FEM Analysis

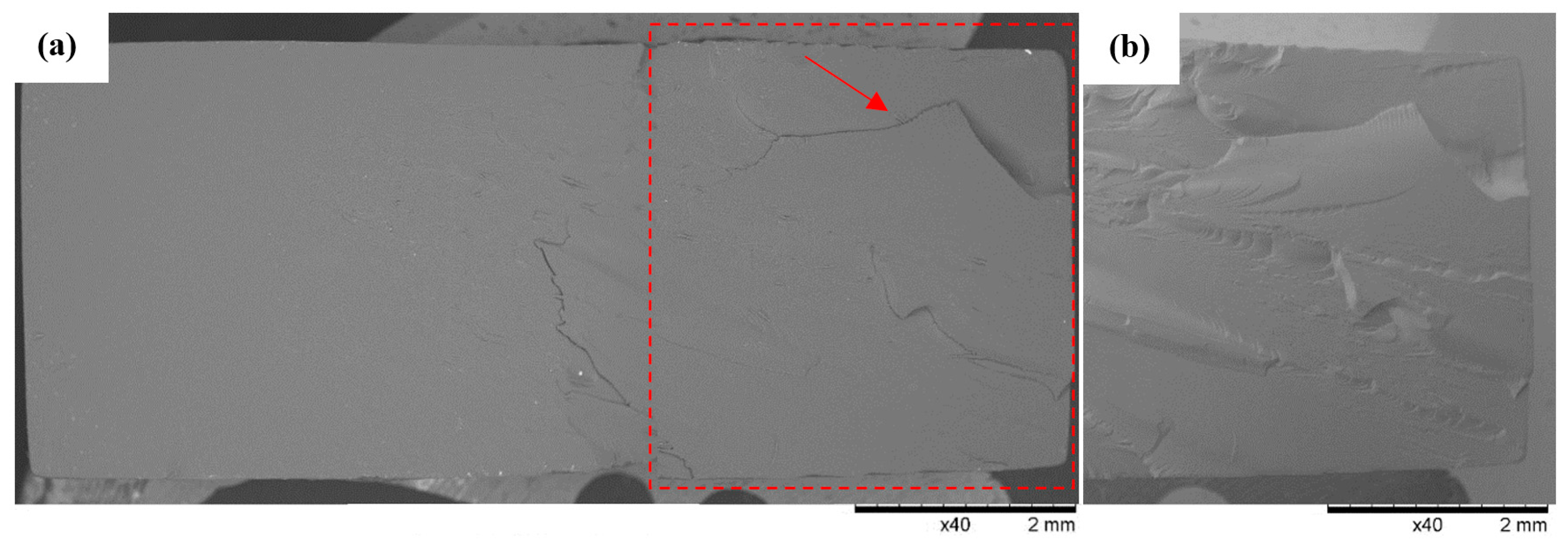

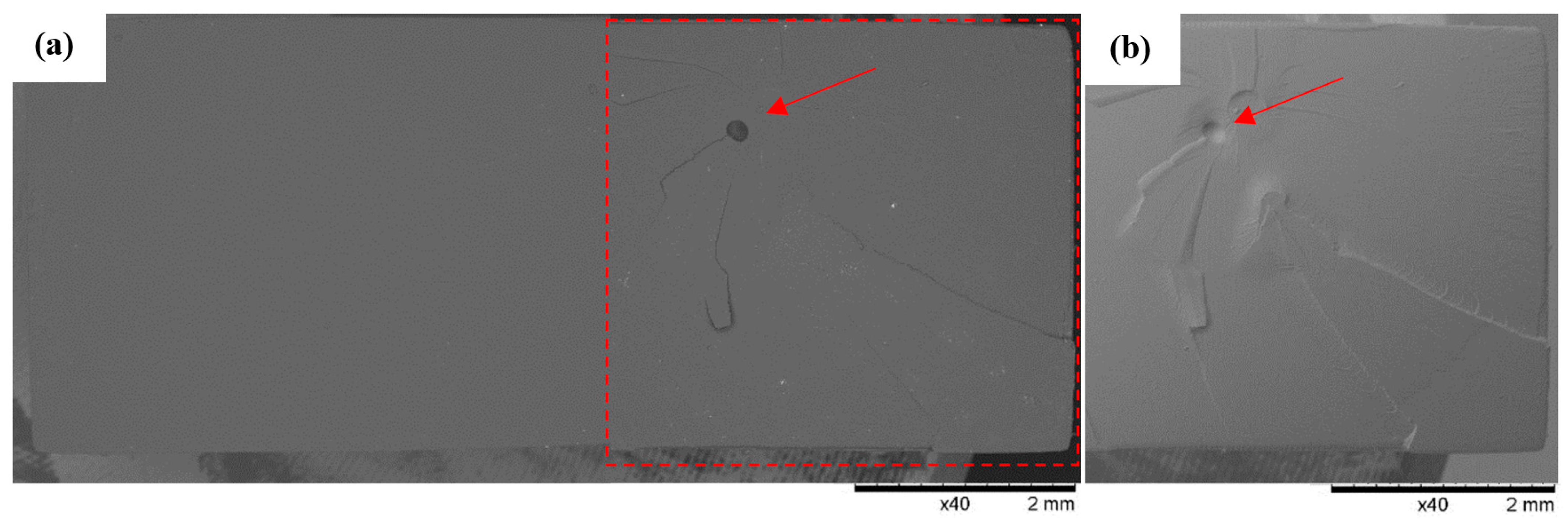

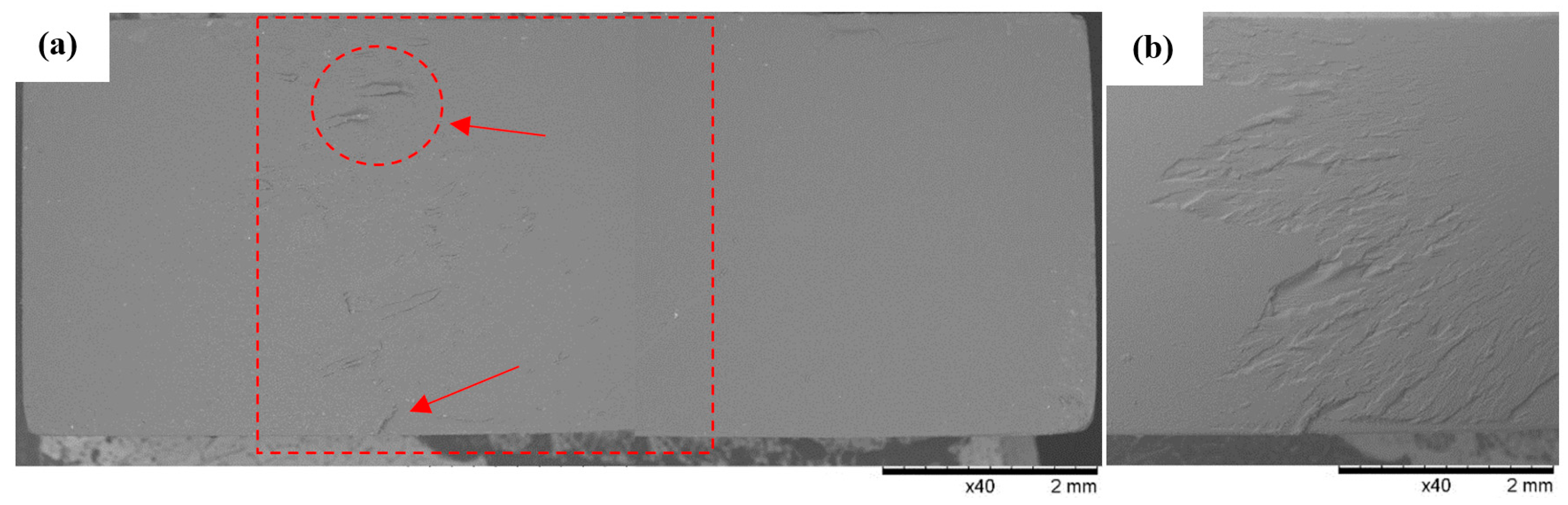

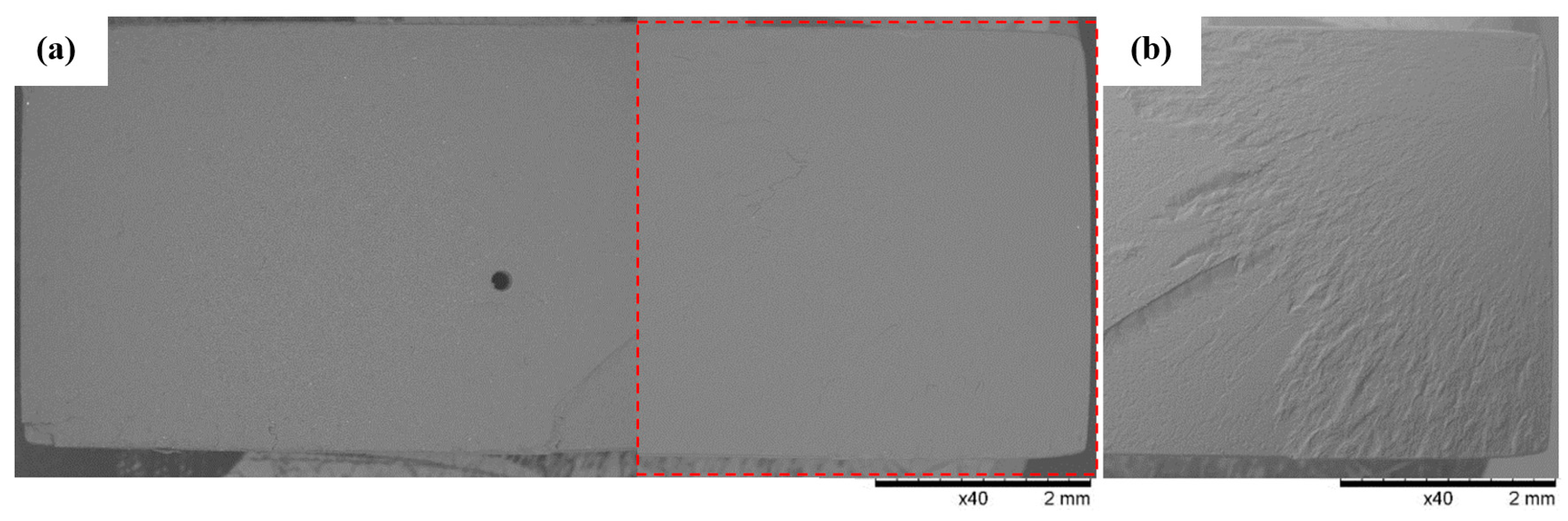

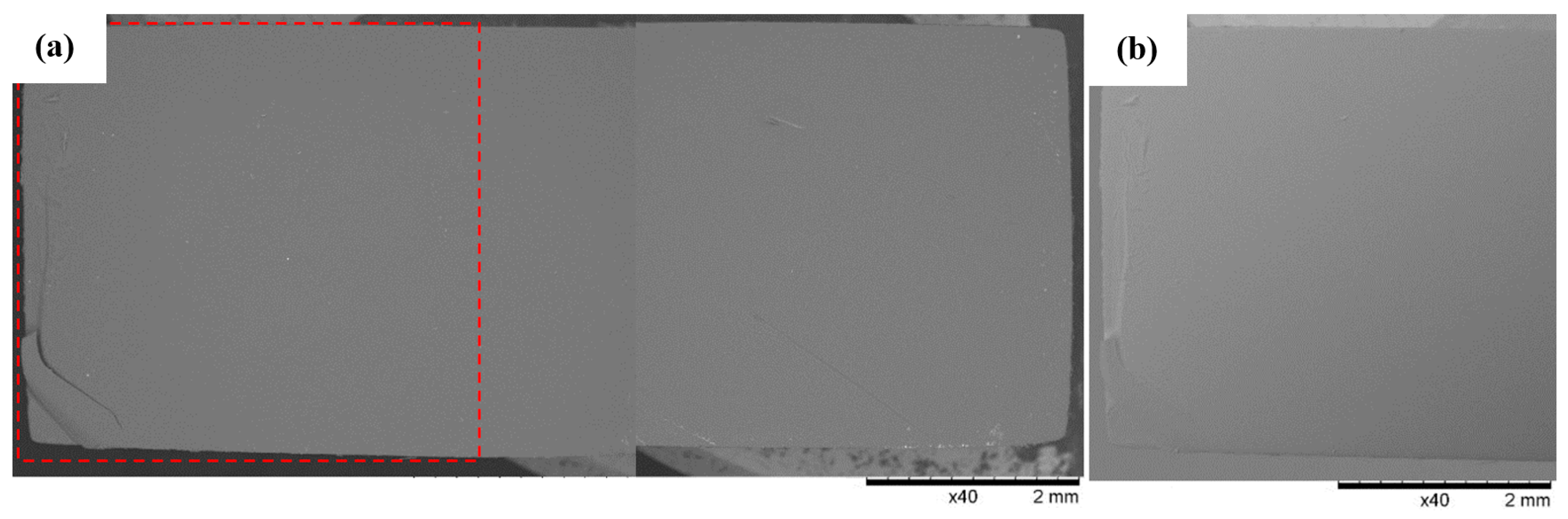

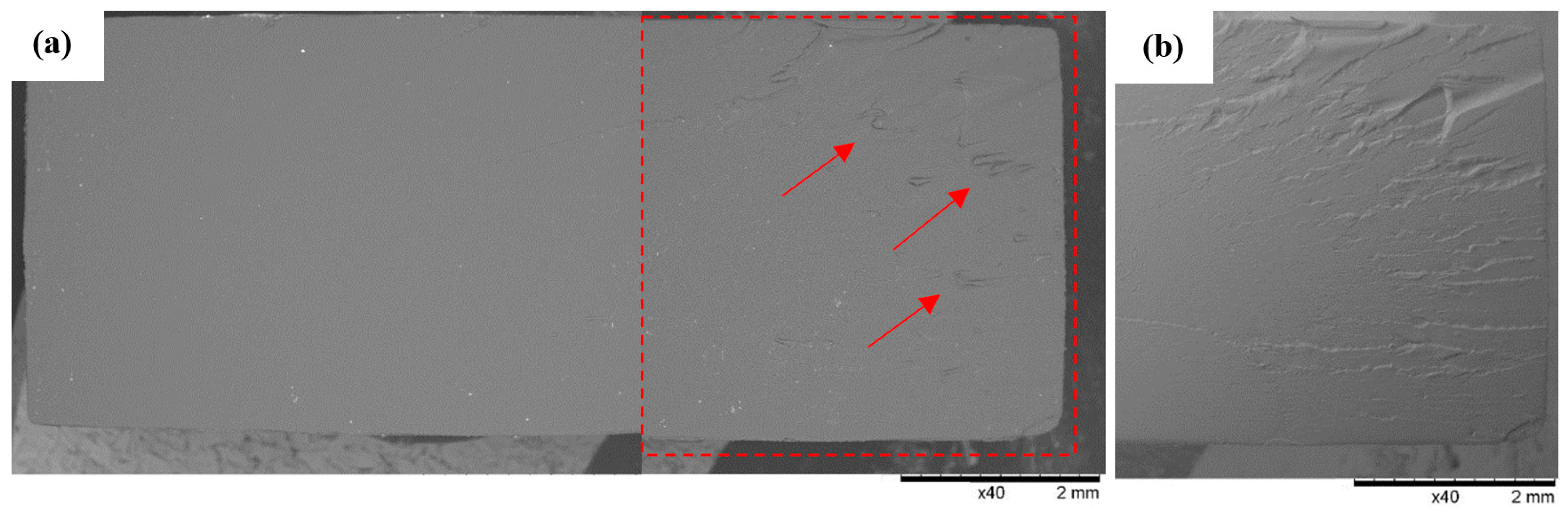

3.3. SEM Observations

3.4. Biological Assessment of Samples

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Prabhakar, M.M.; Saravanan, A.K.; Lenin, A.H.; Leno, I.J.; Mayandi, K.; Ramalingam, P.S. A short review on 3D printing methods, process parameters and materials. Mater. Today Proc. 2021, 45, 6108–6114. [Google Scholar] [CrossRef]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modeling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar] [CrossRef]

- Jiménez, M.; Romero, L.; Domínguez, I.A.; Espinosa, M.D.M.; Domínguez, M. Additive Manufacturing Technologies: An Overview about 3D Printing Methods and Future Prospects. Complexity 2019, 2019, 1–30. [Google Scholar] [CrossRef]

- Izdebska-Podsiadły, J. Classification of 3D printing methods. In Polymers for 3D Printing: Methods, Properties, and Characteristics; William Andrew Publishing: Norwich, NY, USA, 2022; pp. 23–34. [Google Scholar] [CrossRef]

- Nys, N.; König, M.; Neugebauer, P.; Jones, M.J.; Gruber-Woelfler, H. Additive Manufacturing as a Rapid Prototyping and Fabrication Tool for Laboratory Crystallizers—A Proof-of-Concept Study. Org. Process Res. Dev. 2023, 27, 1455–1462. [Google Scholar] [CrossRef]

- Schneider, L.; Gärtner, H. Additive manufacturing for lab applications in environmental sciences: Pushing the boundaries of rapid prototyping. Dendrochronologia 2022, 76, 126015. [Google Scholar] [CrossRef]

- Oztan, C.; Coverstone, V. Utilization of additive manufacturing in hybrid rocket technology: A review. In Acta Astronautica; Elsevier Ltd.: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Takeda, Y.; Lau, J.; Nouh, H.; Hirayama, H. A 3D printing replication technique for fabricating digital dentures. J. Prosthet. Dent. 2020, 124, 251–256. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Yu, H.; Li, K.; Zhang, Y.; Gao, B.; Wu, J. Digital fabrication of complete dentures using a combination of additive and subtractive manufacturing technologies. Heliyon 2023, 9, e16168. [Google Scholar] [CrossRef]

- Deng, K.; Chen, H.; Wei, W.; Wang, X.; Sun, Y. Accuracy of tooth positioning in 3D-printing aided manufactured complete dentures: An in vitro study. J. Dent. 2023, 131, 104459. [Google Scholar] [CrossRef]

- Miljanovic, D.; Seyedmahmoudian, M.; Horan, B.; Stojcevski, A. Novel and accurate 3D-Printed surgical guide for mandibular reconstruction with integrated dental implants. Comput. Biol. Med. 2022, 151, 106327. [Google Scholar] [CrossRef]

- Sim, M.-Y.; Park, J.-B.; Kim, D.-Y.; Kim, H.-Y.; Park, J.-M. Dimensional accuracy and surface characteristics of complete-arch cast manufactured by six 3D printers. Heliyon 2024, 10, e30996. [Google Scholar] [CrossRef]

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.P.; Ermoshkin, A.; et al. Continuous liquid interface production of 3D objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef] [PubMed]

- Bodaghi, M.; Mobin, M.; Ban, D.; Lomov, S.V.; Nikzad, M. Surface quality of printed porous materials for permeability rig calibration. Mater. Manuf. Process. 2022, 37, 548–558. [Google Scholar] [CrossRef]

- Jafferson, J.M.; Chatterjee, D. A review on polymeric materials in additive manufacturing. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; Volume 46, pp. 1349–1365. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. In Additive Manufacturing; Elsevier B.V.: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing. Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing; Springer: New York, NY, USA, 2010; pp. 1–459. [Google Scholar] [CrossRef]

- Islam, M.A.; Mobarak, M.H.; Rimon, M.I.H.; Al Mahmud, M.Z.; Ghosh, J.; Ahmed, M.M.S.; Hossain, N. Additive manufacturing in polymer research: Advances, synthesis, and applications. In Polymer Testing; Elsevier Ltd.: Amsterdam, The Netherlands, 2024. [Google Scholar] [CrossRef]

- Riccio, C.; Civera, M.; Grimaldo Ruiz, O.; Pedullà, P.; Rodriguez Reinoso, M.; Tommasi, G.; Vollaro, M.; Burgio, V.; Surace, C. Effects of Curing on Photosensitive Resins in SLA Additive Manufacturing. Appl. Mech. 2021, 2, 942–955. [Google Scholar] [CrossRef]

- Kanishka, K.; Acherjee, B. Revolutionizing manufacturing: A comprehensive overview of additive manufacturing processes, materials, developments, and challenges. J. Manuf. Process. 2023, 107, 574–619. [Google Scholar] [CrossRef]

- Shuai, C.; Liu, G.; Yang, Y.; Qi, F.; Peng, S.; Yang, W.; He, C.; Wang, G.; Qian, G. A strawberry-like Ag-decorated barium titanate enhances piezoelectric and antibacterial activities of polymer scaffold. Nano Energy 2020, 74, 104825. [Google Scholar] [CrossRef]

- Szykiedans, K.; Credo, W. Mechanical properties of FDM and SLA low-cost 3-D prints. In Procedia Engineering; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; Volume 136, pp. 257–262. [Google Scholar] [CrossRef]

- Saini, J.S.; Dowling, L.; Kennedy, J.; Trimble, D. Investigations of the mechanical properties on different print orientations in SLA 3D printed resin. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 2279–2293. [Google Scholar] [CrossRef]

- Xiang, Y.; Schilling, C.; Arora, N.; Boydston, A.J.; Rudykh, S. Mechanical characterization and constitutive modeling of visco-hyperelasticity of photocured polymers. Addit. Manuf. 2020, 36, 101511. [Google Scholar] [CrossRef]

- The use of a mathematical model to describe isothermal stress-strain curves in glassy thermoplastics. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1968, 302, 453–472. [CrossRef]

- Somireddy, M.; Czekanski, A.; Singh, C.V. Development of constitutive material model of 3D printed structure via FDM. Mater. Today Commun. 2018, 15, 143–152. [Google Scholar] [CrossRef]

- Zhang, P.; To, A.C. Transversely isotropic hyperelastic-viscoplastic model for glassy polymers with application to additive manufactured photopolymers. Int. J. Plast. 2016, 80, 56–74. [Google Scholar] [CrossRef]

- Wang, S.; Ma, Y.; Deng, Z.; Zhang, K.; Dai, S. Implementation of an elastoplastic constitutive model for 3D-printed materials fabricated by stereolithography. Addit. Manuf. 2020, 33, 101104. [Google Scholar] [CrossRef]

- Sælen, R.L.; Hopperstad, O.S.; Clausen, A.H. Mechanical behaviour and constitutive modelling of an additively manufactured stereolithography polymer. Mech. Mater. 2023, 185, 104777. [Google Scholar] [CrossRef]

- Original Prusa SL1S SPEED | Drukarki 3D Original Prusa Bezpośrednio od Josefa Prusy. Available online: https://www.prusa3d.com/pl/produkt/original-prusa-sl1s-speed/ (accessed on 12 April 2024).

- ISO 527-3:2019-01; Plastics—Determination of Tensile Properties—Part 3: Test Conditions for Films and Plates. ISO: Geneva, Switzerland, 2019.

- Nunes, S.G.; Scazzosi, R.; Manes, A.; Amico, S.C.; de Amorim Júnior, W.F.; Giglio, M. Influence of Projectile and Thickness on the Ballistic Behavior of Aramid Composites: Experimental and Numerical Study. Int. J. Impact Eng. 2019, 132, 103307. [Google Scholar] [CrossRef]

- Murugesan, M.; Jung, D.W. Johnson Cook Material and Failure Model Parameters Estimation of AISI-1045 Medium Carbon Steel for Metal Forming Applications. Materials 2019, 12, 609. [Google Scholar] [CrossRef]

- Nowicki, A.; Osypko, K.; Kurzawa, A.; Roszak, M.; Krawiec, K.; Pyka, D. Mechanical and Material Analysis of 3D-Printed Temporary Materials for Implant Reconstructions—A Pilot Study. Biomedicines 2024, 12, 870. [Google Scholar] [CrossRef]

- ISO 10993-5:2009; Biological Evaluation of Medical Devices—Part 5: Tests for In Vitro Cytotoxicity. ISO: Geneva, Switzerland, 2009.

- ISO 10993-12:2021; Sample Preparation and Reference Materials. ISO: Geneva, Switzerland, 2021.

| No. | Material | Brand | Density (g/cm3) | Tensile Strength (MPa) | Hardness (HS) | Shrinkage (%) |

|---|---|---|---|---|---|---|

| 1 | ABS-Like | AnyCubic | 1.15 | 35–55 | 84.0 | 3.72–4.24 |

| 2 | 3D Printing UV-Sensitive | AnyCubic | 1.10 | 36–45 | 84.5 | 3.72–4.24 |

| 3 | UV Tough Resin | AnyCubic | 1.15 | 35–45 | 84.0 | 5.10–6.20 |

| 4 | ECO UV Resin | AnyCubic | 1.15 | 36–52 | 84.0 | 1.88–2.45 |

| 5 | DLP Craftsman Resin | AnyCubic | 1.18 | 35–50 | 85.0 | 3.72–4.24 |

| 6 | 3D Rapid | Monocure | 1.00 | 40–50 | 80.0 | 0.00–0.50 |

| 7 | Prusament Resin Tough | Prusa | 1.00 | 30–52 | 77.5 | 3.72–4.24 |

| Material | E (MPa) | v (-) | ρ (kg/m3) | A (MPa) | B (MPa) | n (-) |

|---|---|---|---|---|---|---|

| ABS-Like | 550 | 0.4 | 1150 | 21.74 | 6.10 | 0.1586 |

| 3D Printing UV Sensitive Resin | 600 | 0.4 | 1100 | 11.51 | 95.46 | 0.5793 |

| UV Tough Resin | 234 | 0.4 | 1150 | 14.23 | 5.98 | 6.1872 |

| ECO UV resin | 450 | 0.4 | 1150 | 14.89 | 20.11 | 0.4304 |

| DLP Craftsman Resin | 590 | 0.4 | 1180 | 21.99 | 11.19 | 0.2152 |

| 3D Rapid | 346 | 0.4 | 1000 | 3.01 | 139.69 | 0.6478 |

| Prusament Resin Tough | 378 | 0.4 | 1000 | 6.98 | 101.77 | 0.5903 |

| Material | Failure Strain (mm/mm) |

|---|---|

| ABS-Like | 0.220 |

| 3D Printing UV-Sensitive Resin | 0.055 |

| UV Tough Resin | 0.770 |

| ECO UV resin | 0.150 |

| DLP Craftsman Resin | 0.123 |

| 3D Rapid | 0.039 |

| Prusament Resin Tough | 0.057 |

| Material | RH | Re | Rm | ||||

|---|---|---|---|---|---|---|---|

| Stress (MPa) | Strain (mm/mm) | Stress (MPa) | Strain (mm/mm) | Stress (MPa) | Strain (mm/mm) | ||

| 1. | ABS-Like | 21.42 ± 1.14 | 0.04 ± 0.0029 | 21.70 ± 1.04 | 0.04 ± 0.0030 | 26.31 ± 0.75 | 0.20 ± 0.052 |

| 2. | UV-Sensitive Resin | 0.01 ± 0.00 | 0.01 ± 0.0001 | 4.52 ± 0.41 | 0.01 ± 0.0006 | 20.74 ± 1.71 | 0.05 ± 0.002 |

| 3. | UV Tough Resin | 6.06 ± 0.29 | 0.02 ± 0.0041 | 6.52 ± 0.28 | 0.02 ± 0.0041 | 18.36 ± 1.85 | 0.76 ± 0.082 |

| 4. | ECO UV Resin | 7.61 ± 0.69 | 0.01 ± 0.0008 | 8.14 ± 0.73 | 0.02 ± 0.0008 | 21.84 ± 2.45 | 0.14 ± 0.055 |

| 5. | DLP Craftsman Resin | 12.86 ± 0.79 | 0.02 ± 0.0003 | 13.38 ± 0.76 | 0.02 ± 0.0021 | 28.28 ± 1.66 | 0.12 ± 0.023 |

| 6. | 3D Rapid | 3.28 ± 0.33 | 0.01 ± 0.0001 | 3.48 ± 0.33 | 0.01 ± 0.0009 | 9.84 ± 0.95 | 0.03 ± 0.002 |

| 7. | Prusament Resin Tough | 6.07 ± 0.28 | 0.01 ± 0.0005 | 6.18 ± 0.25 | 0.02 ± 0.0008 | 15.17 ± 2.28 | 0.05 ± 0.015 |

| ABS-Like | 3D Printing UV Sensitive | UV Tough Resin | ECO UV Resin | DLP Craftsman Resin | 3D Rapid | Prusament Resin Tough | |

|---|---|---|---|---|---|---|---|

| Blank | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Negative Control | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Positive Control | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Test Item | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Cytotoxic | Cytotoxic | Cytotoxic | Cytotoxic | Cytotoxic | Cytotoxic | Cytotoxic |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grygier, D.; Kurzawa, A.; Stachowicz, M.; Krawiec, K.; Stępczak, M.; Roszak, M.; Kazimierczak, M.; Aniszewska, D.; Pyka, D. Investigations into the Material Characteristics of Selected Plastics Manufactured Using SLA-Type Additive Methods. Polymers 2024, 16, 1607. https://doi.org/10.3390/polym16111607

Grygier D, Kurzawa A, Stachowicz M, Krawiec K, Stępczak M, Roszak M, Kazimierczak M, Aniszewska D, Pyka D. Investigations into the Material Characteristics of Selected Plastics Manufactured Using SLA-Type Additive Methods. Polymers. 2024; 16(11):1607. https://doi.org/10.3390/polym16111607

Chicago/Turabian StyleGrygier, Dominika, Adam Kurzawa, Mateusz Stachowicz, Karina Krawiec, Maksymilian Stępczak, Maciej Roszak, Mikołaj Kazimierczak, Dorota Aniszewska, and Dariusz Pyka. 2024. "Investigations into the Material Characteristics of Selected Plastics Manufactured Using SLA-Type Additive Methods" Polymers 16, no. 11: 1607. https://doi.org/10.3390/polym16111607

APA StyleGrygier, D., Kurzawa, A., Stachowicz, M., Krawiec, K., Stępczak, M., Roszak, M., Kazimierczak, M., Aniszewska, D., & Pyka, D. (2024). Investigations into the Material Characteristics of Selected Plastics Manufactured Using SLA-Type Additive Methods. Polymers, 16(11), 1607. https://doi.org/10.3390/polym16111607